The NARX Model-Based System Identification on Nonlinear, Rotor-Bearing Systems

Abstract

:1. Introduction

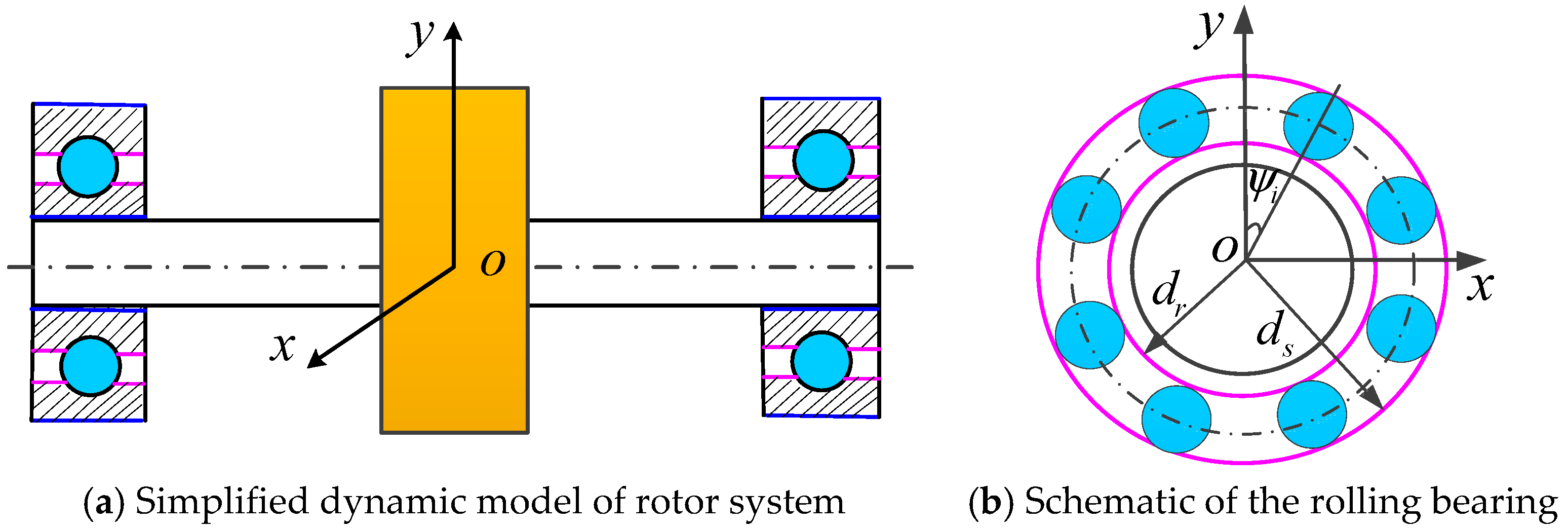

2. Nonlinear, Rotor-Bearing System Structure

2.1. System Structure

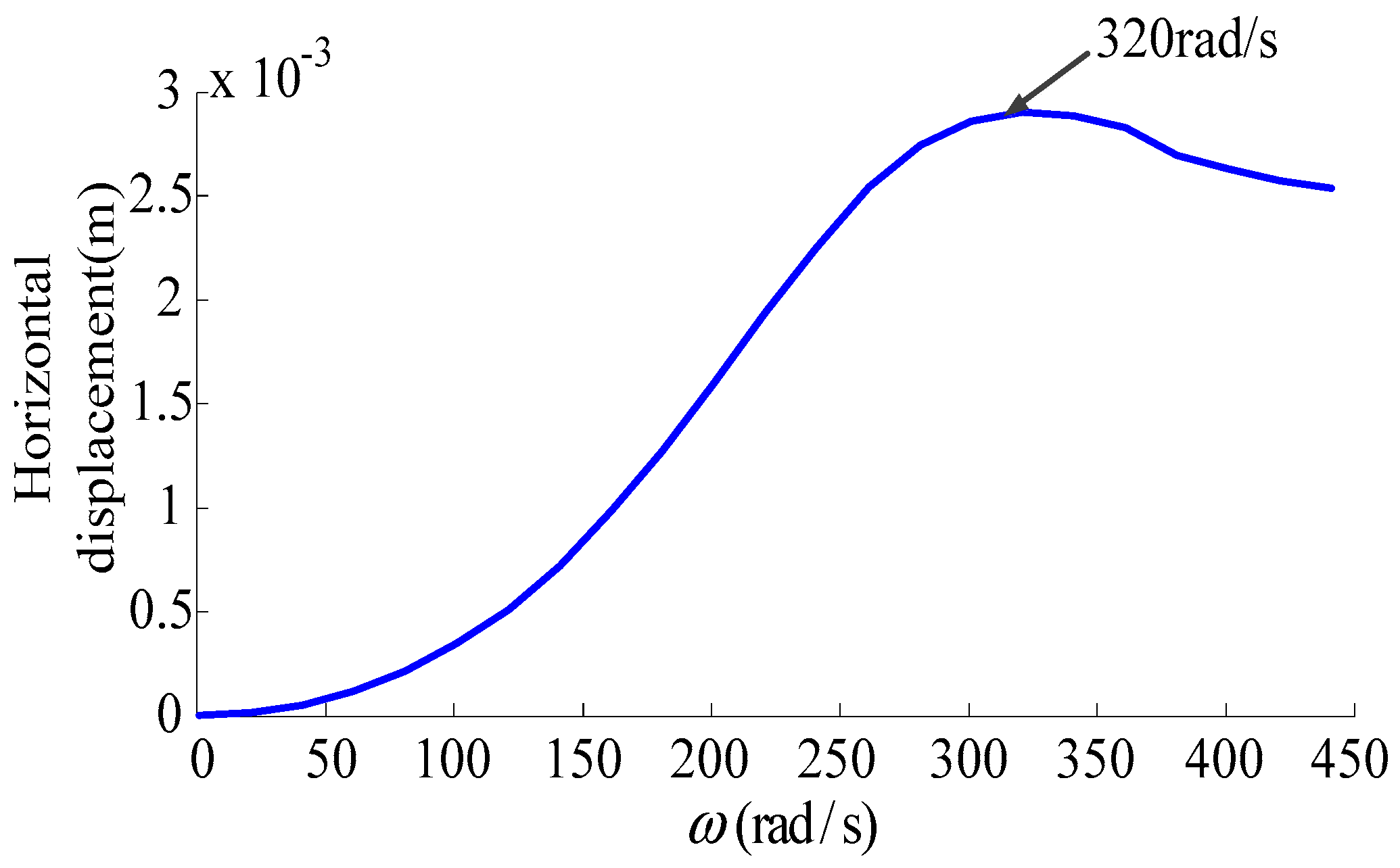

2.2. System Inherent Characteristics

3. NARX Model on the Rotor-Bearing System

3.1. Identification of the NARX Model

- A.

- Given , where the superscript (1) represents the first selecting step. can be calculated based on Equation (11).

- B.

- When the selection goes to step l, define , and based on the selected orthogonalized model term vectors , the lth model term vector is given as:

- C.

- The algorithm will stop selecting at the M’th step when the model structure satisfies the following condition:where is the threshold; M’ represents the total number of the selected model terms.

3.2. NARX Model Subjected to Multi-Harmonic Excitation

3.3. NARX Model under Different Frequency Ranges

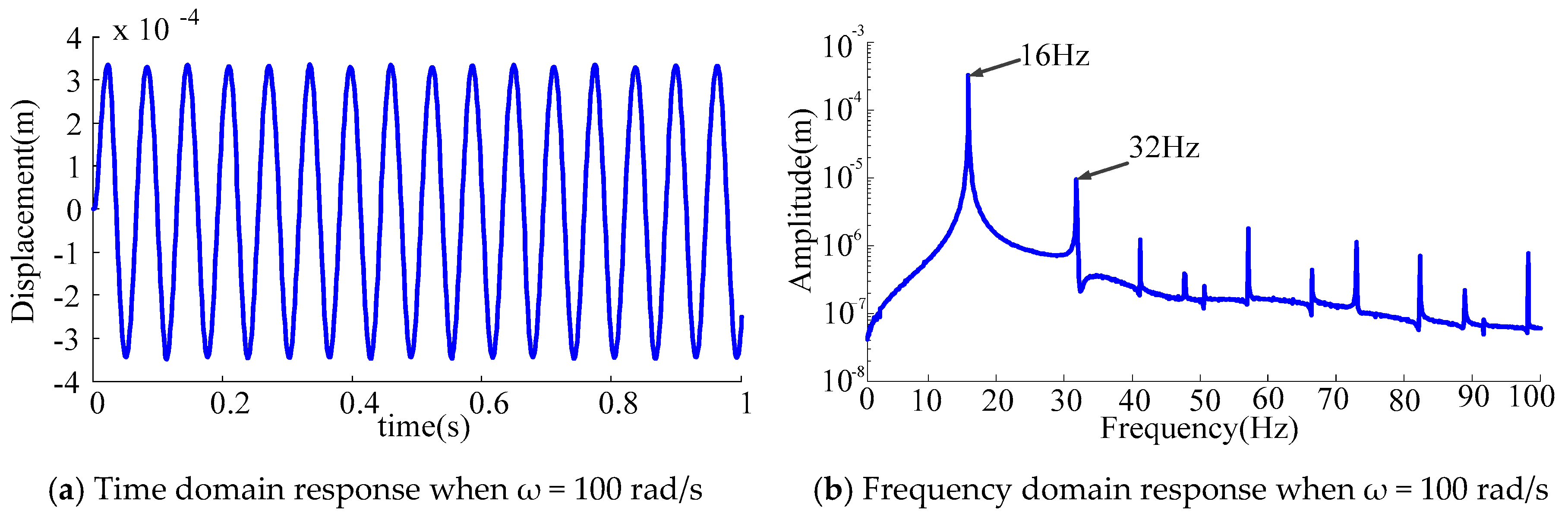

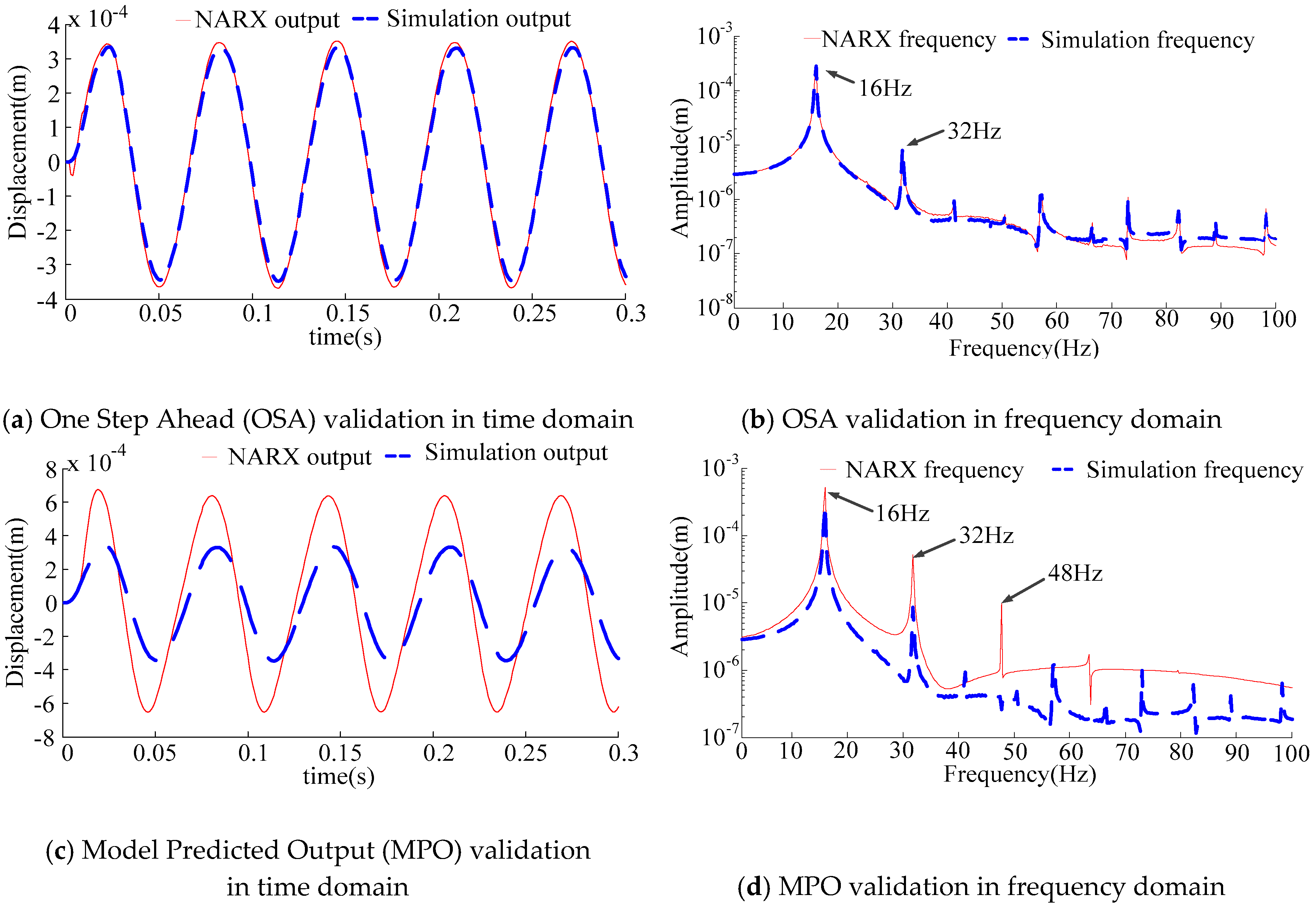

3.3.1 Under the Low-Speed Condition

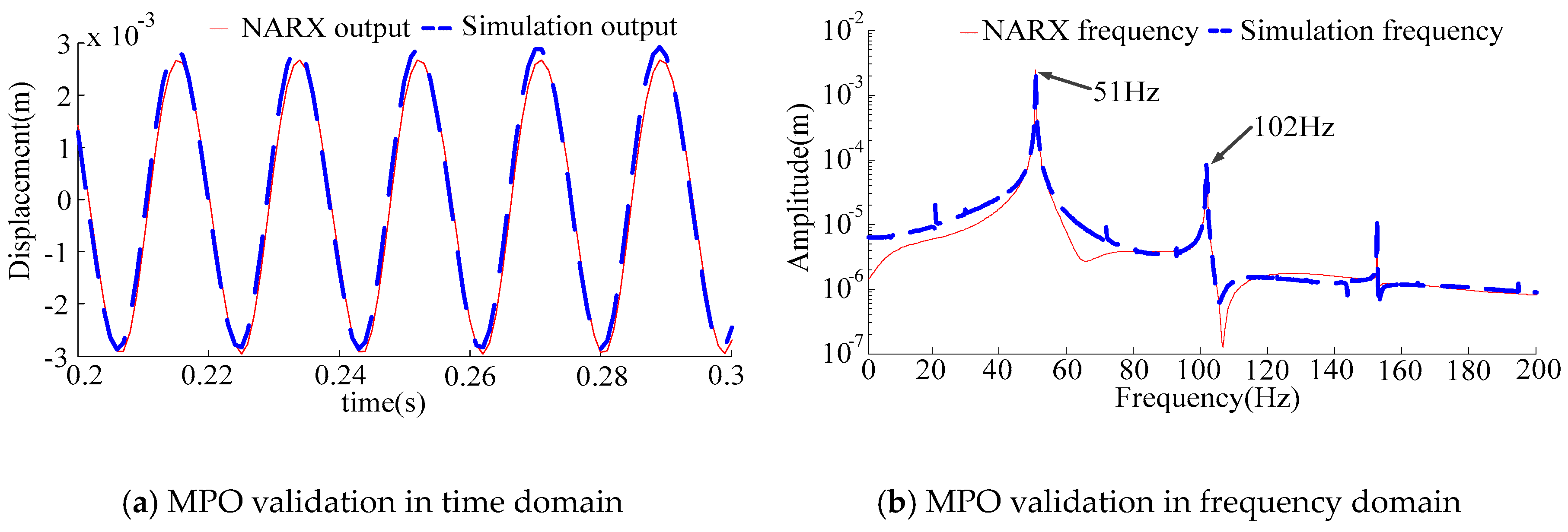

3.3.2 Under the Critical Speed Condition

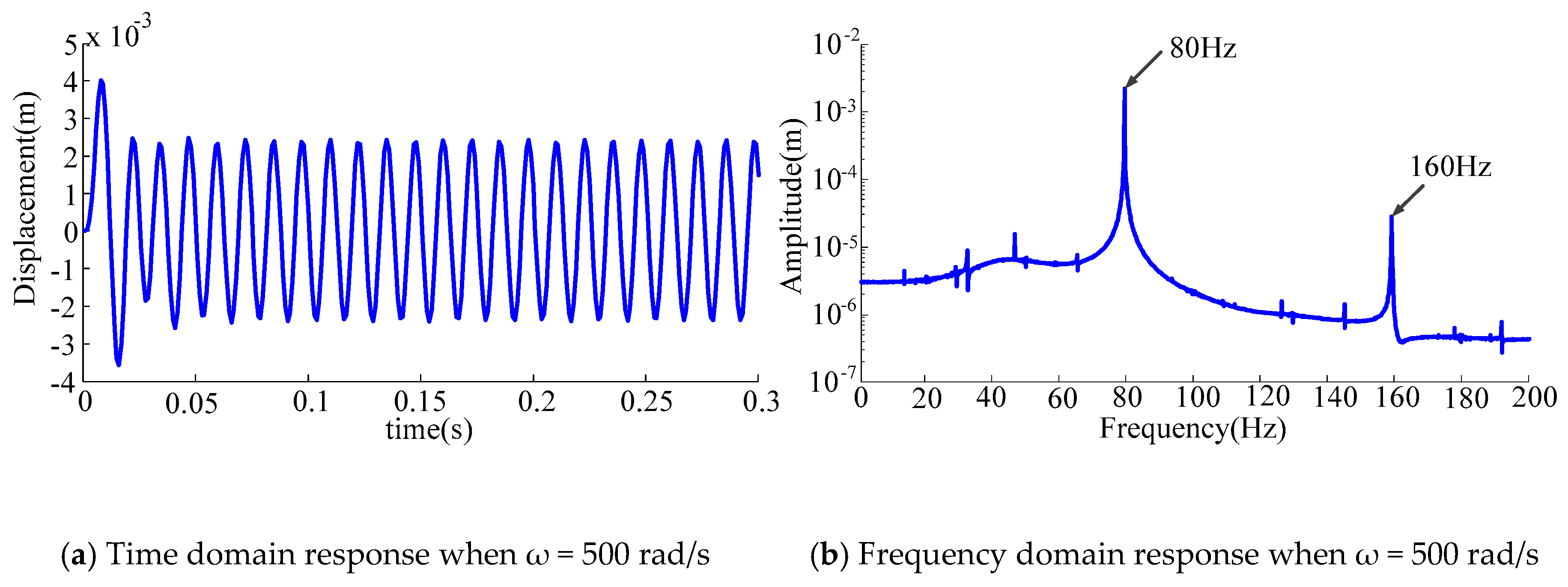

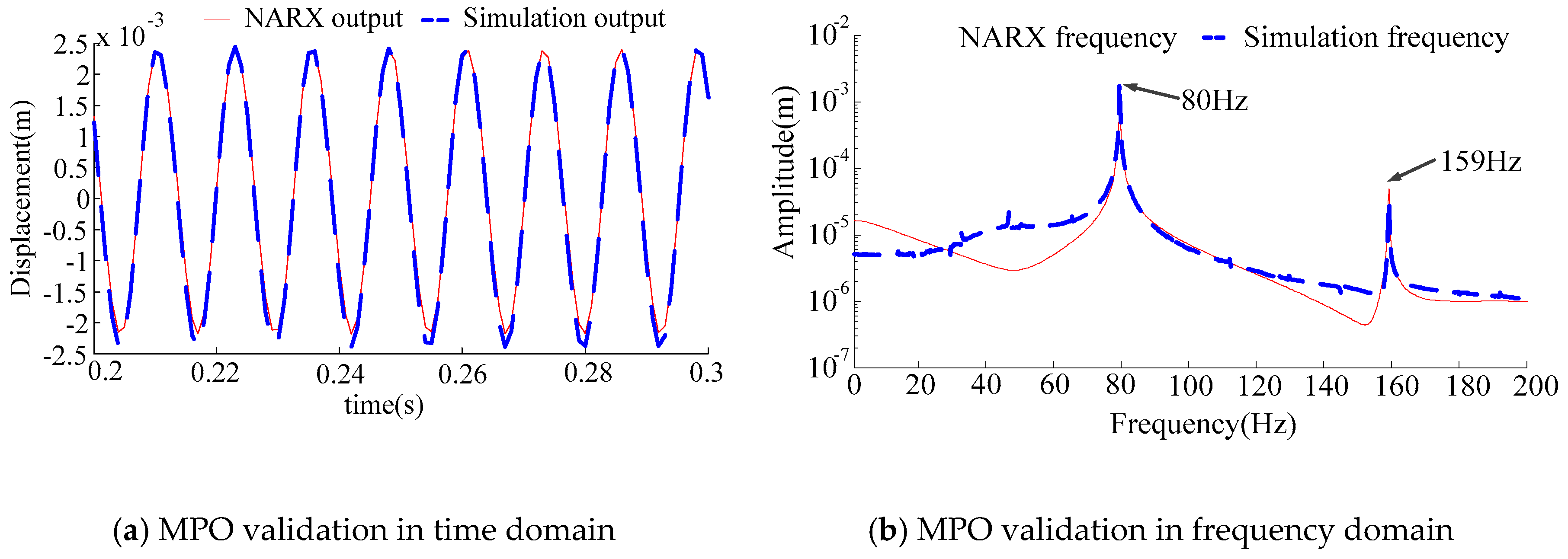

3.3.3. Under the Over-Critical Speed Condition

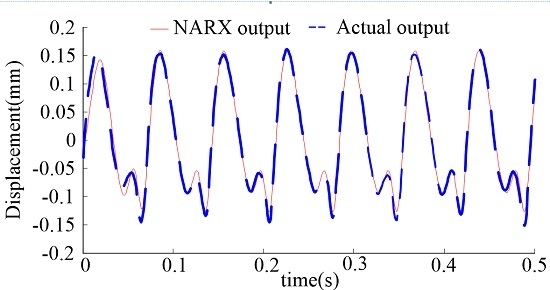

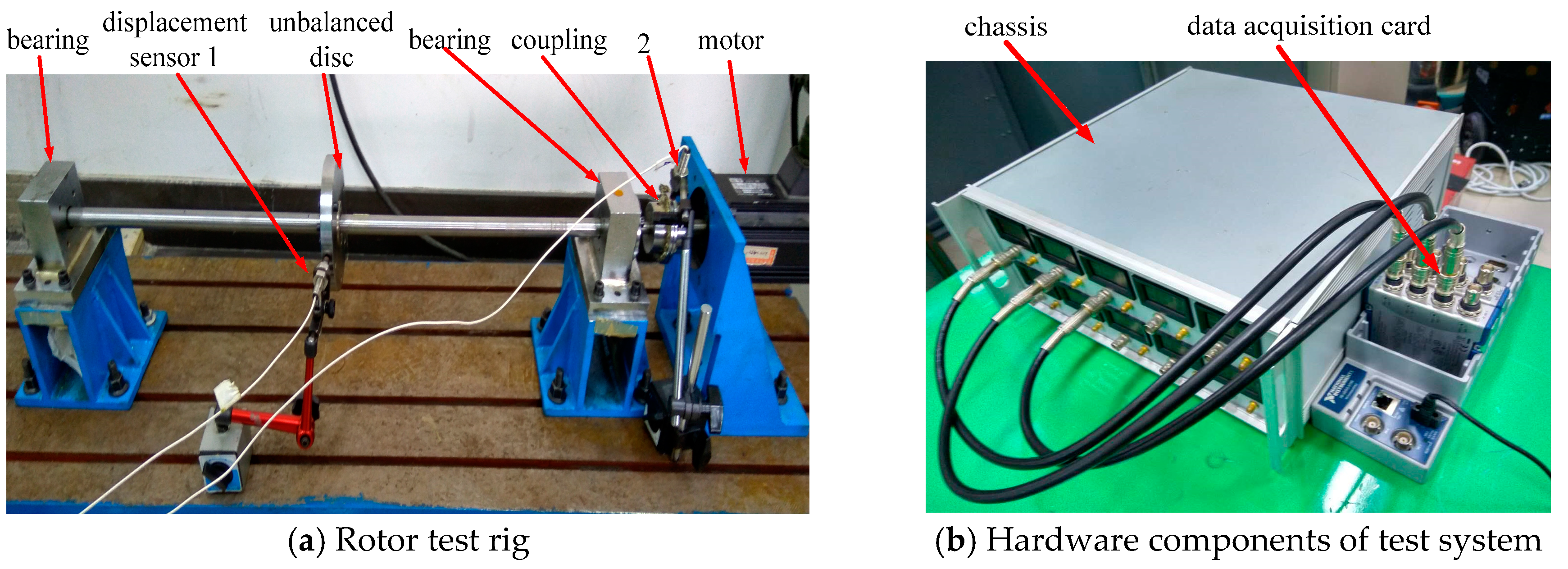

4. Experimental Verification

5. Conclusions

- Mathematical models are important in the analysis, design, and fault diagnose of rotor-bearing systems. However, due to the complex structure and other factors, it is impossible to establish an accurate physical model. Thus, in this paper, an identification method of the nonlinear, rotor-bearing system based on NARX model is proposed.

- The experimental results indicate that the NARX model can reproduce the underlying nonlinear, rotor-bearing system accurately. Furthermore, the method enriches the nonlinear, rotor-bearing modeling theory and provides a reliable model for dynamic analysis, design, and fault diagnosis of the rotor-bearing system, which is of practical significance.

- The NARX model under multi-harmonic excitation can reflect a broad range of system characteristics. The MPO and OSA methods are used in model validation. The results indicate that it is inappropriate to use the OSA method when establishing the nonlinear, rotor-bearing system.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rao, J.S. Rotor Dynamics; New Age International: Delhi, India, 1996. [Google Scholar]

- Xiang, L.; Hu, A.; Hou, L. Nonlinear coupled dynamics of an asymmetric double-disc rotor-bearing system under rub-impact and oil-film forces. J. Appl. Math. Model. 2016, 40, 4505–4523. [Google Scholar] [CrossRef]

- Nowak, R.D. Nonlinear system identification. J. Circuits Syst. Signal Process. 2002, 21, 109–122. [Google Scholar] [CrossRef]

- Fonseca, C.A.; Santos, I.F.; Weber, H.I. Influence of unbalance levels on nonlinear dynamics of a rotor-backup rolling bearing system. J. Sound Vib. 2017, 394, 482–496. [Google Scholar] [CrossRef]

- Luo, Z.; Chen, G.; Li, J. Design of Dynamic Similarity Model of Rotor System Considering the Bearing Stiffness. J. Northeast. Univ. Nat. Sci. 2015, 36, 402–405. [Google Scholar]

- Hu, Q.H.; Sier, D.; Hongfei, T.A. 5-DOF Model for Aeroengine Spindle Dual-Rotor System Analysis. Chin. J. Aeronaut. 2011, 24, 224–234. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, G. Dynamic response analysis of dual rotor-ball bearing-stator coupling system for aero-engine. J. Aerosp. Power 2009, 24, 1284–1291. [Google Scholar]

- Ma, H.; Yu, T.; Han, Q. Time–frequency features of two types of coupled rub-impact faults in rotor systems. J. Sound Vib. 2009, 321, 1109–1128. [Google Scholar] [CrossRef]

- Zhang, Y.; Bang, C.W.; Qiao, L.L. Uncertain responses of rotor-stator systems with rubbing. J. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2003, 46, 150–154. [Google Scholar] [CrossRef]

- Billings, S.A. Identification of nonlinear systems—A survey. IEE Proc. D Control Theory Appl. 1980, 127, 272–285. [Google Scholar] [CrossRef]

- Leontaritis, I.J.; Billings, S.A. Input-output parametric models for non-linear systems part I: Deterministic non-linear systems. J. Int. J. Control 1985, 41, 303–328. [Google Scholar] [CrossRef]

- Xia, X.; Zhou, J.; Xiao, J. A novel identification method of Volterra series in rotor-bearing system for fault diagnosis. J. Mech. Syst. Signal Process. 2016, 66, 557–567. [Google Scholar] [CrossRef]

- Harnischmacher, G.; Marquardt, W. Nonlinear model predictive control of multivariable processes using block-structured models. J. Control Eng. Pract. 2007, 15, 1238–1256. [Google Scholar] [CrossRef]

- Arnaiz-González, Á.; Fernández-Valdivielso, A.; Bustillo, A. Using artificial neural networks for the prediction of dimensional error on inclined surfaces manufactured by ball-end milling. Int. J. Adv. Manuf. Technol. 2016, 83, 847–859. [Google Scholar]

- Billings, S.A. Nonlinear System Identification: NARMAX Methods in the Time, Frequency, and Spatio-Temporal Domains; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Cadenas, E.; Rivera, W.; Campos, A.R. Wind speed prediction using a univariate ARIMA model and a multivariate NARX model. J. Energies 2016, 9, 109. [Google Scholar] [CrossRef]

- Asgari, H.; Chen, X.Q.; Morini, M. NARX models for simulation of the start-up operation of a single-shaft gas turbine. J. Appl. Therm. Eng. 2016, 93, 368–376. [Google Scholar] [CrossRef]

- Ruano, A.E.; Fleming, P.J.; Teixeira, C. Nonlinear identification of aircraft gas-turbine dynamics. J. Neurocomput. 2003, 55, 551–579. [Google Scholar] [CrossRef]

- Peng, Z.K.; Lang, Z.Q.; Wolters, C. Feasibility study of structural damage detection using NARMAX modelling and Nonlinear Output Frequency Response Function based analysis. J. Mech. Syst. Signal Process. 2011, 25, 1045–1061. [Google Scholar] [CrossRef]

- Liu, X.; Lu, C.; Liang, S. Vibration-induced aerodynamic loads on large horizontal axis wind turbine blades. J. Appl. Energy 2017, 185, 1109–1119. [Google Scholar] [CrossRef]

- Urbikain, G.; Campa, F.J.; Zulaika, J.J. Preventing chatter vibrations in heavy-duty turning operations in large horizontal lathes. J. Sound Vib. 2015, 340, 317–330. [Google Scholar] [CrossRef]

- Tang, H.; Liao, Y.H.; Cao, J.Y. Fault diagnosis approach based on Volterra models. J. Mech. Syst. Signal Process. 2010, 24, 1099–1113. [Google Scholar] [CrossRef]

- Jing, J.; Li, Z.N.; Tang, G.S. Fault Diagnosis Method Based on Volterra Kernel Identification for Rotor Crack. J. Mach. Tool Hydraul. 2010, 23, 1001–3881. [Google Scholar]

- Lara, J.M.; Milani, B.E. Identification of neutralization process using multi-level pseudo-random signals. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; pp. 3822–3827. [Google Scholar]

- Chen, S.; Billings, S.A.; Luo, W. Orthogonal least squares methods and their application to non-linear system identification. Int. J. Control 1989, 50, 1873–1896. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.; Chu, F. Fault recognition method for speed-up and speed-down process of rotating machinery based on independent component analysis and Factorial Hidden Markov Model. J. Sound Vib. 2006, 291, 60–71. [Google Scholar] [CrossRef]

- Zhu, X.R.; Zhang, Y.Y.; Zhang, G.L. Fault Diagnosis for Speed-Up and Speed-Down Process of Rotor-Bearing System Based on Volterra Series Model and Neighborhood Rough Sets. J. Adv. Mater. Res. Trans. Tech. Publ. 2012, 411, 567–571. [Google Scholar] [CrossRef]

- Chen, G. Study on nonlinear dynamic response of an unbalanced rotor supported on ball bearing. J. Vib. Acoust. 2009, 131, 061001. [Google Scholar] [CrossRef]

- Wei, H.L.; Billings, S.A. Model structure selection using an integrated forward orthogonal search algorithm assisted by squared correlation and mutual information. Int. J. Model. Identif. Control 2008, 3, 341–356. [Google Scholar] [CrossRef]

- Billings, S.A.; Chen, S.; Korenberg, M.J. Identification of MIMO non-linear systems using a forward-regression orthogonal estimator. Int. J. Control 1989, 49, 2157–2189. [Google Scholar] [CrossRef]

- Wei, H.L.; Lang, Z.Q.; Billings, S.A. Constructing an overall dynamical model for a system with changing design parameter properties. Int. J. Model. Identif. Control 2008, 5, 93–104. [Google Scholar] [CrossRef]

- Ramírez, C.; Acuña, G. Forecasting cash demand in ATM using neural networks and least square support vector machine. J. Prog. Pattern Recognit. Image Anal. Comput. Vis. Appl. 2011, 7042, 515–522. [Google Scholar]

| Step | Term | Coefficient | ERR% |

|---|---|---|---|

| 1 | 1.5806 | 89.2521 | |

| 2 | −0.4635 | 10.3201 | |

| 3 | 2.9713 × 10−4 | 0.0963 | |

| 4 | 0.0931 | 0.0349 | |

| 5 | −2.2028 × 10−4 | 0.0227 | |

| 6 | −3.7178 × 10−4 | 0.0158 | |

| 7 | −5.3027 | 0.0119 | |

| 8 | −0.2637 | 0.0052 | |

| 9 | −0.0418 | 0.0078 | |

| 10 | 3.2374 × 10−4 | 0.0021 | |

| 11 | 1.8632 × 10−4 | 0.0023 | |

| 12 | −0.0091 | 0.0008 | |

| 13 | 0.0301 | 0.0009 | |

| 14 | −1.7955 × 10−4 | 0.0004 | |

| 15 | −8.0035 × 10−4 | 0.0004 | |

| Total | - | - | 99.7728 |

| Frequency Range (rad/s) | RMSE of MPO Method (m) | RMSE of OSA Method (m) |

|---|---|---|

| Low speed | 3.1582 × 10−6 | 2.9461 × 10−7 |

| Critical speed | 5.2704 × 10−6 | 4.7590 × 10−7 |

| Over critical speed | 1.4032 × 10−6 | 2.0754 × 10−6 |

| Step | Term | Coefficient | ERR% |

|---|---|---|---|

| 1 | 1.8444 | 99.4393 | |

| 2 | −0.8595 | 0.5177 | |

| 3 | 0.1788 | 0.0027 | |

| 4 | −0.2439 | 0.0017 | |

| 5 | 0.0642 | 0.0138 | |

| 6 | 0.6580 | 0.0003 | |

| 7 | 0.1268 | 0.0006 | |

| 8 | −0.5515 | 0.0003 | |

| 9 | −0.0243 | 0.0003 | |

| 10 | −0.7159 | 0.0001 | |

| 11 | −0.1019 | 0.0001 | |

| 12 | 0.0250 | 0.0001 | |

| 13 | −0.0020 | 0.0001 | |

| 14 | 0.1688 | 0.0002 | |

| 15 | −0.1482 | 0.0005 | |

| Total | - | - | 99.9778 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Liu, H.; Zhu, Y.; Wang, F.; Luo, Z. The NARX Model-Based System Identification on Nonlinear, Rotor-Bearing Systems. Appl. Sci. 2017, 7, 911. https://doi.org/10.3390/app7090911

Ma Y, Liu H, Zhu Y, Wang F, Luo Z. The NARX Model-Based System Identification on Nonlinear, Rotor-Bearing Systems. Applied Sciences. 2017; 7(9):911. https://doi.org/10.3390/app7090911

Chicago/Turabian StyleMa, Ying, Haopeng Liu, Yunpeng Zhu, Fei Wang, and Zhong Luo. 2017. "The NARX Model-Based System Identification on Nonlinear, Rotor-Bearing Systems" Applied Sciences 7, no. 9: 911. https://doi.org/10.3390/app7090911