Perspective on Double Pulsed Gas Metal Arc Welding

Abstract

:1. Introduction

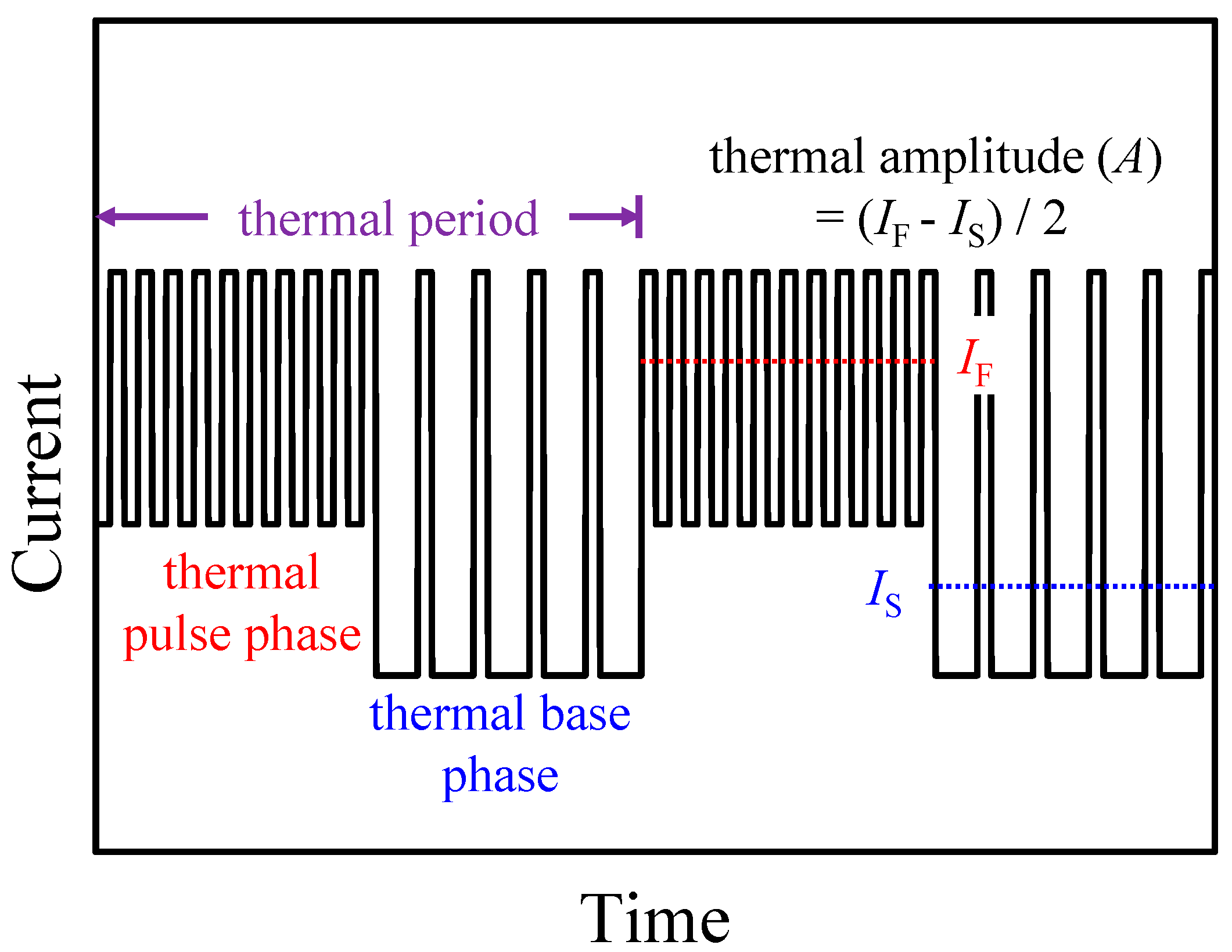

2. Process and Weld Characteristic of DP-GMAW

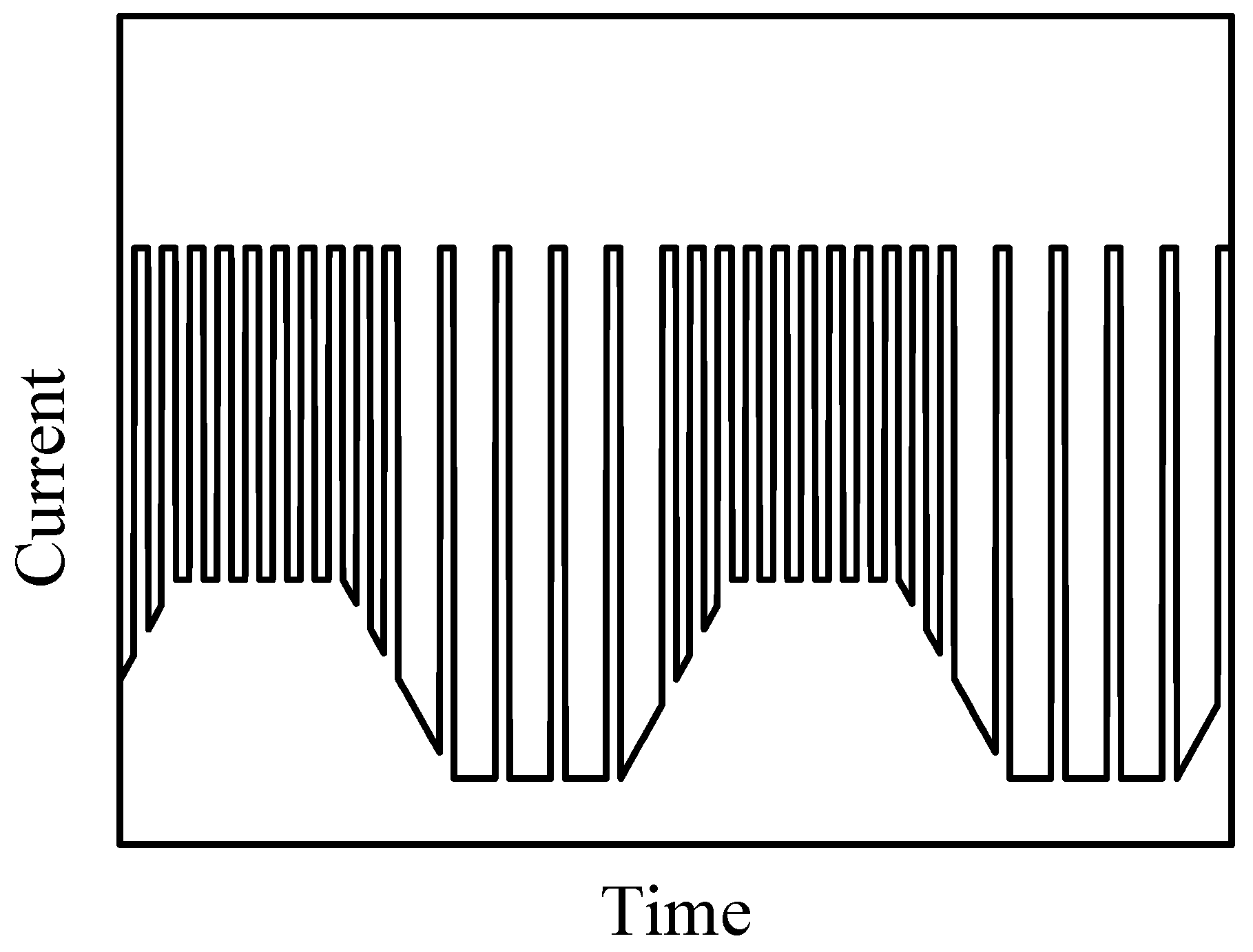

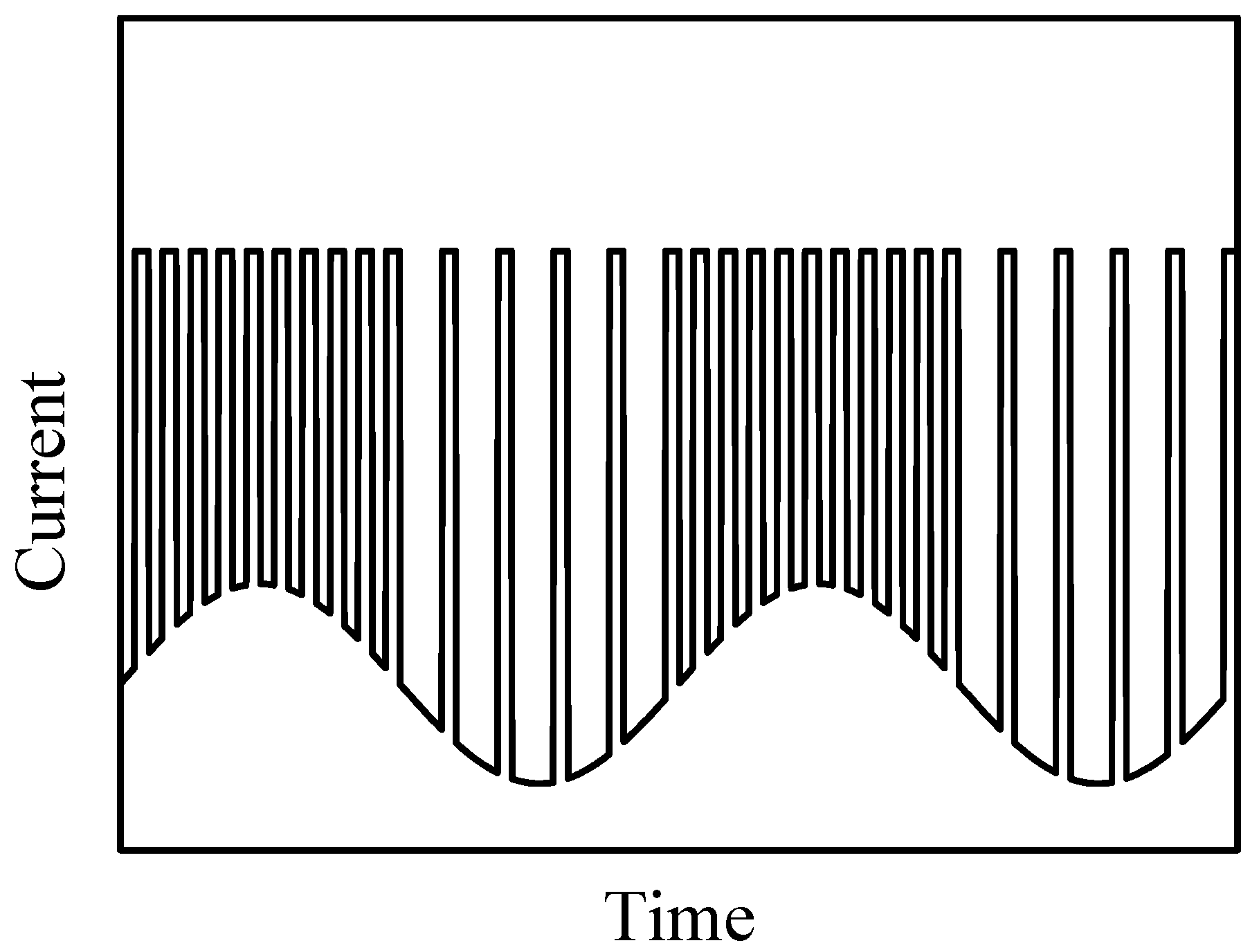

2.1. Arc and Droplet Transfer Characteristic

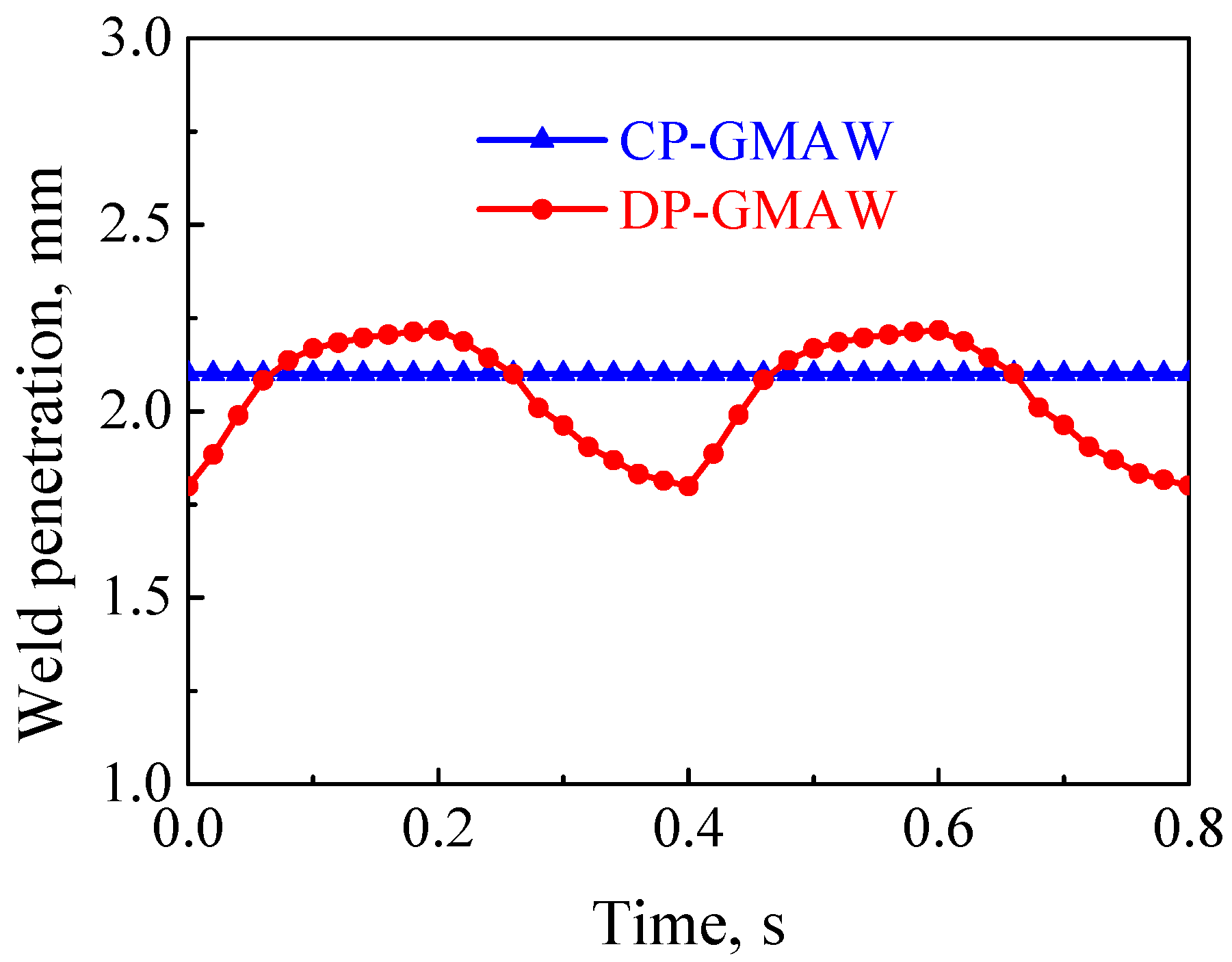

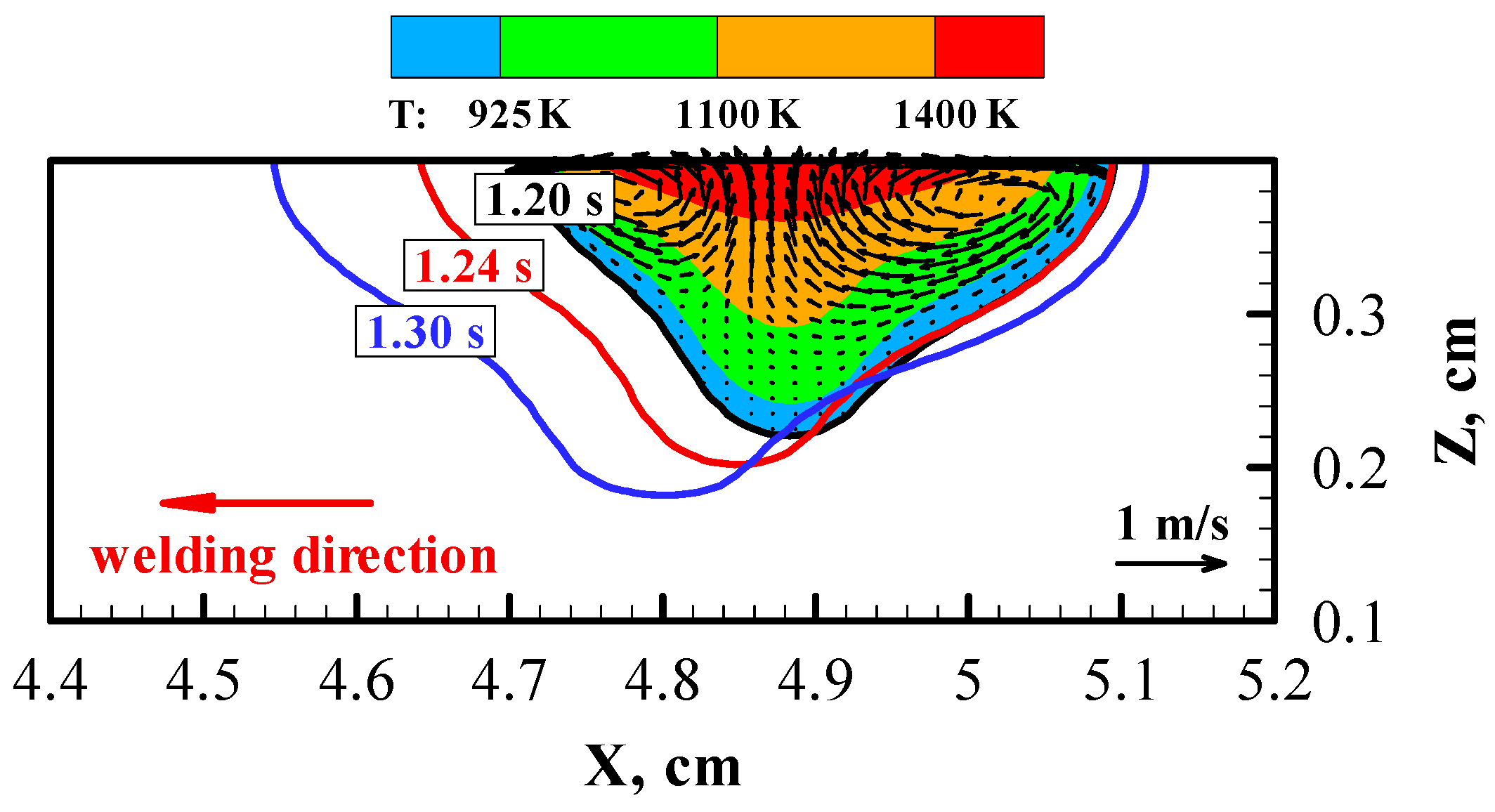

2.2. Weld Pool and Bead Characteristic

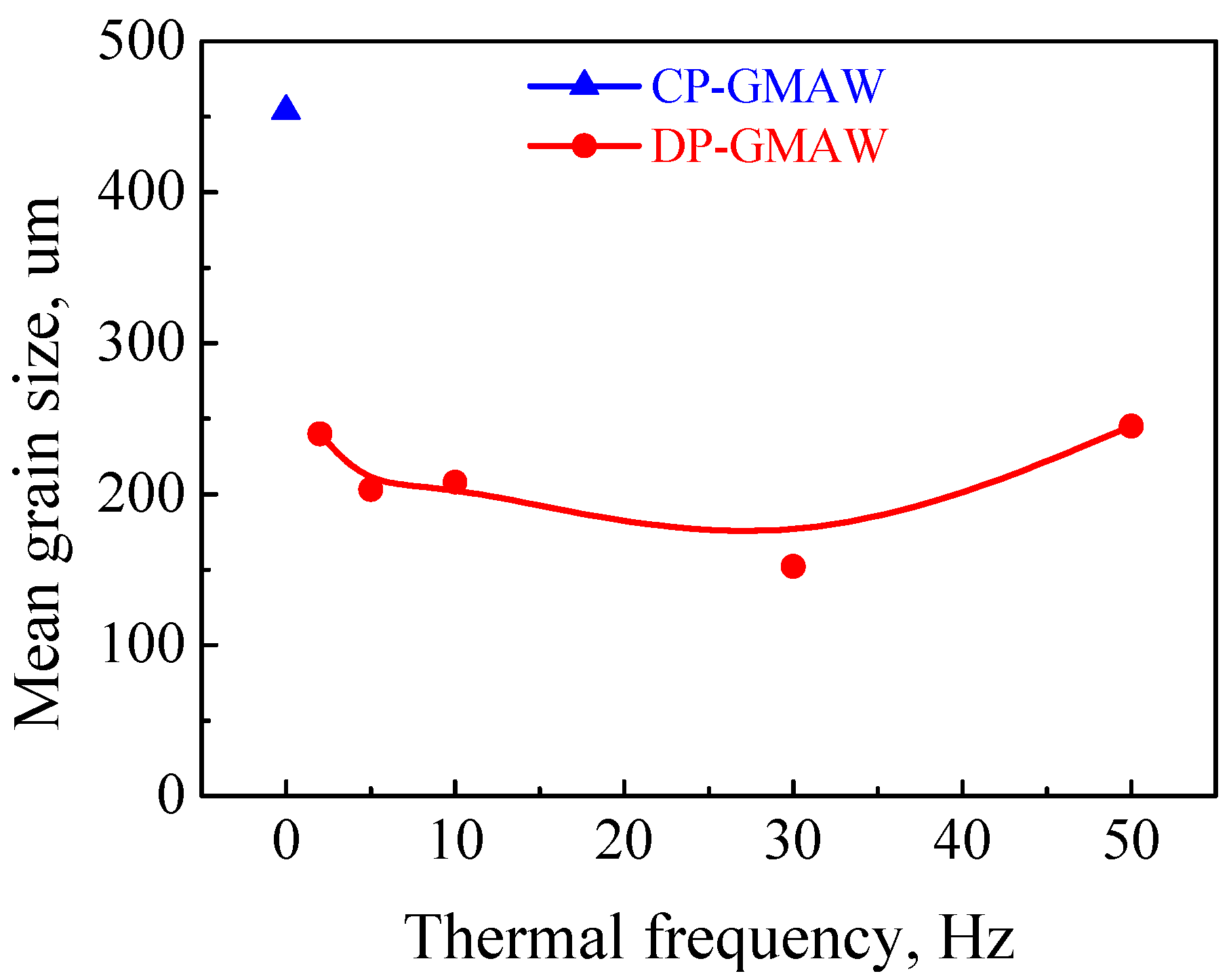

2.3. Solidification Structure

3. Advantages of DP-GMAW

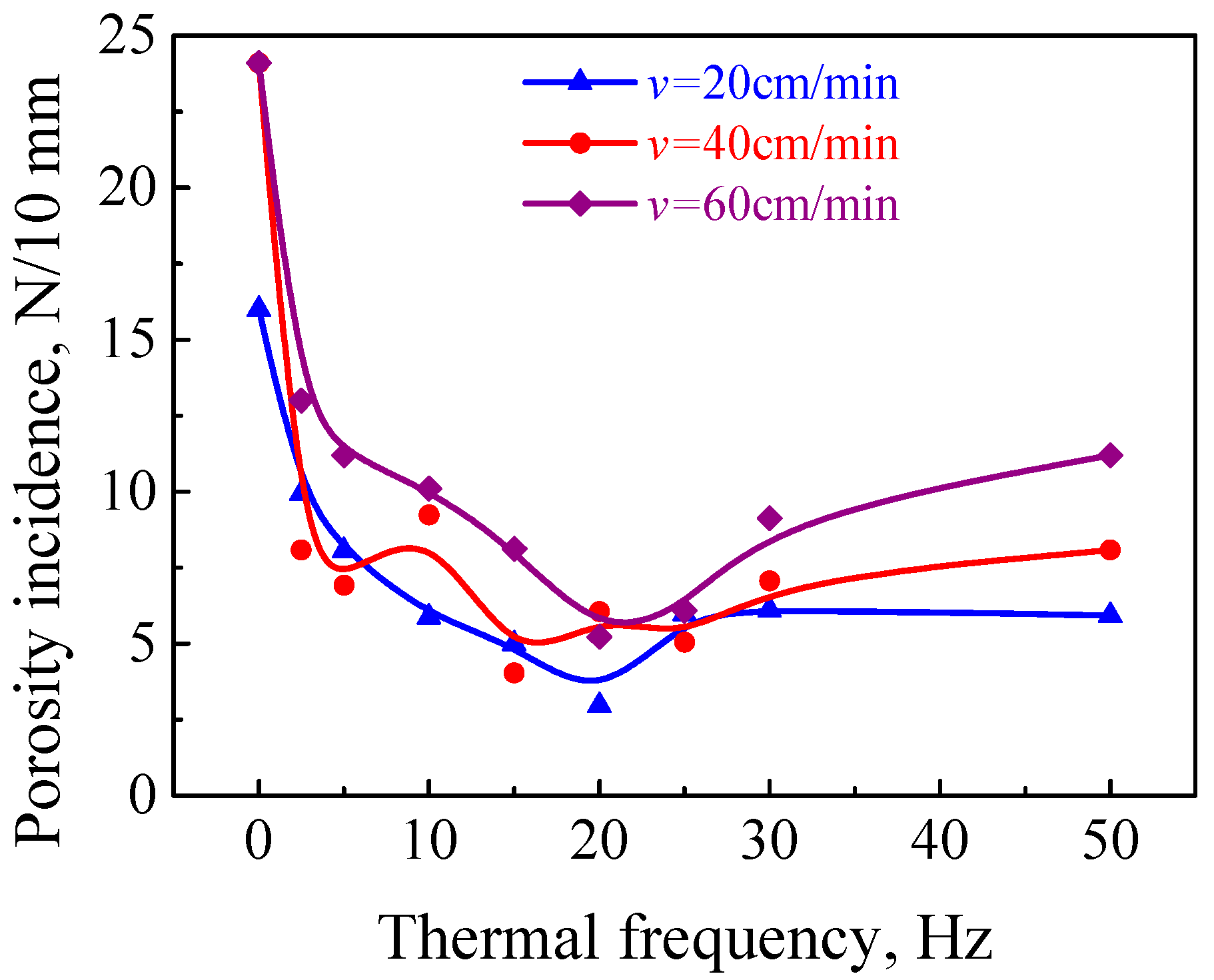

3.1. Reduced Porosity Incidence

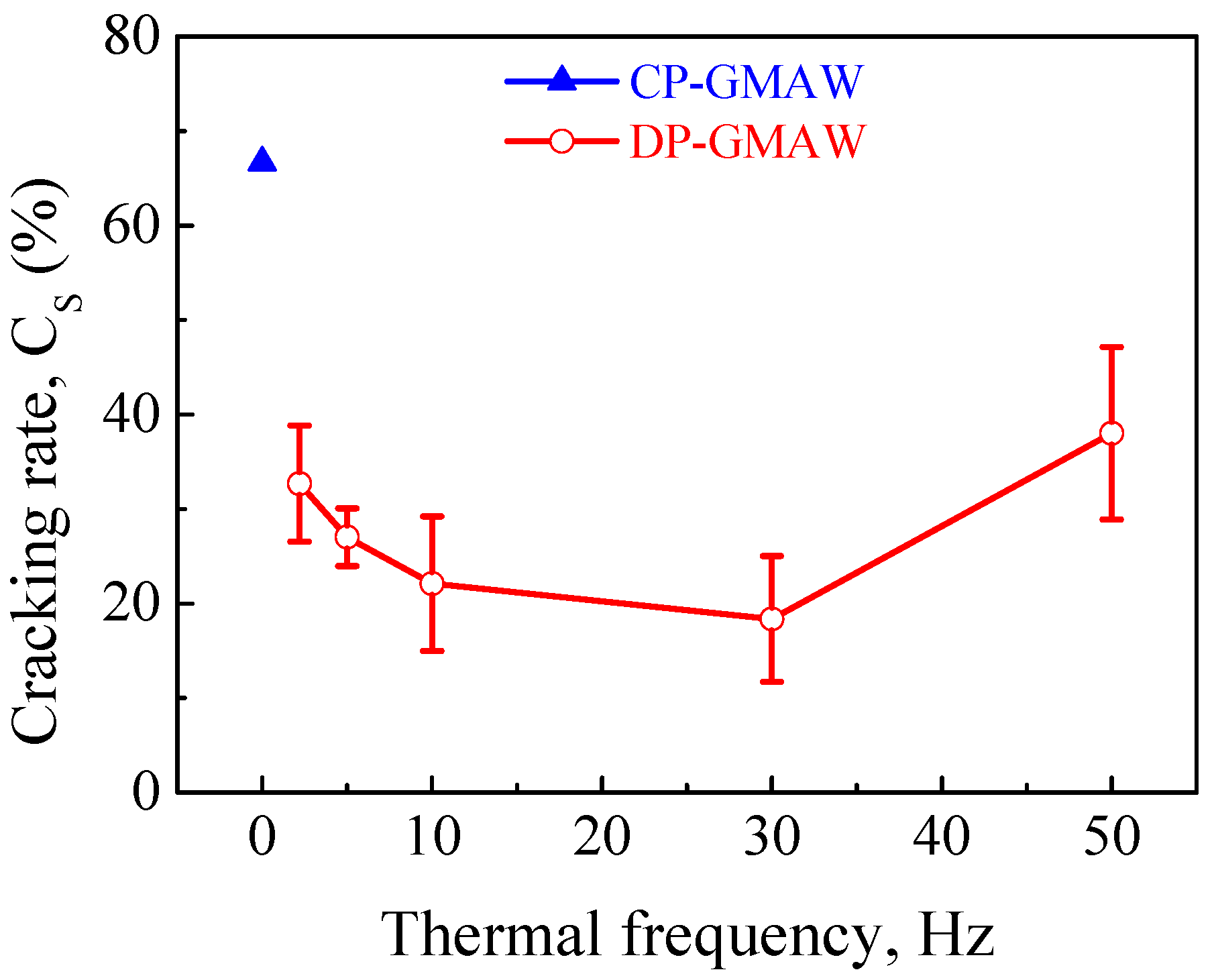

3.2. Improved Solidification Cracking Susceptibility

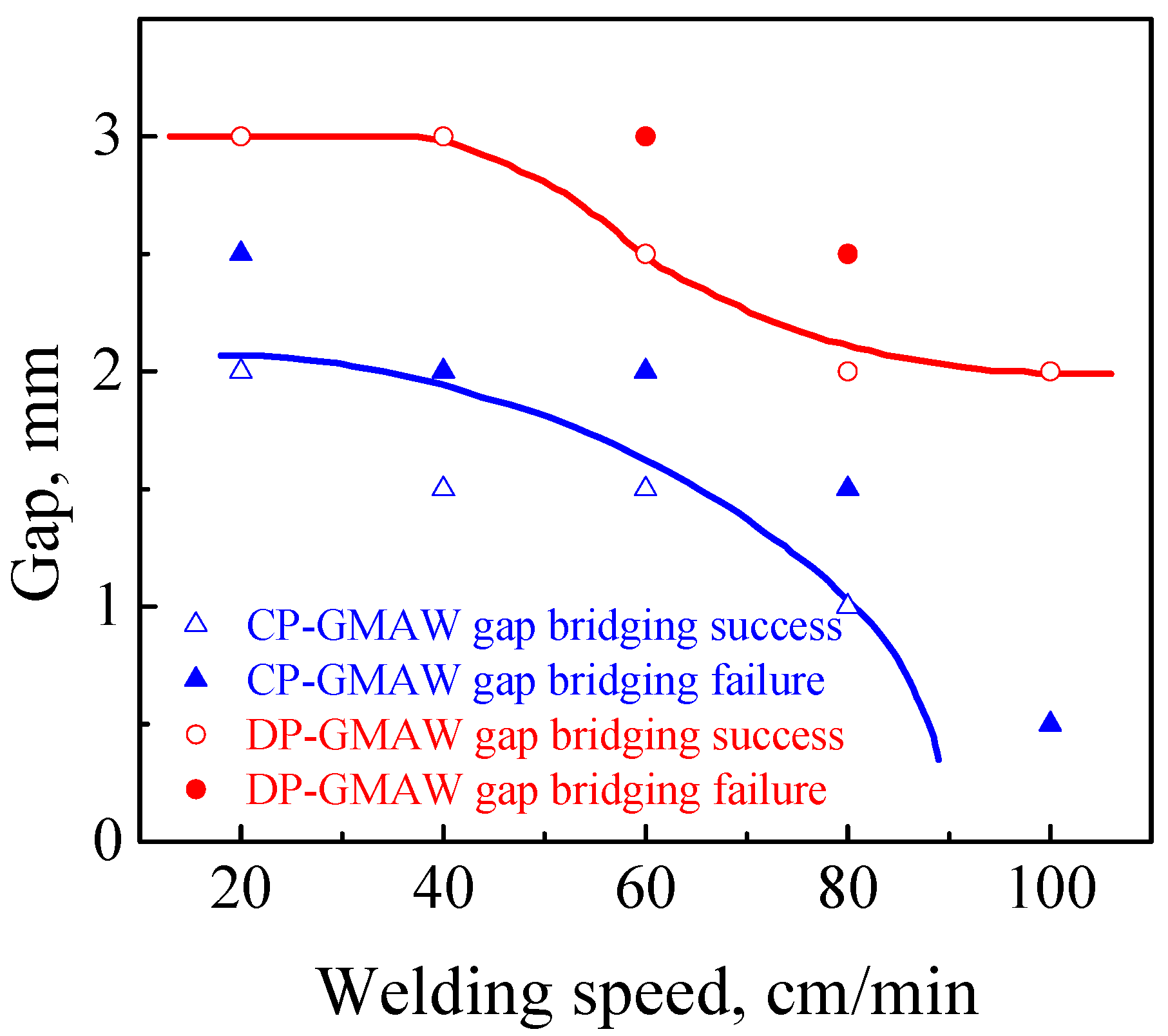

3.3. Precise Current Adjustment and Excellent Gap Bridging Ability

4. Evolution Process and Future Trends of DP-GMAW

4.1. Evolution Process of DP-GMAW

4.2. Future Trend of DP-GMAW

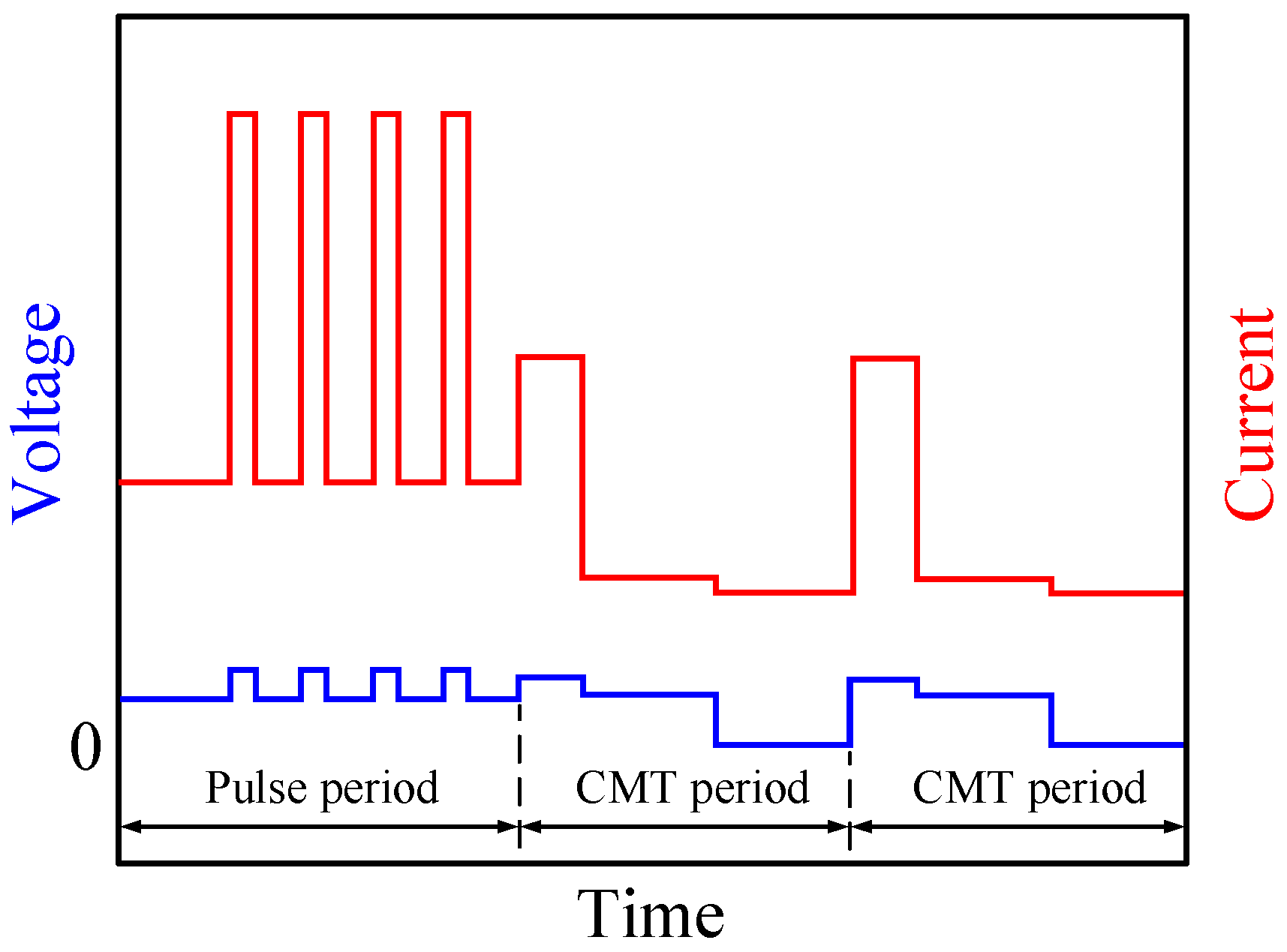

4.2.1. Cold Metal Transfer and Pulsed GMAW (CMT-Pulse)

4.2.2. Variable Polarity Double Pulsed GMAW (VPDP-GMAW)

4.2.3. Hybrid Laser DP-GMAW

5. Conclusions

- (1)

- A periodical welding current generates an oscillation of arc force and droplet pressure, which produces a weld pool stir effect.

- (2)

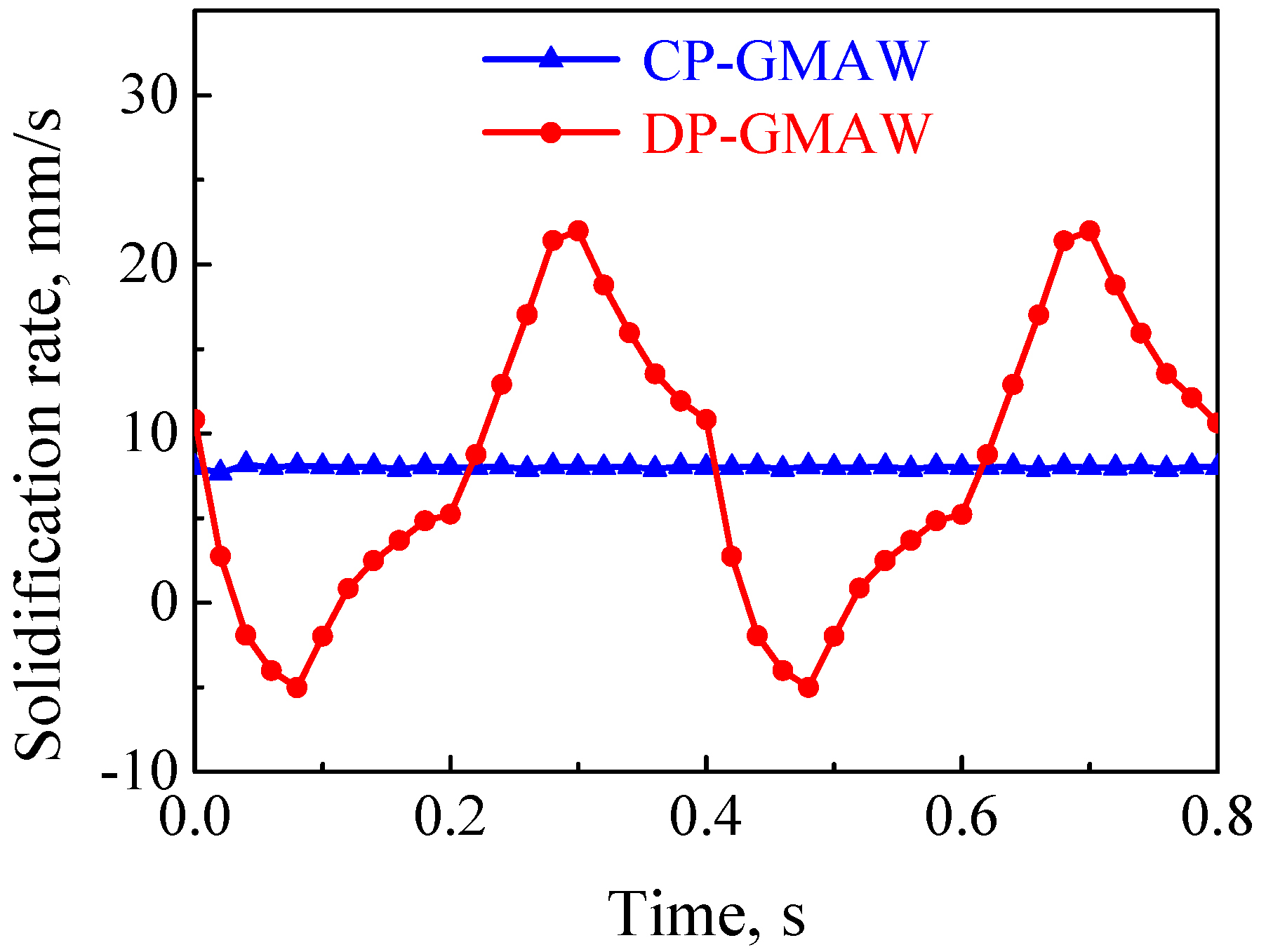

- Periodical heat input generates expansion and shrinkage of the weld pool, which causes an unusual remelting and resolidification of the previously solidified metal. DP-GMAW has an increased solidification growth rate and cooling rate compared with conventional pulsed welding at the same heat input.

- (3)

- Microstructural refinement of fusion metal by DP-GMAW is reported by several researchers. The mechanism of microstructural refinement is revealed as combined effect of the weld pool stir effect and an increased cooling rate. The numerical and experimental results indicate that a refined microstructure can be achieved by adjusting the pulsing parameters instead of changing the heat input. DP-GMAW features diverse grain orientation due to the expansion and shrinkage of the weld pool.

- (4)

- The weld pool stir effect improves the fluidity of liquid metal in the molten pool. Therefore, a larger number of hydrogen bubbles have a chance to float out and release from the molten pool, and fewer hydrogen bubbles are trapped in the solidification wall and form pores.

- (5)

- Improved solidification cracking susceptibility is achieved due to refined solidification structures by DP-GMAW.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Feng, Y.Q.; Luo, Z.; Li, Y.; Ling, Z.X. A Novel Method for Resistance Plug Welding of 7075 Aluminum Alloy. Mater. Manuf. Process. 2016, 31, 2077–2083. [Google Scholar] [CrossRef]

- Shi, J.; Zhou, Y.; Liu, L. Application of Pulsed Laser-TIG Hybrid Heat Source in Root Welding of Thick Plate Titanium Alloys. Appl. Sci. 2017, 7. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.G.; Sun, W.; McCartney, D.G. A review of friction stir welding of aluminium matrix composites. Mater. Des. 2015, 86, 61–71. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Simoncini, M.; Pieralisi, M.; Ciccarelli, D. Effect of welding motion and pre-/post-annealing of friction stir welded AA5754 joints. Mater. Des. 2016, 93, 146–159. [Google Scholar] [CrossRef]

- Dragatogiannis, D.A.; Koumoulos, E.P.; Kartsonakis, I.A.; Pantelis, D.I.; Karakizis, P.N.; Charitidis, C.A. Dissimilar Friction Stir Welding Between 5083 and 6082 Al Alloys Reinforced With TiC Nanoparticles. Mater. Manuf. Process. 2016, 31, 2101–2114. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V.; Reddy, C.; Khatirkar, R.K. Effect of friction stir welding process parameters on Mg-AZ31B/Al-AA6061 joints. Mater. Manuf. Process. 2017, 1–7. [Google Scholar] [CrossRef]

- Zhu, Q.; Xue, J.; Yao, P.; Dong, C.; Wang, L.; Heng, G.; Li, Z. Gaussian pulsed current waveform welding for aluminum alloys. Mater. Manuf. Process. 2015, 30, 1124–1130. [Google Scholar] [CrossRef]

- Yi, J.; Cao, S.F.; Li, L.X.; Guo, P.C.; Liu, K.Y. Effect of welding current on morphology and microstructure of Al alloy T-joint in double-pulsed MIG welding. Trans. Nonferrous Met. Soc. China 2015, 25, 3204–3211. [Google Scholar] [CrossRef]

- Da Silva, C.L.M.; Scotti, A. Performance assessment of the (Trans)Varestraint tests for determining solidification cracking susceptibility when using welding processes with filler metal. Meas. Sci. Technol. 2004, 15, 2215. [Google Scholar] [CrossRef]

- Da Silva, C.L. M.; Scotti, A. The influence of double pulse on porosity formation in aluminum GMAW. J. Mater. Process. Technol. 2006, 171, 366–372. [Google Scholar] [CrossRef]

- Kah, P.; Suoranta, R.; Martikainen, J. Advanced gas metal arc welding processes. Int. J. Adv. Manuf. Technol. 2013, 67, 655–674. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Kong, X.Y. Study on DC Double Pulse Metal Inert Gas (MIG) Welding of Magnesium Alloy. Mater. Manuf. Process. 2012, 27, 462–466. [Google Scholar] [CrossRef]

- Xue, J. Probing improved double pulsed GMAW. Weld. Cut. China 2017, 170–175. [Google Scholar] [CrossRef]

- Devakumaran, K.; Rajasekaran, N.; Ghosh, P.K. Process Characteristics of Inverter Type GMAW Power Source under Static and Dynamic Operating Conditions. Mater. Manuf. Process. 2012, 27, 1450–1456. [Google Scholar] [CrossRef]

- Sen, M.; Mukherjee, M.; Pal, T.K. Evaluation of correlations between DP-GMAW process parameters and bead geometry. Weld. J. 2015, 94, 265S–279S. [Google Scholar]

- Yamamoto, H.; Harada, S.; Ueyama, T.; Ogawa, S. Development of low-frequency pulsed MIG welding for aluminium alloys. Weld. Int. 1992, 6, 580–583. [Google Scholar] [CrossRef]

- Yamamoto, H.; Harada, S.; Ueyama, T.; Ogawa, S.; Matsuda, F.; Nakata, K. Beneficial effects of low-frequency pulsed MIG welding on grain refinement of weld metal and improvement of solidification crack susceptibility of aluminium alloys: Study of low-frequency pulsed MIG welding. Weld. Int. 1993, 7, 456–461. [Google Scholar] [CrossRef]

- Liu, A.; Tang, X.; Lu, F. Study on welding process and prosperities of AA5754 Al-alloy welded by double pulsed gas metal arc welding. Mater. Des. 2013, 50, 149–155. [Google Scholar] [CrossRef]

- Mathivanan, A.; Devakumaran, K.; Kumar, A.S. Comparative study on mechanical and metallurgical properties of AA6061 aluminum alloy sheet weld by pulsed current and dual pulse gas metal arc welding processes. Mater. Manuf. Process. 2014, 29, 941–947. [Google Scholar] [CrossRef]

- Nakata, K.; Matsuda, F.; Jogan, S.; Harada, S.; Ueyama, T. Improvement of weld solidification crack susceptibility of Al-Zn-Mg ternary alloy by low-frequency pulsed GMA (MIG) welding with trial-manufactured Zr-added Al-high-Mg welding wire. Weld. Int. 1994, 8, 690–696. [Google Scholar] [CrossRef]

- Liu, A.; Tang, X.; Lu, F. Arc profile characteristics of Al alloy in double-pulsed GMAW. Int. J. Adv. Manuf. Technol. 2013, 65, 1–7. [Google Scholar] [CrossRef]

- Wang, L.L.; Heng, G.C.; Chen, H.; Xue, J.X.; Lin, F.L.; Huang, W.J. Methods and results regarding sinusoid modulated pulse gas metal arc welding. Int. J. Adv. Manuf. Technol. 2016, 86, 1841–1851. [Google Scholar] [CrossRef]

- Rokhlin, S.; Guu, A. A study of arc force, pool depression, and weld penetration during gas tungsten arc welding. Weld. J. 1993, 72, 381S–390S. [Google Scholar]

- Liu, A. Investigation on Weld Formation Mechanism of DP-GMAW Welding an Al Alloy under Alternative Oscillation of High-low Frequency Pulses. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2014. [Google Scholar]

- Becker, D.W.; Adams, C.M. The role of pulsed GTA welding variables in solidification and grain refinement. Weld. J. 1979, 58, 143S–152S. [Google Scholar]

- Kou, S. Welding Metallurgy; John Wiley & Sons: Hoboken, NJ, USA, 2003; Volume 2, pp. 180–181. [Google Scholar]

- Wang, L.L.; Jin, L.; Huang, W.J.; Xu, M.; Xue, J.X. Effect of thermal frequency on AA6061 aluminum alloy double pulsed gas metal arc welding. Mater. Manuf. Process. 2016, 31, 2152–2157. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, S.; Shen, J.; Ma, L.; Yin, F. Microstructures and mechanical properties of 30Cr-4Mo ferritic stainless steel joints produced by double-pulsed gas metal arc welding. Int. J. Adv. Manuf. Technol. 2015, 80, 1975–1983. [Google Scholar] [CrossRef]

- Wang, L.L.; Wei, H.L.; Xue, J.X.; DebRoy, T. A pathway to microstructural refinement through double pulsed gas metal arc welding. Scr. Mater. 2017, 134, 61–65. [Google Scholar] [CrossRef]

- David, S.A.; Debroy, T. Current issues and problems in welding science. Science 1992, 257, 497–502. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.; Tang, X.; Lu, F. Weld pool profile characteristics of Al alloy in double-pulsed GMAW. Int. J. Adv. Manuf. Technol. 2013, 68, 2015–2023. [Google Scholar] [CrossRef]

- David, S.A.; Vitek, J.M. Correlation between solidification parameters and weld microstructures. Int. Mater. Rev. 1989, 34, 213–245. [Google Scholar] [CrossRef]

- Cicutti, C.; Boeri, R. On the relationship between primary and secondary dendrite arm spacing in continuous casting products. Scr. Mater. 2001, 45, 1455–1460. [Google Scholar] [CrossRef]

- Yuan, T.; Luo, Z.; Kou, S. Grain refining of magnesium welds by arc oscillation. Acta Mater. 2016, 116, 166–176. [Google Scholar] [CrossRef]

- Sreekumar, V.M.; Eskin, D.G. A New Al-Zr-Ti Master Alloy for Ultrasonic Grain Refinement of Wrought and Foundry Aluminum Alloys. JOM 2016, 68, 3088–3093. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Q.; Grujicic, M.; Wan, Z.Y. Monte Carlo simulation of grain growth and welding zones in friction stir welding of AA6082-T6. J. Mater. Sci. 2016, 51, 1882–1895. [Google Scholar] [CrossRef]

- Wang, L.L.; Wei, H.L.; Xue, J.X.; DebRoy, T. Special features of double pulsed gas metal arc welding. J. Mater. Process. Technol. 2017, in press. [Google Scholar] [CrossRef]

- Kumagai, M. Recent technological developments in welding of aluminium and its alloys. Weld. Int. 2003, 17, 173–181. [Google Scholar] [CrossRef]

- Pal, K.; Pal, S.K. Effect of Pulse Parameters on Weld Quality in Pulsed Gas Metal Arc Welding: A Review. J. Mater. Eng. Perform. 2010, 20, 918–931. [Google Scholar] [CrossRef]

- Yamamoto, H.; Harada, S.; Ueyama, T.; Ogawa, S.; Matsuda, F.; Nakata, K. Inhibiting effect of low-frequency pulsed MIG welding on blowhole generation in AI and its alloys (3rd report). Study of low-frequency pulsed MIG welding. Weld. Int. 1994, 8, 606–611. [Google Scholar] [CrossRef]

- Harada, S.; Ueyama, T.; Zhou, D.; Kudo, K.; Nakata, K. Surface modification of aluminium alloy by MIG welding with Al-Cu cladding wire. Weld. Int. 1994, 8, 432–437. [Google Scholar] [CrossRef]

- Kimura, R.; Hatayama, H.; Shinozaki, K.; Murashima, I.; Asada, J.; Yoshida, M. Effect of grain refiner and grain size on the susceptibility of Al-Mg die casting alloy to cracking during solidification. J. Mater. Process. Technol. 2009, 209, 210–219. [Google Scholar] [CrossRef]

- Tang, Z.; Vollertsen, F. Influence of grain refinement on hot cracking in laser welding of aluminum. Weld. World 2014, 58, 355–366. [Google Scholar] [CrossRef]

- Schempp, P.; Cross, C.E.; Pittner, A.; Oder, G.; Neumann, R.S.; Rooch, H.; Dorfel, I.; Osterle, W.; Rethmeier, M. Solidification of GTA Aluminum Weld Metal: Part 1-Grain Morphology Dependent upon Alloy Composition and Grain Refiner Content. Weld. J. 2014, 93, 53S–59S. [Google Scholar]

- Schempp, P.; Rethmeier, M. Understanding grain refinement in aluminium welding. Weld. World 2015, 59, 767–784. [Google Scholar] [CrossRef]

- Takai, R.; Kimura, S.; Kashiuchi, R.; Kotaki, H.; Yoshida, M. Grain refinement effects on the strain rate sensitivity and grain boundary sliding in partially solidified Al–5 wt%Mg alloy. Mater. Sci. Eng. A 2016, 667, 417–425. [Google Scholar] [CrossRef]

- Kou, S. Solidification and liquation cracking issues in welding. JOM 2003, 55, 37–42. [Google Scholar] [CrossRef]

- Mathivanan, A.; Senthilkumar, A.; Devakumaran, K. Pulsed current and dual pulse gas metal arc welding of grade AISI: 310S austenitic stainless steel. Def. Technol. 2015, 11, 269–274. [Google Scholar] [CrossRef]

- Tong, H.; Ueyama, T. Features of low frequency modulated type pulsed MIG welding process. Weld. Join. 2001, 33–35. [Google Scholar] [CrossRef]

- Chen, X.; Lin, F.; Wei, Z.; Xue, J. Double-pulsed MIG expert database based on mathematical modeling. Trans. China Weld. Inst. 2011, 32, 37–40. [Google Scholar]

- Wei, Z.; Chen, X.; Xue, J. Research on sinusoid modulated pulse MIG welding methodology. China Weld. 2011, 20, 75–80. [Google Scholar]

- Wei, Z.; Long, P.; Chen, X.; Xue, J. Application of control parameter in sinusoid modulation pulsed MIG welding of aluminum alloy. Trans. China Weld. Inst. 2012, 33, 9–12. [Google Scholar]

- Wei, Z.H.; Long, P.; Xue, J.-X. Regulation of sinusoidal swing parameters in aluminum welding using sinusoidal pulsed MIG welding. J. South China Univ. Technol. 2012, 40, 7–12. [Google Scholar] [CrossRef]

- Pang, J.; Hu, S.; Shen, J.; Wang, P.; Liang, Y. Arc characteristics and metal transfer behavior of CMT + P welding process. J. Mater. Process. Technol. 2016, 238, 212–217. [Google Scholar] [CrossRef]

- Fink, C.; Zinke, M. Welding of nickel-based alloy 617 using modified dip arc processes. Weld. World 2013, 57, 323–333. [Google Scholar] [CrossRef]

- Pickin, C.G.; Young, K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. Sci. Technol. Weld. Join. 2006, 11, 583–585. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, S.; Wang, Z.; Liang, Y. The effect of welding speed on microstructures of cold metal transfer deposited AZ31 magnesium alloy clad. Mater. Des. 2015, 86, 894–901. [Google Scholar] [CrossRef]

- Madhavan, S.; Kamaraj, M.; Vijayaraghavan, L. Cold metal transfer welding of aluminium to magnesium: Microstructure and mechanical properties. Sci. Technol. Weld. Join. 2016, 21, 310–316. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, H.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Tong, H.; Ueyama, T.; Harada, S.; Ushio, M. Quality and productivity improvement in aluminium alloy thin sheet welding using alternating current pulsed metal inert gas welding system. Sci. Technol. Weld. Join. 2001, 6, 203–208. [Google Scholar] [CrossRef]

- Arif, N.; Chung, H. Alternating current-gas metal arc welding for application to thick plates. J. Mater. Process. Technol. 2015, 222, 75–83. [Google Scholar] [CrossRef]

- Harwig, D.D.; Dierksheide, J.E.; Yapp, D.; Blackman, S. Arc behavior and melting rate in the VP-GMAW process. Weld. J. 2006, 85, 52S–62S. [Google Scholar]

- Vilarinho, L.O.; Nascimento, A.S.; Fernandes, D.B.; Mota, C.A. M. Methodology for Parameter Calculation of VP-GMAW. Weld. J. 2009, 88, 92S–98S. [Google Scholar]

- Park, H.J.; Kim, D.C.; Kang, M.J.; Rhee, S. The arc phenomenon by the characteristic of EN ratio in AC pulse GMAW. Int. J. Adv. Manuf. Technol. 2013, 66, 867–875. [Google Scholar] [CrossRef]

- Tong, H.; Ueyama, T.; Nakata, K.; Ushio, M. High speed welding of aluminium alloy sheets using laser assisted alternating current pulsed metal inert gas process. Sci. Technol. Weld. Join. 2003, 8, 229–234. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Fan, C.L.; Lin, S.B.; Yang, C.L. Novel soft variable polarity plasma arc and its influence on keyhole in horizontal welding of aluminium alloys. Sci. Technol. Weld. Join. 2014, 19, 493–499. [Google Scholar] [CrossRef]

- Babu, N.K.; Cross, C.E. Grain Refinement of AZ31 Magnesium Alloy Weldments by AC Pulsing Technique. Metall. Mater. Trans. A 2012, 43A, 4145–4154. [Google Scholar] [CrossRef]

- Kumar, R.; Dilthey, U.; Dwivedi, D.K.; Ghosh, P.K. Thin sheet welding of Al 6082 alloy by AC pulse-GMA and AC wave pulse-GMA welding. Mater. Des. 2009, 30, 306–313. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y. Influence of alloy elements on microstructure and mechanical property of aluminum–steel lap joint made by gas metal arc welding. J. Mater. Process. Technol. 2014, 214, 750–755. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y.; Zhang, Y.; Guo, Y. Characterization of intermetallic compound layer thickness at aluminum-steel interface during overlaying. Mater. Des. 2015, 78, 1–4. [Google Scholar] [CrossRef]

- Su, Y.; Hua, X.; Wu, Y. Effect of input current modes on intermetallic layer and mechanical property of aluminum-steel lap joint obtained by gas metal arc welding. Mater. Sci. Eng. A 2013, 578, 340–345. [Google Scholar] [CrossRef]

- Subashini, L.; Prabhakar, K.V.P.; Ravi, C.G.; Swati, G.; Padmanabham, G. Single Pass Laser-Arc Hybrid Welding of Maraging Steel Thick Sections. Mater. Manuf. Process. 2016, 31, 2186–2198. [Google Scholar] [CrossRef]

- Kang, K.; Kawahito, Y.; Gao, M.; Zeng, X. Effects of laser-arc distance on corrosion behavior of single-pass hybrid welded stainless clad steel plate. Mater. Des. 2017, 123, 80–88. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Casalino, G. Hybrid welding of AA5754 annealed alloy: Role of post weld heat treatment on microstructure and mechanical properties. Mater. Des. 2016, 90, 777–786. [Google Scholar] [CrossRef]

- Blecher, J.J.; Palmer, T.A.; DebRoy, T. Mitigation of Root Defect in Laser and Hybrid Laser-Arc Welding. Weld. J. 2015, 94, 73S–82S. [Google Scholar]

- Mazar Atabaki, M.; Ma, J.; Liu, W.; Kovacevic, R. Pore formation and its mitigation during hybrid laser/arc welding of advanced high strength steel. Mater. Des. 2015, 67, 509–521. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Bai, Q.-L.; Ning, J.; Wang, A.; Yang, J.-N.; Yin, X.-Q.; Zhang, J.-X. A comparative study on the microstructure and properties of copper joint between MIG welding and laser-MIG hybrid welding. Mater. Des. 2016, 110, 35–50. [Google Scholar] [CrossRef]

- He, C.; Huang, C.; Liu, Y.; Li, J.; Wang, Q. Effects of mechanical heterogeneity on the tensile and fatigue behaviours in a laser-arc hybrid welded aluminium alloy joint. Mater. Des. 2015, 65, 289–296. [Google Scholar] [CrossRef]

- Wang, P.; Chen, X.; Pan, Q.; Madigan, B.; Long, J. Laser welding dissimilar materials of aluminum to steel: an overview. Int. J. Adv. Manuf. Technol. 2016, 1–10. [Google Scholar] [CrossRef]

- You, D.; Gao, X.; Katayama, S. Monitoring of high-power laser welding using high-speed photographing and image processing. Mech. Syst. Signal Proc. 2014, 49, 39–52. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Xue, J. Perspective on Double Pulsed Gas Metal Arc Welding. Appl. Sci. 2017, 7, 894. https://doi.org/10.3390/app7090894

Wang L, Xue J. Perspective on Double Pulsed Gas Metal Arc Welding. Applied Sciences. 2017; 7(9):894. https://doi.org/10.3390/app7090894

Chicago/Turabian StyleWang, Leilei, and Jiaxiang Xue. 2017. "Perspective on Double Pulsed Gas Metal Arc Welding" Applied Sciences 7, no. 9: 894. https://doi.org/10.3390/app7090894