Precision Irrigation System (PIS) Using Sensor Network Technology Integrated with IOS/Android Application

Abstract

:1. Introduction

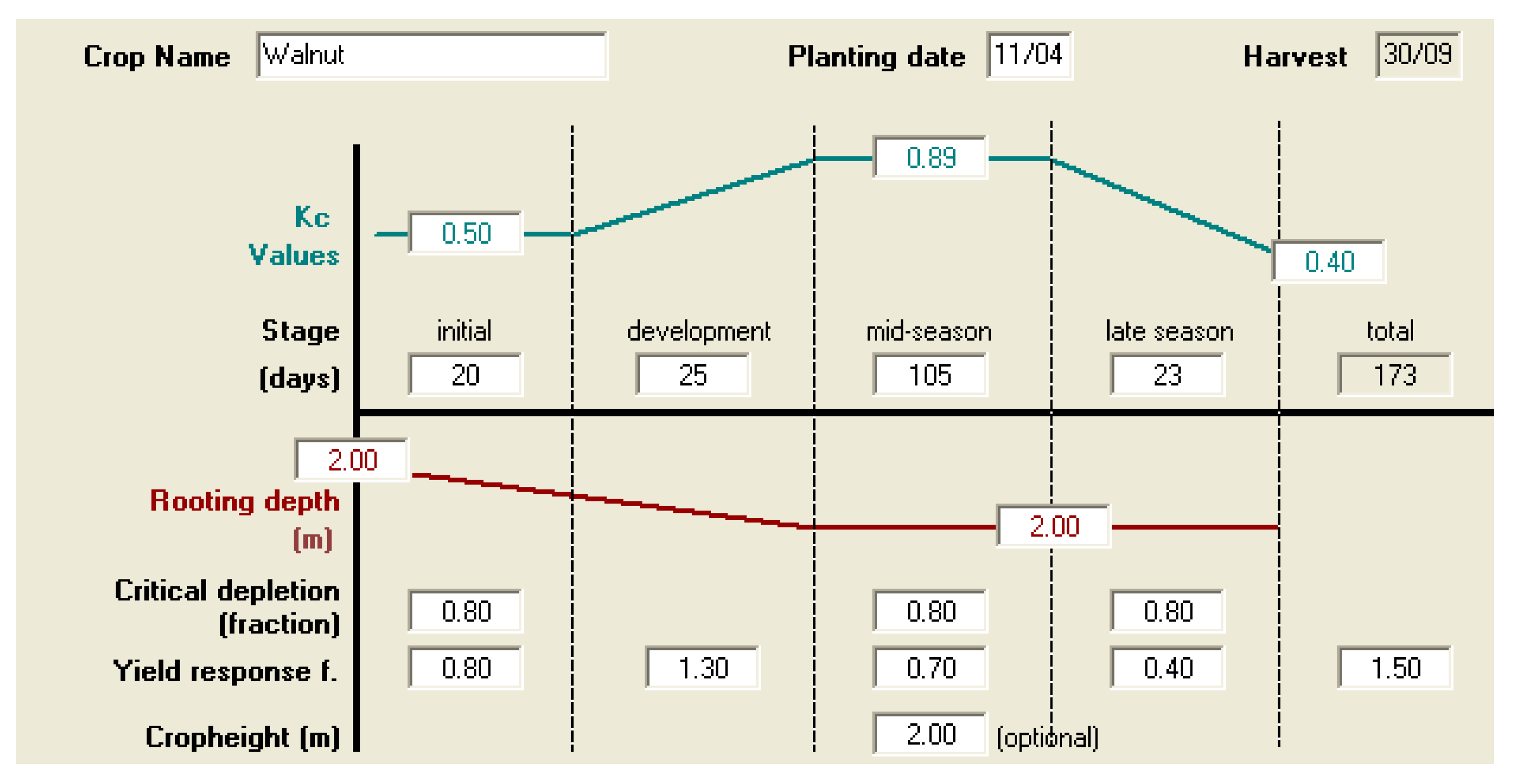

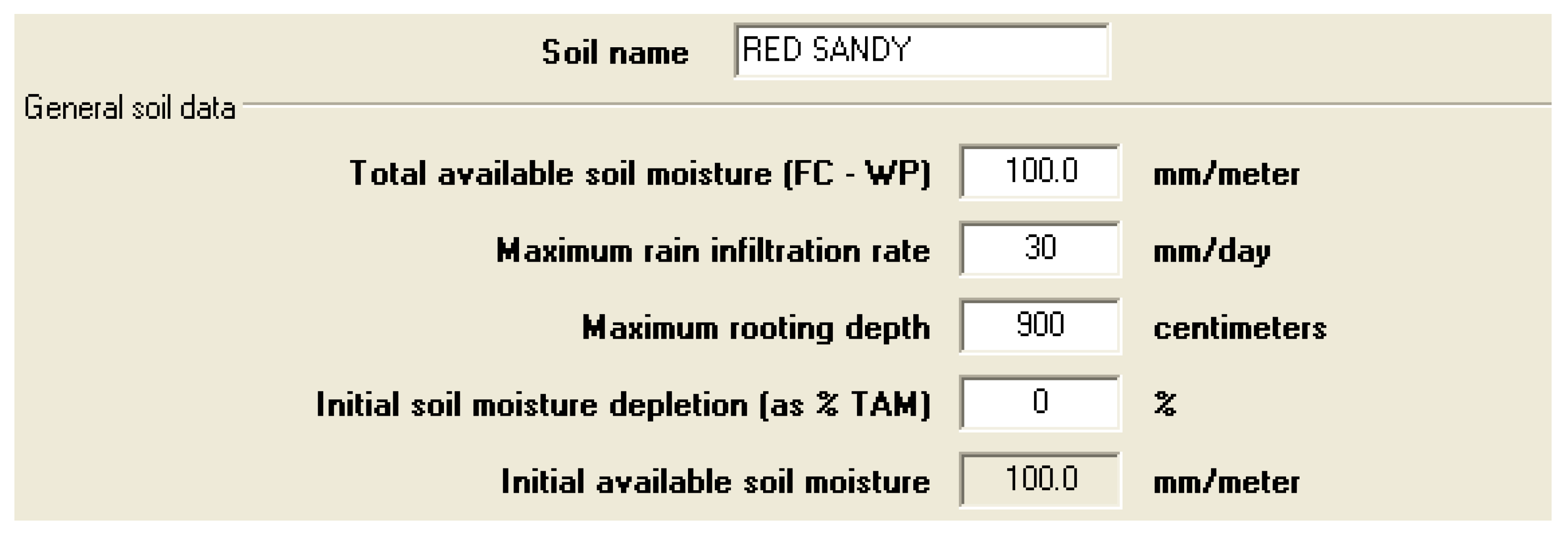

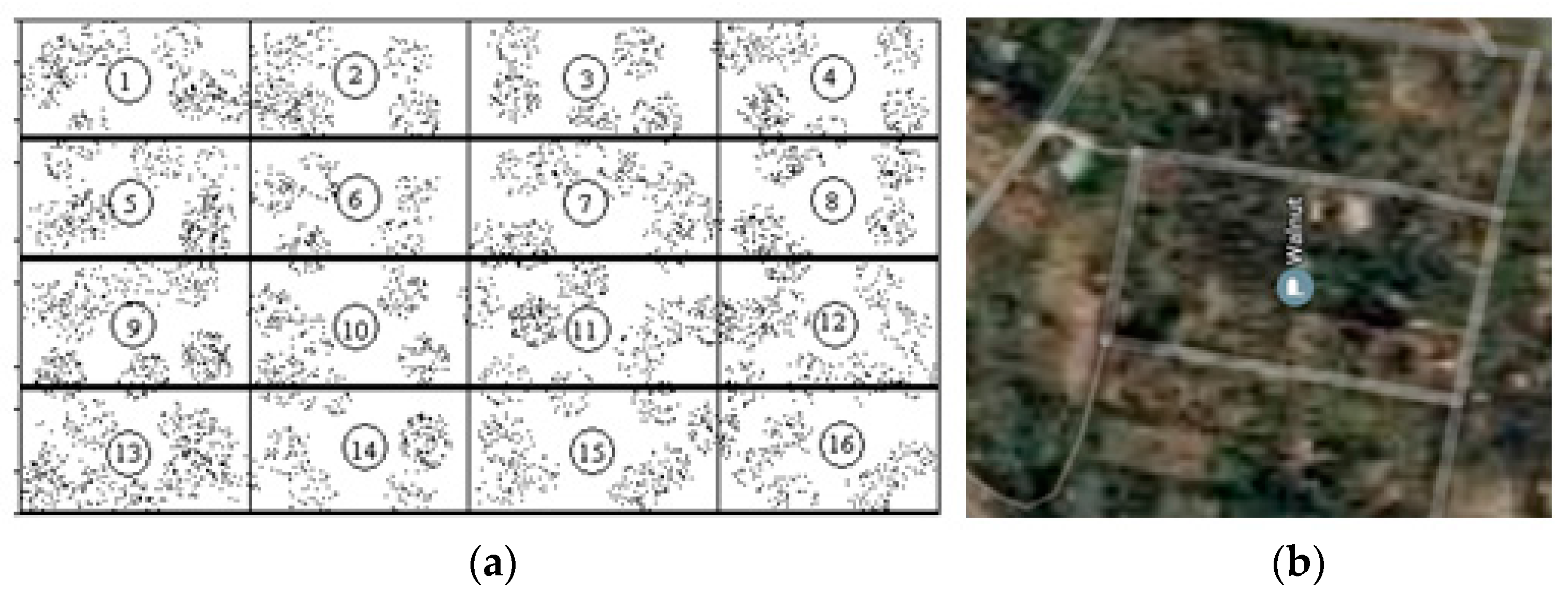

2. Irrigation System

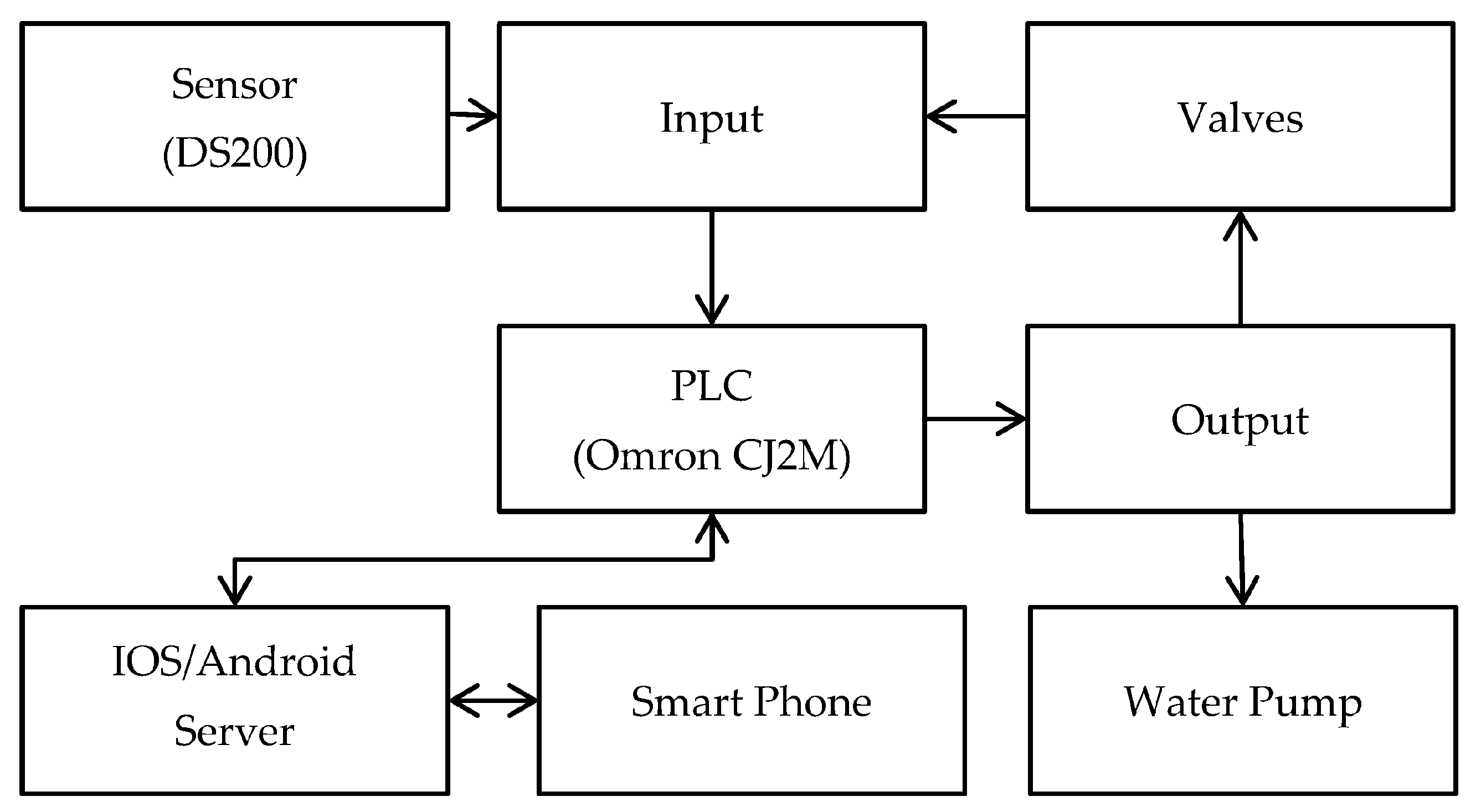

3. System Architecture

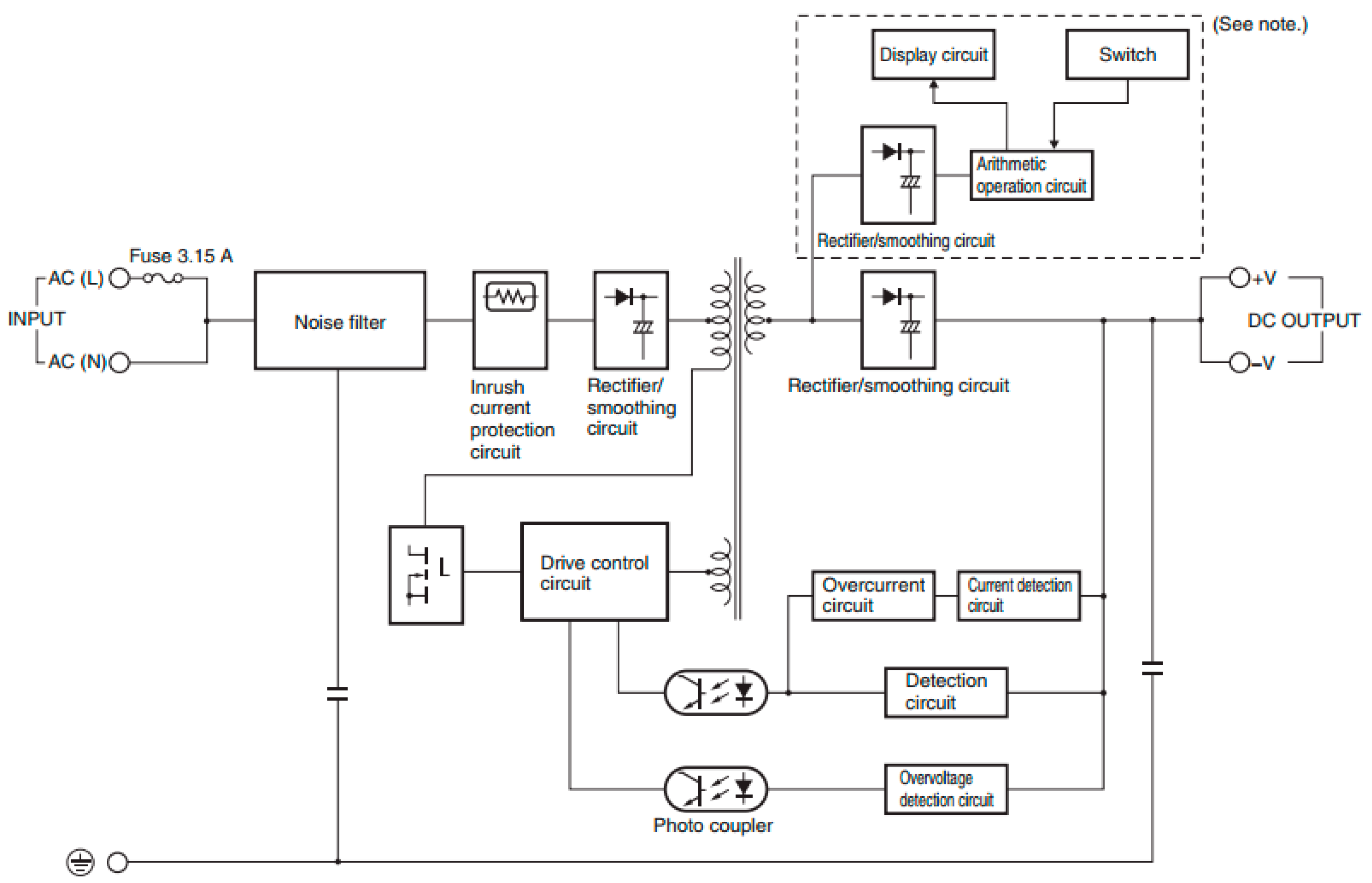

3.1. Water Booster

3.2. Water Tank

3.3. Filter

3.4. Valves

3.5. Soil Moisture Sensor

3.6. Solar Panel and Setup

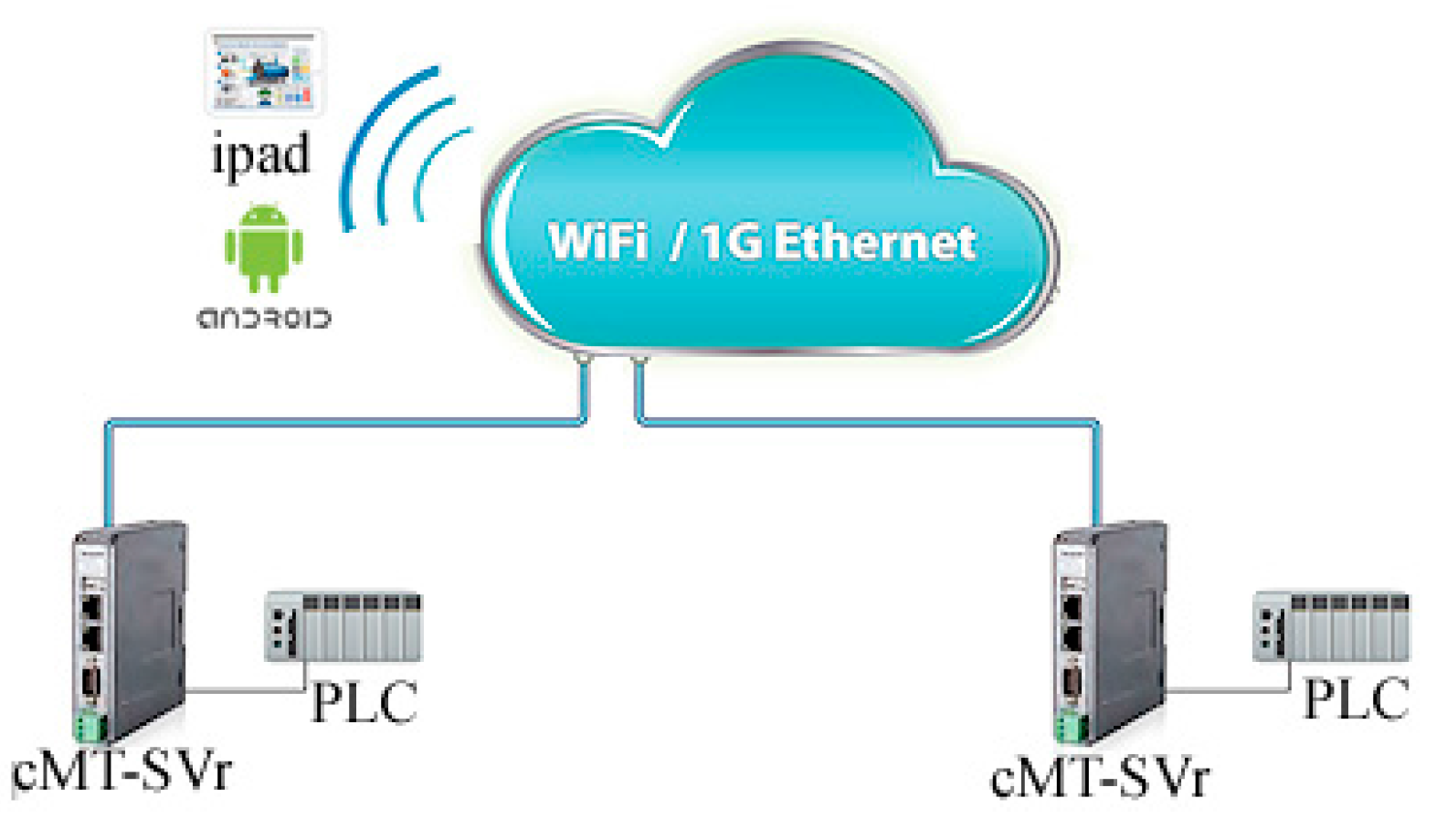

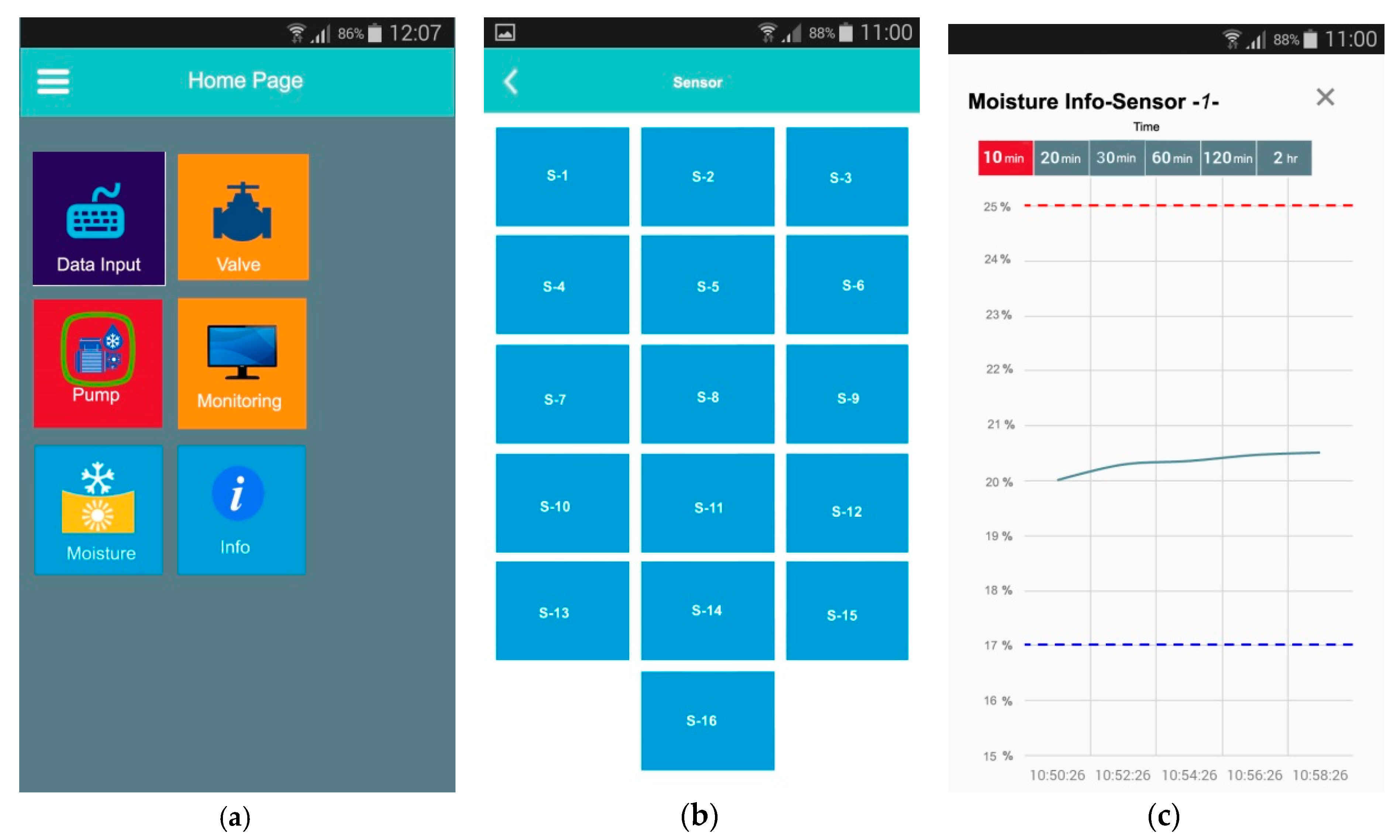

3.7. Control Unit

3.8. Irrigation System Operation

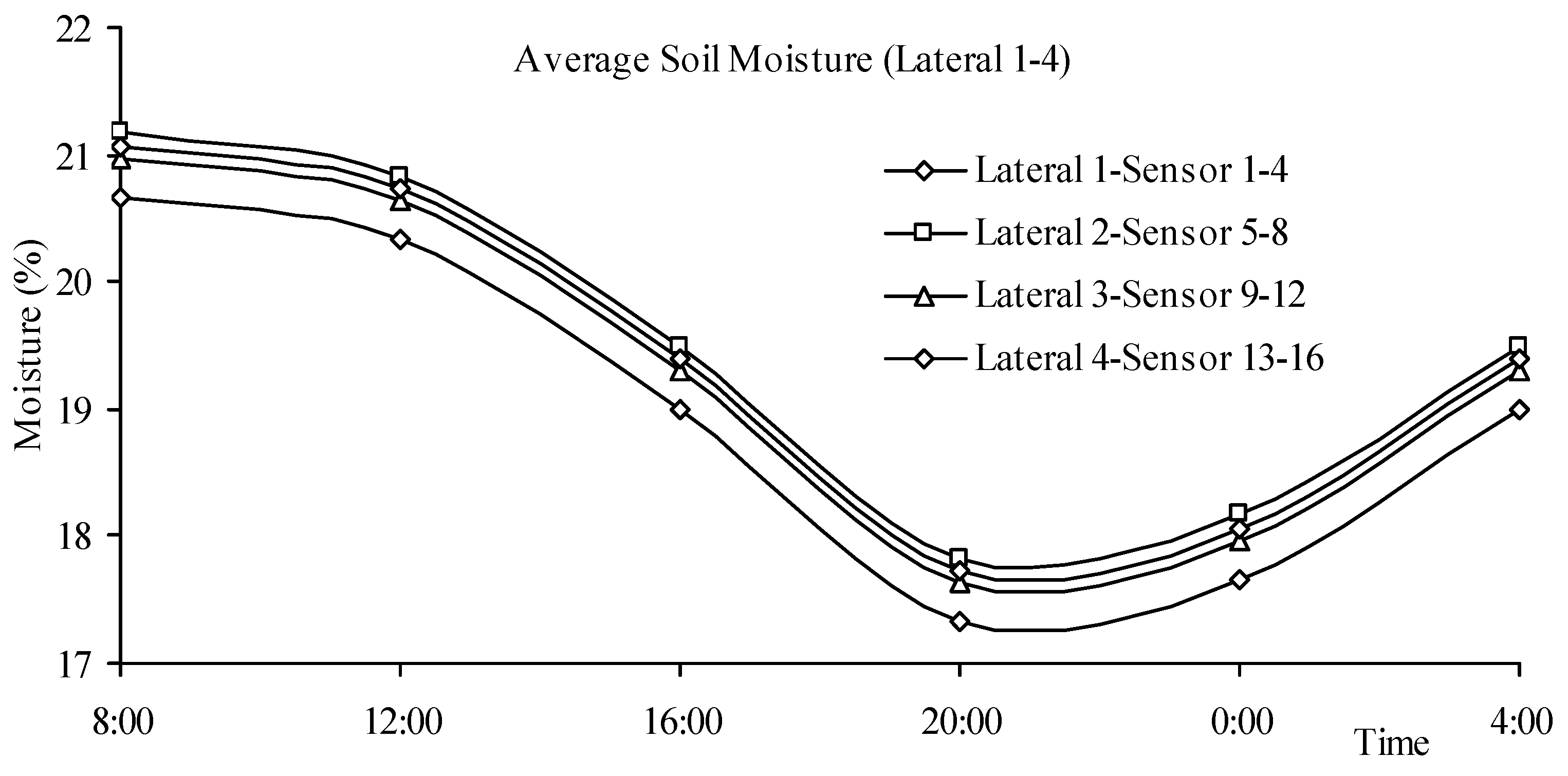

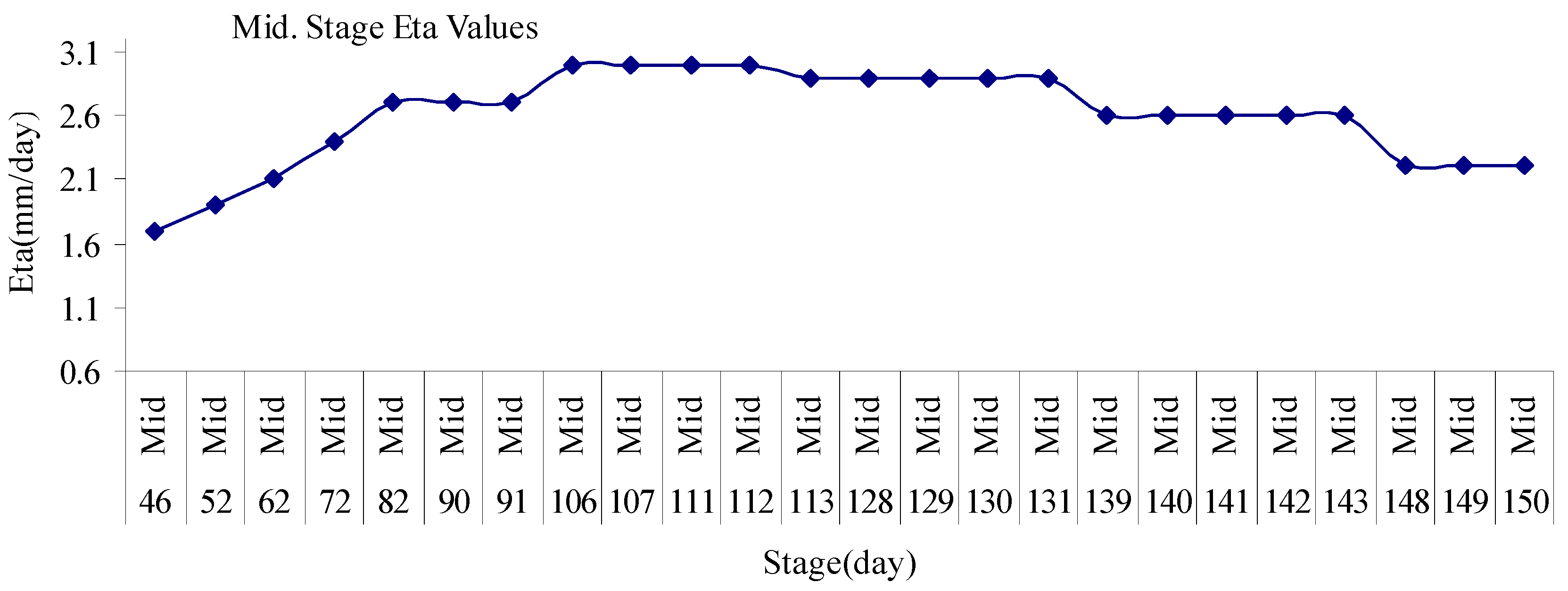

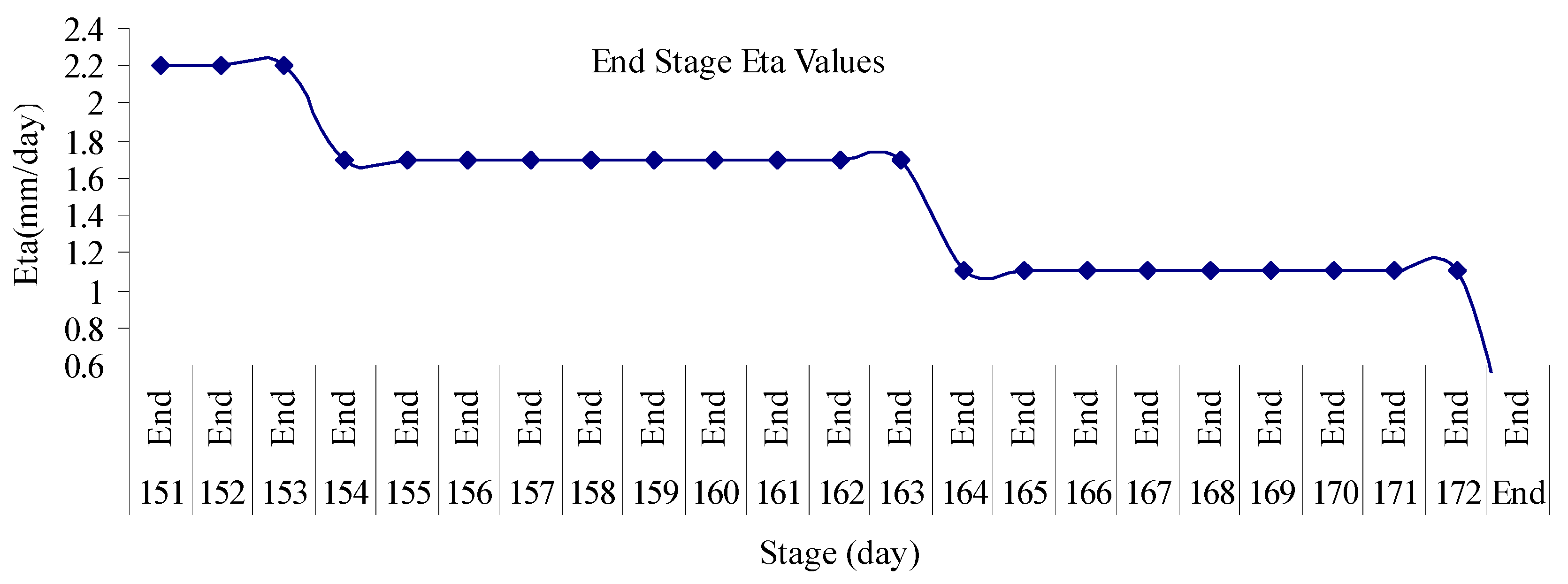

4. Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Dursun, M.; Özden, S. Control of soil moisture with radio frequency in a photovoltaic-powered drip irrigation system. Turk. J. Electr. Eng. Comput. Sci. 2015, 23, 447–458. [Google Scholar] [CrossRef]

- Weng, Q. (Ed.) Advances in Environmental Remote Sensing: Sensors, Algorithms, and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Committee on the Earth System Science for Decisions about Human Welfare: Contributions of Remote Sensing. Contributions of Land Remote Sensing for Decisions about Food Security and Human Health; Workshop Report; National Academies Press: Washington, DC, USA, 2007. [Google Scholar]

- Xu, G. GPS: Theory, Algorithms and Applications; Springer Science & Business Media: London, UK, 2007. [Google Scholar]

- Pierce, F.J.; Clay, D. (Eds.) GIS Applications in Agriculture; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- El-Kader, S.M.A.; El-Basioni, B.M.M. Precision farming solution in Egypt using the wireless sensor network technology. Egypt. Inf. J. 2013, 14, 221–233. [Google Scholar] [CrossRef]

- Topp, G.C.; Davis, J.L.; Annan, A.P. Electromagnetic determination of soil water content: Measurements in coaxial transmission lines. Water Resour. Res. 1980, 16, 574–582. [Google Scholar] [CrossRef]

- Broeders, J.; Croux, D.; Peeters, M.; Beyens, T.; Duchateau, S.; Cleij, J.T.; Wagner, P.; Thoelen, R.; De Ceuninck, W. Mobile Application for Impedance-Based Biomimetic Sensor Readout. IEEE Sens. J. 2013, 13, 2659–2665. [Google Scholar] [CrossRef]

- Lee, B.G.; Chung, W. Driver alertness monitoring using the fusion of facial features and bio-signals. IEEE Sens. J. 2012, 12, 2416–2422. [Google Scholar] [CrossRef]

- Ishigaki, Y.; Matsumoto, Y.; Ichimiya, R.; Tanaka, K. Development of mobile radiation monitoring system utilizing smartphone and its field tests in Fukushima. IEEE Sens. J. 2013, 13, 3520–3526. [Google Scholar] [CrossRef]

- Lee, J.; Reyes, B.; McManus, D.D.; Mathias, O.; Chon, K.H. Atrial fibrillation detection using an iPhone 4S. IEEE Trans. Biomed. Eng. 2013, 60, 203–206. [Google Scholar] [CrossRef] [PubMed]

- Koukoumidis, E.; Martonosi, M.; Peh, L.S. Leveraging smartphone cameras for collaborative road advisories. IEEE Trans. Mob. Comput. 2012, 11, 707–723. [Google Scholar] [CrossRef]

- Qin, C.; Bao, X.; Choudhury, R.R.; Nelakuditi, S. Tagsense: Leveraging smartphones for automatic image tagging. IEEE Trans. Mob. Comput. 2014, 13, 61–74. [Google Scholar] [CrossRef]

- Lehmann, R.J.; Reiche, R.; Schiefer, G. Future internet and the agri-food sector: State-of-the-art in literature and research. Comput. Electron. Agric. 2012, 89, 158–174. [Google Scholar] [CrossRef]

- Li, M.; Qian, J.P.; Yang, X.T.; Sun, C.H.; Ji, Z.T. A PDA-based record-keeping and decision-support system for traceability in cucumber production. Comput. Electron. Agric. 2010, 70, 69–77. [Google Scholar] [CrossRef]

- Car, N.J.; Christen, E.W.; Hornbuckle, J.W.; Moore, G.A. Using a mobile phone Short Messaging Service (SMS) for irrigation scheduling in Australia–Farmers’ participation and utility evaluation. Comput. Electron. Agric. 2012, 84, 132–143. [Google Scholar] [CrossRef]

- Sallabi, F.; Fadel, M.; Hussein, A.; Jaffar, A.; El Khatib, H. Design and implementation of an electronic mobile poultry production documentation system. Comput. Electron. Agric. 2011, 76, 28–37. [Google Scholar] [CrossRef]

- Arroqui, M.; Mateos, C.; Machado, C.; Zunino, A. RESTful Web Services improve the efficiency of data transfer of a whole-farm simulator accessed by Android smartphones. Comput. Electron. Agric. 2012, 87, 14–18. [Google Scholar] [CrossRef]

- Delgado, J.A.; Kowalski, K.; Tebbe, C. The first Nitrogen Index app for mobile devices: Using portable technology for smart agricultural management. Comput. Electron. Agric. 2013, 91, 121–123. [Google Scholar] [CrossRef]

- Cunha, C.R.; Peres, E.; Morais, R.; Oliveira, A.A.; Matos, S.G.; Fernandes, M.A.; Ferreira, P.J.S.G.; Reis, M.J.C.S. The use of mobile devices with multi-tag technologies for an overall contextualized vineyard management. Comput. Electron. Agric. 2010, 73, 154–164. [Google Scholar] [CrossRef]

- Gong, A.; Wu, X.; Qiu, Z.; He, Y. A handheld device for leaf area measurement. Comput. Electron. Agric. 2012, 98, 74–80. [Google Scholar] [CrossRef]

- Confalonieri, R.; Foi, M.; Casa, R.; Aquaro, S.; Tona, E.; Peterle, M.; Boldini, A.; de Carli, G.; Ferrari, A.; Finotto, G.; et al. Development of an app for estimating leaf area index using a smartphone. Trueness and precision determination and comparison with other indirect methods. Comput. Electron. Agric. 2013, 96, 67–74. [Google Scholar] [CrossRef]

- Montoya, F.G.; Gómez, J.; Cama, A.; Zapata, A.; Martínez, F.; de la Cruz, J.; Manzano, F. A monitoring system for intensive agriculture based on mesh networks and the android system. Comput. Electron. Agric. 2013, 99, 14–20. [Google Scholar] [CrossRef]

- Gómez-Robledo, L.; López-Ruiz, N.; Melgosa, M.; Palma, A.J.; Capitán-Vallvey, L.F.; Sánchez-Marañón, M. Using the mobile phone as Munsell soil-colour sensor: An experiment under controlled illumination conditions. Comput. Electron. Agric. 2013, 99, 200–208. [Google Scholar] [CrossRef]

- Sumriddetchkajorn, S.; Somboonkaew, A.; Chanhorm, S. Mobile device-based digital microscopy for education, healthcare, and agriculture. In Proceedings of the 2012 9th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phetchaburi, Thailand, 16–18 May 2012; pp. 1–4. [Google Scholar]

- Lajara, R.; Alberola, J.; Pelegrí-Sebastiá, J. A solar energy powered autonomous wireless actuator node for irrigation systems. Sensors 2010, 11, 329–340. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, N.; Hong, T.; Franzen, A.; Li, J. Closed-loop drip irrigation control using a hybrid wireless sensor and actuator network. Sci. China Inf. Sci. 2011, 54, 577–588. [Google Scholar] [CrossRef]

- Cardenas-Lailhacar, B.; Dukes, M.D. Precision of soil moisture sensor irrigation controllers under field conditions. Agric. Water Manag. 2010, 97, 666–672. [Google Scholar] [CrossRef]

- Cardenas-Lailhacar, B.; Dukes, M.D.; Miller, G.L. Sensor-based automation of irrigation on bermudagrass during dry weather conditions. J. Irrig. Drain. Eng. 2010, 136, 184–193. [Google Scholar] [CrossRef]

- Pardossi, A.; Incrocci, L.; Incrocci, G.; Malorgio, F.; Battista, P.; Bacci, L.; Rapi, B.; Marzialetti, P.; Hemming, J.; Balendonck, J.; et al. Root zone sensors for irrigation management in intensive agriculture. Sensors 2009, 9, 2809–2835. [Google Scholar] [CrossRef] [PubMed]

- Chávez, J.L.; Varble, J.L.; Andales, A.A. Performance evaluation of selected soil moisture sensors. In Proceedings of the 23rd Annual Central Plains Irrigation Conference, Burlington, CO, USA, 22–23 February 2011; pp. 29–38. [Google Scholar]

- Sudha, M.N.; Valarmathi, M.L.; Babu, A.S. Energy efficient data transmission in automatic irrigation system using wireless sensor networks. Comput. Electron. Agric. 2011, 78, 215–221. [Google Scholar] [CrossRef]

- Tahsimcioğlu, M.S.T.C.; Ministry of Forestry and Water Affairs General Directorate of State Hydraulic Works. Plant Water Consumption Studies in Turkey; Directorate of Survey, Planning and Allocation: Istanbul, Turkey, March 2015.

- Uytun, A.; Pekey, B.; Kalemci, M. Soil Moisture Measurements, 8rd ed.; National Measurement Science Congress: Gebze-Kocaeli, Turkey, 2013; pp. 1–9. [Google Scholar]

| Country | Çorum | Latitude | 40.37 °N | Longitude | Station | Merkez |

|---|---|---|---|---|---|---|

| Altitude | 840 m | 34.53 °E | ||||

| Month | Avg. Temp °C | Humidity % | Wind km/day | Sun Hours | Rad MJ/mm2/day | ETo mm/day |

| January | −0.6 | 76 | 1 | 1.9 | 5.3 | 0.39 |

| February | 1.1 | 74 | 2 | 1.9 | 6.9 | 0.58 |

| March | 4.9 | 67 | 2 | 3.4 | 10.8 | 1.08 |

| April | 10.5 | 62 | 2 | 3.2 | 12.9 | 1.70 |

| May | 14.9 | 61 | 2 | 4.1 | 15.6 | 2.41 |

| June | 18.4 | 57 | 2 | 7.0 | 20.3 | 3.32 |

| July | 21.0 | 52 | 2 | 13.5 | 29.0 | 4.72 |

| August | 20.8 | 53 | 2 | 14.9 | 29.0 | 4.56 |

| September | 17.0 | 57 | 2 | 12.2 | 22.2 | 3.06 |

| October | 11.8 | 62 | 2 | 8.8 | 14.5 | 1.57 |

| November | 6.6 | 70 | 2 | 4.5 | 7.7 | 0.71 |

| December | 1.8 | 77 | 2 | 2.0 | 4.8 | 0.44 |

| Average | 10.7 | 64 | 2 | 6.5 | 14.9 | 2.05 |

| Station Çorum-Merkez | Meteorological Data | Effect Rain Method USDA S.C. Method |

|---|---|---|

| Month | Rain | Effect Rain |

| mm | mm | |

| January | 39.5 | 37.0 |

| February | 30.3 | 28.8 |

| March | 37.8 | 35.5 |

| April | 45.9 | 42.5 |

| May | 60.8 | 54.9 |

| June | 49.2 | 45.3 |

| July | 17.4 | 16.9 |

| August | 11.9 | 11.7 |

| September | 20.3 | 19.6 |

| October | 25.0 | 24.0 |

| November | 30.9 | 29.4 |

| December | 43.4 | 40.4 |

| Total | 412.4 | 386.1 |

| ETo Station | Merkez | Plant Factor | Plant Water Consumption | Crop | Walnut | ||

|---|---|---|---|---|---|---|---|

| Rain Station | Çorum-Merkez | Planting Date | 11/04 | ||||

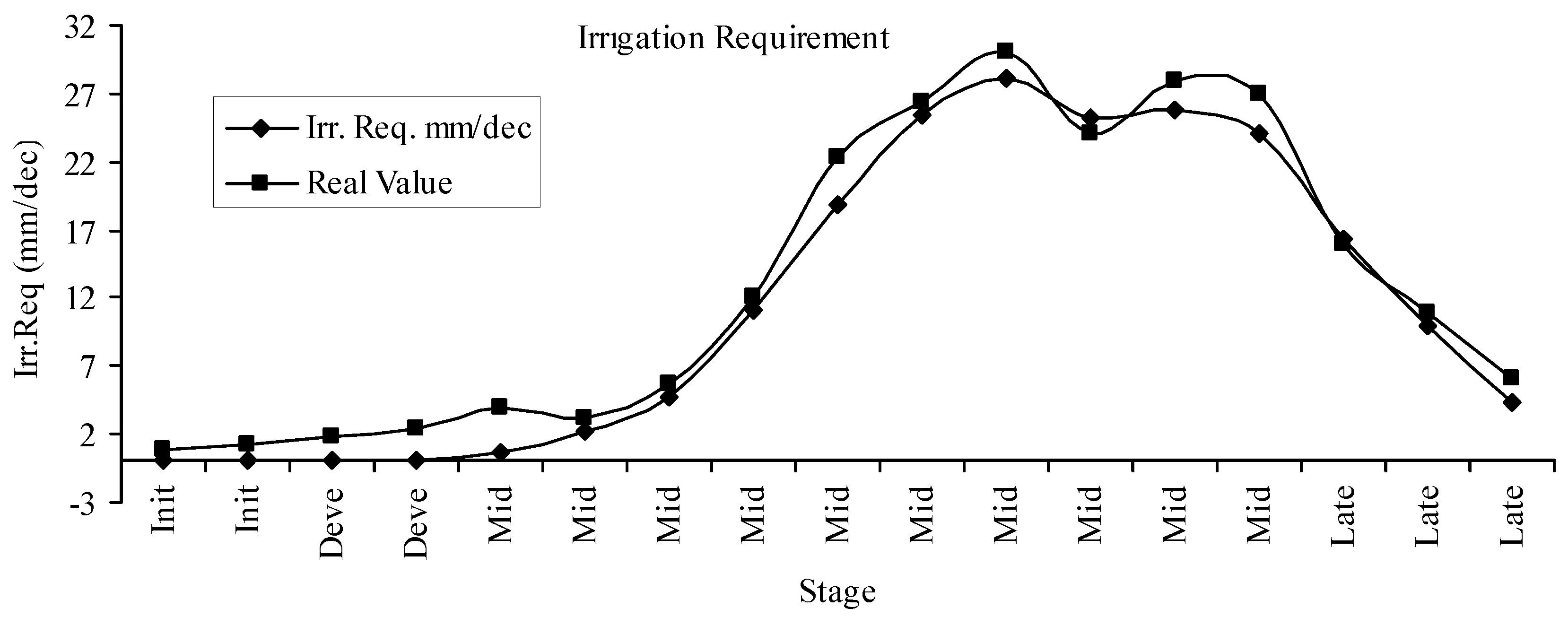

| Month | Decade | Stage | Kc coeff | Etc mm/day | Etc mm/dec | Effect Rain mm/dec | Irrigation Requirement mm/dec |

| April | 2 | Init. | 0.50 | 0.85 | 8.5 | 14.0 | 0.0 |

| April | 3 | Init. | 0.50 | 0.97 | 9.7 | 15.4 | 0.0 |

| May | 1 | Deve. | 0.53 | 1.15 | 11.5 | 17.6 | 0.0 |

| May | 2 | Deve. | 0.58 | 1.39 | 13.9 | 19.3 | 0.0 |

| May | 3 | Mid. | 0.62 | 1.69 | 18.6 | 17.9 | 0.7 |

| June | 1 | Mid. | 0.63 | 1.89 | 18.9 | 16.7 | 2.2 |

| June | 2 | Mid. | 0.63 | 2.08 | 20.8 | 16.0 | 4.8 |

| June | 3 | Mid. | 0.63 | 2.37 | 23.7 | 12.5 | 11.2 |

| July | 1 | Mid. | 0.63 | 2.70 | 27.0 | 8.1 | 18.9 |

| July | 2 | Mid. | 0.63 | 3.01 | 30.1 | 4.6 | 25.5 |

| July | 3 | Mid. | 0.63 | 2.96 | 32.5 | 4.4 | 28.2 |

| August | 1 | Mid. | 0.63 | 2.93 | 29.3 | 4.1 | 25.2 |

| August | 2 | Mid. | 0.63 | 2.92 | 29.2 | 3.3 | 25.9 |

| August | 3 | Mid. | 0.63 | 2.58 | 28.4 | 4.4 | 24.0 |

| September | 1 | Late | 0.62 | 2.21 | 22.1 | 5.8 | 16.3 |

| September | 2 | Late | 0.54 | 1.66 | 16.6 | 6.7 | 9.9 |

| September | 3 | Late | 0.44 | 1.14 | 31.4 | 7.1 | 4.3 |

| 352.1 | 177.8 | 197.0 | |||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Işık, M.F.; Sönmez, Y.; Yılmaz, C.; Özdemir, V.; Yılmaz, E.N. Precision Irrigation System (PIS) Using Sensor Network Technology Integrated with IOS/Android Application. Appl. Sci. 2017, 7, 891. https://doi.org/10.3390/app7090891

Işık MF, Sönmez Y, Yılmaz C, Özdemir V, Yılmaz EN. Precision Irrigation System (PIS) Using Sensor Network Technology Integrated with IOS/Android Application. Applied Sciences. 2017; 7(9):891. https://doi.org/10.3390/app7090891

Chicago/Turabian StyleIşık, Mehmet Fatih, Yusuf Sönmez, Cemal Yılmaz, Veysel Özdemir, and Ercan Nurcan Yılmaz. 2017. "Precision Irrigation System (PIS) Using Sensor Network Technology Integrated with IOS/Android Application" Applied Sciences 7, no. 9: 891. https://doi.org/10.3390/app7090891