New Approaches for Supervision of Systems with Sliding Wear: Fundamental Problems and Experimental Results Using Different Approaches

Abstract

:1. Introduction

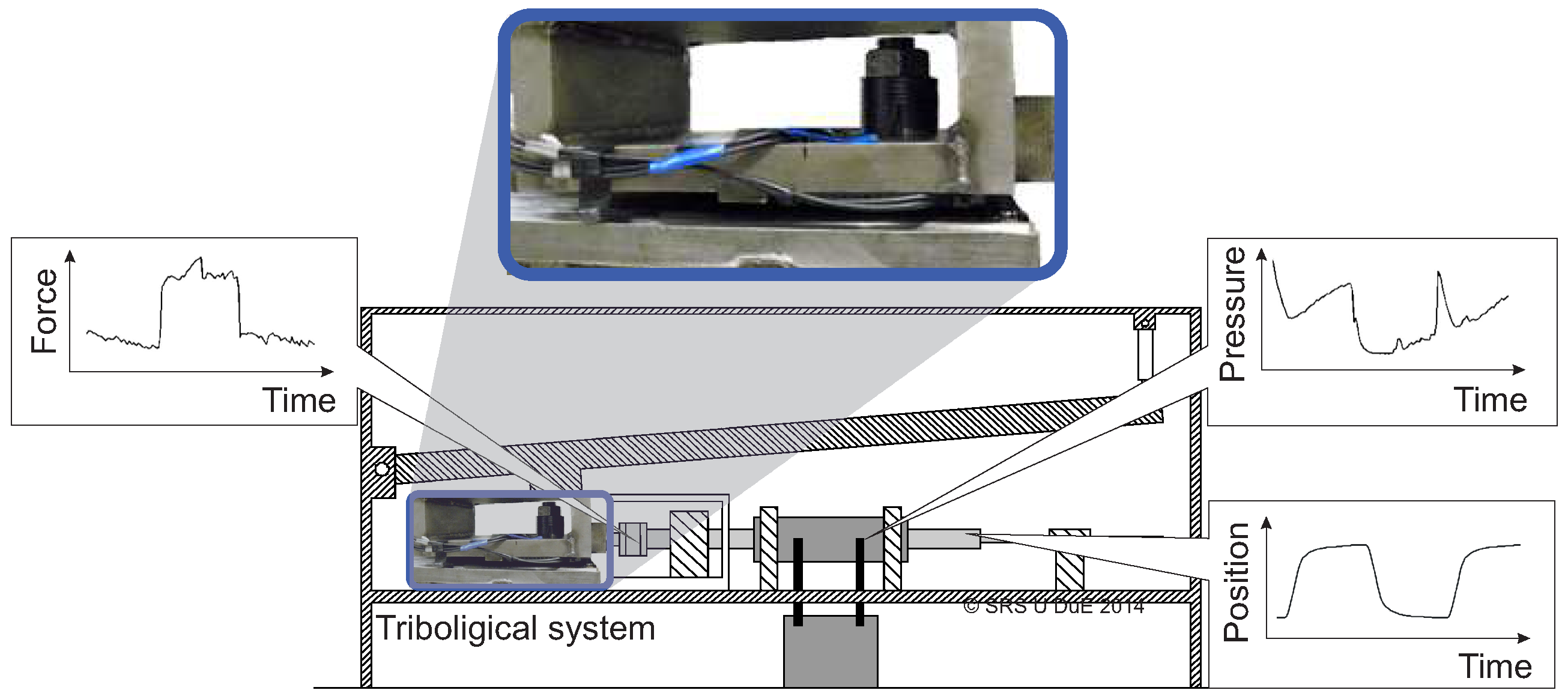

2. Four New Signal-Based Approaches to Be Compared

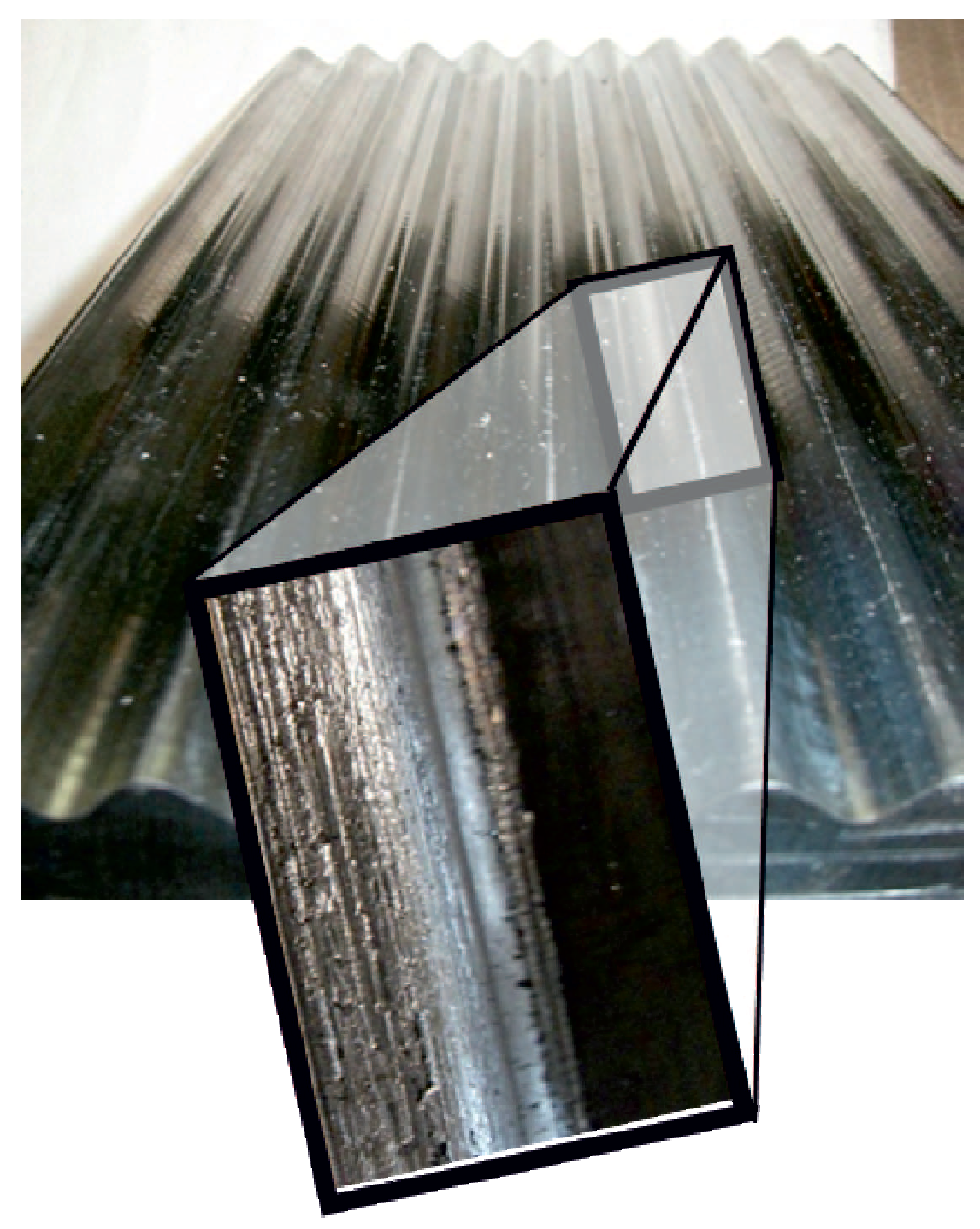

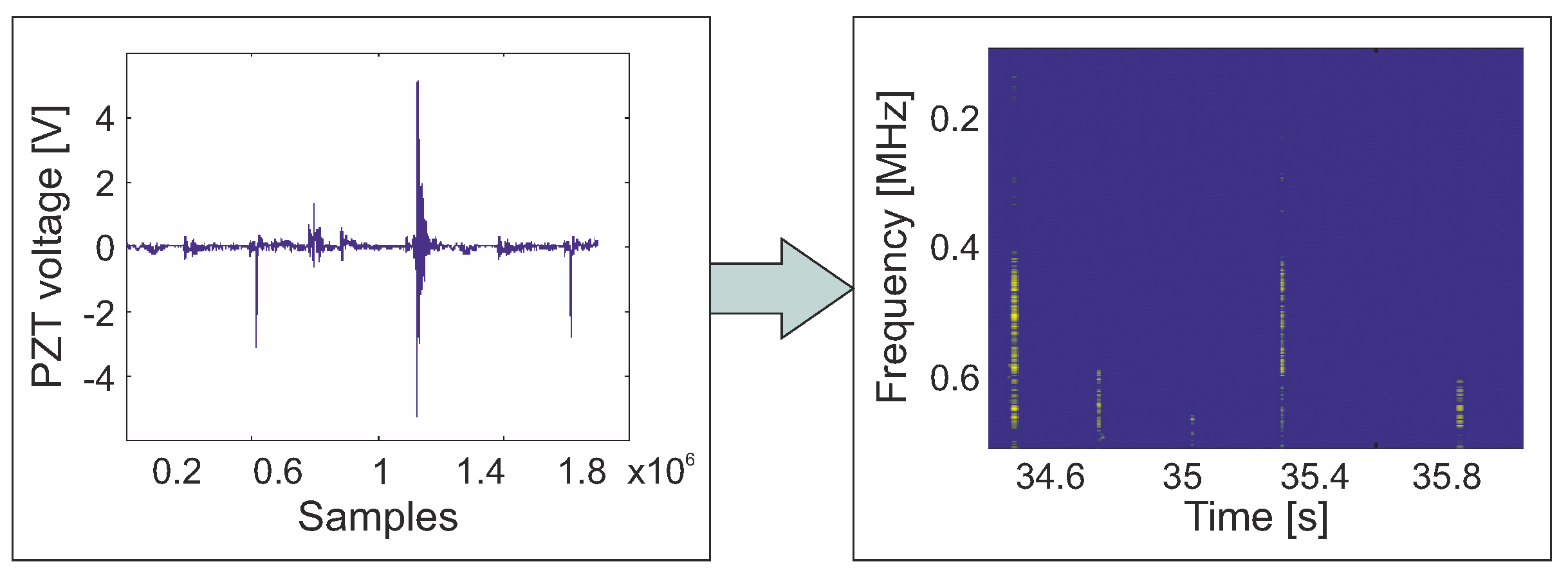

2.1. Acoustic Emission Analysis (Approach A)

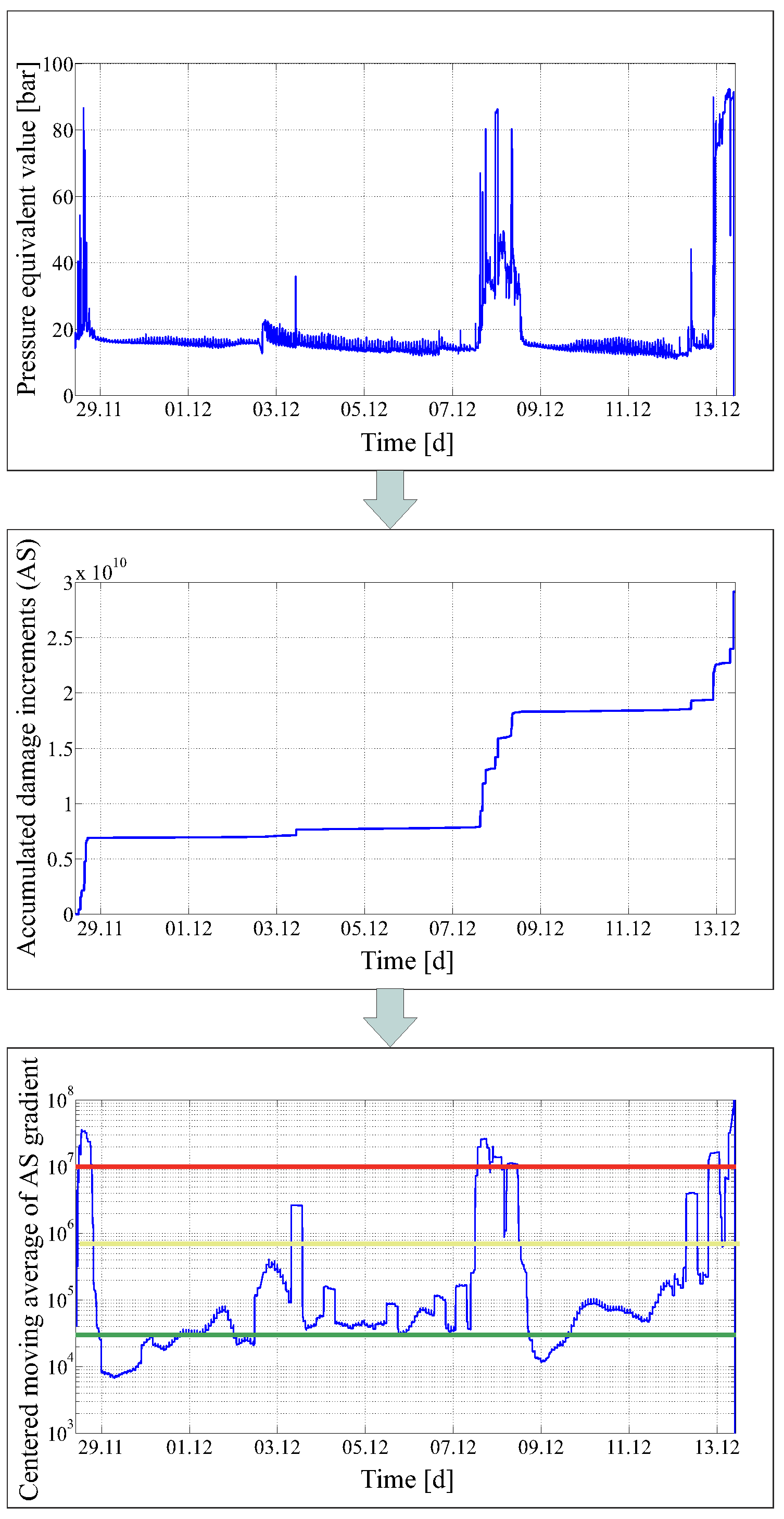

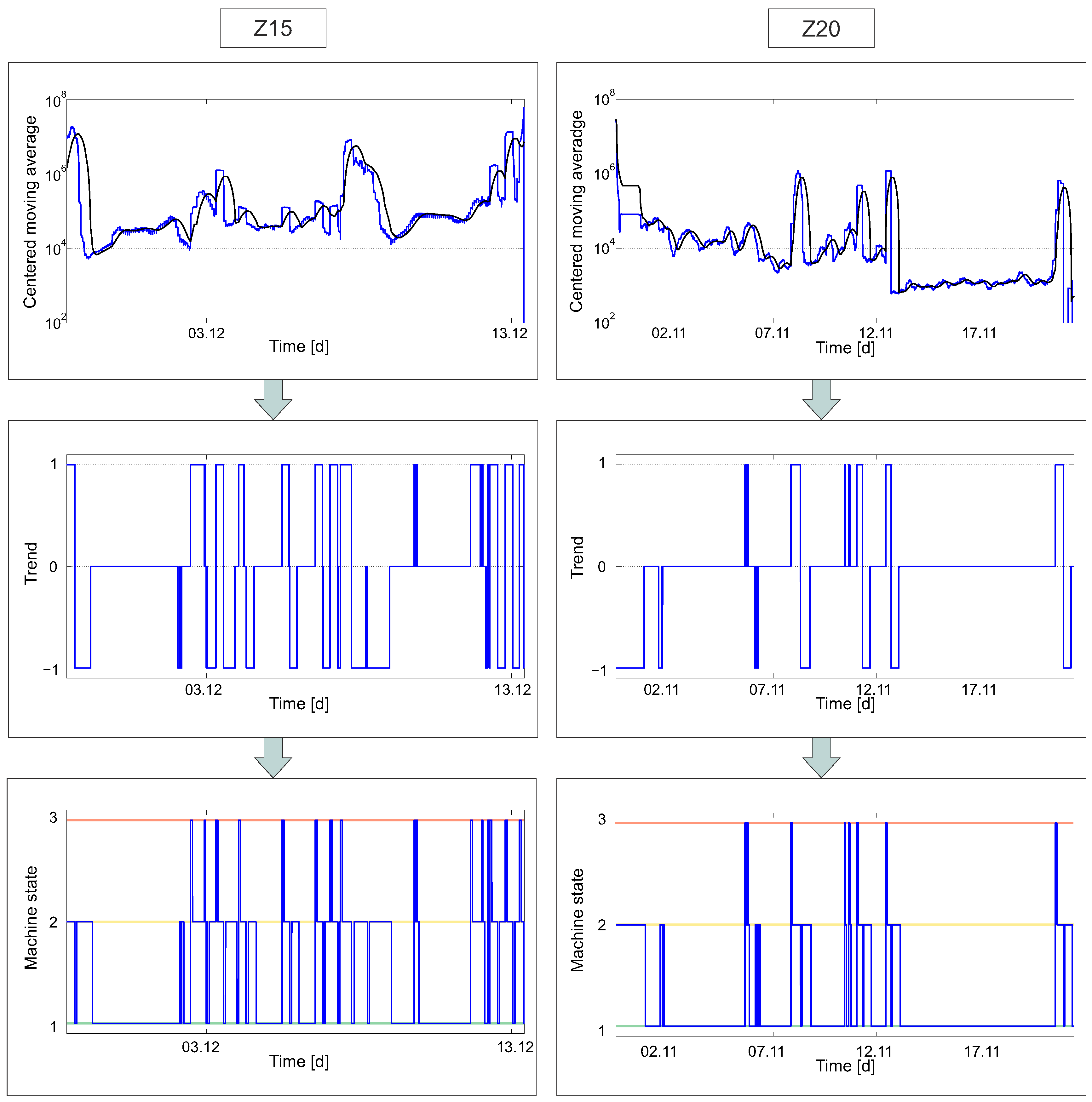

2.2. Diagnosis-Oriented Data Filtering and Threshold-Based Classification (Approach B)

- State 1: Stable and error-free operation (below the green line).

- State 2: Stable with small changes in the surface condition (between the yellow and green lines).

- State 3: Acceptable changes in the surface condition (between the red and yellow lines).

- State 4: Significant changes in the surface condition (above the red line).

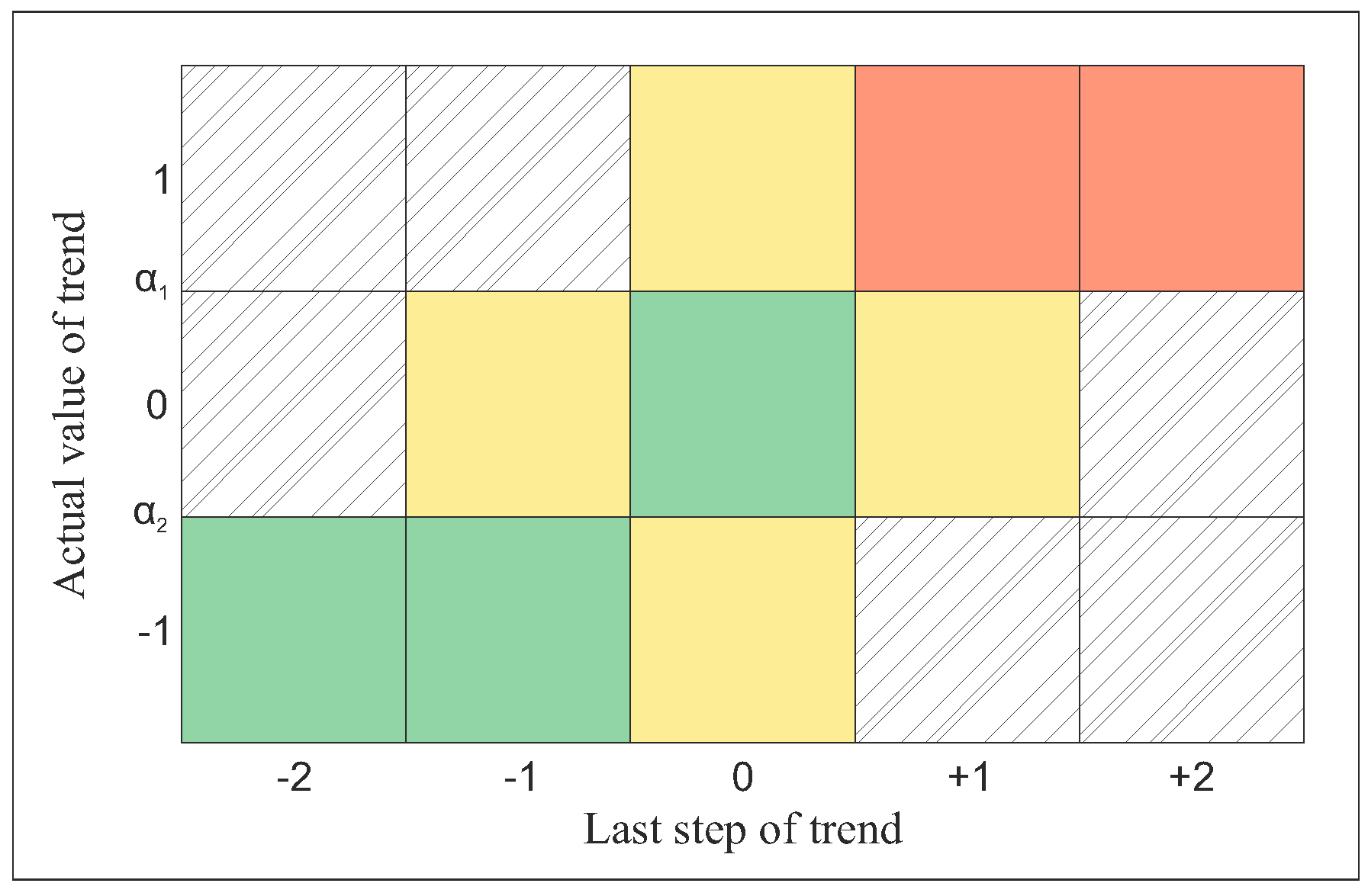

2.3. Condition Evaluation Based on a Sensitivity Matrix (Approach C)

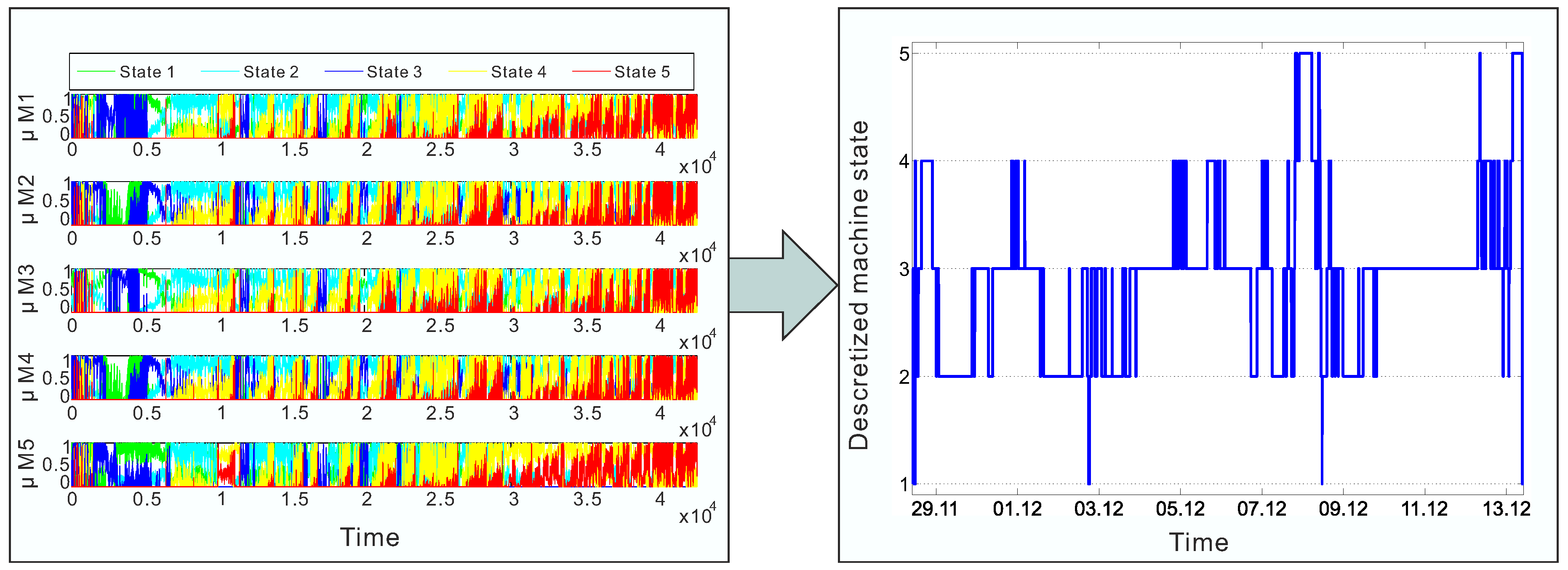

2.4. Data-Based Classification Approach (Approach D)

- Regular behavior 1:Stable and error-free operation: Green.

- Regular behavior 2:Stable with small changes: Blue.

- Regular behavior 3:Stable operation with changes: Cyan.

- Abnormal behavior 1:Acceptable changes in the surface condition due to minor surface condition changes: Yellow.

- Abnormal behavior 2:Significant changes in the surface condition due to major changes in the surface condition, ranging up to the destruction of the surface with partial loss of functionality: Red.

3. Application Results

3.1. Acoustic Emission Analysis (Approach A)

3.2. Diagnosis-Oriented Data Filtering and Threshold-Based Classification (Approach B)

3.3. Condition Evaluation Based on a Sensitivity Matrix (Approach C)

- The probability of sudden changes increases as the system is used longer.

- Sudden changes are often connected to other sudden changes.

- The periods of reliable use alternate with periods where strong changes in operation occur.

- After some periods with changes, the system is not capable of stable problem-free usage.

3.4. Data-Based Classification Approach (Approach D)

4. Discussion

- More detailed sensor information can yield a more complex diagnosis. Here detailed information with respect to the frequency content was provided by the AE-sensor providing more frequency-based information.

- The implementation becomes more difficult when the underlying physics behind and related mathematical background are more complex.

- Surprisingly, the simplest methods (approaches B and C) can yield similar quality of evaluation results with respect to the general goal of Structural Health Monitoring (SHM)-systems (qualitative evaluation of health based on the system’s state).

- The implementation and use of suitable filtering algorithms is important, especially for methods based on operational data. Thus, knowledge and experience are required for tuning, similar to experienced previous signal analysis methods.

5. Summary and Conclusions

Author Contributions

Conflicts of Interest

References

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. In New Trends in Vibration Based Structural Health Monitoring; Deraemaeker, A., Worden, K., Eds.; Springer: New York, NY, USA, 2010; Volume 520, pp. 1–18. ISBN 978-3-7091-0399-9. [Google Scholar]

- Abu-Mahfouz, I.; Banerjee, A. Drill wear identification under varying cutting conditions using vibration and cutting force signals and data mining techniques. Complex Adapt. Syst. Procedia Comput. Sci. 2014, 36, 556–563. [Google Scholar] [CrossRef]

- Rafiee, J.; Arvani, F.; Harifi, A.; Sadeghi, M.H. Intelligent condition monitoring of a gearbox using artificial neural network. Mech. Syst. Signal Process. 2007, 21, 1746–1754. [Google Scholar] [CrossRef]

- Gajewski, J.; Jedlinski, L.; Jonak, J. Classification of wear level of mining tools with the use of fuzzy neural network. Tunn. Undergr. Space Technol. 2013, 35, 30–36. [Google Scholar] [CrossRef]

- Aliustaouglu, C.; Ertunc, H.M.; Ocak, H. Tool wear condition monitoring using a sensor fusion model based on fuzzy inference system. Mech. Syst. Signal Process. 2009, 23, 539–546. [Google Scholar] [CrossRef]

- Klaic, M.; Staroveski, T.; Udiljak, T. Tool wear classification using decision treesin stone drilling applications: A preliminary study. In Proceedings of the 24th DAAAM International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 20–27 October 2013; Katalinic, B., Ed.; pp. 1326–1335. [Google Scholar]

- Teti, R.; Jemielniak, K.; O’Donnel, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. Manuf. Technol. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Qu, J.; Zuo, M.J. Support vector machine based data processing algorithm for wear degree classification of slurry pump systems. Measurement 2010, 43, 781–791. [Google Scholar] [CrossRef]

- Wang, D.; Tse, P.W. Prognostics of slurry pumps based on a moving-average wear degradation index and a general sequential Monte Carlo method. Mech. Syst. Signal Process. 2015, 56–57, 213–229. [Google Scholar] [CrossRef]

- Yang, F.; Shah, S.L.; Xiao, D. Correlation analysis of alarm data and alarm limit design for industrial processes. In Proceedings of the American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 5850–5855. [Google Scholar]

- Beganovic, N.; Söffker, D. Remaining lifetime modeling using State-of-Health estimation. Mech. Syst. Signal Process. 2017, 92, 107–123. [Google Scholar] [CrossRef]

- Painuli, S.; Elangovan, M.; Sugumaran, V. Tool condition monitoring using K-star algorithm. Expert Syst. Appl. 2014, 41, 2638–2643. [Google Scholar] [CrossRef]

- Cao, W.; Dong, G.; Chen, W.; Wu, J.; Xie, Y. Multisensor information integration for online wear condition monitoring of diesel engines. Tribol. Int. 2015, 82, 68–77. [Google Scholar] [CrossRef]

- Söffker, D.; Rothe, S.; Schiffer, S.; Baccar, D. Smart, tough, and successful: Three new innovative approaches for diagnosis and prognosis of technical systems. In Proceedings of the 9th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 10–12 September 2013; Chang, F.K., Ed.; pp. 81–88. [Google Scholar]

- Rothe, S.; Söffker, D. Wear-oriented state-of-health calculation and classification using operating data. In Proceedings of the 7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014; Le Cam, V., Mevel, L., Schoefs, F., Eds.; pp. 81–88. [Google Scholar]

- Rothe, S.; Söffker, D. Development of a state-related evaluation for diagnostic-oriented data filtering approach. In Proceedings of the 10th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 1–3 September 2015; Chang, F.K., Ed.; pp. 593–600. [Google Scholar]

- Kato, K. Classification of wear mechanism/models. In Wear: Materials, Mechanisms and Practice; Stachowiak, G.W., Ed.; John Wiley & Sons Ltd.: Chichester, UK, 2014; pp. 9–18. [Google Scholar] [CrossRef]

- Neis, P.D.; Ferreira, N.F.; Da Silva, F.P. Comparison between methods for measuring wear in brake friction materials. Wear 2014, 319, 191–199. [Google Scholar] [CrossRef]

- Miao, Q.; Makis, V. Condition monitoring and classification of rotating machinery using wavelets and hidden Markov models. Mech. Syst. Signal Process. 2007, 21, 840–855. [Google Scholar] [CrossRef]

- Zhou, J.H.; Pang, C.K.; Lewis, F.L.; Zhong, Z. Intelligent diagnosis and prognosis of tool wear using dominant feature identification. IEEE Trans. Ind. Inform. 2009, 5, 454–464. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Jablonski, A.; Barszcz, T.; Bielecka, M.; Breuhaus, P. Modeling of probability distribution functions for automatic threshold calculation in condition monitoring systems. Measurement 2013, 46, 727–738. [Google Scholar] [CrossRef]

- Naghoosi, E.; Izadi, I.; Chen, T. A study on the relation between alarm deadbands and optimal alarm limits. In Proceedings of the American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011; pp. 3627–3632. [Google Scholar]

- Bechhoefer, E.; He, D.; Dempsey, P. Gear health threshold setting based on probability of false alarm. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Montreal, QC, Canada, 25–29 September 2011; pp. 23–28. [Google Scholar]

- Standard Terminology for Nondestructive Examinations; E 1316-90; American Society for Testing and Materials: West Conshohocken, PA, USA, 1990.

- Jin, Z.; Gong, B.; Jin, W.; Wen, B. Analysis of acoustic emission signals from stainless steel with different wavelet bases. In Proceedings of the IEEE International Symposium on Knowledge Acquisition and Modeling, Wuhan, China, 21–22 December 2008; pp. 892–895. [Google Scholar]

- Kalyanasundaram, P.; Raj, B.; Jayakuma, T. Characterization of microstructures in metallic materials using static and dynamic acoustic signal processing techniques. In Proceedings of the 7th International Workshop on Advances in Signal Processing for Non Destructive Evaluation of Materials, Québec City, QC, Canada, 2–4 August 2005; pp. 43–50. [Google Scholar]

- Baccar, D.; Söffker, D. Wear detection by means of wavelet-based Acoustic Emission analysis. Mech. Syst. Signal Process. 2015, 60–61, 198–207. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W.; Stachowiak, G.B. Experimental Methods in Tribology; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 978-0-08-047273-7. [Google Scholar]

- Neale, M.J.; Gee, M.G. Guide to Wear Problems and Testing for Industry; William Andrew Pub.: Norwich, UK, 2001; ISBN 978-0-8155-1471-8. [Google Scholar]

- Rothe, S.; Leite, A.; Padrao, P.; Söffker, D. Improvement and comparison of wear-oriented state-of- health classification methods using optimization techniques. In Proceedings of the 10th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 1–3 September 2015; Chang, F.K., Kopsaftopoulos, F., Eds.; pp. 625–632. [Google Scholar]

- Abe, S. Support Vector Machines for Pattern Classification; Springer: New York, NY, USA, 2010; ISBN 978-1-84996-098-4. [Google Scholar]

- Duda, R.O.; Hart, P.E.; Stork, D.G. Pattern Classification; Wiley Interscience: New York, NY, USA, 2001; ISBN 978-0-471-05669-0. [Google Scholar]

- Murty, M.N.; Devi, V.S. Pattern Recognition, an Algorithmic Approach; Springer-Verlag London & Press Pvt. Ltd.: New Delhi, India, 2011; ISBN 978-0-85729-495-1. [Google Scholar]

| Method | Acoustic Emission analysis (approach A) | Diagnosis-oriented data filtering and threshold-based classification (approach B) | Condition evaluation based on a sensitivity matrix (approach C) | Data-based classification approach (approach D) | |

|---|---|---|---|---|---|

| Criteria | |||||

| Effort for sensor application | - | - - | - - | - - | |

| Effort for filtering | + | 0 | 0 | 0 | |

| Costs and complexity of technical equipment | + | - - | - - | - - | |

| Real-time capability | - - | + | + | + | |

| Usage complexity (users) | + | 0 | - | - - | |

| Usage complexity (developers) | 0 | - - | - - | + + | |

| Capability for reliable fault detection | 0 | + | + | + | |

| Capability for reliable diagnosis | + + | 0 | 0 | 0 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Söffker, D.; Rothe, S. New Approaches for Supervision of Systems with Sliding Wear: Fundamental Problems and Experimental Results Using Different Approaches. Appl. Sci. 2017, 7, 843. https://doi.org/10.3390/app7080843

Söffker D, Rothe S. New Approaches for Supervision of Systems with Sliding Wear: Fundamental Problems and Experimental Results Using Different Approaches. Applied Sciences. 2017; 7(8):843. https://doi.org/10.3390/app7080843

Chicago/Turabian StyleSöffker, Dirk, and Sandra Rothe. 2017. "New Approaches for Supervision of Systems with Sliding Wear: Fundamental Problems and Experimental Results Using Different Approaches" Applied Sciences 7, no. 8: 843. https://doi.org/10.3390/app7080843