Experimental Study and Numerical Simulation of a Laminated Reinforced Concrete Shear Wall with a Vertical Seam

Abstract

:1. Introduction

2. Experimental Setup

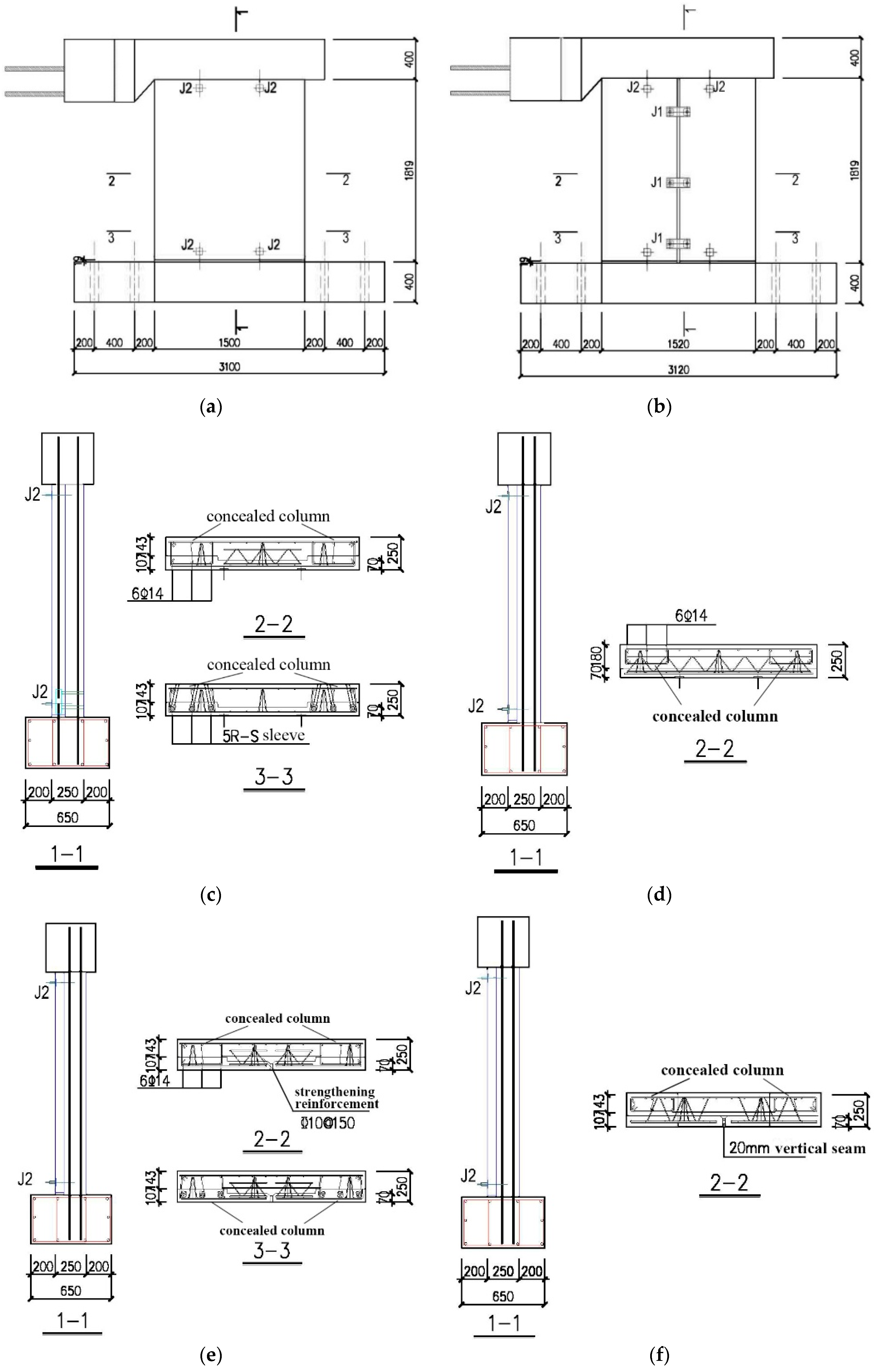

2.1. Specimens Design

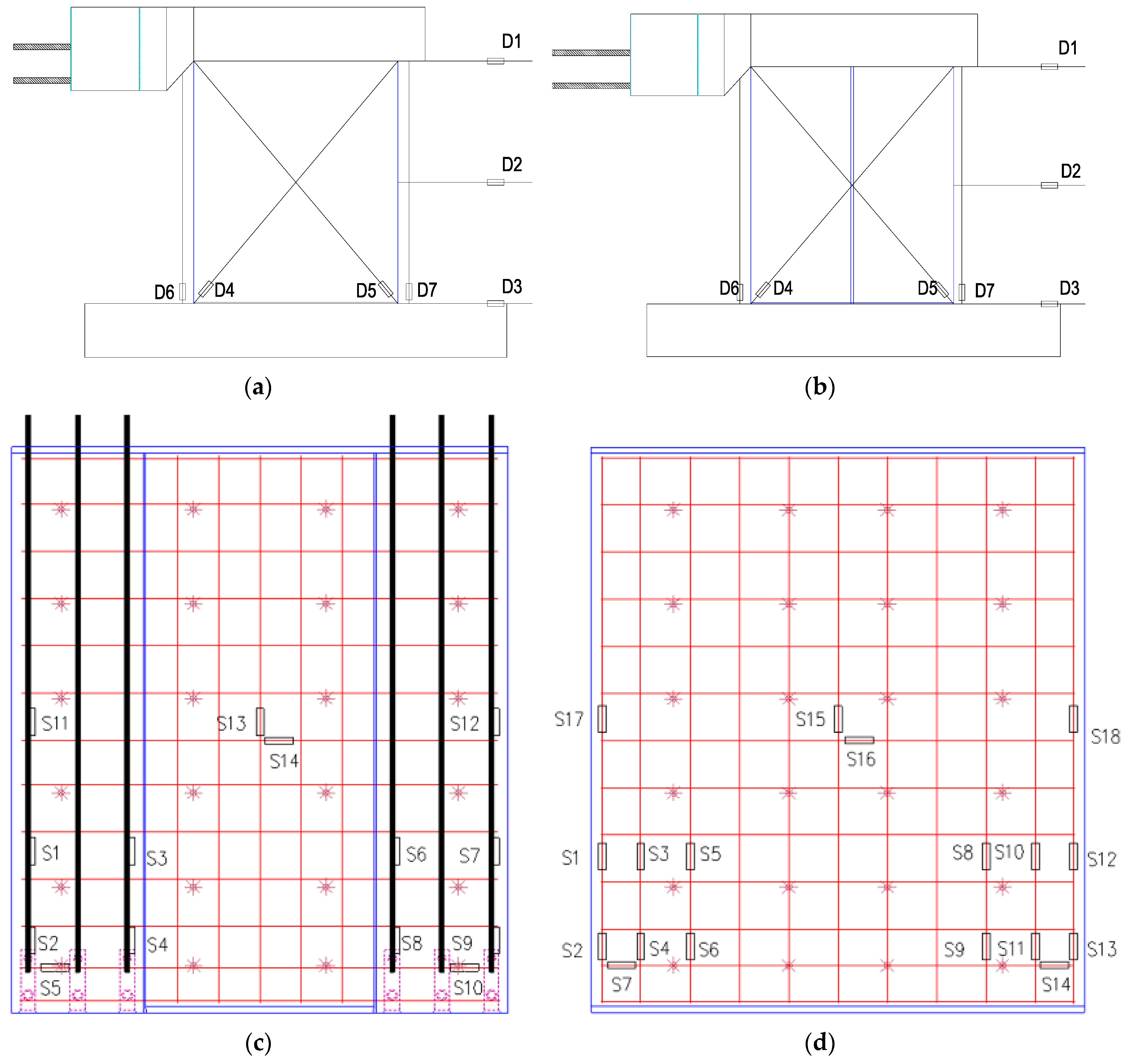

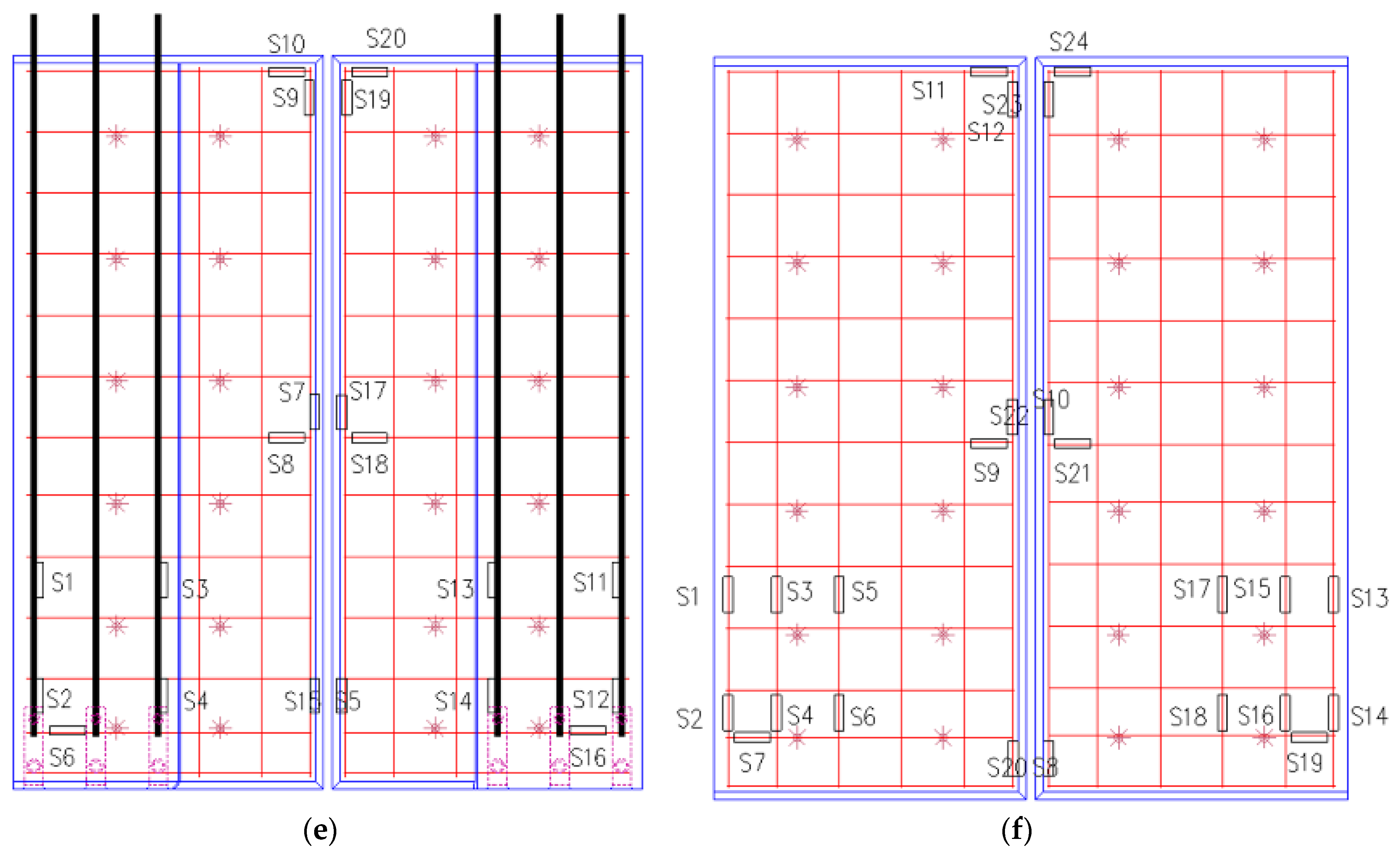

2.2. Sensor Placement

2.3. Specimen Fabrication

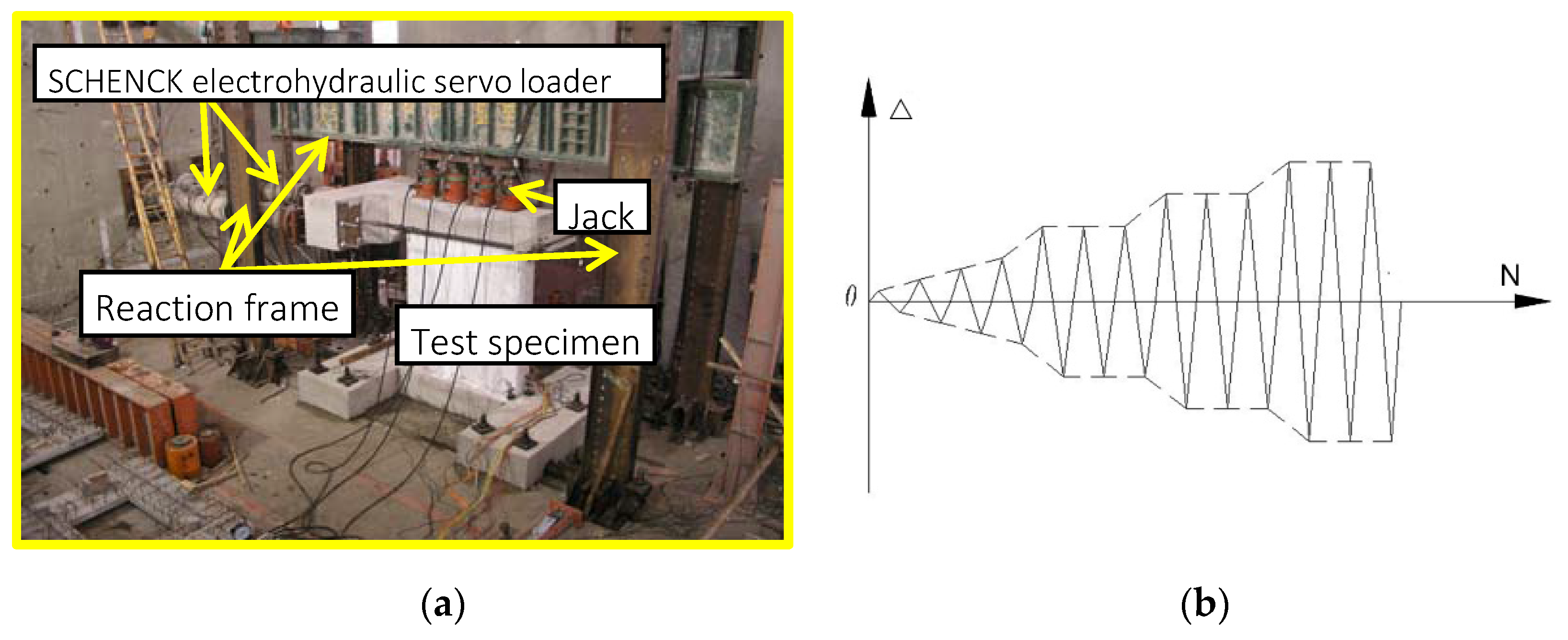

2.4. Test Loading Device and Loading Process

3. Experimental Results

3.1. Test Phenomena

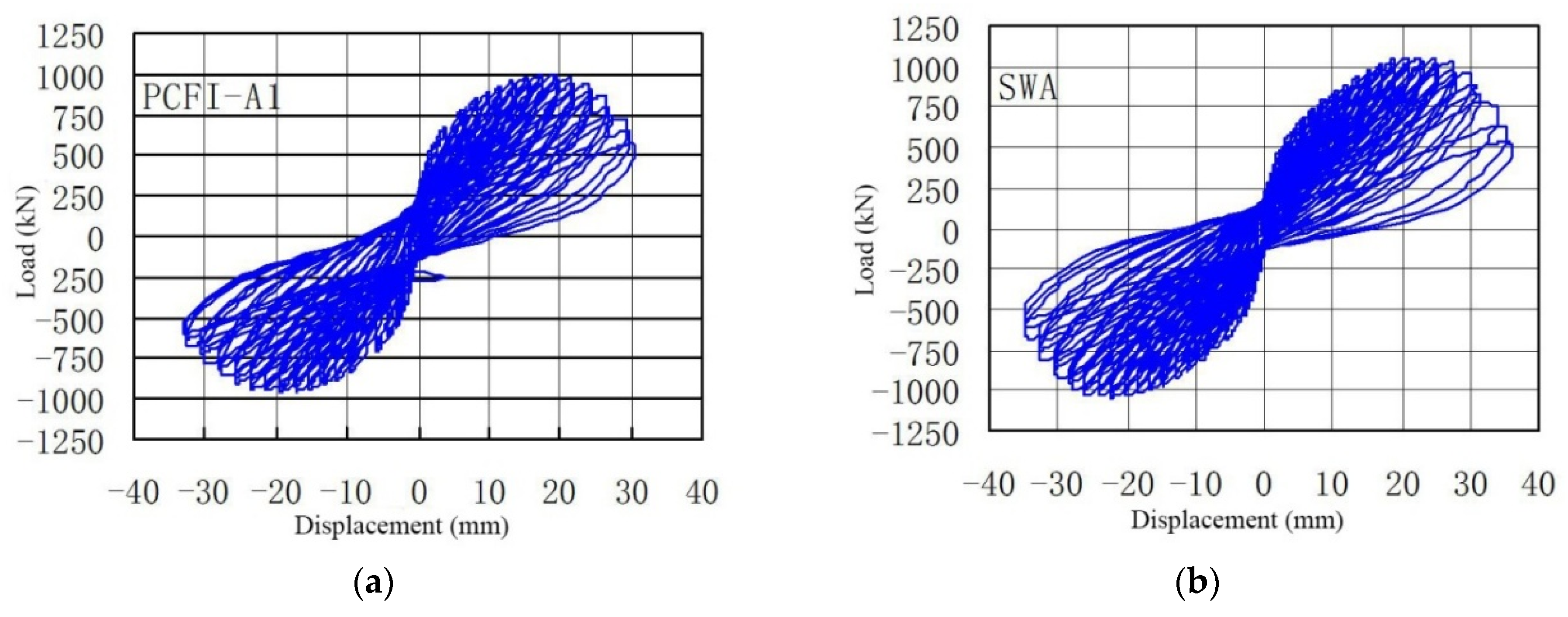

3.2. Horizontal Load-Displacement Hysteretic Curve and Skeleton Curve

3.3. Energy Dissipation Capacity

- Whether it is the whole wall or a seam wall, the energy dissipation capacity of the laminated wall is no worse than the cast-in-place wall, indicating that the laminated wall has as good a seismic performance as the cast-in-place wall.

- The PCFI-C has a generally higher equivalent viscosity coefficient than PCFI-A, indicating that the energy dissipation of the seam wall is better than that of the whole wall. This may be due to the greater deformation caused by the seam; thus, more energy is dissipated. Such a seam effect is also reported in the literature [44].

- Compared with PCFI, PCFII has a higher equivalent viscous coefficient, which may be due to the fact that the concrete strength of PCFII is larger than PCFI by about 10%. The structural measures have little effect on its energy consumption capacity.

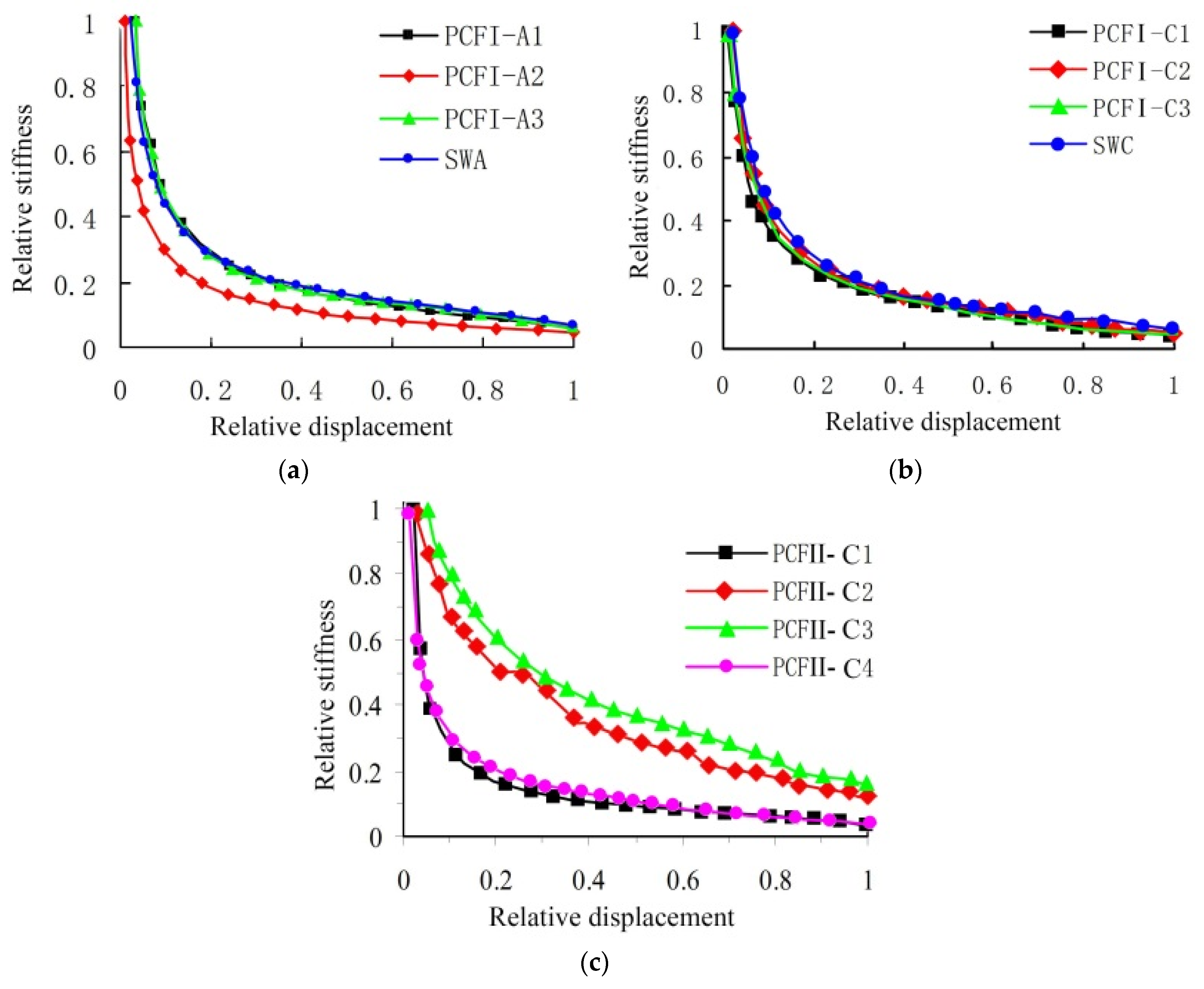

3.4. Stiffness Degradation

4. Numerical Simulation

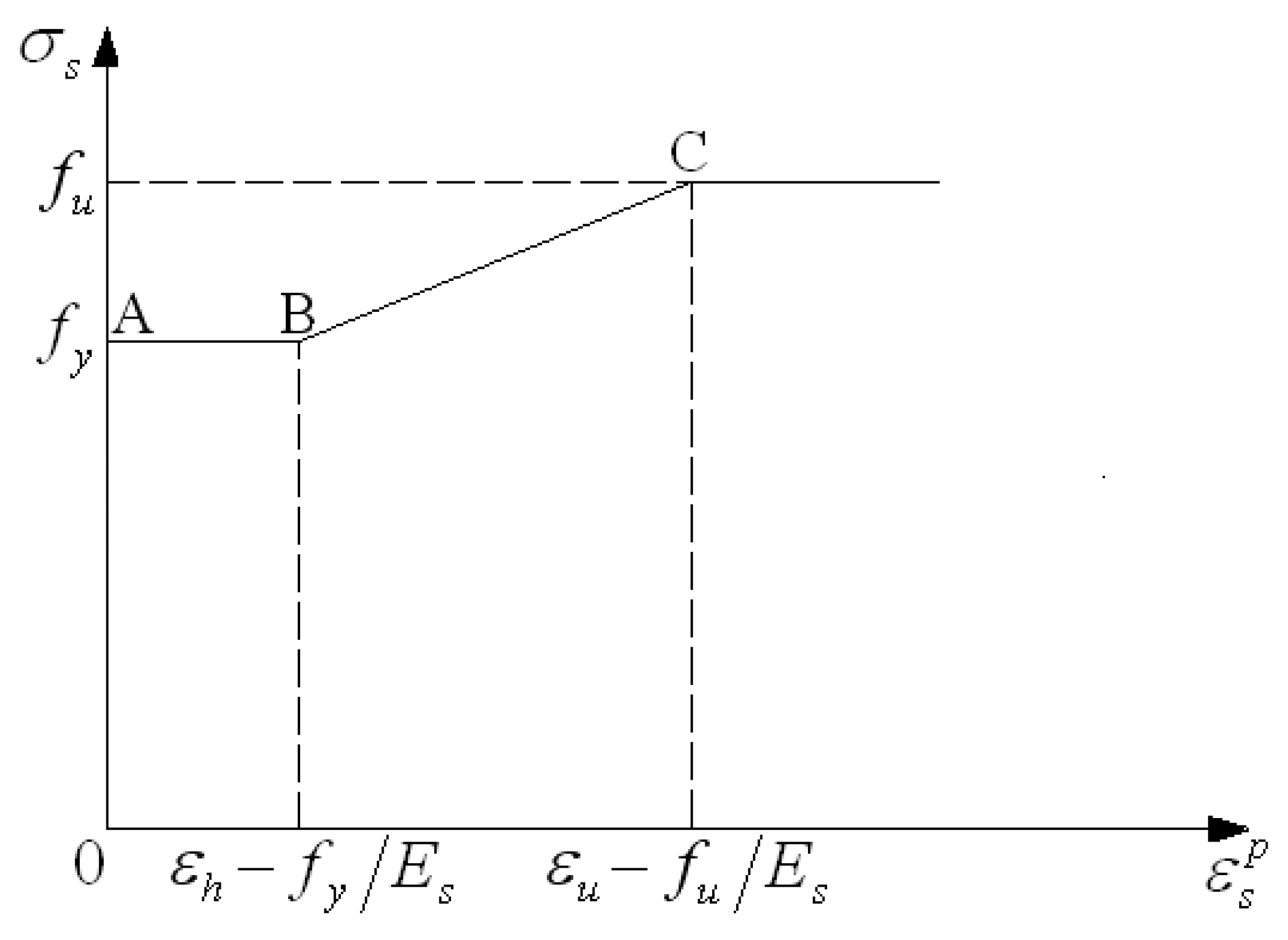

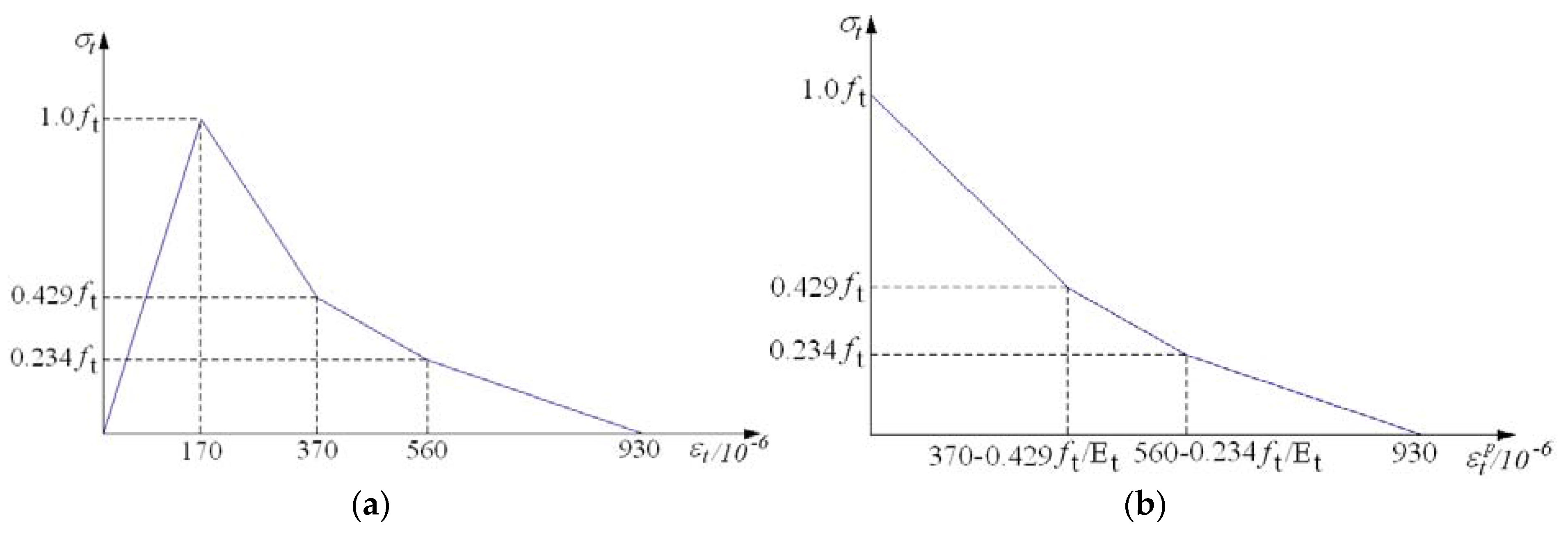

4.1. Material Constitutive Model

4.2. Elements

4.3. Loading System

4.4. Simulation Results

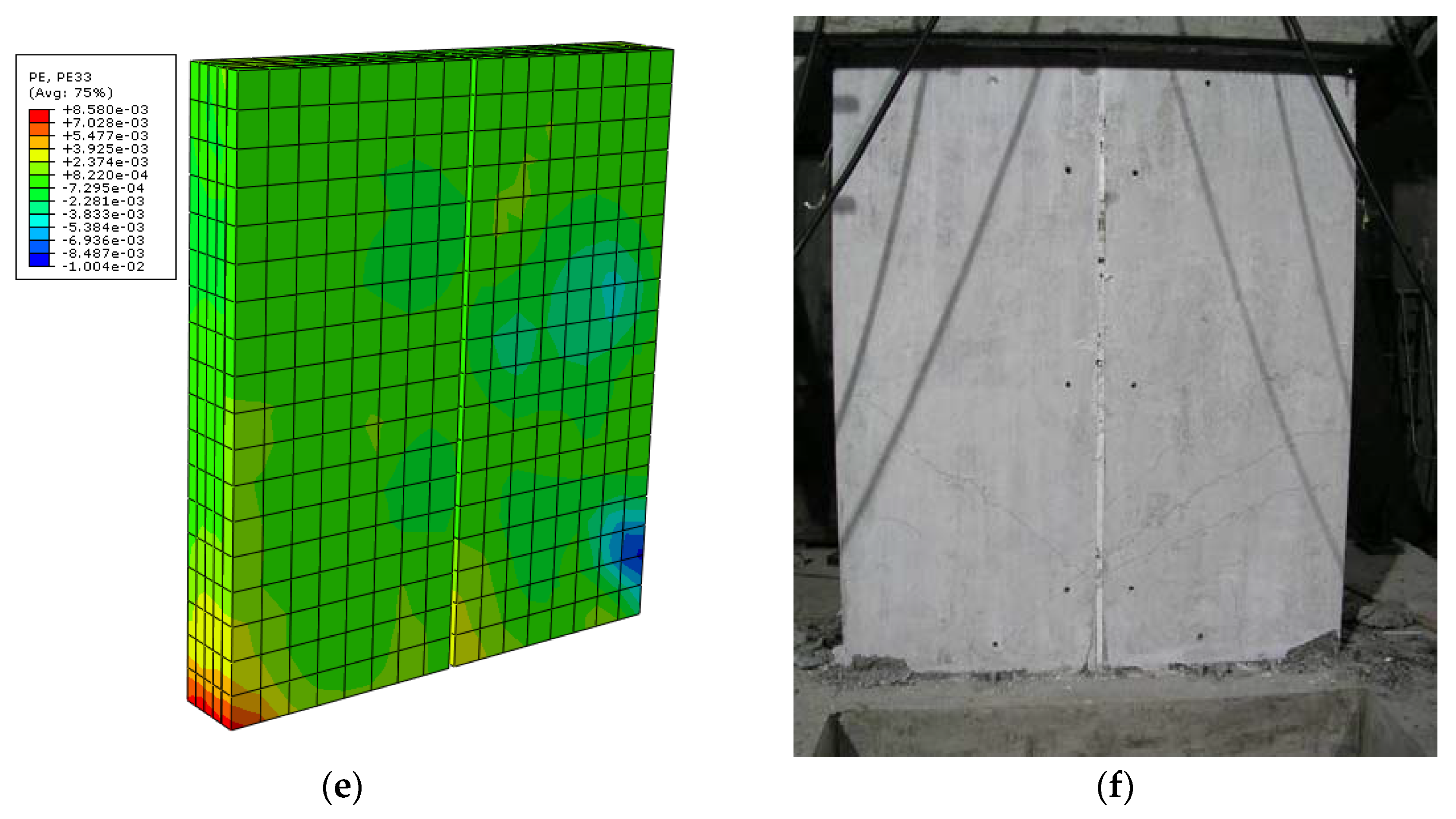

4.4.1. Strain Distribution

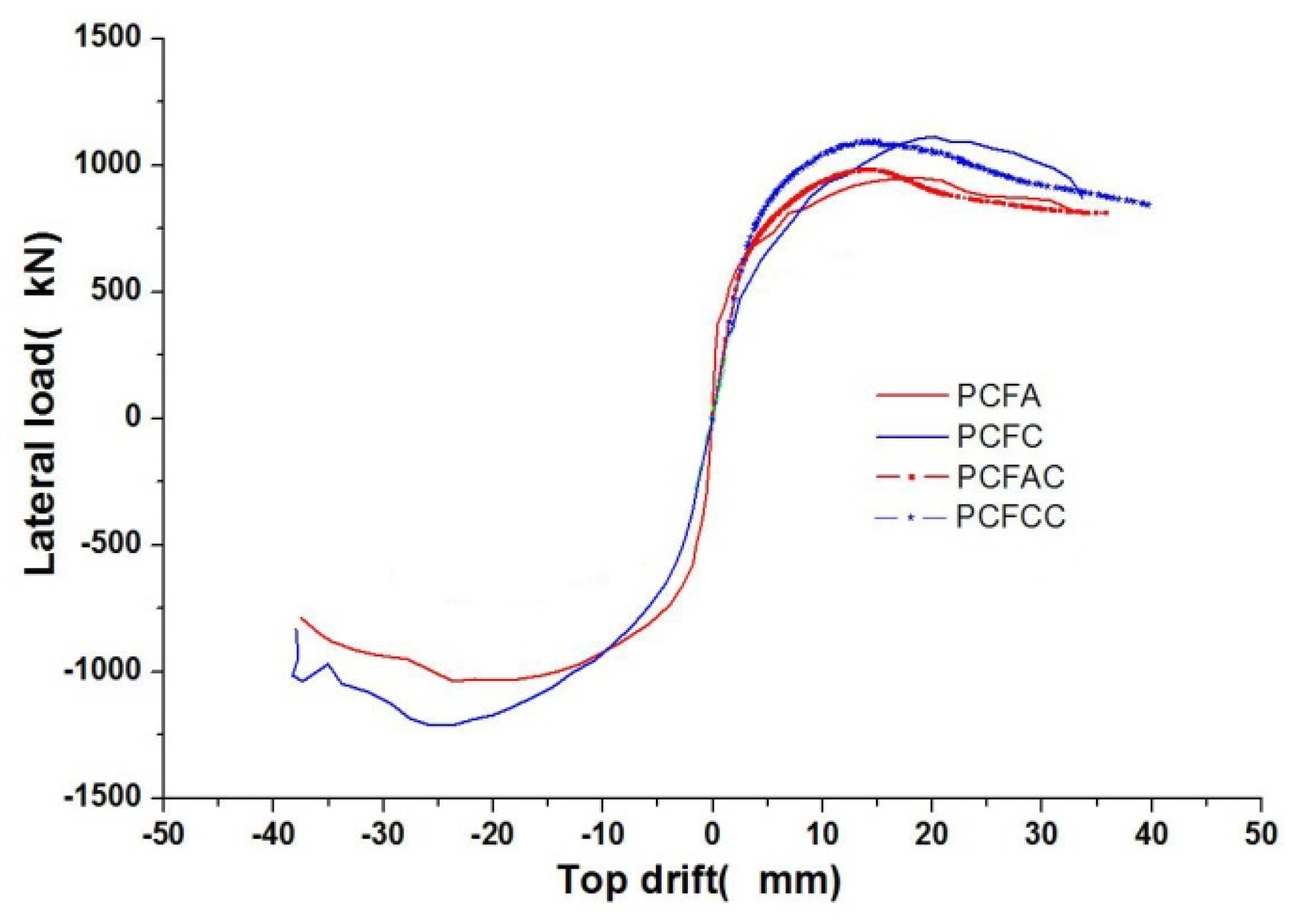

4.4.2. Displacement-Base Shear Curve

5. Conclusions

- The failure mode, the hysteretic curve and the skeleton curve, the stiffness degradation law, the energy dissipation capacity and the bearing capacity of the laminated shear wall are similar to that of the cast-in-place shear wall, indicating that laminated walls have good seismic performance.

- The seam can effectively transfer the load when it is well-constructed, and whose performance is similar to the whole wall. At the same time, due to the greater deformation caused by the seam, the wall’s energy dissipation capacity is slightly better than the whole wall.

- Whether the napping treatment or sprayed surface retarder is applied on the surface between the prefabricated part and the cast-in-place part, the old and new concrete can connect with each other well, and work together with integrity.

- The two structural constructions of the concealed column and the shear wall have little effect on the seismic performance of the shear wall; hence, the appropriate method can be selected according to the actual construction needs.

- The finite element simulation of the laminated reinforced concrete shear wall is in good agreement with the experimental results. The stress cloud is consistent with the final failure phenomena in the experiments. The simulated displacement-the base shear curve is consistent with the experimental results.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, Z.; Chen, X.Y.; Lu, X.L.; Yang, Z. Shaking table test and numerical simulation of an RC frame-core tube structure for earthquake-induced collapse. Earthq. Eng. Struct. Dyn. 2016, 45, 1537–1556. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Z.; Lu, Z. Optimization design and experimental verification of track nonlinear energy sink for vibration control under seismic excitation. Struct. Control Health Monit. 2017. [Google Scholar] [CrossRef]

- Lu, Z.; He, X.D.; Zhou, Y. Studies on damping behavior of vertically mixed structures with upper steel and lower concrete substructures. Struct. Des. Tall Spec. Build. 2017. [Google Scholar] [CrossRef]

- Dai, K.; Wang, J.; Mao, R.; Lu, Z.; Chen, S.E. Experimental investigation on dynamic characterization and seismic control performance of a TLPD system. Struct. Des. Tall Spec. Build. 2017, 26, e1350. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, X.Y.; Zhang, D.C.; Dai, K.S. Experimental and analytical study on the performance of particle tuned mass dampers under seismic excitation. Earthq. Eng. Struct. Dyn. 2016, 46, 697–714. [Google Scholar] [CrossRef]

- Liu, C.Q.; Wei, X.D.; Lu, Z.; Wu, H.D.; Yang, Y.L.; Chen, L.Y. Studies on passive flexible protection to resist landslides caused by the May 12 2008 Wenchuan earthquake. Struct. Des. Tall Spec. Build. 2017. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, X.L.; Lu, W.S.; Masri, S.F. Shaking table test of the effects of multi-unit particle dampers attached to an MDOF system under earthquake excitation. Earthq. Eng. Struct. Dyn. 2012, 41, 987–1000. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, D.C.; Masri, S.F.; Lu, X.L. An experimental study of vibration control of wind-excited high-rise buildings using particle tuned mass dampers. Smart Struct. Syst. 2016, 18, 93–115. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, X.L.; Jiang, H.J.; Masri, S.F. Discrete element method simulation and experimental validation of particle damper system. Eng. Comput. 2014, 31, 810–823. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, Z.X.; Masri, S.F.; Lu, X.L. Particle Impact Dampers: Past, Present, and Future. Struct. Control Health Monit. 2017. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, X.Y.; Li, X.W.; Li, P.Z. Optimization and application of multiple tuned mass dampers in the vibration control of pedestrian bridges. Struct. Eng. Mech. 2017, 62, 55–64. [Google Scholar]

- Lu, Z.; Wang, D.C.; Zhou, Y. Experimental parametric study on wind-induced vibration control of particle tuned mass damper on a benchmark high-rise building. Struct. Des. Tall Spec. Build. 2017. [Google Scholar] [CrossRef]

- Lu, Z.; Yang, Y.L.; Lu, X.L.; Liu, C.Q. Preliminary study on the damping effect of a lateral damping buffer under a debris flow load. Appl. Sci. 2017, 7, 201. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, X.L.; Masri, S.F. Studies of the performance of particle dampers under dynamic loads. J. Sound Vib. 2010, 26, 5415–5433. [Google Scholar] [CrossRef]

- Lu, Z.; Masri, S.F.; Lu, X.L. Studies of the performance of particle dampers attached to a two-degree-of-freedom system under random excitation. J. Vib. Control 2011, 10, 1454–1471. [Google Scholar]

- Lu, Z.; Lu, X.L.; Lu, W.S.; Masri, S.F. Experimental studies of the effects of buffered particle dampers attached to a multi-degree-of-freedom system under dynamic loads. J. Sound Vib. 2012, 9, 2007–2022. [Google Scholar] [CrossRef]

- Lu, Z.; Masri, S.F.; Lu, X.L. Parametric studies of the performance of particle dampers under harmonic excitation. Struct. Control Health Monit. 2011, 2, 79–98. [Google Scholar] [CrossRef]

- Foti, D.; Diaferio, M.; Nobile, R. Optimal Design of a New Seismic Passive Protection Device Made in Aluminium and Steel. Int. J. Struct. Eng. Mech. 2010, 35, 119–122. [Google Scholar] [CrossRef]

- Foti, D.; Diaferio, M.; Nobile, R. Dynamic Behavior of New Aluminum-Steel Energy Dissipating Devices. Struct. Control Health Monit. 2013, 20, 1106–1119. [Google Scholar] [CrossRef]

- Oliva, M.G.; Clough, R.W. Shaking Table Tests of Large-Panel Precast Concrete Building System Assemblages; Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 1985. [Google Scholar]

- Soudki, K.A.; West, J.S.; Rizkalla, S.H.; Blackett, B. Horizontal connections for precast concrete shear wall panels under cyclic shear loading. PCI J. 1996, 41, 64–80. [Google Scholar] [CrossRef]

- Chakrabarti, S.C.; Nayak, G.C.; Paul, D.K. Shear characteristics of cast-in-place vertical joints in story-high precast wall assembly. ACI Struct. J. 1988, 85, 30–45. [Google Scholar]

- Pekau, O.A.; Hum, D. Seismic response of friction jointed precast panel shear Walls. PCI J. 1991, 36, 56–71. [Google Scholar] [CrossRef]

- Hutchinson, R.; Rizkalla, S.; Lau, M.; Huevel, J.S. Horizontal Post-Tensioned Connections for Precast Concrete Load bearing Shear Wall Panels. PCI J. 1991, 36, 64–76. [Google Scholar] [CrossRef]

- Kurama, Y.; Sause, R.; Pessiki, S.; Lu, L.W. Lateral load behavior and seismic design of unbonded post-tensioned precast concrete walls. ACI Struct. J. 1999, 96, 622–633. [Google Scholar]

- Kurama, Y.C. Seismic design of unbonded post tensioned precast concrete walls with supplemental viscous damping. ACI Struct. J. 2000, 97, 648–658. [Google Scholar]

- Rodriguez, M.; Restrepo, J.; BlandóN, J.J. Seismic Design Forces for Rigid Floor Diaphragms in Precast Concrete Building Structures. J. Struct. Eng. 2007, 133, 1604–1615. [Google Scholar] [CrossRef]

- Holden, T.; Restrepo, J.; Mander, J.B. Seismic performance of precast reinforced and prestressed concrete walls. J. Struct. Eng. 2003, 129, 286–296. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, Z.X.; Li, J.B.; Huang, B. Studies on seismic performance of precast concrete columns with grouted splice sleeve. Appl. Sci. 2017, 7, 571. [Google Scholar] [CrossRef]

- Palermo, M.; Trombetti, T. Experimentally-validated modelling of thin RC sandwich walls subjected to seismic loads. Eng. Struct. 2016, 119, 95–109. [Google Scholar] [CrossRef]

- Ricci, I.; Palermo, M.; Gasparini, G.; Silvestri, S.; Trombetti, T. Results of pseudo-static tests with cyclic horizontal load on cast in situ sandwich squat concrete walls. Eng. Struct. 2013, 54, 131–149. [Google Scholar] [CrossRef]

- Palermo, M.; Ricci, I.; Silvestri, S.; Gasparini, G.; Trombetti, T.; Foti, D.; Ivorra, S. Preliminary interpretation of shaking-table response of a full-scale 3-storey building composed of thin reinforced concrete sandwich walls. Eng. Struct. 2014, 76, 75–89. [Google Scholar] [CrossRef]

- Ivorra, S.; Foti, D.; Ricci, I.; Gasparini, G.; Silvestri, S.; Trombetti, T. Shaking table test design to evaluate earthquake capacity of a 3-storey building specimen composed of cast-in-situ concrete walls. Geotech. Geol. Earthq. Eng. 2015, 35, 345–358. [Google Scholar]

- Gasparini, G.; Trombetti, T.; Silvestri, S.; Ricci, I.; Ivorra, C.S.; Foti, D. Preliminary Results of a Shaking Table Tests on a 3-Storey Building Realized With Cast in Place Sandwich Squat Concrete Walls. In Proceedings of the Conference New Developments in Structural Engineering and Construction (ISEC7), Honolulu, HI, USA, 18–23 June 2013; Yazdani, S., Singh, A., Eds.; Research Publishing Services: Singapore, 2013. [Google Scholar]

- Ricci, I.; Palermo, M.; Silvestri, S.; Gasparini, G.; Trombetti, T.; Foti, D.; Ivorra, C.S. Shake table response of a full-scale 3-storey building composed of thin reinforced concrete sandwich walls. In Proceedings of the AES-RSESS’2013 First International Conference on Reliability and Safety of Engineering Systems and Structures, Vancouver, BC, Canada, 12–16 August 2013; pp. 29–41. [Google Scholar]

- Chong, X.; Ye, X.G.; Wang, D.C.; Lian, X. Seismic response of superposed wall panel with different edge components. Adv. Mater. Res. 2011, 163, 1074–1079. [Google Scholar] [CrossRef]

- Chong, X.; Huang, J.Q.; Ye, X.G. Numerical analysis on nonlinear behavior of the superimposed wall under quasi-static reversed cyclic loading. In Proceedings of International Conference on Sustainable Development of Critical Infrastructure, Shanghai, China, 16–18 May 2014. pp. 238–246.

- Chong, X.; Xie, L.; Ye, X.; Jiang, Q.; Wang, D.C. Experimental study and numerical model calibration of full-scale superimposed reinforced concrete walls with I-shaped cross sections. Adv. Struct. Eng. 2016, 19, 1902–1916. [Google Scholar] [CrossRef]

- Xiao, Q.D.; Guo, Z.X.; Zhang, Z.Y. Behavior of double-wall precast concrete shear wall under low-cyclic reversed loading test. Adv. Mater. Res. 2015, 1079, 354–358. [Google Scholar] [CrossRef]

- Shen, X.; Wei, M.A.; Chen, X.; Zhang, W.; Wang, R.; Wang, J.G. Experimental Study on the Seismic Performance of the Vertical Joint Seam of Superimposed Concrete Wall Panels. J. Hefei Univ. Technol. 2010, 33, 1366–1371. (In Chinese) [Google Scholar]

- Zhang, H.; Lu, X.; Li, J.; Liang, L. Cyclic load experiment study on the laminated composite RC walls with different concrete ages. Struct. Eng. Mech. 2010, 36, 745–758. [Google Scholar] [CrossRef]

- Zhang, H.M.; Lu, X.L.; Duan, Y.F.; Li, J.B. Experimental Study and Numerical Simulation of Partially Prefabricated Laminated Composite RC Walls. Adv. Struct. Eng. 2011, 14, 967–980. [Google Scholar] [CrossRef]

- Ministry of Construction of the People’s Republic of China. The Code for Design of Concrete Structures (GB50010-2002); China Architecture & Building Press: Beijing, China, 2002. (In Chinese)

- Lu, X.L.; Jiang, H.J. Hysteretic analysis of a new type of energy dissipation shear walls. Earthq. Eng. Eng. Vib. 2000, 1, 17. [Google Scholar]

| Type | Number | Thickness | Size of the Concealed Column | Interface Processing |

|---|---|---|---|---|

| A(Whole wall) | PCFI-A1 | 250 | 250 × 400 | Napping treatment |

| PCFI-A2 | Spray surface retarder | |||

| PCFI-A3 | Napping treatment | |||

| SWA | 200 | 200 × 400 | / | |

| C(Seam wall) | PCFI-C1 | 250 | 250 × 400 | Napping treatment |

| PCFI-C2 | Spray surface retarder | |||

| PCFI-C3 | Napping treatment | |||

| SWC | 200 | 200 × 400 | / | |

| PCFII-C1 | 250 | 180 × 400 | Napping treatment | |

| PCFII-C2 | Spray surface retarder | |||

| PCFII-C3 | Napping treatment | |||

| PCFII-C4 | Spray surface retarder |

| Specimen | fcu (MPa) | fc (MPa) | Ec (M/mm2) |

|---|---|---|---|

| PCFI-A & SWA | 27.7 | 19.7 | 2.90 × 104 |

| PCFI-C & SWC | 30 | 19.5 | 2.98 × 104 |

| PCFII-C | 35.3 | 31 | 3.14 × 104 |

| Reinforcement | Measured Diameter | Type | fy (MPa) | fb (MPa) | Es (MPa) | |

|---|---|---|---|---|---|---|

| Column longitudinal reinforcement HRB335 | 14 mm | I | 382.5 | 655 | 2.0 × 105 | 2913 |

| II | 372.8 | 546.93 | 1864 | |||

| Strengthening reinforcement HRB400 | 10 mm | I | 357.5 | 480 | 1788 | |

| II | 380.24 | 604.5 | 1901 | |||

| Distributing reinforcement HRB400 | 8 mm | I | 370 | 647.5 | 2850 | |

| II | 385.03 | 617.04 | 1925 |

| Number | Designed Peak Load (kN) | Measured Peak Load (kN) | Average Peak Load (kN) | Ductility Coefficient |

|---|---|---|---|---|

| PCFI-A1 | 1003.2 | 1046.6 | 3.46 | |

| PCFI-A2 | 774.8 | 1039 | 3.16 | |

| PCFI-A3 | (873.2) | 1097.6 | 3.15 | |

| SWA | 1053.1 | 1053.1 | 3.45 | |

| PCFI-C1 | 1104 | 1054.5 | 3.63 | |

| PCFI-C2 | 777.2 | 1024.9 | 3.59 | |

| PCFI-C3 | (891.6) | 1034.6 | 3.73 | |

| SWC | 980.3 | 980.3 | 4.52 | |

| PCFII-C1 | 1174 | 1150 | 3.43 | |

| PCFII-C2 | 777.2 | 1251 | 3.38 | |

| PCFII-C3 | (943.2) | 950 | 3.3 | |

| PCFII-C4 | 1225 | 3.62 |

| Type | Number | Equivalent Viscous Damping Coefficient | Average |

|---|---|---|---|

| A (Whole wall) | PCFI-A1 | 0.089 | 0.080 |

| PCFI-A2 | 0.082 | ||

| PCFI-A3 | 0.074 | ||

| SWA | 0.075 | ||

| C (wall with vertical seam) | PCFI-C1 | 0.075 | 0.090 |

| PCFI-C2 | 0.088 | ||

| PCFI-C3 | 0.110 | ||

| SWC | 0.086 | ||

| PCFII-C1 | 0.118 | 0.122 | |

| PCFII-C2 | 0.125 | ||

| PCFII-C3 | 0.120 | ||

| PCFII-C4 | 0.125 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, Y.; Lu, Z.; Li, J. Experimental Study and Numerical Simulation of a Laminated Reinforced Concrete Shear Wall with a Vertical Seam. Appl. Sci. 2017, 7, 629. https://doi.org/10.3390/app7060629

Li J, Wang Y, Lu Z, Li J. Experimental Study and Numerical Simulation of a Laminated Reinforced Concrete Shear Wall with a Vertical Seam. Applied Sciences. 2017; 7(6):629. https://doi.org/10.3390/app7060629

Chicago/Turabian StyleLi, Jianbao, Yan Wang, Zheng Lu, and Junzuo Li. 2017. "Experimental Study and Numerical Simulation of a Laminated Reinforced Concrete Shear Wall with a Vertical Seam" Applied Sciences 7, no. 6: 629. https://doi.org/10.3390/app7060629