Thermal Management of Concentrated Multi-Junction Solar Cells with Graphene-Enhanced Thermal Interface Materials

Abstract

:1. Introduction

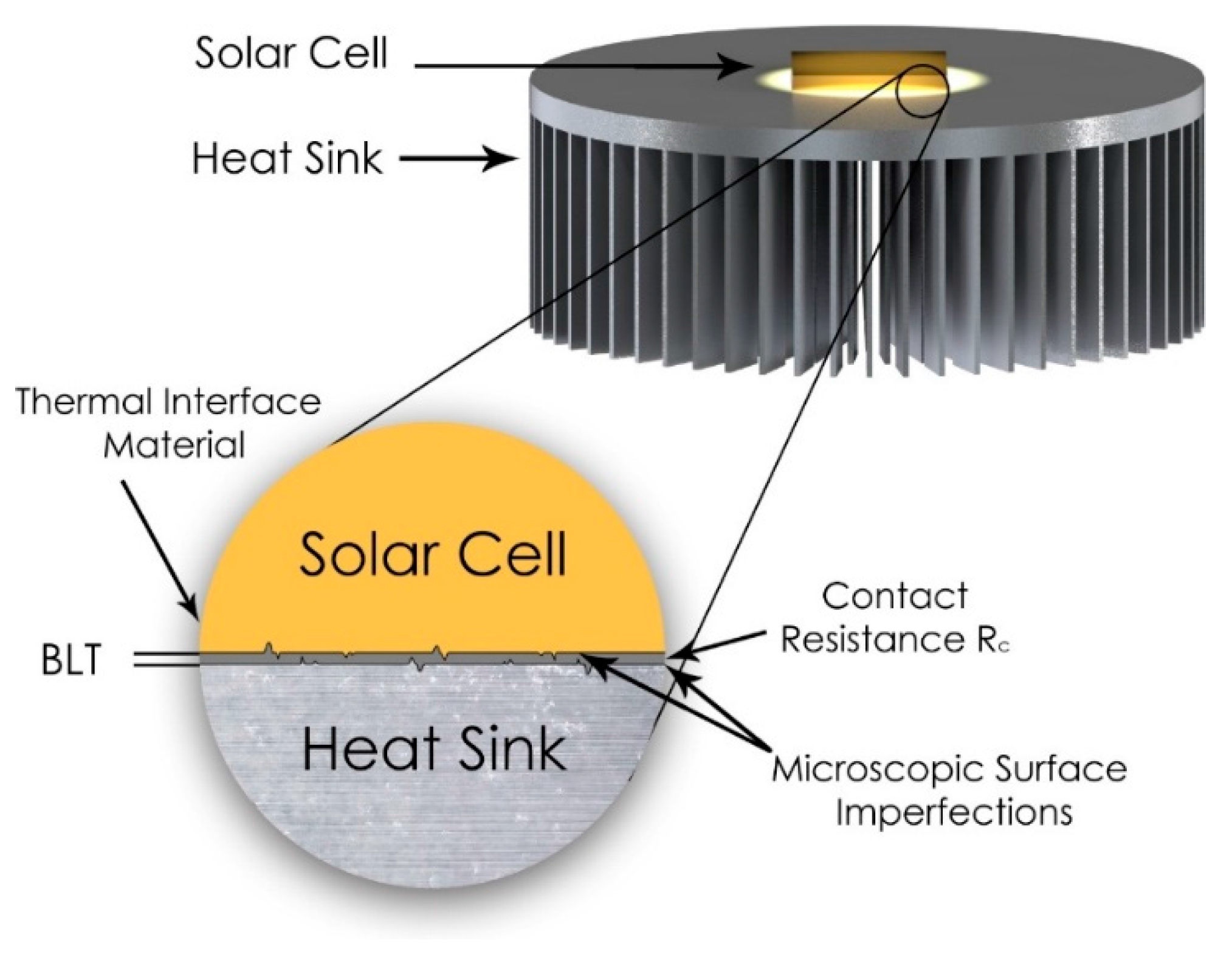

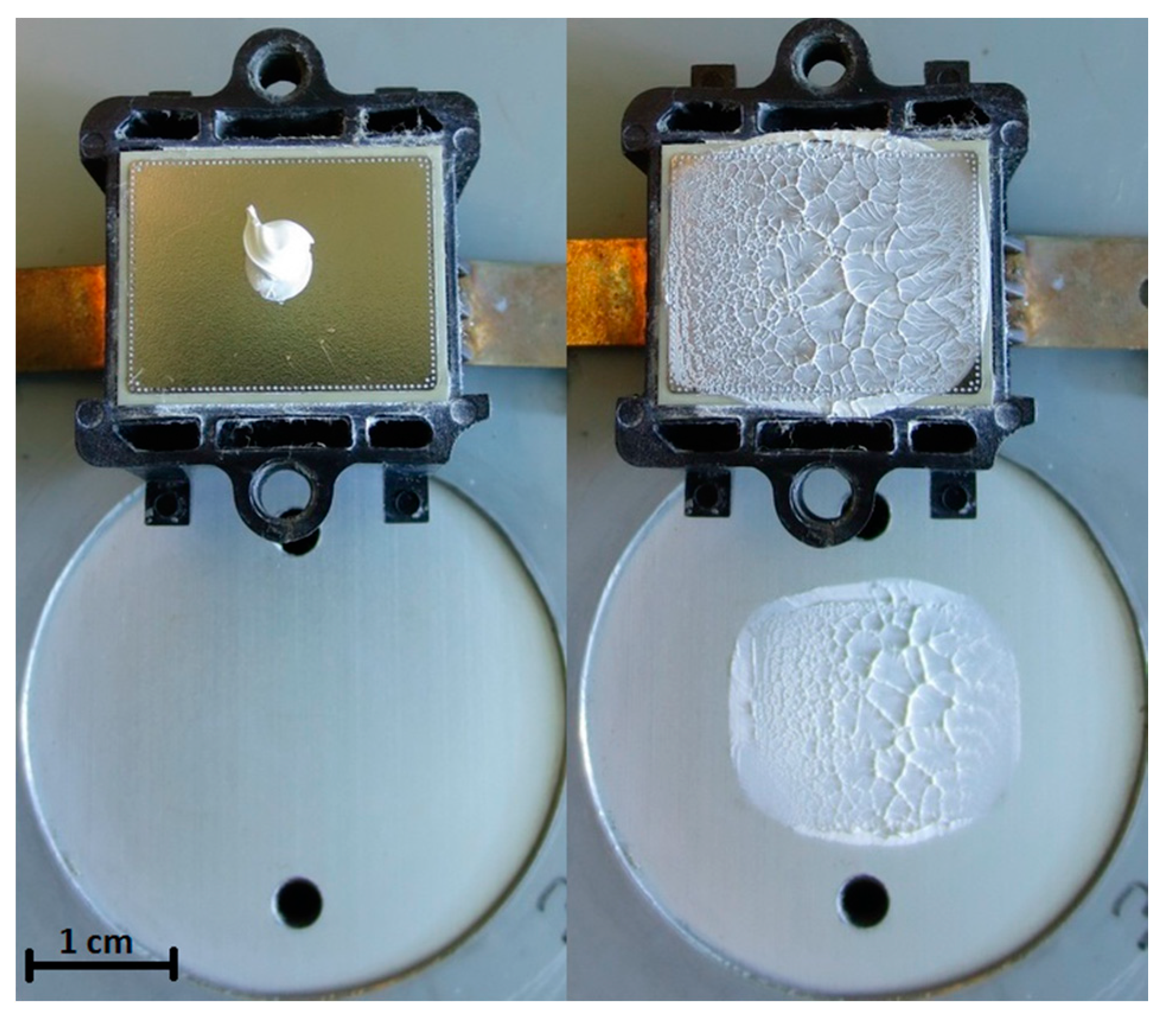

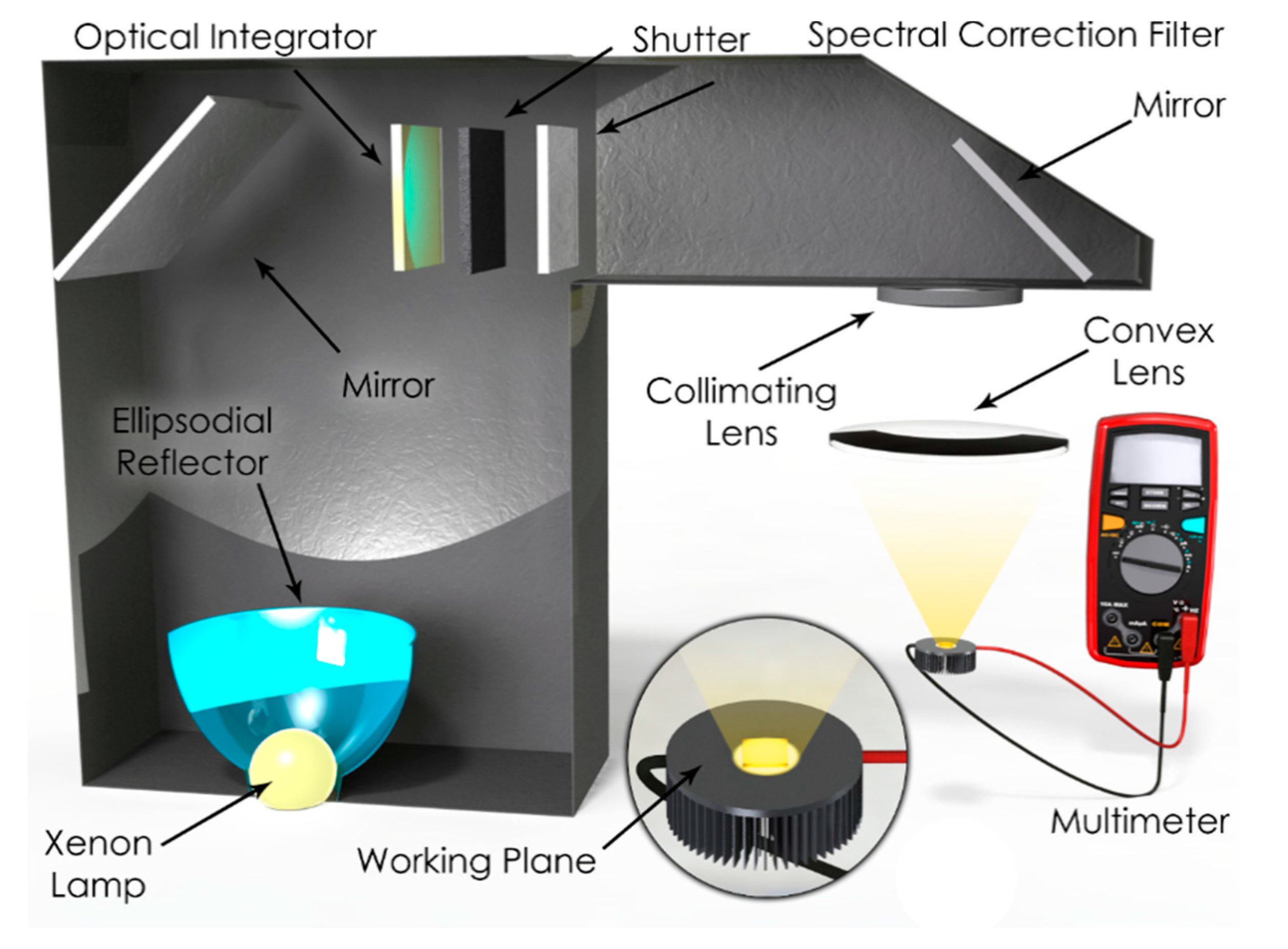

2. Material Preparation and Characterization

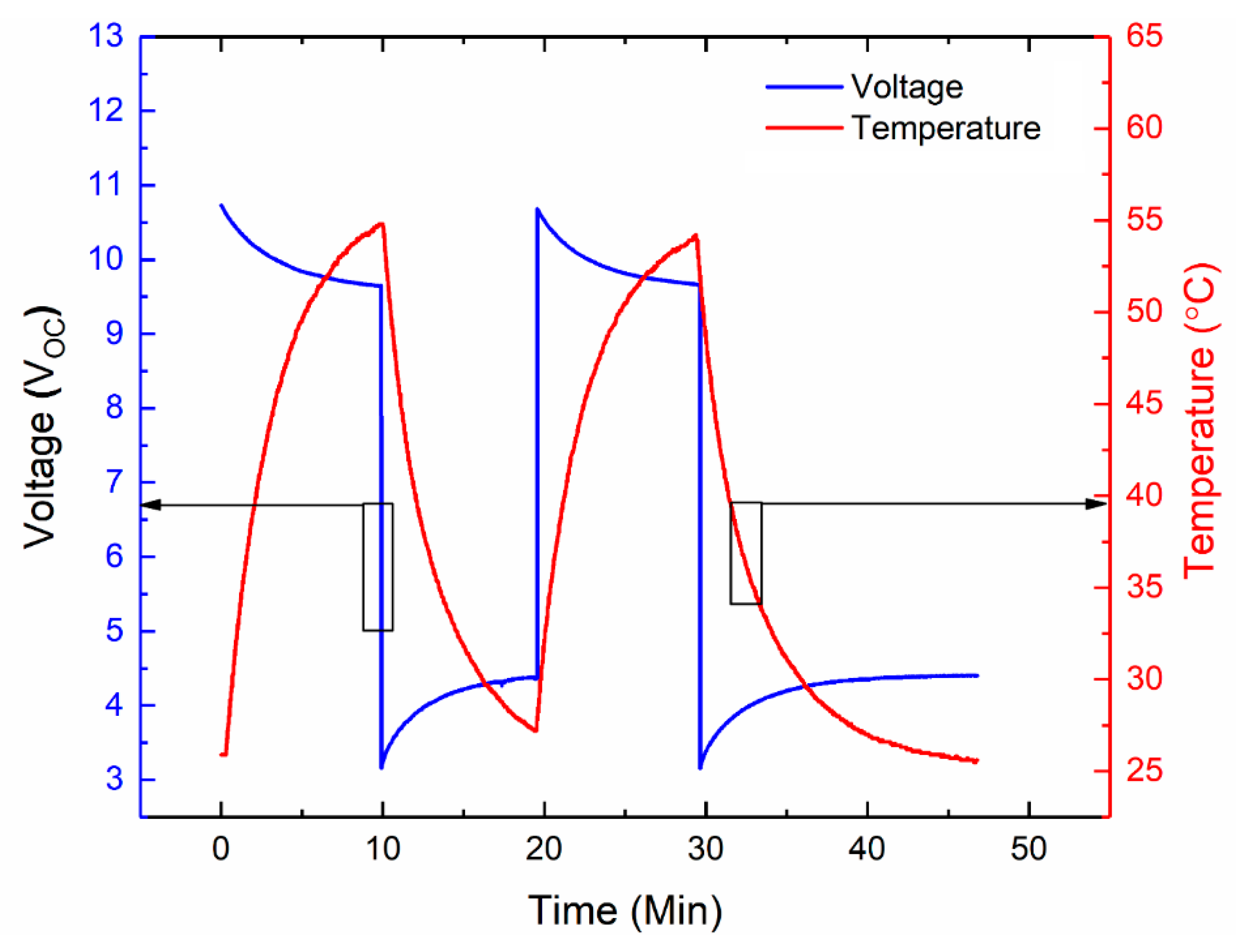

3. Testing of the Photovoltaic Solar Cells

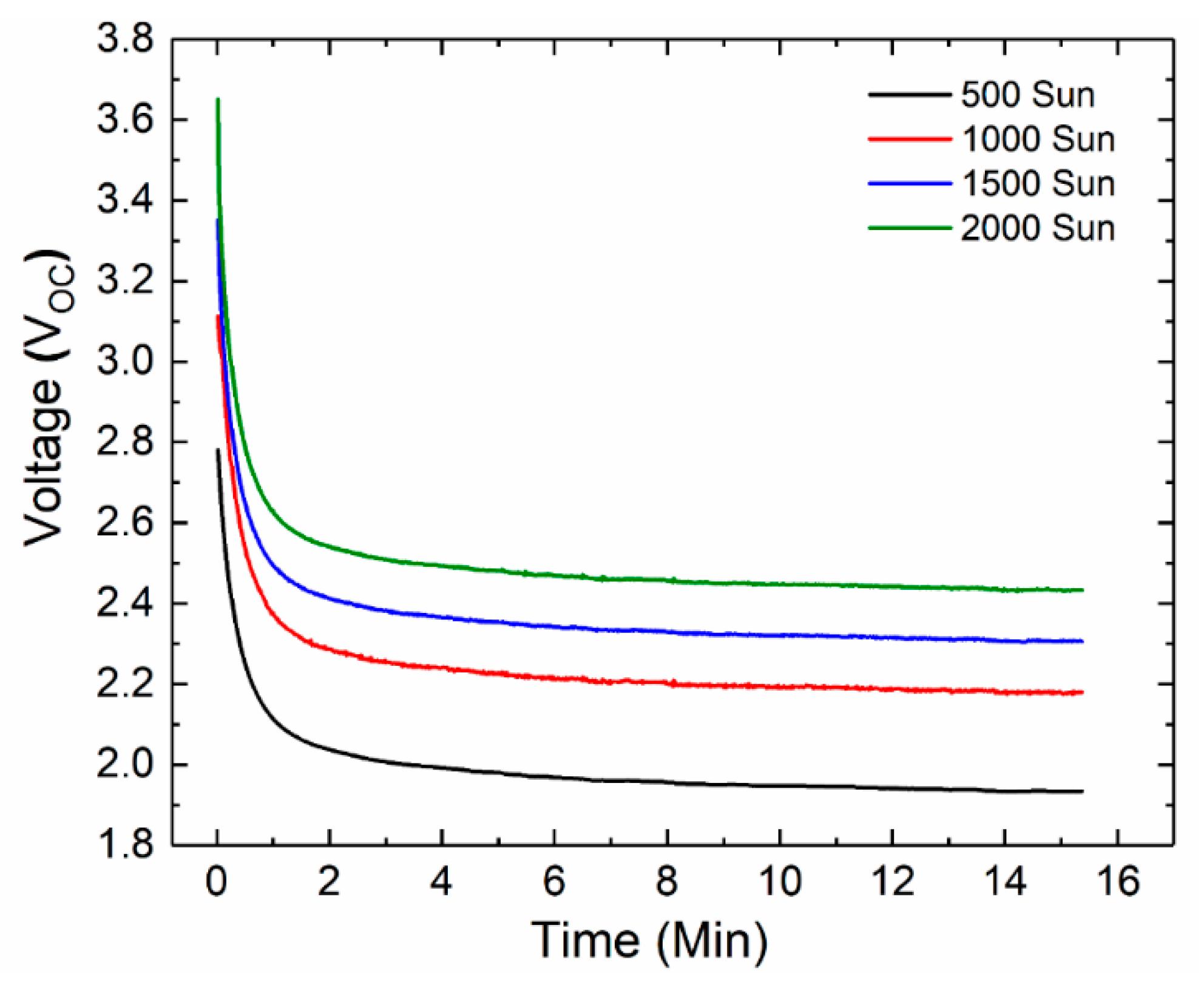

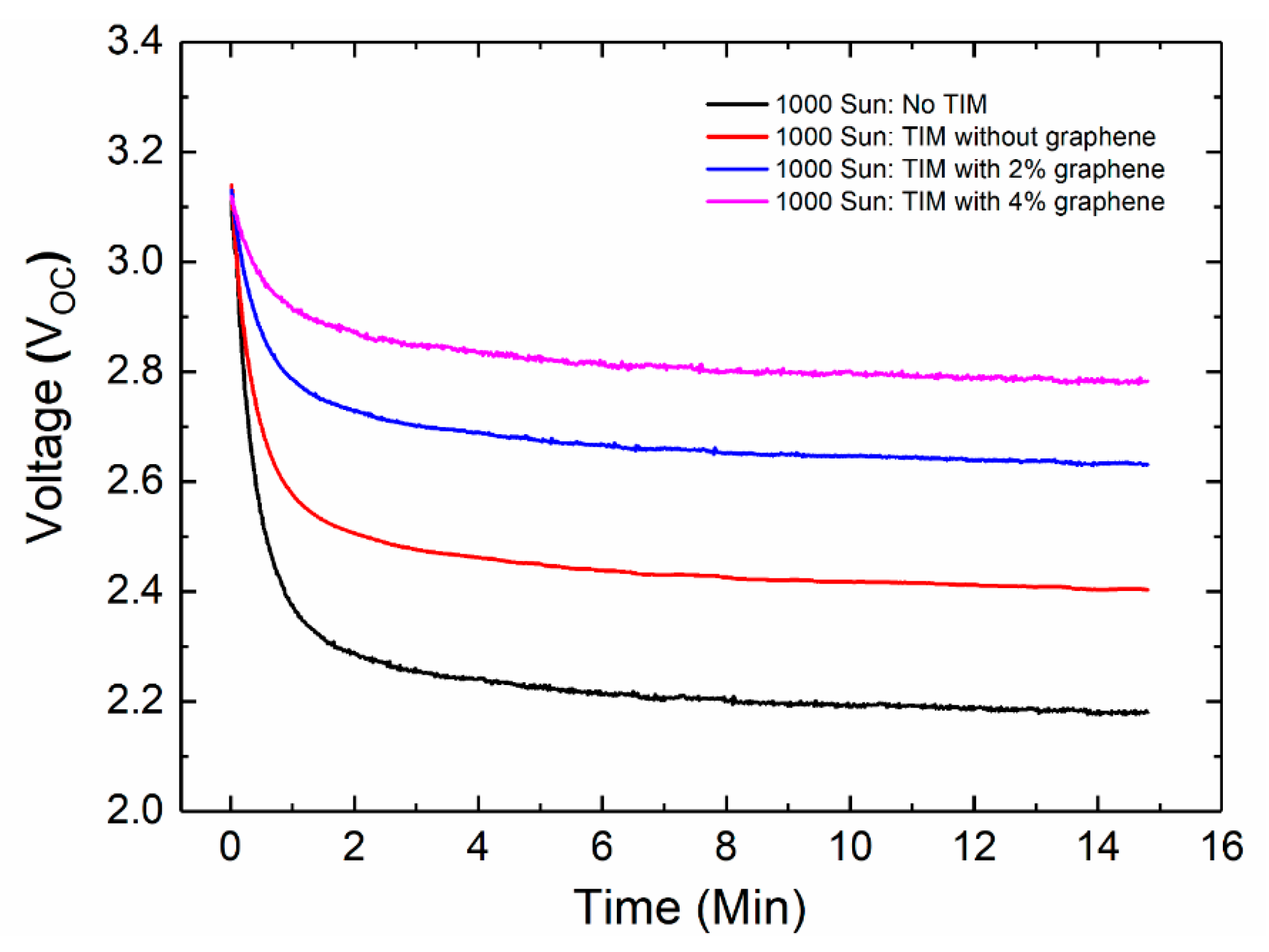

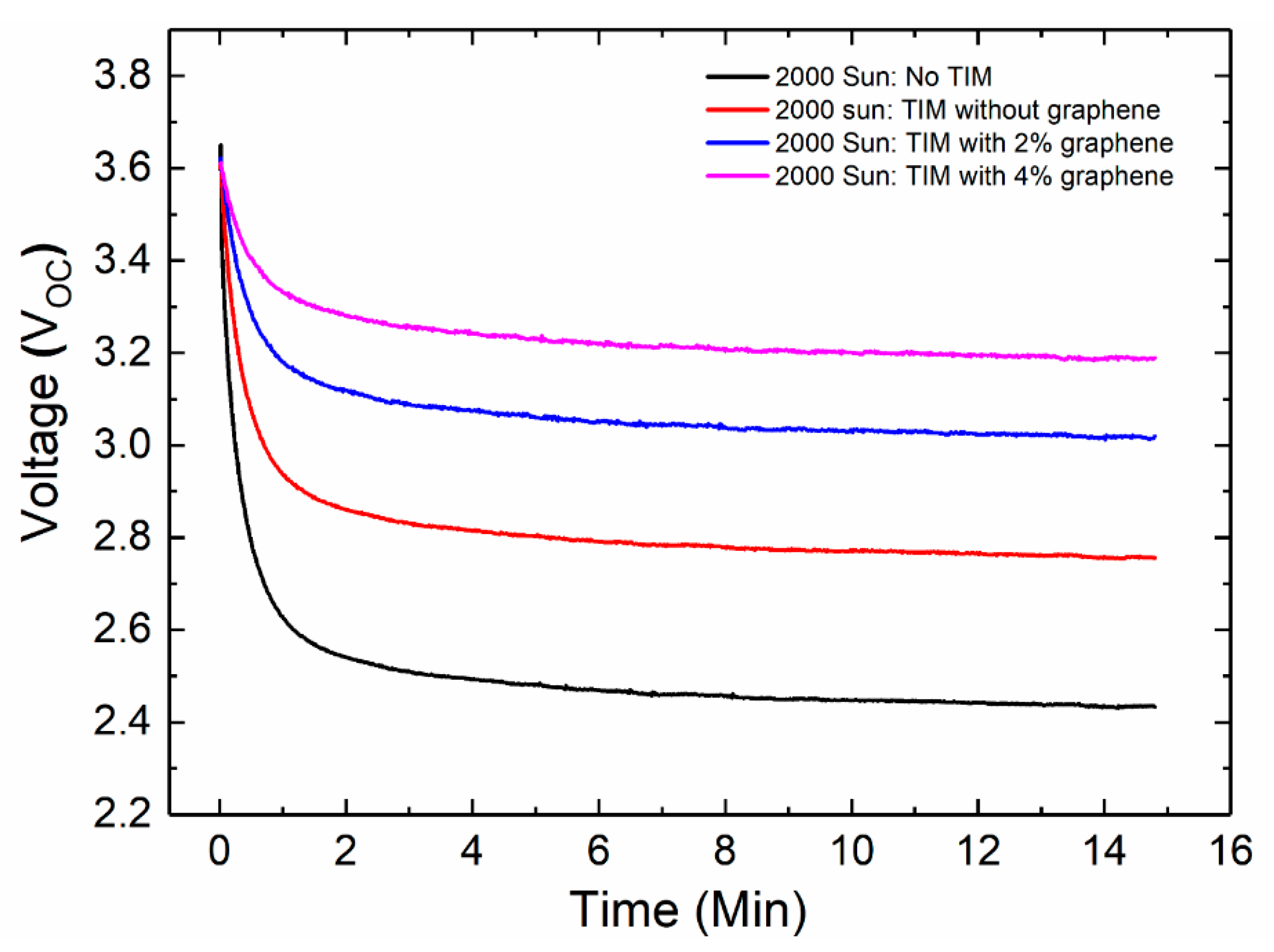

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sohrabi, F.; Nikniazi, A.; Movla, H. Optimization of Third Generation Nanostructured Silicon-Based Solar Cells. In Solar Cells—Research and Application Perspectives; Morales-Acevedo, A., Ed.; In Tech: Rijeka, Croatia, 2013; pp. 1–26. [Google Scholar]

- Nalwa, H.S. Encyclopedia of Nanoscience and Nanotechnology; American Scientific Publishers: Valencia, CA, USA, 2004; p. 727. [Google Scholar]

- Masuko, K.; Shigematsu, M.; Hashiguchi, T.; Fujishima, D.; Kai, M.; Yoshimura, N.; Yamaguchi, T.; Ichihashi, Y.; Mishima, T.; Matsubara, N.; et al. Achievement of More Than 25% Conversion Efficiency with Crystalline Silicon Heterojunction Solar Cell. IEEE J. Photovolt. 2014, 4, 1433–1435. [Google Scholar] [CrossRef]

- Van Sark, W.; Korte, L.; Roca, F. Introduction—Physics and Technology of Amorphous-Crystalline Heterostructure Silicon. In Physics and Technology Amorphous-Crystalline Heterostructure Silicon Solar Cells; Springer-Verlag: Berlin/Heidelberg, Germany, 2012; pp. 1–12. [Google Scholar] [CrossRef]

- Glunz, S.W. High-efficiency crystalline silicon solar cells. Adv. OptoElectron. 2007. [Google Scholar] [CrossRef] [PubMed]

- Snaith, H.J. Perovskites: The Emergence of a New Era for Low-Cost, High-Efficiency Solar Cells. J. Phys. Chem. Lett. 2013, 4, 3623–3630. [Google Scholar] [CrossRef]

- Becker, C.; Amkreutz, D.; Sontheimer, T.; Preidel, V.; Lockau, D.; Haschke, J.; Jogschies, L.; Klimm, C.; Merkel, J.J.; Plocica, P.; et al. Polycrystalline silicon thin-film solar cells: Status and perspectives. Sol. Energy Mater. Sol. Cells 2013, 119, 112–123. [Google Scholar] [CrossRef]

- Konagai, M. Present status and future prospects of silicon thin-film solar cells. Jpn. J. Appl. Phys. 2011, 50. [Google Scholar] [CrossRef]

- Avrutin, V.; Izyumskaya, N.; Morko, H. Semiconductor solar cells: Recent progress in terrestrial applications. Superlattices Microstruct. 2011, 49, 337–364. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Rahim, N.A.A.; Rahim, N.A.; Selvaraj, J.A.L. Progress in solar PV technology: Research and achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Lee, H.S. Thermal Design: Heat Sinks, Thermoelectrics, Heat Pipes, Compact Heat Exchangers, and Solar Cells; John Wiley & Sons: New York, NY, USA, 2010; p. 482. [Google Scholar] [CrossRef]

- Green, M.A.; Emery, Y.; Hishikawa, W.; Warta, E.D. Dunlop, Solar cell efficiency tables (version 47). Prog. Photovolt. Res. Appl. 2016, 24, 3–11. [Google Scholar] [CrossRef]

- Xie, W.T.; Dai, Y.J.; Wang, R.Z.; Sumathy, K. Concentrated solar energy applications using Fresnel lenses: A review. Renew. Sustain. Energy Rev. 2011, 15, 2588–2606. [Google Scholar] [CrossRef]

- Huang, B.J.; Yang, P.E.; Lin, Y.P.; Lin, B.Y.; Chen, H.J.; Lai, R.C.; Cheng, J.S. Solar cell junction temperature measurement of PV module. Sol. Energy. 2011, 85. [Google Scholar] [CrossRef]

- McConnell, R.; Symko-Davies, M. Multijunction photovoltaic technologies for high-performance concentrators. In Proceedings of the Conference Record of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion (WCPEC-4), Waikoloa, HI, USA, 7–12 May 2006; pp. 733–736. [Google Scholar] [CrossRef]

- Baig, H.; Heasman, K.C.; Mallick, T.K. Non-uniform illumination in concentrating solar cells. Renew. Sustain. Energy Rev. 2012, 16, 5890–5909. [Google Scholar] [CrossRef]

- Saga, T. Advances in crystalline silicon solar cell technology for industrial mass production. NPG Asia Mater. 2010, 2, 96–102. [Google Scholar] [CrossRef]

- Chander, S.; Purohit, A.; Sharma, A.; Arvind; Nehra, S.P.; Dhaka, M.S. A study on photovoltaic parameters of mono-crystalline silicon solar cell with cell temperature. Energy Rep. 2015, 1, 104–109. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hasanuzzaman, M.; Rahim, N.A. Effects of various parameters on PV-module power and efficiency. Energy Convers. Manag. 2015, 103, 348–358. [Google Scholar] [CrossRef]

- Meneses-Rodríguez, D.; Horley, P.P.; González-Hernández, J.; Vorobiev, Y.V.; Gorley, P.N. Photovoltaic solar cells performance at elevated temperatures. Sol. Energy 2005, 78, 243–250. [Google Scholar] [CrossRef]

- Radziemska, E. Thermal performance of Si and GaAs based solar cells and modules: A review. Prog. Energy Combust. Sci. 2003, 29, 407–424. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- El-Adawi, M.K.; Al-Nuaim, I.A. The temperature functional dependence of VOC for a solar cell in relation to its efficiency new approach. Desalination 2007, 209, 91–96. [Google Scholar] [CrossRef]

- Radziemska, E.; Klugmann, E. Thermally affected parameters of the current-voltage characteristics of silicon photocell. Energy Convers. Manag. 2002, 43, 1889–1900. [Google Scholar] [CrossRef]

- Cuce, E.; Bali, T. Variation of cell parameters of a p-Si PV cell with different solar irradiances and cell temperatures in humid climates. In Proceedings of the 4th International Energy, Exergy and Environment Symposium, Sharjah, UAE, 19–23 April 2009. [Google Scholar]

- Cuce, E.; Bal, T. A Comparison of Energy and Power Conversion Efficiencies of m-Si and p-Si PV Cells in Trabzon. In Proceedings of the 5th International Advanced Technologies Symposium, Karabuk, Turkey, 15–19 May 2009. [Google Scholar]

- Natarajan, S.K.; Mallick, T.K.; Katz, M.; Weingaertner, S. Numerical investigations of solar cell temperature for photovoltaic concentrator system with and without passive cooling arrangements. Int. J. Therm. Sci. 2011, 50, 2514–2521. [Google Scholar] [CrossRef]

- Ye, Z.; Li, Q.; Zhu, Q.; Pan, W. The cooling technology of solar cells under concentrated system. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference (IPEMC’09), Wuhan, China, 17–20 May 2009; pp. 2193–2197. [Google Scholar] [CrossRef]

- Bojanampati, S.; Rodgers, P. Experimental assessment of flat-type photovoltaic module thermal behavior. In Proceedings of the 13th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Cascais, Portugal, 16–18 April 2012. [Google Scholar] [CrossRef]

- Tong, X.C. Advanced Materials for Thermal Management of Electronic Packaging. Adv. Mater. 2011, 30, 201–232. [Google Scholar] [CrossRef]

- Gwinn, J.P.; Webb, R.L. Performance and testing of thermal interface materials. Microelectron. J. 2003, 34, 215–222. [Google Scholar] [CrossRef]

- Prasher, R. Thermal Interface Materials: Historical Perspective, Status, and Future Directions. Proc. IEEE 2006, 94, 1571–1586. [Google Scholar] [CrossRef]

- Renteria, J.D.; Nika, D.L.; Balandin, A.A. Graphene Thermal Properties: Applications in Thermal Management and Energy Storage. Appl. Sci. 2014, 4, 525–547. [Google Scholar] [CrossRef]

- Goli, P.; Legedza, S.; Dhar, A.; Salgado, R.; Renteria, J.; Balandin, A.A. Graphene-enhanced hybrid phase change materials for thermal management of Li-ion batteries. J. Power Sources 2014, 248, 37–43. [Google Scholar] [CrossRef]

- Yan, Z.; Nika, D.L.; Balandin, A.A. Special Issue on Graphene Electronics Thermal properties of graphene and few-layer graphene: Applications in electronics. IET Circuits Devices Syst. 2014, 9, 4–12. [Google Scholar] [CrossRef]

- Malekpour, H.; Chang, K.H.; Chen, J.C.; Lu, C.Y.; Nika, D.L.; Novoselov, K.S.; Balandin, A.A. Thermal conductivity of graphene laminate. Nano Lett. 2014, 14, 5155–5161. [Google Scholar] [CrossRef] [PubMed]

- Renteria, J.; Legedza, S.; Salgado, R.; Balandin, M.P.; Ramirez, S.; Saadah, M.; Kargar, F.; Balandin, A.A. Magnetically-functionalized self-aligning graphene fillers for high-efficiency thermal management applications. Mater. Des. 2015, 88, 214–221. [Google Scholar] [CrossRef]

- Khandelwal, R.; Kishen, J.M.C. Thermal weight functions for bi-material interface crack system using energy principles. Int. J. Solids Struct. 2008, 45, 6157–6176. [Google Scholar] [CrossRef]

- Memon, M.O.; Haillot, S.; Lafdi, K. Carbon nanofiber based buckypaper used as a thermal interface material. Carbon 2011, 49, 3820–3828. [Google Scholar] [CrossRef]

- Li, X.; Yang, R. Effect of lattice mismatch on phonon transmission and interface thermal conductance across dissimilar material interfaces. Phys. Rev. B Condens. Matter Mater. Phys. 2012, 86. [Google Scholar] [CrossRef]

- Shahil, K.M.F.; Balandin, A.A. Thermal properties of graphene and multilayer graphene: Applications in thermal interface materials. Solid State Commun. 2012, 152, 1331–1340. [Google Scholar] [CrossRef]

- Sarvar, F.; Whalley, D.; Conway, P. Thermal Interface Materials—A Review of the State of the Art. In Proceedings of the 2006 1st Electronics Systemintegration Technology Conference, Dresden, Germany, 5–7 September 2006; pp. 1292–1302. [Google Scholar] [CrossRef]

- Goyal, V.; Balandin, A.A. Thermal properties of the hybrid graphene-metal nano-micro-composites: Applications in thermal interface materials. Appl. Phys. Lett. 2012, 100, 073113. [Google Scholar] [CrossRef]

- McNamara, A.J.; Joshi, Y.; Zhang, Z.M. Characterization of nanostructured thermal interface materials—A review. Int. J. Therm. Sci. 2012, 62, 2–11. [Google Scholar] [CrossRef]

- Shahil, K.M.F.; Balandin, A.A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef] [PubMed]

- Nika, D.L.; Balandin, A.A. Phonons and thermal transport in graphene and graphene-based materials. Rep. Prog. Phys. 2017, 80, 36502. [Google Scholar] [CrossRef] [PubMed]

- Guter, W.; Schöne, J.; Philipps, S.P.; Steiner, M.; Siefer, G.; Wekkeli, A.; Welser, E.; Oliva, E.; Bett, A.W.; Dimroth, F. Current-matched triple-junction solar cell reaching 41.1% conversion efficiency under concentrated sunlight. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Dimroth, F.; Grave, M.; Beutel, P.; Fiedeler, U.; Karcher, C.; Tibbits, T.N.D.; Oliva, E.; Siefer, G.; Schachtner, M.; Wekkeli, A.; et al. Wafer bonded four-junction GaInP/GaAs//GaInAsP/GaInAs concentrator solar cells with 44.7% efficiency. Prog. Photovolt. Res. Appl. 2014, 22, 277–282. [Google Scholar] [CrossRef]

- Dahal, R.; Li, J.; Aryal, K.; Lin, J.Y.; Jiang, H.X. InGaN/GaN multiple quantum well concentrator solar cells. Appl. Phys. Lett. 2010, 97. [Google Scholar] [CrossRef]

- Wheeldon, J.F.; Valdivia, C.E.; Walker, A.W.; Kolhatkar, G.; Jaouad, A.; Turala, A.; Riel, B.; Masson, D.; Puetz, N.; Fafard, S.; et al. Performance comparison of AlGaAs, GaAs and InGaP tunnel junctions for concentrated multijunction solar cells. Prog. Photovolt. Res. Appl. 2011, 19, 442–452. [Google Scholar] [CrossRef]

- Lee, S. Thermal challenges and opportunities in concentrated photovoltaics. In Proceedings of the 12th Electronics Packaging Technology Conference (EPTC), Singapore, 8–10 December 2010; pp. 608–613. [Google Scholar] [CrossRef]

- Buljan, M.; Mendes-Lopes, J.; Benítez, P.; Miñano, J.C. Recent trends in concentrated photovoltaics concentrators’ architecture. J. Photonics Energy 2014, 4, 40995. [Google Scholar] [CrossRef]

- Tromholt, T.; Katz, E.A.; Hirsch, B.; Vossier, A.; Krebs, F.C. Effects of concentrated sunlight on organic photovoltaics. Appl. Phys. Lett. 2010, 96. [Google Scholar] [CrossRef]

- Barlev, D.; Vidu, R.; Stroeve, P. Innovation in concentrated solar power. Sol. Energy Mater. Sol. Cells 2011, 95, 2703–2725. [Google Scholar] [CrossRef]

- Chemisana, D. Building integrated concentrating photovoltaics: A review. Renew. Sustain. Energy Rev. 2011, 15, 603–611. [Google Scholar] [CrossRef]

- Gulotty, R.; Castellino, M.; Jagdale, P.; Tagliaferro, A.; Balandin, A.A. Effects of Functionalization on Thermal Properties of Single-Wall and Nanotube À Polymer Nanocomposites. ACS Nano 2013, 7, 5114–5121. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, S.; Chan, K.; Hernandez, R.; Recinos, E.; Hernandez, E.; Salgado, R.; Khitun, A.G.; Garay, J.E.; Balandin, A.A. Thermal and magnetic properties of nanostructured densified ferrimagnetic composites with grapheme-graphite fillers. Mater. Des. 2017, 118, 75–80. [Google Scholar] [CrossRef]

- Kinsey, G.S.; Hebert, P.; Barbour, K.E.; Krut, D.D.; Cotal, H.L.; Sherif, R.A. Concentrator multijunction solar cell characteristics under variable intensity and temperature. Prog. Photovolt. Res. Appl. 2008, 16, 503–508. [Google Scholar] [CrossRef]

- Chen, C.J. Physics of Solar Energy; Wiley: New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Markvart, T.; Castañer, L. Practical Handbook of Photovoltaics: Fundamentals and Applications; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar] [CrossRef]

- Radziemska, E. The effect of temperature on the power drop in crystalline silicon solar cells. Renew. Energy Int. J. 2003, 28, 1. [Google Scholar] [CrossRef]

- Singh, P.; Ravindra, N.M. Temperature dependence of solar cell performance—An analysis. Sol. Energy Mater. Sol. Cells 2012, 101, 36–45. [Google Scholar] [CrossRef]

- Cheknane, A.; Benyoucef, B.; Chaker, A. Performance of concentrator solar cells with passive cooling. Semicond. Sci. Technol. 2006, 21, 144–147. [Google Scholar] [CrossRef]

- Anderson, W.G.; Dussinger, P.M.; Sarraf, D.B.; Tamanna, S. Heat Pipe Cooling of Concentrating Photovoltaic Cells. In Proceedings of the Photovoltaic Specialists Conference, PVSC ’08, San Diego, CA, USA, 11–16 May 2008. [Google Scholar] [CrossRef]

- Yue, D.; You, F.; Darling, S.B. Domestic and overseas manufacturing scenarios of silicon-based photovoltaics: Life cycle energy and environmental comparative analysis. Sol. Energy 2014, 105, 669–678. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saadah, M.; Hernandez, E.; Balandin, A.A. Thermal Management of Concentrated Multi-Junction Solar Cells with Graphene-Enhanced Thermal Interface Materials. Appl. Sci. 2017, 7, 589. https://doi.org/10.3390/app7060589

Saadah M, Hernandez E, Balandin AA. Thermal Management of Concentrated Multi-Junction Solar Cells with Graphene-Enhanced Thermal Interface Materials. Applied Sciences. 2017; 7(6):589. https://doi.org/10.3390/app7060589

Chicago/Turabian StyleSaadah, Mohammed, Edward Hernandez, and Alexander A. Balandin. 2017. "Thermal Management of Concentrated Multi-Junction Solar Cells with Graphene-Enhanced Thermal Interface Materials" Applied Sciences 7, no. 6: 589. https://doi.org/10.3390/app7060589