Hybrid Electric Vehicle Performance with Organic Rankine Cycle Waste Heat Recovery System

Abstract

:1. Introduction

2. Operational Modes of Hybrid Vehicles

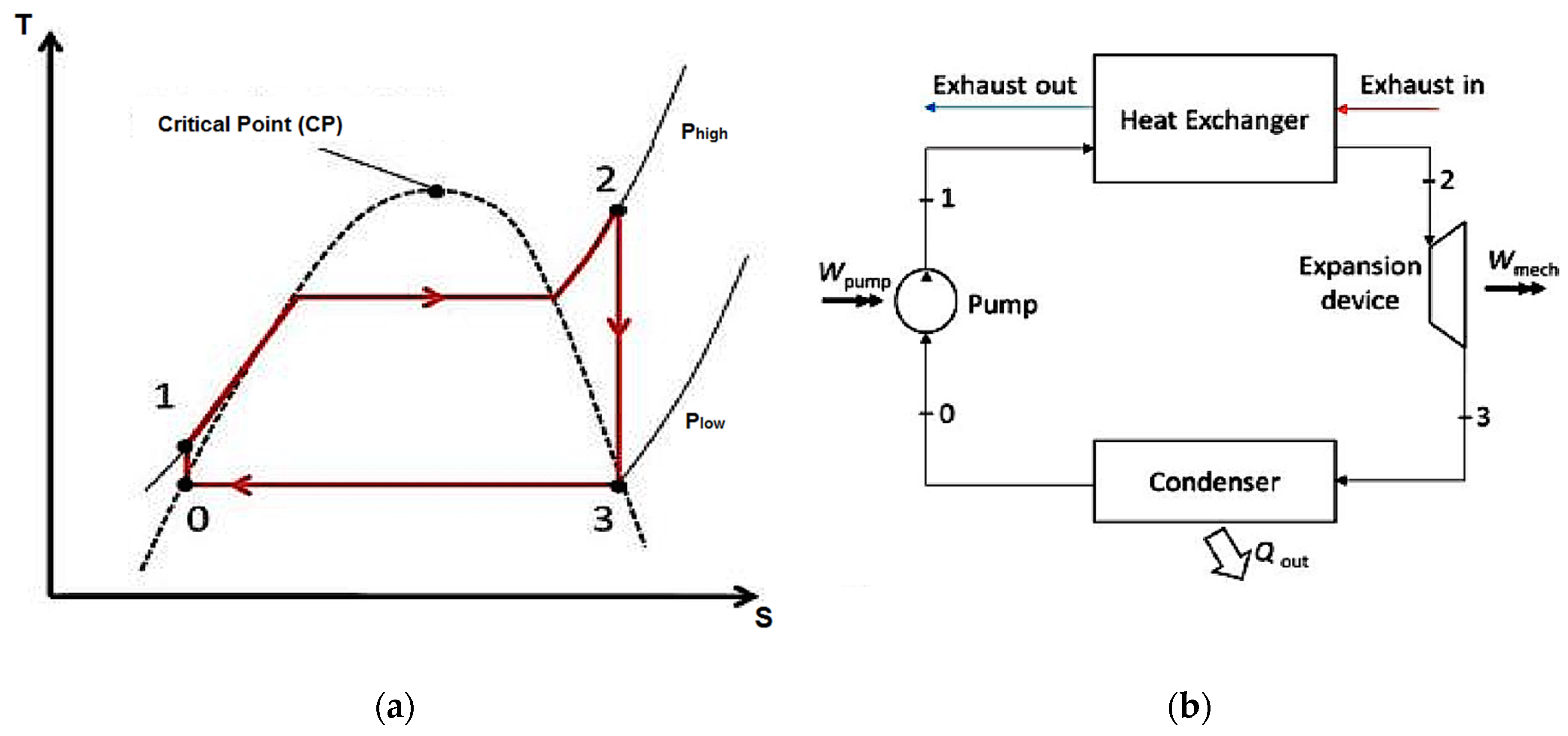

3. Waste Heat Recovery

4. Organic Rankine Cycle (ORC)

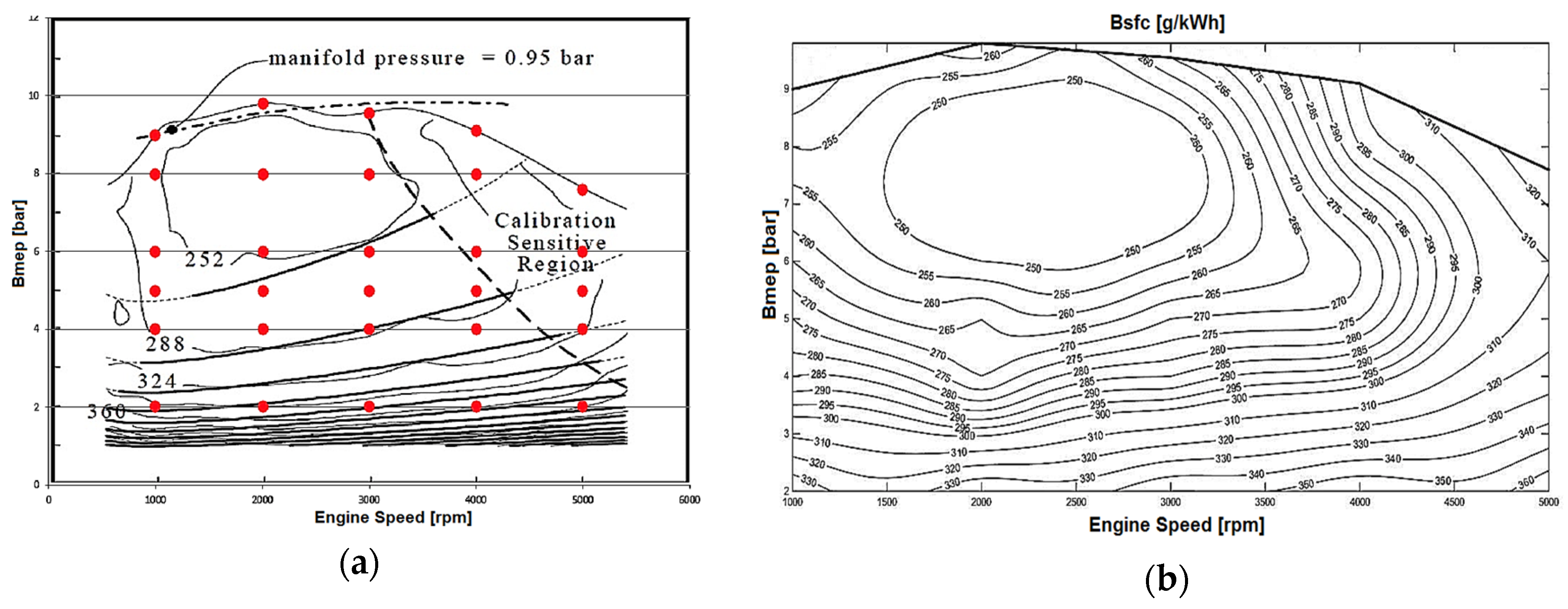

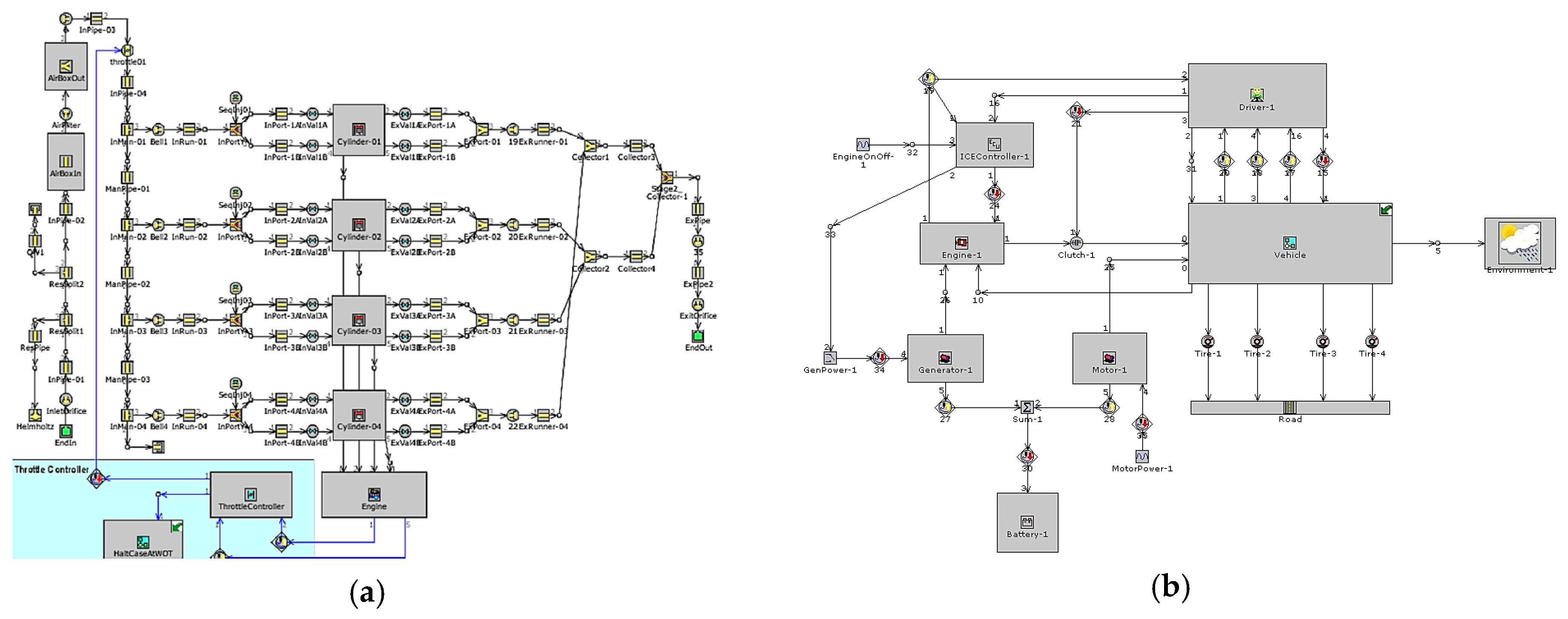

5. Engine Model Calibration

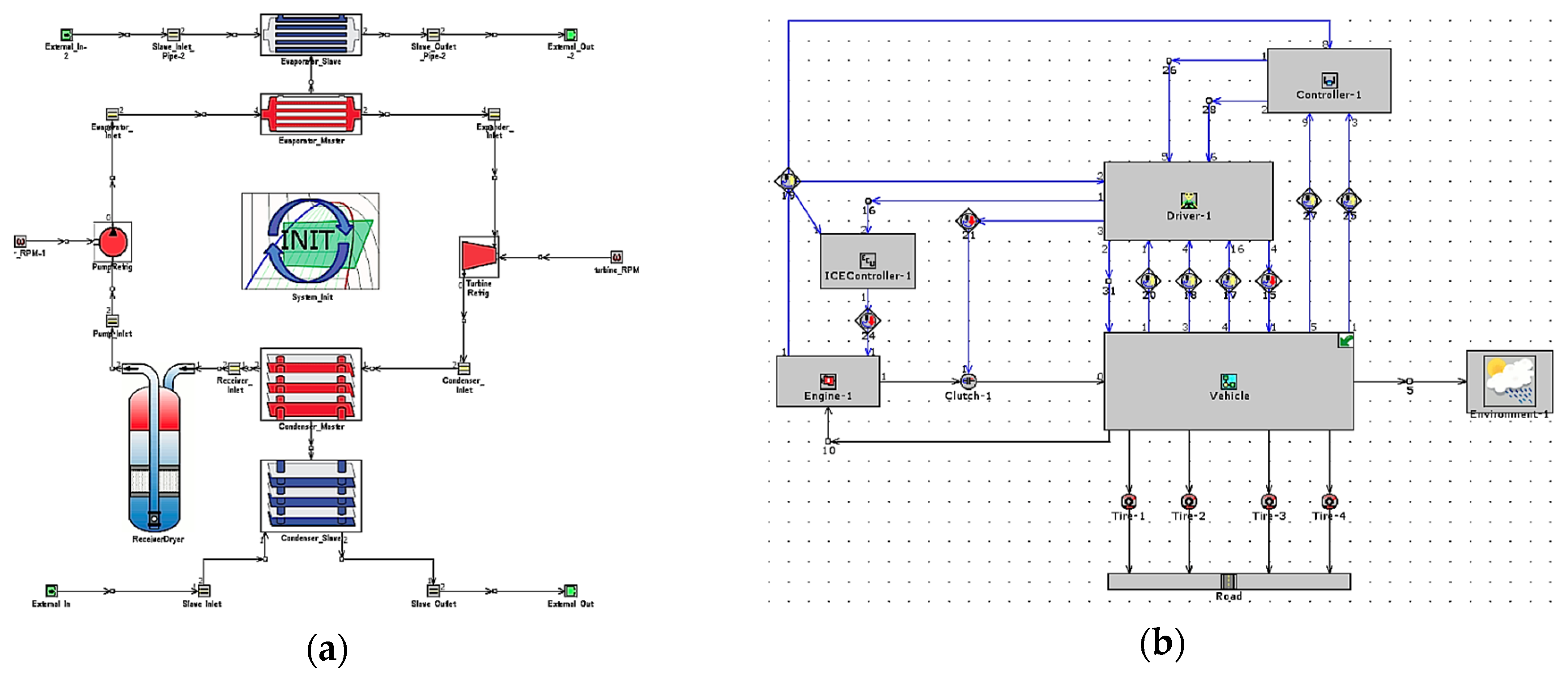

6. Organic Rankine Cycle Fluid Selection and System Optimization

- Low condensation temperature

- Very low freezing point

- No need to superheat (dry fluid)

- Eco-friendly (low global warming potential and ozone depletion potential)

- Low flammability and toxicity

- The evaporator exhaust gas initial pressure and temperature are equal with the exhaust gas outlet pressure and temperature, respectively.

- The condenser coolant initial pressure and temperature are equal with the coolant outlet pressure and temperature, respectively.

- No heat is lost to the surroundings.

7. Driving Cycles Testing

- NEDC (New European Driving Cycle, EU)

- FTP-75 (Federal Test Procedure, US)

- US06 (a more realistic, aggressive supplement to FTP-75)

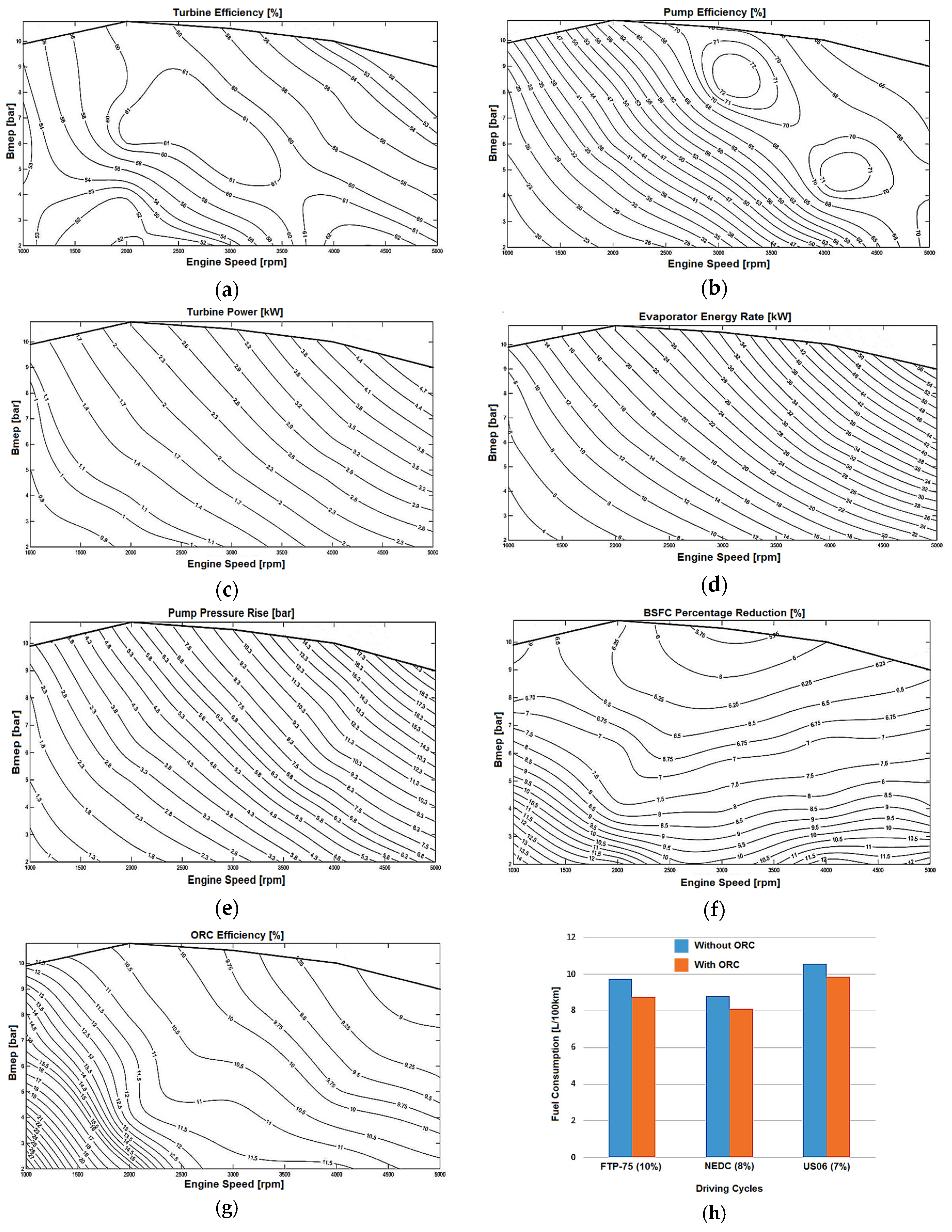

8. Results and Discussion

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pesiridis, A. Automotive Exhaust Emissions and Energy Recovery; Nova Science Publishers: New York, NY, USA, 2014. [Google Scholar]

- Oyewunmi, O.A.; Markides, C.N. Thermo-economic and heat transfer optimization of working-fluid mixtures in a low-temperature organic Rankine cycle system. Energies 2016, 9, 448. [Google Scholar] [CrossRef]

- Andwari, M.A.; Aziz, A.A.; Farid, M.; Said, M.; Zulkarnain, A.L. Controlled auto-ignition combustion in a two-stroke cycle engine using hot burned gases. Appl. Mech. Mater. 2013, 388, 201–205. [Google Scholar] [CrossRef]

- Teng, H.; Regner, G.; Cowland, C. Waste heat recovery of heavy-duty diesel engines by organic Rankine cycle Part I: Hybrid energy system of diesel and Rankine engines. SAE Tech. Pap. 2007. [Google Scholar] [CrossRef]

- Feneley, A.J.; Pesiridis, A.; Andwari, A.M. Variable geometry turbocharger technologies for exhaust energy recovery and boosting—A review. Renew. Sustain. Energy Rev. 2017, 71, 959–971. [Google Scholar] [CrossRef]

- Kulkarni, K.; Sood, A. Performance analysis of organic Rankine cycle (ORC) for recovering waste heat from a heavy duty diesel engine. SAE Tech. Pap. 2015. [Google Scholar] [CrossRef]

- Stanzel, N.; Streule, T.; Preißinger, M.; Brüggemann, D. Comparison of cooling system designs for an exhaust heat recovery system using an organic Rankine cycle on a heavy duty truck. Energies 2016, 9, 928. [Google Scholar] [CrossRef]

- Amin, M.A.; Azhar, A.A. Homogenous Charge Compression Ignition (HCCI) technique: A review for application in two-stroke gasoline engines. Appl. Mech. Mater. 2012, 165, 53–57. [Google Scholar] [CrossRef]

- Zhang, X.; Zeng, K.; Bai, S.; Zhang, Y.; He, M. Exhaust recovery of vehicle gasoline engine based on organic Rankine cycle. SAE Tech. Pap. 2011. [Google Scholar] [CrossRef]

- Zhou, L.; Tan, G.; Guo, X.; Chen, M.; Ji, K.; Li, Z.; Yang, Z. Study of energy recovery system based on organic Rankine cycle for hydraulic retarder. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Ringler, J.; Seifert, M.; Guyotot, V.; Hübner, W. Rankine cycle for waste heat recovery of IC engines. SAE Int. J. Engines 2009, 2, 67–76. [Google Scholar] [CrossRef]

- Shu, G.; Zhao, J.; Tian, H.; Wei, H.; Liang, X.; Yu, G.; Liu, L. Theoretical analysis of engine waste heat recovery by the combined thermo-generator and organic Rankine cycle system. SAE Tech. Pap. 2012. [Google Scholar] [CrossRef]

- Sprouse, C., III; Depcik, C. Organic Rankine cycles with dry fluids for small engine exhaust waste heat recovery. SAE Int. J. Altern. Powertrains 2013, 2, 96–104. [Google Scholar] [CrossRef]

- Zhang, X.; Mi, C. Vehicle Power Management; Modeling, Control and Optimization; Springer: London, UK, 2011. [Google Scholar]

- Arsie, I.; Cricchio, A.; Pianese, C.; Ricciardi, V.; De Cesare, M. Modeling and optimization of organic Rankine cycle for waste heat recovery in automotive engines. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Boretti, A. Improving the efficiency of turbocharged spark ignition engines for passenger cars through waste heat recovery. SAE Tech. Pap. 2012. [Google Scholar] [CrossRef]

- Kirmse, C.J.W.; Oyewunmi, O.A.; Haslam, A.J.; Markides, C.N. Comparison of a novel organic-fluid thermofluidic heat converter and an organic Rankine cycle heat engine. Energies 2016, 9, 479. [Google Scholar] [CrossRef]

- Cipollone, R.; Di Battista, D.; Perosino, A.; Bettoja, F. Waste heat recovery by an organic Rankine cycle for heavy duty vehicles. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Cochran, D.L. Working fluids for high temperature, Rankine cycle, space power plants. SAE Tech. Pap. 1961. [Google Scholar] [CrossRef]

- El Chammas, R.; Clodic, D. Combined cycle for hybrid vehicles. SAE Tech. Pap. 2005. [Google Scholar] [CrossRef]

- Lodwig, E. Performance of a 35 HP organic Rankine cycle exhaust gas powered system. SAE Tech. Pap. 1970. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Chen, T.; Zhuge, W.; Zhang, Y.; Zhang, L. A novel cascade organic Rankine cycle (ORC) system for waste heat recovery of truck diesel engines. Energy Convers. Manag. 2017, 138, 210–223. [Google Scholar] [CrossRef]

- Hsieh, J.-C.; Fu, B.-R.; Wang, T.-W.; Cheng, Y.; Lee, Y.-R.; Chang, J.-C. Design and preliminary results of a 20-kW transcritical organic Rankine cycle with a screw expander for low-grade waste heat recovery. Appl. Therm. Eng. 2017, 110, 1120–1127. [Google Scholar] [CrossRef]

- Read, M.; Smith, I.; Stosic, N.; Kovacevic, A. Comparison of organic Rankine cycle systems under varying conditions using turbine and twin-screw expanders. Energies 2016, 9, 614. [Google Scholar] [CrossRef]

- Shu, G.; Wang, X.; Tian, H. Theoretical analysis and comparison of rankine cycle and different organic rankine cycles as waste heat recovery system for a large gaseous fuel internal combustion engine. Appl. Therm. Eng. 2016, 108, 525–537. [Google Scholar] [CrossRef]

- Wang, E.; Yu, Z.; Zhang, H.; Yang, F. A regenerative supercritical-subcritical dual-loop organic Rankine cycle system for energy recovery from the waste heat of internal combustion engines. Appl. Energy 2017, 190, 574–590. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, H.; Yu, Z.; Wang, E.; Meng, F.; Liu, H.; Wang, J. Parametric optimization and heat transfer analysis of a dual loop ORC (organic Rankine cycle) system for CNG engine waste heat recovery. Energy 2017, 118, 753–775. [Google Scholar] [CrossRef]

- Kolasiński, P.; Błasiak, P.L.; Jozef, R. Experimental and numerical analyses on the rotary vane expander operating conditions in a micro organic Rankine cycle system. Energies 2016, 9, 606. [Google Scholar] [CrossRef]

- Reck, M.; Randolf, D. An organic Rankine cycle engine for a 25-passenger bus. SAE Tech. Pap. 1973. [Google Scholar] [CrossRef]

- Thaddaeus, J.; Pesiridis, A.; Karvountzis-Kontakiotis, A. Design of variable geometry waste heat recovery turbine for high efficiency internal combustion engine. Int. J. Sci. Eng. Res. 2016, 7, 1001–1017. [Google Scholar]

- Karvountzis-Kontakiotis, A.; Pesiridis, A.; Zhao, H.; Franchetti, B.; Pesmazoglou, I.; Alshammari, F.; Tocci, L. Effect of an ORC waste heat recovery system on diesel engine fuel economy for off-highway vehicles. In Proceedings of the SAE World Congress, Detroit, MI, USA, 4–6 April 2017. [Google Scholar]

- Franchetti, B.; Pesiridis, A.; Pesmazoglou, I.; Sciubba, E.; Tocci, L. Thermodynamic and technical criteria for the optimal selection of the working fluid in a mini-ORC. In Proceedings of the 29th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2016), Portorož, Slovenia, 19–23 June 2016. [Google Scholar]

- Karvountzis-Kontakiotis, A.; Alshammari, F.; Pesiridis, A.; Franchetti, B.; Pesmazoglou, I.; Tocci, L. Variable geometry turbine design for off-highway vehicle organic Rankine cycle waste heat recovery. In Proceedings of the THIESEL 2016, Valencia, Spain, 13–16 September 2016. [Google Scholar]

| Design Parameters | ORC’s Main Components | |||||

|---|---|---|---|---|---|---|

| Evaporator (Slave) | Evaporator (Master) | Condenser (Slave) | Condenser (Master) | Turbine Expander | Pump | |

| Average Inlet Pressure (bar) | 1.00102 | 24.9 | 2.15 | 3.28 | 24.3 | 2.6 |

| Average Outlet Pressure (bar) | 1 | 24.3 | 2 | 2.6 | 3.28 | 24.9 |

| Average Pressure Drop (bar) | 0.0010197 | 0.631 | 0.148264 | 0.674932 | - | - |

| Average Inlet Temperature (K) | 973.1 | 315.8 | 296.1 | 405.1 | 445.2 | 314.1 |

| Average Outlet Temperature (K) | 450.7 | 445.2 | 302.6 | 314.1 | 405.263 | 315.8 |

| Average Mass Flow Rate (g/s) | 140 | 269.2 | 3394.6 | 269.3 | 0.269 | 0.269 |

| Combined Energy Rate out of Fluid (kW) | 78.7 | −78.7 | −73.2 | 73.2 | - | - |

| Average Speed (rpm) | - | - | - | - | 1350 | 2000 |

| Average Map Pressure Ratio | - | - | - | - | 7.37 | - |

| Average Efficiency (%) | - | - | - | - | 51.61 | 61.42 |

| Average Power (kW) | - | - | - | - | 5.3 | 0.75 |

| Average Pressure Rise (bar) | - | - | - | - | - | 22.3 |

| Heat Exchanger Volume (L) | 11.75 | 3.33 | 6.5 | 5.65 | - | - |

| Heat Exchanger Reference Length (m) | 0.007 | 0.007 | 0.003 | 0.003 | - | - |

| Heat Exchanger Heat Transfer Area (m2) | 1.87 | 1.87 | 9.33 | 9.33 | - | - |

| Heat Exchanger Flow Area (m2) | 0.0138 | 0.0038 | 0.02 | 0.02 | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmoudzadeh Andwari, A.; Pesiridis, A.; Karvountzis-Kontakiotis, A.; Esfahanian, V. Hybrid Electric Vehicle Performance with Organic Rankine Cycle Waste Heat Recovery System. Appl. Sci. 2017, 7, 437. https://doi.org/10.3390/app7050437

Mahmoudzadeh Andwari A, Pesiridis A, Karvountzis-Kontakiotis A, Esfahanian V. Hybrid Electric Vehicle Performance with Organic Rankine Cycle Waste Heat Recovery System. Applied Sciences. 2017; 7(5):437. https://doi.org/10.3390/app7050437

Chicago/Turabian StyleMahmoudzadeh Andwari, Amin, Apostolos Pesiridis, Apostolos Karvountzis-Kontakiotis, and Vahid Esfahanian. 2017. "Hybrid Electric Vehicle Performance with Organic Rankine Cycle Waste Heat Recovery System" Applied Sciences 7, no. 5: 437. https://doi.org/10.3390/app7050437