1. Introduction

The combustion process in an automotive engine is never perfect and small amounts of more harmful emissions are also produced in internal combustion engines. In order to reduce engine emissions, modern automotive engines carefully control the amount of fuel that they burn. The thermal efficiency of a combustion engine is defined as the relationship between the total energy contained in the fuel, and the amount of energy used to perform useful work or generate kinetic energy. Carbon dioxide (CO

2) emissions, as a product of combustion by bonding the carbon in the fuel with the oxygen in the air, are by far the largest amount of emissions produced by internal combustion engine vehicles. Until recently, they were thought to pose no immediate threat to the environment and the health of human beings. Therefore, CO

2 has not been regulated in the same way as HC, CO, and NO

x. However, due to recent concerns about the increasing production of greenhouse gases and the increasing use of fossil fuels, regulators have begun attempts to limit the release of CO

2 and other greenhouse gases into the atmosphere. The ICCT (International Council on Clean Transportation) [

1] says that most developed countries have set CO

2 emissions targets for new vehicles. Compared to the EU’s target of 95 g CO

2/km by 2020/2021, the US’s 97 g CO

2/km by 2025 for passenger cars, Canada’s 97 g CO

2/km by 2025, China’s 117 g CO

2/km by 2020, and South Korea’s 97 g CO

2/km by 2020, illustrate similar targets.

Recently, combustion engine vehicles with a high fuel economy have also been included as eco-friendly vehicles that have less harmful impacts on the environment. In general, modern practical engines are always compromised by trade-offs between different properties, such as efficiency, weight, power, exhaust emissions, or NVH (noise, vibration, harshness). Sometimes, the economy not only plays a role in the engine manufacturing cost, but also in the manufacturing and distributing of the fuel. Increasing the engine’s efficiency produces a better fuel economy. Reduced exhaust emissions have been strengthened in passenger cars and light duty trucks after EURO 1 was initiated in 1992. Europe adopted EURO 6 in 2013, and it was applied in South Korea in 2014. Nitrogen oxides (NOx) of 80% and particulate matters (PM) of 60% are now more tightened than EURO 5. Some countermeasure technologies have been developed for satisfying this regulation. Among them, clean diesel vehicles and combustion engine-based hybrid electric vehicles have been studied, requiring a great deal of high-tech concentration. Specifically, a common-rail direct injection system is at the core of clean diesel technology. This makes it possible to pressurize above 200 MPa and then spray fuel into the combustion chamber through an electro-hydraulic injector. This presents accurate and precise fuel spraying using electronic control and is a great development for clean diesel engines.

Typical solenoid-driven and piezo-driven fuel injectors can generate a favorable response and provide an effective injection in a common-rail direct injection system. These effects reduce exhaust emissions and improve the combustion performance in a clean diesel engine. Therefore, a rapid injector needle response and multiple injections are needed to obtain a high degree of freedom spray strategy, in order to improve diffusion combustion with a higher air to fuel (A/F) mixing ratio, reduce exhaust emissions, and increase engine performance. Research [

2,

3] has shown that five to seven multiple injections and rapid On/Off switching of the injector hole by the needle can freely control the shape of the injection rate. Daiji Ueda, etc., announced G4P (4th generation diesel piezo) injector concepts, structures, and hydraulic performances, using a rectangular injection rate and shorter multiple injection intervals. Also, they showed engine performance improvement results with G4P [

2]. Arpaia, A., etc., reported that a numerical model for simulating a piezo indirect acting fuel injection system under a steady state and transient operating conditions was conducted through a commercial code [

3]. Other papers [

4], referring to the above result, showed that an injection mechanism with a high-pressure performance reduces not only harmful PM exhaust emissions, but also the auto-ignition combustion performance. However, the design of the piezo injector needs further improvement to increase the response of the injector needle.

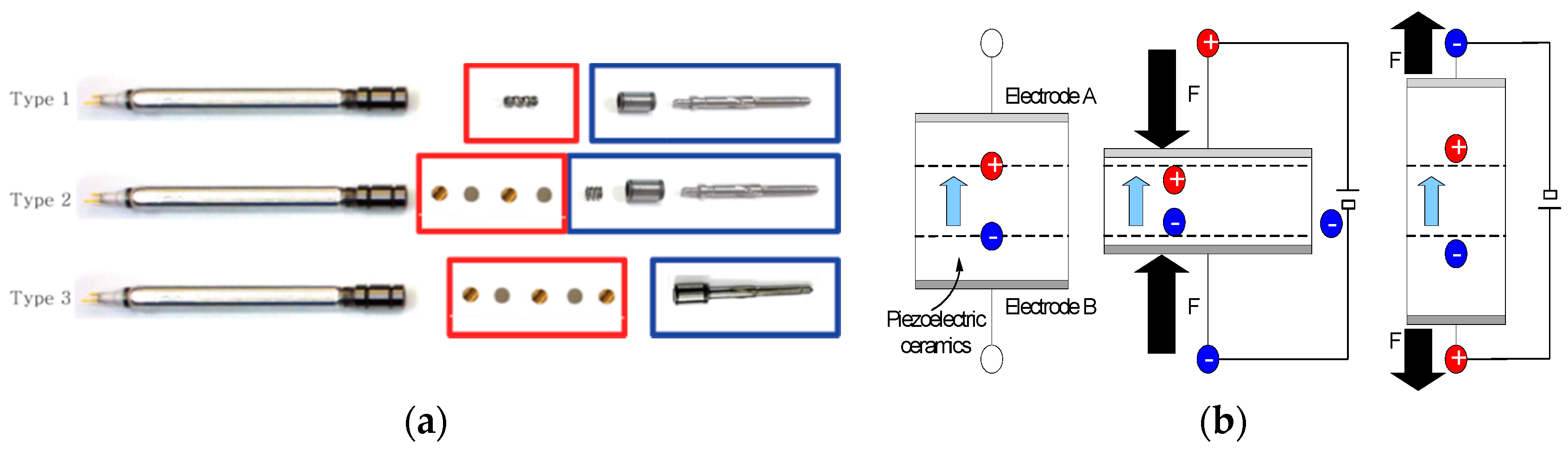

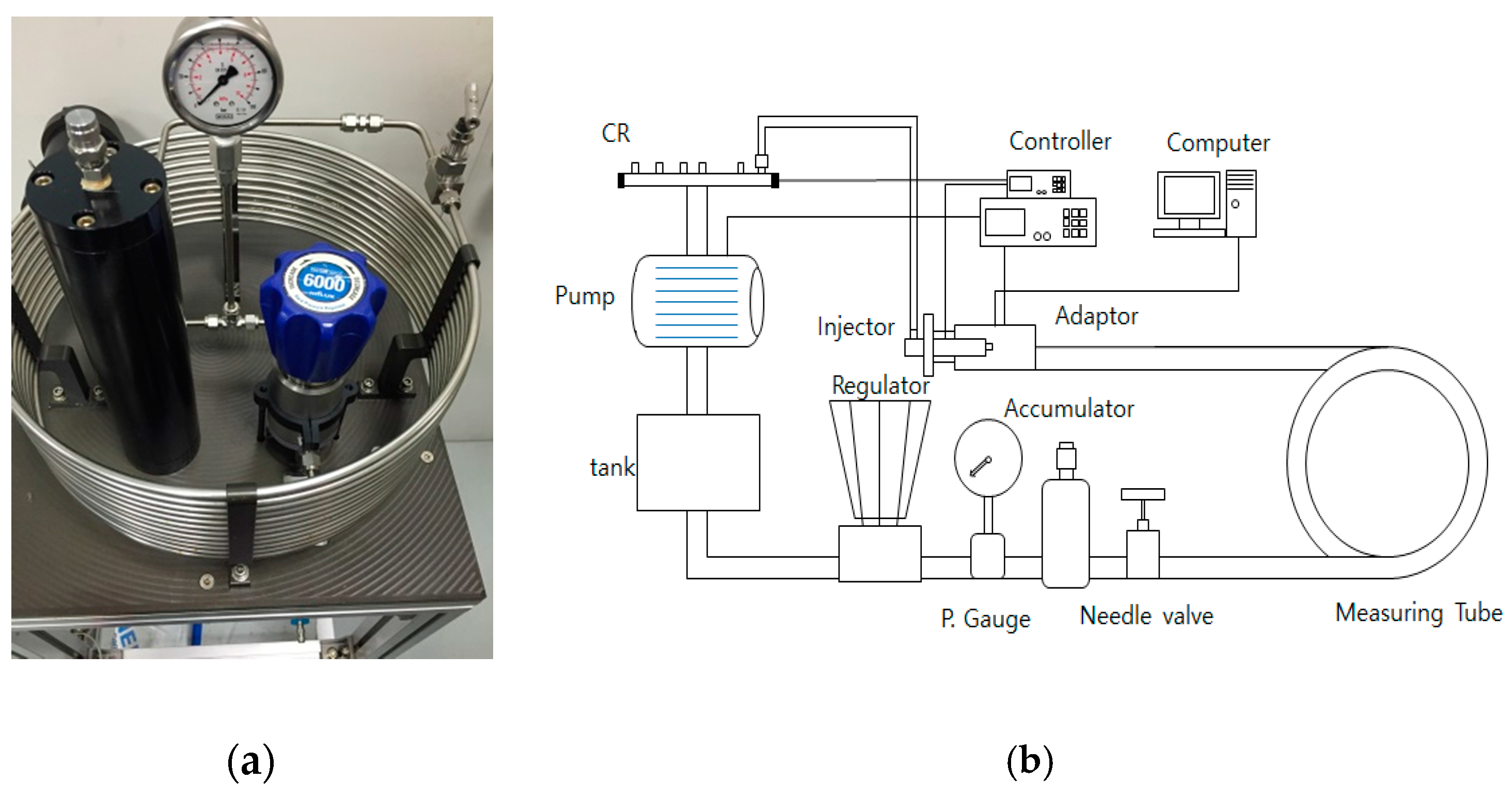

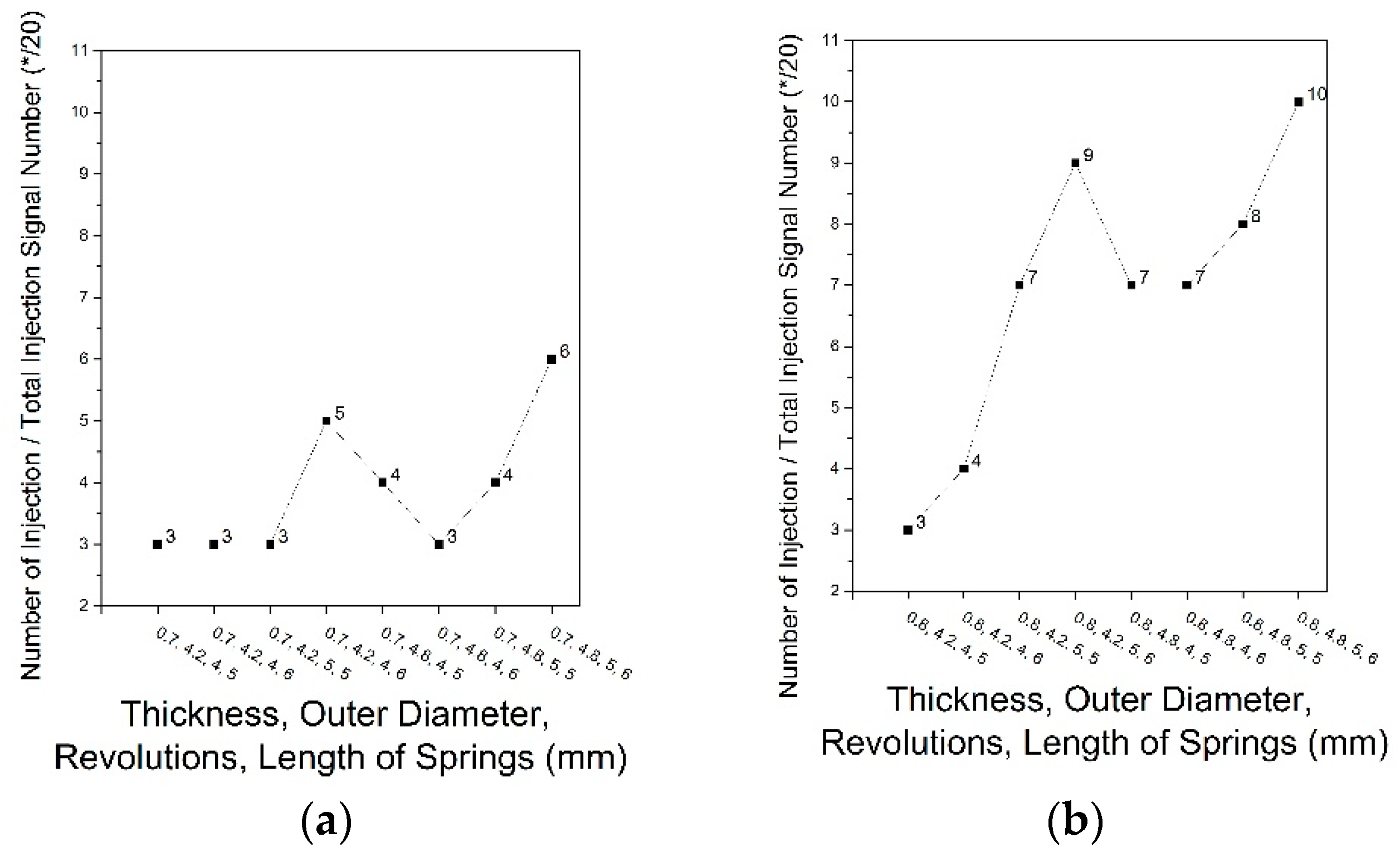

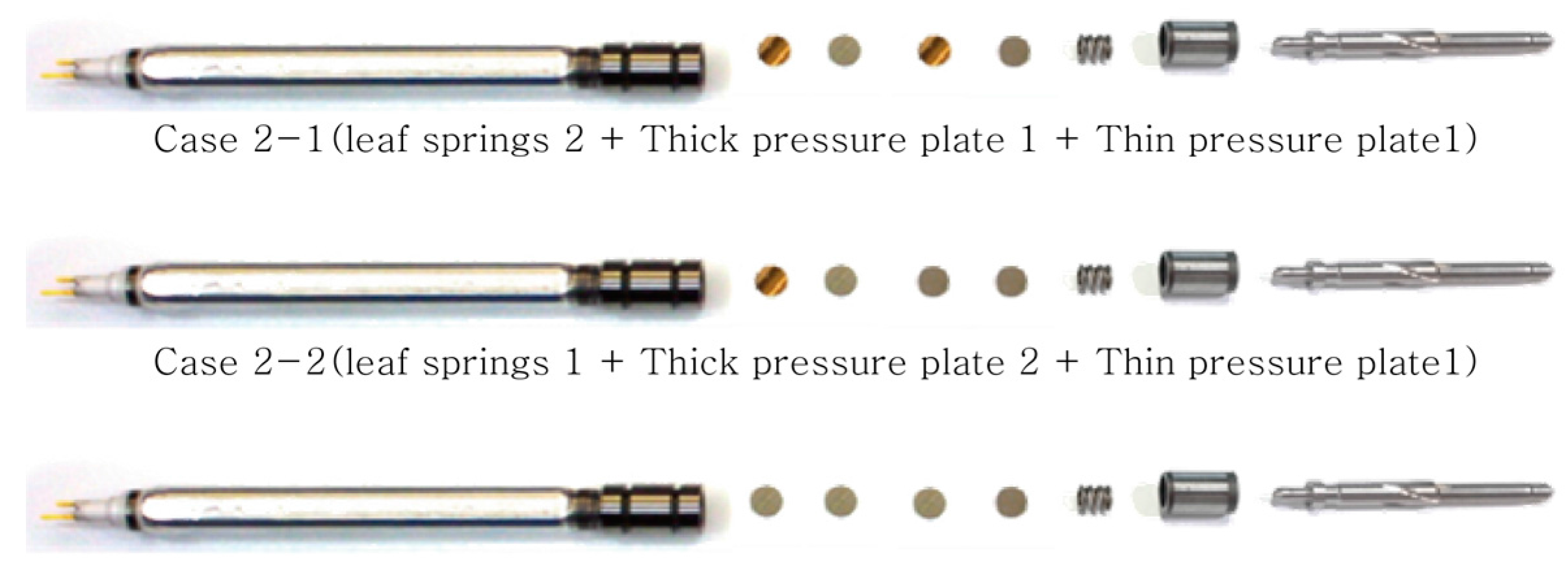

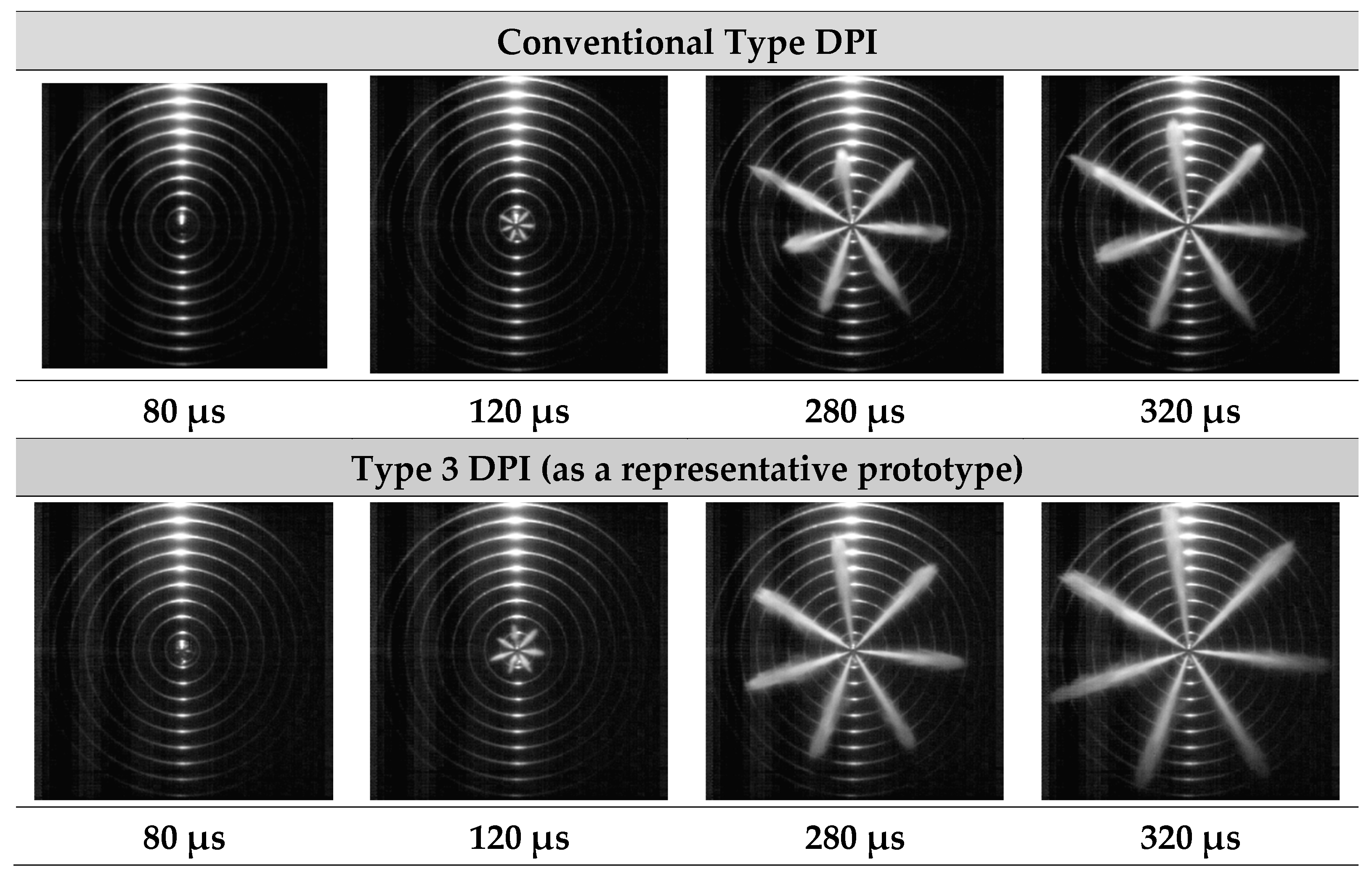

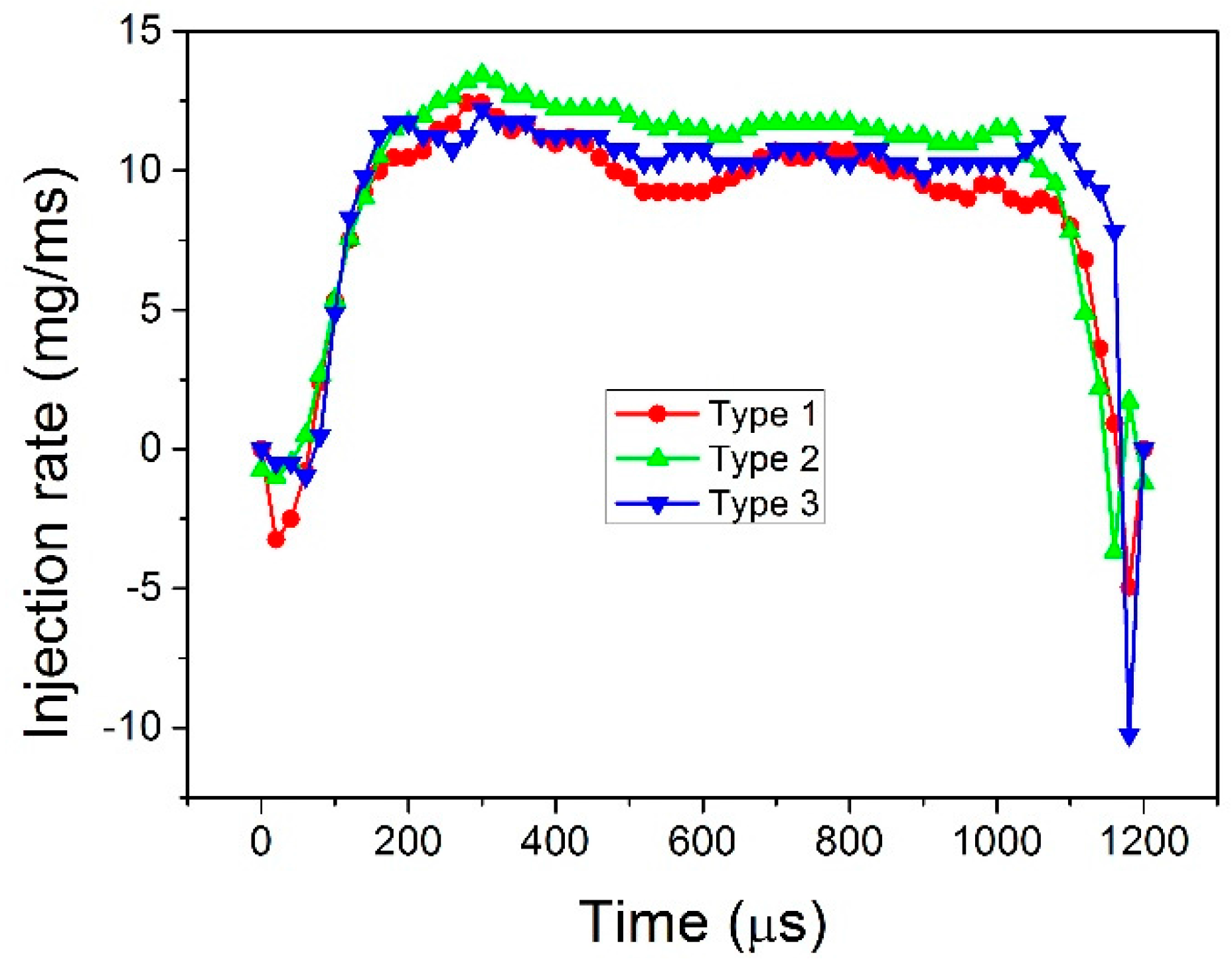

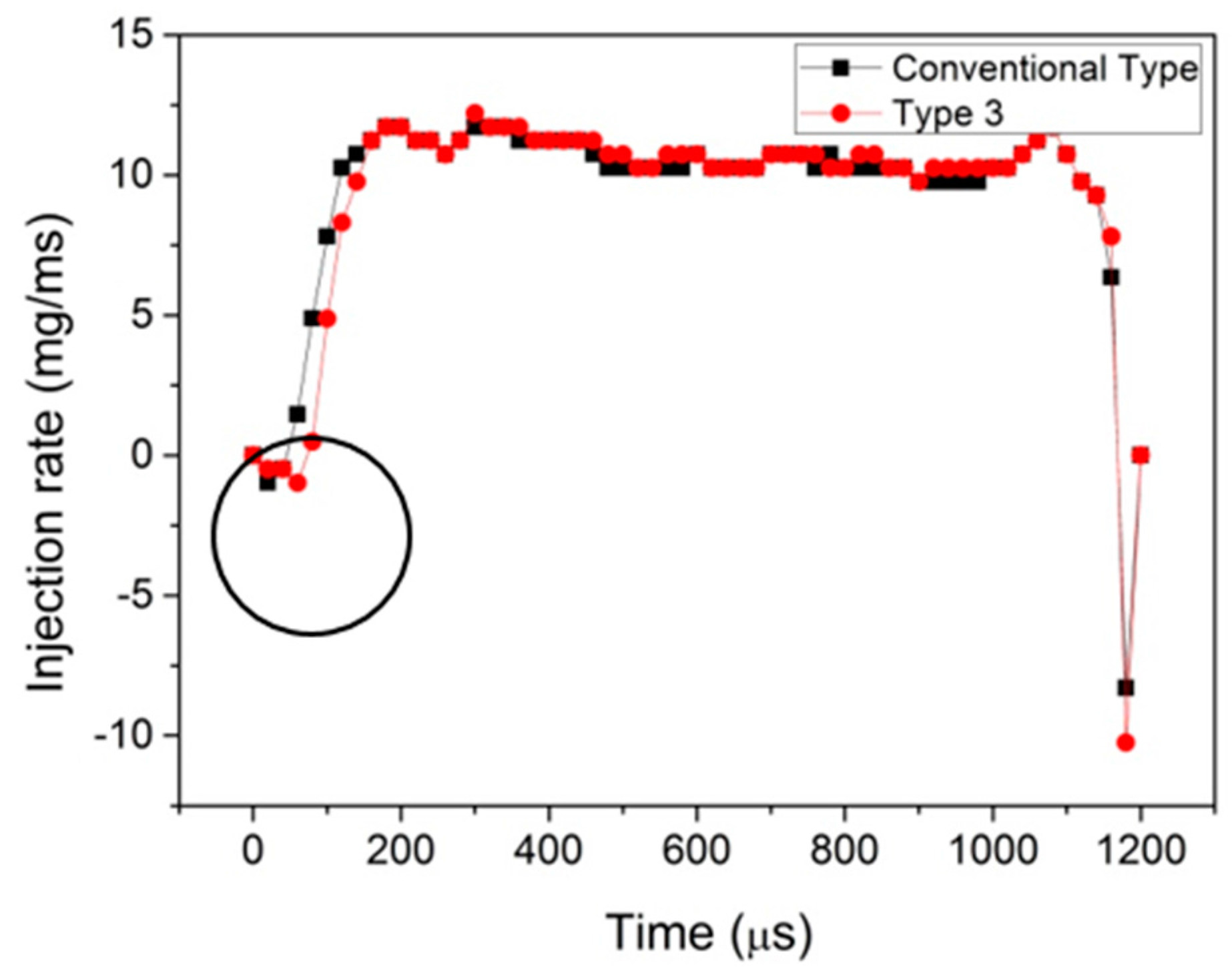

In this study, a direct needle-driven piezo injector (DPI) based on the Delphi product [

5] was considered to improve injection characteristics with a maximum injection pressure, injection response, and manufacturing simplicity. For investigation, three steps were followed in this study: spray visualization based on Mie-scattering, an injection rate measurement, and a compression ignition (CI) combustion experiment based on a single-cylinder CRDi engine. DPI prototype design concepts focused on an internal DPI constitution, depending on whether or not a hydrodynamic needle was used. This study investigates the injection characteristics and combustion performance of three prototype DPIs, to obtain practical results. The effects of the internal design structure of the direct needle-driven piezo-injector and its optimal design parameters on the spray formation and CI combustion are discussed experimentally.