Functional Elastic Knits Made of Bamboo Charcoal and Quick-Dry Yarns: Manufacturing Techniques and Property Evaluations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

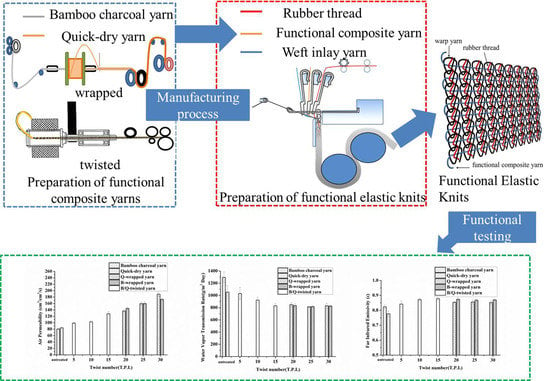

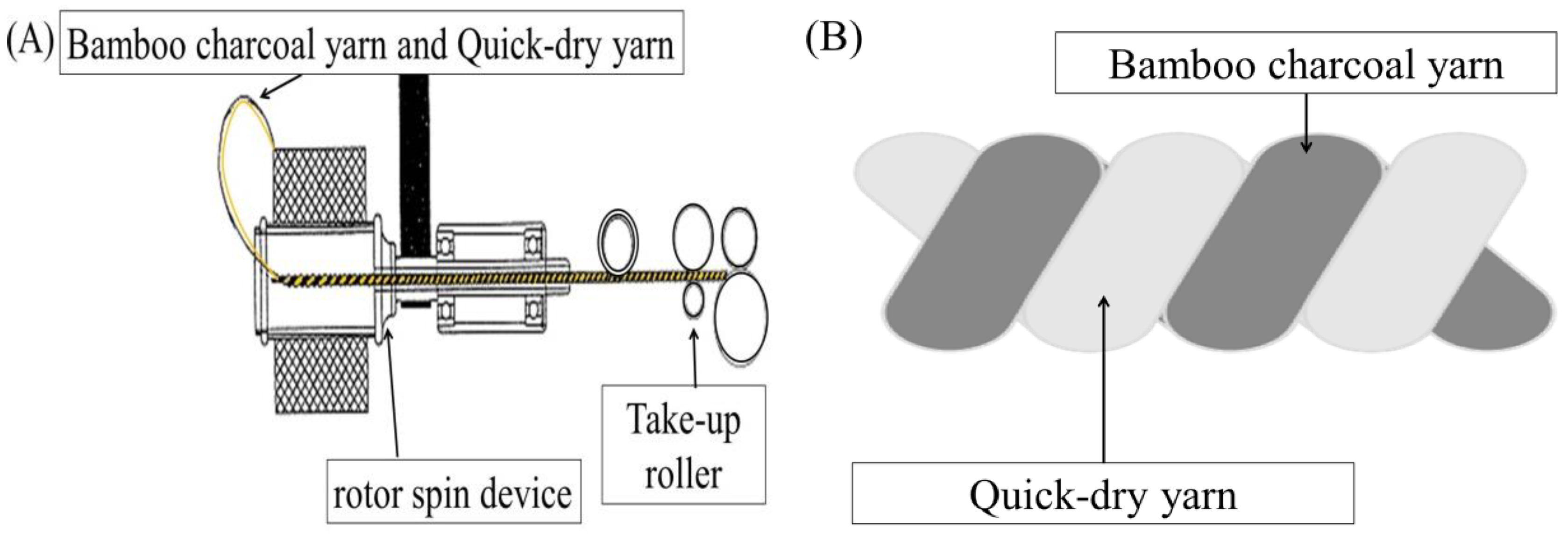

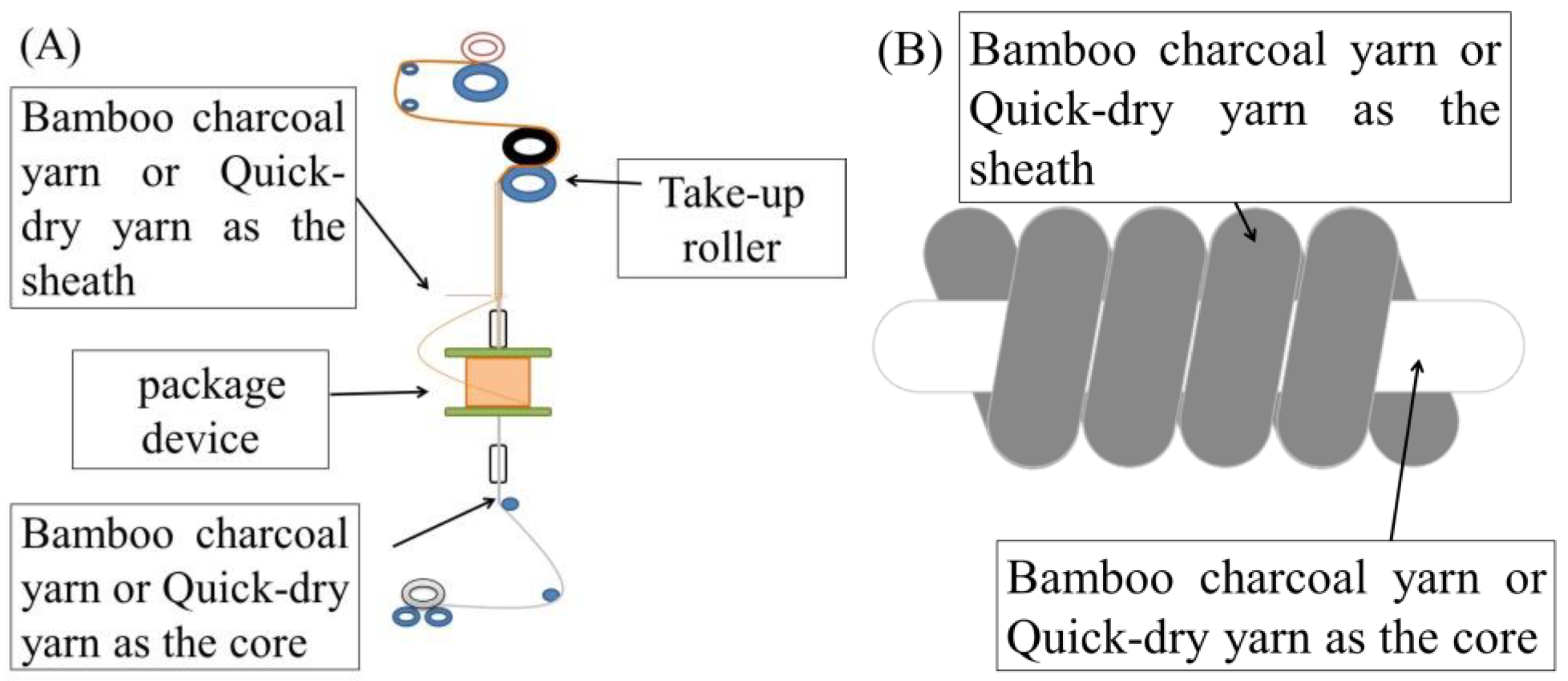

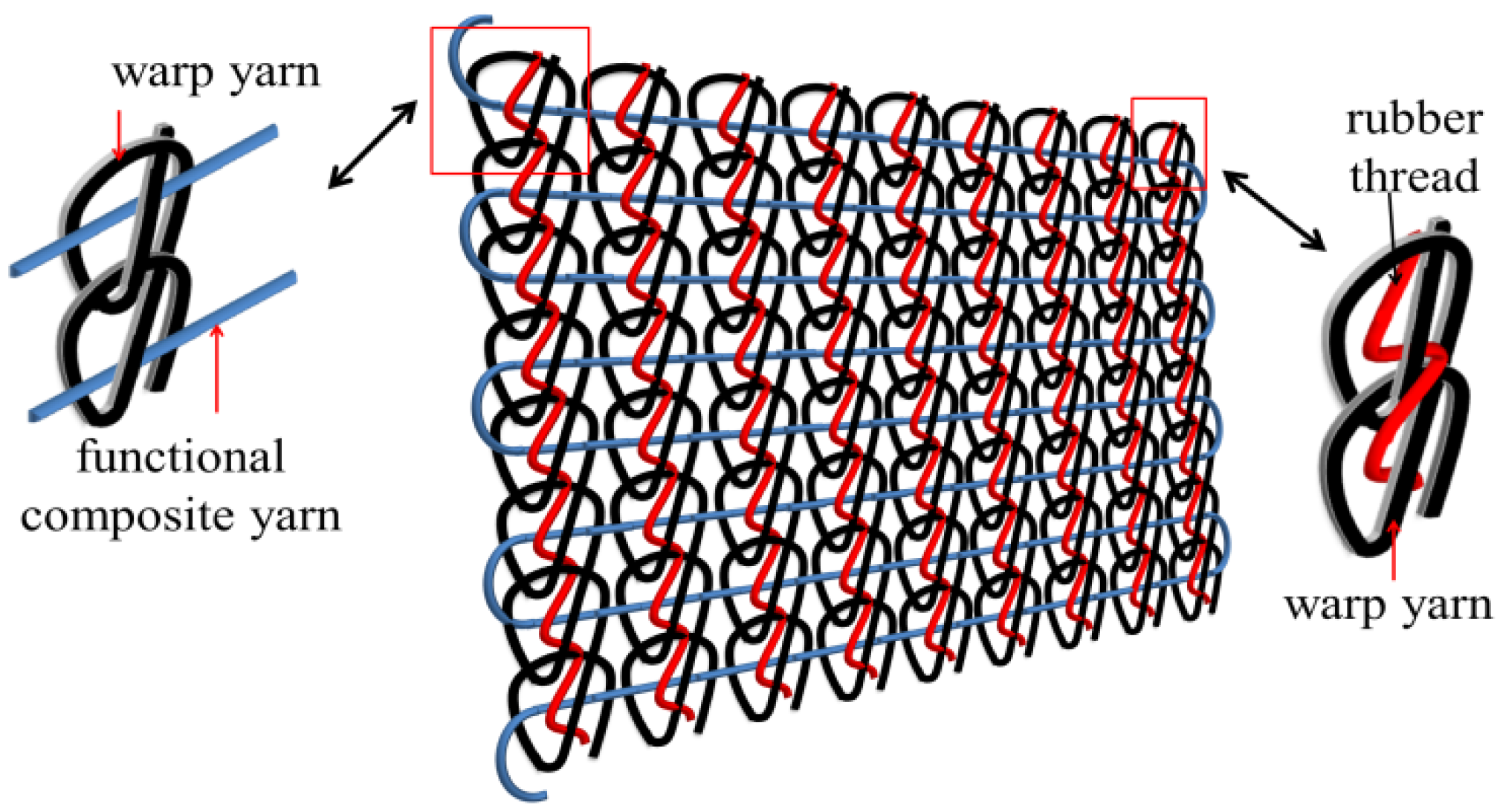

2.2. Preparation of Functional Composite Yarns and Functional Elastic Knits

2.3. Tests

2.3.1. Mechanical Properties of Yarns

2.3.2. Mechanical Properties of Knits

2.3.3. Water Vapor Transmission Rate

2.3.4. Water Absorption Rate

2.3.5. Far-Infrared (FIR) Emissivity

2.3.6. Air Permeability Test

2.3.7. Bursting Strength

3. Results and Discussion

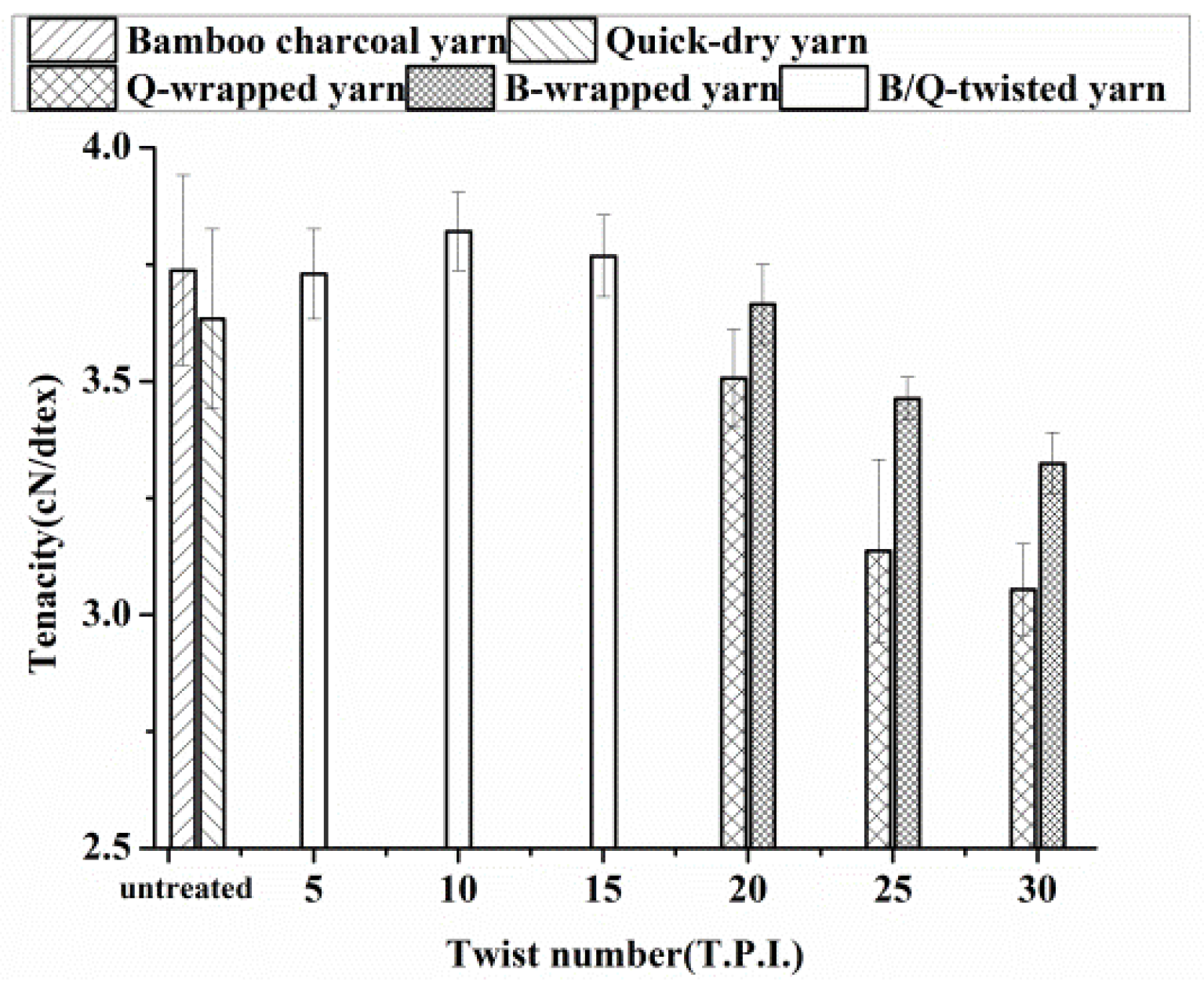

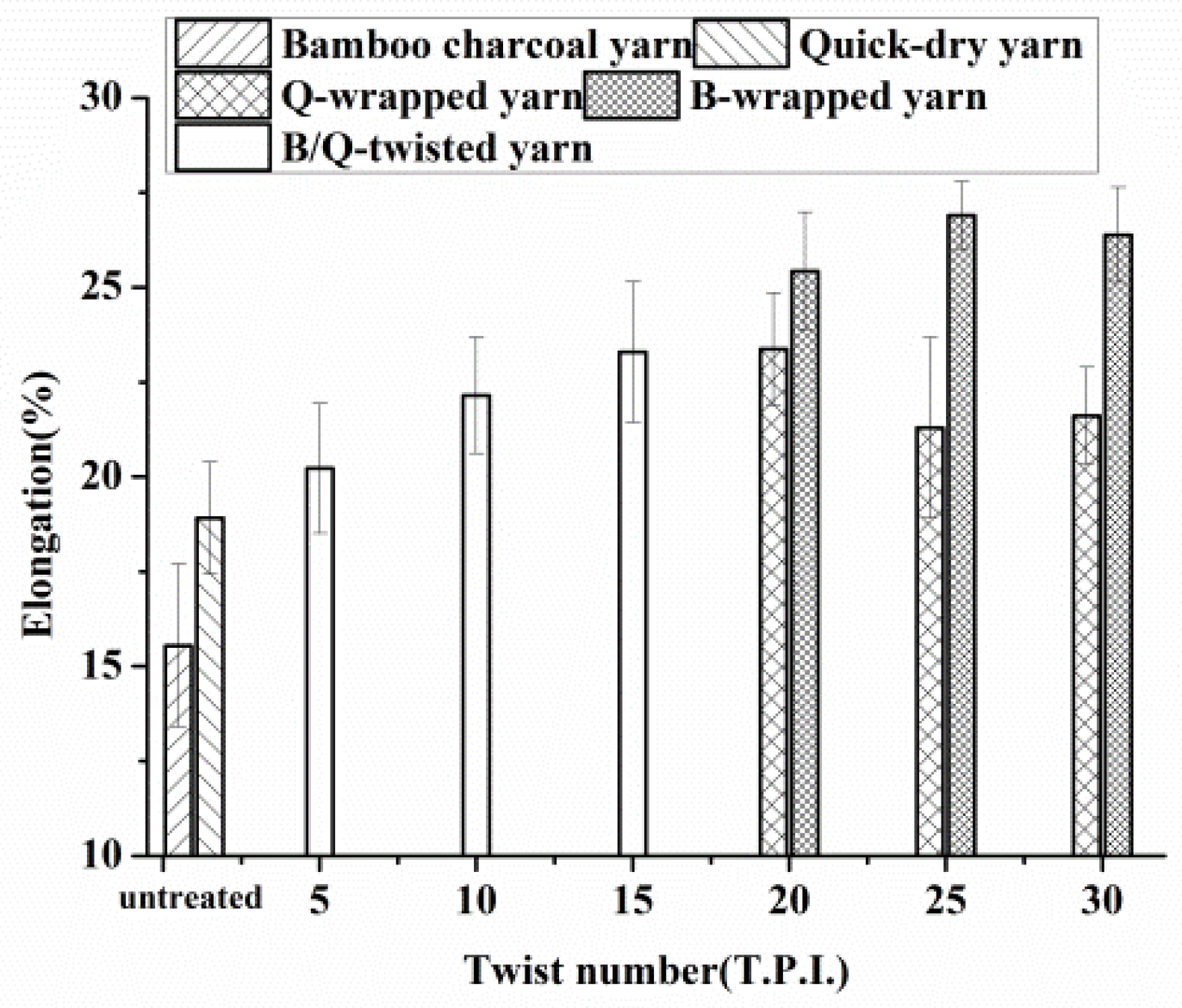

3.1. Effects of Twist Number on the Mechanical Properties of Yarns

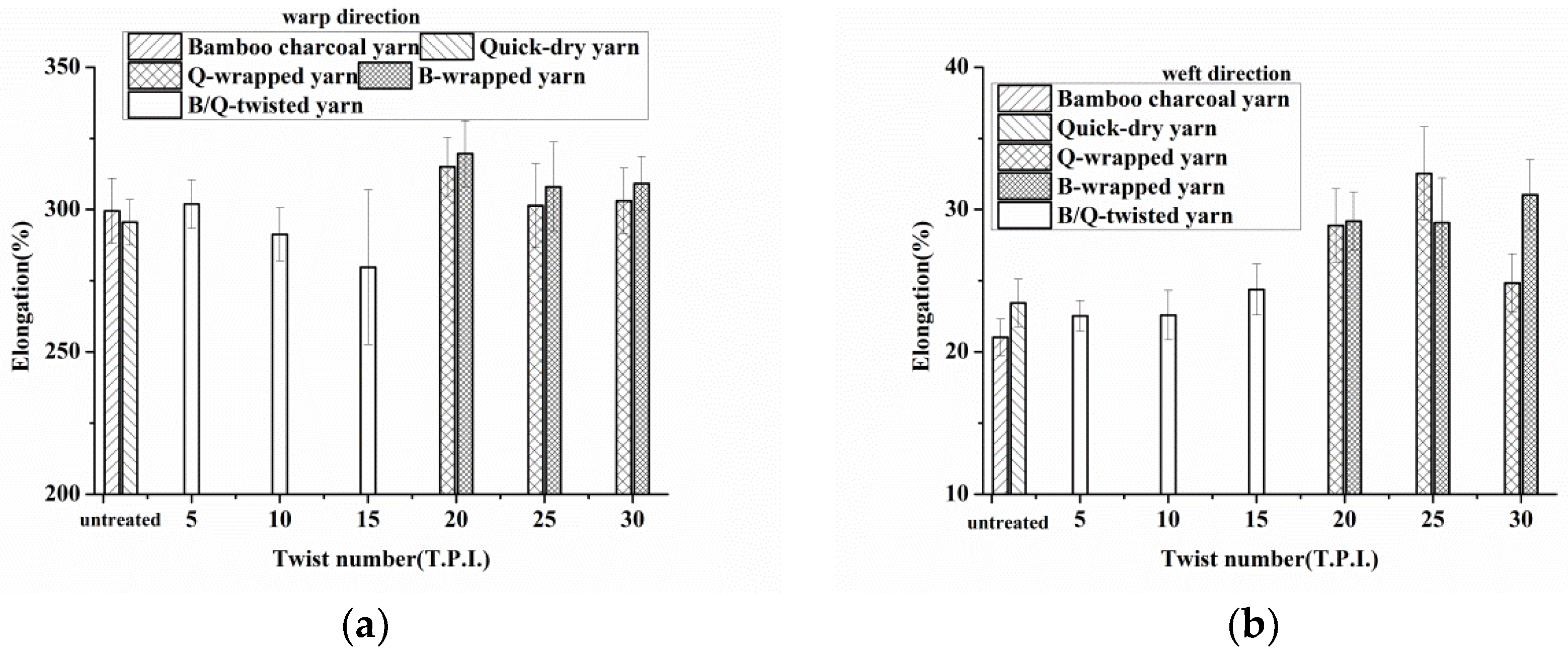

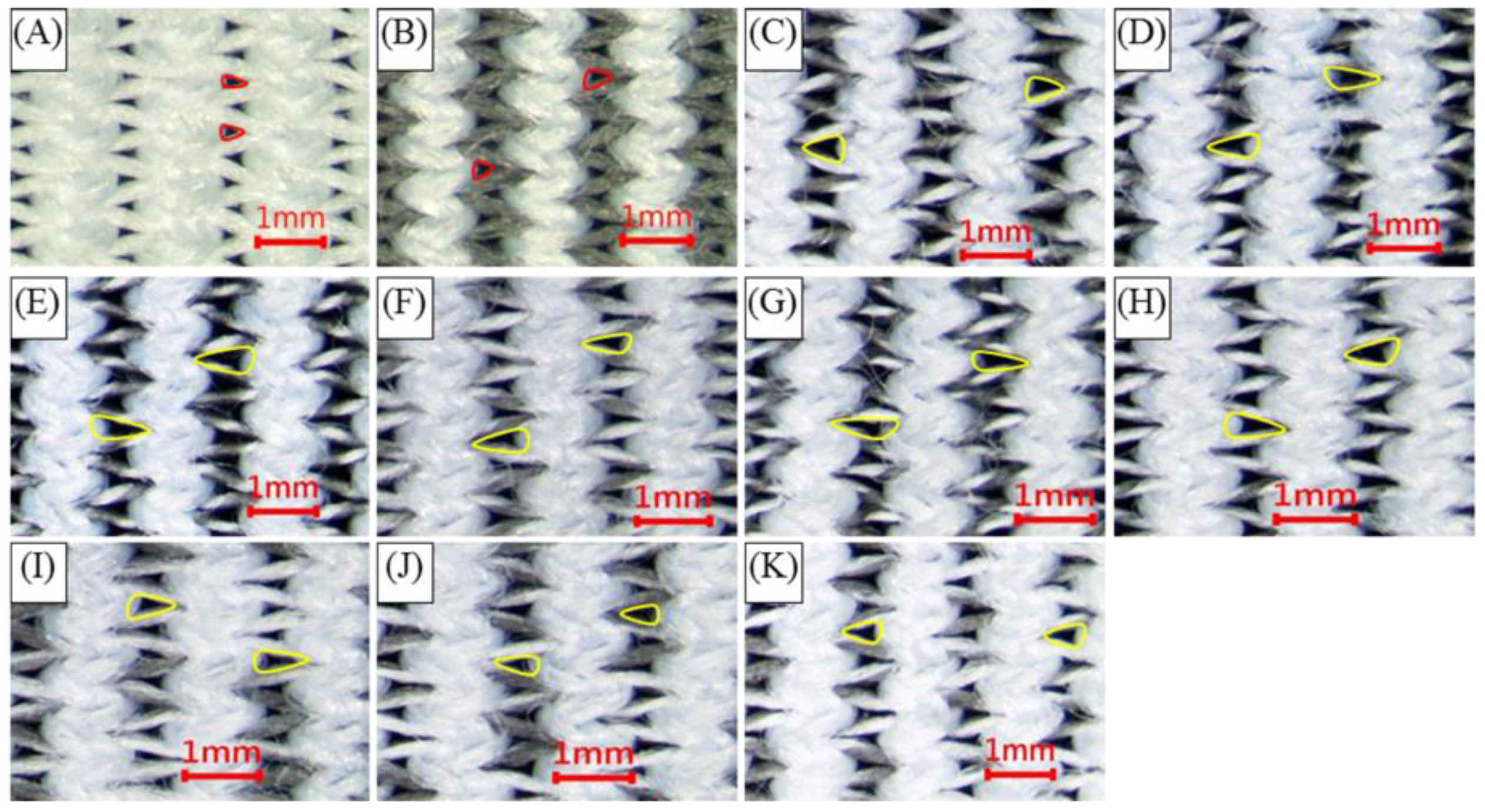

3.2. Effects of Twist Number on the Mechanical Properties of Functional Elastic Knits

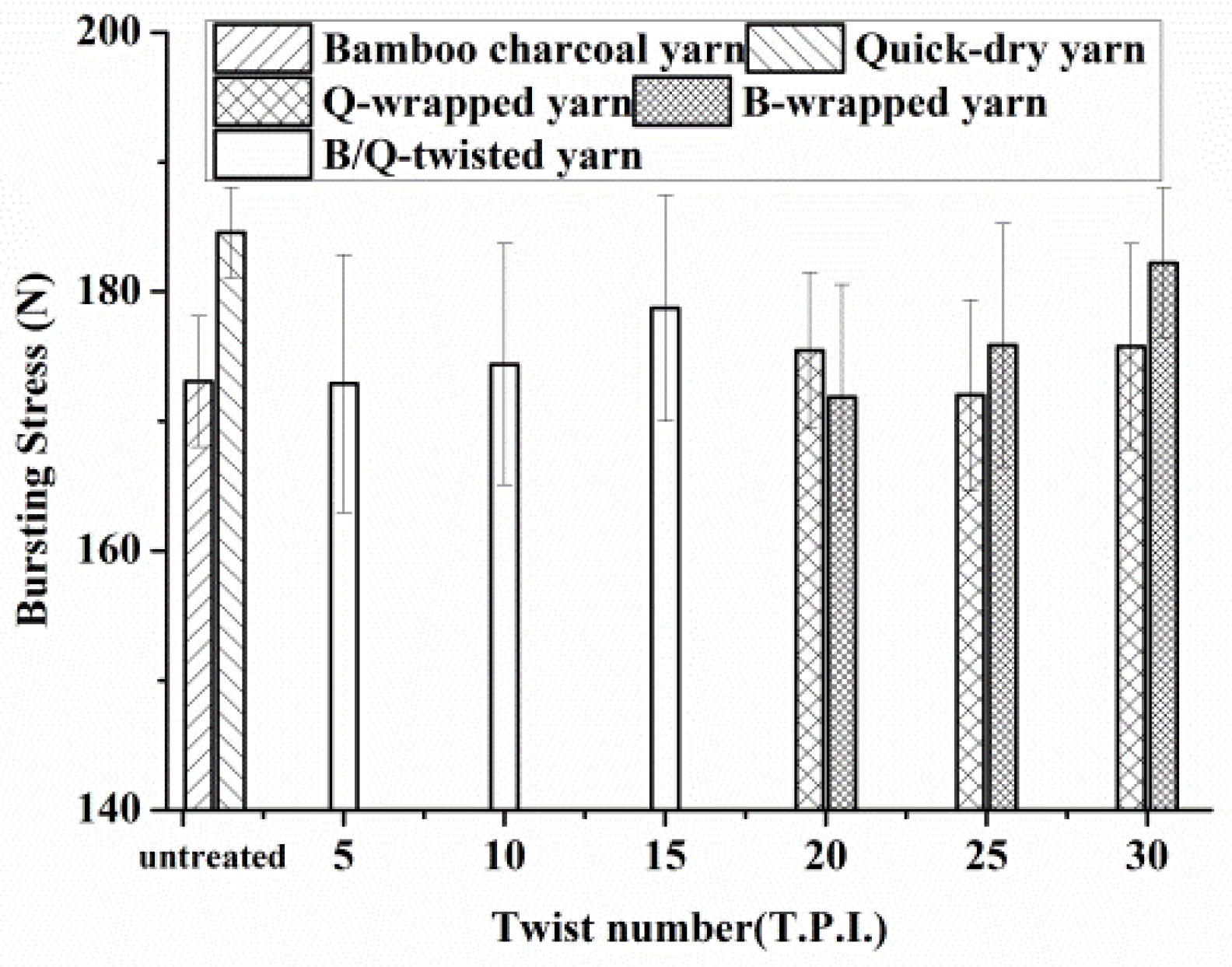

3.3. Effects of Twist Number on the Bursting Strength of Functional Elastic Knits

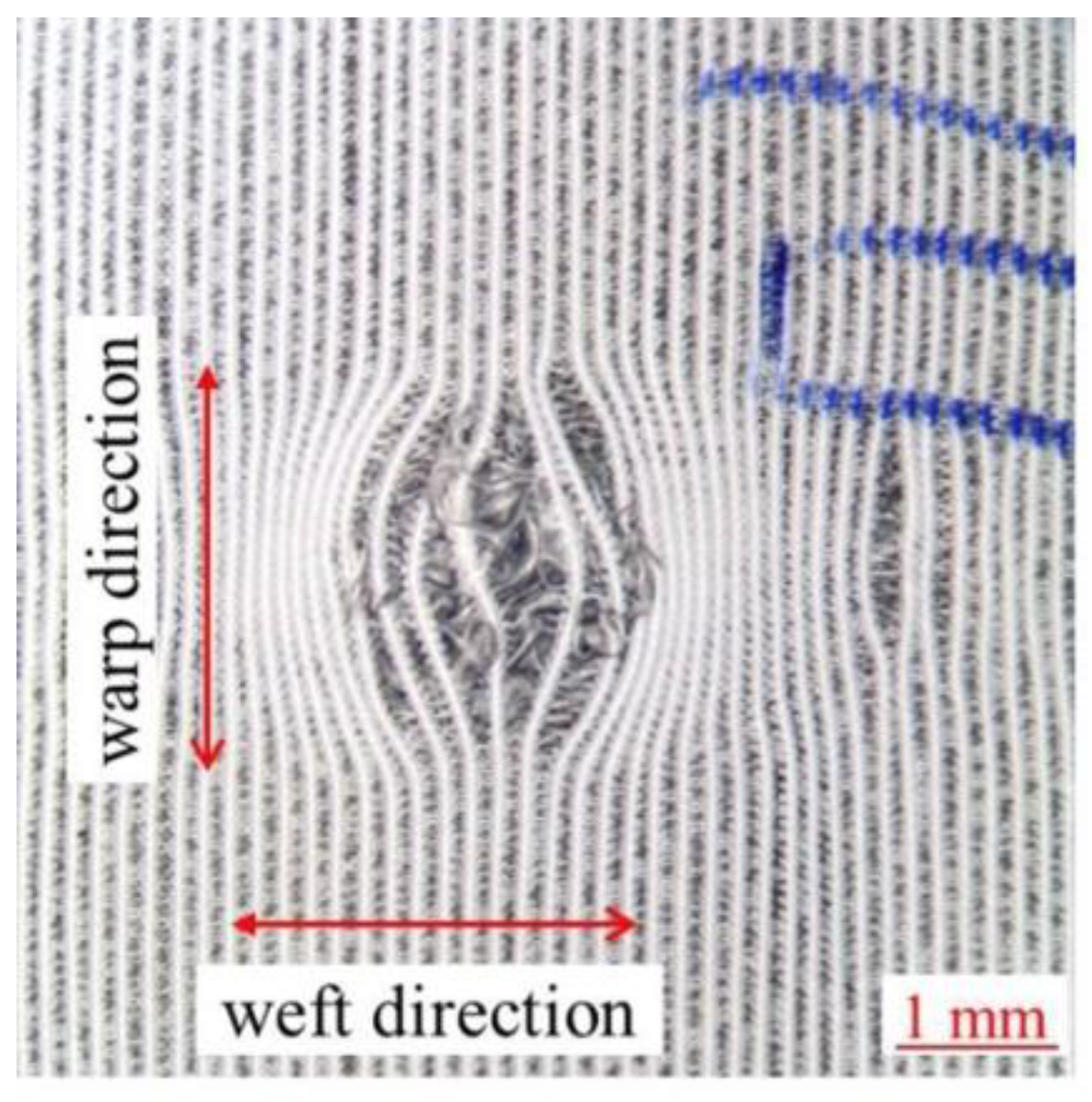

3.4. Effects of Twist Number on the Air Permeability of Functional Elastic Knits

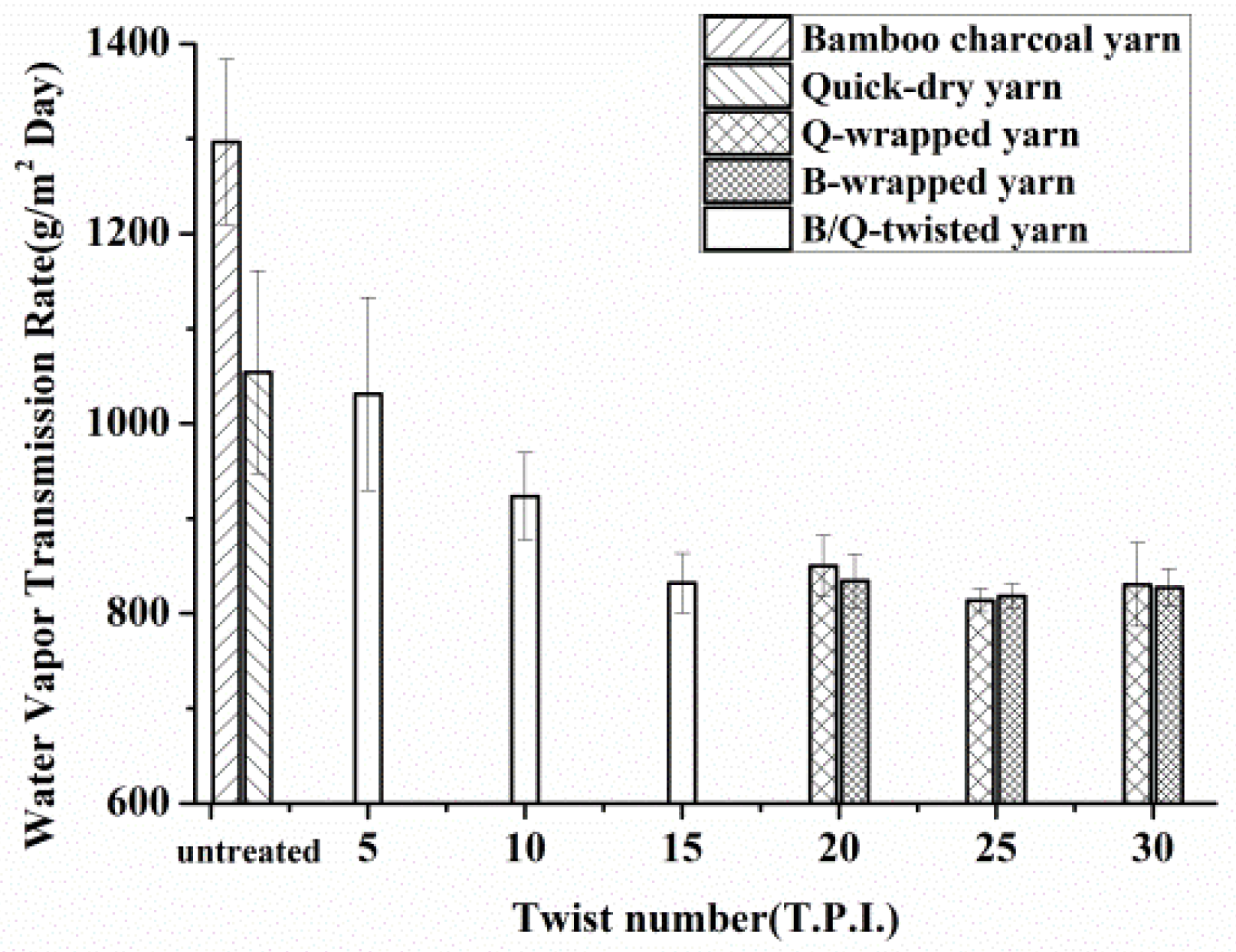

3.5. Effects of Twist Number on the Water Vapor Transmission Rate of Functional Elastic Knits

3.6. Effects of Twist Number on the Water Absorption Rate of Functional Elastic Knits

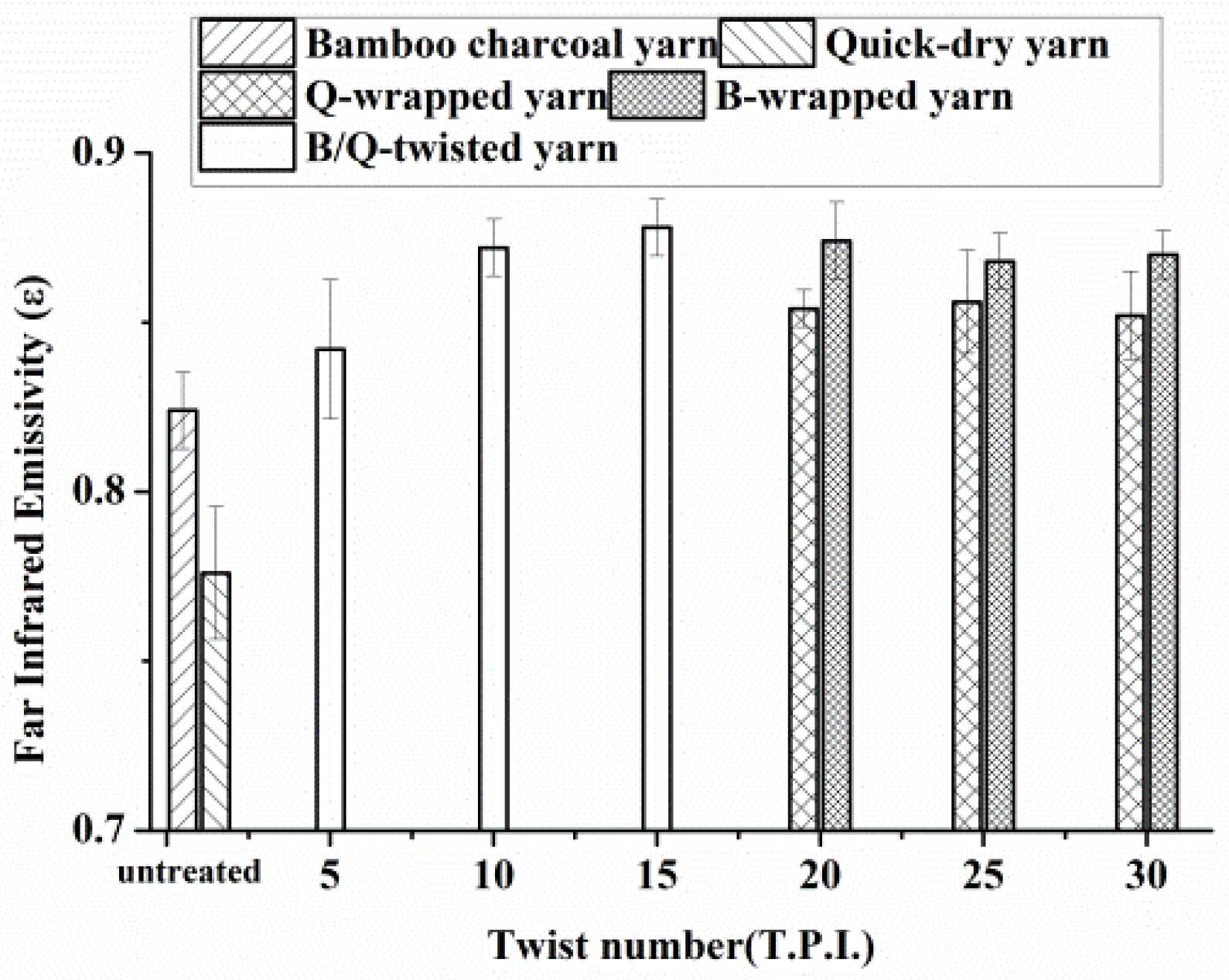

3.7. Effects of Twist Number on the Far-Infrared Emissivity of Functional Elastic Knits

4. Conclusions

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gambichler, T. Ultraviolet protection of clothing. In Functional Textiles for Improved Performance, Protection and Health; Woodhead Publishing: Cambridge, UK, 2011; pp. 45–63. [Google Scholar]

- Zhang, X. Antistatic and conductive textiles. In Functional Textiles for Improved Performance, Protection and Health; Woodhead Publishing: Cambridge, UK, 2011; pp. 27–44. [Google Scholar]

- Kothari, V.K.; Bhattacharjee, D. Artificial neural network modelling for prediction of thermal transmission properties of woven fabrics. In Soft Computing in Textile Engineering; Woodhead Publishing: Cambridge, UK, 2011; pp. 403–423. [Google Scholar]

- Lawrence, C. Chapter 10—Fibre to yarn: Filament yarn spinning. In Textiles and Fashion; Woodhead Publishing: Cambridge, UK, 2015; pp. 213–253. [Google Scholar]

- Li, T.T.; Pan, Y.J.; Hsieh, C.T.; Lou, C.W.; Chuang, Y.C.; Huang, Y.T.; Lin, J.H. Comfort and functional properties of far-infrared/anion-releasing warp-knitted elastic composite fabrics using bamboo charcoal, copper, and phase change materials. Appl. Sci. 2016, 6, 62. [Google Scholar] [CrossRef]

- Dong, Y.; Kong, J.; Mu, C.; Zhao, C.; Thomas, N.L.; Lu, X. Materials design towards sport textiles with low-friction and moisture-wicking dual functions. Mater Des. 2015, 88, 82–87. [Google Scholar] [CrossRef] [Green Version]

- Li, Y. Perceptions of temperature, moisture and comfort in clothing during environmental transients. Ergonomics 2005, 48, 234–248. [Google Scholar] [CrossRef] [PubMed]

- Classen, E. Comfort testing of textiles. In Advanced Characterization and Testing of Textiles; Vermeersch, O., Izquierdo, V., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 59–69. [Google Scholar]

- McCann, J. Environmentally conscious fabric selection in sportswear design. In Textiles for Sportswear; Woodhead Publishing: Cambridge, UK, 2015; pp. 17–52. [Google Scholar]

- Dyer, J. Infrared functional textiles. In Functional Textiles for Improved Performance, Protection and Health; Woodhead Publishing: Cambridge, UK, 2011; pp. 184–197. [Google Scholar]

- Daanen, H. Physiological strain and comfort in sports clothing. In Textiles for Sportswear; Woodhead Publishing: Cambridge, UK, 2015; pp. 153–168. [Google Scholar]

- Majumdar, A.; Mukhopadhyay, S.; Yadav, R. Thermal properties of knitted fabrics made from cotton and regenerated bamboo cellulosic fibres. Int. J. Therm. Sci. 2010, 49, 2042–2048. [Google Scholar] [CrossRef]

- Deopura, B.L.; Padaki, N.V. Chapter 5—Synthetic textile fibres: Polyamide, polyester and aramid fibres a2 -sinclair, rose. In Textiles and Fashion; Woodhead Publishing: Cambridge, UK, 2015; pp. 97–114. [Google Scholar]

- Alexander, J.; Selfe, J.; Oliver, B.; Mee, D.; Carter, A.; Scott, M.; Richards, J.; May, K. An exploratory study into the effects of a 20 minute crushed ice application on knee joint position sense during a small knee bend. Phys. Ther. Sport 2016, 18, 21–26. [Google Scholar] [CrossRef] [PubMed]

- Kobara, K.; Fujita, D.; Osaka, H.; Ito, T.; Watanabe, S. Influence of distance between the rotation axis of back support and the hip joint on shear force applied to buttocks in a reclining wheelchair’s back support. Prosthet. Orthot. Int. 2013, 37, 459–464. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jorgensen, M.J.; Marras, W.S. The effect of lumbar back support tension on trunk muscle activity. Clin. Biomech. 2000, 15, 292–294. [Google Scholar] [CrossRef]

- Rønning, R.; Rønning, I.; Gerner, T.; Engebretsen, L. The efficacy of wrist protectors in preventing snowboarding injuries. Am. J. Sports Med. 2001, 29, 581–585. [Google Scholar] [CrossRef] [PubMed]

- Stuart, P.; Briggs, P. Closed extensor tendon rupture and distal radial fracture with use of a gymnast’s wrist support. Br. J. Sports Med. 1993, 27, 92–93. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.M.; Lin, C.W.; Yang, Y.C.; Lou, C.W.; Chen, A.P.; Lin, J.H. Evaluation of the manufacturing and functions of complex yarn and fabrics. Fibres Text. East. Eur. 2012, 20, 47–50. [Google Scholar]

- Lin, J.H.; Lin, C.M.; Huang, C.H.; Chen, A.P.; Chen, C.P.; Lou, C.W. Physical properties of electrically conductive complex-ply yarns and woven fabrics made from recycled polypropylene. J. Eng. Fibers Fabr. 2013, 8, 30–38. [Google Scholar]

- Lin, J.H.; Huang, Y.T.; Li, T.T.; Lin, C.M.; Lou, C.W. Bamboo charcoal/phase change material/stainless steel ring-spun complex yarn and its far-infrared/anion-releasing elastic warp-knitted fabric: Fabrication and functional evaluation. J. Ind. Text. 2016, 46, 624–642. [Google Scholar] [CrossRef]

- Yu, Z.C.; Zhang, J.F.; Lou, C.W.; Lin, J.H. Wicking behavior and antibacterial properties of multifunctional knitted fabrics made from metal commingled yarns. J. Text. Inst. 2015, 106, 862–871. [Google Scholar] [CrossRef]

- Lou, C.W.; Hu, J.J.; Lu, P.C.; Lin, J.H. Effect of twist coefficient and thermal treatment temperature on elasticity and tensile strength of wrapped yarns. Text. Res. J. 2016, 86, 24–33. [Google Scholar] [CrossRef]

- Liu, T.; Choi, K.F.; Li, Y. Wicking in twisted yarns. J. Colloid Interface Sci. 2008, 318, 134–139. [Google Scholar] [CrossRef] [PubMed]

- Perwuelz, A.; Casetta, M.; Caze, C. Liquid organisation during capillary rise in yarns—Influence of yarn torsion. Polym. Test. 2001, 20, 553–561. [Google Scholar] [CrossRef]

- Qu, H.; Skorobogatiy, M. 2–Conductive polymer yarns for electronic textiles. In Electronic textiles; Woodhead Publishing: Oxford, UK, 2015; pp. 21–53. [Google Scholar]

- Tessier, D. Testing thermal properties of textiles a2-dolez, patricia. In Advanced Characterization and Testing of Textiles; Vermeersch, O., Izquierdo, V., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 71–92. [Google Scholar]

- Fung, W. Coated and laminated textiles in sportswear. In Textiles in Sport; Woodhead Publishing: Cambridge, UK, 2005; pp. 134–174. [Google Scholar]

- Van Amber, R.R.; Wilson, C.A.; Laing, R.M.; Lowe, B.J.; Niven, B.E. Thermal and moisture transfer properties of sock fabrics differing in fiber type, yarn, and fabric structure. Text. Res. J. 2015, 85, 1269–1280. [Google Scholar] [CrossRef]

- Lamke, L.O.; Nilsson, G.E.; Reithner, H.L. The evaporative water loss from burns and the water-vapour permeability of grafts and artificial membranes used in the treatment of burns. Burns 1977, 3, 159–165. [Google Scholar] [CrossRef]

- RuizCardona, L.; Sanzgiri, Y.D.; Benedetti, L.M.; Stella, V.J.; Topp, E.M. Application of benzyl hyaluronate membranes as potential wound dressings: Evaluation of water vapour and gas permeabilities. Biomaterials 1996, 17, 1639–1643. [Google Scholar] [CrossRef]

- Li, Y. The science of clothing comfort. Text. Prog. 2001, 31, 1–135. [Google Scholar] [CrossRef]

- Lin, J.H.; Chen, A.P.; Hsieh, C.T.; Lin, C.W.; Lin, C.M.; Lou, C.W. Physical properties of the functional bamboo charcoal/stainless steel core-sheath yarns and knitted fabrics. Text. Res. J. 2011, 81, 567–573. [Google Scholar] [CrossRef]

| Code | Compositions |

|---|---|

| Bamboo charcoal yarn | Combination of two 75D bamboo charcoal yarns without twisting or wrapping. |

| Quick-dry yarn | Combination of two 75D quick-dry yarns without twisting or wrapping. |

| Q-wrapped yarn | The wrapped yarns have one 75D bamboo charcoal yarn as the core and one 75D quick-dry yarn as the sheath. |

| B-wrapped yarn | The wrapped yarns have one 75D quick-dry yarn as the core and one 75D bamboo charcoal yarn as the sheath. |

| B/Q-twisted yarn | The twisted yarns are composed of 75D bamboo charcoal yarn and one 75D quick-dry yarn. |

| Sample Code | Twist Number (T.P.I.) | ||

|---|---|---|---|

| Bamboo charcoal yarn | N/A | ||

| Quick-dry yarn | N/A | ||

| B-wrapped yarn | 20 | 25 | 30 |

| Q-wrapped yarn | 20 | 25 | 30 |

| B/Q twisted yarn | 5 | 10 | 15 |

| Yarn Type | Twist Number (T.P.I.) | Strength of Yarn (cN) | Linear density (Denier) | Diameter of Yarn (mm) |

|---|---|---|---|---|

| Bamboo charcoal yarn | 0 | 560.60 ± 30.57 | 148.90 ± 0.01 | 0.38 ± 0.01 |

| Quick-dry yarn | 0 | 605.65 ± 28.75 | 151.50 ± 0.03 | 0.47 ± 0.04 |

| Q-wrapped yarn | 20 | 610.48 ± 18.36 | 156.69 ± 0.01 | 0.28 ± 0.01 |

| 25 | 555.34 ± 34.70 | 159.35 ± 0.01 | 0.26 ± 0.02 | |

| 30 | 542.85 ± 17.42 | 159.97 ± 0.03 | 0.21 ± 0.01 | |

| B-wrapped yarn | 20 | 635.01 ± 14.82 | 155.95 ± 0.02 | 0.23 ± 0.03 |

| 25 | 616.29 ± 8.16 | 160.19 ± 0.01 | 0.21 ± 0.01 | |

| 30 | 599.45 ± 11.95 | 162.31 ± 0.04 | 0.17 ± 0.02 | |

| B/Q-twisted yarn | 5 | 624.80 ± 16.17 | 150.77 ± 0.02 | 0.38 ± 0.03 |

| 10 | 643.19 ± 14.21 | 151.51 ± 0.03 | 0.36 ± 0.04 | |

| 15 | 636.23 ± 14.72 | 151.98 ± 0.03 | 0.22 ± 0.02 |

| Knit Type | Twist Number of the Yarn (T.P.I.) | Weight of the Knits (g/m2) | Thickness of the Knits (mm) |

|---|---|---|---|

| Bamboo charcoal functional elastic knits | 0 | 409.10 | 1.06 ± 0.02 |

| Quick-dry functional elastic knits | 0 | 403.70 | 1.07 ± 0.01 |

| Q-wrapped functional elastic knits | 20 | 406.30 | 1.12 ± 0.01 |

| 25 | 411.30 | 1.13 ± 0.02 | |

| 30 | 411.60 | 1.12 ± 0.01 | |

| B-wrapped functional elastic knits | 20 | 405.60 | 1.14 ± 0.01 |

| 25 | 411.00 | 1.08 ± 0.01 | |

| 30 | 420.40 | 1.14 ± 0.02 | |

| B/Q-twisted functional elastic knits | 5 | 405.90 | 1.11 ± 0.01 |

| 10 | 411.70 | 1.10 ± 0.01 | |

| 15 | 416.00 | 1.12 ± 0.01 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.-H.; He, C.-H.; Huang, Y.-T.; Lou, C.-W. Functional Elastic Knits Made of Bamboo Charcoal and Quick-Dry Yarns: Manufacturing Techniques and Property Evaluations. Appl. Sci. 2017, 7, 1287. https://doi.org/10.3390/app7121287

Lin J-H, He C-H, Huang Y-T, Lou C-W. Functional Elastic Knits Made of Bamboo Charcoal and Quick-Dry Yarns: Manufacturing Techniques and Property Evaluations. Applied Sciences. 2017; 7(12):1287. https://doi.org/10.3390/app7121287

Chicago/Turabian StyleLin, Jia-Horng, Chih-Hung He, Yu-Tien Huang, and Ching-Wen Lou. 2017. "Functional Elastic Knits Made of Bamboo Charcoal and Quick-Dry Yarns: Manufacturing Techniques and Property Evaluations" Applied Sciences 7, no. 12: 1287. https://doi.org/10.3390/app7121287