Research on the Rational Yield Ratio of Isolation System and Its Application to the Design of Seismically Isolated Reinforced Concrete Frame-Core Tube Tall Buildings

Abstract

:Featured Application

Abstract

1. Introduction

2. Rational Range of the Yield Ratio of Isolation System

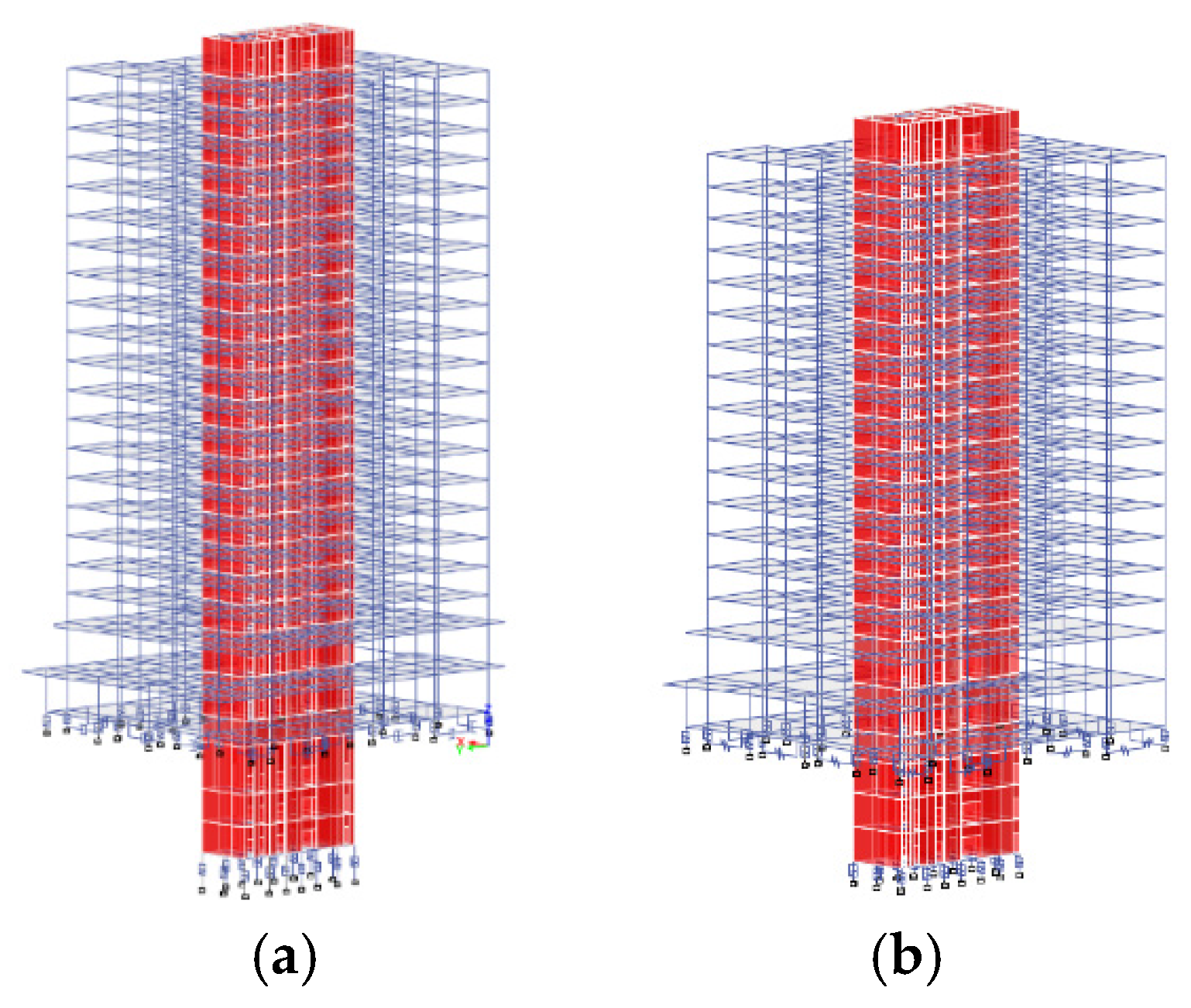

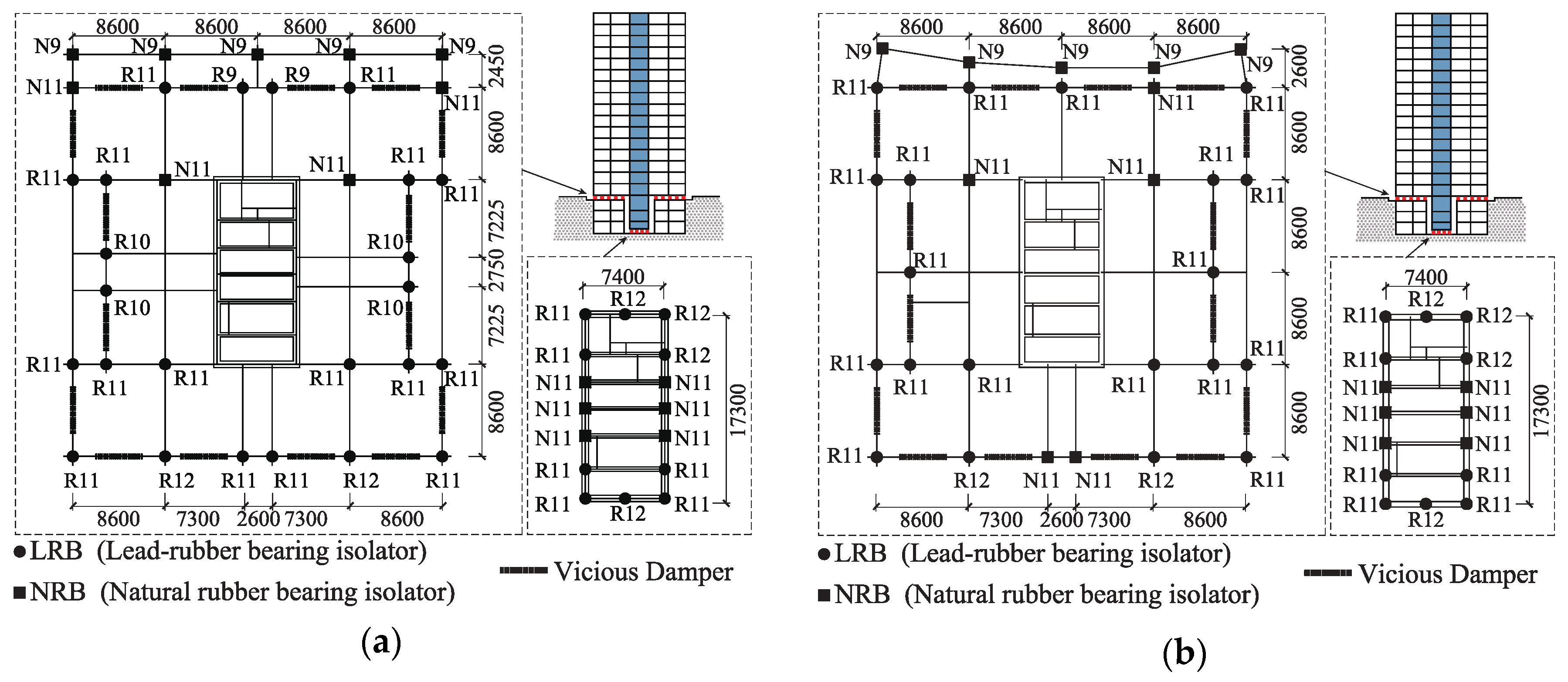

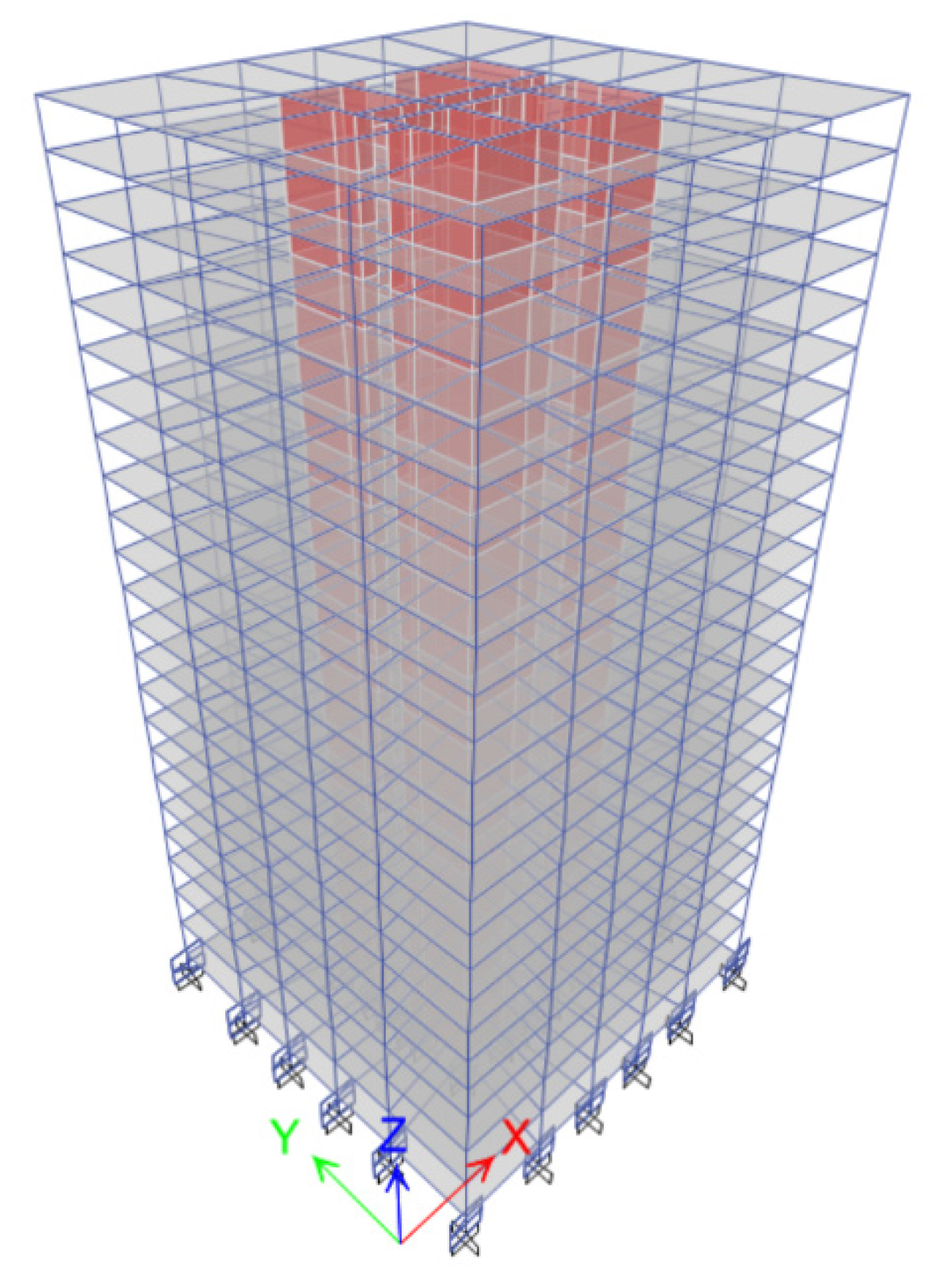

2.1. Overview of the Prototype Buildings

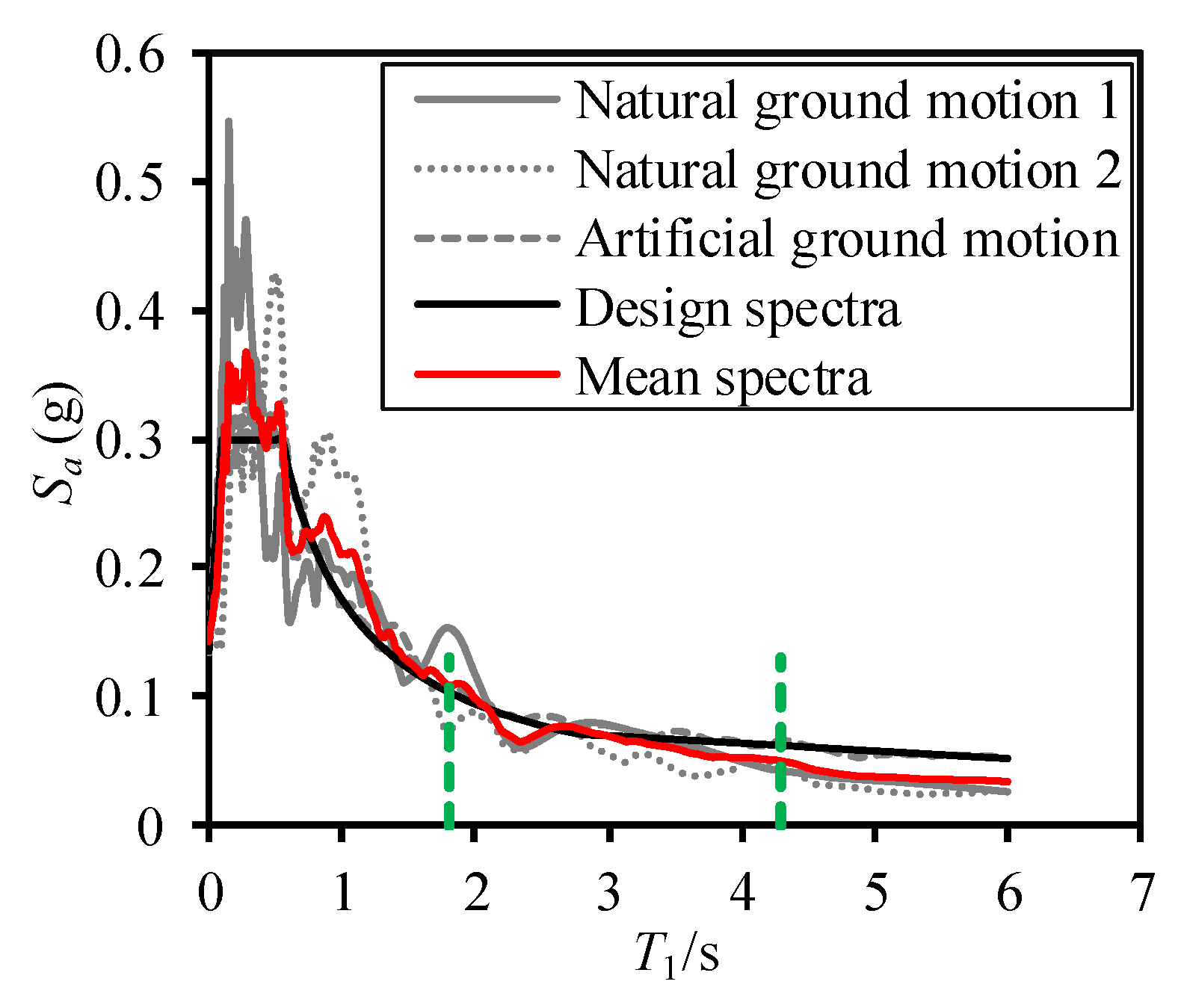

2.2. Design of the Study Cases

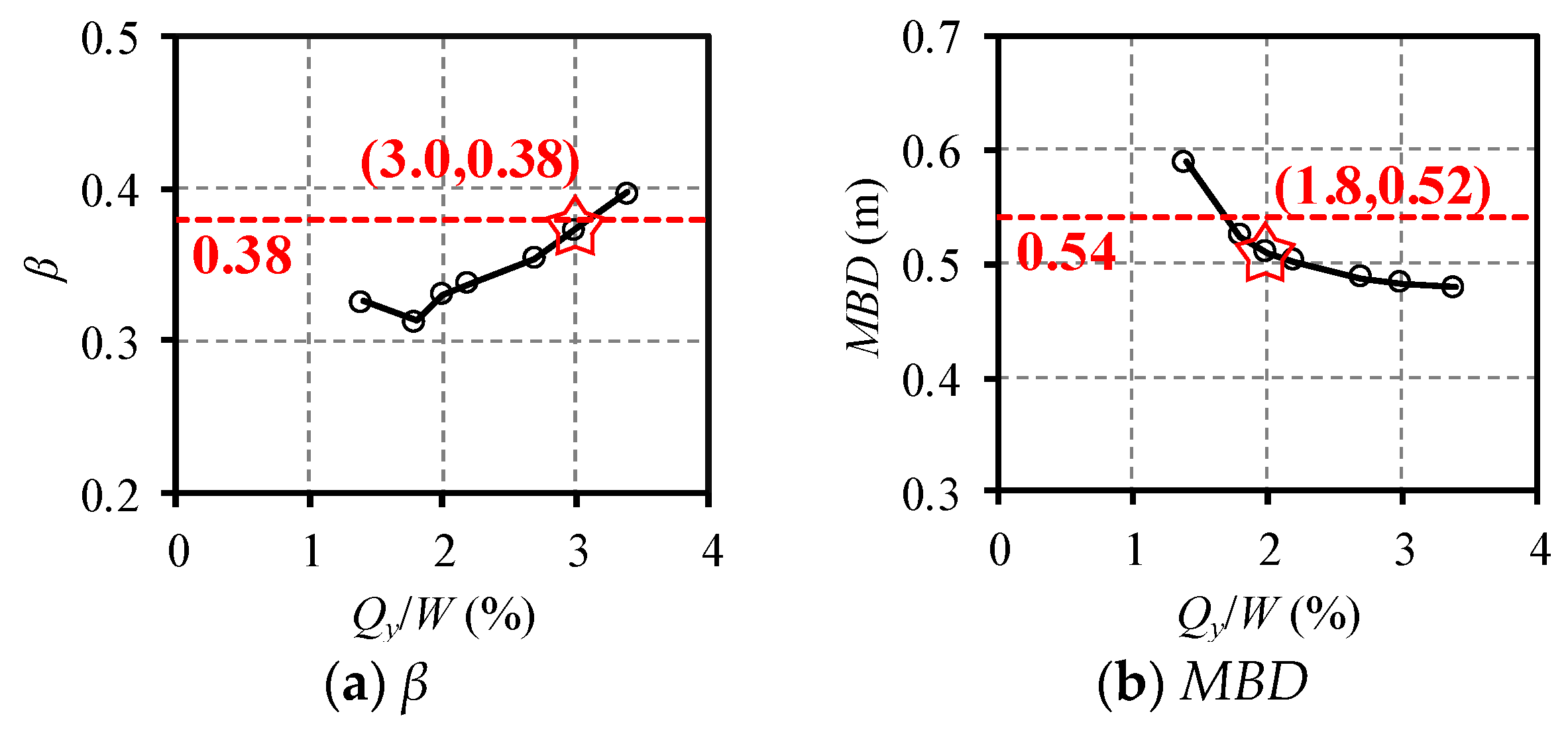

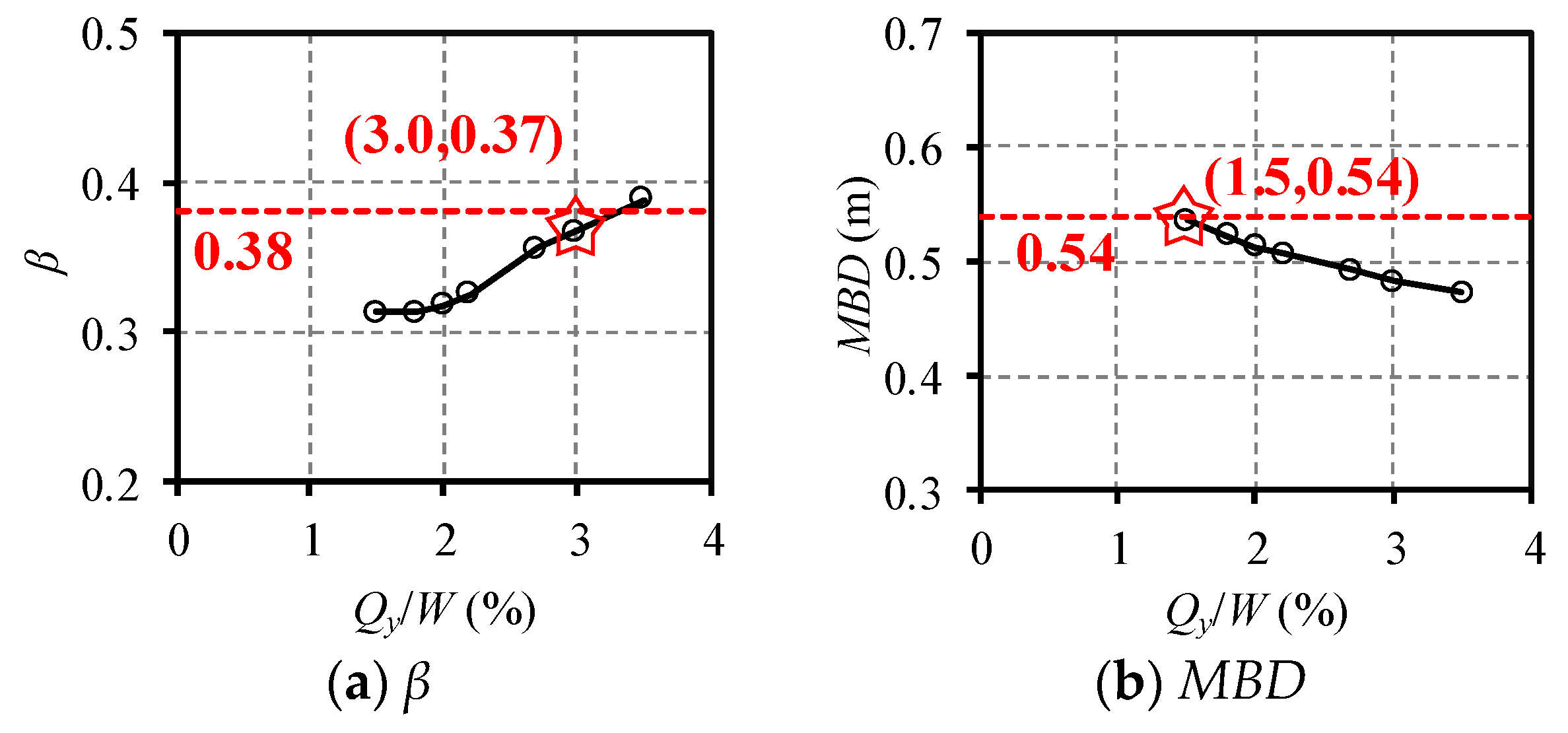

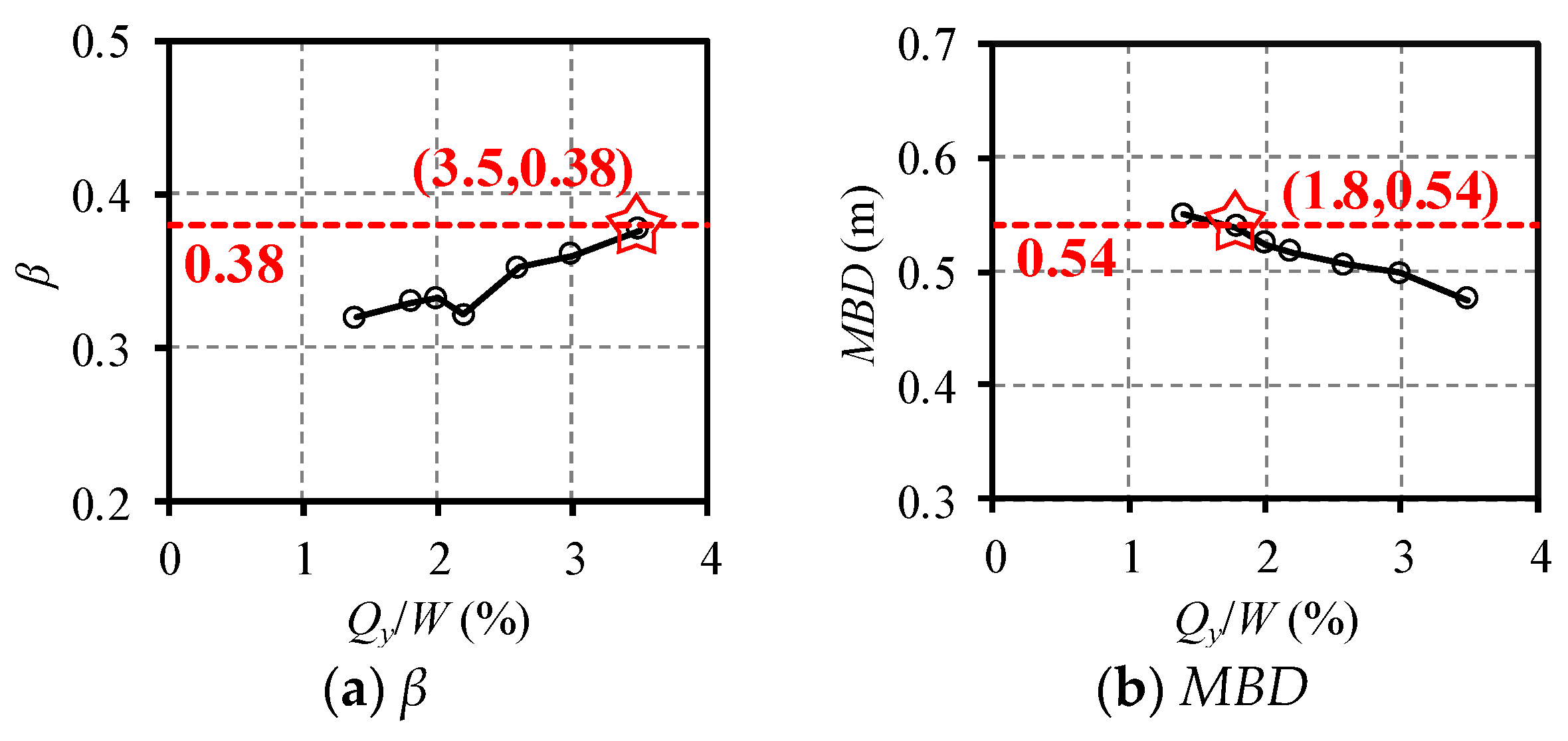

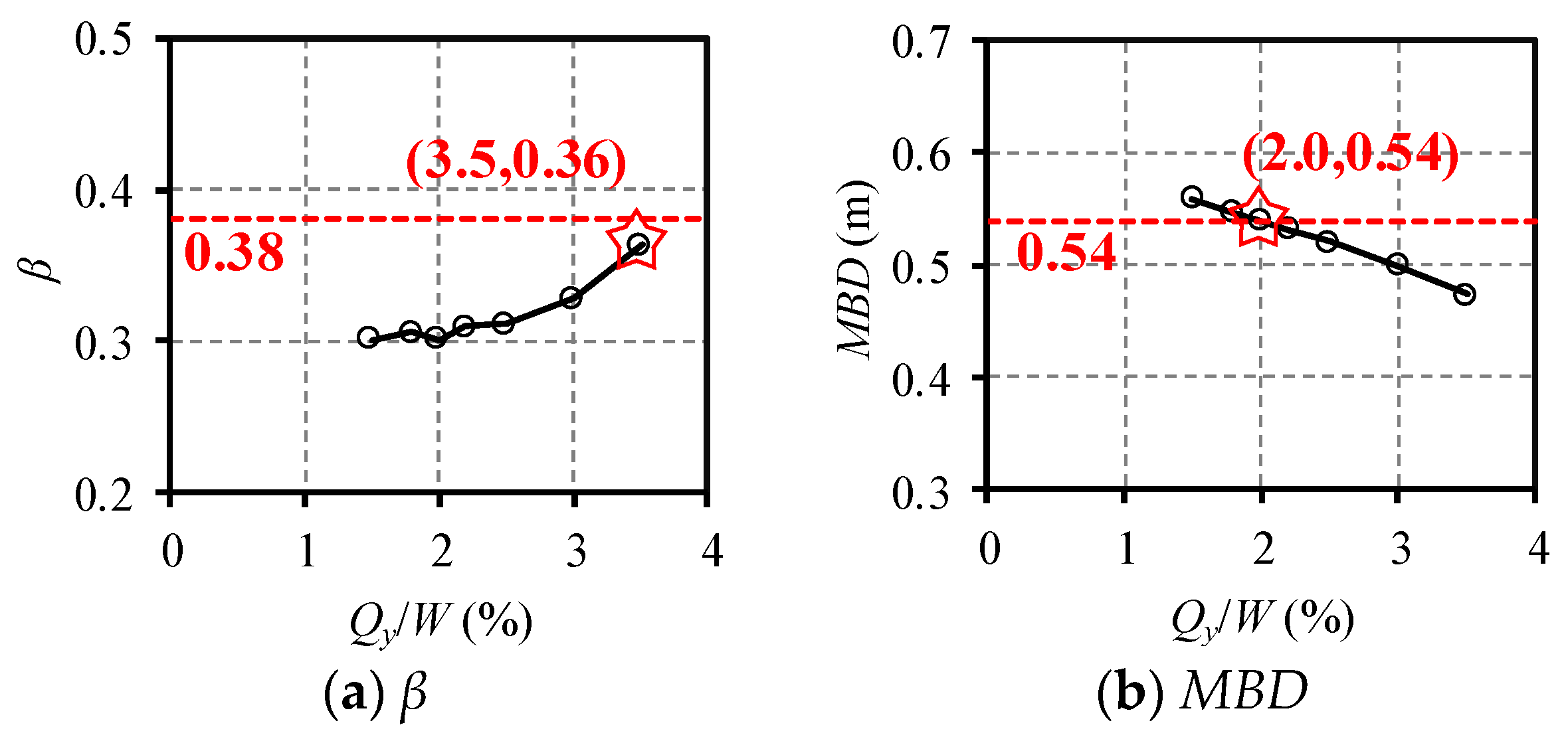

2.3. Rational Value of the Yield Ratio

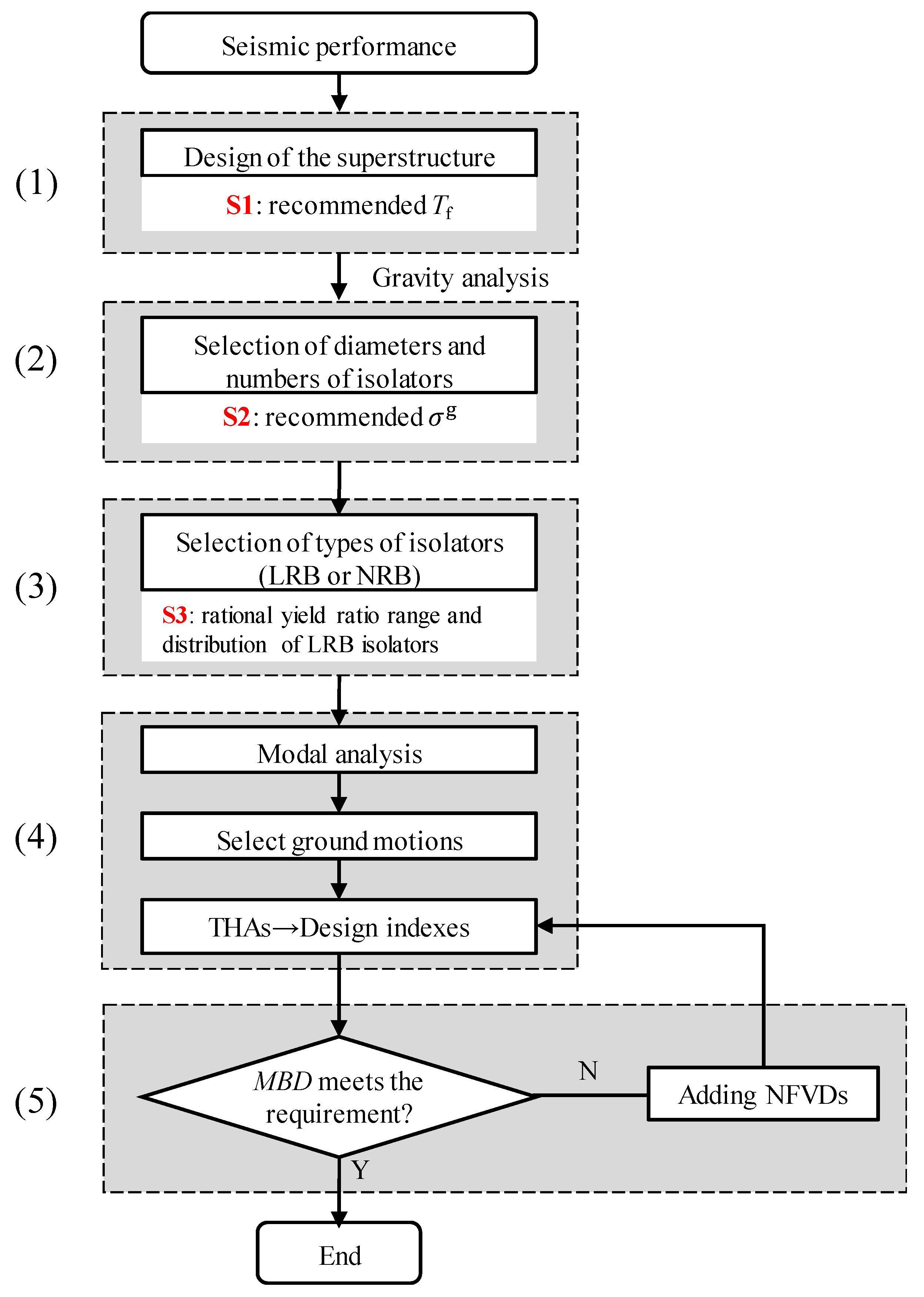

3. Design Method for Seismically Isolated RC Frame-Core Tube Tall Building

3.1. Traditional Design Method

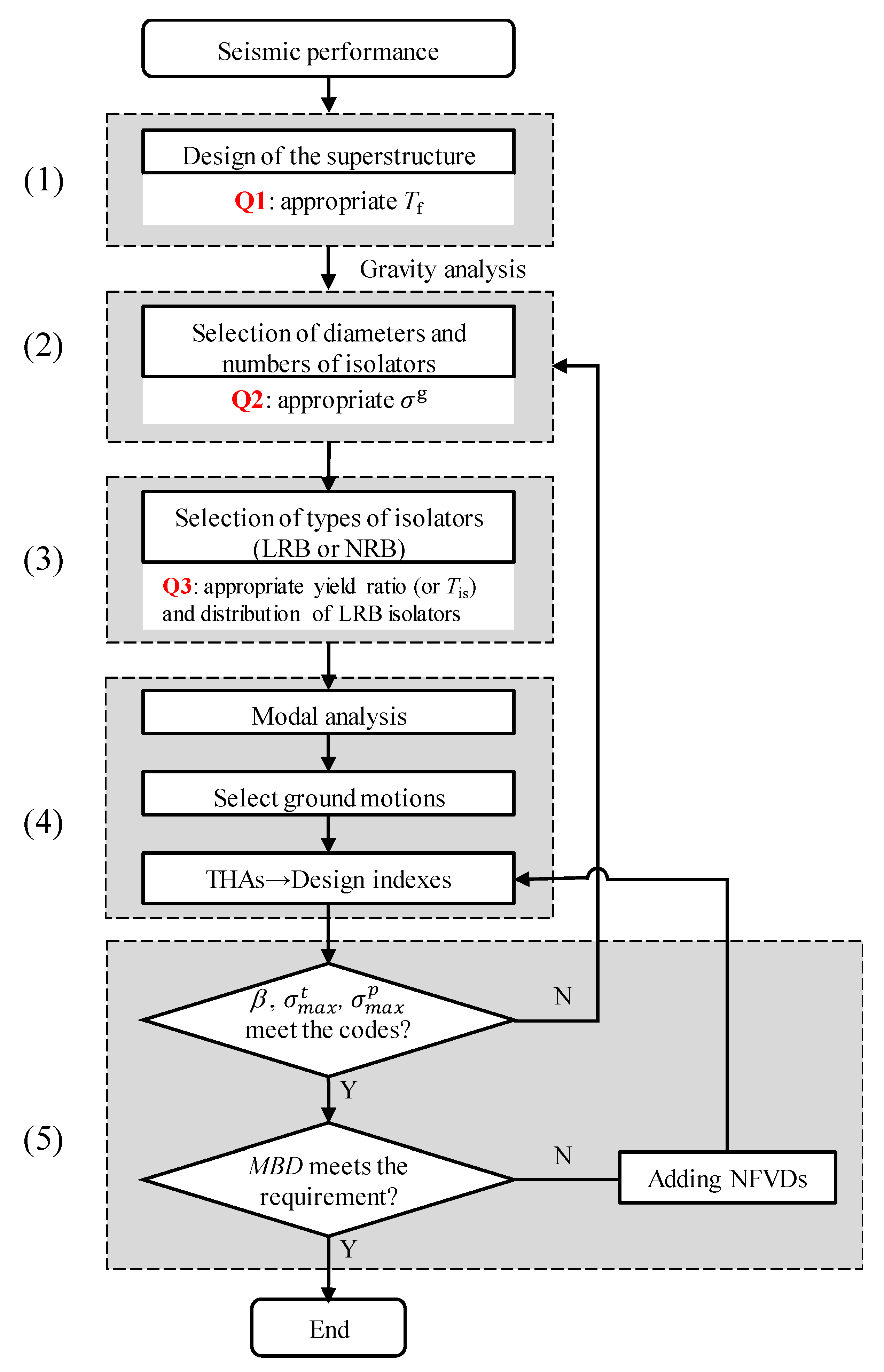

3.2. Proposed High-Efficiency Design Method

4. Application of the Design Method

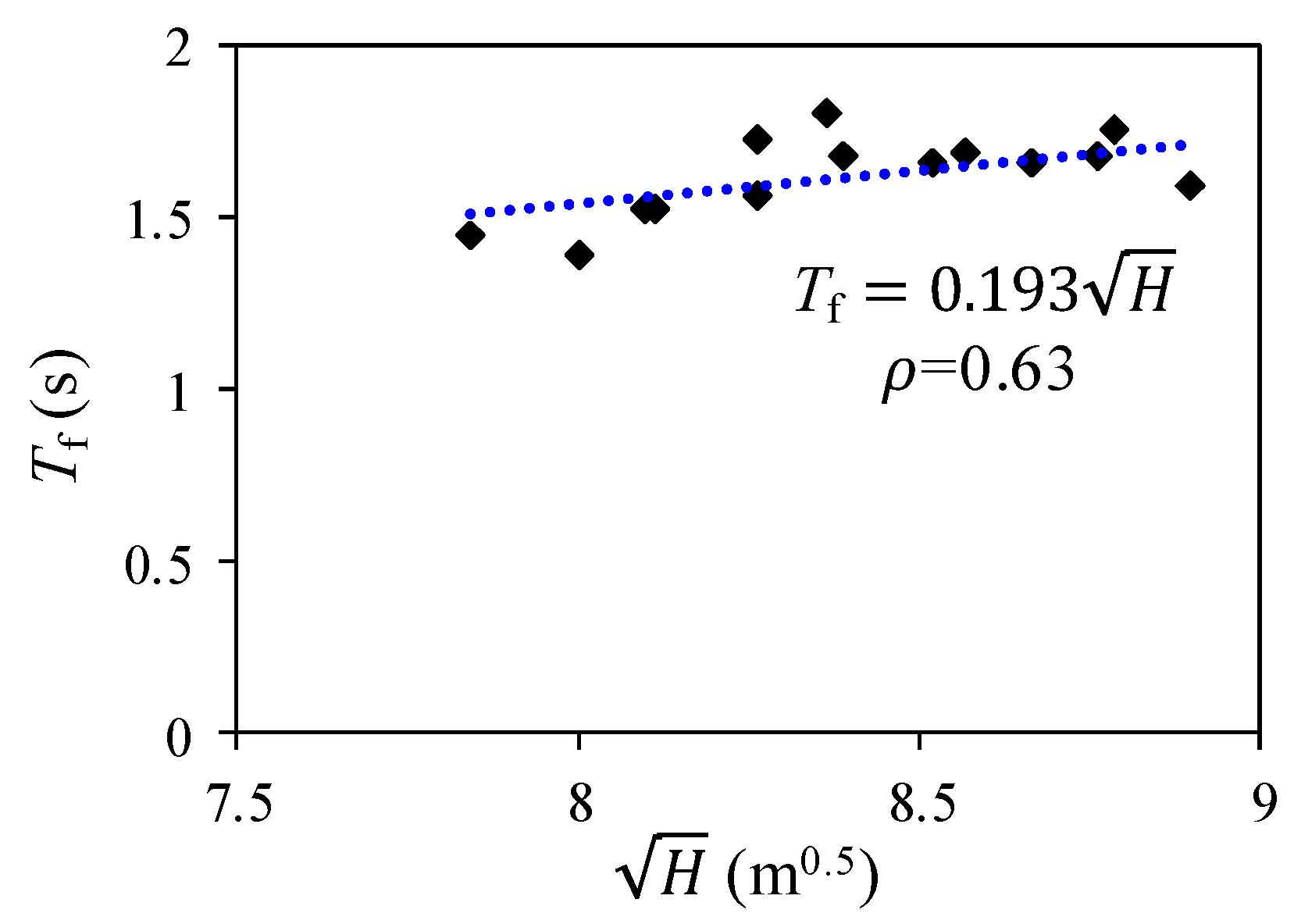

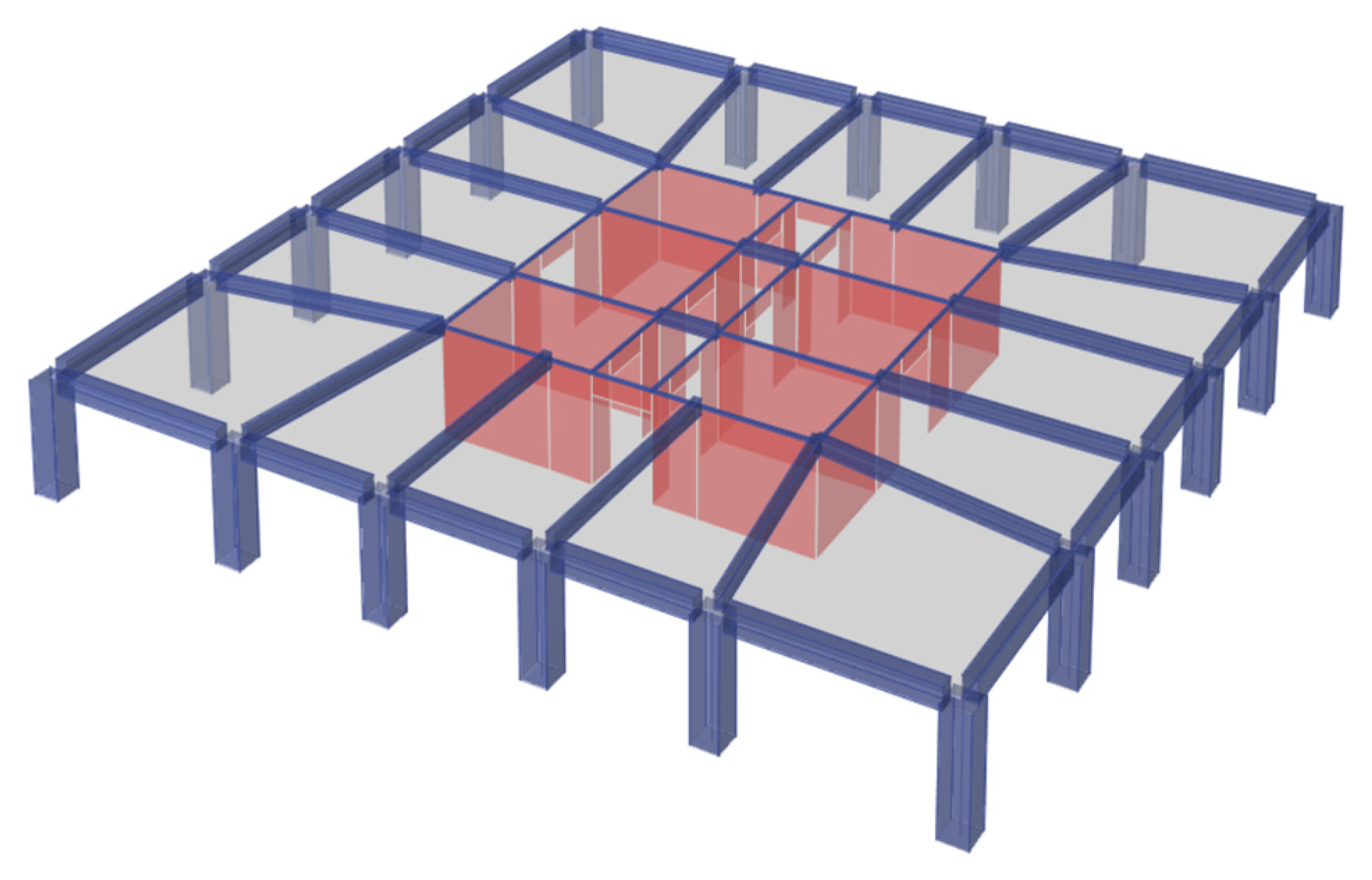

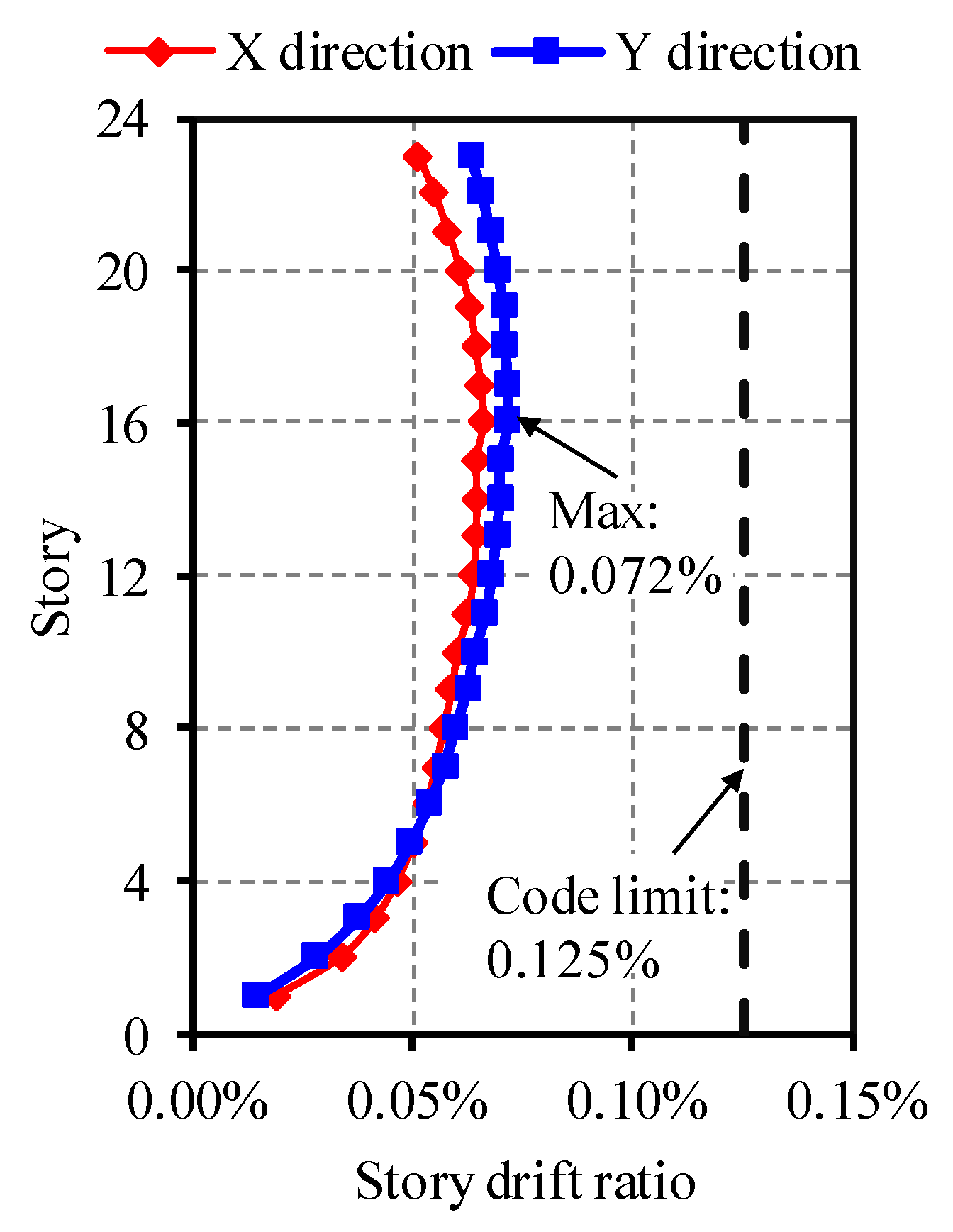

4.1. Design of the Superstructure

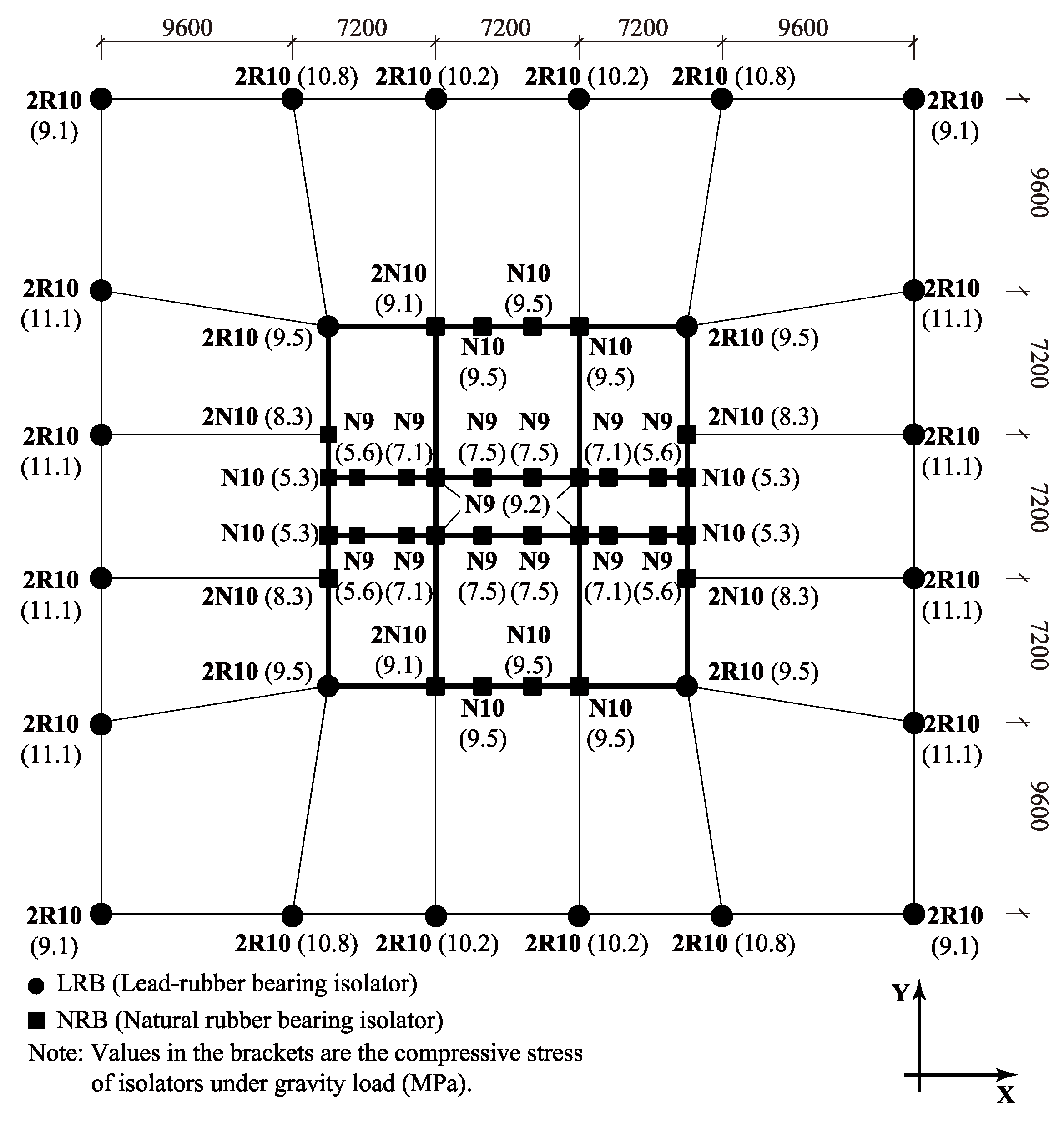

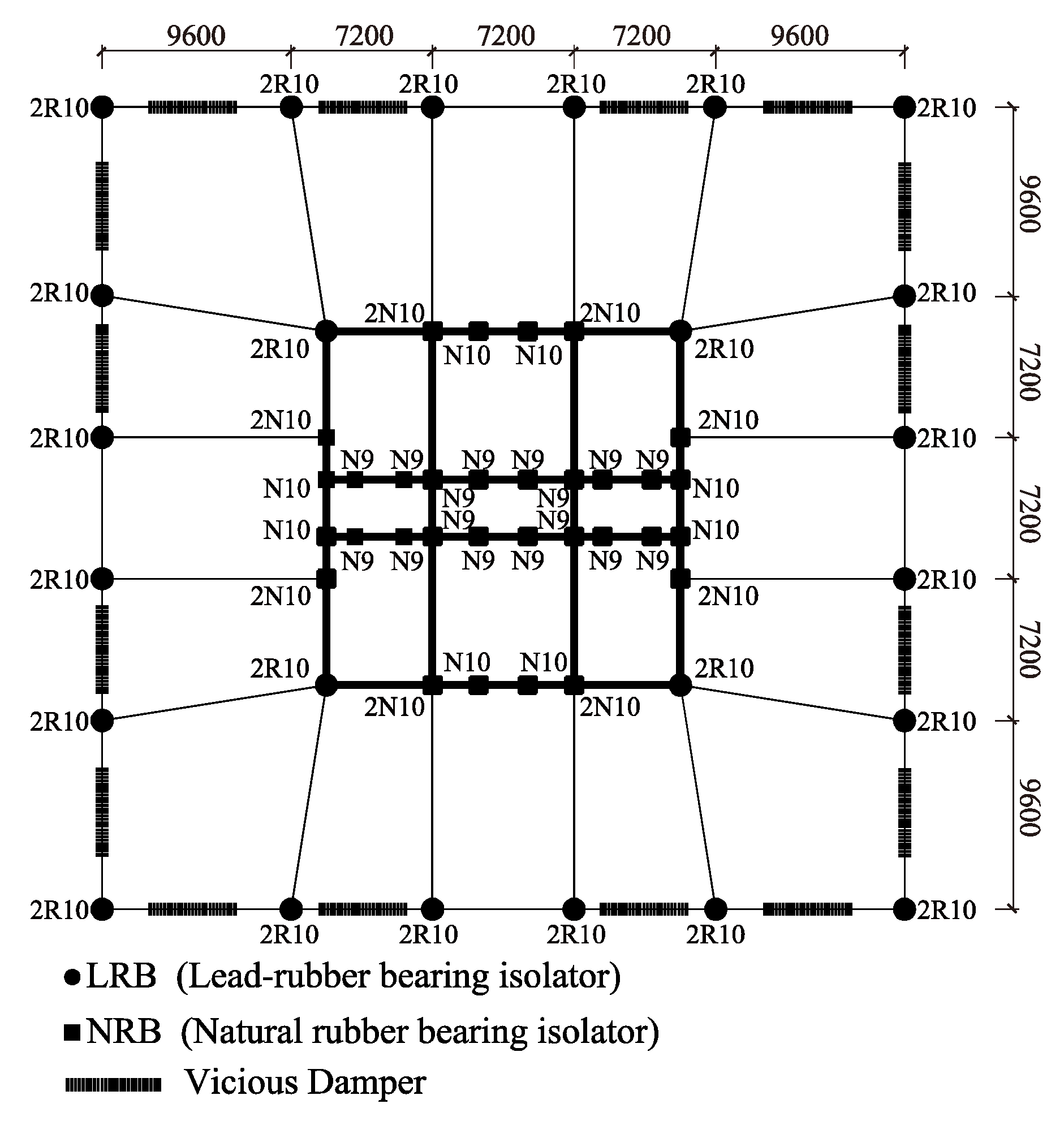

4.2. Selection of the Isolator Numbers and Sizes

4.3. Selection of the Isolator Types (LRB or NRB)

4.4. Calculation of the Design Indexes

4.5. Validation and Modification of the Isolation System

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Formisano, A.; Chieffo, N.; Marius, M. Fragility and resilience curves of an urbanised sector in the district of Naples. Int. J. Constr. Res. Civ. Eng. 2017, 3, 58–67. [Google Scholar] [CrossRef]

- Bozza, A.; Asprone, D.; Fabbrocino, F. Urban resilience: A civil engineering perspective. Sustainability 2017, 9. [Google Scholar] [CrossRef]

- Tipler, J.; Deierlein, G.; Almufti, I. Seismic Resilience of tall Buildings-Benchmarking Performance and Quantifying Improvements; Stanford University: Stanford, CA, USA, 2014. [Google Scholar]

- Pant, D.; Montgomery, M.; Christopoulos, C.; Xu, B.; Poon, D. Viscoelastic coupling dampers for the enhanced seismic resilience of a megatall building. In Proceedings of the 16th World Conference on Earthquake Engineering, Santiago, Chile, 9–13 January 2017. [Google Scholar]

- Tian, Y.; Lu, X.; Lu, X.Z.; Li, M.K.; Guan, H. Quantifying the seismic resilience of two tall buildings designed using Chinese and US codes. Earthq. Struct. 2016, 11, 925–942. [Google Scholar] [CrossRef]

- Heaton, T.; Hall, J.; Wald, D.; Halling, M. Response of highrise and base-isolated buildings to a hypothetical M(w)7.0 blind thrust earthquake. Science 1995, 267, 206–211. [Google Scholar] [CrossRef] [PubMed]

- Pan, P.; Zamfirescu, D.; Nakashima, M.; Nakayasu, N.; Kashiwa, H. Base-isolation design practice in Japan: Introduction to the post-Kobe approach. J. Earthq. Eng. 2005, 9, 147–171. [Google Scholar] [CrossRef]

- Zhu, H.; Zhou, F.; Yuan, Y. Development and analysis of the research on base isolated structures. Eng. Mech. 2014, 3. [Google Scholar] [CrossRef]

- Higashino, M.; Okamoto, S. Response Control and Seismic Isolation of Buildings; Routledge: Abingdon, UK, 2006; ISBN 978-0-415-36623-6. [Google Scholar]

- Zhou, Y.; Chen, P. Shaking table tests and numerical studies on the effect of viscous dampers on an isolated RC building by friction pendulum bearings. Soil Dyn. Earthq. Eng. 2017, 100, 330–344. [Google Scholar] [CrossRef]

- Pan, P.; Shen, S.; Shen, Z.; Gong, R. Experimental investigation on the effectiveness of laminated rubber bearings to isolate metro generated vibration. Measurement 2017. [Google Scholar] [CrossRef]

- Ye, K.; Li, L.; Zhu, H. A modified Kelvin impact model for pounding simulation of base-isolated building with adjacent structures. Earthq. Eng. Eng. Vib. 2009, 8, 433–446. [Google Scholar] [CrossRef]

- Ubertini, F.; Comodini, F.; Fulco, A.; Mezzi, M. A Simplified parametric study on occupant comfort conditions in base isolated buildings under wind loading. Adv. Civ. Eng. 2017. [Google Scholar] [CrossRef]

- Sorace, S.; Terenzi, G. Analysis and demonstrative application of a base isolation/supplemental damping technology. Earthq. Spectra 2008, 24, 775–793. [Google Scholar] [CrossRef]

- Cancellara, D.; De Angelis, F. Assessment and dynamic nonlinear analysis of different base isolation systems for a multi-storey RC building irregular in plan. Comput. Struct. 2017, 180, 74–88. [Google Scholar] [CrossRef]

- Becker, T.; Bao, Y.; Mahin, S. Extreme behavior in a triple friction pendulum isolated frame. Earthq. Eng. Struct. Dyn. 2017. [Google Scholar] [CrossRef]

- China Ministry of Construction. Code for Design of Concrete Structures (GB 50010-2010); China Ministry of Construction: Beijing, China, 2010.

- Hu, K.; Zhou, Y.; Jiang, L.; Chen, P.; Qu, G. A mechanical tension-resistant device for lead rubber bearings. Eng. Struct. 2017, 152, 238–250. [Google Scholar] [CrossRef]

- Park, J.-G.; Otsuka, H. Optimal yield level of bilinear seismic isolation devices. Earthq. Eng. Struct. Dyn. 1999, 28, 941–955. [Google Scholar] [CrossRef]

- Providakis, C.P. Effect of LRB isolators and supplemental viscous dampers on seismic isolated buildings under near-fault excitations. Eng. Struct. 2008, 30, 1187–1198. [Google Scholar] [CrossRef]

- Li, B. Computational Analysis and Research on Relevant Parameters of Isolation Layer and Seismic Response Based on Base-Isolated Benchmark Building. Master’s Thesis, Guangzhou University, Guangzhou, China, 2013. [Google Scholar]

- Mollaioli, F.; Lucchini, A.; Cheng, Y.; Monti, G. Intensity measures for the seismic response prediction of base-isolated buildings. Bull. Earthq. Eng. 2013, 11, 1841–1866. [Google Scholar] [CrossRef]

- Avşar, Ö.; Özdemir, G. Response of seismic-isolated bridges in relation to intensity measures of ordinary and pulselike ground motions. J. Bridge Eng. 2011, 18, 250–260. [Google Scholar] [CrossRef]

- Pourzeynali, S.; Zarif, M. Multi-objective optimization of seismically isolated high-rise building structures using genetic algorithms. J. Sound Vib. 2008, 311, 1141–1160. [Google Scholar] [CrossRef]

- Shen, S.; Liu, W.; Du, D.; Wang, S. Effects of nonlinear seismic response of isolated structures on spectrum characteristics of ground motions. J. Nanjing Univ. Technol. Nat. Sci. Ed. 2013, 35, 1–5. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Miao, Q.; Liu, W.; Du, D. Parameter optimization of isolator in structure with added floors and related shaking tabsle tests. J. Vib. Eng. 2013, 26, 722–731. [Google Scholar] [CrossRef]

- Ma, C.F.; Zhang, Y.H.; Tan, P.; Zhou, F.L. Seismic response of base-isolated high-rise buildings under fully nonstationary excitation. Shock Vib. 2014, 2014. [Google Scholar] [CrossRef]

- Takewaki, I. Robustness of base-isolated high-rise buildings under code-specified ground motions. Struct. Des. Tall Spec. Build. 2008, 17, 257–271. [Google Scholar] [CrossRef]

- Kaplan, H.; Seireg, A. Optimal design of a base isolated system for a high-rise steel structure. Earthq. Eng. Struct. Dyn. 2001, 30, 287–302. [Google Scholar] [CrossRef]

- Xiong, C.; Lu, X.Z.; Guan, H.; Xu, Z. A nonlinear computational model for regional seismic simulation of tall buildings. B. Earthq. Eng. 2016, 14, 1047–1069. [Google Scholar] [CrossRef]

- Lu, X.; Xie, L.; Guan, H.; Huang, Y.; Lu, X. A shear wall element for nonlinear seismic analysis of super-tall buildings using OpenSees. Finite Elem. Anal. Des. 2015, 98, 14–25. [Google Scholar] [CrossRef]

- Lu, X.; Lu, X.Z.; Zhang, W.K.; Ye, L.P. Collapse simulation of a super high-rise building subjected to extremely strong earthquakes. Sci. China Technol. Sci. 2011, 54, 2549–2560. [Google Scholar] [CrossRef]

- Pan, P.; Li, W.; Nie, X.; Deng, K.; Sun, J. Seismic performance of a reinforced concrete frame equipped with a double-stage yield buckling restrained brace. Struct. Des. Tall Spec. Build. 2017, 26. [Google Scholar] [CrossRef]

- Su, N.; Lu, X.; Zhou, Y.; Yang, T.Y. Estimating the peak structural response of high-rise structures using spectral value-based intensity measures. Struct. Des. Tall Spec. Build. 2017, 26. [Google Scholar] [CrossRef]

- Computers and Structures Inc. ETABS (Version 2016). Windows; Computers and Structures Inc.: Berkeley, CA, USA, 2016. [Google Scholar]

- Faal, H.N.; Poursha, M. Applicability of the N2, extended N2 and modal pushover analysis methods for the seismic evaluation of base-isolated building frames with lead rubber bearings (LRBs). Soil Dyn. Earthq. Eng. 2017, 98, 84–100. [Google Scholar] [CrossRef]

- Cardone, D.; Gesualdi, G. Seismic rehabilitation of existing reinforced concrete buildings with seismic isolation: A case study. Earthq. Spectra 2013, 30, 1619–1642. [Google Scholar] [CrossRef]

- Chen, J.; Ding, J. Aseismic design of tall building of concrete filled square steel tube with energy dissipation braces. J. Tongji Univ. Nat. Sci. 2006, 34, 1431–1435. [Google Scholar]

- China Academy of Building Research. PKPM (Version 2010). Windows; China Academy of Building Research: Beijing, China, 2010. [Google Scholar]

- Guangzhou University; China Academy of Building Research. Technical Specification for Seismic Isolation with Laminated Rubber Bearing Isolators (CECS126:2001); CECS: Beijing, China, 2001. [Google Scholar]

| Type | NRB 900 | NRB 1100 | LRB 900 | LRB 1000 | LRB 1100 | LRB 1200 |

|---|---|---|---|---|---|---|

| Notation | N9 | N11 | R9 | R10 | R11 | R12 |

| Effective diameter (mm) | 900 | 1100 | 900 | 1000 | 1100 | 1200 |

| Total rubber thickness (mm) | 176 | 216 | 176 | 197 | 216 | 235 |

| Vertical stiffness (kN/m) | 3,630,000 | 4,519,000 | 4,168,000 | 4,639,000 | 5,550,000 | 5,940,000 |

| Equivalent stiffness at 100% shear strain (kN/m) | 1110 | 1358 | 2070 | 2300 | 2450 | 2600 |

| Post-yield stiffness (kN/m) | / | / | 1070 | 1190 | 1310 | 1470 |

| Horizontal yield force (kN) | / | / | 238 | 294 | 355 | 410 |

| Rubber shear modulus (N/mm2) | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 |

| Indexes | C1 | C4 |

|---|---|---|

| Tf (s) | 1.59 | 1.52 |

| Tis (s) | 4.44 | 4.08 |

| Qy/W (%) | 2.7 | 3.2 |

| β | 0.36 | 0.36 |

| MBD (mm) | 488 | 488 |

| (MPa) | 12.38 | 13.17 |

| (MPa) | 29.07 | 26.43 |

| (MPa) | 0.00 | 0.09 |

| Prototype Buildings | Seismically Isolated Schemes | Yield Ratio/% | Tis/s |

|---|---|---|---|

| C1 (79.2 m) | PBI scheme | 1.4 | 4.95 |

| 1.8 | 4.70 | ||

| 2.0 | 4.63 | ||

| 2.2 | 4.58 | ||

| 2.7 | 4.44 | ||

| 3.0 | 4.36 | ||

| 3.4 | 4.27 | ||

| CBI scheme | 1.5 | 4.65 | |

| 1.8 | 4.55 | ||

| 2.0 | 4.48 | ||

| 2.2 | 4.43 | ||

| 2.7 | 4.30 | ||

| 3.0 | 4.23 | ||

| 3.5 | 4.15 | ||

| C4 (65.8 m) | PBI scheme | 1.4 | 4.51 |

| 1.8 | 4.40 | ||

| 2.0 | 4.35 | ||

| 2.2 | 4.30 | ||

| 2.6 | 4.21 | ||

| 3.0 | 4.12 | ||

| 3.5 | 4.00 | ||

| CBI scheme | 1.5 | 4.35 | |

| 1.8 | 4.27 | ||

| 2.0 | 4.22 | ||

| 2.2 | 4.17 | ||

| 2.5 | 4.11 | ||

| 3.0 | 3.99 | ||

| 3.5 | 3.90 |

| Component | Story | Concrete | Section/mm | |

|---|---|---|---|---|

| Column | 1–8 | C50 | 1200 × 1200 | |

| 9–10 | C50 | 1000 × 1000 | ||

| 11–15 | C40 | 1000 × 1000 | ||

| 16–18 | C40 | 800 × 800 | ||

| 19–27 | C30 | 800 × 800 | ||

| Frame beam | 1–15 | C30 | 600 × 900 | |

| 16–27 | C30 | 500 × 900 | ||

| Floor beam | 1–27 | C30 | 350 × 750 | |

| Shear wall | External | Internal | ||

| 1–10 | C50 | 400 | 300 | |

| 11–15 | C40 | 400 | 200 | |

| 16–18 | C40 | 300 | 200 | |

| 19–27 | C30 | 300 | 200 | |

| Height of coupling beam | External | Internal | ||

| 1–3 | Same as shear wall | 1000 | 1000 | |

| 4–27 | 600 | 1000 | ||

| Index | Value |

|---|---|

| Tf (s) | 1.798 |

| Tis (s) | 4.294 |

| Qy/W (%) | 2.3 |

| β | 0.40 ≤ 0.40 |

| MBD (mm) | 788 > 500 |

| (MPa) | 11.1 < 15 |

| (MPa) | 29.95 < 30 |

| (MPa) | 0.00 < 1 |

| Index | Value |

|---|---|

| Tf (s) | 1.798 |

| Tis (s) | 4.294 |

| Qy/W (%) | 2.3 |

| β | 0.37 < 0.38 |

| MBD (mm) | 492 < 500 |

| (MPa) | 11.1 < 15 |

| (MPa) | 27.5 < 30 |

| (MPa) | 0.00 < 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, A.; Yang, C.; Xie, L.; Liu, L.; Zeng, D. Research on the Rational Yield Ratio of Isolation System and Its Application to the Design of Seismically Isolated Reinforced Concrete Frame-Core Tube Tall Buildings. Appl. Sci. 2017, 7, 1191. https://doi.org/10.3390/app7111191

Li A, Yang C, Xie L, Liu L, Zeng D. Research on the Rational Yield Ratio of Isolation System and Its Application to the Design of Seismically Isolated Reinforced Concrete Frame-Core Tube Tall Buildings. Applied Sciences. 2017; 7(11):1191. https://doi.org/10.3390/app7111191

Chicago/Turabian StyleLi, Aiqun, Cantian Yang, Linlin Xie, Lide Liu, and Demin Zeng. 2017. "Research on the Rational Yield Ratio of Isolation System and Its Application to the Design of Seismically Isolated Reinforced Concrete Frame-Core Tube Tall Buildings" Applied Sciences 7, no. 11: 1191. https://doi.org/10.3390/app7111191