Quality Changes of N-3 PUFAs Enriched and Conventional Eggs under Different Home Storage Conditions with Wireless Sensor Network

Abstract

:Practical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experiment Design

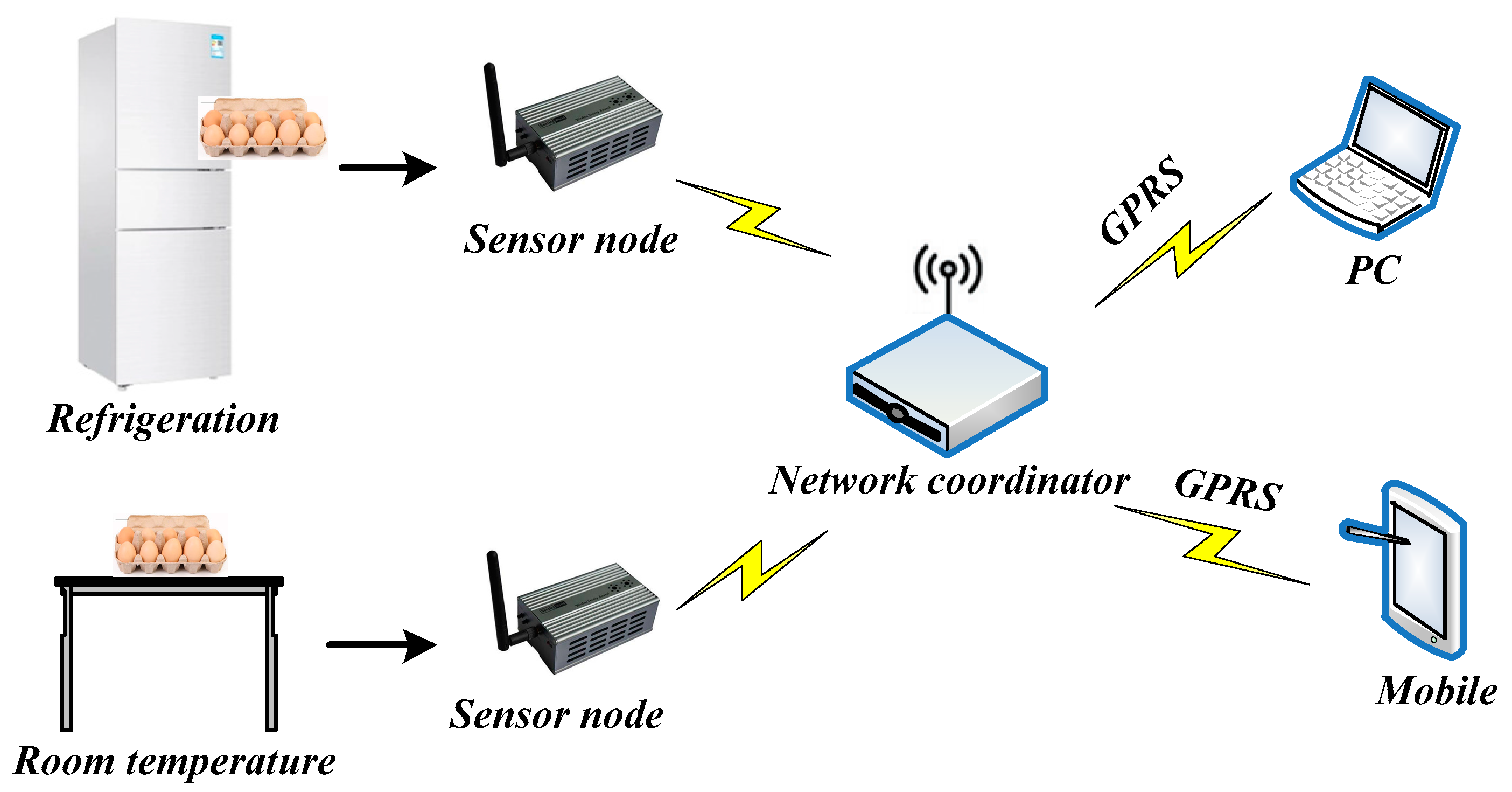

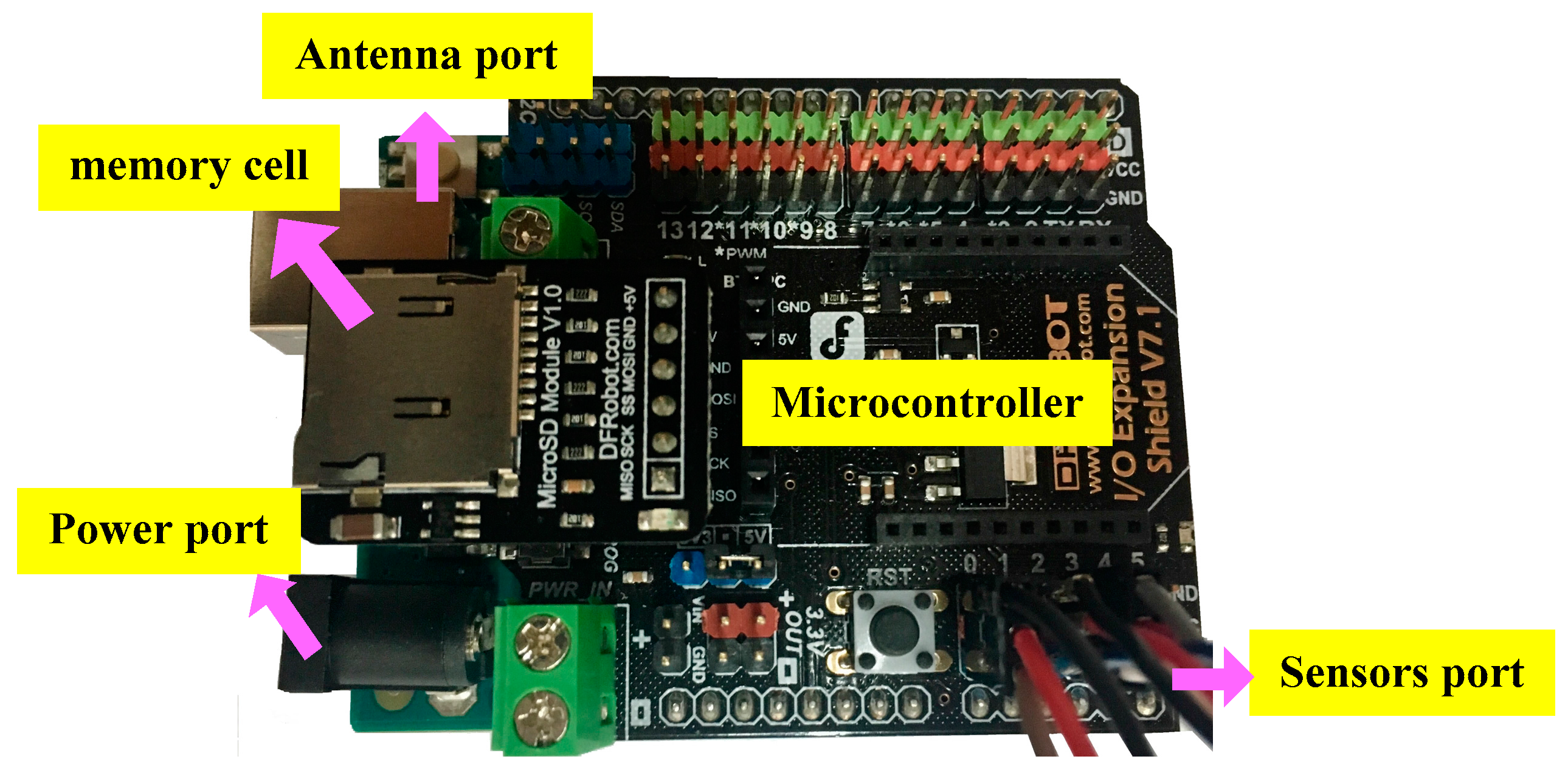

2.3. Monitoring Scheme

2.4. Egg Quality Parameters

2.5. Statistical Analysis

3. Results and Discussion

3.1. Performance Evaluation of the WSN

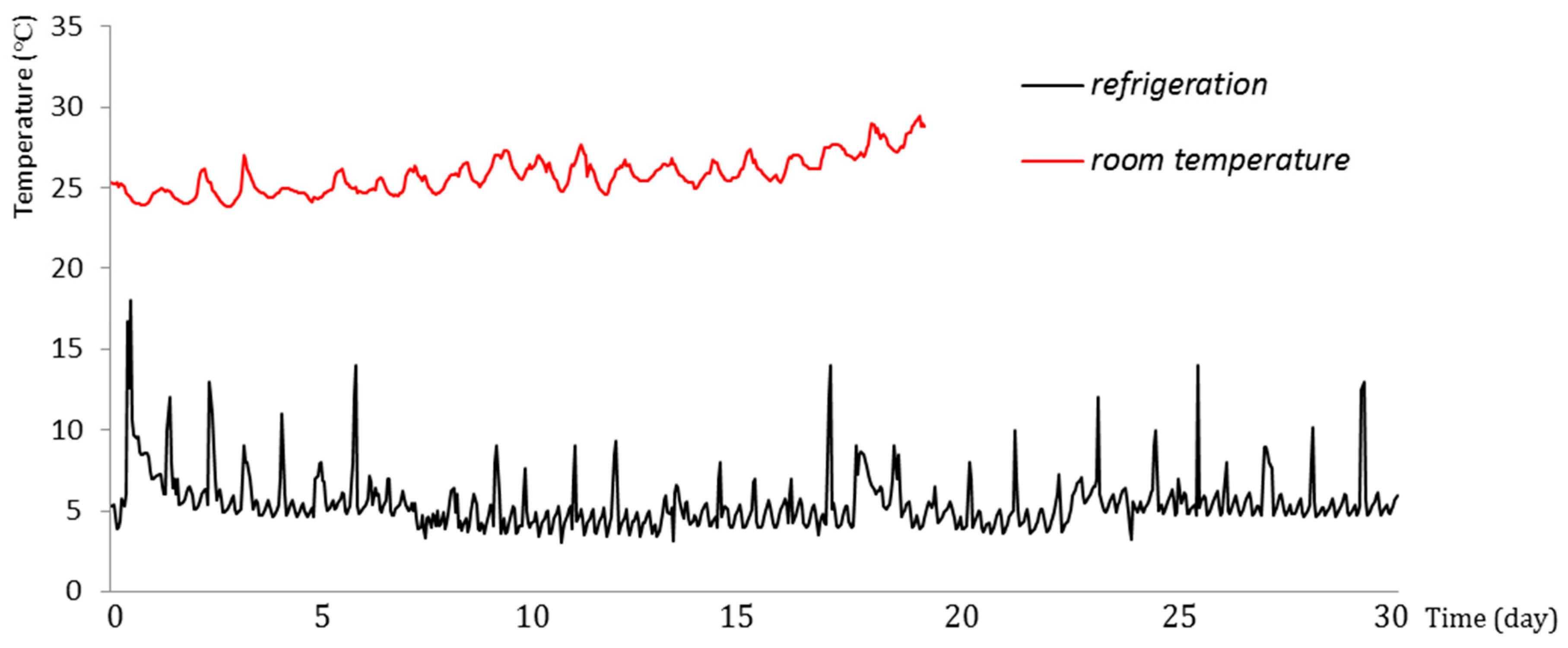

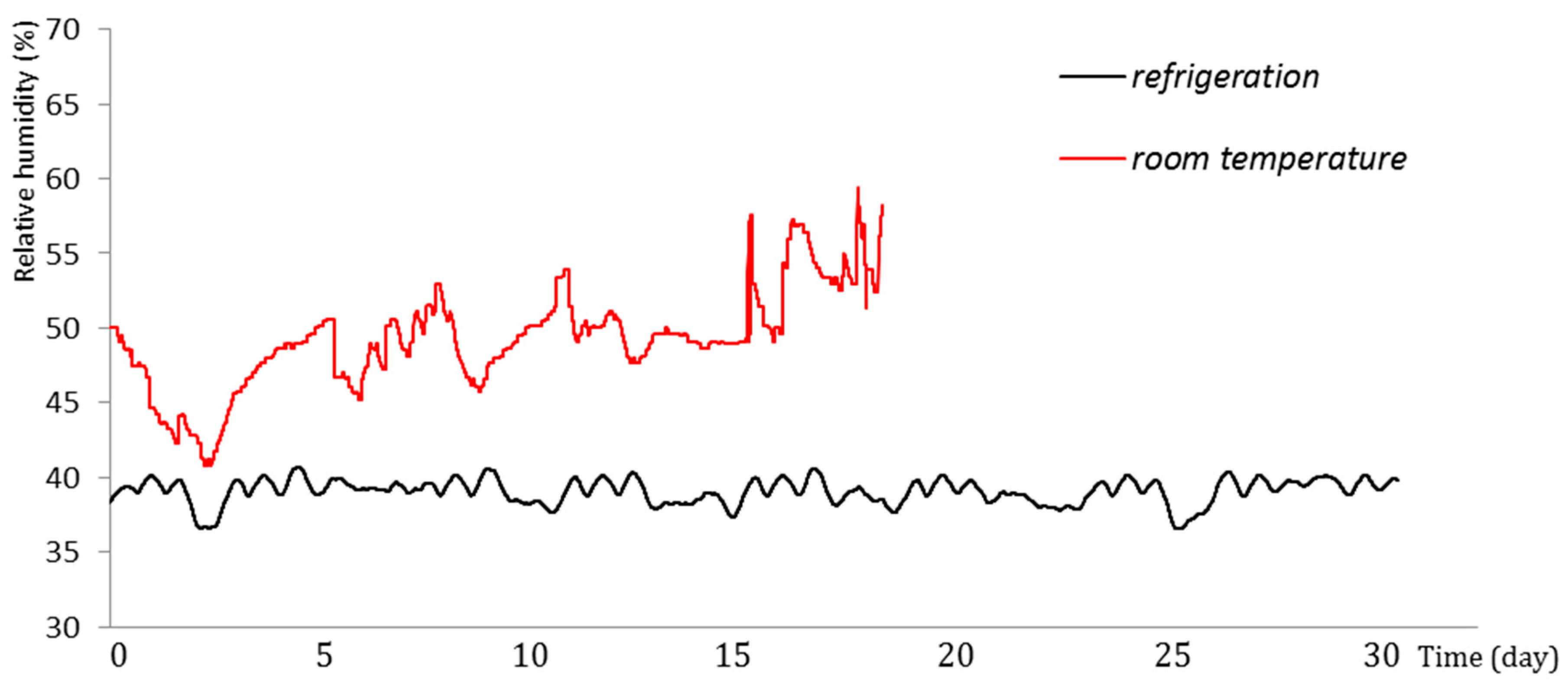

3.2. Fluctuation of Environment Factors

3.2.1. Time-Temperature Fluctuation

3.2.2. Time-Humidity Fluctuation

3.3. Eggs Quality Changes

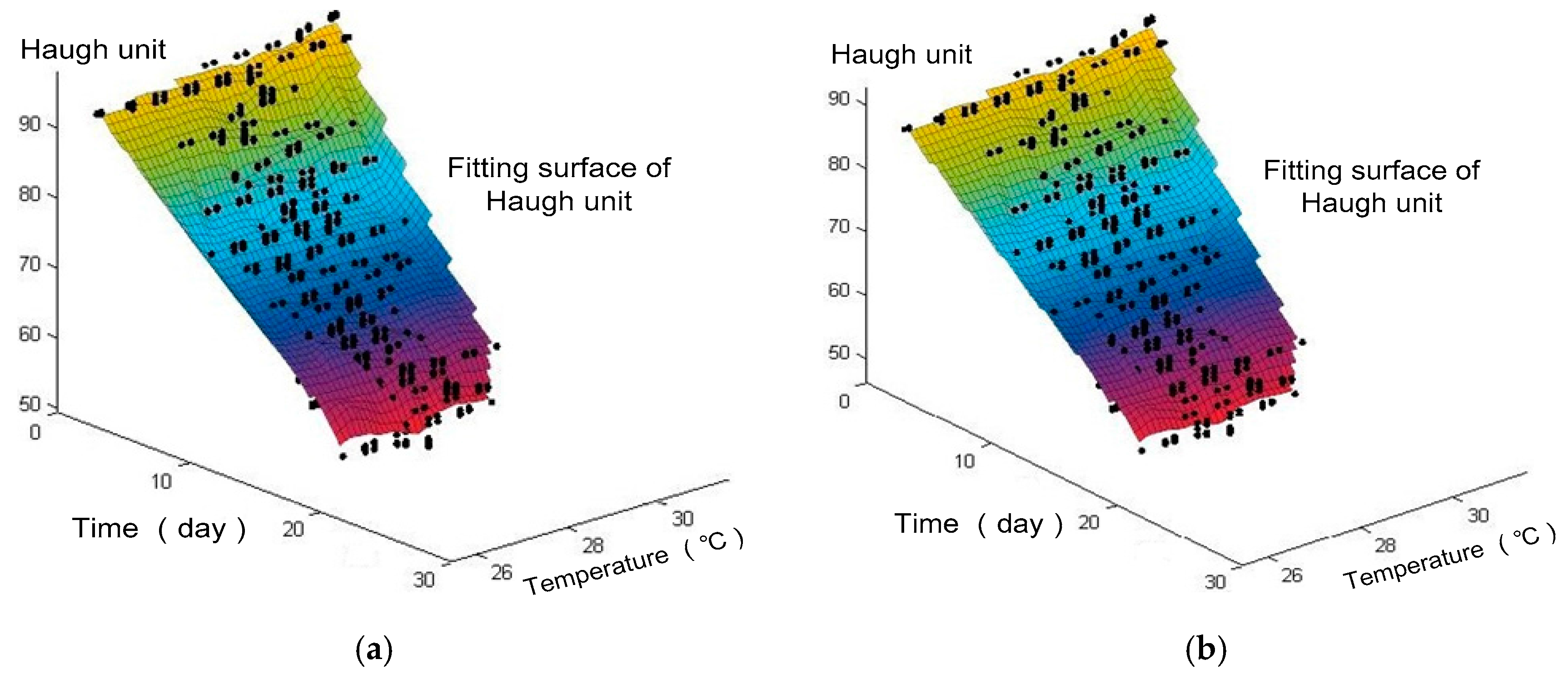

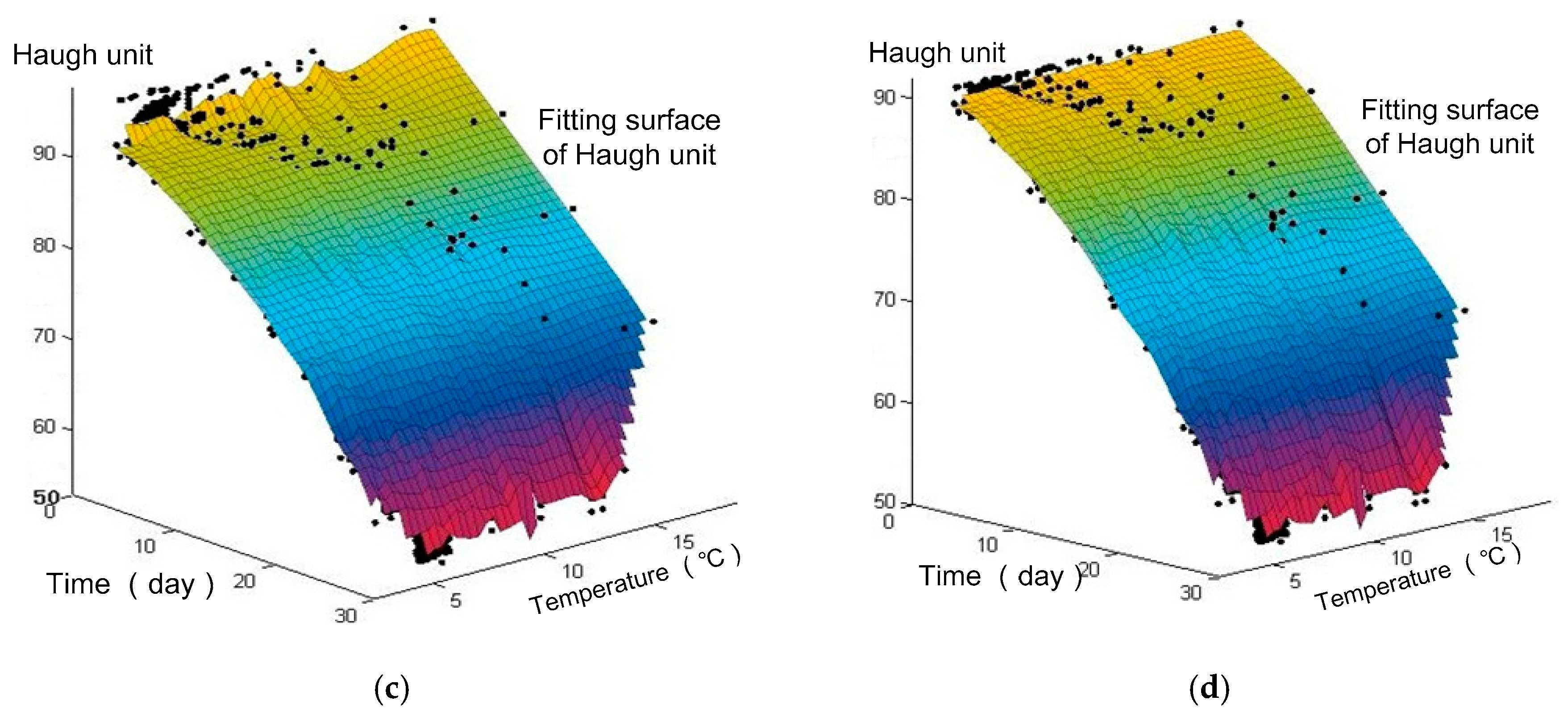

3.3.1. Changes of Haugh Unit (HU)

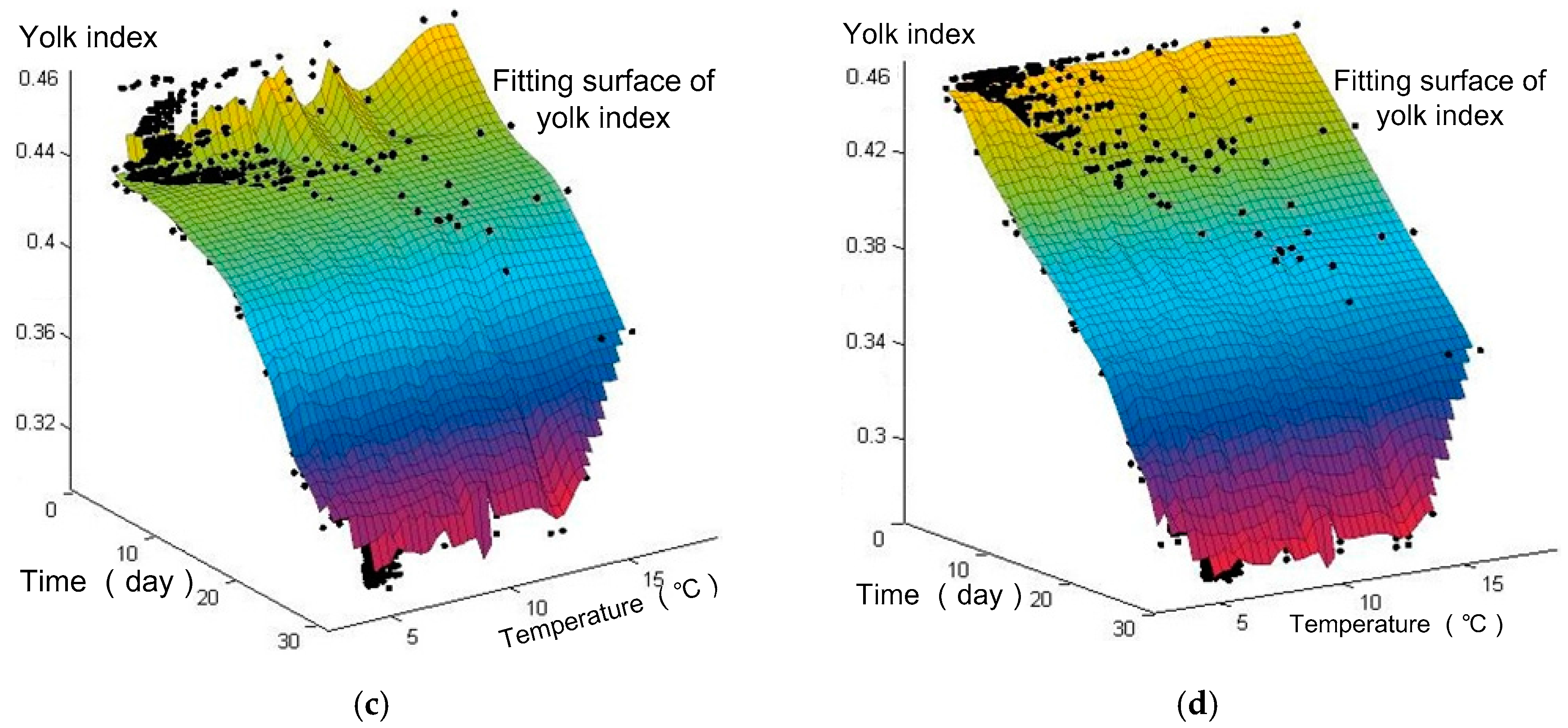

3.3.2. Changes of YI

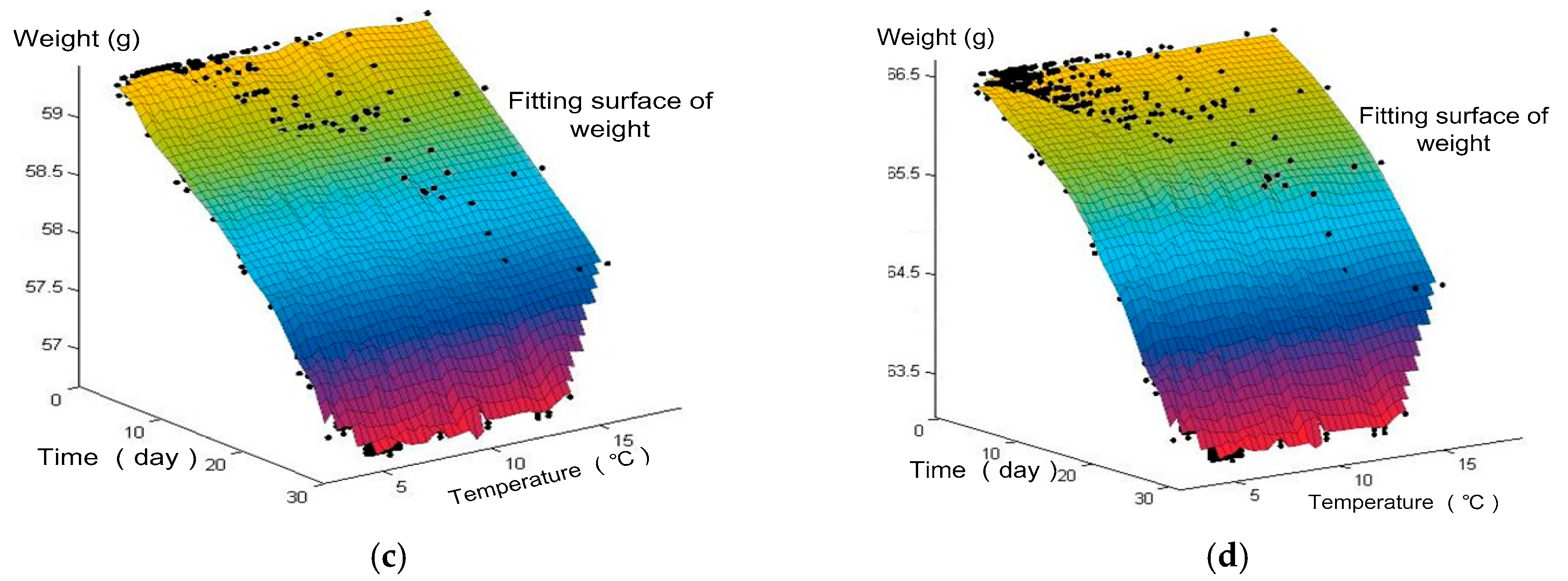

3.3.3. Changes of Weight

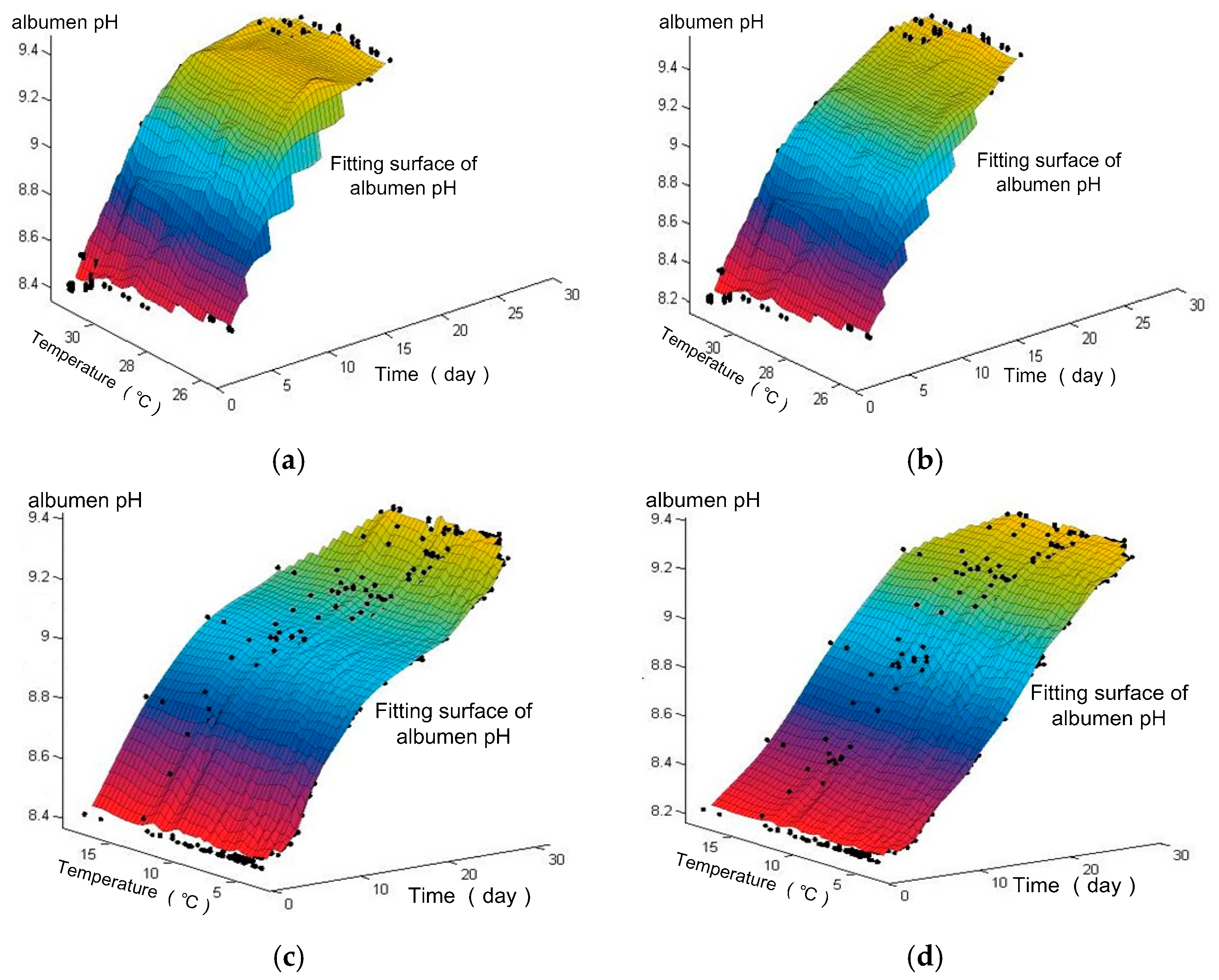

3.3.4. Changes of Albumen pH

3.3.5. Comparison of Quality Changes of N-3 PUFAs Enriched and Conventional Eggs

4. Conclusions and Implications

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ebeid, T.A. The impact of incorporation of n-3 fatty acids into eggs on ovarian follicular development, immune response, antioxidative status and tibial bone characteristics in aged laying hensx. Animal 2011, 5, 1554–1562. [Google Scholar] [CrossRef] [PubMed]

- Adabi, S.G.; Fani, A.; Ceyian, N.; Hajibabaei, A.; Casey, N.H. Enrichment of quail (Coturnix cot. Japonica) eggs by omega-3 fatty acids and its nutritional effect on young healthy women. Eur. Poult. Sci. 2016, 80, 20. [Google Scholar]

- Gladkowski, W.; Kielbowicz, G.; Chojnacka, A.; Bobak, L.; Spychaj, R.; Dobrzanski, Z.; Trziszka, T.; Wawrzenczyk, C. The effect of feed supplementation with dietary sources of n-3 polyunsaturated fatty acids, flaxseed and algae schizochytrium sp., on their incorporation into lipid fractions of japanese quail eggs. Int. J. Food Sci. Technol. 2014, 49, 1876–1885. [Google Scholar] [CrossRef]

- Panse, M.L.; Atakare, S.P.; Hegde, M.V.; Kadam, S.S. Omega-3 egg. In Omega-3 Fatty Acids: Keys to Nutritional Health; Hegde, M.V., Zanwar, A.A., Adekar, S.P., Eds.; Springer: Cham, Switzerland, 2016; pp. 51–66. [Google Scholar]

- Liu, X.D.; Jang, A.; Kim, D.H.; Lee, B.D.; Lee, M.; Jo, C. Effect of combination of chitosan coating and irradiation on physicochemical and functional properties of chicken egg during room-temperature storage. Radiat. Phys. Chem. 2009, 78, 589–591. [Google Scholar] [CrossRef]

- Parpinello, G.P.; Meluzzi, A.; Sirri, F.; Tallarico, N.; Versari, A. Sensory evaluation of egg products and eggs laid from hens fed diets with different fatty acid composition and supplemented with antioxidants. Food Res. Int. 2006, 39, 47–52. [Google Scholar] [CrossRef]

- Kakani, R.; Fowler, J.; Haq, A.U.; Murphy, E.J.; Rosenberger, T.A.; Berhow, M.; Bailey, C.A. Camelina meal increases egg n-3 fatty acid content without altering quality or production in laying hens. Lipids 2012, 47, 519–526. [Google Scholar] [CrossRef] [PubMed]

- Adeniyi, P.O.; Obatolu, V.A.; Farinde, E.O. Comparative evaluation of cholesterol content and storage quality of chicken and quail eggs. World J. Nutr. Health 2016, 4, 5–9. [Google Scholar]

- Ragni, L.; Al-Shami, A.; Mikhaylenko, G.; Tang, J. Dielectric characterization of hen eggs during storage. J. Food Eng. 2007, 82, 450–459. [Google Scholar] [CrossRef]

- Alsobayel, A.A.; Albadry, M.A. Effect of storage period and strain of layer on internal and external quality characteristics of eggs marketed in Riyadh area. J. Saudi Soc. Agric. Sci. 2011, 10, 41–45. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Wang, X.; Wu, S.; Zhang, H.; Yue, H.; Qi, G.; Li, J. Effect of dietary protein sources and storage temperatures on egg internal quality of stored shell eggs. Anim. Nutr. 2015, 1, 299–304. [Google Scholar] [CrossRef]

- Singh, J.; Sharma, H.K.; Premi, M.; Kumari, K. Effect of storage conditions of egg on rheological properties of liquid whole egg. J. Food Sci. Technol. 2014, 51, 543–550. [Google Scholar] [CrossRef] [PubMed]

- Akyurek, H.; Okur, A.A. Effect of storage time, temperature and hen age on egg quality in free-range layer hens. J. Anim. Vet. Adv. 2012, 8, 1953–1958. [Google Scholar]

- Lin, H.; Zhao, J.; Sun, L.; Chen, Q.; Zhou, F. Freshness measurement of eggs using near infrared (NIR) spectroscopy and multivariate data analysis. Innov. Food Sci. Emerg. Technol. 2011, 12, 182–186. [Google Scholar] [CrossRef]

- Roccato, A.; Uyttendaele, M.; Membré, J.-M. Analysis of domestic refrigerator temperatures and home storage time distributions for shelf-life studies and food safety risk assessment. Food Res. Int. 2017, 96, 171–181. [Google Scholar] [CrossRef] [PubMed]

- Garrido, V.; García-Jalón, I.; Vitas, A.I. Temperature distribution in Spanish domestic refrigerators and its effect on listeria monocytogenes growth in sliced ready-to-eat ham. Food Control 2010, 21, 896–901. [Google Scholar] [CrossRef]

- Saccomori, F.; Wigmann, É.F.; Bernardi, A.O.; Alcano-González Mde, J.; Copetti, M.V. Influence of storage temperature on growth of Penicillium polonicum and Penicillium glabrum and potential for deterioration of frozen chicken nuggets. Int. J. Food Microbiol. 2015, 200, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Aung, M.M.; Chang, Y.S. Temperature management for the quality assurance of a perishable food supply chain. Food Control 2014, 40, 198–207. [Google Scholar] [CrossRef]

- The Commission of the European Communities. Commission REgulation (EC) No 589/2008. Off. J. Eur. Union 2008, 163, 6–23. [Google Scholar]

- United States Department of Agricultural. Egg Grading Manual. Available online: https://www.ams.usda.gov/publications/content/egg-grading-manual (accessed on 25 Septemebr 2017).

- Parreno-Marchante, A.; Alvarez-Melcon, A.; Trebar, M.; Filippin, P. Advanced traceability system in aquaculture supply chain. J. Food Eng. 2014, 122, 99–109. [Google Scholar] [CrossRef]

- Cedro, T.; Calixto, L.; Gaspar, A.; Curvello, F.; Hora, A. Internal quality of conventional and omega-3-enriched commercial eggs stored under different temperatures. Braz. J. Poult. Sci. 2009, 11, 181–185. [Google Scholar] [CrossRef]

- Adame, T.; Bel, A.; Carreras, A.; Melia-Segui, J.; Oliver, M.; Pous, R. Cuidats: An RFID-WSN hybrid monitoring system for smart health care environments. Future Gener. Comput. Syst. Int. J. Esci. 2018, 78, 602–615. [Google Scholar] [CrossRef]

- Altaharwa, R.; Abdulkareem, S.; Mansoor, A.M. Performance Evaluations Power Consumption, and Heterogeneousity of Wsns in Medical Field; Springer: Singapore, 2018; pp. 231–240. [Google Scholar]

- Qi, L.; Xu, M.; Fu, Z.; Mira, T.; Zhang, X. (CSLDS)-S-2: A WSN-based perishable food shelf-life prediction and lsfo strategy decision support system in cold chain logistics. Food Control 2014, 38, 19–29. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Matetić, M.; Zhou, H.; Zhang, X.; Jemrić, T. Postharvest quality monitoring and variance analysis of peach and nectarine cold chain with multi-sensors technology. Appl. Sci. 2017, 7, 133. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, X.; Zhang, X.; Chen, E.; Li, J. Effect of the quality property of table grapes in cold chain logistics-integrated WSN and AOW. Appl. Sci. 2015, 5, 747–760. [Google Scholar] [CrossRef]

- Xu, G.; Shen, W.; Wang, X. Applications of wireless sensor networks in marine environment monitoring: A survey. Sensors 2014, 14, 16932–16954. [Google Scholar] [CrossRef] [PubMed]

- Karoui, R.; Kemps, B.; Bamelis, F.; De Ketelaere, B.; Decuypere, E.; De Baerdemaeker, J. Methods to evaluate egg freshness in research and industry: A review. Eur. Food Res. Technol. 2005, 222, 727–732. [Google Scholar] [CrossRef]

- Ahmadi, S.; Soleimanian-Zad, S.; Sheikh-Zeinoddin, M. Effect of heat, nisin and ethylene diamine tetra-acetate treatments on shelf life extension of liquid whole egg. Int. J. Food Sci. Technol. 2016, 51, 396–402. [Google Scholar] [CrossRef]

- Haugh, R.R. The Haugh unit for measuring egg quality. U.S. Egg Poult. Mag. 1937, 43, 552–555. [Google Scholar]

- Afonso Freitas, M.; Borges, W.; Lee Ho, L. A statistical model for shelf life estimation using sensory evaluations scores. Commun. Stat. 2003, 32, 1559–1589. [Google Scholar] [CrossRef]

- Ruiz-Garcia, L.; Barreiro, P.; Robla, J.I. Performance of ZigBee-based wireless sensor nodes for real-time monitoring of fruit logistics. J. Food Eng. 2008, 87, 405–415. [Google Scholar] [CrossRef] [Green Version]

- James, C.; Onarinde, B.A.; James, S.J. The use and performance of household refrigerators: A review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 160–179. [Google Scholar] [CrossRef]

- Eke, M.O.; Olaitan, N.I.; Ochefu, J.H. Effect of storage conditions on the quality attributes of shell (table) eggs. Niger. Food J. 2013, 31, 18–24. [Google Scholar] [CrossRef]

- Samli, H.E.; Agma, A.; Senkoylu, N. Effects of storage time and temperature on egg quality in old laying hens. J. Appl. Poult. Res. 2005, 14, 548–553. [Google Scholar] [CrossRef]

- Silversides, F.G.; Scott, T.A. Effect of storage and layer age on quality of eggs from two lines of hens. Poult. Sci. 2001, 80, 1240–1245. [Google Scholar] [CrossRef] [PubMed]

- Wardy, W.; Torrico, D.D.; Jirangrat, W.; No, H.K.; Saalia, F.K.; Prinyawiwatkul, W. Chitosan-soybean oil emulsion coating affects physico-functional and sensory quality of eggs during storage. LWT Food Sci. Technol. 2011, 44, 2349–2355. [Google Scholar] [CrossRef]

- Yannakopoulos, A.L.; Tservenigousi, A.S. Quality characteristics of quail eggs. Br. Poult. Sci. 1986, 27, 171–176. [Google Scholar] [CrossRef]

- Schmidt, L.D.; Blank, G.; Boros, D.; Slominski, B.A. The nutritive value of egg by-products and their potential bactericidal activity: In vitro and in vivo studies. J. Sci. Food Agric. 2007, 87, 378–387. [Google Scholar] [CrossRef]

- Al-Hajo, N.N.A.; Zangana, B.S.R.; Al-Janabi, L.A.F.; Al-Khalani, F.M.H. Effect of coating materials (gelatin) and storage time on internal quality of chicken and quail eggs under refrigerated storage. Egypt. Poult. Sci. J. 2012, 32, 107–115. [Google Scholar]

- Mazalli, M.R.; Faria, D.E.; Salvado, D.; Ito, D.T. A comparison of the feeding value of different sources of fats for laying hens: 1. Performance characteristics. J. Appl. Poult. Res. 2004, 13, 274–279. [Google Scholar] [CrossRef]

- Pappas, A.C.; Acamovic, T.; Sparks, N.H.C.; Surai, P.F.; McDevitt, R.M. Effects of supplementing broiler breeder diets with organic selenium and polyunsaturated fatty acids on egg quality during storage. Poult. Sci. 2005, 84, 865–874. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Temperature Sensor | Humidity Sensor |

|---|---|---|

| Sensor range | −55–125 °C | 0–99% |

| Data accuracy | 0.1 °C | 1% |

| Response time | 5 s | 5 s |

| Sampling interval | 1.5 s | 1.5 s |

| Voltage range | 3.0–5.5 V | 3.0–6.0 V |

| Power consumption | <0.1 mW | <0.1 mW |

| Battery charge | 90–99% (1 day) | |

| Packet losses rate | <0.5% (3000 *) | |

| Sample | Parameters | Initial Value | 6 Days | 12 Days | 18 Days |

|---|---|---|---|---|---|

| n-3 PUFAs enriched eggs | Weight | 61.31 ± 4.82 a | 59.67 ± 4.91 a,b | 59.04 ± 4.68 b,c | 57.53 ± 4.32 c |

| HU ① | 95.66 ± 1.41 a | 78.98 ± 3.73 b | 67.35 ± 2.17 c | 51.42 ± 1.84 d | |

| YI ② | 0.46 ± 0.03 a | 0.28 ± 0.02 c | 0.21 ± 0.02 c | 0.18 ± 0.03 c | |

| Albumen pH | 8.40 ± 0.12 a | 9.18 ± 0.11 b | 9.35 ± 0.37 b,c | 9.42 ± 0.14 c | |

| Conventional eggs | Weight | 64.33 ± 3.13 a | 63.04 ± 3.11 a,b | 61.01 ± 2.67 b | 58.59 ± 3.37 c |

| HU ① | 90.56 ± 0.39 a | 75.66 ± 4.14 b | 63.63 ± 1.51 c | 48.25 ± 3.73 d | |

| YI ② | 0.45 ± 0.01 a | 0.30 ± 0.02 b | 0.23 ± 0.01 c | 0.19 ± 0.03 c | |

| Albumen pH | 8.24 ± 0.18 a | 8.98 ± 0.37 a,b | 9.28 ± 0.17 b,c | 9.51 ± 0.12 c |

| Sample | Parameter | Initial Value | 9 Days | 18 Days | 30 Days |

|---|---|---|---|---|---|

| n-3 PUFAs enriched eggs | Weight | 59.34 ± 2.81 a | 59.03 ± 2.13 a,b | 58.18 ± 2.31 b | 56.75 ± 2.05 c |

| HU * | 95.66 ± 1.44 a | 88.97 ± 3.68 a,b | 76.62 ± 6.33 c | 54.89 ± 4.03 d | |

| YI * | 0.46 ± 0.01 a | 0.43 ± 0.01 b | 0.38 ± 0.03 b | 0.30 ± 0.01 c | |

| albumen pH | 8.40 ± 0.14 a | 8.67 ± 0.73 a | 9.04 ± 0.15 b,c | 9.36 ± 0.12 c | |

| Conventional eggs | Weight | 66.45 ± 3.71 a | 66.43 ± 3.87 a | 65.32 ± 3.25 b | 64.18 ± 3.43 c |

| HU * | 90.56 ± 0.43 a | 86.93 ± 1.52 a,b | 72.69 ± 2.31 b,c | 52.14 ± 2.37 d | |

| YI * | 0.45 ± 0.02 a | 0.42 ± 0.01 a,b | 0.36 ± 0.02 b,c | 0.27 ± 0.03 c | |

| albumen pH | 8.24 ± 0.13 a | 8.38 ± 0.08 a | 8.99 ± 0.23 b,c | 9.41 ± 0.29 c |

| Sample | Weight Loss | Loss Rate | HU * Decline | HU * Decline Rate | YI * Decline | YI * Decline Rate | Albumen pH Increase | pH Increase Rate |

|---|---|---|---|---|---|---|---|---|

| n-3 ref ② | 2.5 a | 4.2% | 40.8 a | 42.6% | 0.2 a | 34.7% | 0.9 a | 11.4% |

| con ref ③ | 2.3 a | 3.4% | 38.4 a | 42.4% | 0.2 a | 40.0% | 1.2 a | 14.2% |

| n-3 room ④ | 3.8 b | 6.2% | 44.2 b | 46.2% | 0.3 b | 60.9% | 1.0 a,b | 12.1% |

| con room ⑤ | 5.7 b | 8.9% | 42.2 a,b | 46.6% | 0.3 b | 57.8% | 1.3 b | 13.4% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Zhang, X.; Jia, Y.; Liu, X. Quality Changes of N-3 PUFAs Enriched and Conventional Eggs under Different Home Storage Conditions with Wireless Sensor Network. Appl. Sci. 2017, 7, 1151. https://doi.org/10.3390/app7111151

Li W, Zhang X, Jia Y, Liu X. Quality Changes of N-3 PUFAs Enriched and Conventional Eggs under Different Home Storage Conditions with Wireless Sensor Network. Applied Sciences. 2017; 7(11):1151. https://doi.org/10.3390/app7111151

Chicago/Turabian StyleLi, Wenkang, Xiaoshuan Zhang, Yaxiong Jia, and Xue Liu. 2017. "Quality Changes of N-3 PUFAs Enriched and Conventional Eggs under Different Home Storage Conditions with Wireless Sensor Network" Applied Sciences 7, no. 11: 1151. https://doi.org/10.3390/app7111151