1. Introduction

The thermal energy produced during the welding process in the area around the welding beads is not equally distributed. Contraction is caused by the temperature of the heat affected zone (HAZ)—the area where the filler material is applied to the welding plates—in conjunction with the temperature of the surrounding areas. This internal tension arises from solidification of the filler metal and cooling of the material. When the welding workpiece cools to room temperature, the filler metal and the welding beads respond differently, leading to a problematic contraction on the welding plate. This results in high residual stress around the area where the heat affects the welding beads and the workpiece, causing a permanent deformation to offset the internal stress that the welding produces on the plate. If such deformation cannot be prevented, the strength of the workpiece will likely be compromised, at best reducing the lifespan of the material and at worst causing serious accidents.

Due to requirements regarding welding speed, welding quality, and plate thickness (3–100 mm or greater), gas metal arc welding (GMAW) is generally adopted in practical applications. A shielding gas is used to protect against melting pools during welding. When workpieces are melted and joined together, the welding beads are subjected to a high temperature from a highly concentrated heat source, causing deformation. The application of jig fixtures is the most common method to reduce such deformation of the workpiece. Many researchers have worked on finding solutions to reduce welding deformation. Ueda and Yamakawa [

1] suggested using the finite element method (FEM) to simulate a thermoplastic phenomenon during welding. Ando et al. [

2] studied pipe welding, and applied an outside heat source to the welding tube to reduce residual stress. They were able to reduce the residual stress distribution and thereby decrease workpiece deformation. Wang et al. [

3] found that applying a linear heat source yields significant deformation, which is detrimental for large-scale structures. Ueda et al. [

4] applied a linear heat source opposite the welding arc to reduce buckling and distortion. Guan et al. [

5] studied the application of low stress and no distortion (LSND) surface-plate welding to prevent buckling distortion in thin-walled structures. A method called dynamically controlled LSND has been proposed to greatly reduce residual stress and buckling in flat-position welding by applying a cooling source (between a low temperature and a cold temperature) to the back of the welding arc [

6]. Mochizuki et al. [

7] applied a cooling source on T-butt welding workpieces, and thus significantly reduced deformation. Schenk et al. [

8] applied jigs to T-butt welding as well as lap-joint welding and found that the jigs greatly reduced residual stress and deformation. Ziaee et al. [

9] found that adding outside welding to sheet metal welding greatly reduced buckling, but it was impossible to eliminate buckling completely. Hajduk et al. [

10] researched manual and machine-controlled spot welding in the automotive industry to investigate how jig attachments could control deformation. Park et al. [

11] found that applying pressure to the four corners of a workpiece could inhibit welding deformation. Deng and Kiyoshima [

12] used the FEM to predict welding residual stresses in a SUS304 girth-welded pipe induced by heating with a tungsten inert gas arc welding torch. Gua et al. [

13] studied laser welding in 13 mm thick high-strength steel in the two-dimensional (2D) position to reduce welding defects in the flat welding position. The fluid dynamic simulation results showed that an appropriate balance between surface tension, hydrostatic pressure (gravity), and recoil pressure from the metal vapor could be achieved to assist the welding. Nezamdost et al. [

14] investigated the temperature distribution and residual stress in submerged arc welding for pipeline steel by using the Goldak model and considering thermophysical material properties. The proposed 2D axis-symmetric model could be employed to simulate thermal cycles and welding residual stress in test steel. Using jigs to inhibit deformation is currently the most common method in mechanical welding. However, apart from Ma et al. [

15] applying jigs to common flat steel plates of type SS400, not much research has been conducted using simulations to discuss the relationships between jig position and plate deformation.

In the present study, we used the finite element analysis software MSC.MARC to analyze, test, and discuss the residual stress and deformation on a workpiece when a jig fixture is or is not applied. We then propose the best position for applying a jig fixture to prevent welding deformation in a workpiece.

2. Methods

Welding is generally considered a complex mechanical, non-linear phenomenon. From the macroscopic perspective, welding problems are related to heat, heat transfer, and solid elastic–plastic mechanical issues. However, at the microscopic level, problems are also connected with the welding plate material, the filler material, and their solidification relationship. The present research focuses on the macroscopic level to analyze and discuss the welding process. Welding is a thermomechanical coupling problem. As it is very difficult to analyze a solid-bodied elastic–plastic energy problem with linear partial differential equations, it is highly unrealistic to seek analytical solutions in this way. Scientists and engineers therefore have found methods that chart a middle course between mathematical theory and applied science by developing numerical analysis that yields results close to analytical ones, including the finite difference method (FDM), the boundary element method (BEM), the boundary domain integral method (BDIM), the FEM, and the finite volume method (FVM).

In GMAW, an electric arc is produced between the consumable wire electrodes and the workpieces, heating the metal of the workpieces and thereby melting and joining them. The welding pool thus formed has a heat flux moment, which transposes heat to the welding workpieces, causing counteractive movement. The entire welding process is therefore strongly influenced by the movement of heat, and simulation using numerical analysis is crucial for obtaining accurate data. Krutz et al. [

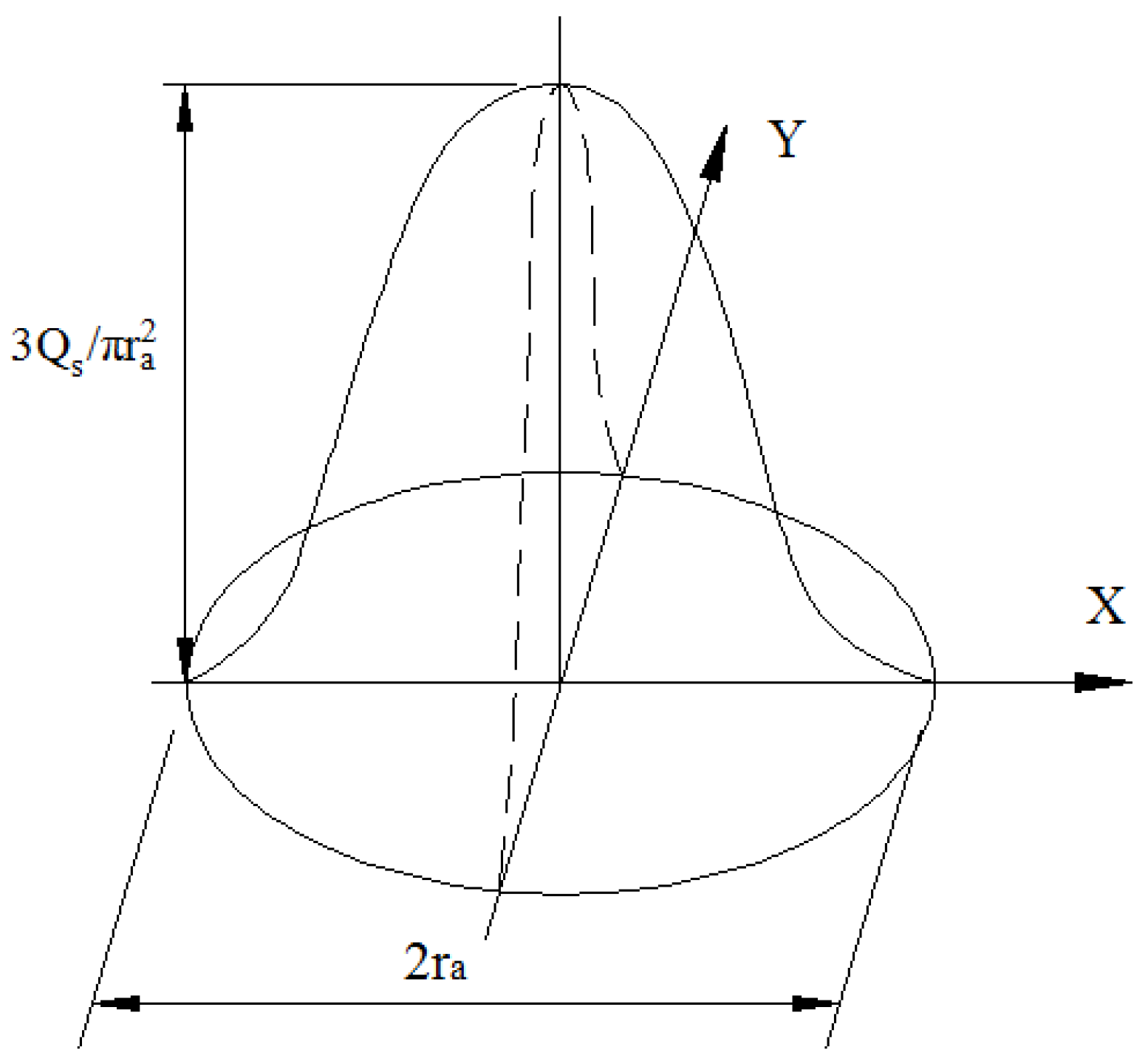

16] combined the Gaussian normal heat source distribution model with the finite element method to simulate the welding process. The Gaussian normal heat source distribution model is the most extensive application of heat source analysis for flat welding (

Figure 1); its equations are:

where:

ra is the radius of a heat spot and represents a heat strength of 95% for electronic arc welding applied to a workpiece;

r is the radius of the welding heat source;

q(

x,

y) stands for the heat density at a distance

r from the heat center;

Qs is the amount of heat distribution during welding; and

η is the efficiency of the welding heat.

In 1983, Eagar and Tsai [

17] were the first to study three-dimensional (3D) moving ellipsoid heat sources. This form of heat source model completely overcomes the weaknesses of the 2D Gaussian normal distribution heat source model, so even heat deep beneath the welding surface can be simulated. The result is similar to an actual electric arc welding outcome because it is not a simple surface analysis of the heat situation at the welding bead. The proposed equation is

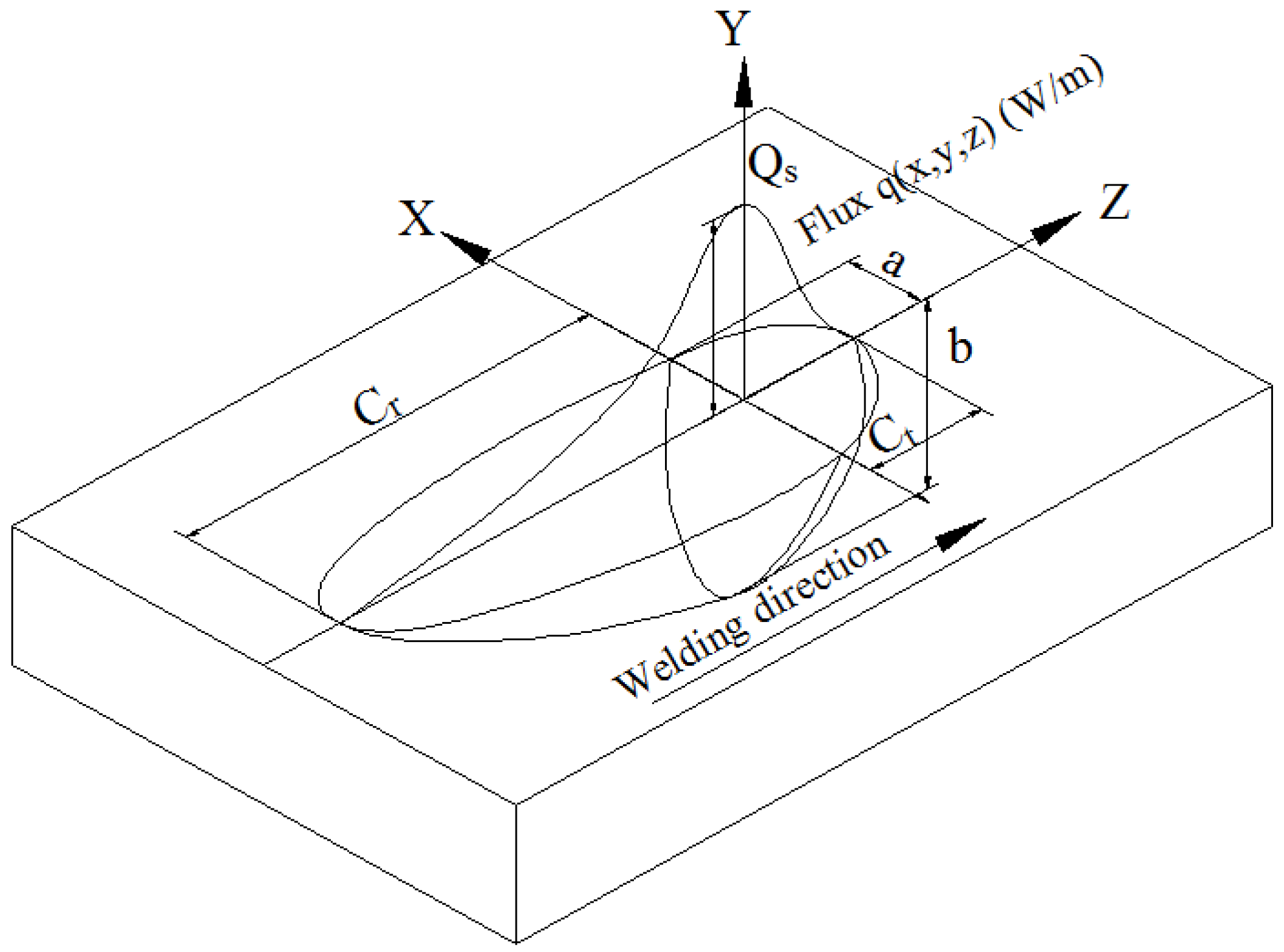

However, experimental results have shown that the temperature gradient is very steep for the first half of the welding pool but not for the second half. Goldak et al. [

18] therefore made the welding heat source ellipsoid, combining two half ellipses into an ellipsoid of Gaussian heat source distribution, as shown in

Figure 2. The modified equations are

where:

Qs is the heat distribution of the welding heat source;

qf(

x,

y,

z) is the first half of the ellipsoid heat distribution amount at a point (

x,

y,

z);

qr(

x,

y,

z) is the second half of the ellipsoid heat distribution amount at a point (

x,

y,

z);

a is the half width of the distributed heat source;

b is the welding heat source depth;

cf is the length of the first half of the ellipsoid;

cr is the length of the other half of the ellipsoid;

ff is the strength distribution on the first half of the ellipsoid;

fr is the strength distribution on the other half of the ellipsoid; and

x,

y, and

z are the moving coordinates of the heat source.

Since the welding heat source in MSC.MARC software adopts the ellipsoid Gaussian heat source distribution model depicted in

Figure 2, the welding simulation for a moving straight line and for a heat source applied in a single direction can be directly used in a simulation study. However, if the heat source spreads in a non-linear pattern or does not conform to the ellipsoid Gaussian normal distribution, another subroutine should be designed and inserted in MSC.MARC to play the role of this heat source [

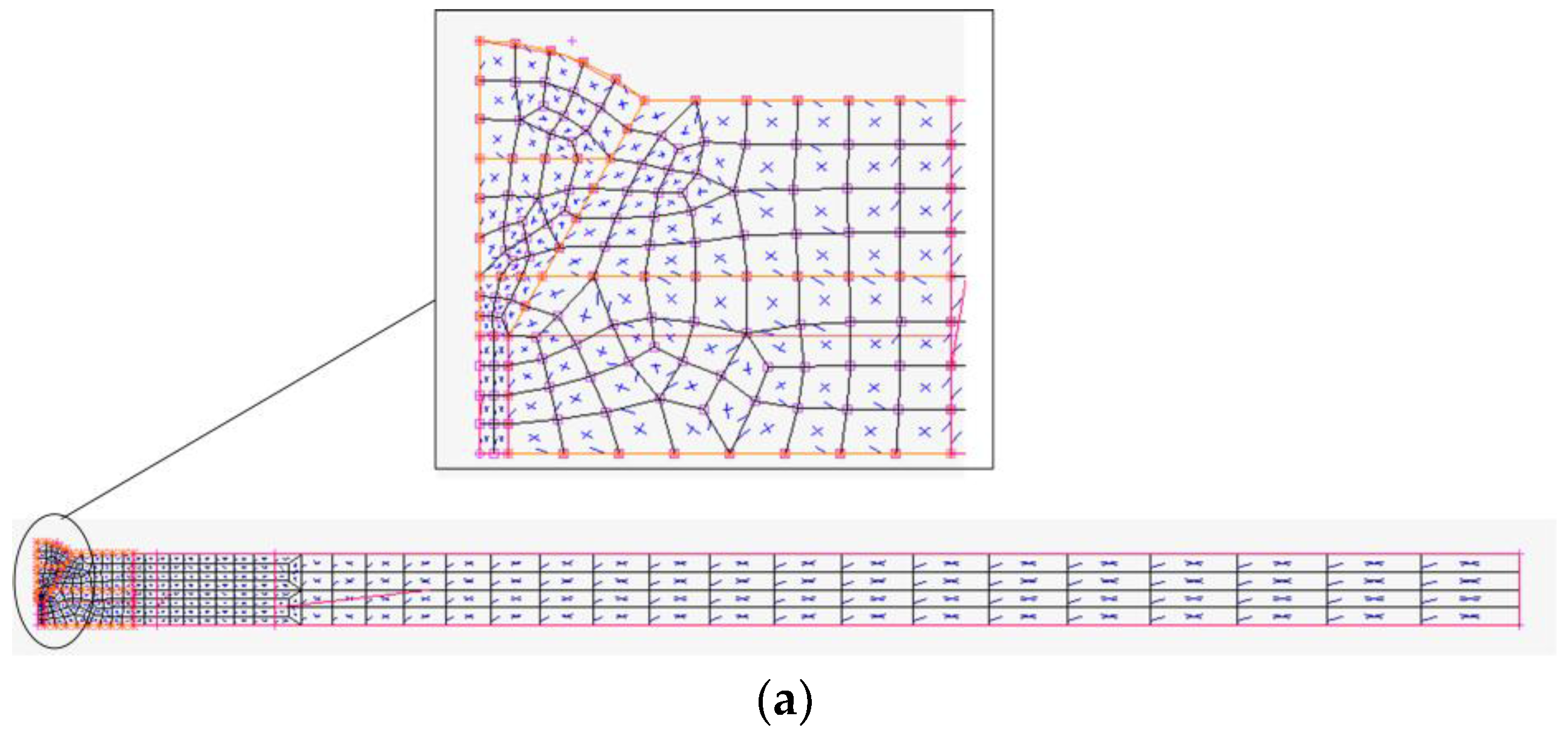

19]. Our research studies the simulation of single-V butt welding using two steel plates 300 × 125 × 6 mm of type SUS304 with a 60° groove angle. The dimensions of the plates follow the specifications in AWS D1.6:2007—Structural Welding Code—Stainless Steel for a horizontal sample plate welding simulation, as shown [

20]. Since the geometric shape of the welding pieces is quite simple, inserting a 2D drafting frame designed by Solidwork into MSC.MARC was sufficient to build a grid plan. After a 2D grid was generated for all four sides, additional mesh density was added to the area of the welding bead, as shown in

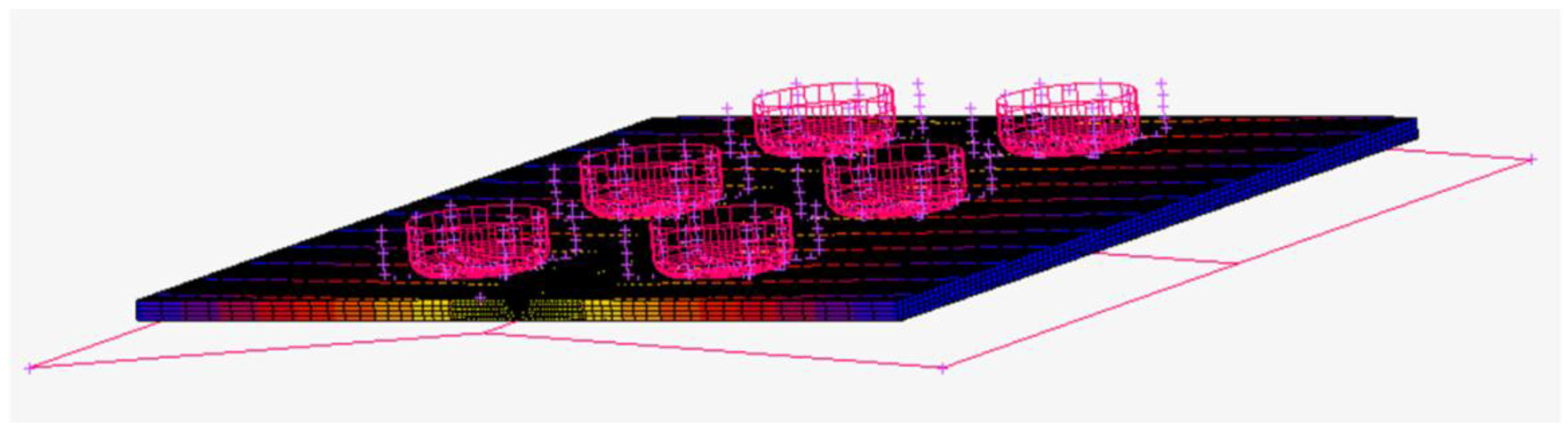

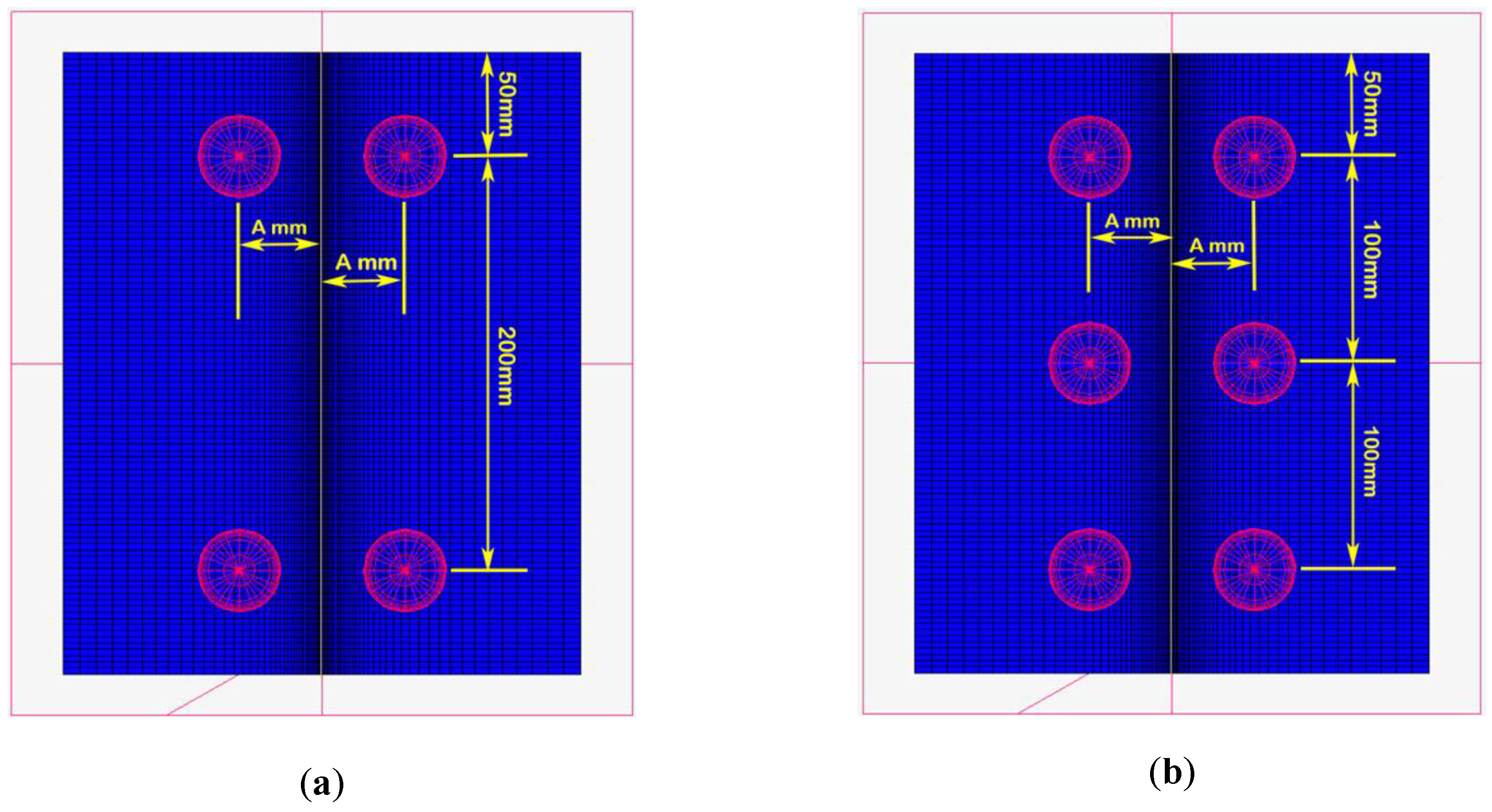

Figure 3a,b. Because welding deformation can be partially inhibited by adding jigs to the workpieces, this applied downward pressure is also incorporated into the simulation (

Figure 4). Note that the jig model is considered a rigid body.

The simulation assumptions for this article are as follows: (1) the thermal and mechanical characteristics of the welding test pieces of type JIS SUS304 are equal in all directions [

21]; (2) the welding filler material is of the same type as the test pieces [

22]; (3) the jigs used to inhibit deformation are steel jigs; and (4) the influence of gravity is ignored. Note that two independent plates are used for the simulation analysis. When a high-calorie welding filler is directly applied to the workpieces, the working plates are easily separated due to thermal deformation problems and cause divergence in the simulation analysis. So, we use a pre-welding spot at both ends of the welding bead to stabilize the simulation analysis for the two separate test pieces, which is similar to the procedure during actual welding.

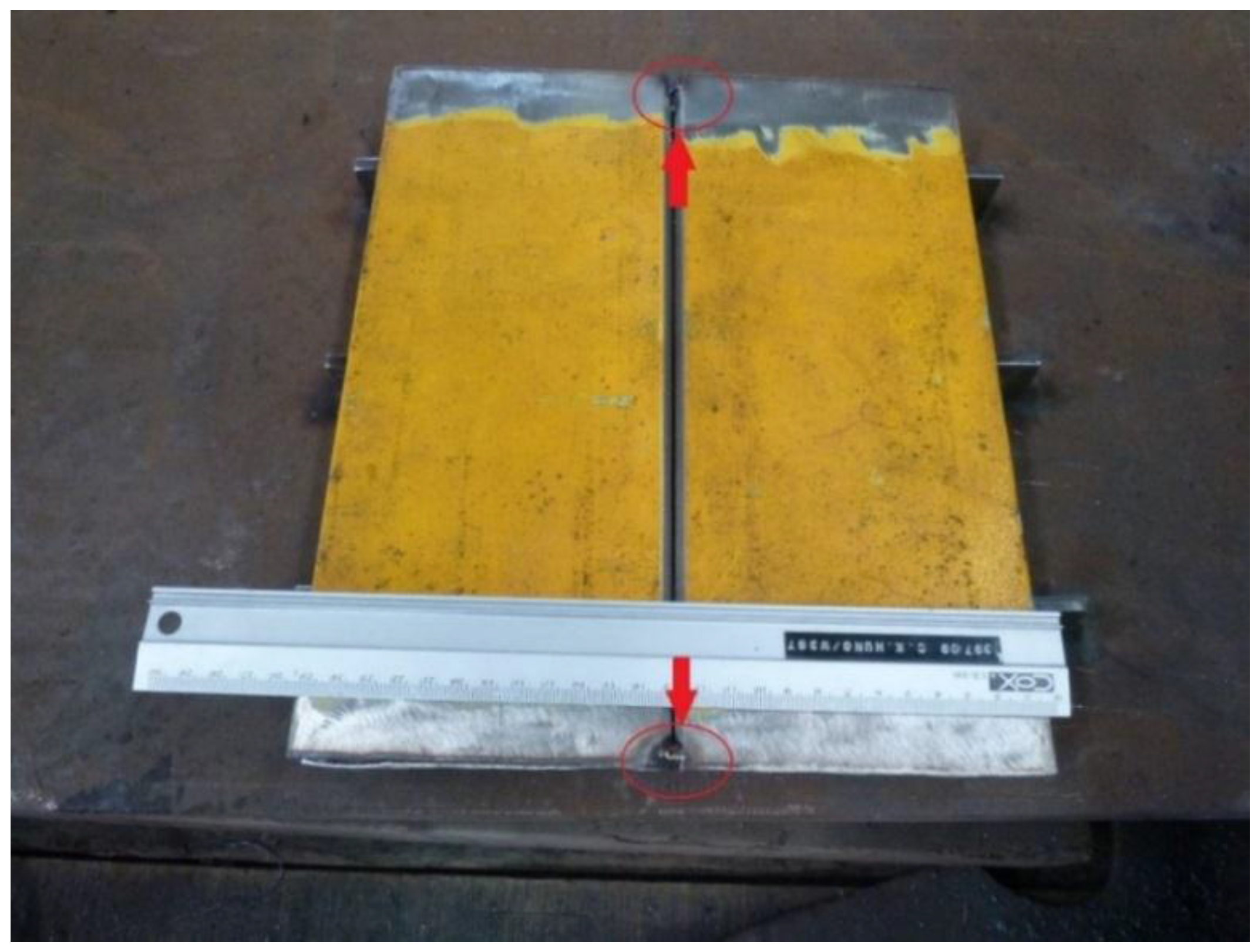

Figure 5 shows the pre-welding spots to attach the two pieces together, and

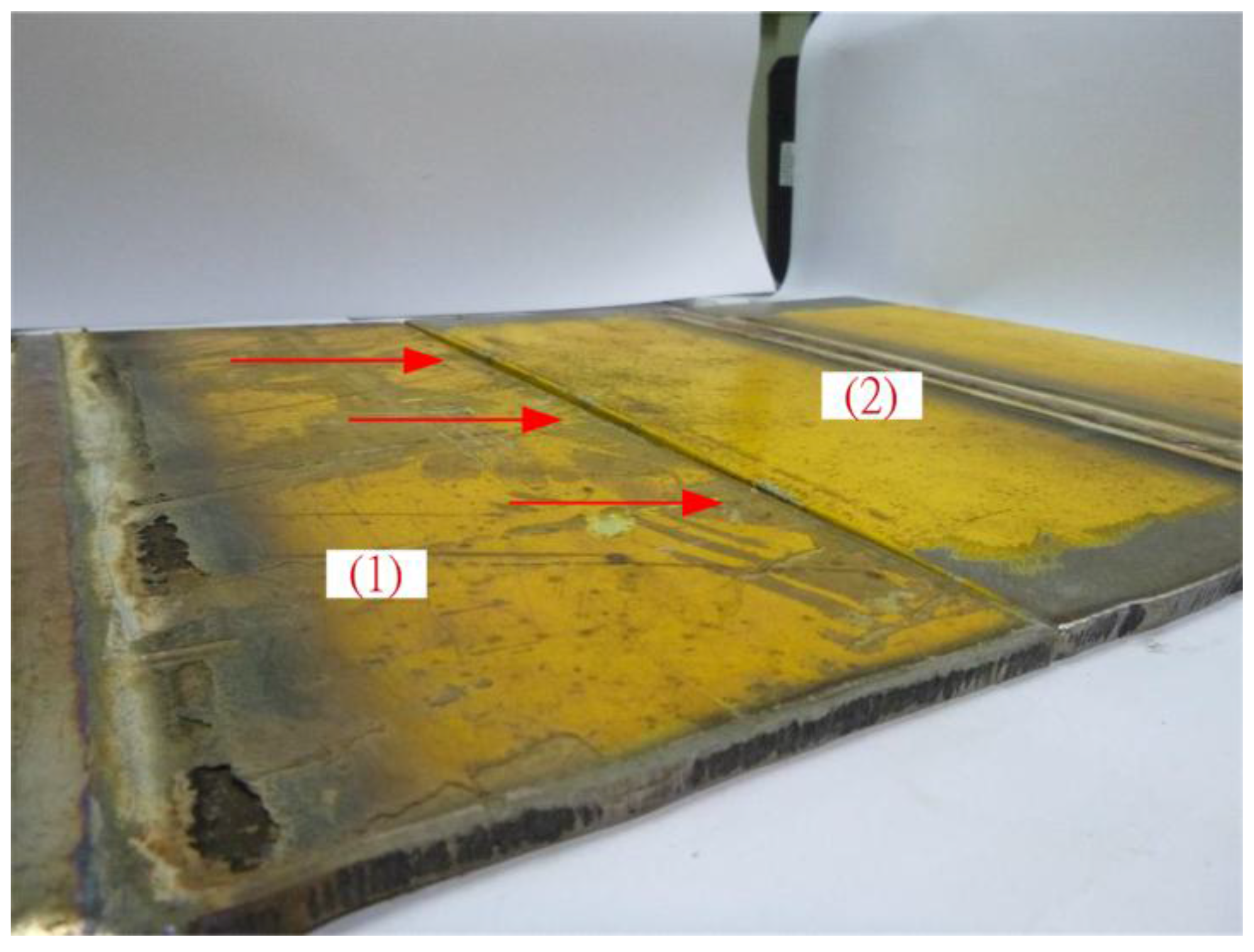

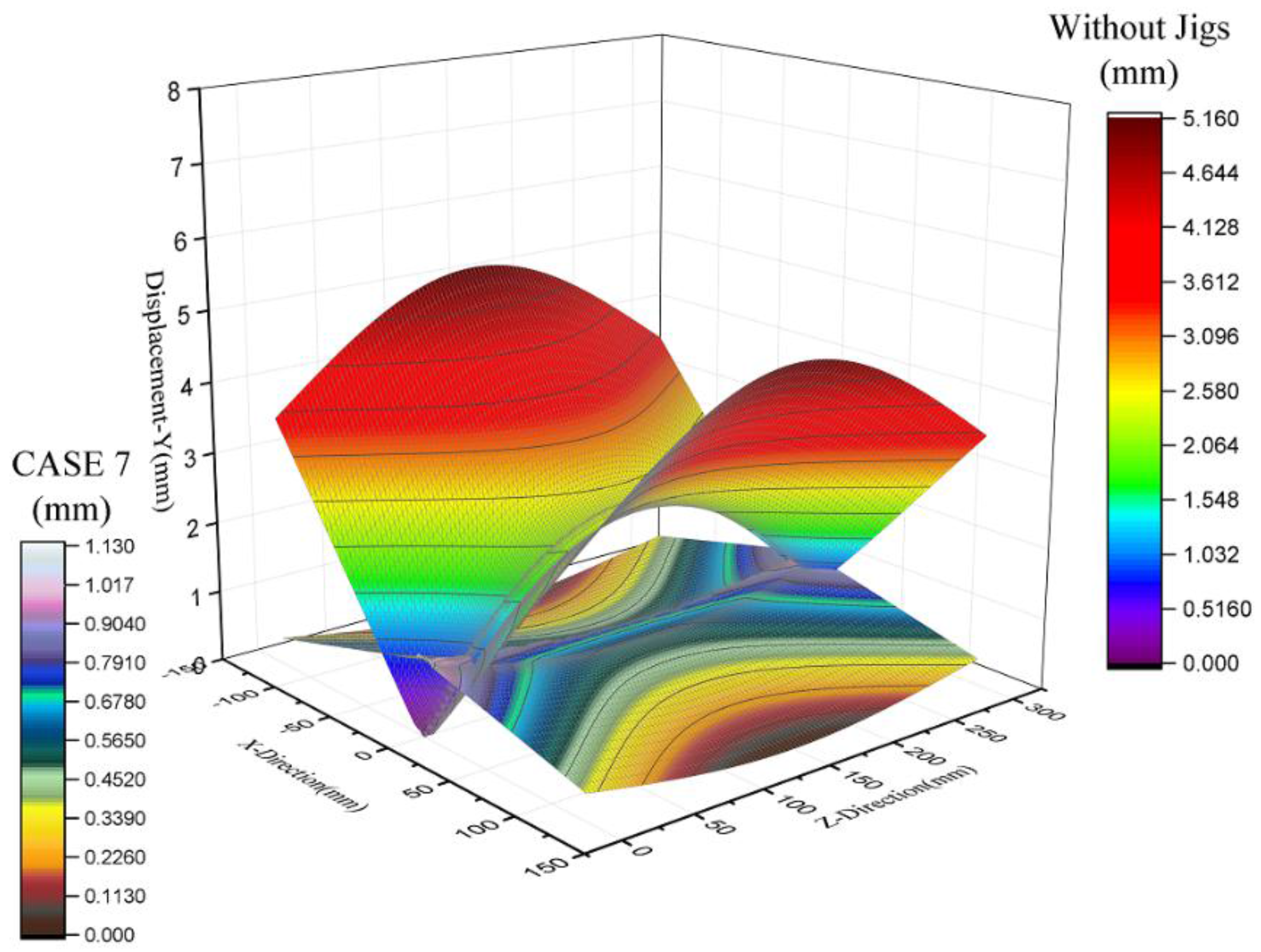

Figure 6 represents the stabilization welding spots inserted into the simulation model, which is a key point in the numerical analysis. In general, the deformation produced on the welded plates is in a saddle-bulge shape vertically and has a twisted formation horizontally, as shown in

Figure 7. This study mainly implemented 6 mm thick SUS304 steel plates as realistic test pieces for CO

2 GMAW.

Table 1 presents the practical welding parameters for the test workpiece with and without jig constraints. Variation in the parameters is due to the manual nature of the welding process.

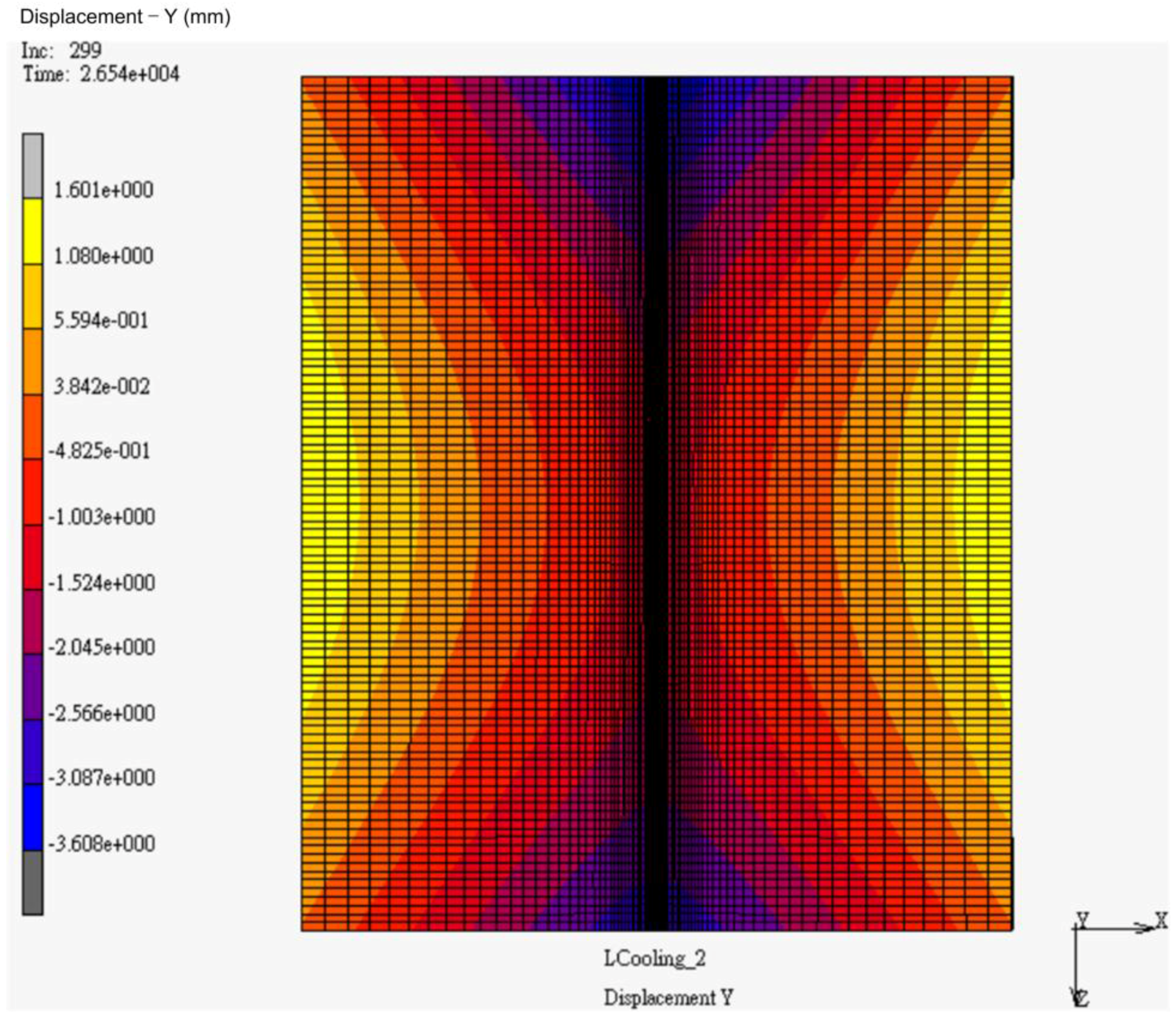

Table 2 shows the simulation parameters of the welding heat source for the test workpiece. Note that the welding process includes two welding passes, and the welding interval is about 30 s. Under the test conditions without jigs, the deformation after cooling to room temperature was identical to what resulted from the numerical simulation analysis, as shown in

Figure 8a,b; both displayed a vertical saddle bulge.

Figure 9 compares the results for the practical welding process with and without jig constraints, showing that the jig constraints effectively reduced deformation.

4. Conclusions

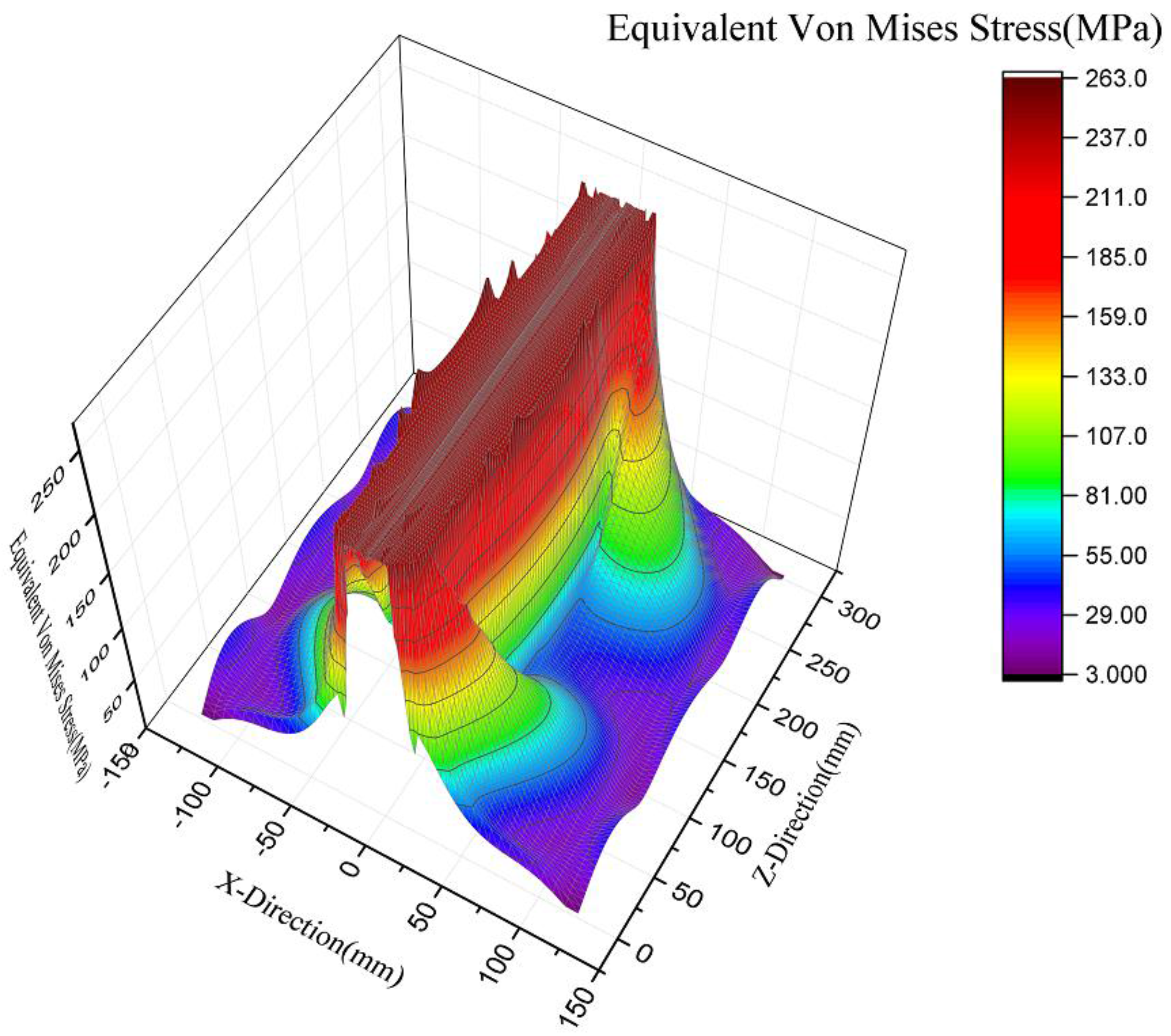

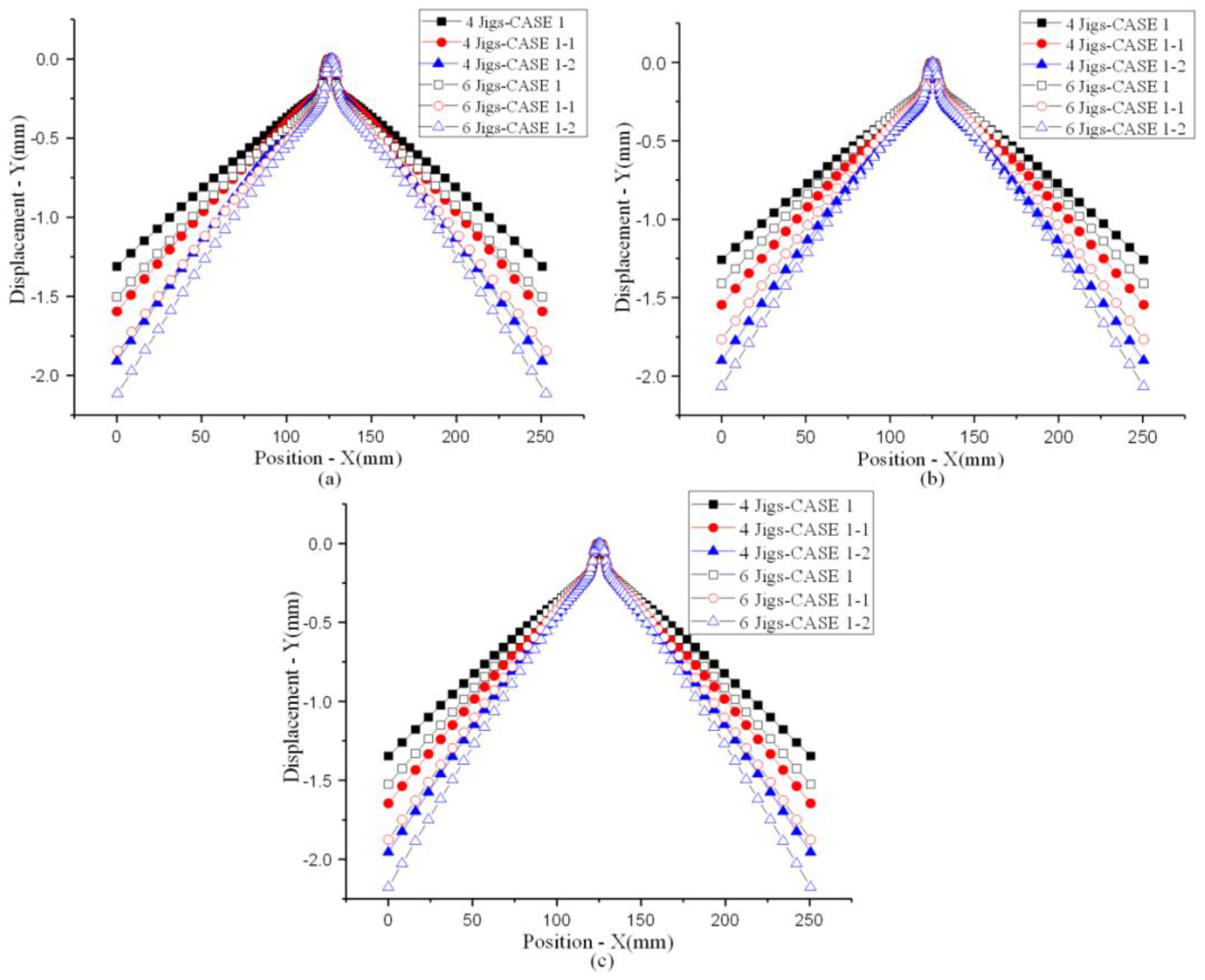

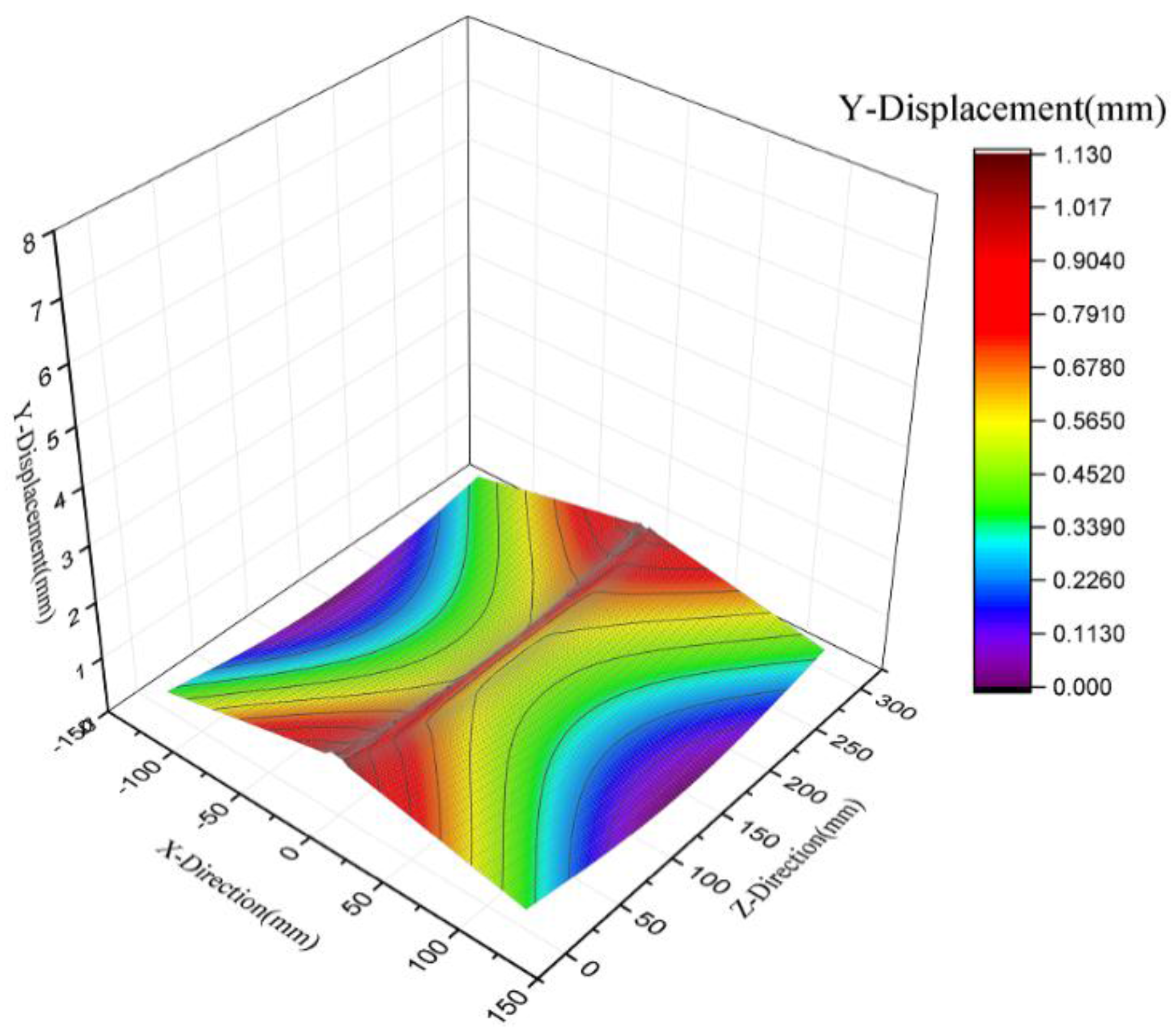

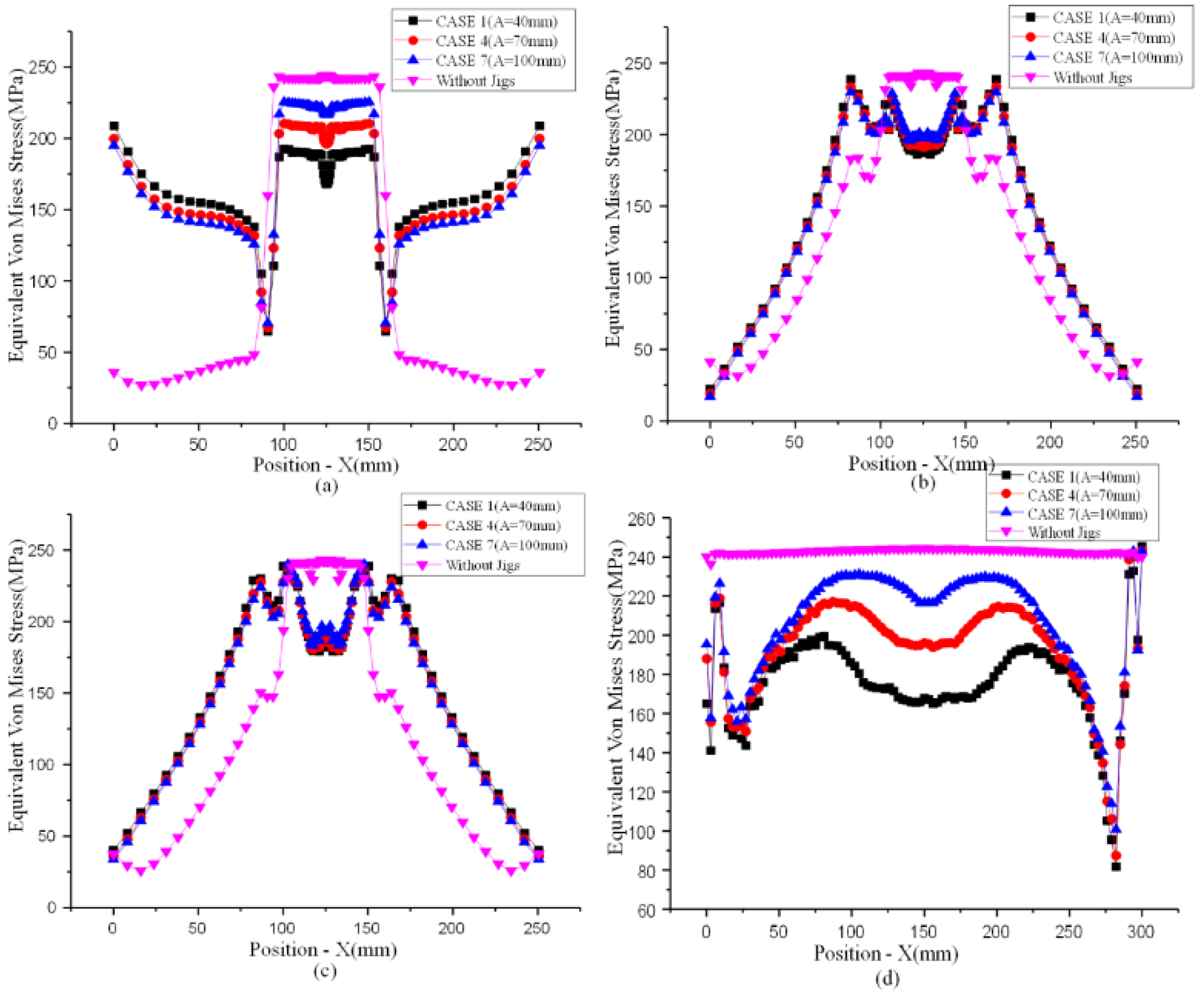

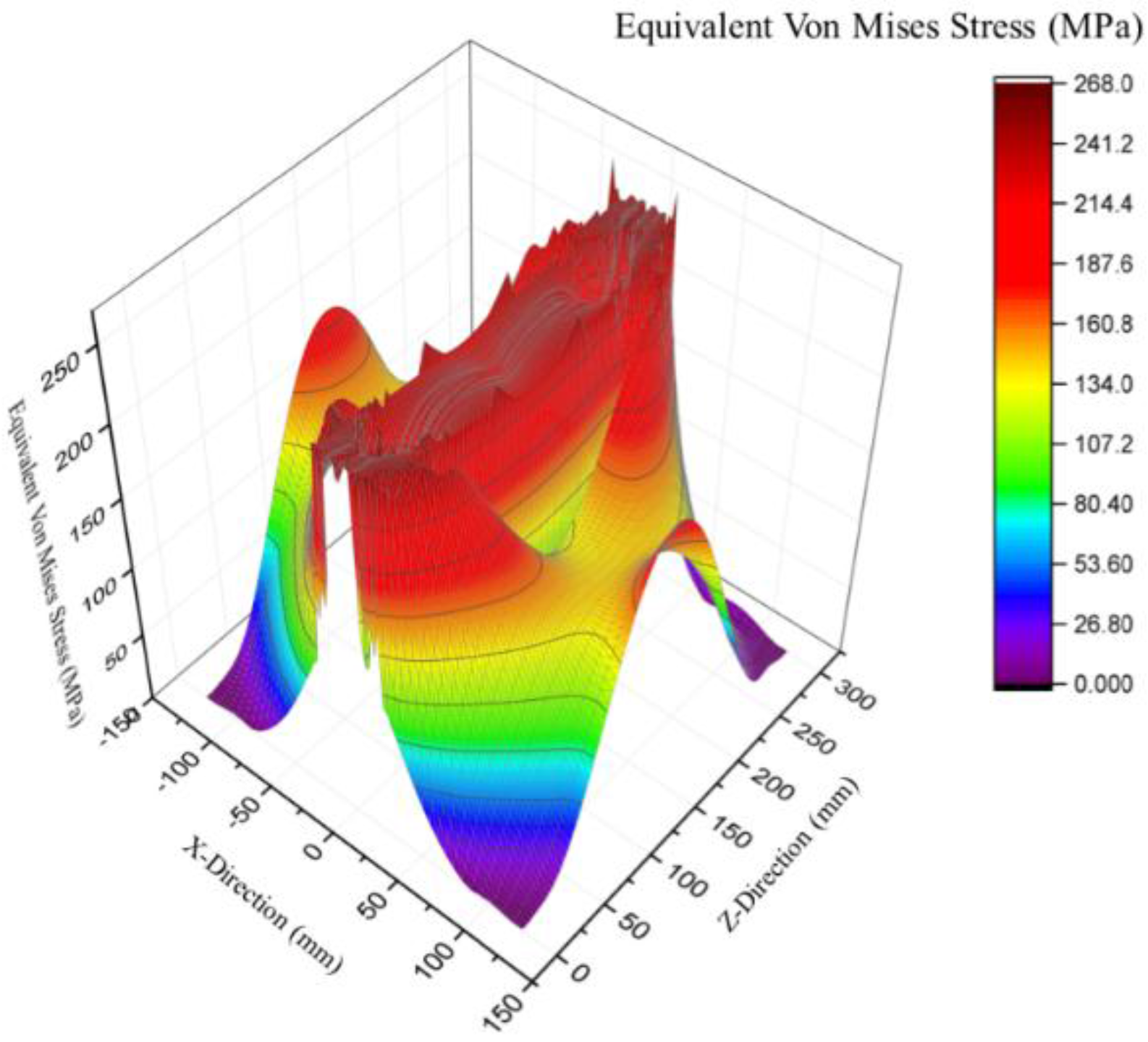

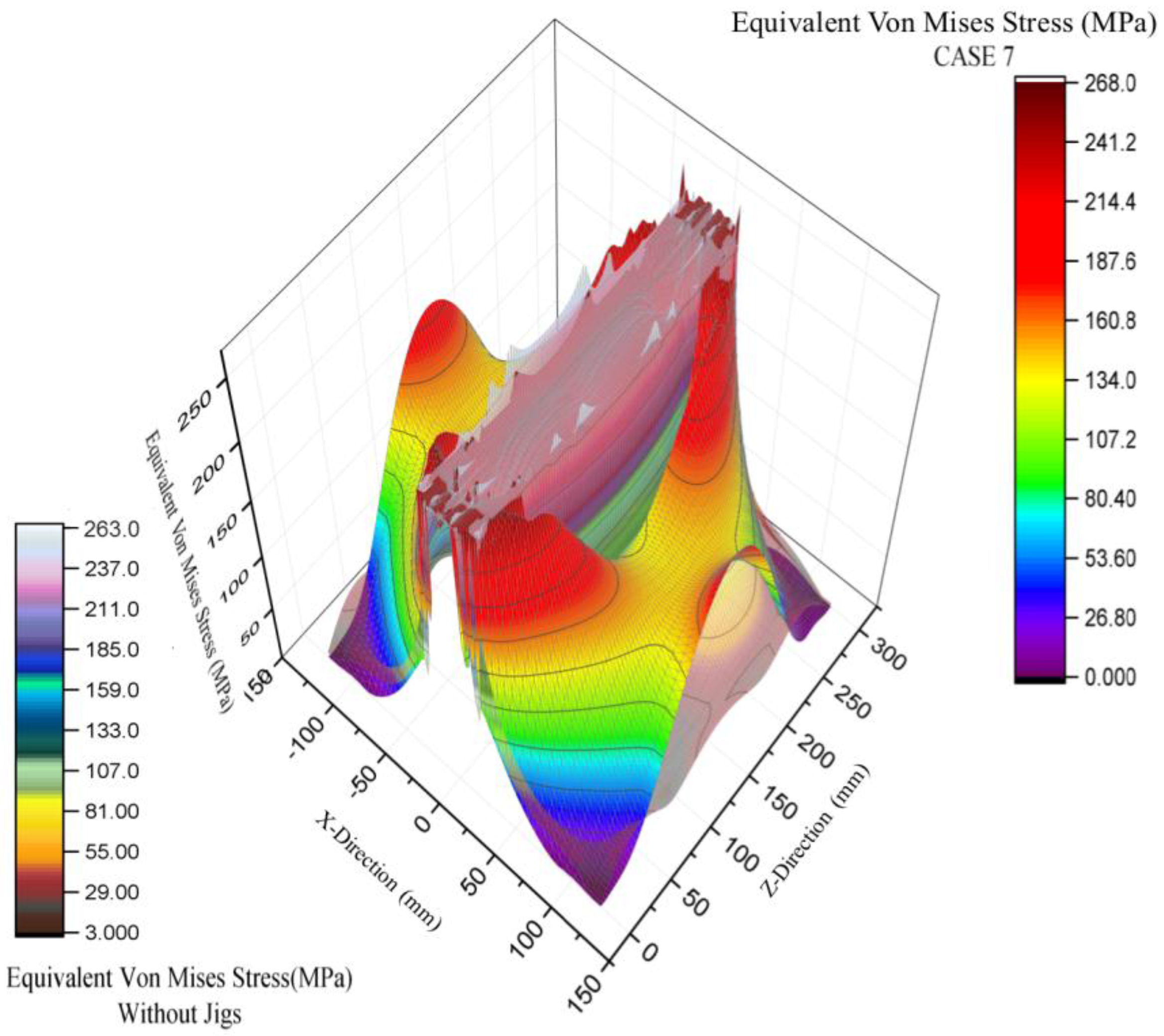

Applying jig fixtures to prevent welding deformation is widely used in industry, but there are currently no standards for how to use jigs, and it is common simply to decide based on personal experience. This study applied the finite element analysis software MSC.MARC to simulate residual stress and deformation in butt welding workpieces on 300 × 250 × 6 mm SUS304 steel with jig fixtures using gas metal arc welding, so as to determine the best location for applying jig fixtures to prevent deformation. Our findings suggest that applying jigs to these steel plates with a depressed displacement of 0 mm produces the best deformation inhibition results for steel plates after welding. They also show that four jigs spaced 200 mm apart inhibit deformation better than six jigs spaced 100 mm apart. The best deformation inhibition results are achieved not when the jigs are attached closer to the welding bead, but when they are attached at a suitable distance from the welding bead. This research suggests that the optimal location for applied jigs is 100 mm from the welding bead, which is similar to actual welding practice. The total difference between the maximum and minimum displacement after welding in the case of 300 × 250 × 6 mm SUS304 steel plates is about 1.1 mm. Regardless of whether or not jigs are applied, the equivalent von Mises stress or residual stress is highest at the welding bead and reaches the yield stress of the welding plates. Adding jigs to inhibit deformation significantly increases the equivalent von Mises stress/residual stress. Therefore, we suggest that to lessen the residual stress, heat treatment should be applied to the area around the welding bead or to the whole workpiece.

This article provides a novel method for analyzing residual stress and deformation in butt welding using the finite element method with a customized subroutine program designed to exactly simulate the actual nonlinear physical phenomenon of this welding process. In the future, we will use this approach to conduct simulation analysis of T-shaped steel plates, a very common form of structural steel used in industry. With the help of custom-designed subroutine programs, the proposed approach can be also extended to analyze multi-layer welding as well as welding with different metals.