1. Introduction

Variable thickness (VT) plates have been widely applied in engineering practice such as, for example, advanced gas turbines, high-powered aircraft jet engines and high-speed centrifugal separators [

1,

2,

3]. The vibration problems of the plate structures in these engineering machines are important for consideration in the design process [

4,

5,

6].

By using the finite element method, vibration problems of VT plates are widely studied. Huang et al. [

7] investigated the free vibration problem of orthotropic rectangular VT plates by using a discrete method. Based on the Green function, Sakiyama et al. [

8] discussed an approximate method for analyzing the free vibration of rectangular VT plates, and Guo et al. [

9] introduced a dynamic function in the finite strip method, where numerical analysis was used to demonstrate the application of the approaches by analyzing simply supported stepped thickness (ST) plates. It has been shown that the numerical solutions of the approximate method had good accuracy for various types of rectangular plates with uniform or non-uniform thickness.

Moreover, Eisenberger and Jabareen [

10], in 2001, computed exact axisymmetric vibration frequencies of VT circular and annular plates by approximating the variation in thickness into an infinite power series. Jiang and Redekop [

11] studied the free vibration characteristics of linear elastic orthotropic toroidal VT shells based on the Sanders–Budiansky shell equations, and Kang and Leissa [

12] also discussed the free vibration on VT paraboloids shells by using a three-dimensional method. Recently, based on the polynomial fitted thickness, VT plates’ various combinations of boundary conditions were investigated by Shufrin and Eisenberger [

13], where two shear deformation plate theories were applied to provide accurate results in solving natural frequencies. By using the Generalized Differential Quadrature (GDQ) method, most recently, Tornabene et al. [

14] and Bacciocchi et al. [

15] investigated the free vibration of doubly-curved shells, singly-curved shells and plates with continuous thickness variation, showing that the GDQ method provides an accurate, stable and reliable numerical tool in analyzing variable thickness thin walled structures.

However, although theoretical studies have been widely discussed, experimental tests of the actual structure are still necessary. The issue is that, in practice, experimental investigation on thin walled structures like VT plates are actually expensive and time-consuming. Consequently, a scaled down model, which is usually designed based on similitude theory, is employed to reflect the prototype behavior. In general, due to the lack of the availability of materials, or the unavailability of members’ specified dimensions, researchers often use thin plates for the analysis [

16,

17], but this may limit the application of the test results.

Dynamic similitude design of thin walled plate structures is important in engineering practice and has been discussed by many researchers. For example, De Rosa et al. [

18] investigated the distorted scaling laws in predicting the dynamic response of rectangular flexural plates based on the analysis of the vibration energy. Ramu et al. [

19] considered the scaled model made of different materials to predict the dynamic behavior of the prototype by using a scaling law, which has been established based on dimension analysis, for free vibration. Qian et al. [

20] established the scaling laws of laminated plates based on the governing equation analysis to predict the impulse response of the prototype. The results indicate that scaling laws can accurately predict the undamaged response of impact. Moreover, scaling laws of isotropic laminated plates have been studied by Ungbhakorn et al. [

21]. In their study, governing equations of buckling and frequency were used to derive the scaling laws, and partial similitude was also considered, recommending the scaling laws with good accuracy. Rezaeepazhand et al. [

22] studied the scaling laws of distortion models for predicting the laminate plate’s buckling and free vibration, deriving the scaling laws on different material and geometrical properties by using the governing equations of laminated plates and shells.

Basically, dynamical similitude design of complex structures, especially the design of distorted models, still focus on the distortion of materials. However, due to the structure’s complexity of the prototype, the study of geometrically distorted models is a real need. Most recently, Luo and Zhu et al. [

23,

24,

25] presented a series of methods in the design of geometrically distorted models of plates and shells. In their work, the sensitivity analysis was employed in deriving accurate distorted scaling laws to predict the dynamic characteristics of the prototype [

26,

27]. In this study, in order to address the problem in designing a scaled model for a VT plate, a simplified ST plate, which has the same dynamic properties of the VT plate, is introduced. By using the transfer matrix method, the equivalent thickness of the corresponding thin plate is derived for each vibration modals. Then, a unified thickness of the Model Thin (MT) plate is selected and the corresponding scaling law is proposed such that the dynamic properties of the prototype VT plate can be predicted by using the MT plate.

The manuscript is organized as follows. In

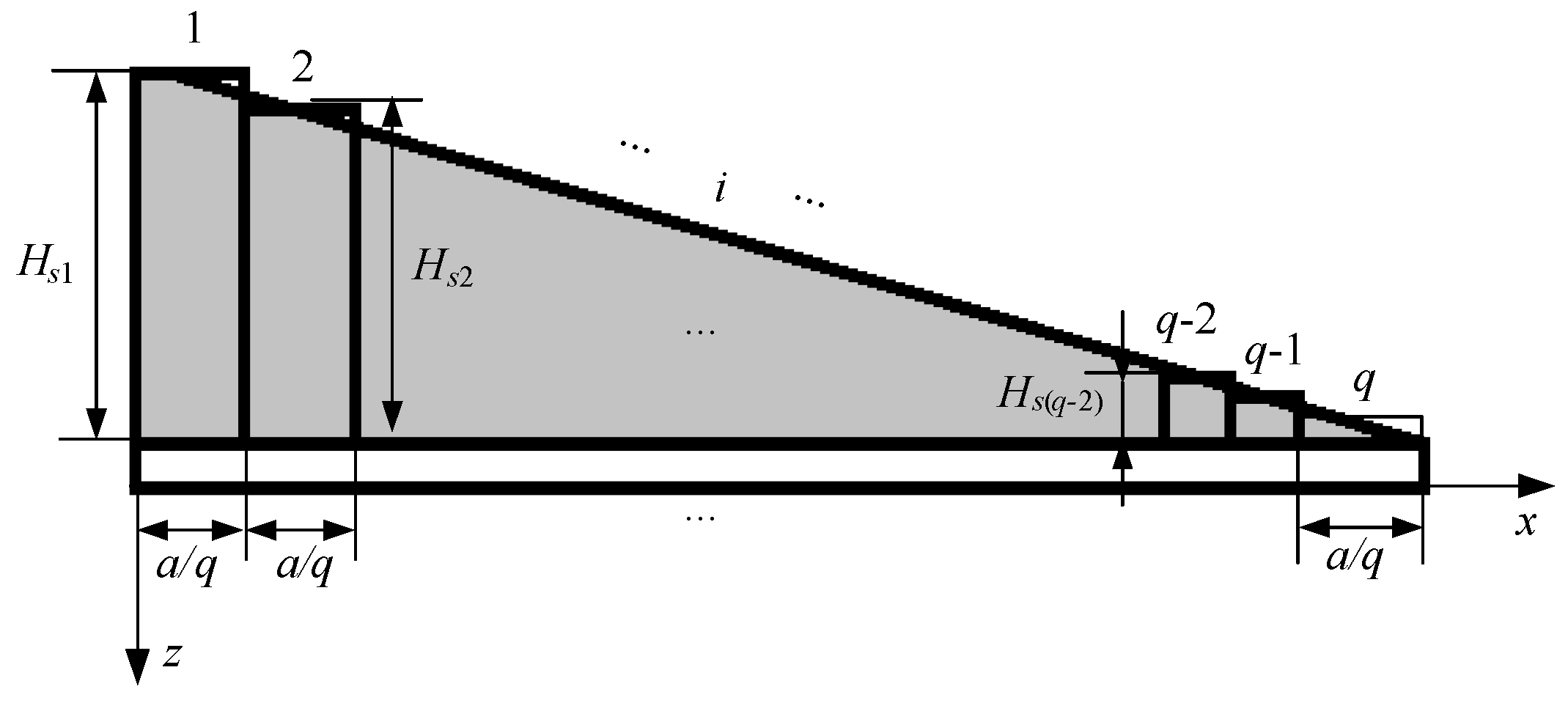

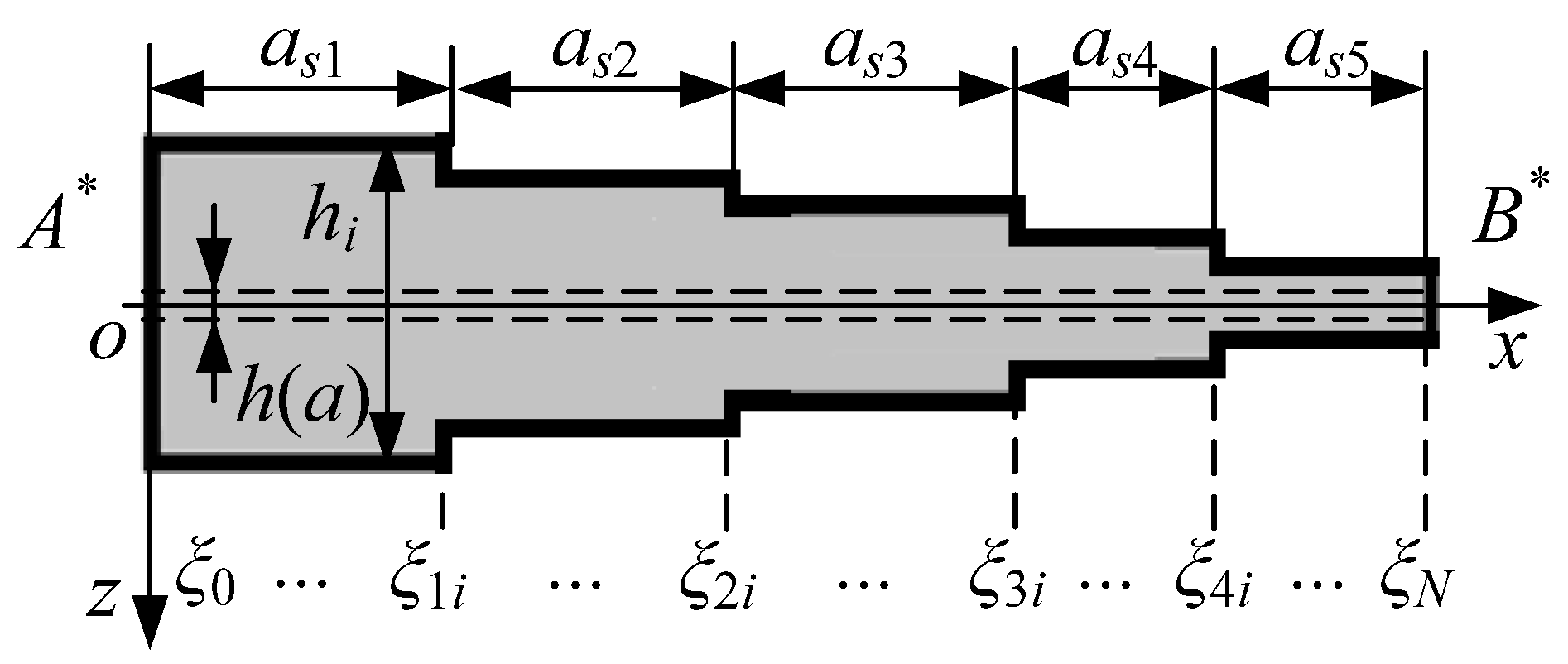

Section 2, the distorted scaling law of thin walled plates is derived based on the governing equation. The simplified ST plate is then proposed in

Section 3, where the transfer matrices of both ST plates and thin plates with the cantilever boundary condition are discussed, and the equivalent thicknesses of different vibration modals are computed. In

Section 4, the scaled down model of the VT plate is designed with a unified thickness, and the corresponding scaling laws are derived to predict the dynamic properties of the prototype VT plate. A case study is also provided to validate the proposed design method and a general process of designing the MT plate is summarized. Finally, conclusions are presented in

Section 5.

2. Distorted Scaling Law of Thin Cantilever Plates

Considering a cantilever plate and the coordinate system

,

and

are the length and the width along

and

directions, as shown in

Figure 1.

,

and

represent the displacement of

x, y and

z directions, respectively. The Young's modulus, Poisson's ratio and the density of the plate’s material are separately denoted by

E, µ and

.

The governing equation of the thin plate is [

28]

where

is the Laplace operator,

.

The cantilever boundary condition can be found in [

23] for more details.

Denote the deflection of the plate by using the equation

where

is the natural frequency of the plate.

Substituting Equation (2) into Equation (1) yields:

where

.

Considering that Equation (3) is satisfied by both the model and the prototype:

where subscript

p represents the prototype; subscript

m represents the model, which can be rewritten as

where

is used to represent the scaling laws,

j represents the symbol of each physical quality, for example,

, and so on.

According to the similitude theory [

22]:

is obtained from Equation (5), and according to

and

, there is

Let

, and

can be derived by substituting Equation (7) into Equation (6), where (8) is the distorted scaling laws with respect to the material parameters and the thickness

h.

By using the scaling law (8), the natural frequency of a cantilever thin plate can be predicted by using an MT plate, under the same boundary condition, made of different materials in arbitrary thickness. However, if the prototype is a VT plate, its dynamic properties cannot be predicted by using such a simple scaling law, and an effective approach of designing the scaled down model in predicting the prototype VT plate is needed.

4. The Distorted Model of the VT Plate

4.1. Distorted Models and the Scaling Law

It has been discussed in the previous sections that for each vibration modal, an equivalent thickness of a VT plate can be calculated as via the simplified ST plate by using the transfer matrix method. However, in practice, it is obviously impossible to design an MT plate with a specific thickness for each modal of the prototype VT plate. Usually, a unified thickness, , is chosen in the design of the scaled model.

In order to address this issue, denote the ration of the thickness as

According to the frequency scaling law (8), the frequency relationship between the prototype equivalent thin plate and its scaled down model is

while the scaling law between the scaled model thin plate and the distorted model plate with the unified thickness

hUni is calculated as

where

represents the model thickness against the

th modal of the thin plate.

Consequently, the scaling law between the unified distorted model and the prototype equivalent thin plate, as well as the VT plate, is derived as

when

.

Next, a similitude design case study is provided to illustrate the design process of the scaled down plate. In this case study, the simplified steps of the ST plate are given as

, and the material and the geometrical parameters are shown in

Table 2, where in the ANSYS simulation (ANSYS 14.0, ANSYS, Pittsburgh, PA, USA), the element Solid 186 is used. The equivalent thickness of the previous fourth flexural vibration modal defined as

, and the relative prediction error is calculated by

as shown in

Table 4, where the width, length and material parameters of the equivalent thin plate are the same as the ST plate as shown in

Table 2, and

and

are the natural frequencies of the equivalent thickness thin plate and the ST plate, respectively.

The results in

Table 4 show that the ST plate has the same order and shape of the vibration modal as the equivalent thin plate, and the natural frequencies of each order’s vibration are also close to a small relative error of

. This indicates that the design algorithm on calculating the equivalent thickness is applicable, and, therefore, the connections between the VT plate, ST plate and the thin plate are established.

Consider that, in a scaled down model, the material of the model plate is NO. 45 steel and the geometrical parameters of the plate are shown in

Table 5 with

. The unified thickness of the model plate is

, and the predicted natural frequencies obtained by using the scaling law (35) are shown in

Table 6, where

is the relative error of predictive values.

Table 6 shows accurate predicted results that in the same vibration modal, the predicted natural frequencies are close to that of the prototype with a relative error

, indicating that the method of predicting a VT plate’s vibration characteristics by using an MT plate is applicable.

In this example, it can be seen that the dynamic properties of a VT plate can be accurately predicted by using a designed MT plate of different materials. It is worth noting that the present proposed method can be simply achieved by using the MATLAB program (MATLAB 2010b, MathWorks, Natick, MA, USA), such that the design of the MT plate can be easily conducted. Moreover, two additional cases are discussed as below.

Firstly, only flexible vibration is considered in the proposed example. It is noticeable that the coefficient

of the torsional vibration and the chordwise bending vibration can be obtained by replacing

with transfer matrices shown in Reference [

29].

Secondly, the length and width of the MT plate are completely scaled down as

, a more complex case, where the geometric parameters are all distorted as

, can be discussed by using the similar process by referring to the scaling laws present in [

22,

23,

24] between the equivalent thin plate and the MT plate.

4.2. A General Design Process

According to the discussion in the above sections, a distorted scaled model of the VT plate is designed and the method of reducing the predicted errors is investigated. To be clear, the process of the similitude design is summarized as below and illustrated in

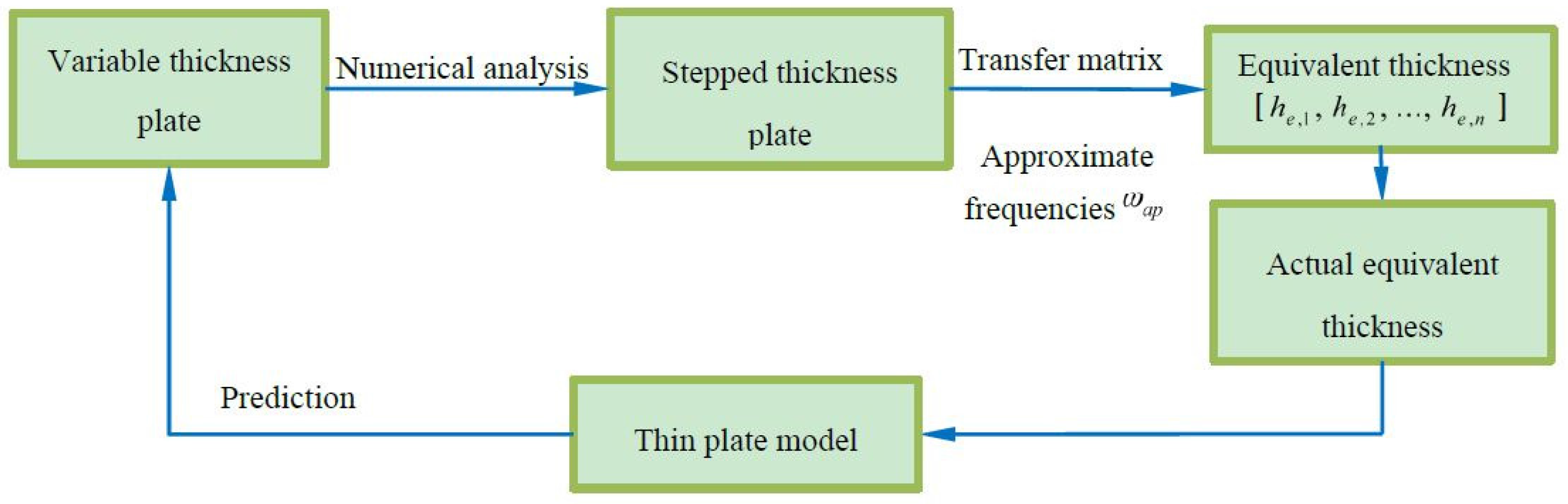

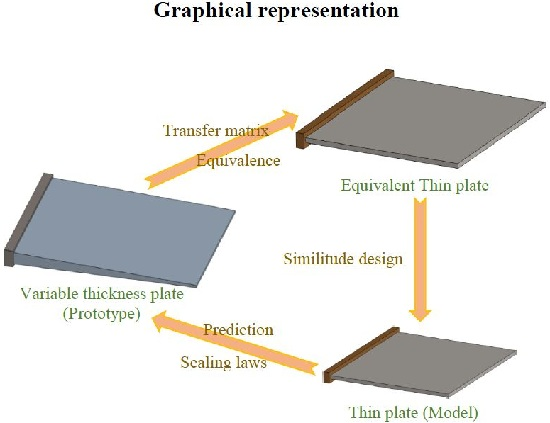

Figure 5.

Step 1: Simplify the VT plate by using an ST plate with finite steps , such that the simplified ST plate can reveal the dynamic properties of the VT plate in a certain order.

Usually, this process can be facilitated by using a numerical analysis method. For example, in the case study of this paper, the frequency errors of different vibration modals between the VT plate and the ST plate with different

steps are shown in

Figure 6.

Fitting the curves with a four-order polynomials yields:

where the adjusted determination coefficient

is given as:

where

is the sample size;

is the order of the polynomial;

,

and

are the fitted value, the average value and the actual value (simulation value), respectively.

Substituting relevant parameters into Equation (38) yields:

where Equation (39) indicates that the fitted curves can be used to determine

and

.

Assuming is acceptable, the step number is solved: . Similarly, calculating the frequency errors of high order vibrations (previous six modals), is chosen as the number of the steps in the case study.

Step 2: Calculate the equivalent thickness of each order’s vibration by using the transfer matrix method, which is obtained as .

Step 3: Unify the equivalent thickness obtained in Step 2 into any thickness of interest as , and design the similitude model of the thin plate with the thickness .

Step 4: Derive the distorted scaling laws (35) according to the equivalent thickness and the simplified thickness , as well as the different materials of the model and the prototype.

Step 5: Test the distorted model and predict the dynamic characteristics of the prototype VT plate.

It is worth noting that the design process summarized above is a general process on designing a distorted similitude model of thin walled structures with continuous thickness variations. Based on the sketch shown in

Figure 5, two main issues are addressed in the present study. Firstly, find a simple equivalent structure that has the same dynamic properties of interest to the prototype complex structure. Then, design the similitude model of the simple equivalent structure according to the requirement of the designer, where, in this step, dynamic similitude design approaches that have been studied by the authors can be well applied. The proposed technique in the present study can be extended to dealing with, i.e., thin walled shells, annular plates, etc. that have the characteristic of variable thickness.

5. Conclusions

Much research has been done on the similitude design of thin walled structures, such as plates and cylindrical shells. However, in engineering practice, the real structures do not always have the same thickness characteristic. The variable thickness can significantly affect the dynamic properties of the structure such that the prediction of the simple scaled down model may fail in its accuracy.

In order to address this issue, a new technique for the similitude design of a cantilever VT plate is proposed in the present study based on the transfer matrix method. In this approach, a simplified ST plate is introduced as a connection between the VT plate and the equivalent thin plate, such that the distorted similitude design method of the thin walled structure can be directly applied in designing the scaled model. The transfer matrices of the ST plate and the thin plate have been derived in this study, and the equivalent thickness of the thin plate corresponding to the specific vibration modal of the VT plate are calculated according to these transfer matrices. Moreover, a unified model plate is defined as the Model Thin (MT) plate such that different orders’ dynamic properties of the prototype VT plate can be predicted by using only one scaled model with the thickness , and the scaling law between the scaled model and the prototype are also derived as (35). Finally, a case study is employed to validate the proposed approach in the present study, and a general process of determining the scaled model and its scaling laws are summarized to emphasis its significance in engineering practice.