1. Introduction

Nonwoven geotextiles are commonly used in geotechnical, hydraulic engineering, and environmentally protective fields, and have functions of filtration, drainage, separation, protection, and reinforcement [

1,

2,

3,

4]. Thermoplastic materials are made into geotextiles via mechanical or chemical bonding methods. The used synthetic fibers include polypropylene (PP), polyester (PET), polyethylene, polyvinyl chloride, and polyamide, and PP and PET are the most commonly used. In comparison to PP, PET has greater mechanical properties, lower creep property and better thermal resistance. PET has a melting point of 259–269 °C [

5,

6].

Furthermore, Thwe

et al. [

7] and Jawaid

et al. [

8] reported that, with appropriate material designs, uses of two or more fibers to form composites can compensate for the drawbacks of using a single material, and further provide the products with greater mechanical properties, physical properties, and a production that consumes low energy. In recent years, there have been a great deal of studies examining the ability of high modulus fibers to fortify nonwoven composites, while glass-fiber woven fabrics, aramide fibers, and carbon fibers are currently used to reinforce composites. In the study by Li

et al., Kevlar

®/high-strength polyamide 6/low-melting PET nonwoven and low-melting PET/PET nonwoven served as the top and bottom layers, enclosing a layer of glass woven fabric to form three-dimensional compound fabrics. The results indicate that increasing polyamide fibers benefits the static and dynamic punctures of the compound fabrics [

9]. Yan

et al. also published a study that combined a high-density flexible polyurethane foam as the interlayer with a recycled Kevlar

®/low-melting-point polyester nonwoven fabric as the top layer and a glass woven fabric as the bottom layer. The tensile strength and tear resistance of the resulting sandwiches were distinctly increased [

10].

Therefore, this study combines recycled Kevlar

® fibers and low-melting-point fibers to form geotextiles in order to improve the mechanical and physical properties of PET geotextiles. Kevlar

® fibers are featured by having a high modulus, high tenacity, chemical resistance, impact resistance, thermal resistance, and abrasion resistance. As a result, Kevlar

® fibers have commonly been used for body armor, stab-resistant protective products, tires, steamships, light aircraft, and submarine cables. Meanwhile, there is also by-product of Kevlar

® selvages, which are mostly burned [

11]. The burning process results in greater energy consumption and worst-case forms of pollutions. It benefits the environment and new products if Kevlar

® selvages can be recycled for other applications. Li

et al. indicated that using recycled Kevlar

® fibers resulted in cost reduction, environmental benefits, and mechanical property reinforcement [

12]. In addition, the incorporation of low-melting-point PET (LPET) fibers improves the properties of nonwoven products and the pollution problems that are caused by massive usage of adhesives. LPET fibers are modified composite fibers and have a sheath-core structure. Their outer layer has a melting point of 110 °C, and LPET fibers are thus commonly used for thermal consolidation. Thermal treatment melts part of LPET fibers, thereby yielding the function of adhesives. Relative literature sources also confirm that the incorporation of LPET fiber reinforces the mechanical properties of the nonwoven fabrics [

13,

14]. Therefore, this study combines PET fibers, Kevlar

® fibers, and LPET fibers to form nonwoven geotextiles. This product design for geotextiles emphasizes both their initial performance and their durability. Geotextiles are commonly closely associated with aqueous acid/alkali solutions or dissolved oxygen. It is thus essential to evaluate the chemical resistance of geotextiles that are greatly dependent on their polymer compositions, manufacturing parameters, fabric structures, as well as external factors, including liquid composition and

in situ conditions [

15,

16,

17,

18].

In the study by East

et al., polyester and polypropylane geotextiles were immersed in saline, strong acidic solution (pH 3), and strong alkaline solution (pH 10) at room temperature and 95 °C, thereby examining the influence of the accelerated aging experiment on the properties of geotextiles. The test results indicated that the influence of groundwater chemistry on the durability of geotextiles was important when geotextiles were used in hazardous waste landfills, slopes, subgrades and earth retention systems [

16]. As indicated in ISO 13434 (Geosynthetics—Guidelines for the Assessment of Durability), the pH value of the environment reaches 9–11 for specified soils or a special construction process [

19]. In addition, the pH value of soils in Taiwan is between 4 and 6. Due to a limited time, this study thus uses extreme conditions to examine the influence of adding recycled Kevlar

® fibers on tensile strength of nonwoven geotextiles. In order to examine possible factors that change the durability and mechanical properties of geotextiles in diverse environments, this study immerses recycled Kevlar

®/PET/LPET nonwoven geotextiles in neutral, acid, and alkaline solutions that is at different temperatures, and measures their tensile strength every month for four consecutive months. Strong alkali and acid solutions are thus used for a maximum of a 4 month immersion in order to exert as much severe influence over the tensile strength of the nonwoven geotextiles. Statistical analyses are then used to analyze the differences in the tensile strength of the nonwoven fabrics, in relation to fiber ratios, thermal treatment, and immersion periods. The influential levels of different variables that are demonstrated on recycled Kevlar

®/PET/LPET nonwoven geotextiles are determined by using multiple regression analyses. The experimental results can serve as a reference for designing novel geotextile products with their associated environmental requirements.

2. Experimental Section

2.1. Materials

Recycled Kevlar® fibers are obtained from Kevlar® uni-directional selvages (Dupont, Pierce County, WA, USA) that include 2820 Denier (D) K129, 1000 D K29, and 2160 D K49 multi-filaments. The length of the Kevlar® fiber ranges from 50 mm to 60 mm. The three-dimensional, crimped, hollow polyester (PET) fiber (Far Eastern New Century, Taipei, Taiwan) has a fineness of 7 D and a length of 64 mm. Low-melting-point PET (LPET) fiber (Far Eastern New Century, Taipei, Taiwan) has a fineness of 4 D and a length of 51 mm. LPET has a sheath-core structure. The sheath is PET fiber with a melting-point of 110 °C and the core is PET fiber with a melting-point of 260 °C.

2.2. Sample Preparation

Kevlar® selvages are processed with opening in order to obtain Kevlar® fibers. Kevlar® fibers are high strength and the machine for nonwoven fabrics also has limits in capacity of processing materials. Kevlar® fibers are thus added with 5 weight percent (wt. %) in this trial experiment, thereby obtaining the optimal production. Kevlar® fibers, PET fibers, and LPET fibers are mixed with various ratios of 0/80/20, 5/75/20, 10/70/20, 15/65/20, and 20/60/20. They are processed with opening, blending, carding, lapping, and needle-punching, in order to form recycled Kevlar®/PET/LPET nonwoven geotextiles with a basis weight of 200 ± 10 g/m2. The geotextiles are then thermally treated through a calendar at 120 °C. This process melts the sheath structure of LPET fibers and causes thermal bonding points.

2.3. Testing Methods

2.3.1. Tensile Strength of Nonwoven Geotextiles under Diverse Environmental Conditions

Jeon

et al. examined the tensile strength retention of high-tenacity PET yarn textile geogrids as specified in ASTM D5322, in order to evaluate their chemical resistance [

17]. Lodi

et al. used the same measurement to examine the mechanical and thermal properties of the chemically degraded polyvinyl chloride and high density polyethylene geo-membranes [

20]. Therefore, this study proposes nonwoven geotextiles and evaluates their tensile strength and variations in weight. As statistical analyses need continuous variables, the yielded tensile strength data is used for comparison, not tensile strength retention. According to ASTM D5322–98 (Standard Practice for Laboratory Immersion Procedures for Evaluating the Chemical Resistance of Geosynthetics to Liquids) [

21], samples are immersed in solutions at different pH and temperature conditions for four months. The solutions for this test are acetic acid and sodium hydroxide as specified in ASTM D543–14 (Standard Practices for Evaluating The Resistance of Plastics to Chemical Reagents) [

22]. The solution for the control group is deionized water.

Table 1 shows the specifications of three solutions as well as the test conditions. Recycled Kevlar

®/PET/LPET nonwoven geotextiles are cut along the cross machine direction (CD) and along the machine direction (MD). Samples have a size of 180 mm × 25.4 mm. Samples are weighed before they are immersed in the solutions for different periods (1, 2, 3, and 4 months). After the immersion for various periods, samples are removed from the solutions, rinsed with deionized water, thermally dried at 30 °C for 24 h, and weighed again. They are respectively tested for tensile strength by using an Instron 5566 universal tester (Instron, Norfolk County, MA, USA), as specified in ASTM D5035-11 [

23]. The tensile test speed is 305 ± 13 mm/min, and the distance between clamps is 75 mm. The tensile strength along the CD and MD for different samples is tested with their maximum breaking force being recorded as the tensile strength.

2.3.2. Fourier-Transform Infrared Spectroscopy (FT-IR) Analysis

FT-IR spectra are recorded by using a Lab Solutions IR software program (Version 1.2, Shimadzu Corporation, Kyoto, Japan, 2000) on an IRAffinity-1S FT-IR spectrometer (Shimadzu Corporation, Kyoto, Japan), using the Attenuated Total Reflection (ATR) mode, in the range of 4000–600 cm−1 with a resolution of 8 cm−1. Each spectrum is obtained from 20 successive scans.

2.4. Statistical Analyses

Test result data is analyzed with the incorporation of a t-test, one-way ANOVA, and multiple regression analyses of a SPSS statistics software program (Version 20.0, International Business Machines Corporation, Armonk, NY, USA, 2011). Both t-test and one-way ANOVA are for the analyses of variance. The α (alpha level) is commonly set as 5% with a confidence interval of 95%. When p < 0.05 is sustained, the results indicate significance. For specific analyses of variations between groups that is exemplified by the statistically significant differences in one-way ANOVA, this study then uses the post hoc Scheffe's test in order to examine between what specified parameters that the statistically significant difference is present. Finally, multiple regression analyses are used to analyze the influences of multiple independent variables on a specified dependent variable. When the significance is below 0.05, the results stand for a statistical significance that enables β-distribution to determine the influential level of independent variables on the dependent variables.

3. Results and Discussion

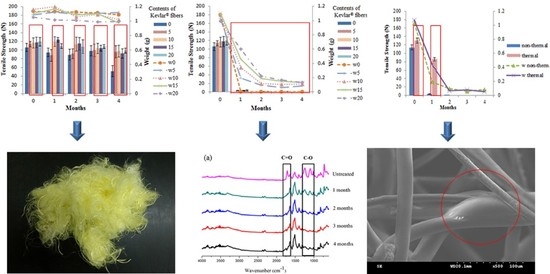

3.1. Effects of Fiber Ratios on Tensile Strength

Table 2 shows the contents of Kevlar

® fibers of recycled Kevlar

®/PET/LPET nonwoven geotextiles. The geotextiles without immersion in any solutions have a tensile strength that is proportional to the content of recycled Kevlar

® fibers. In comparison to the control group containing zero Kevlar

® fibers, the experimental groups containing 15 wt. %–20 wt. % of Kevlar

® fibers exhibit statistically significant differences at (

F (4, 20) = 5.201,

p < 0.05). In addition, PET fibers have a lower alkali resistance, and therefore, one-way ANOVA and post hoc Scheffe’s tests are performed on the recycled Kevlar

®/PET/LPET nonwoven geotextiles in order to determine the influence of Kevlar

® contents on their tensile strength. According to one-way ANOVA, the differences are statistically significant (

p < 0.05) among different contents of recycled Kevlar

® fibers, indicating that the contents of Kevlar

® pertain to tensile strength. Next, Scheffe’s test is used to analyze the differences in tensile strength among nonwoven geotextiles containing various contents of Kevlar

® fibers that are immersed in NaOH, in terms of combinations of immersion temperatures of 23 °C (

T1) and 50 °C (

T2) and immersion periods of 1, 2 and 3 months (hereafter

P1,

P2, and

P3). The analyses indicate that in comparison of the four combinations of

T1P1,

T1P2,

T1P3, and

T2P1, the experimental groups (

i.e., nonwoven geotextiles containing 5 wt. %–20 wt. % Kevlar

® fibers) have a statistically significant higher tensile strength than the control group (

i.e., nonwoven geotextiles without Kevlar

® fibers).

According to Scheffe’s analysis, there are statistically significant differences in the tensile strength among nonwoven geotextiles with immersion conditions of T1P2, T1P3, and T2P1. The tensile strength of nonwoven geotextiles is ranked according to the content of Kevlar® fibers as 20, 15 wt. % > 10, 5 wt. % > 0 wt. % (T1P2), 20, 15, 10 wt. % > 5 wt. % > 0 wt. % (T1P3), and 20, 15 wt. % > 10, 5 wt. % > 0 wt. % (T2P1). Such results are ascribed to Kevlar® fibers that have a high modulus and high strength. The molecular chains of Kevlar® fibers have a benzene structure, and their molecular bonding has high compactness and stiffness. A value of 15 wt. % or 20 wt. % of Kevlar® fibers can effectively improve the tensile strength of nonwoven geotextiles. In addition, the majority of the fibers are arranged along the CD during the nonwoven process, and thus tensile strength along the CD is greater than that along the MD.

3.2. Effects of Immersion Durations on Tensile Strength

The effects of immersion periods in neutral, acid, and alkaline solutions on the tensile strength of recycled Kevlar

®/PET/LPET nonwoven geotextiles are examined.

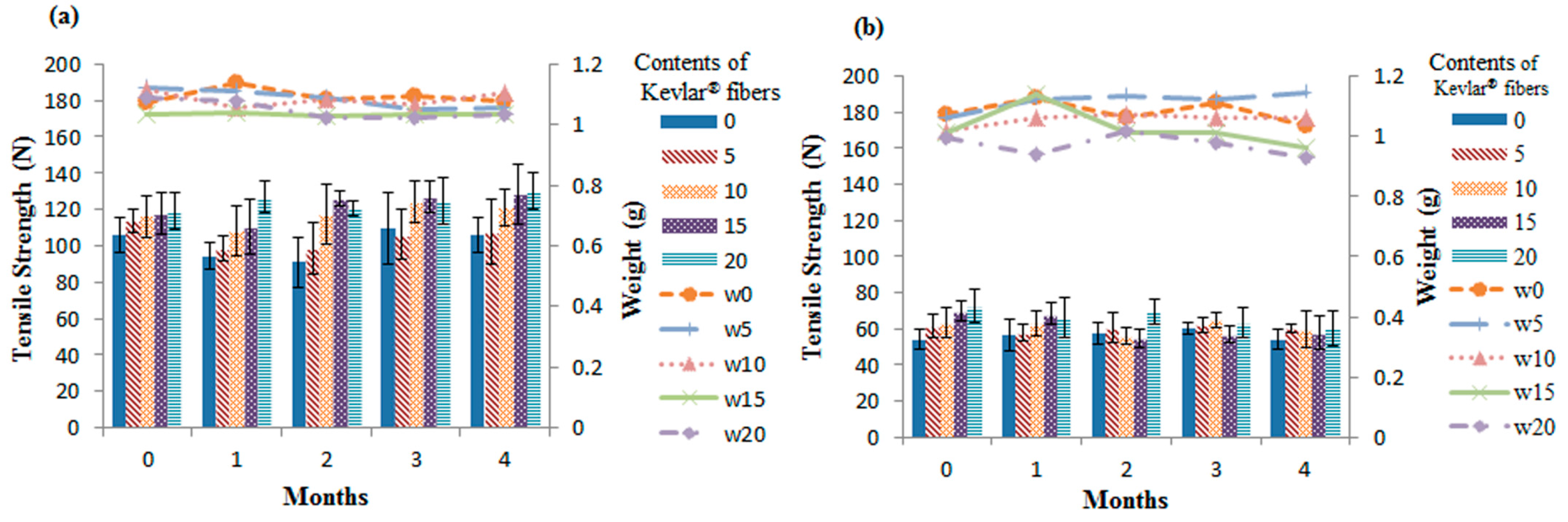

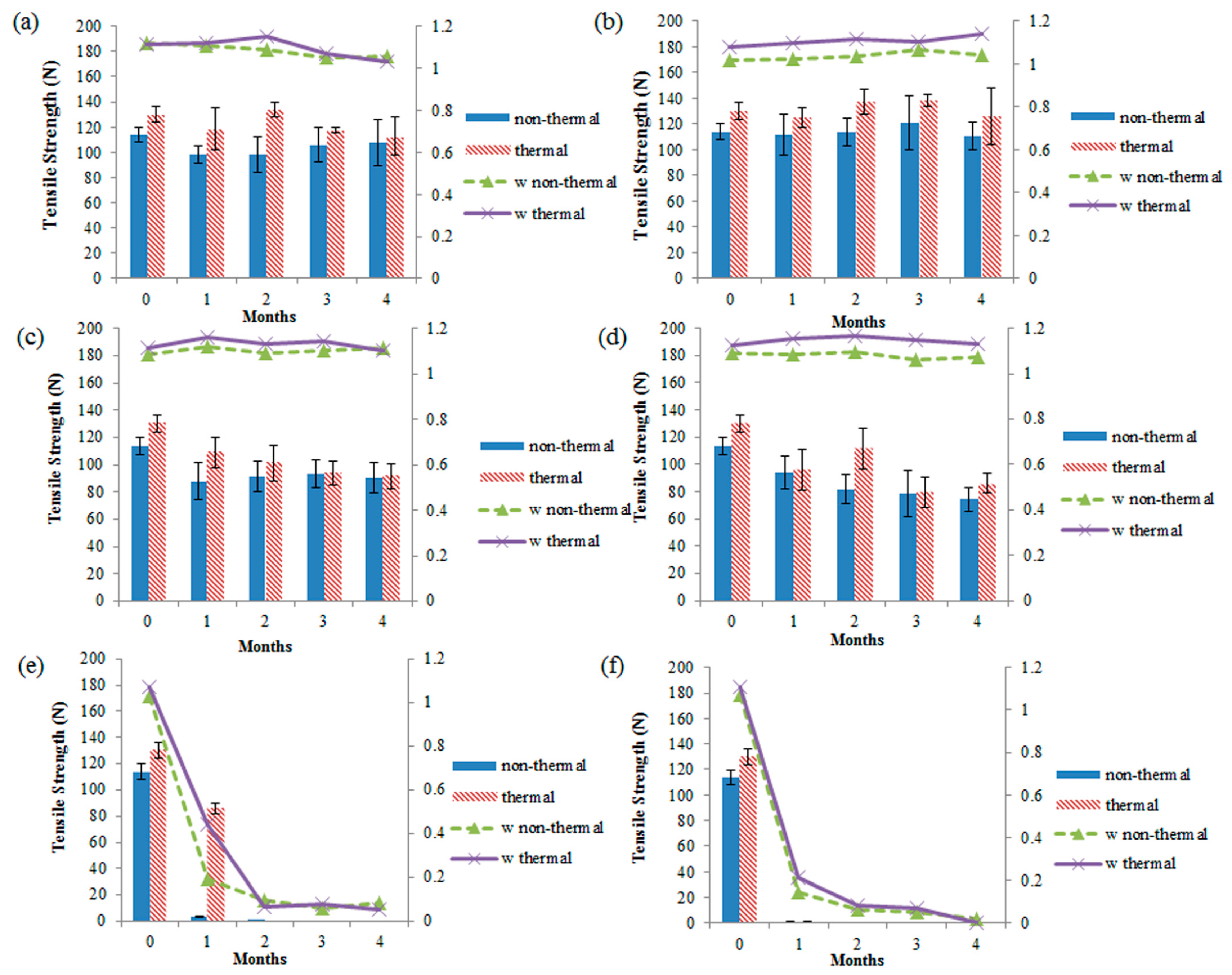

Figure 1 and

Figure 2 indicate the tensile strength of nonwoven geotextiles that are immersed in water for different periods. Thus, the tensile strength of nonwoven geotextiles does not significantly fluctuate as a result of the immersion temperatures, or of the sample types that are taken along CD or MD. Furthermore,

p > 0.05 in one-way ANOVA analysis also indicates the differences in tensile strength are not statistically significant, indicating that the tensile strength of nonwoven fabrics is not influenced by being in a neutral environment for 4 months.

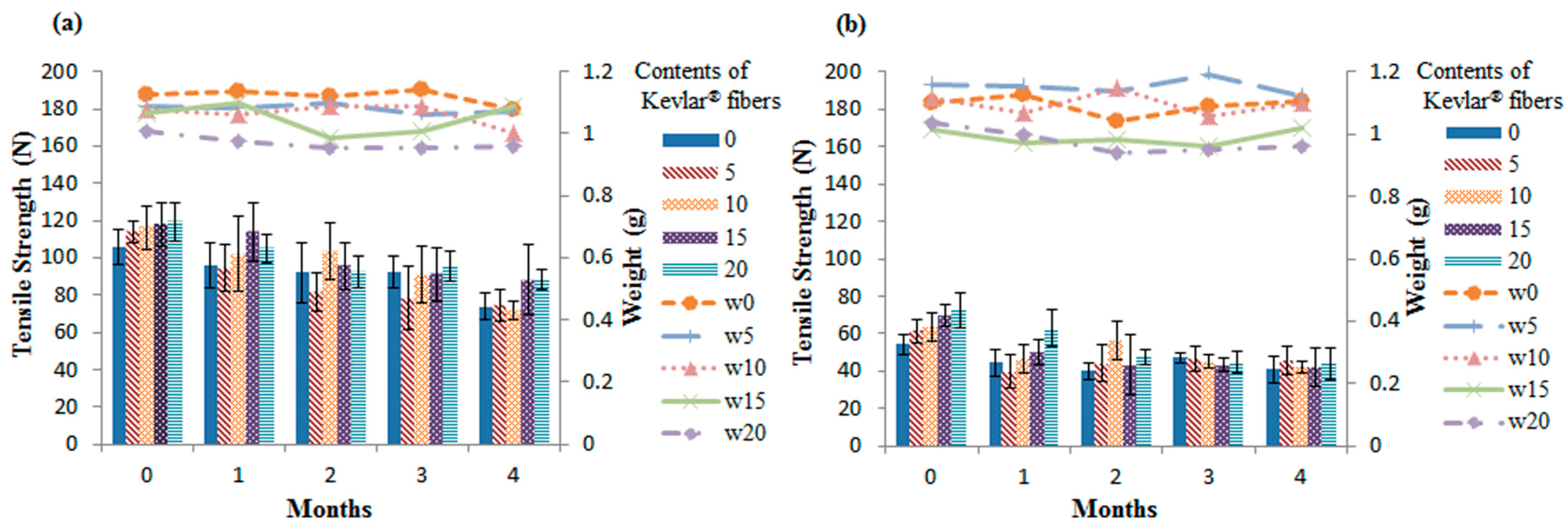

Figure 3 and

Figure 4 indicate the tensile strength of nonwoven geotextiles that are immersed in a strong acid solution for 1, 2, 3, or 4 months (

i.e., the experimental group). The control group is the nonwoven geotextiles without immersion.

Table 3 indicates the tensile strength of samples that are immersed in CH

3COOH in four months. With an acid solution at 23 °C, the nonwoven geotextiles without Kevlar

® fibers have a tensile strength that is in inversely proportion to the immersion periods (1, 2, 3, and 4 months), while the nonwoven geotextiles containing 5, 10, 15, or 20 wt. % Kevlar

® fibers exhibit comparable tensile strength regardless of the immersion periods. However, this trend is not observed for nonwoven fabrics that are immersed in an acid solution at 50 °C, and the tensile strength slightly decreases as a result of the increasing immersion period. These differences in tensile strength of the control group and the experimental group are then further analyzed using statistical analyses. The one-way ANOVA analysis indicates that the 0/80/20 exhibits a statistically significant difference (

p < 0.05) in tensile strength of nonwoven geotextiles that are immersed in an acid solution at 23 °C. Furthermore, when the immersion periods are considered, the post hoc Scheffe's test indicates that the significance in the 0/80/20 is ranked as 4 < 0, 1, 2, 3 (months). Namely, a 4-month immersion in an acid solution statistically significant debilitates the tensile strength of the control group, in comparison with a 0-, 1-, 2-, or 3-month immersion. In contrast, the content of Kevlar

® fibers of being 10, 15, or 20 wt. % is

p > 0.05. This shows the experimental group is acid resistant. In addition, when the experimental group is immersed in an acid solution at 50 °C, the one-way ANOVA analysis shows statistically significant differences in its acid resistance. This result suggests that the experimental group fails at remaining at its original tensile strength under an acid environment at a high temperature, which confirms to the results of the study conducted by Jeon

et al. [

17].

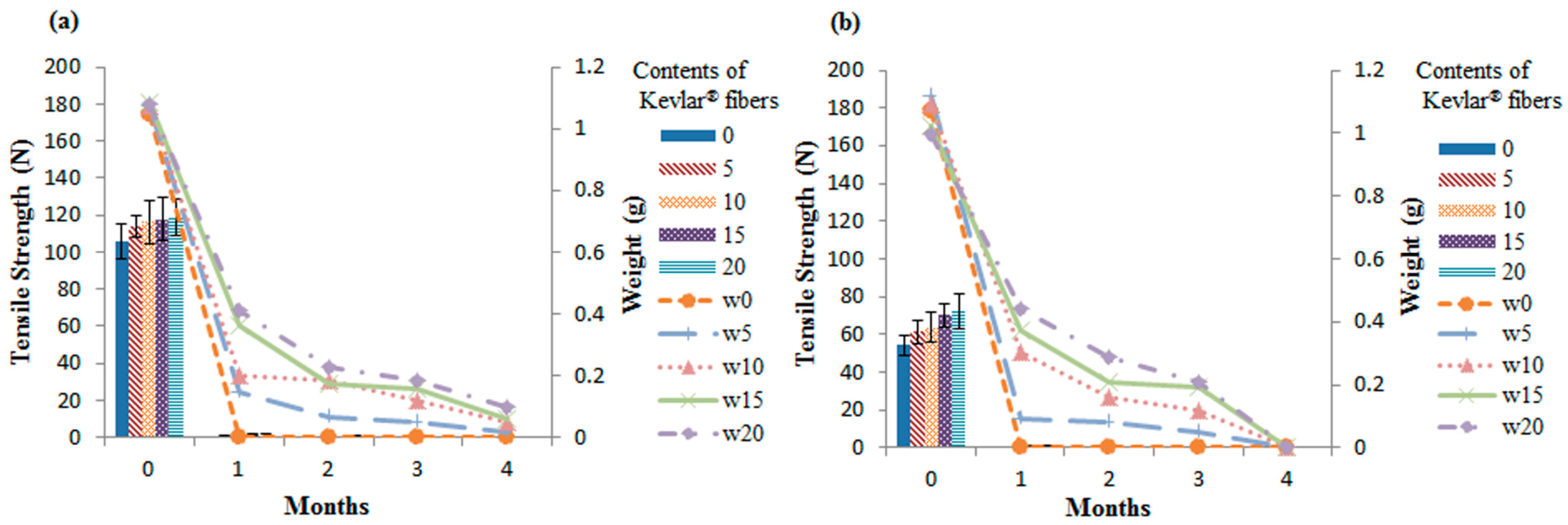

Figure 5 and

Figure 6 show the tensile strength of the recycled Kevlar

®/PET/LPET nonwoven geotextiles (experimental group) that are immersed in an alkali solution for 1, 2, 3, and 4 months. Regardless of the immersion temperatures of 23 °C or 50 °C, and regardless of the fact that samples are taken along the MD or along the CD, a 1-month immersion results in a significant decrease in the tensile strength of the experimental group. Although it is least possible for geotextiles to be used in an environment that has a pH below 13, the strong alkali solution is used in this study in order to examine the alkali resistance of recycled Kevlar

®/PET/LPET nonwoven geotextiles. The control group (

i.e., PET/LPET nonwoven geotextile) has a complete decomposition in a NaOH solution. However, the remaining tensile strength of the experimental group is 3%–5%. This indicates that the incorporation of Kevlar

® fibers improves the tensile strength of the nonwoven geotextiles. Strong alkali results in the decrease in the tensile strength of the experimental group because PET fibers undergo hydrolysis. Similarly, Mathur

et al. state that PET is subjected to a hydrolysis as a result of being exposed to an acid or an alkali environment [

15], while Bartolome

et al. points out that a combination of water and an acid, alkali, or neutral environment renders PET with a hydrolysis that involves the depolymerization of PET to terephthalic acid (TPA), and that can be aggravated by applying a high temperature [

24].

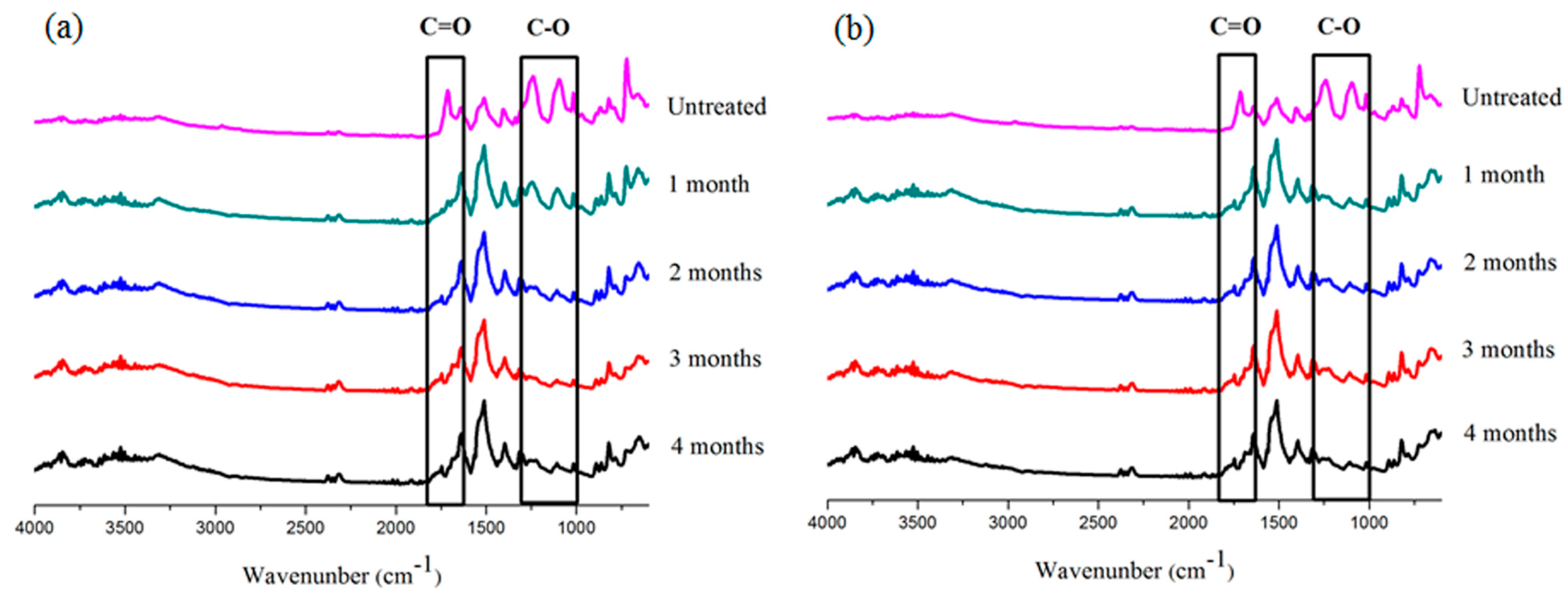

FT-IR analysis indicates that the characteristic absorption peak of PET’s ester bond is C=O at a frequency of 1750–1735 cm

−1 and C–O at 1300–1000 cm

−1, and the same characteristic peak is absent after the immersion in an alkali solution, as indicated in

Figure 7, which shows that the ester bonds exhibit bond breaking. Cassidy,

et al. [

25] indicate that hydrolysis of ester group results in bond breaking. PET encounters alkaline hydrolysis as a result of its contact with NaOH solution. The available ester linkage on the surface is broken, and then the original polymer chain is converted to the small molecules that turn into hydroxyl and carboxylate end groups [

26,

27]. In addition, alkaline hydrolysis starts with pores in fibers, and the coalescence of the pores become cracks that cause PET to discompose [

16,

17]. As a result, the recycled Kevlar

®/PET/LPET nonwoven geotextiles have a significant decrease in their weight loss, as indicated in

Figure 5 and

Figure 6, which is ascribed to the decrease in their tensile strength.

3.3. Effects of Thermal Treatment on Tensile Strength

According to

Figure 1,

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7, the geotextiles have a higher fiber orientation along the CD, and samples taken along this direction are thus used for this section. Recycled Kevlar

®/PET/LPET nonwoven geotextiles are composed of LPET fibers that have a sheath-core structure. The sheath has a melting point of 110 °C, based on which the thermal treatment is set to be at 120 °C. The tensile strength of nonwoven fabrics in relation to thermal treatment conditions is presented in

Table 4. Regardless of the environment being neutral, acid, or alkaline, the tensile strength of the nonwoven geotextile is greater when they are thermally treated, rather than when they are not thermally treated, as indicated in

Figure 8. A

t-test is conducted in order to examine the influence of thermal treatment on the tensile response of the nonwoven geotextiles tested the tensile strength. The

t-test results report

p < 0.05 that there is a statistical significance as thermal treatment results in a higher tensile strength. However, the statistical analyses for NaOH solution is absent in

Table 4 due to the fact that the immersion in a strong alkaline solution for 4 months results in the disappearance of tensile strength of nonwoven geotextiles. The available data is insufficient to satisfy the hypothesis for a normal distribution, and a

t-test cannot be performed. One-way ANOVA and Scheffe's test are used to compare the tensile strength of the thermally treated and non-thermally treated geotextiles in relation to immersion periods (1, 2, 3, and 4 months) and solution temperatures (23 °C and 50 °C). For geotextiles immersed in H

2O, there is no statistical significance in the tensile strength between different immersion periods and solution temperatures. This statistical analysis is in conformity with the results in section 3.2. When applying CH

3COOH at 23 °C, the non-thermally treated geotextiles show the statistical significant difference as 1 < 0 (months), while the thermally treated geotextiles show the statistical significant difference as 2, 3, 4 < 0. In addition, the thermally treated geotextiles also have a higher alkali resistance than non-thermally treated geotextiles, as indicated in

Figure 8e. Such a result is due to the constituent LPET fibers that undergo softening as a result of the thermal treatment for the nonwoven geotextiles. The fibers that are crossed are bonded by the bonding points, and thereby increase the contact areas between fibers and eventually improve the strength of nonwoven fabrics. Therefore, thermally treated nonwoven geotextiles have a higher tensile strength.

3.4. Multiple Regression Analyses of Tensile Strength

Multiple regression is used to statistically analyze the influence of the independent variables (

X) on the dependent variables (

Y).

X refers to independent variables that are represented in

X1,

X2,

X3…,

Xn, while

Y refers to dependent variable. In this study, the independent variables (

X1,

X2,

X3…,

Xn) are: Contents of Kevlar

® fibers, immersion periods, and immersion temperatures. The dependent variable (

Y) is the tensile strength of the nonwoven geotextiles after immersion under the specific conditions considered.

Table 5 summarizes the results of multiple regression analyses, where

B is the unstandardized regression coefficient that indicates the coefficient of

X. β is the standardized regression coefficient that has a value between −1 ~ +1. The greater the absolute value of β, the higher the influence level of the dependent variable. The

F value is the result of the

F test, and

p < 0.05 suggests that the multiple regression result has statistical significance. Adjusted

R2 stands for the explanatory power of the independent variables for dependent variables. VIF value represents the collinear influence, when VIF > 5, the independent variables are highly correlated. When VIF > 10, the accuracy of multiple regression analyses is low.

The multiple regression model (1) is composed of correlations among the three designated independent variables and the tensile strength of recycled Kevlar®/PET/LPET nonwoven geotextiles that are immersed in H2O for 1, 2, 3, and 4 months. There is no statistically significant difference in their tensile strength when samples are immersed for different lengths of time or different solution temperatures. The statistical analyses indicate that contents of Kevlar® fibers is the only influential factor of a neutral environment (H2O) on the tensile strength of nonwoven geotextiles. The F test results demonstrate that this multiple regression analyses have statistical significance with (F (1,229) = 65.76, p = 0.00). The explanatory power is 22% without collinearity.

The multiple regression model (2) is composed of correlations among the three designated independent variables and the tensile strength of recycled Kevlar®/PET/LPET nonwoven geotextiles that are immersed in CH3COOH for 1, 2, 3, and 4 months. The influential factors to the tensile strength of the nonwoven geotextiles that are immersed in CH3COOH are ranked as immersion periods, contents of Kevlar® fibers, and immersion temperatures. According to the results of one-way ANOVA analyses in section 3.2, there are statistically significant differences in the tensile strength of the nonwoven geotextiles that are immersed in an acid solution for 4 months, including the five combinations of 0 wt. % of Kevlar® fibers and 23 °C, as well as 0/5/10/15/20 wt. % of Kevlar® fibers and 50 °C. In addition, the tensile strength is proportional to the contents of Kevlar® fibers. In other words, the contents of Kevlar® fibers demonstrate an influence on the tensile strength. Immersion temperature is the last independent variable that is involved in the multiple regression model (2). Because a high immersion temperature expedites the hydrolysis of PET, the tensile strength of nonwoven geotextiles is slightly lower when they are immersed in an acid solution at 50 °C, rather than when they are immersed in an acid solution at 23 °C. Based on the F test results, this multiple regression analyses have statistical significance with (F (3,192) = 60.14, p = 0.00). The explanatory power of the equation is 48% without collinearity.

The tensile strength against NaOH of recycled Kevlar®/PET/LPET nonwoven geotextiles is depicted by model (3). The analytic results indicate that the major factor is immersion periods. As a strong alkali solution with a pH = 13 is used in this study, the nonwoven geotextiles exhibit alkaline hydrolysis regardless of the immersion temperature of 23 °C or 50 °C, and is exemplified by a statistically significant decrease in the tensile strength. Based on the F test results, this multiple regression analyses have statistical significance with (F (1,115) = 217.58, p = 0.00). The explanatory power of the equation is 65% without collinearity.

4. Conclusions

This study proposes synthesizing recycled Kevlar® fibers, LPET fibers, and PET fibers to successfully create recycled Kevlar®/PET/LPET nonwoven geotextiles. First, the influences of different contents of Kevlar® fibers on the tensile strength of nonwoven geotextiles are examined. In light of experimental results and statistically analyses, the incorporation of Kevlar® fibers can improve the tensile strength of the nonwoven geotextiles. In particular, 15 wt. % and 20 wt. % of Kevlar® fibers strengthen the tensile strength by 20% to 90%, and reaches the statistical significance of p < 0.05. Second, the influences of immersion periods on the tensile strength of the nonwoven geotextiles are examined. The correlations between a 4-month immersion in different environment conditions and the differences in the tensile strength of the nonwoven geotextiles are 0% in a neutral environment, while there is a 30%–50% decrease for the control group and a 17%–20% decrease for the experimental group in an acid environment, and a 100% decrease for the control group and a 95%–97% decrease for the experimental group in an acid environment. Statistical analyses also confirm that the experimental group has a higher tensile strength than the control group. Third, the influences of thermal treatment on the tensile strength of the nonwoven geotextiles are examined. The thermal treatment is proved to provide a 15%–45% greater tensile strength to the nonwoven geotextiles and yields a statistical significance at p < 0.05. Finally, demonstrated by the multiple regression analyses, the factors that influence the tensile strength of the nonwoven geotextiles with their corresponding environments is contents of Kevlar® fibers (neutral environment), immersion periods, contents of Kevlar® fibers, and immersion temperatures (acid environment), and immersion periods (alkaline environment). The combination of recycled Kevlar® fibers and LPET fibers have been proven to significantly improve the tensile strength of nonwoven geotextiles in terms of a neutral, acid, and alkali treatment.