2.1. Resistance Capacity Evaluation of the Sample Bridge

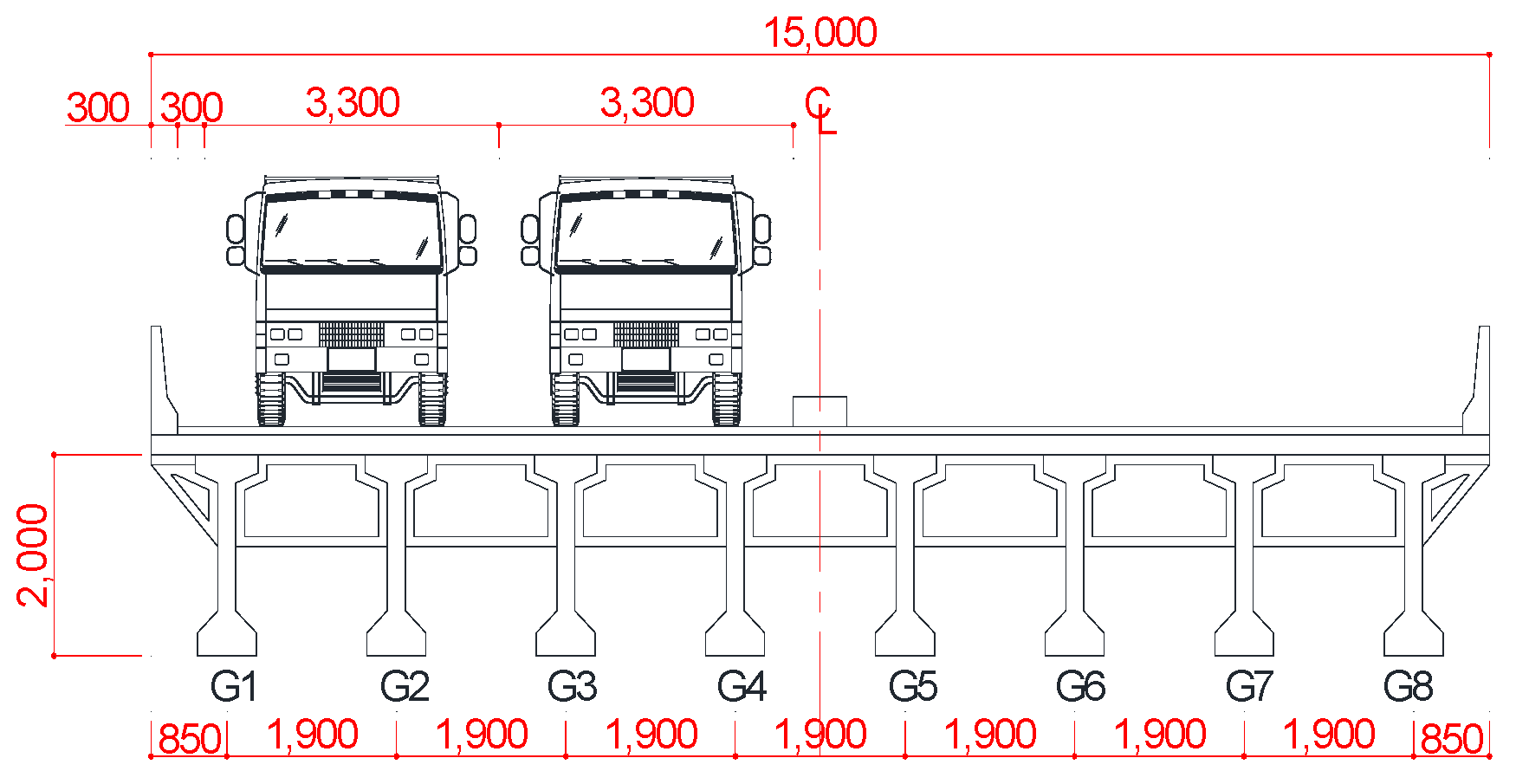

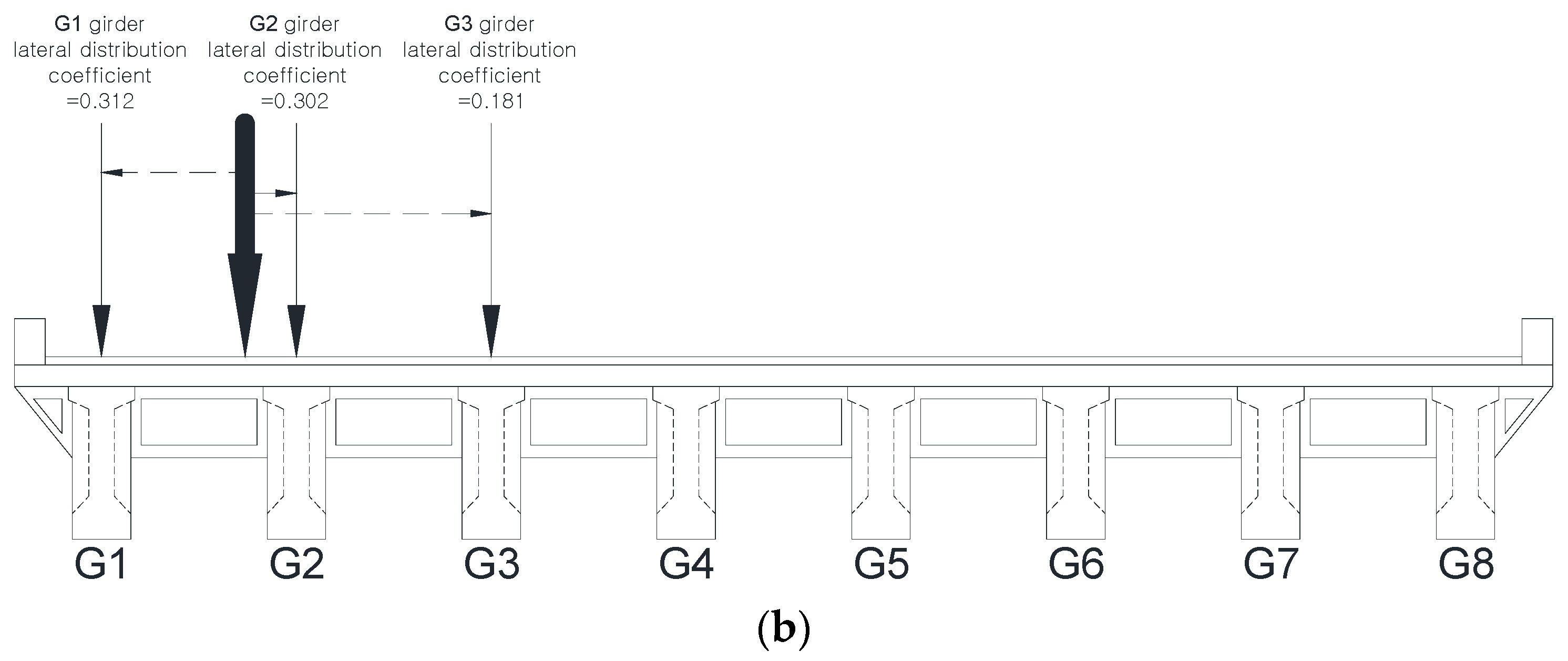

In this study, a PSC-I type girder bridge was specifically selected for examination in order to develop a method for analyzing the resistance capacity and performance degradation of bridges. The sample bridge was to be used in a two-lane expressway and comprised a single span that was 15 m in width. It was designed to satisfy the DB-24 load as outlined in the Korea highway bridge specifications [

6]. The total span length of the sample bridge was set as 30 m.

To determine the appropriate cross section of the PSC-I girder, the standard cross-section of a 30-m-long PSC-I girder provided by the Korea Express Corporation (Seoul, Korea) was utilized.

Table 1 and

Figure 1 present the data specifications and cross-sectional profiles of the sample bridge at the mid-span.

The resistance capacity of the sample bridge was evaluated by calculating the flexural resistance, which is the material property that resists the effects of the two major loads applied to the structure: the dead load and live load. As discussed in the following sections, the resistance capacity of the PSC-I girder bridge was evaluated by using the flexural strength equation from the load-and-resistance factor design (LRFD) bridge design specifications [

7].

The equations for the flexural strength of a PSC-I girder vary with the depth of the concrete stress block

and the position of the compression flange

. If the depth of the concrete stress block is shallower than the thickness of the compression flange (i.e.,

), the equations for the flexural strength of a rectangular cross-section are used:

where

) is the area of the pre-stressed (PS) tendon,

) is the area of the non-pre-stressed tension reinforcing bar,

) is the area of the compression reinforcing bar,

(MPa) is the average stress in the PS tendon,

(MPa) is the stress in the mild steel tension reinforcing bar,

(MPa) is the stress in the mild steel compression reinforcing bar,

(MPa) is the yield strength in the PS tendon,

(

) is the depth of the equivalent stress block,

(

) is the width of the compression face of the member,

(

) is the distance from the center of the longitudinal reinforcement to the nearest face of the concrete-encased shape on the bending plane,

(

) is the distance from the extreme compression fiber to the centroid of the non-pre-stressed tensile reinforcement, and

(

) is the stress block factor.

In contrast, if the depth of the concrete stress distribution block is greater than the thickness of the compression flange

, the flexural strength equation for an I-type or T-type cross-section is used, as shown in Equations (3) and (4), respectively:

where

(MPa) is the compressive strength of the concrete,

(

) is the width of the compression face of the member,

(

) is the web width, and

(

) is the compression flange depth. Based on the concrete compressive strength (i.e., 28 MPa) of the stress block factor (

), the flexural strength was calculated to be in the range of 0.65–0.85. According to American Association of State Highway and Transportation Officials (AASHTO) [

7], the stress block factor (

) is calculated by considering the ductility of concrete as follows:

In addition, when the flexural strength of a PSC-I girder is calculated, the stress of a PS tendon (

) generated when a girder is destroyed is used instead of the yield strength (

) of the stress of the PS tendon. For the convenience of hands-on workers, AASHTO [

7] presented the following approximation:

where

(MPa) is the yield strength in the PS tendon,

is a type of PS tendon correction factor,

(

) is the distance from the center of the longitudinal reinforcement to the nearest face of the concrete-encased shape along the plane of bending, and

(

) is the distance from the extreme compression fiber to the centroid of the PS tendons.

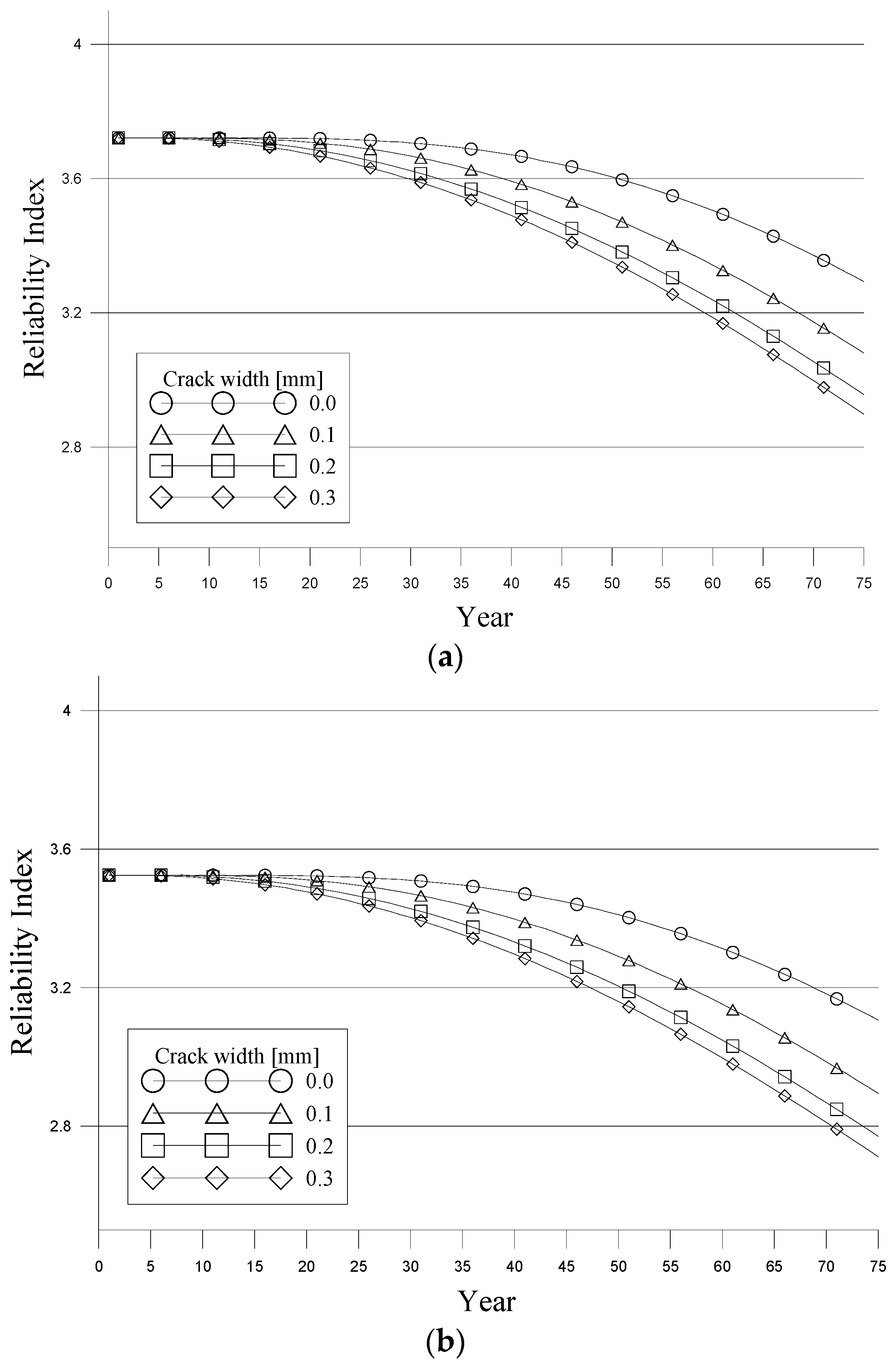

2.2. Determination of the Degradation Initiation Time of the PSC-I Girder

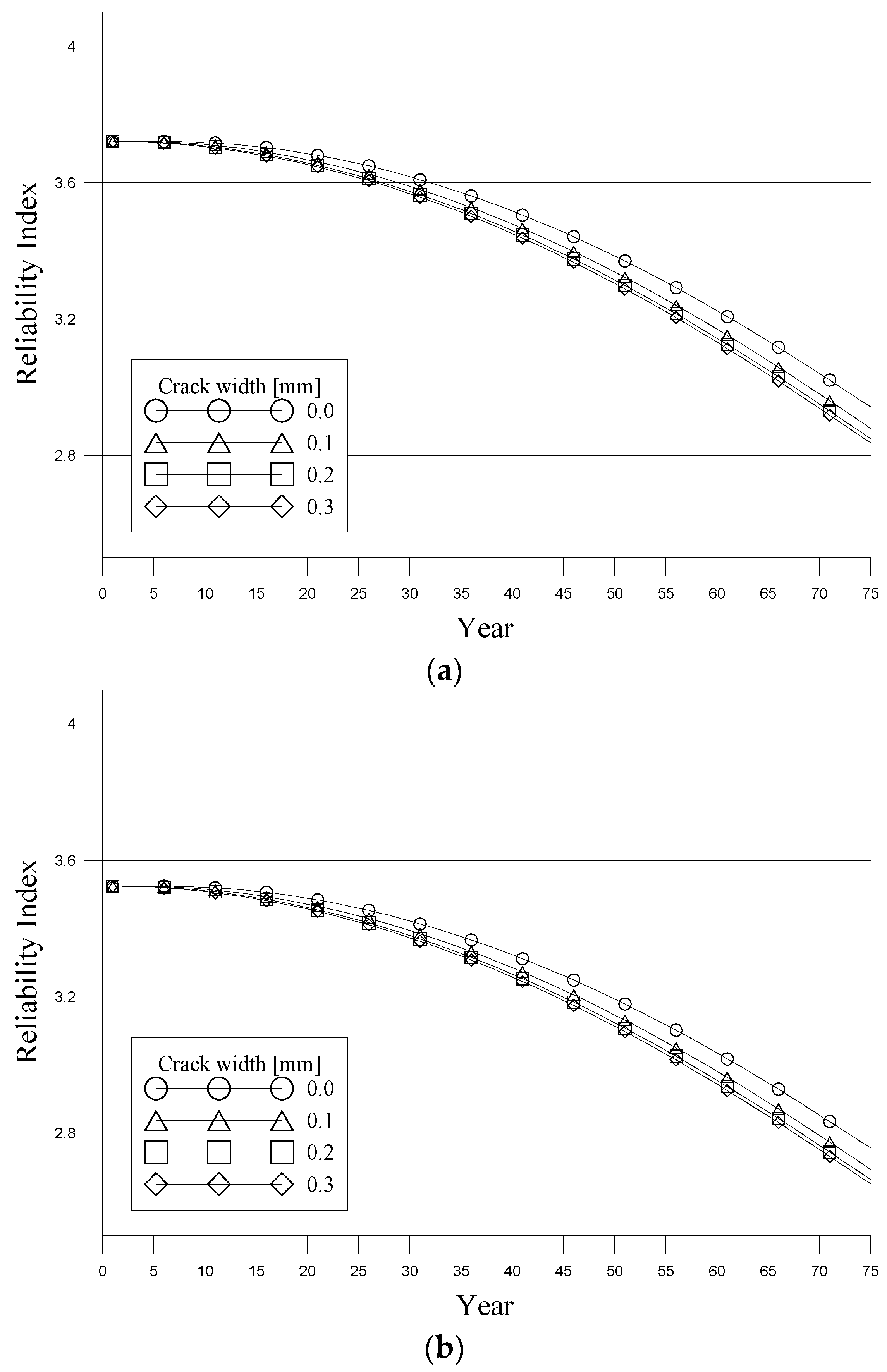

The performance of a reinforced concrete structure often degrades because of corrosion of the reinforcing bars. Chloride attack is a major factor in the corrosion of reinforcing bars embedded in concrete. Kwon et al. [

8] proposed a chloride diffusion model based on a diffusion equation derived from Fick’s second law that considers the time dependence of the chloride diffusion coefficient (

) and the dependence of the diffusion coefficient correction factor

) on the width of cracks in the concrete. In this study, the initiation time for the performance of the structure to degrade was calculated by using the improved chloride diffusion equations given below:

where

is the diffusion coefficient dependent on time,

is the crack effect function,

(

) is the crack width,

is the diffusion coefficient at

,

is constant depending on the mix proportion,

is the reference time, and

is the time at which the diffusion coefficient is assumed to be constant.

When the diffused chloride reaches a certain concentration level at the depth of the rebar, the rebar corrodes. The chloride concentration that causes corrosion of the steel reinforcement is called the chloride threshold level (

). The point at which the resistance capacity degrades can be predicted by calculating the time

at which the chloride concentration in the cover thickness of the concrete

exceeds the chloride threshold value (

). Thus, the initiation time for the performance degradation of a reinforced concrete structure by steel corrosion can be determined by using the chloride concentration around the steel reinforcement in the concrete:

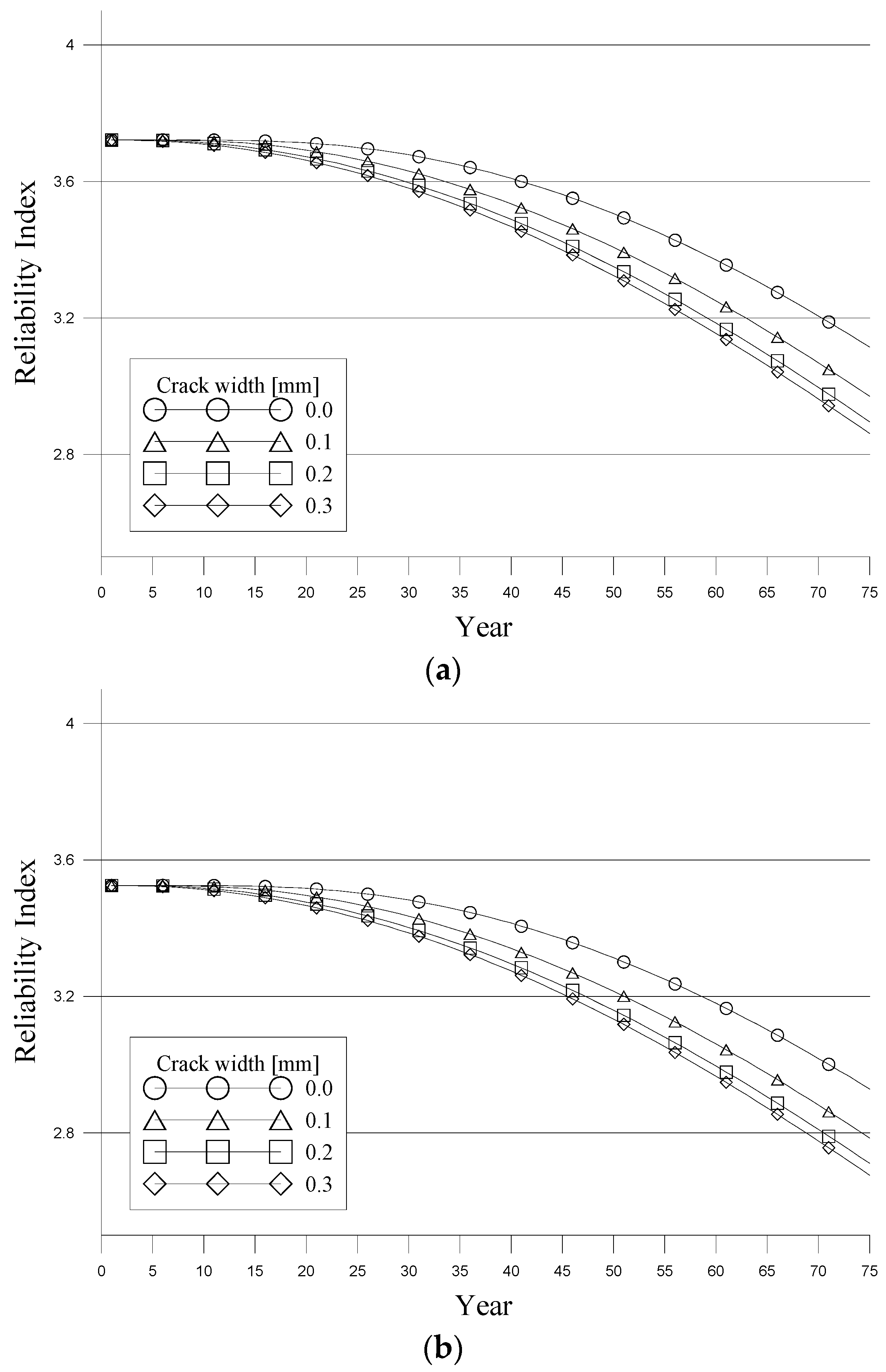

The carbonation depth from the surface of the concrete due to the presence of carbon dioxide in the atmosphere can be expressed as Equation (12), which is dependent on time [

9]. The progression of internal carbonation is proportional to the square root of the total elapsed time. Based on this equation, the estimated time (

) when the carbonation depth exceeds its limit in the concrete can be calculated by using the degradation initial time of the PSC-I girder caused by carbonation (Equation (13)). The carbonation rate coefficient (

) signifies the progress rate of carbonation and depends on the material properties of the concrete and the environmental conditions that the concrete is subjected to. The work by Park [

10] was used to calculate the degradation initiation time according to the appropriate carbonation rate coefficient for the given material properties and environmental conditions (

Table 2):

where

(

) is the carbonation rate coefficient,

(year) is the service life,

(

) is the predicted carbonation depth, and

(

) is the limit depth.

2.3. Corrosion Damage Model for Reinforcing Bars Embedded in Concrete

Damage to the materials comprising the cross-sectional area of the bridge structure directly affects the resistance capacity of the bridge. The effective area of the steel reinforcement decreases when the steel is corroded by chloride penetration and carbonation. In this study, the decrease in the effective cross-section by corrosion of the reinforced steel of a floor plate and girder was considered. Val and Melchers [

11] presented an equation for calculating the effective area based on the form of the corrosion (Equation (14)). The corrosion depth (

) and current corrosion density (

) required to calculate the effective area (

) according to the service period were determined by using Equations (15) and (16):

where

and

are the effective area factors,

is the penetration ratio between the maximum and average penetration,

(year) is the time of corrosion initiation,

(

) is the corrosion current density,

(%) is the relative humidity,

(K) is the absolute temperature,

is the water–cement ratio, and

(

) is the effective depth.