Effects of Coupling Agents on the Structure and Electrical Properties of PZT-Poly (Vinylidene Fluoride) Composites

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Preparation of PZT-PVDF Composites with Coupling Agents

2.3. Measurements

3. Results and Discussion

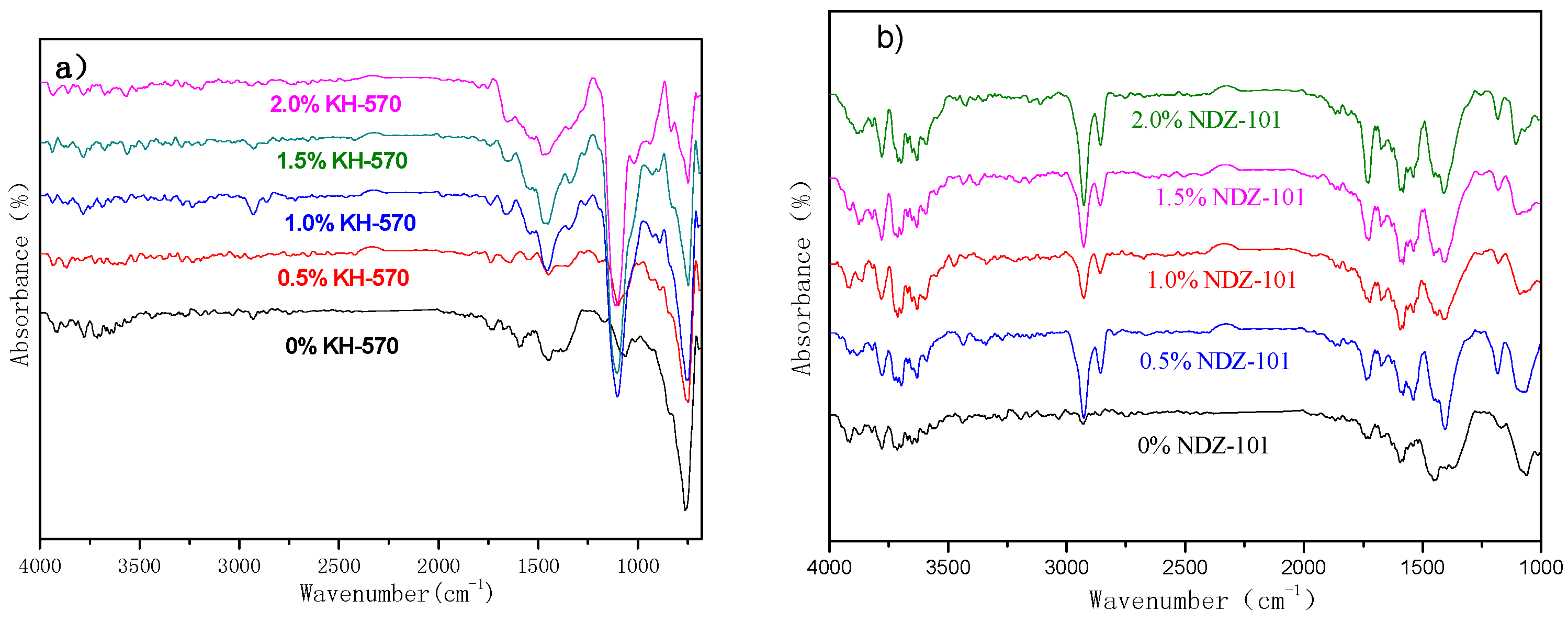

3.1. FTIR (Fourier Transform infrared spectroscopy)

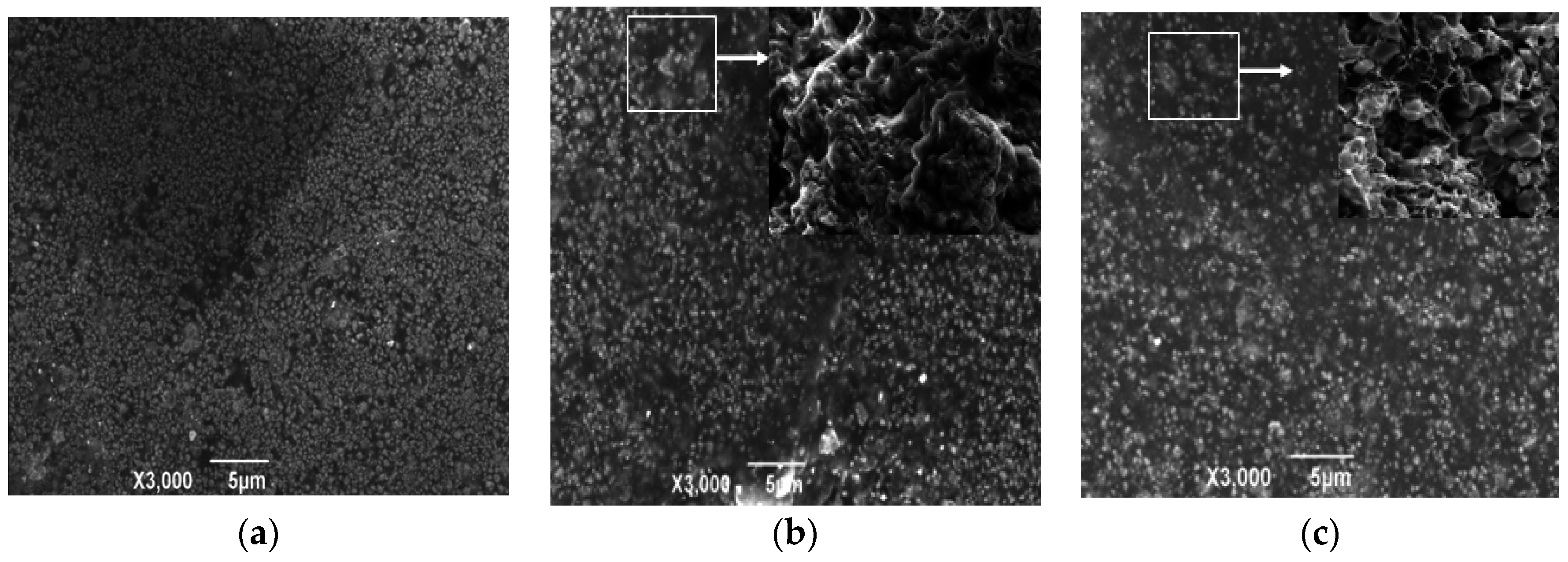

3.2. SEM (Scanning Electron Microscopy)

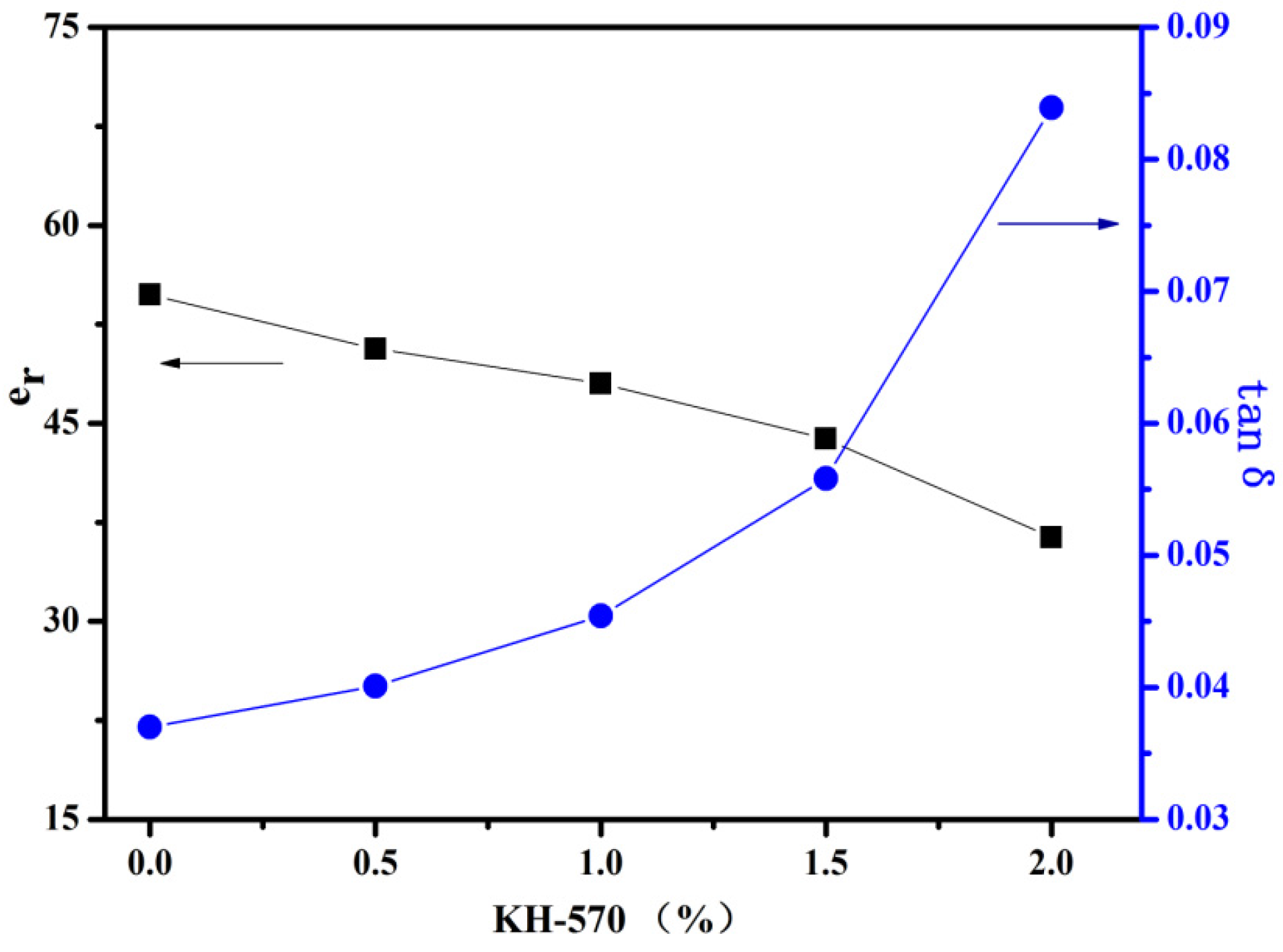

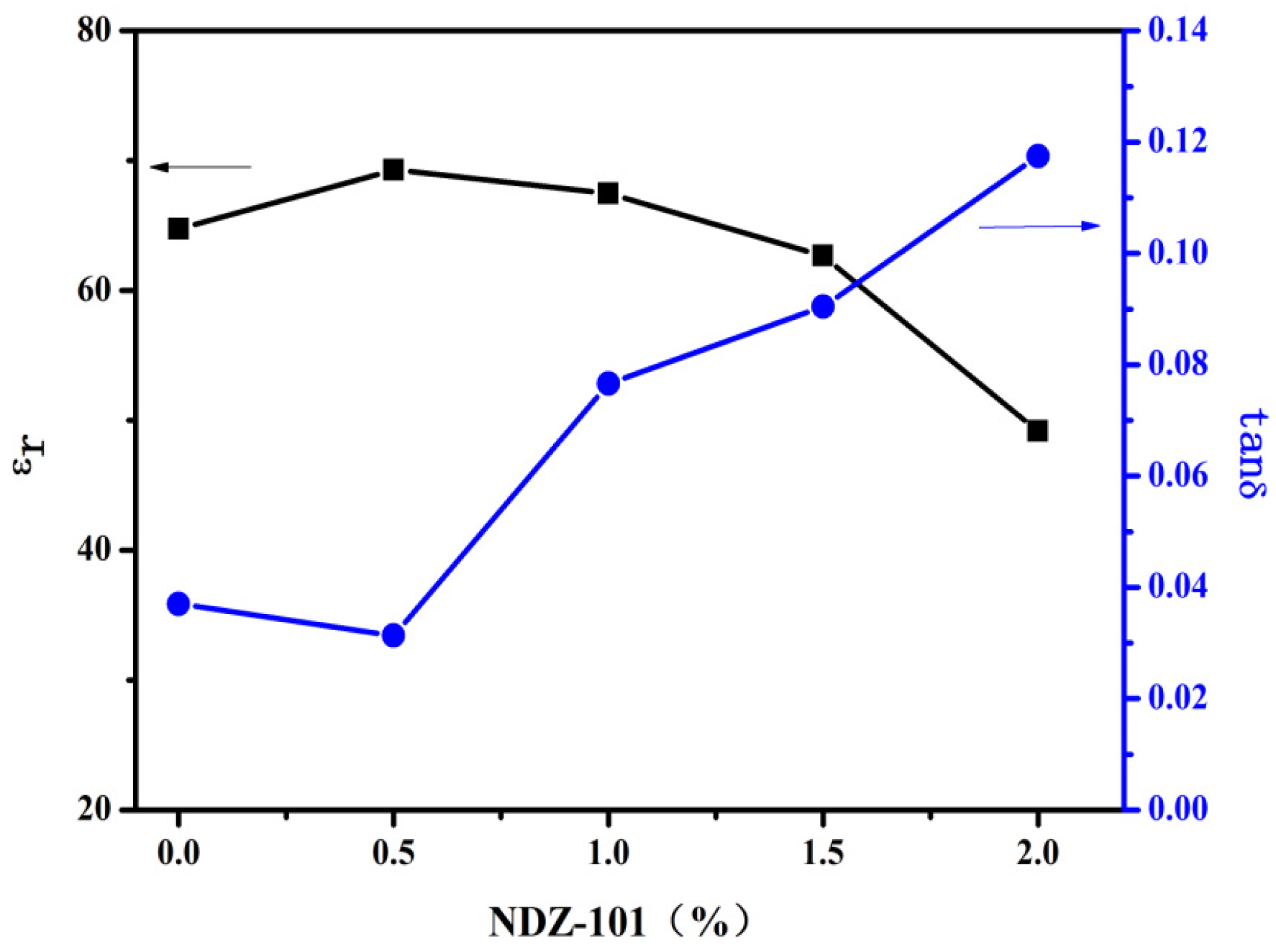

3.3. Effects of Coupling Agent on the Dielectric Properties of PZT-PVDF

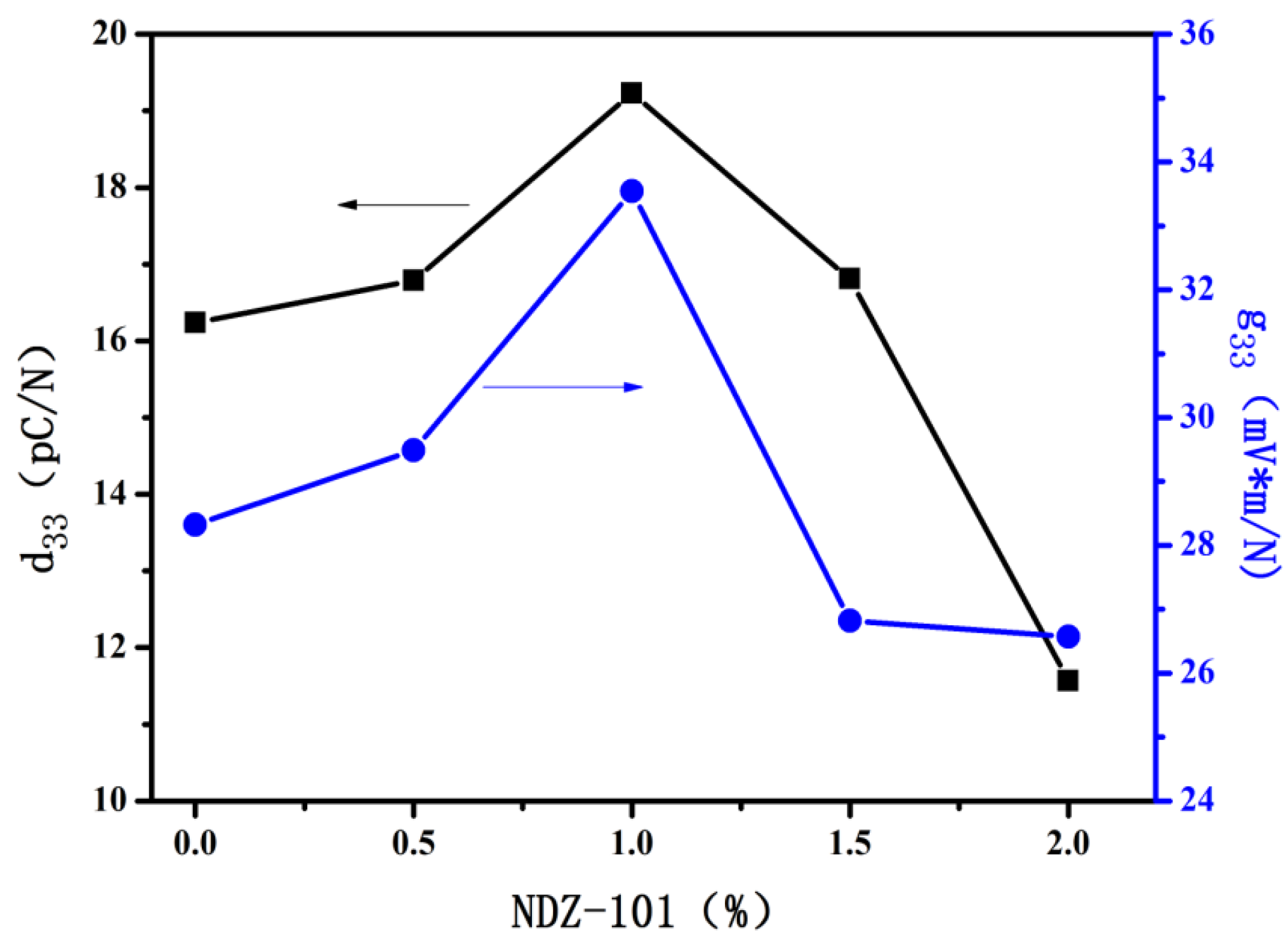

3.4. Effects of Coupling Agent on the Piezoelectric Properties of PZT-PVDF

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mascia, L.; Kioul, A. Influence of siloxane composition and morphology on properties of polyimide-silica hybrids. Polymer 1995, 36, 3649–3659. [Google Scholar] [CrossRef]

- Rubia, L.; Vasconcelos, F.S.; Wander, L. Synthesis of titania-silica materials by sol-gel. Mater. Res. 2002, 5, 497–502. [Google Scholar]

- Liu, L.Z.; Weng, L.; Song, Y.X.; Gao, L.; Lei, Q.Q. The effects of coupling agents on the properties of Polyimide/Nano-Al2O3 Three Layer Hybrid Films. J. Nanomater. 2010, 2010. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, D.H.; Kim, B.K. Nanocomposite films. Macromol. Rapid Commun. 2006, 27, 1821–1825. [Google Scholar] [CrossRef]

- Bharti, V.; Kaura, T.; Nath, R. Ferroelectric hysteresis in simultaneously stretched and corona-poled PVDF film. IEEE Trans. Dielectr. Electr. Insul. 1997, 4, 738–741. [Google Scholar] [CrossRef]

- Savakus, H.P.; Klicker, K.A.; Newnham, R.E. PZT-Epoxy piezoelectric transducers: A simplified fabrication procedure. Mater. Res. Bull. 1981, 16, 677–680. [Google Scholar] [CrossRef]

- Bayer, I.S.; Biswas, A.; Megaridis, C.M. Biocompatible poly vinylidene fluoride cyanoacrylate composite coatings with tunable hydrophobicity and bonding strength. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- Li, R.; Pei, J.Z.; Sun, C.L. Effect of nano-ZnO with modified mofified surface on properties of bitumen. Constr. Build. Mater. 2015, 98, 656–661. [Google Scholar] [CrossRef]

- Wise, S.A. Displacement Properties of RAINBOW and THUNDER Piezoelectric Actuators. Sens. Actuators A Phys. 1998, 69, 33–38. [Google Scholar] [CrossRef]

- Gao, Q.; Scheinbeim, J.I. Dipolar intermolecular interactions, structural development, and electromechanical properties in ferroelectric polymer blends of nylon and poly (vinylidene fluoride). Macromolecules 2000, 33, 7564–7572. [Google Scholar] [CrossRef]

- Amash, A.; Zugenmaier, P. Thermal and dynamic mechanical investigations on fiber reinforced polypropylene composites. J. Appl. Polym. Sci. 1997, 63, 1143–1154. [Google Scholar] [CrossRef]

- George, S.; Varughese, K.T. Dynamic mechanical properties of isotactic polypropylene/nitrile rubber blends: Effects of blends ratio, reactive compatibilization and dynamic vulcanization. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2309–2327. [Google Scholar] [CrossRef]

- Kuang, D.L.; Li, R.; Pei, J.Z. Polyamide 11/Poly(vinylidene fluoride)/VinylAcetate-Maleic Anhydride Copolymer as Flexible Materials for Capacitors. Polymers 2014, 6, 2146–2156. [Google Scholar] [CrossRef]

- Nwabunma, D.; Kyu, T. Polyolefin Blends; John Willey & Sons, Inc.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Li, R.; Pei, J. High Dielectric Performance of Polyamide11/Poly (vinylidene fluoride) Blend Films Induced by Interfacial Glycidyl Methacrylate. Polym. Sci. Ser. A 2015, 57, 792–798. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Zhang, L.; Shi, Z.; Pei, J. Effects of Coupling Agents on the Structure and Electrical Properties of PZT-Poly (Vinylidene Fluoride) Composites. Appl. Sci. 2016, 6, 282. https://doi.org/10.3390/app6100282

Li R, Zhang L, Shi Z, Pei J. Effects of Coupling Agents on the Structure and Electrical Properties of PZT-Poly (Vinylidene Fluoride) Composites. Applied Sciences. 2016; 6(10):282. https://doi.org/10.3390/app6100282

Chicago/Turabian StyleLi, Rui, Liu Zhang, Zhiliang Shi, and Jianzhong Pei. 2016. "Effects of Coupling Agents on the Structure and Electrical Properties of PZT-Poly (Vinylidene Fluoride) Composites" Applied Sciences 6, no. 10: 282. https://doi.org/10.3390/app6100282