Spatially Resolved Analysis of Bragg Selectivity

Abstract

:1. Introduction

2. Experimental Section

2.1. Hologram Generation

2.2. Lateral Scanning

3. Results and Discussion

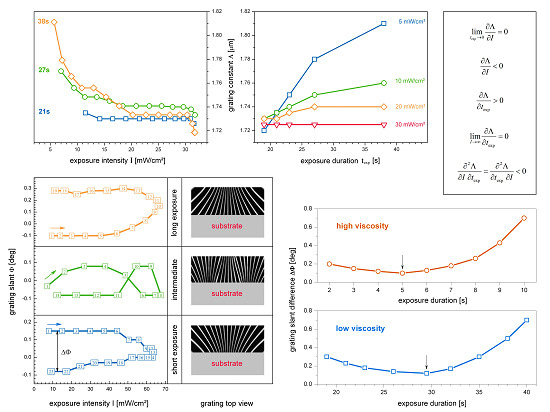

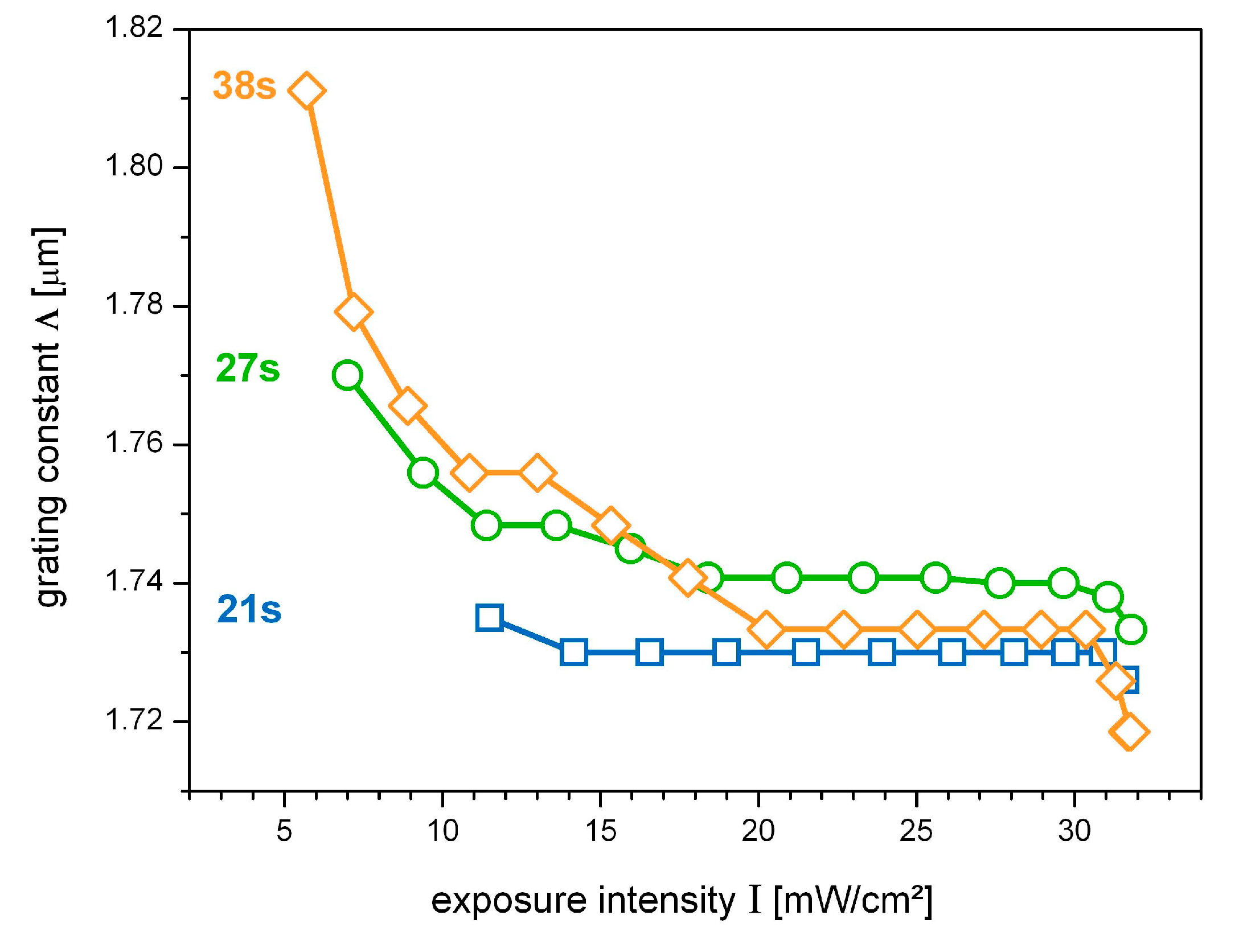

3.1. The Grating Constant Λ

3.1.1. Impact of the Recording Intensity: Λ(I)

3.1.2. Impact of the Exposure Duration: Λ(texp)

3.1.3. Mutual Consistency: Λ(I, texp)

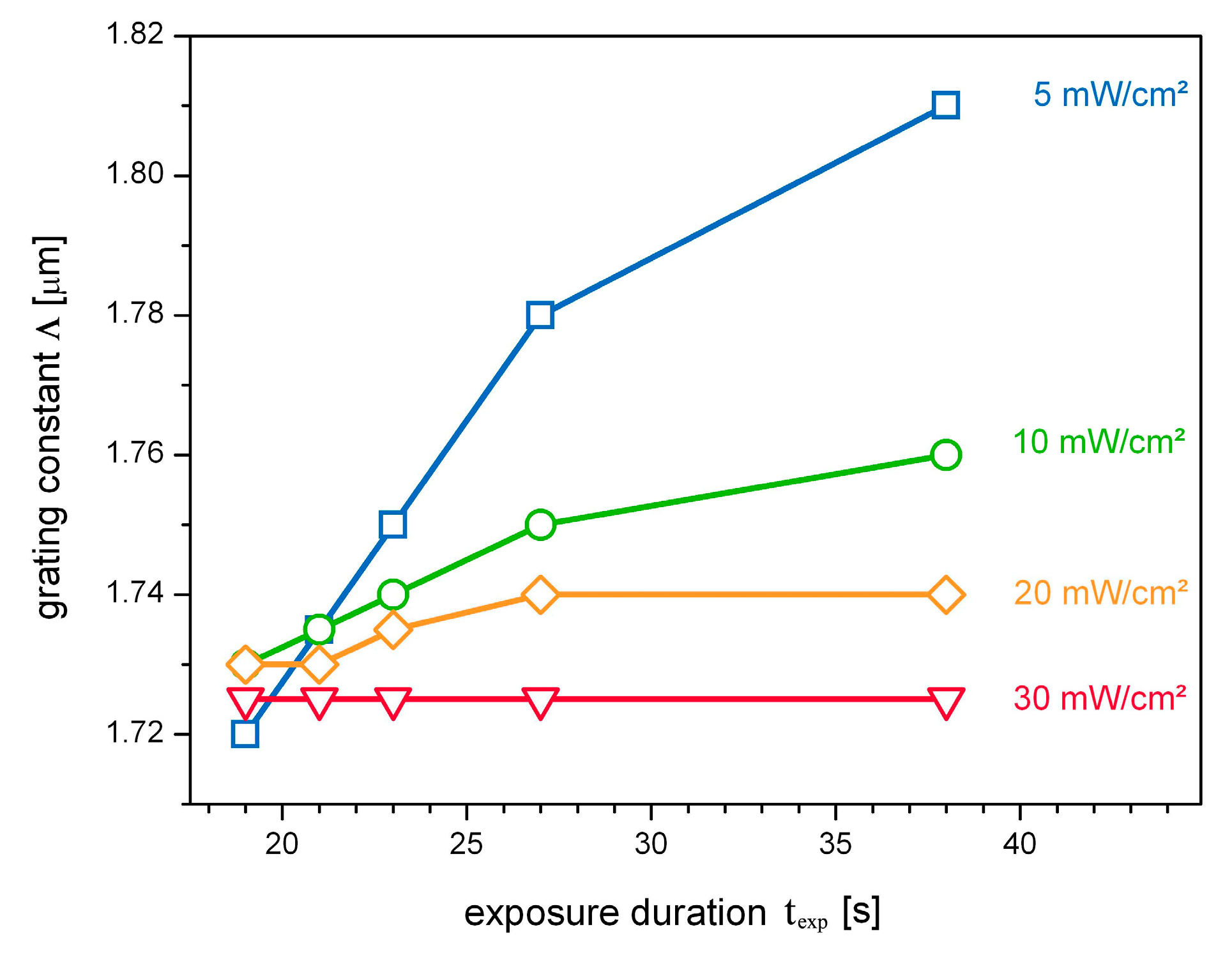

3.2. The Grating Slant Φ

3.2.1. Impact of the Recording Intensity: Φ(I)

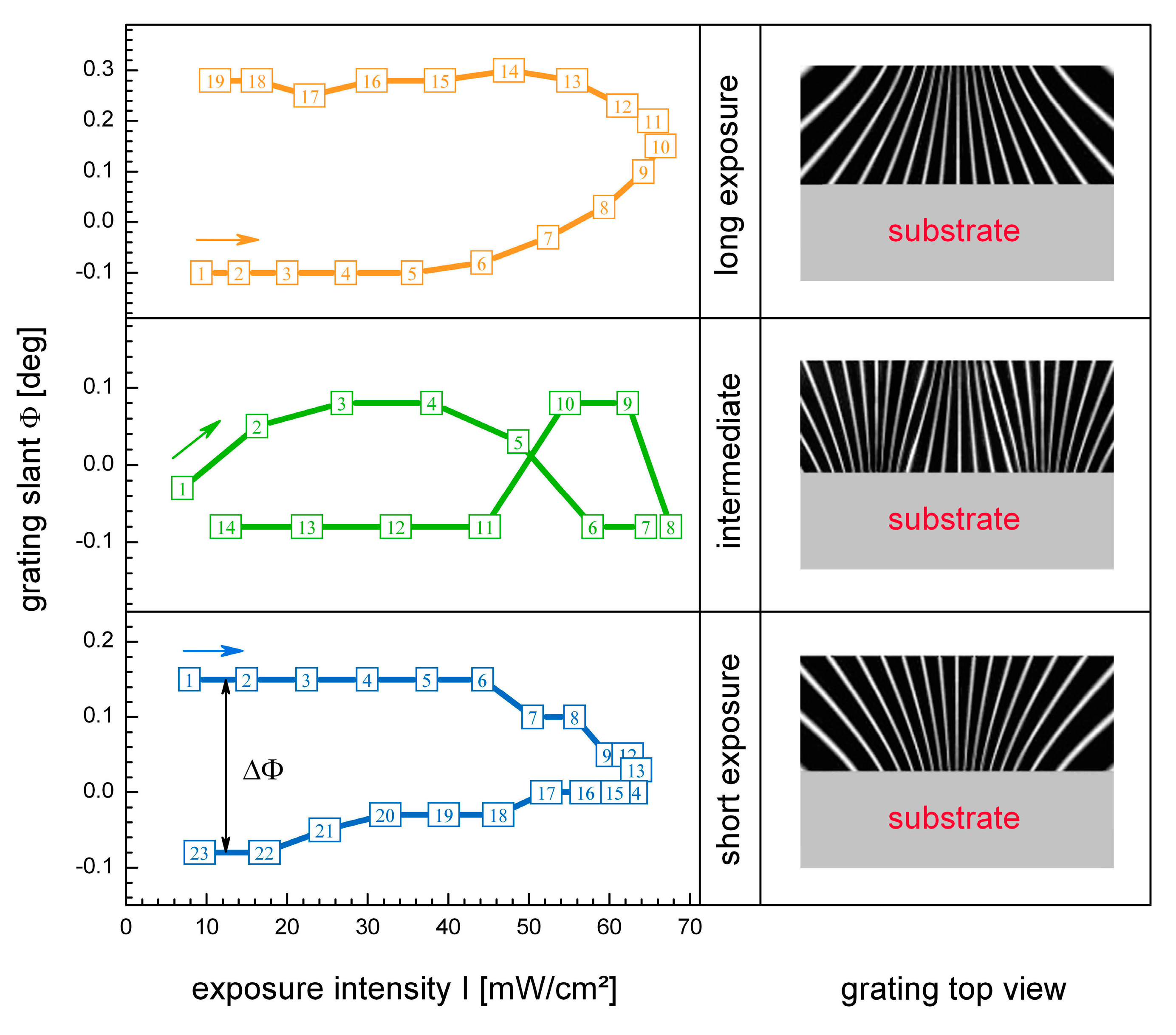

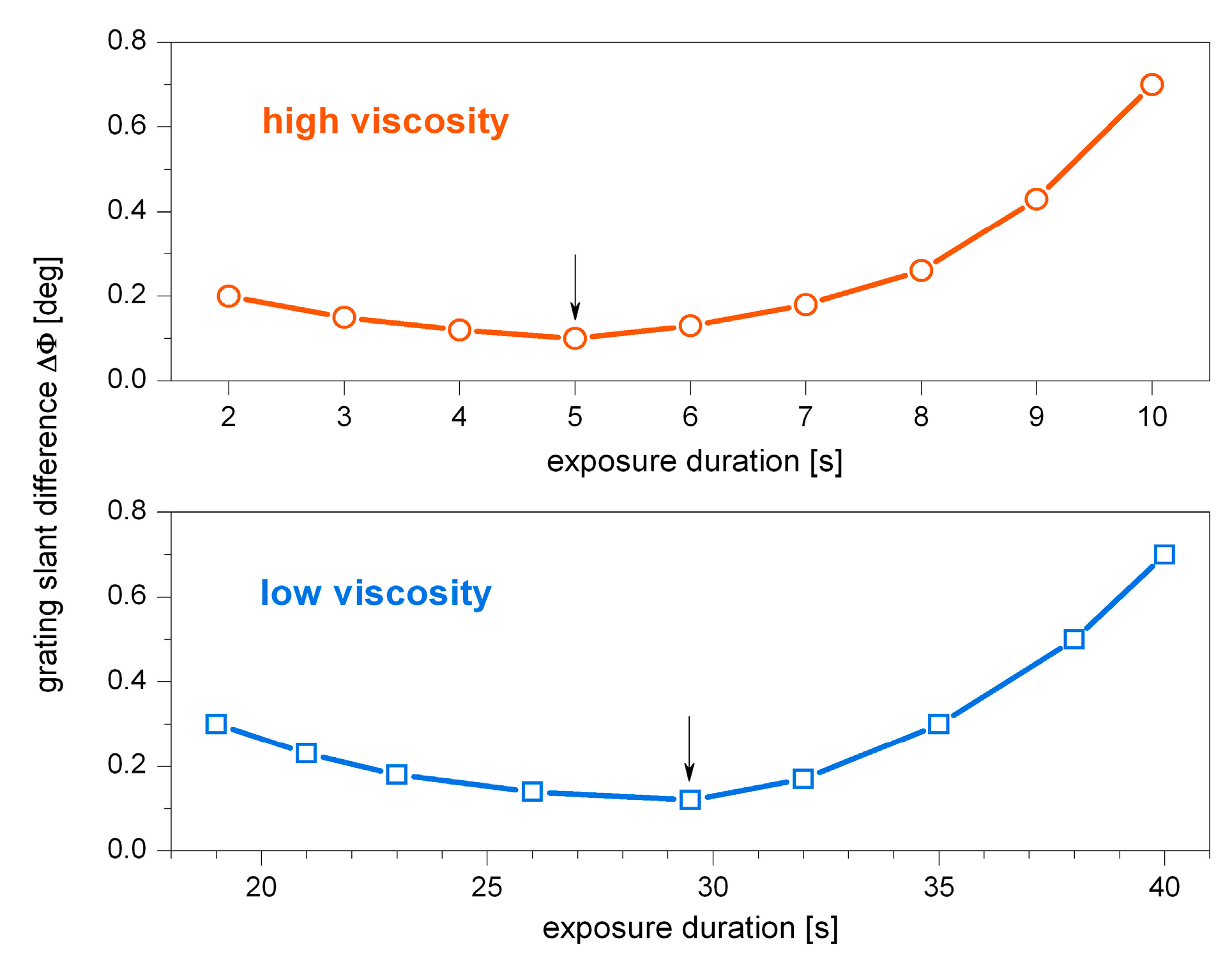

3.2.2. Impact of the Exposure Duration: Φ(texp)

3.2.3. Impact of the Material’s Viscosity

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Trout, T.J.; Schmieg, J.J.; Gambogi, W.J.; Weber, A.M. Optical photopolymers: Design and applications. Adv. Mater. 1998, 10, 1219–1224. [Google Scholar] [CrossRef]

- Trentler, T.J.; Boyd, J.E.; Colvin, V.L. Epoxy resin-photopolymer composites for volume holography. Chem. Mater. 2000, 12, 1431–1438. [Google Scholar] [CrossRef]

- Hagen, R.; Bieringer, T. Photoaddressable polymers for optical data storage. Adv. Mater. 2001, 13, 1805–1810. [Google Scholar] [CrossRef]

- Ma, H.; Jen, A.K.Y.; Dalton, L.R. Polymer-based optical waveguides: Materials, processing, and devices. Adv. Mater. 2002, 14, 1339–1365. [Google Scholar] [CrossRef]

- Baylor, M.; Cerjan, B.; Pfiefer, C.; Boyne, R.; Couch, C.; Cramer, N.; Bowman, C.; McLeod, R. Monolithic integration of optical waveguide and fluidic channel structures in a thiol-ene/methacrylate photopolymer. Opt. Mater. Express 2012, 2, 1548–1555. [Google Scholar] [CrossRef]

- De Sio, L.; Ferjani, S.; Strangi, G.; Umeton, C.; Bartolino, R. Universal soft matter template for photonic applications. Soft Matter 2011, 7, 3739–3743. [Google Scholar] [CrossRef]

- Sabel, T.; Orlic, S.; Pfeiffer, K.; Ostrzinski, U.; Grützner, G. Free-surface photopolymerizable recording material for volume holography. Opt. Mater. Express 2012, 3, 329–338. [Google Scholar] [CrossRef]

- Guo, J.; Gleeson, M.R.; Sheridan, J.T. A review of the optimisation of photopolymer materials for holographic data storage. Phys. Res. Int. 2012. [Google Scholar] [CrossRef]

- Sabel, T.; Zschocher, M. Transition of refractive index contrast in course of grating growth. Sci. Rep. 2013, 3, 2552. [Google Scholar] [CrossRef] [PubMed]

- Sakhno, O.V.; Goldenberg, L.M.; Smirnova, T.N.; Stumpe, J. Holographic patterning of organic-inorganic photopolymerizable nanocomposites. In Proceedings of SPIE—The International Society for Optical Engineering, Berlin, Germany, 31 August–1 September 2009.

- Sabel, T.; Zschocher, M. Imaging of volume phase gratings in a photosensitive polymer, recorded in transmission and reflection geometry. Appl. Sci. 2014, 4, 19–27. [Google Scholar] [CrossRef]

- Castagna, R.; Milner, A.; Zyss, J.; Prior, Y. Nanoscale Poling of Polymer Films. Adv. Mater. 2013, 25, 2234–2238. [Google Scholar] [CrossRef] [PubMed]

- Sabel, T.; Zschocher, M. Dynamic Bragg angle shift in the course of volume hologram formation. Mater. Res. Lett. 2013. [Google Scholar] [CrossRef]

- Criante, L.; Castagna, R.; Vita, F.; Lucchetta, D.E.; Simoni, F. Nanocomposite polymeric materials for high density optical storage. J. Opt. A Pure Appl. Opt. 2009, 11, 024011. [Google Scholar] [CrossRef]

- Gallego, S.; Márquez, A.; Méndez, D.; Neipp, C.; Ortuño, M.; Alvarez, M.; Fernandez, E.; Beléndez, A. Real-time interferometric characterization of a polyvinyl alcohol based photopolymer at the zero spatial frequency limit. Appl. Opt. 2007, 46, 7506–7512. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kawana, M.; Takahashi, J.; Guo, J.; Tomita, Y. Measurement of polymerization-shrinkage evolution during curing in photopolymer with a white-light Fabry-Perot interferometer. Opt. Express 2015, 23, 15356–15364. [Google Scholar] [CrossRef] [PubMed]

- Semenova, I.; Popov, A.; Bartsch, E.; Veniaminov, A. Rigid polymer materials with hologram enhancement by molecular diffusion. In Proceedings of SPIE, Practical Holography XVII and Holographic Materials IX, Santa Clara, CA, USA, 20 January 2003.

- Veniaminov, A.; Bartsch, E.; Semenova, I.; Popov, A. Hologram development by diffusion in a polymer glass. In Proceedings of SPIE, Organic Holographic Materials and Applications, San Diego, CA, USA, 3 August 2003.

- Zhao, C.; Liu, J.; Fu, Z.; Chen, R.T. Shrinkage-corrected volume holograms based on photopolymeric phase media for surface-normal optical interconnects. Appl. Phys. Lett. 1997, 71, 1464–1466. [Google Scholar] [CrossRef]

- Hata, E.; Mitsube, K.; Momose, K.; Tomita, Y. Holographic nanoparticle-polymer composites based on step-growth thiol-ene photopolymerization. Opt. Mater. Express 2011, 1, 207–222. [Google Scholar] [CrossRef]

- Ingwall, R.T.; Waldmann, D. Photopolymer systems. In Holographic Data Storage; Coufal, H.J., Psaltis, D., Sincerbox, G.T., Eds.; Springer: Berlin, Germany, 2007; pp. 171–197. [Google Scholar]

- Ramos, G.; Álvarez-Herrero, A.; Belenguer, T.; del Monte, F.; Levy, D. Shrinkage control in a photopolymerizable hybrid solgel material for holographic recording. Appl. Opt. 2004, 43, 4018–4024. [Google Scholar] [CrossRef] [PubMed]

- Květoň, M.; Ledl, V.; Havranek, A.; Fiala, P. Photopolymer for optical holography and holographic interferometry. Macromol. Symp. 2010, 295, 107–113. [Google Scholar] [CrossRef]

- Hata, E.; Tomita, Y. Stoichiometric thiol-to-ene ratio dependences of refractive index modulation and shrinkage of volume gratings recorded in photopolymerizable nanoparticle-polymer composites based onstep-growth polymerization. Opt. Mater. Express 2011, 1, 1113–1120. [Google Scholar] [CrossRef]

- Hayek, A.; Xu, Y.; Okada, T.; Barlow, S.; Zhu, X.; Moon, J.H.; Marder, S.R.; Yang, S. Poly(glycidyl methacrylate)s with controlled molecular weights as low-shrinkage resins for 3D multibeam interference lithography. J. Mater. Chem. 2008, 18, 3316–3318. [Google Scholar] [CrossRef]

- Waldman, D.A.; Li, H.Y.S.; Horner, M.G. Volume shrinkage in slant fringe gratings of a cationic ring-opening volume hologram recording material. J. Imaging Sci. Technol. 1997, 41, 497–514. [Google Scholar]

- Steckman, G.J.; Havermeyer, F. High spatial resolution measurement of volume holographic gratings. In Proceedings of SPIE, Practical Holography XX: Materials and Applications, San Jose, CA, USA, 27 February 2006.

- Moothanchery, M.; Naydenova, I.; Toal, V. Study of the shrinkage caused by holographic grating formation in acrylamide based photopolymer film. Opt. Express 2011, 19, 13395–13404. [Google Scholar] [CrossRef] [PubMed]

- Moothanchery, M.; Bavigadda, V.; Toal, V.; Naydenova, I. Shrinkage during holographic recording in photopolymer films determined by holographic interferometry. Appl. Opt. 2013, 52, 8519–8527. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Soper, S.A.; Wang, W. A new UV lithography photoresist based on composite of EPON resins 165 and 154 for fabrication of high-aspect-ratio microstructures. Sens. Actuators A Phys. 2007, 135, 625–636. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabel, T. Spatially Resolved Analysis of Bragg Selectivity. Appl. Sci. 2015, 5, 1064-1075. https://doi.org/10.3390/app5041064

Sabel T. Spatially Resolved Analysis of Bragg Selectivity. Applied Sciences. 2015; 5(4):1064-1075. https://doi.org/10.3390/app5041064

Chicago/Turabian StyleSabel, Tina. 2015. "Spatially Resolved Analysis of Bragg Selectivity" Applied Sciences 5, no. 4: 1064-1075. https://doi.org/10.3390/app5041064