Strengthening Masonry Arches with Lime-Based Mortar Composite

Abstract

:1. Introduction

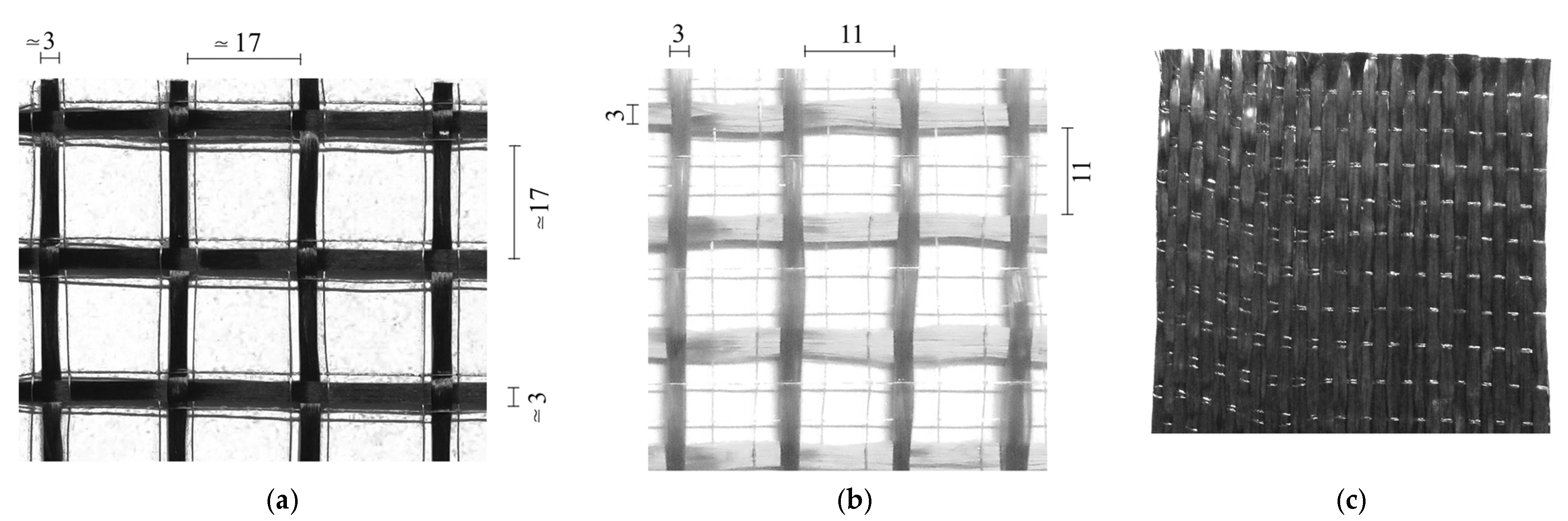

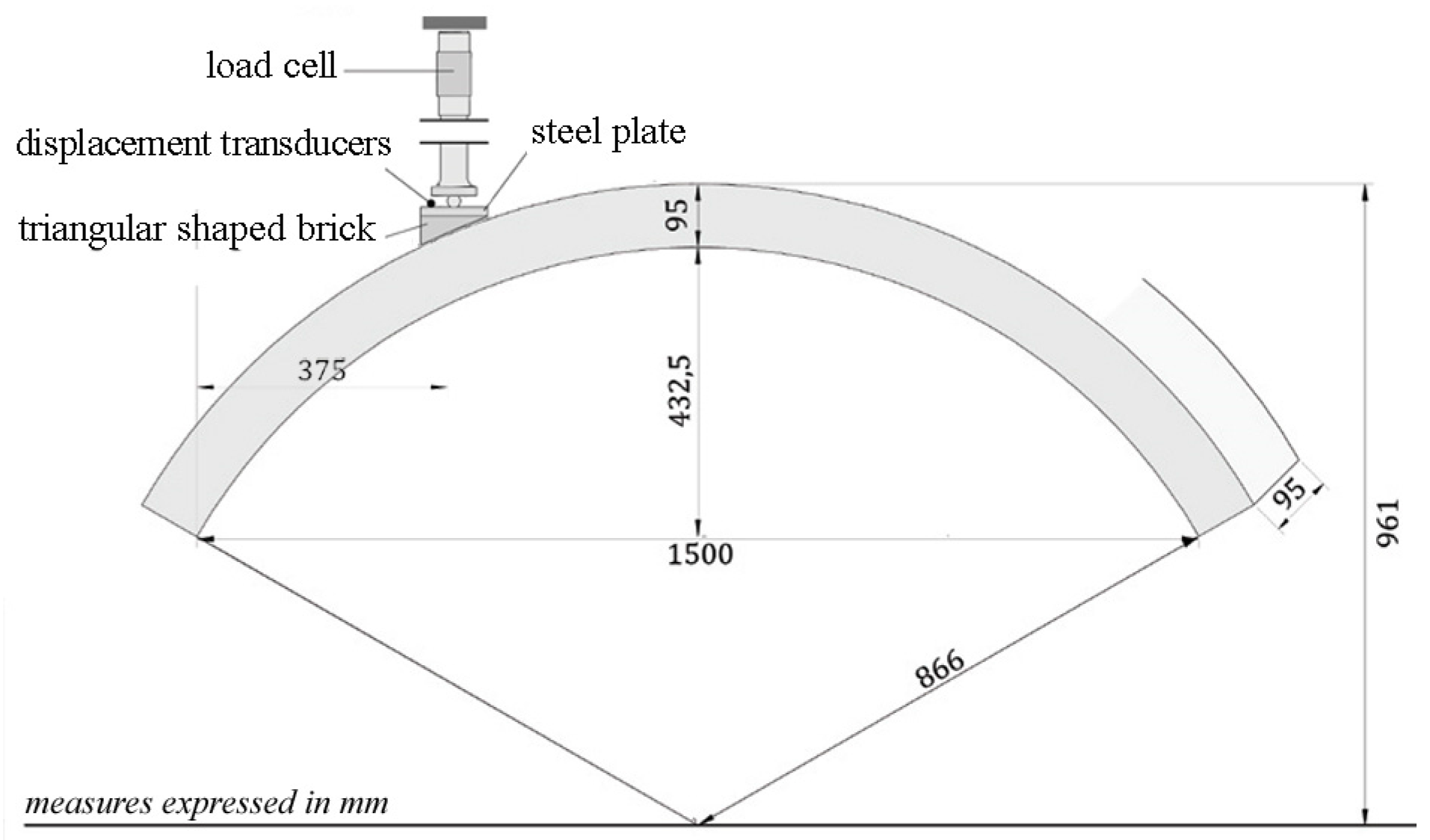

2. Experimental Program

3. Test Results

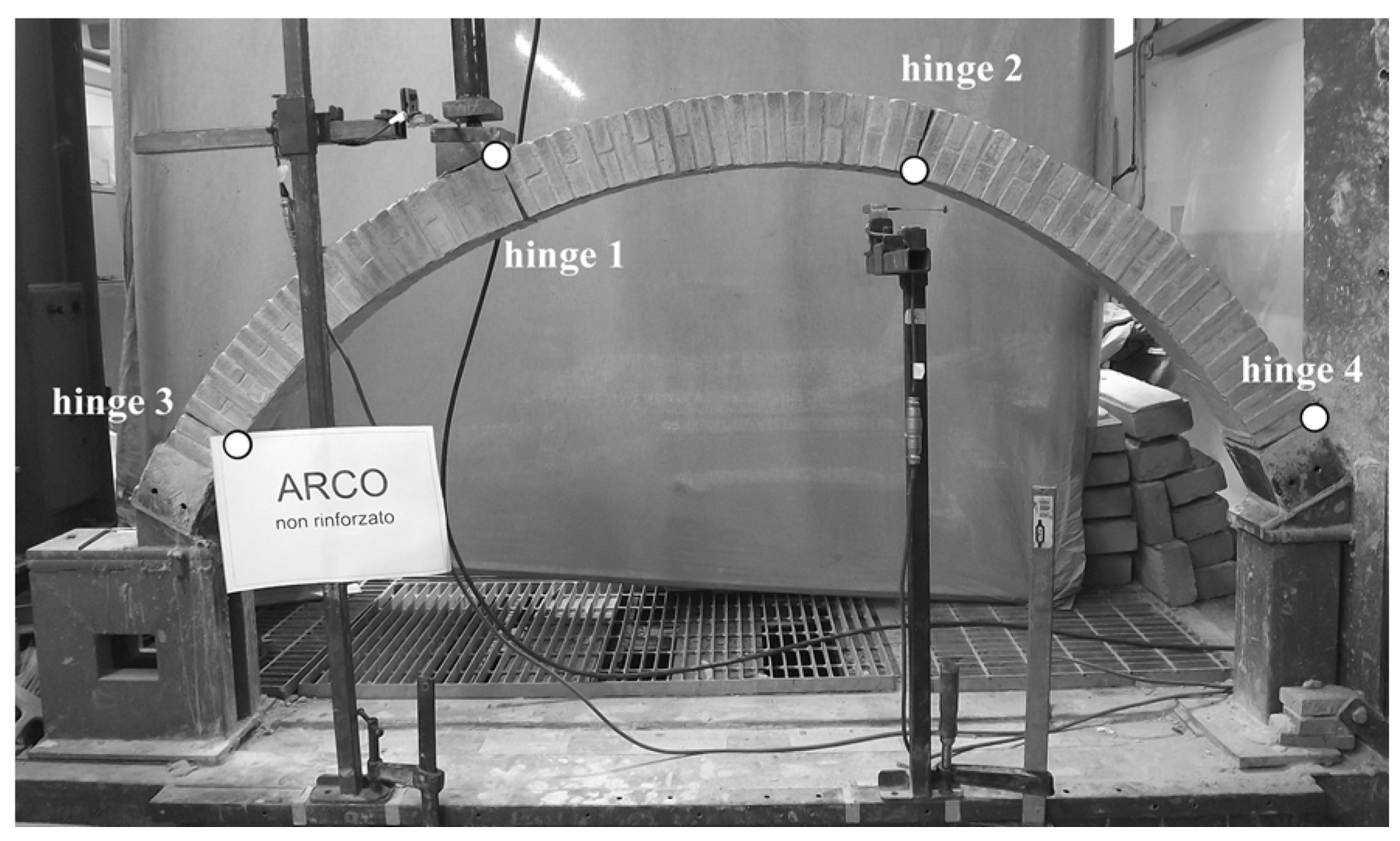

3.1. Un-Strengthened Arch Models

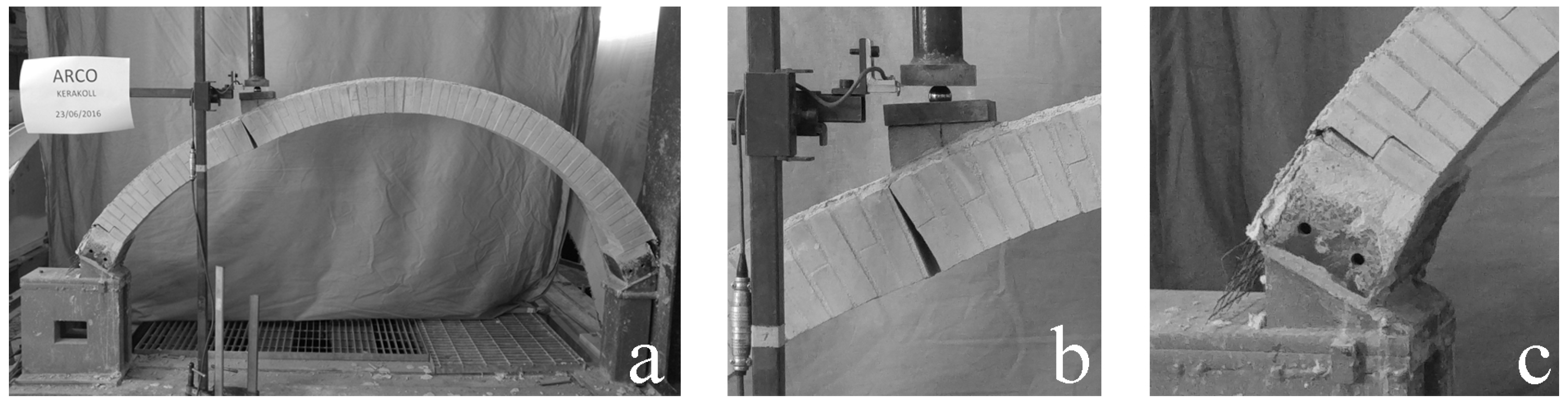

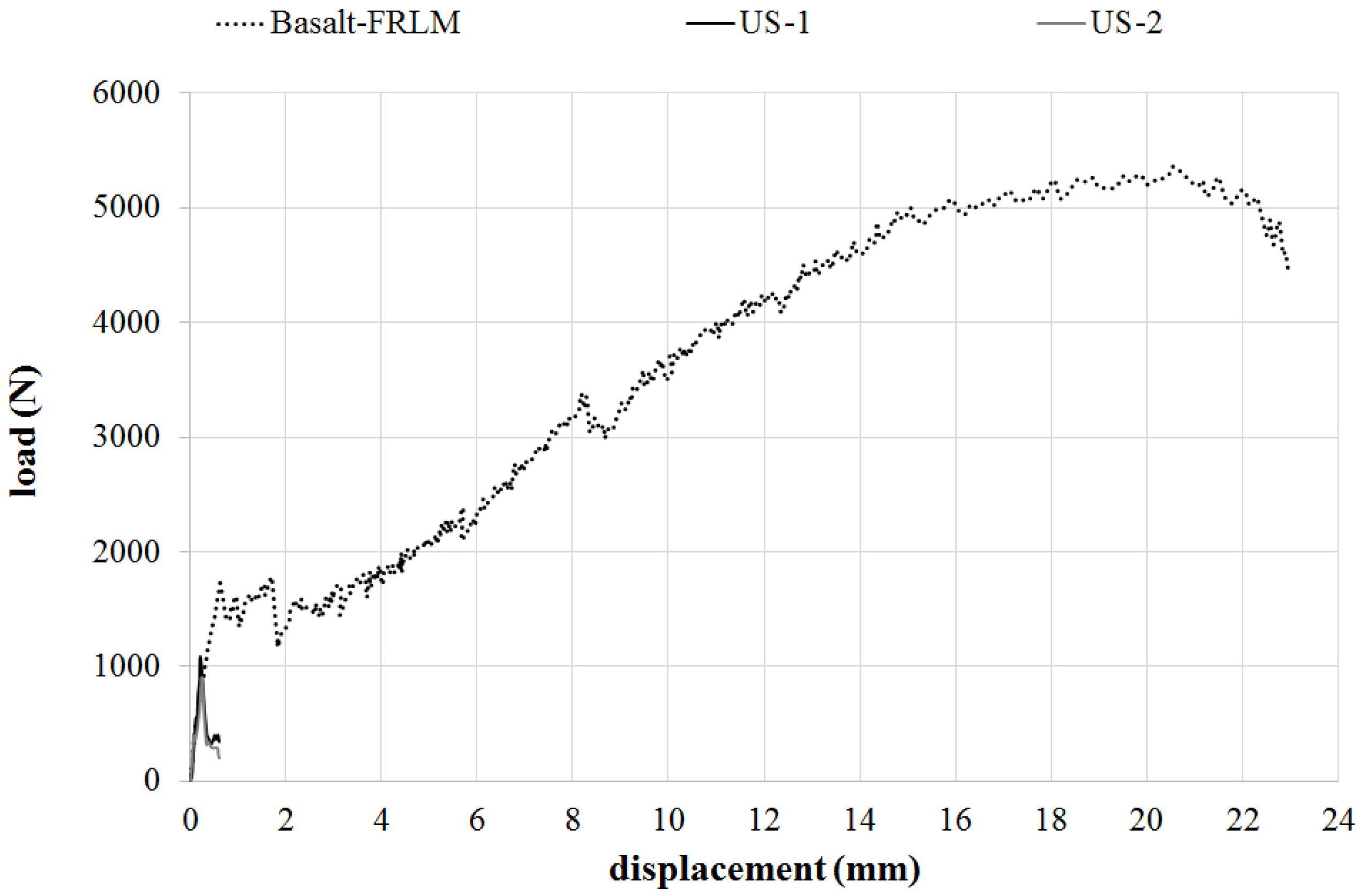

3.2. Arch Models Strengthened with Basalt-FRLM

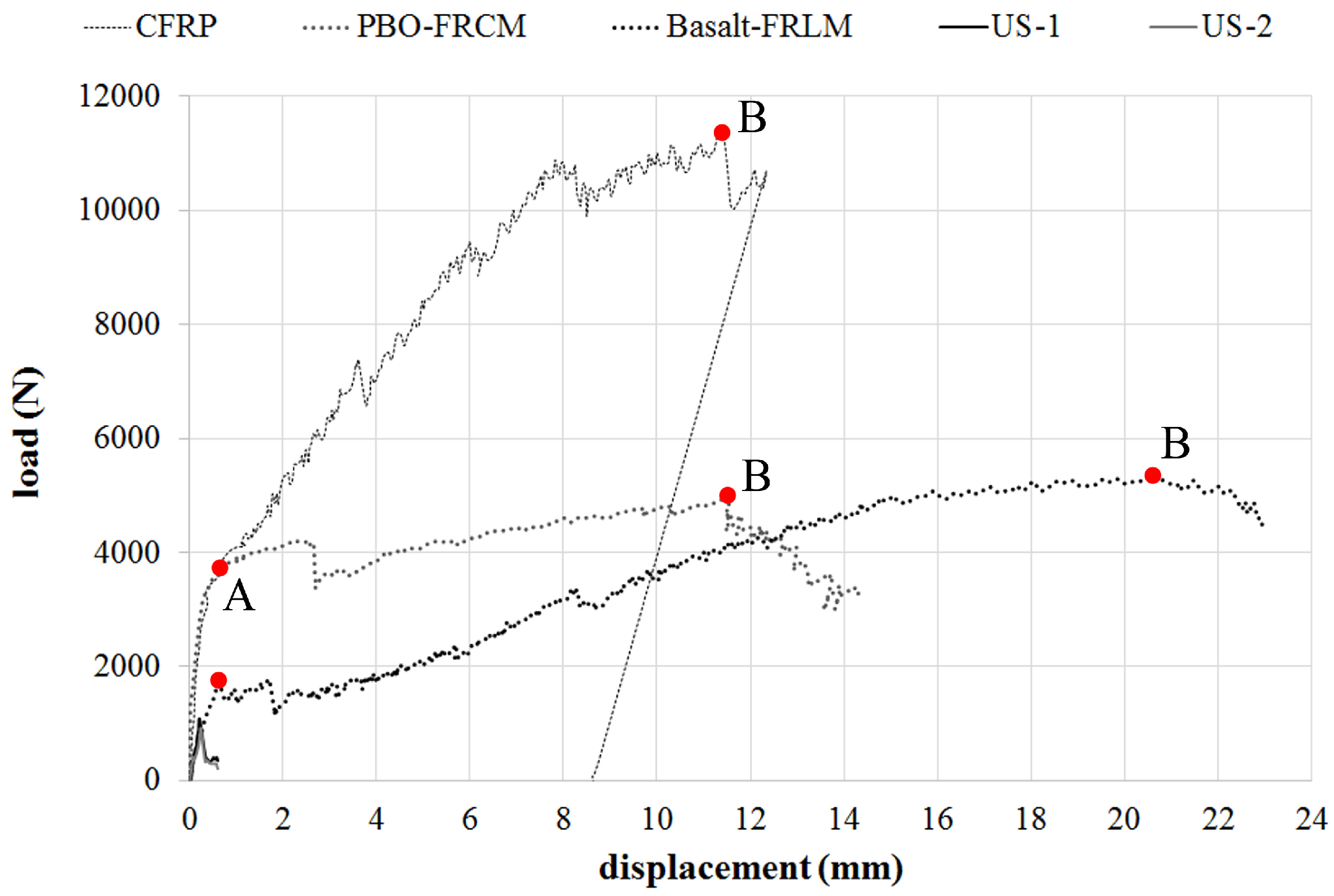

3.3. Comparison with Arches Strengthened with Cementitious and Polymeric Matrix Composites

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Giresini, L.; Sassu, M. Horizontally restrained rocking blocks: evaluation of the role of boundary conditions with static and dynamic approaches. Bull. Earthq. Eng. 2016, 15, 385–410. [Google Scholar] [CrossRef]

- Giresini, L.; Fragiacomo, M.; Sassu, M. Rocking analysis of masonry walls interacting with roofs. Eng. Struct. 2016, 116, 107–120. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Masonry arches strengthened with composite unbonded tendons. Compos. Struct. 2013, 98, 323–329. [Google Scholar] [CrossRef]

- Foraboschi, P. Resisting system and failure modes of masonry domes. Eng. Fail. Anal. 2014, 44, 315–337. [Google Scholar] [CrossRef]

- Foraboschi, P.; Vanin, A. Non-linear static analysis of masonry buildings based on a strut-and-tie modeling. Soil Dyn. Earthq. Eng. 2013, 55, 44–58. [Google Scholar] [CrossRef]

- Misseri, G.; Rovero, L. Parametric investigation on the dynamic behaviour of masonry pointed arches. Arch. Appl. Mech. 2017, 87, 385–404. [Google Scholar] [CrossRef]

- Giresini, L. Energy-based method for identifying vulnerable macro-elements in historic masonry churches. Bull. Earthq. Eng. 2015, 14, 919–942. [Google Scholar] [CrossRef]

- Andreini, M; De Falco, A.; Giresini, L.; Sassu, M. Structural damage in the cities of Reggiolo and Carpi after the earthquake on May 2012 in Emilia Romagna. Bull. Earthq. Eng. 2014, 12, 2445–2480. [Google Scholar] [CrossRef]

- Andreini, M.; De Falco, A.; Giresini, L.; Sassu, M. Structural analysis and consolidation strategy of the historic Mediceo Aqueduct in Pisa (Italy). Appl. Mech. Mater. 2013, 351–352, 1354–1357. [Google Scholar] [CrossRef]

- De Falco, A.; Giresini, L.; Sassu, M. Temporary preventive seismic reinforcements on historic churches: Numerical modeling of San Frediano in Pisa. Appl. Mech. Mater. 2013, 352, 1393–1396. [Google Scholar] [CrossRef]

- Giresini, L.; Sassu, M. Tests Results and Simple Structural Analysis of the Main Lighthouse in the Harbor of Livorno (Italy). Adv. Mater. Res. 2014, 834, 1299–1303. [Google Scholar] [CrossRef]

- Larrinaga, P.; Chastre, C.; San-José, J.T.; Garmendia, L. Non-linear analytical model of composites based on basalt textile reinforced mortar under uniaxial tension. Compos. Part B Eng. 2013, 55, 518–527. [Google Scholar] [CrossRef]

- Prota, A.; Marcari, G.; Fabbrocino, G.; Manfredi, G.; Aldea, C. Experimental In-Plane Behavior of Tuff Masonry Strengthened with Cementitious Matrix–Grid Composites. J. Compos. Constr. 2006, 10, 223–233. [Google Scholar] [CrossRef]

- Alecci, V.; De Stefano, M.; Luciano, R.; Rovero, L.; Stipo, G. Experimental Investigation on Bond Behavior of Cement-Matrix–Based Composites for Strengthening of Masonry Structures. J. Compos. Constr. 2015, 20, 04015041. [Google Scholar] [CrossRef]

- Garmendia, L.; Larrinaga, P.; San-Mateos, R.; San-José, J.T. Strengthening masonry vaults with organic and inorganic composites: an experimental approach. Mater. Des. 2015, 85, 102–114. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Focacci, F.; Luciano, R.; Alecci, V.; De Stefano, M. Carbon-FRCM materials for structural upgrade of masonry arch road bridges. Compos. Part B Eng. 2015, 75, 355–366. [Google Scholar] [CrossRef]

- Alecci, V.; Focacci, F.; Rovero, L.; Stipo, G.; De Stefano, M. Extrados strengthening of brick masonry arches with PBO-FRCM composites: Experimental and analytical investigations. Compos. Struct. 2016, 149, 184–196. [Google Scholar] [CrossRef]

- Alecci, V.; Misseri, G.; Rovero, L.; Stipo, G.; De Stefano, M.; Feo, L.; Luciano, R. Experimental investigation on masonry arches strengthened with PBO-FRCM composite. Compos. Part B Eng. 2016, 100, 228–239. [Google Scholar] [CrossRef]

- Rovero, L.; Focacci, F.; Stipo, G. Structural behavior of arch models strengthened using FRP strips of different lengths. J. Compos. Constr. 2013, 17, 249–258. [Google Scholar] [CrossRef]

- Briccoli Bati, S.; Rovero, L.; Tonietti, U. Strengthening of masonry arches with composite materials. J. Compos. Mater. 2007, 11, 33–42. [Google Scholar] [CrossRef]

- Briccoli Bati, S.; Rovero, L. Towards a methodology for estimating strength and collapse mechanism in masonry arches strengthened with fibre reinforced polymer applied on external surfaces. Mater. Struct. 2008, 41, 1291–1306. [Google Scholar] [CrossRef]

- Rotunno, T.; Rovero, L.; Tonietti, U.; Briccoli Bati, S. Experimental study of bond behavior of CFRP-to-brick joints. J. Compos. Constr. 2015, 19, 04014063. [Google Scholar] [CrossRef]

- Alecci, V.; Briccoli Bati, S.; Ranocchiai, G. Study of brickwork columns confined with CFRP composite. J. Compos. Constr. 2009, 13, 179–187. [Google Scholar] [CrossRef]

- De Felice, G.; De Santis, S.; Garmendia, L.; Ghiassi, B.; Larrinaga, P.; Lourenco, P.B.; Oliveira, D.V.; Paolacci, F.; Papanicolaou, C.G. Mortar-based systems for externally bonded strengthening of masonry. Mater. Struct. 2014, 47, 2021–2037. [Google Scholar] [CrossRef]

- Alecci, V.; Focacci, F.; Rovero, L.; Stipo, G.; De Stefano, M. Intrados strengthening of brick masonry arches with different FRCM composites: experimental and analytical investigations. Compos. Struct. 2017, in press. [Google Scholar] [CrossRef]

- UNI EN 1015-11. Methods of Test for Mortar for Masonry—Determination of Flexural and Compressive Strength of Hardened Mortar; European Standard; BSI: London, UK, 2007. [Google Scholar]

- UNI EN 772-1. Methods of Test for Masonry Units—Determination of Compressive Strength; European Standard: Milton Keynes, UK, 2011. [Google Scholar]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Bond-slip relations for PBO–FRCM materials externally bonded to concrete. Compos. Part B Eng. 2012, 43, 2938–2949. [Google Scholar] [CrossRef]

- Caggegi, C.; Carozzi, F.G.; De Santis, S.; Fabbrocino, F.; Focacci, F.; Hojdys, Ł.; Lanoye, E.; Zuccarino, L. Experimental analysis on tensile and bond properties of PBO and aramid fabric reinforced cementitious matrix for strengthening masonry structures. Compos Part B: Eng. 2017, in press. [Google Scholar] [CrossRef]

- Carloni, C.; D’Antino, T.; Sneed, L.; Pellegrino, C. Role of the matrix layers in the stress transfer mechanism of FRCM composites bonded to a concrete substrate. J. Eng. Mech. 2014, 141. [Google Scholar] [CrossRef]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Matrix-fiber bond behavior in PBO FRCM composites: A fracture mechanics approach. Eng. Fract. Mech. 2014, 117, 94–111. [Google Scholar] [CrossRef]

- Focacci, F.; D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. An indirect method to calibrate the interfacial cohesive material law for FRCM-concrete joints. Mater. Des. 2017, 128, 206–217. [Google Scholar] [CrossRef]

- Focacci, F.; Carloni, C. Periodic variation of the transferable load at the FRP-masonry interface. Compos. Struct. 2015, 129, 90–100. [Google Scholar] [CrossRef]

- Carloni, C.; Focacci, F. FRP-masonry interfacial debonding: An energy balance approach to determine the influence of the mortar joints. Eur. J. Mech.—A/Solids 2016, 55, 122–133. [Google Scholar] [CrossRef]

- Malena, M.; Focacci, F.; Carloni, C.; De Felice, G. The effect of the shape of the cohesive material law on the stress transfer at the FRP-masonry interface. Compos. Part B Eng. 2017, 110, 368–380. [Google Scholar] [CrossRef]

- Foraboschi, P. Effectiveness of novel methods to increase the FRP-masonry bond capacity. Compos. Part B Eng. 2016, 107, 214–232. [Google Scholar] [CrossRef]

| Material | εu | fc | Ec | ftf |

|---|---|---|---|---|

| [MPa] | [MPa] | [MPa] | ||

| Cement-lime mortar | / | 3.22 | 727.7 | 1.49 |

| (0.31; 9.72) | (69.82; 9.59) | (0.025;1.68) | ||

| Brick | / | 24.08 | 2701.81 | 5.60 |

| (2.73; 11.37) | (585.05; 21.65) | (0.58; 10.44) | ||

| Masonry | 0.0076 | 8.53 | 1753.7 | / |

| (0.002; 17.66) | (1.29; 13.95) | (282.52; 16.11) |

| Composite Material | Fibers Material | tf | ff | Ef | εfu | Matrix Material | fmc | Em | fmtf |

|---|---|---|---|---|---|---|---|---|---|

| [mm] | [MPa] | [GPa] | [%] | [MPa] | [GPa] | [MPa] | |||

| Basalt-FRLM | Basalt | 0.032 | ≥3000 | ≥87 | - | Lime | 11.2 (*) | 1.3 (*) | 3.72 (*) |

| PBO-FRCM | PBO | 0.014 | 5800 | 270 | 2.5 | Cement | 20 (*) | 2.8 (*) | 6.15 (*) |

| CFRP | Carbon | 0.17 | 4800 | 240 | 2.00 | Epoxy | >50 | - | - |

| Specimen | Failure Load | Tangent Stiffness | Kinematic Ductility | ∆f |

|---|---|---|---|---|

| [N] | [N/mm] | [N/mm2] | ||

| 1-US | 910 | 7179 | 1.85 | - |

| 2-US | 1066 | 6197 | 1.11 | - |

| Basalt-FRLM | 5366 | 7200 | 36.6 | 1.37 |

| PBO-FRCM | 4968 | 16,221 | 20.32 | 2.84 |

| CFRP | 11,345 | 10,106 | 10.93 | 0.61 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alecci, V.; De Stefano, M.; Focacci, F.; Luciano, R.; Rovero, L.; Stipo, G. Strengthening Masonry Arches with Lime-Based Mortar Composite. Buildings 2017, 7, 49. https://doi.org/10.3390/buildings7020049

Alecci V, De Stefano M, Focacci F, Luciano R, Rovero L, Stipo G. Strengthening Masonry Arches with Lime-Based Mortar Composite. Buildings. 2017; 7(2):49. https://doi.org/10.3390/buildings7020049

Chicago/Turabian StyleAlecci, Valerio, Mario De Stefano, Francesco Focacci, Raimondo Luciano, Luisa Rovero, and Gianfranco Stipo. 2017. "Strengthening Masonry Arches with Lime-Based Mortar Composite" Buildings 7, no. 2: 49. https://doi.org/10.3390/buildings7020049