Local Characterization of Precipitation and Correlation with the Prior Austenitic Microstructure in Nb-Ti-Microalloyed Steel by SEM and AFM Methods

Abstract

:1. Introduction

2. Materials and Methods

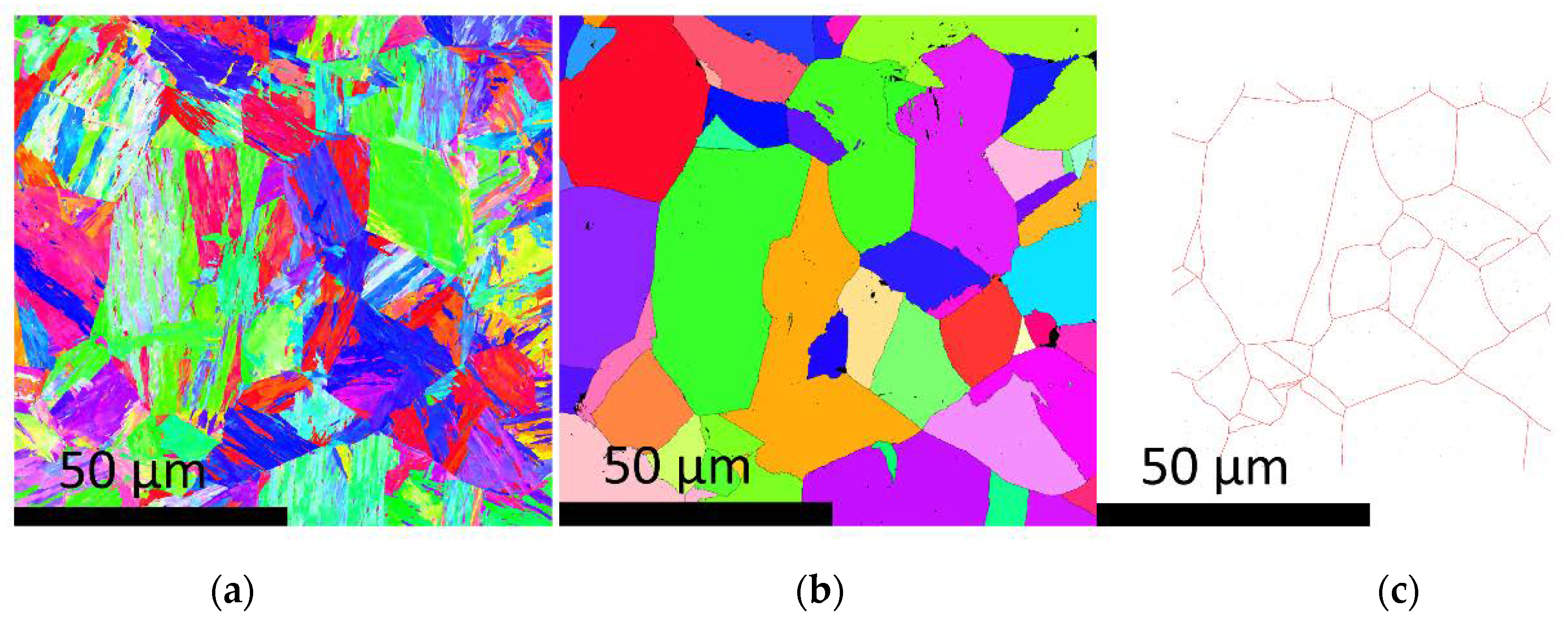

- Identification of clusters of at least three neighboring domains related to a unique parent orientation within a tolerance of 3°, called fragments.

- All child domains were browsed recursively starting from a fragment within a tolerance of 3°, from neighbor to neighbor. If they share the parent orientation of the fragment, they were assigned to the according parent.

3. Results

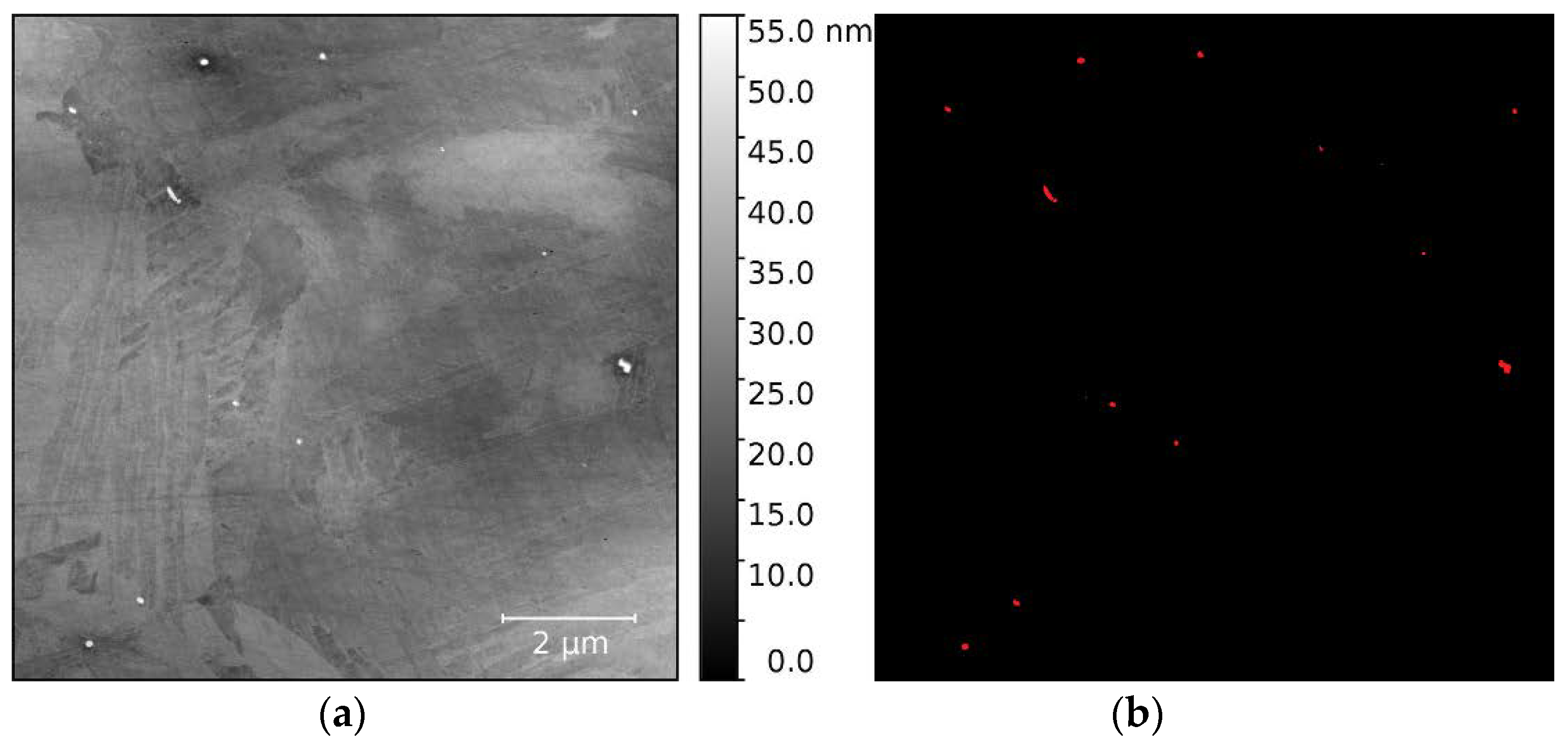

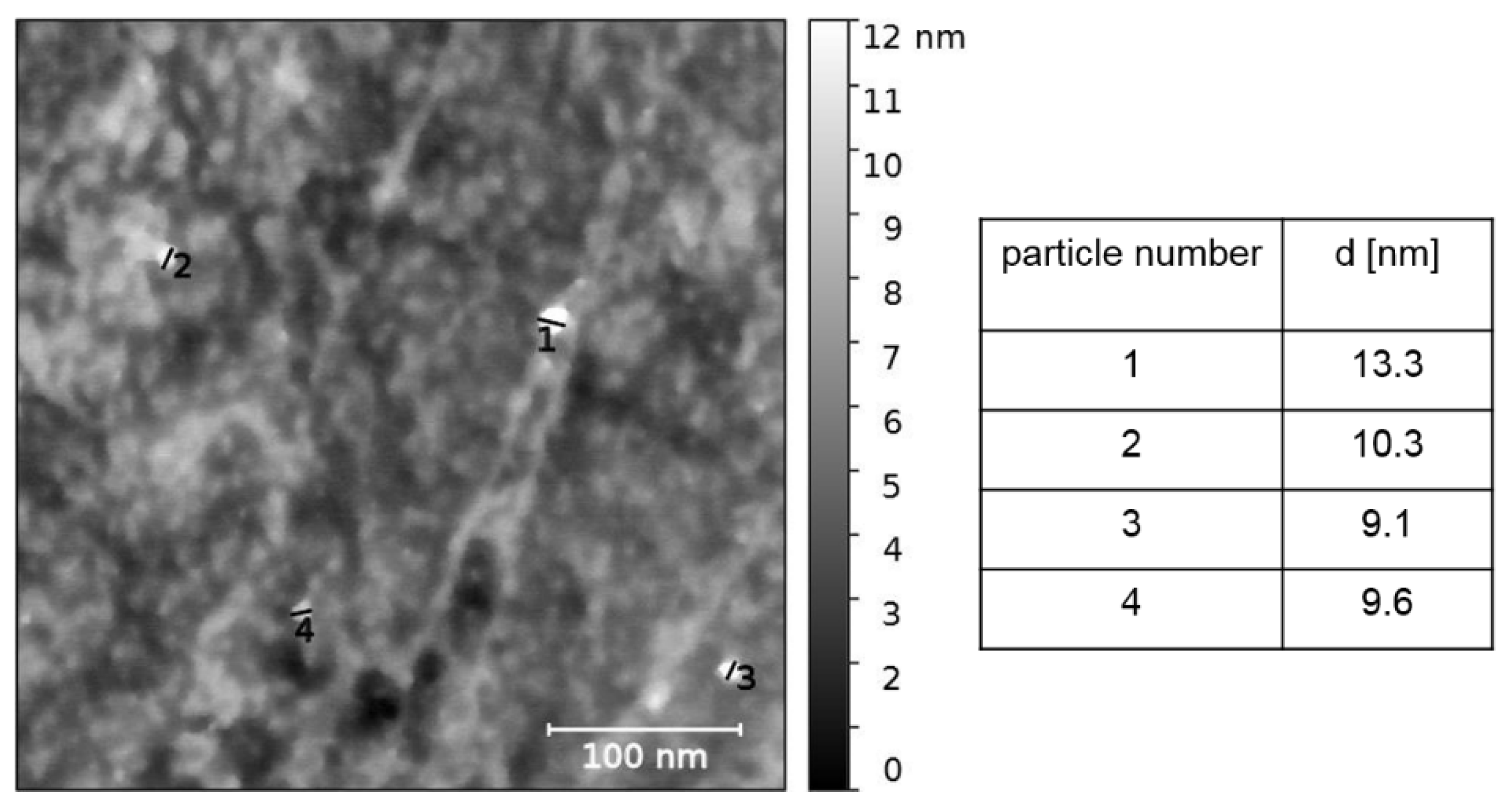

3.1. Precipitation Detection with AFM and Chemical Verification by EDX

3.2. Correlation of Precipitates with the PAG Structure and Comparison of Two Austenitization States

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chapa, M.; Medina, S.F.; Lopez, V.; Fernandez, B. Influence of Al and Nb on Optimum Ti/N Ratio in Controlling Austenite Grain Growth at Reheating Temperatures. ISIJ Int. 2002, 42, 1288–1296. [Google Scholar] [CrossRef]

- Manohar, P.A.; Ferry, M.; Chandra, T. Five Decades of the Zener Equation. ISIJ Int. 1998, 38, 913–924. [Google Scholar] [CrossRef]

- Sha, Q.Y.; Sun, Z.Q. Grain growth behavior of coarse-grained austenite in a Nb-V-Ti microalloyed steel. Mater. Sci. Eng. A 2009, 523, 77–84. [Google Scholar] [CrossRef]

- Medina, S.F.; Chapa, M.; Valles, P.; Quispe, A.; Vega, M.I. Influence of Ti and N contents on austenite grain control and precipitate size in structural steels. ISIJ Int. 1999, 39, 930–936. [Google Scholar] [CrossRef]

- Dutta, B.; Valdes, E.; Sellars, C.M. Mechanism and kinetics of strain induced precipitation of Nb(C, N) in austenite. Acta Metall. Mater. 1992, 40, 653–662. [Google Scholar] [CrossRef]

- Le Bon, A.; Rofes-Vernis, J.; Rossard, C. Recrystallization and Precipitation during Hot Working of a Nb-Bearing HSLA Steel. Met. Sci. 1975, 9, 36–40. [Google Scholar] [CrossRef]

- Pereloma, E.V.; Crawford, B.R.; Hodgson, P.D. Strain-induced precipitation behaviour in hot rolled strip steel. Mater. Sci. Eng. A 2001, 299, 27–37. [Google Scholar] [CrossRef]

- Shanmugam, S.; Ramisetti, N.K.; Misra, R.D.K.; Hartmann, J.; Jansto, S.G. Microstructure and high strength-toughness combination of a new 700 MPa Nb-microalloyed pipeline steel. Mater. Sci. Eng. A 2008, 478, 26–37. [Google Scholar] [CrossRef]

- Shanmugam, S.; Misra, R.D.K.; Hartmann, J.; Jansto, S.G. Microstructure of high strength niobium-containing pipeline steel. Mater. Sci. Eng. A 2006, 441, 215–229. [Google Scholar] [CrossRef]

- Charleux, M.; Poole, W.J.; Militzer, M.; Deschamps, A. Precipitation behavior and its effect on strengthening of an HSLA-Nb/Ti steel. Metall. Mater. Trans. A 2001, 32, 1635–1647. [Google Scholar] [CrossRef]

- Zhang, L.P.; Davis, C.L.; Strangwood, M. Effect of TiN particles and microstructure on fracture toughness in simulated heat-affected zones of a structural steel. Metall. Mater. Trans. A 1999, 30, 2089–2096. [Google Scholar] [CrossRef]

- Jorge-Badiola, D.; Gutiérrez, I. Study of the strain reversal effect on the recrystallization and strain-induced precipitation in a Nb-microalloyed steel. Acta Mater. 2004, 52, 333–341. [Google Scholar] [CrossRef]

- Jia, Z.; Misra, R.D.K.; O’Malley, R.; Jansto, S.J. Fine-scale precipitation and mechanical properties of thin slab processed titanium-niobium bearing high strength steels. Mater. Sci. Eng. A 2011, 528, 7077–7083. [Google Scholar] [CrossRef]

- Lu, J.F.; Wiskel, J.B.; Omotoso, O.; Henein, H.; Ivey, D.G. Matrix dissolution techniques applied to extract and quantify precipitates from a microalloyed steel. Metall. Mater. Trans. A 2011, 42, 1767–1784. [Google Scholar] [CrossRef]

- Hegetschweiler, A.; Kraus, T.; Staudt, T. Colloidal analysis of particles extracted from microalloyed steel. Metall. Ital. 2017, 3, 23–28. [Google Scholar]

- Rentería-Borja, L.; Hurtado-Delgado, E.; Garnica-González, P.; Domínguez-López, I.; García-García, A.L. Atomic force microscopy applied to the quantification of nano-precipitates in thermo-mechanically treated microalloyed steels. Mater. Charact. 2012, 69, 9–15. [Google Scholar] [CrossRef]

- Weyand, S.; Britz, D.; Rupp, D.; Mücklich, F. Investigation of Austenite Evolution in Low-Carbon Steel by Combining Thermo-Mechanical Simulation and EBSD Data. Mater. Perform. Charact. 2015, 4, 322–340. [Google Scholar] [CrossRef]

- Germain, L.; Gey, N.; Mercier, R.; Blaineau, P.; Humbert, M. An advanced approach to reconstructing parent orientation maps in the case of approximate orientation relations: Application to steels. Acta Mater. 2012, 60, 4551–4562. [Google Scholar] [CrossRef]

- Nolze, G. Improved determination of FCC/BCC orientation relationships by use of high-indexed pole figures. Cryst. Res. Technol. 2006, 41, 72–74. [Google Scholar] [CrossRef]

- Humbert, M.; Germain, L.; Gey, N.; Boucard, E. Evaluation of the orientation relations from misorientation between inherited variants: Application to ausformed martensite. Acta Mater. 2015, 82, 137–144. [Google Scholar] [CrossRef]

- Krämer, T.; Eisenhut, L.; Germain, L.; Rupp, D.; Detemple, E.; Motz, C. Assessment of EBSD Analysis and Reconstruction Methods as a Tool for the Determination of Recrystallized Fractions in Hot-Deformed Austenitic Microstructures. Metall. Mater. Trans. A 2018, 49, 2795–2802. [Google Scholar] [CrossRef]

- Eisenhut, L.; Rupp, D.; Motz, C. Evolution of the austenitic grain growth of micro-alloyed steels was studied by metallography and EBSD analysis and compared to a grain growth model. In Proceedings of the 5th International Conference on Thermomechanical Processing (TMP), Milan, Italy, 26–28 October 2016; p. 5026. [Google Scholar]

- Humbert, M.; Blaineau, P.; Germain, L.; Gey, N. Refinement of orientation relations occurring in phase transformation based on considering only the orientations of the variants. Scr. Mater. 2011, 64, 114–117. [Google Scholar] [CrossRef]

- Blaineau, P.; Germain, L.; Humbert, M.; Gey, N. A New Approach to Calculate the γ Orientation Maps in Steels. Solid State Phenom. 2010, 160, 203–210. [Google Scholar] [CrossRef]

- Bernier, N.; Bracke, L.; Malet, L.; Godet, S. An alternative to the crystallographic reconstruction of austenite in steels. Mater. Charact. 2014, 89, 23–32. [Google Scholar] [CrossRef]

| C | Mn | Si | Nb | Ti |

|---|---|---|---|---|

| 0.09 | 1.6 | 0.2 | 0.038 | 0.015 |

| Sample | (°C) | (min) | Expected Mean Particle Diameter (MatCalc Simulations) (nm) |

|---|---|---|---|

| 1 | 1000 | 10 | 25 |

| 2 | 1000 | 240 | 45.4 |

| Step | Characteristics | Time |

|---|---|---|

| Grinding | 800, 1200, 2500 | - |

| Polishing | 6, 3, 1, 0.25 µm | 5 min |

| Final Polishing | Masterprep® (Buehler), 0.05 µm | 180 s |

| Parameter | Value |

|---|---|

| Scan Size | 100 × 100 µm2 |

| Scan Rate | 0.0494 Hz |

| Samples/Line | 10,240 |

| Peak Force Amplitude | 150 nm |

| Peak Force Frequency | 2 kH |

| Lift Height | 47.9 nm |

| Spring Constant | 0.4 N/m |

| Sample | Mean Prior Austenite Grain Size (µm) | # of Measured Particles | Mean Particle Diameter (nm) | # of Particles on the PAG |

|---|---|---|---|---|

| 1 | 30 | 2090 | 50 | 111 |

| 2 | 32.6 | 1670 | 65.3 | 79 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eisenhut, L.; Fell, J.; Motz, C. Local Characterization of Precipitation and Correlation with the Prior Austenitic Microstructure in Nb-Ti-Microalloyed Steel by SEM and AFM Methods. Metals 2018, 8, 636. https://doi.org/10.3390/met8080636

Eisenhut L, Fell J, Motz C. Local Characterization of Precipitation and Correlation with the Prior Austenitic Microstructure in Nb-Ti-Microalloyed Steel by SEM and AFM Methods. Metals. 2018; 8(8):636. https://doi.org/10.3390/met8080636

Chicago/Turabian StyleEisenhut, Lena, Jonas Fell, and Christian Motz. 2018. "Local Characterization of Precipitation and Correlation with the Prior Austenitic Microstructure in Nb-Ti-Microalloyed Steel by SEM and AFM Methods" Metals 8, no. 8: 636. https://doi.org/10.3390/met8080636