Fatigue Behavior of As-Built L-PBF A357.0 Parts

Abstract

:1. Introduction

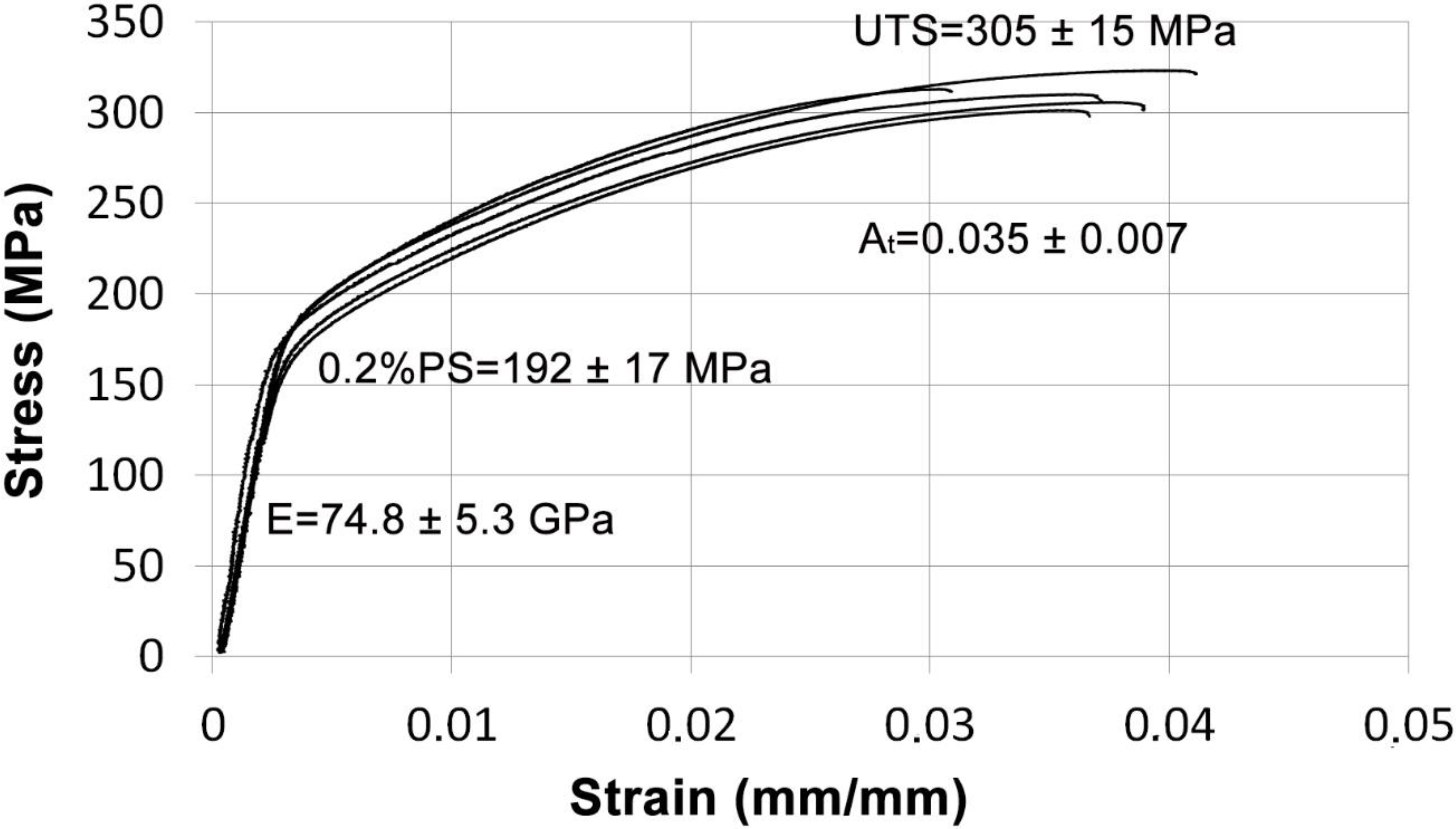

2. Materials and Methods

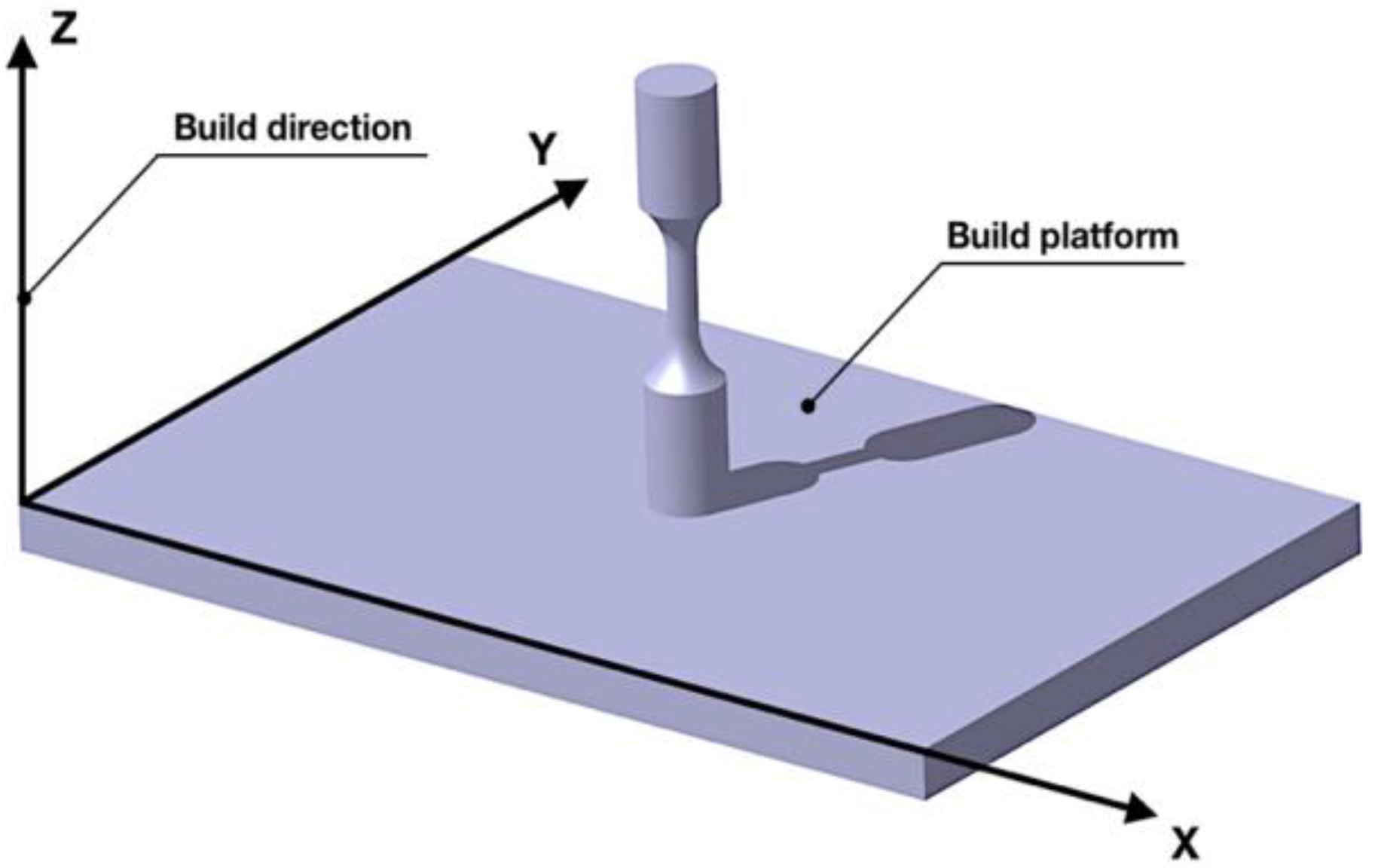

2.1. AM Conditions

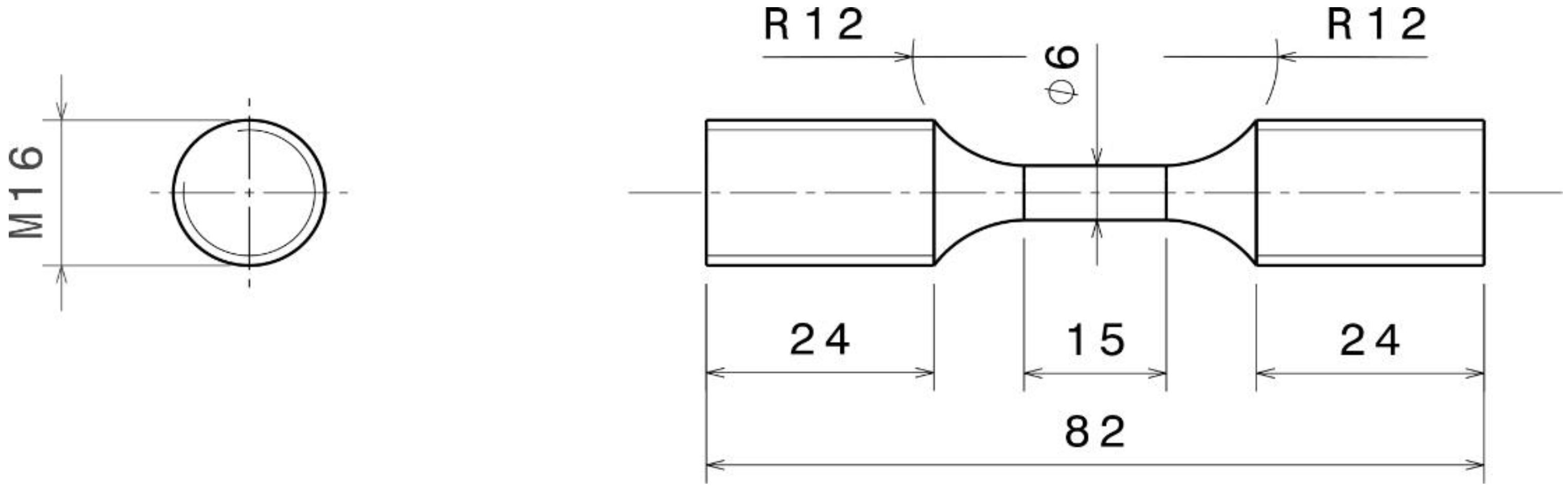

2.2. Axial Fatigue Tests

2.2.1. Construction of the Wohler Diagram

- An initial test is performed at a peak stress level that is likely to induce a failure in 1 × 105 cycles; according to the standard, if no other information is available but tensile test data exist, it is expected that an initial test at a stress of ((UTS + 0.2% PS)/2) will produce a failure, where UTS is the ultimate tensile stress and 0.2% PS is the stress at which 0.2% plastic deformation occurs.

- The peak stress level is reduced by 40 MPa for the next test; according to standard UNI EN 3987:2010, this stress reduction should produce a life in the order of 1 × 107 stress-cycles unbroken. However, it is worth noting that the infinite lifetime limit in the present investigation was set to 2 × 106 cycles, as previously stated.

- If the test “2” fails before attaining the critical number of stress cycles, the peak stress level must be reduced by a further 20 MPa and the fatigue test must be repeated to provide an unbroken test result at the critical number of stress cycles.

- The next test must be performed at a peak stress level up to 40 MPa higher than that used for the initial test “1”. This increment is expected to bring about a test endurance of around 1 × 104 stress-cycles.

- If the sample in test “4” is able to survive more than 1 × 104 stress cycles, the peak stress must be increased by a further 20 MPa and the test must be repeated.

- The procedure is repeated until any obvious gaps in the S-N curve are filled.

2.2.2. Statistical Estimation of Fatigue Strength

- Rough estimates of the mean fatigue strength and related standard deviation should be known a priori. The first sample, randomly chosen, is tested at a peak stress level preferably close to the estimated mean fatigue strength. A stress step, d, is fixed preferably close to the standard deviation; if no other information is available, d can be assumed to be 5% of the estimated mean fatigue strength.

- If the first specimen fails before reaching the given number of cycles (2 × 106 in the present test, as previously stated), the peak stress level for the next specimen is reduced by step d; otherwise, if no failure occurs, the peak stress level for the next specimen is increased by the same step.

- The procedure is repeated until all of the specimens have been tested.

- The test data are rearranged in order to count the occurrence of “failure” and “non-failure” events of specimens tested at different stress levels; the statistical analysis must be applied to the group of events with the lower number of observations.

- If S0 ≤ S1 ≤ … ≤ Sl denote the stress levels arranged in ascending order, where l is the number of stress levels tested, and if fi denotes the number of events associated with the Si stress level and d denotes the stress step, the mean and the standard deviation of the fatigue strength at the given fatigue life are calculated from Equations (1) and (2), respectively:where:

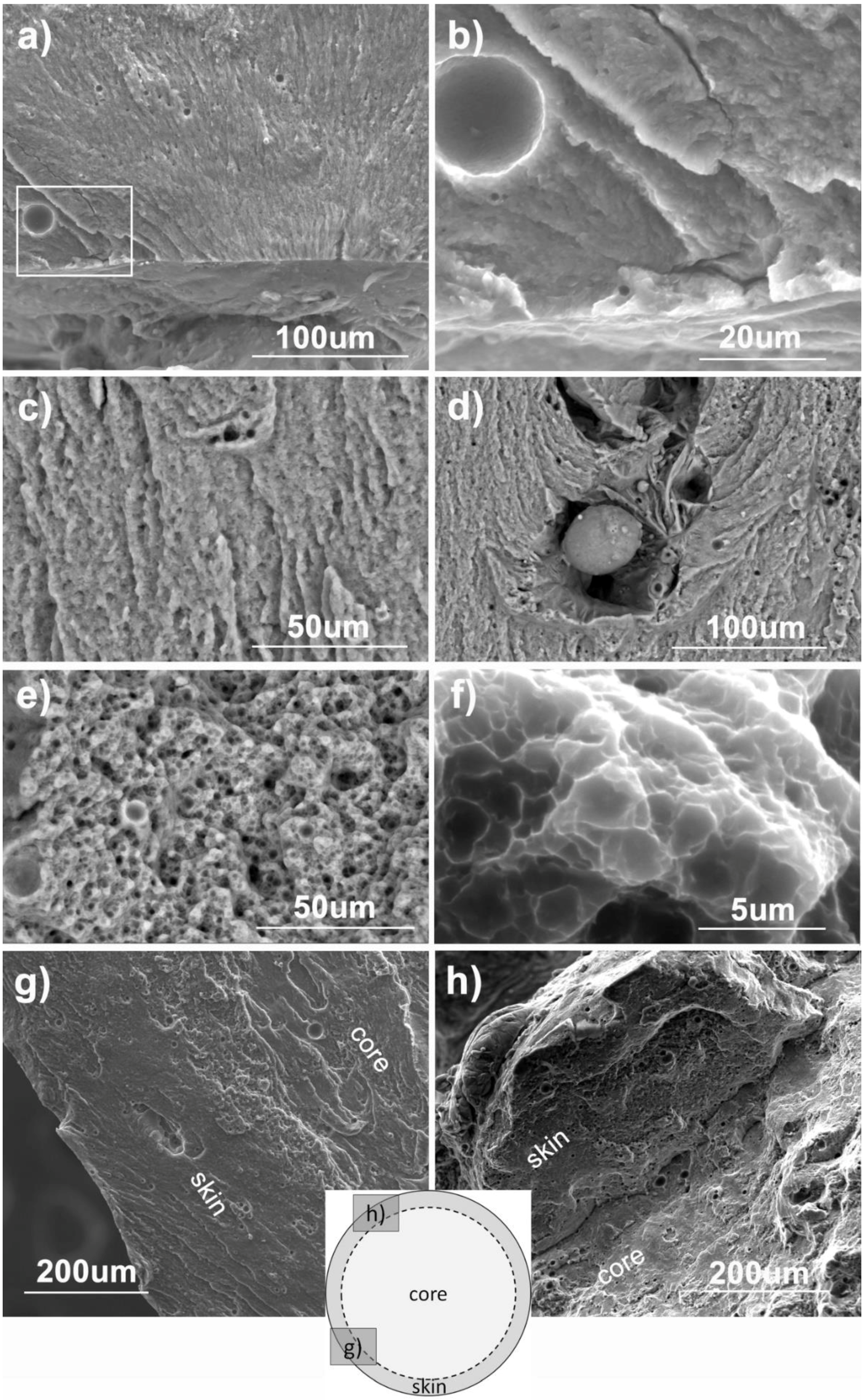

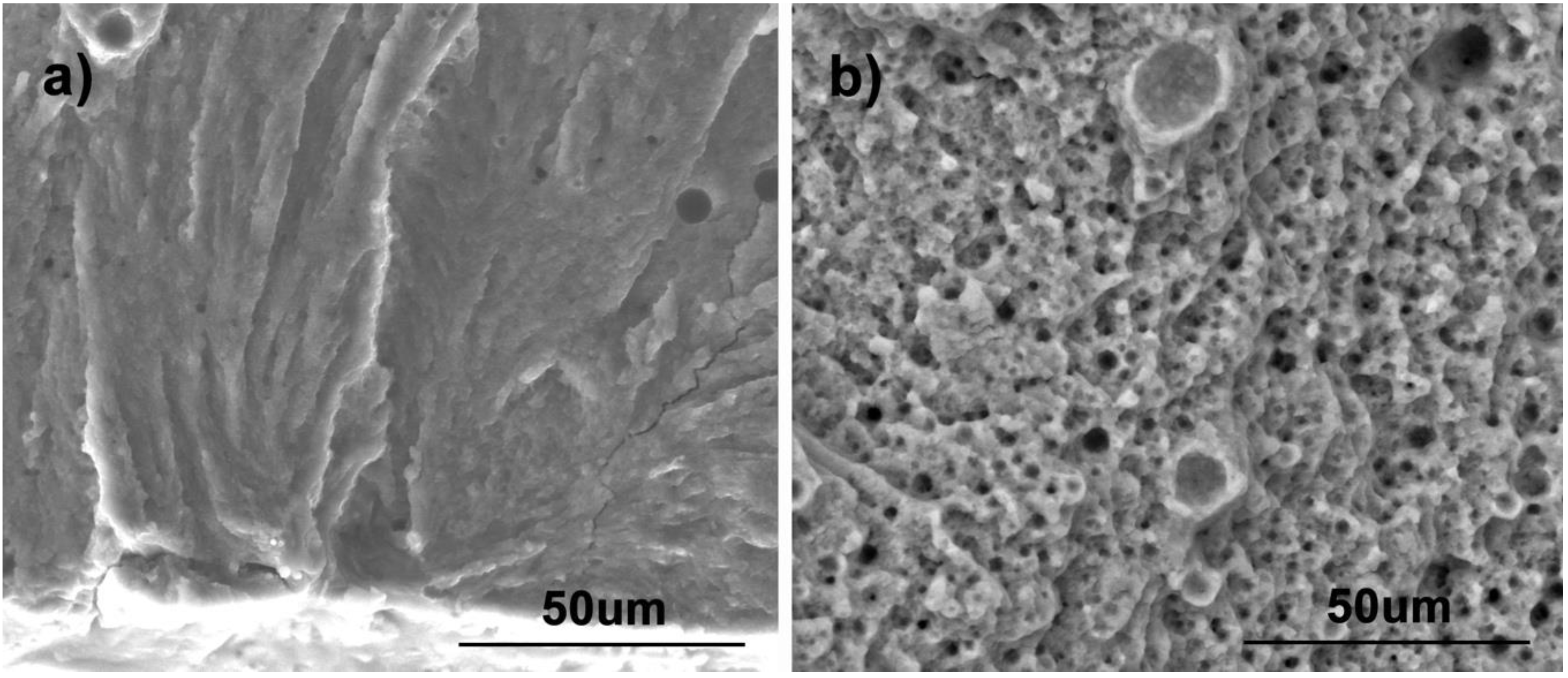

2.2.3. Analysis of Fracture Surfaces

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Additive Manufacturing of Aluminum Alloys. Augmenting or Competing with Traditional Manufacturing? Available online: https://www.lightmetalage.com/news/industry-news/3d-printing/article-additive-manufacturing-of-aluminum-alloys/ (accessed on 20 June 2018).

- Brøtan, V.; Fahlstroöm, J.; Sørby, K. Industrialization of metal powder bed fusion through machine shop networking. Procedia CIRP 2016, 54, 181–185. [Google Scholar] [CrossRef]

- Iebba, M.; Astarita, A.; Mistretta, D.; Colonna, I.; Liberini, M.; Scherillo, F.; Pirozzi, C.; Borrelli, R.; Franchitti, S.; Squillace, A. Influence of powder characteristics on formation of porosity in additive manufacturing of Ti-6Al-4V components. J. Mater. Eng. Perform. 2017, 26, 4138–4147. [Google Scholar] [CrossRef]

- Wohlers Associates. Available online: https://wohlersassociates.com/press74.html (accessed on 20 June 2018).

- International Organization for Standardization. ISO/ASTM 52900 Additive Manufacturing—General Principles—Terminology; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Bhavar, V.; Kattire, P.; Patil, V.; Khot, S.; Gujar, K.; Singh, R. A review on powder bed fusion technology of metal additive manufacturing. In Proceedings of the 4th International Conference and Exhibition on Additive Manufacturing Technologies-AM-2014, Bangalore, India, 1–2 September 2014. [Google Scholar]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies—Rapid Prototyping to Direct Digital Manufacturing; Springer: New York, NY, USA, 2010; ISBN 978-1-4419-1119-3. [Google Scholar]

- Tapia, G.; Elwany, A. A review on process monitoring and control in metal-based additive manufacturing. J. Manuf. Sci. E 2014, 136, 060801. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Fatigue assessment of laser additive manufactured AlSi12 eutectic alloy in the Very High Cycle Fatigue (VHCF) range up to 1E9 cycles. Mater. Today Proc. 2016, 3, 2853–2860. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Irrinki, H.; Dexter, M.; Barmore, B.; Enneti, R.; Pasebani, S.; Badwe, S.; Stitzel, J.; Malhotra, R.; Atre, S. Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17-4 PH stainless steel. JOM 2016, 68, 860–868. [Google Scholar] [CrossRef]

- Agarwala, M.; Bourell, D.; Beaman, J.; Marcus, H.; Barlow, J. Direct selective laser sintering of metals. Rapid Prototyp. J. 1995, 1, 26–36. [Google Scholar] [CrossRef]

- Valencia, J.J.; Quested, P.N. ASM Handbook Volume 15: Casting, 9th ed.; ASM International: Materials Park, OH, USA, 2008; ISBN 978-0-87170-711-6. [Google Scholar]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. Improving the fatigue behaviour of a selectively laser melted aluminium alloy: Influence of heat treatment and surface quality. Mater. Des. 2016, 104, 174–182. [Google Scholar] [CrossRef] [Green Version]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the AlSi10Mg alloy: Process, microstructure, and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

- Uzan, N.E.; Shneck, R.; Yeheskel, O.; Frage, N. Fatigue of AlSi10Mg specimens fabricated by additive manufacturing selective laser melting (AM-SLM). Mater. Sci. Eng. A 2017, 704, 229–237. [Google Scholar] [CrossRef]

- Romano, S.; Beretta, S.; Brandão, A.; Gumpinger, J.; Ghidini, T. HCF resistance of AlSi10Mg produced by SLM in relation to the presence of defects. Procedia Struct. Integr. 2017, 7, 101–108. [Google Scholar] [CrossRef]

- Romano, S.; Brückner-Foit, A.; Brandão, A.; Gumpinger, J.; Ghidini, T.; Beretta, S. Fatigue properties of AlSi10Mg obtained by additive manufacturing: Defect-based modelling and prediction of fatigue strength. Eng. Fact. Mech. 2018, 187, 165–189. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Vollert, F.; Gibmeier, J.; Schulze, V. Process dependent porosity and the influence of shot peening on porosity morphology regarding selective laser melted AlSi10Mg parts. Addit. Manuf. 2018, 20, 77–89. [Google Scholar] [CrossRef]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the effect of shot-peening on fatigue resistance of AlSi10Mg specimens fabricated by additive manufacturing using selective laser melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Tridello, A.; Biffi, C.A.; Fiocchi, J.; Bassani, P.; Chiandussi, G.; Rossetto, M.; Tuissi, A.; Paolino, D.S. VHCF response of as-built SLM AlSi10Mg specimens with large loaded volume. FFEMS Fatigue Fract. Eng. Mater. Struct. 2018, in press. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Influence of process-induced microstructure and imperfections on mechanical properties of AlSi12 processed by selective laser melting. J. Mater. Process. Technol. 2015, 221, 205–213. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Walther, F. Very high cycle fatigue and fatigue crack propagation behavior of selective laser melted AlSi12 alloy. Int. J. Fatigue 2017, 92, 246–254. [Google Scholar] [CrossRef]

- Siddique, S.; Awd, M.; Tenkamp, J.; Walther, F. Development of a stochastic approach for fatigue life prediction of AlSi12 alloy processed by selective laser melting. Eng. Fail. Anal. 2017, 79, 34–50. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Sercombe, T.B.; Li, X. Selective laser melting of aluminium and aluminium metal matrix composites: Review. Mater. Technol. 2016, 31, 77–85. [Google Scholar] [CrossRef]

- Kaufman, J.G. Understanding wrought and cast aluminum alloy designations. In Introduction to Aluminum Alloys and Tempers; ASM International: Materials Park, OH, USA, 2000; Chapter 3; pp. 23–37. [Google Scholar] [CrossRef]

- Aversa, A.; Lorusso, M.; Trevisan, F.; Ambrosio, E.P.; Calignano, F.; Manfredi, D.; Biamino, S.; Fino, P.; Lombardi, M.; Pavese, M. Effect of process and post-process conditions on the mechanical properties of an A357 alloy produced via laser powder bed fusion. Metals 2017, 8, 68. [Google Scholar] [CrossRef]

- Rao, H.; Giet, S.; Yang, K.; Wu, X.; Davies, C.H.J. The influence of processing parameters on aluminium alloy A357 manufactured by Selective Laser Melting. Mater. Des. 2016, 109, 334–346. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Fang, X.; Chen, Y.; Wu, X.; Davies, C.H.J. The origins for tensile properties of selective laser melted aluminium alloy A357. Addit. Manuf. 2017, 17, 113–122. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.H.J.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- European Committee for Standardization. Aerospace Series—Test Methods for Metallic Materials—Constant Amplitude Force-Controlled High Cycle Fatigue Testing; UNI EN 3987; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- International Organization for Standardization. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; UNI EN ISO 6892-1; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- International Organization for Standardization. Metallic Materials—Fatigue Testing—Statistical Planning and Analysis of Data; ISO 12107; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Lin, S.-K.; Lee, Y.-L.; Lu, M.-W. Evaluation of the staircase and the accelerated test methods for fatigue limit distributions. Int. J. Fatigue 2001, 23, 75–83. [Google Scholar] [CrossRef]

- Pollak, R.; Palazotto, A.; Nicholas, T. A simulation-based investigation of the staircase method for fatigue strength testing. Mech. Mater. 2006, 38, 1170–1181. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect formation mechanisms in selective laser melting: A review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv. Eng. Mater. 2018, 1700952. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P.; Huang, J.; Zhu, W. Microstructure and mechanical properties of aluminium alloy cellular lattice structures manufactured by direct metal laser sintering. Mater. Sci. Eng. A 2015, 628, 238–246. [Google Scholar] [CrossRef]

| Process Parameter | Value |

|---|---|

| Laser power | 950 W |

| Laser scan speed | 2000 mm/s |

| Laser spot | 400 µm |

| Hatch distance | 0.2 mm |

| Layer thickness | 50 µm |

| Inert gas | nitrogen |

| Platform pre-heating temperature | 200 °C |

| Scan strategy | skin-core |

| Maximum Stress (MPa) | Cycles to Failure |

|---|---|

| 190 | 4.0 × 103 |

| 190 | 1.6 × 104 |

| 150 | 2.5 × 104 |

| 150 | 2.9 × 104 |

| 140 | 5.8 × 104 |

| 140 | 3.2 × 104 |

| 130 | 5.1 × 104 |

| 130 | 4.9 × 104 |

| 110 | 9.5 × 104 |

| 110 | 9.4 × 104 |

| 90 | 1.7 × 105 |

| 70 | 2.1 × 105 |

| 50 | >2 × 106 |

| Si (MPa) | Sequence Number of Specimens | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | X | O | |

| 70 | X | X | X | O | 3 | 1 | |||||||||||

| 60 | X | O | O | X | X | O | O | 3 | 4 | ||||||||

| 50 | O | O | O | O | 0 | 4 | |||||||||||

| 6 | 9 | ||||||||||||||||

| Stress Si | Level | Values | ||

|---|---|---|---|---|

| i | fi | i fi | i2fi | |

| S1 = 70 (MPa) | 1 | 3 | 3 | 3 |

| S0 = 60 (MPa) | 0 | 3 | 0 | 0 |

| Sum | __ | C = 6 | A = 3 | B = 3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bassoli, E.; Denti, L.; Comin, A.; Sola, A.; Tognoli, E. Fatigue Behavior of As-Built L-PBF A357.0 Parts. Metals 2018, 8, 634. https://doi.org/10.3390/met8080634

Bassoli E, Denti L, Comin A, Sola A, Tognoli E. Fatigue Behavior of As-Built L-PBF A357.0 Parts. Metals. 2018; 8(8):634. https://doi.org/10.3390/met8080634

Chicago/Turabian StyleBassoli, Elena, Lucia Denti, Andrea Comin, Antonella Sola, and Emanuele Tognoli. 2018. "Fatigue Behavior of As-Built L-PBF A357.0 Parts" Metals 8, no. 8: 634. https://doi.org/10.3390/met8080634