2. Materials and Methods

CASS plates, with the dimensions of 140.0 × 65.0 × 9.0 (mm), were used as the base metals of this study. They were machined from the static castings with reference to ASTM A351/CF8A. Of the compositions of this casting specification, the sulfur content was intended to increase to the upper limit for a study with a high susceptibility to hot cracking. ER308L with a diameter of 0.9 mm was employed as the filler metal. The welding process was performed with a mechanical gas tungsten arc welding (GTAW) process with/without the application of EMS. The EMS effects on the microstructure and mechanical properties of the CASS weldments were investigated.

Table 1 gives the compositions of the base metal and the filler metal.

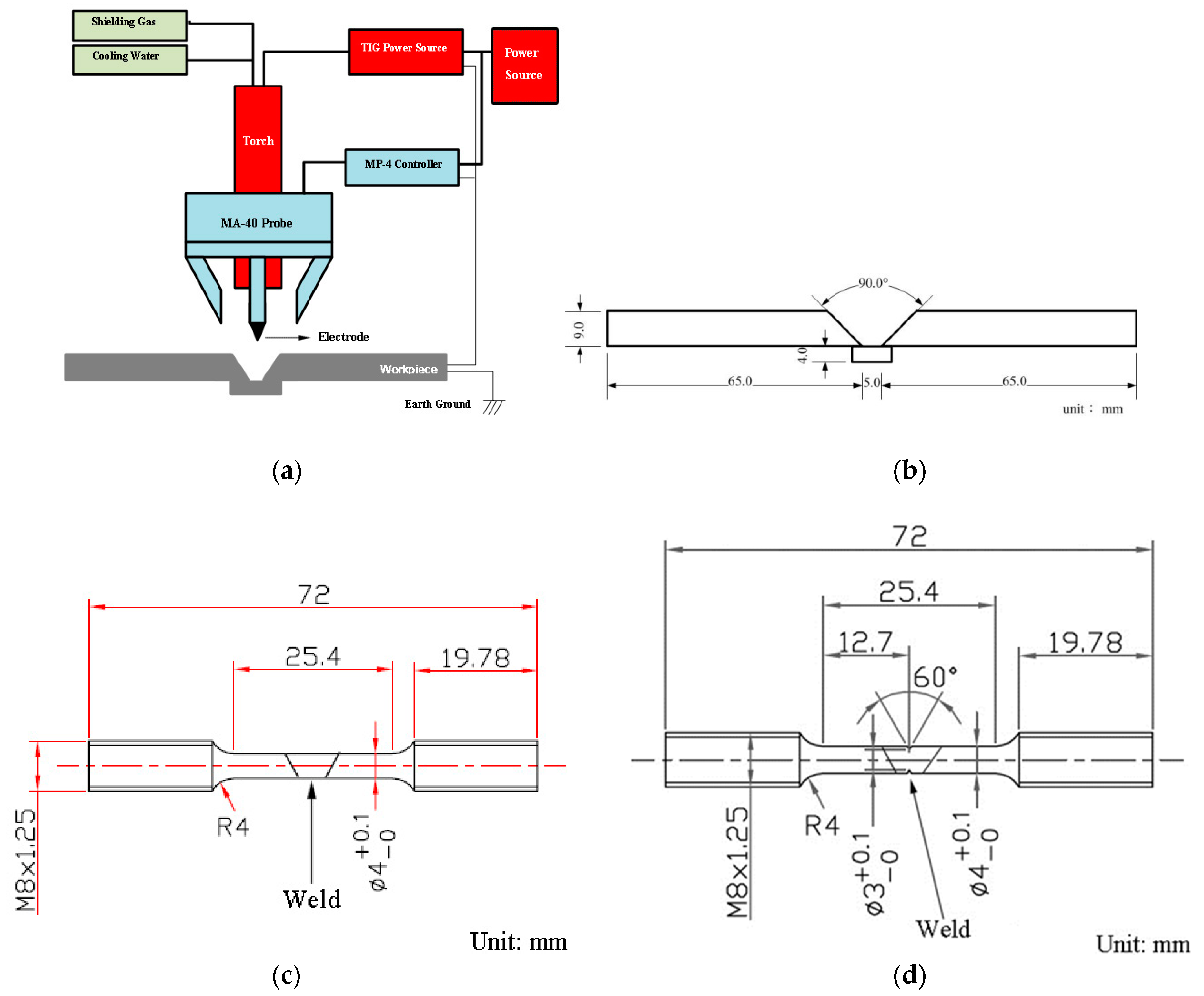

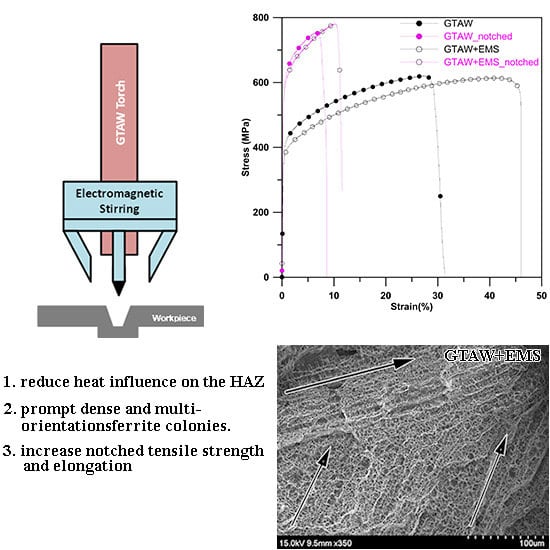

Before welding, the specimens were positioned on the fixture of the welding machine. The grooved surface of the specimens were cleaned with alcohol. The welding was performed with a mechanical GTAW process under a mode of direct current electrode negative (DCEN). The welding current was set at 180 A, while the welding voltage was about 11 V with a fixed distance between the electrode and the base metal. An MA-40 probe and an MP-4 controller, produced by Arc Products Inc., San Diego, CA, USA, were applied for the external EMS equipment. The EMS frequency was set at 3 Hz. The scheme diagram of the experimental set-up for the external EMS equipment and the weldment are presented in

Figure 1a,b, respectively.

After welding, visual inspection and a radiography test were both conducted to confirm that there were no defects present in the welds. The ferrite content of the welds and the base metals in the weldments were measured using FERITSCOPE® MP30 (Fischer Technology Inc., CT, USA), produced by Fischer Technology Inc., Connecticut, USA, with a testing mode of the ferrite number (FN). Each FN data was an average of seven tests. The specimens were then sampled with a mechanical process.

Bead-on-plate welding tests were performed to evaluate the temperature profiles of the HAZ and the weld areas. The temperature profiles of the heat affected zones were recorded by a high-speed radiation pyrometer, Sensortherm H316, produced by Sensortherm GmbH, Sulzbach, Taunus, Germany, while those for the welds were measured with R-type thermocouples, produced by Grandtek Instruments Co., Ltd., Taipei, Taiwan.

After mechanical polishing, the metallographic samples were electrolytically etched with a solution of 10 g oxalic acid and 100 mL H2O under 6~10 V DC for 30 s. An optical microscope (OM) was employed to examine the microstructure of the welds. Microstructural characterization and compositional analysis were performed with a scanning electron microscope (SEM), JSM-7100F, produced by JEOL Ltd., Tokyo, Japan, that was equipped with an energy dispersive spectroscope (EDS) and an electron backscatter diffraction (EBSD) system, produced by Oxford Instruments, Abingdon, UK. The areal fraction of the phases and the grain size all resulted from the EBSD analysis.

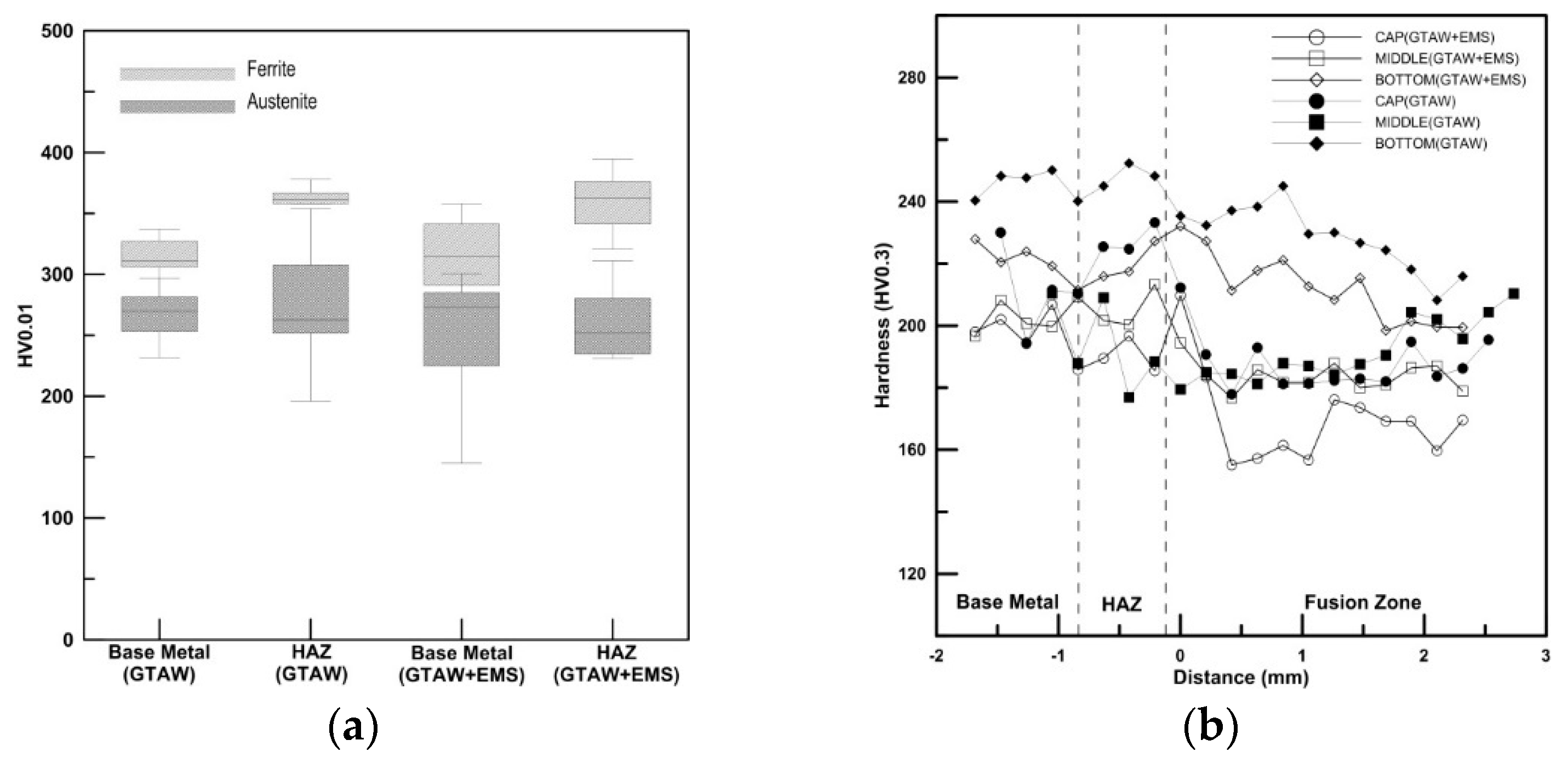

The micro-hardness measurements were taken with a load of 300 g. To further evaluate the influence of the welding heat on the microstructure, the hardness of the ferritic and austenitic phases were both measured at least at 10 points in the heat affected zone and the base metals, respectively. Hardness profiles through the weld metal, HAZ, and the base metal were also measured with a distance of 0.25 mm between two indentations in the root, middle, and the cap regions.

Uniaxial tensile tests were conducted with an MTS810 testing machine at a strain rate of 3 × 10

−4 mm/s at room temperature. The tensile specimens were prepared according to ASTM-E8, as shown in

Figure 1b. Some tensile specimens were notched at the welds to test their mechanical properties. The dimensions of the notched specimens are presented in

Figure 1c. The fracture surface of the tested tensile specimen was further observed by SEM. The effects of electromagnetic stirring on the welds were then discussed based on the results of mechanical tests, fractographic examinations, and microstructural characterization.

4. Discussion

The base metal (CF8A) and filler metals (308L) of this study were Fe-Cr-Ni steel alloys which have similar compositions to 304 stainless steel. According to the constitution diagram, their main phases are austenites and ferrites [

3]. The ferrite content, which is governed by the compositions, is often denoted by FN. At present, WRC-1992 is the most reliable and accurate diagram that is available for the ferritic prediction in the austenitic and duplex stainless steel weld metal [

20]. Its FN is predicted with the relationship between the Cr-and Ni-equivalent. These two equivalency formulas are given as:

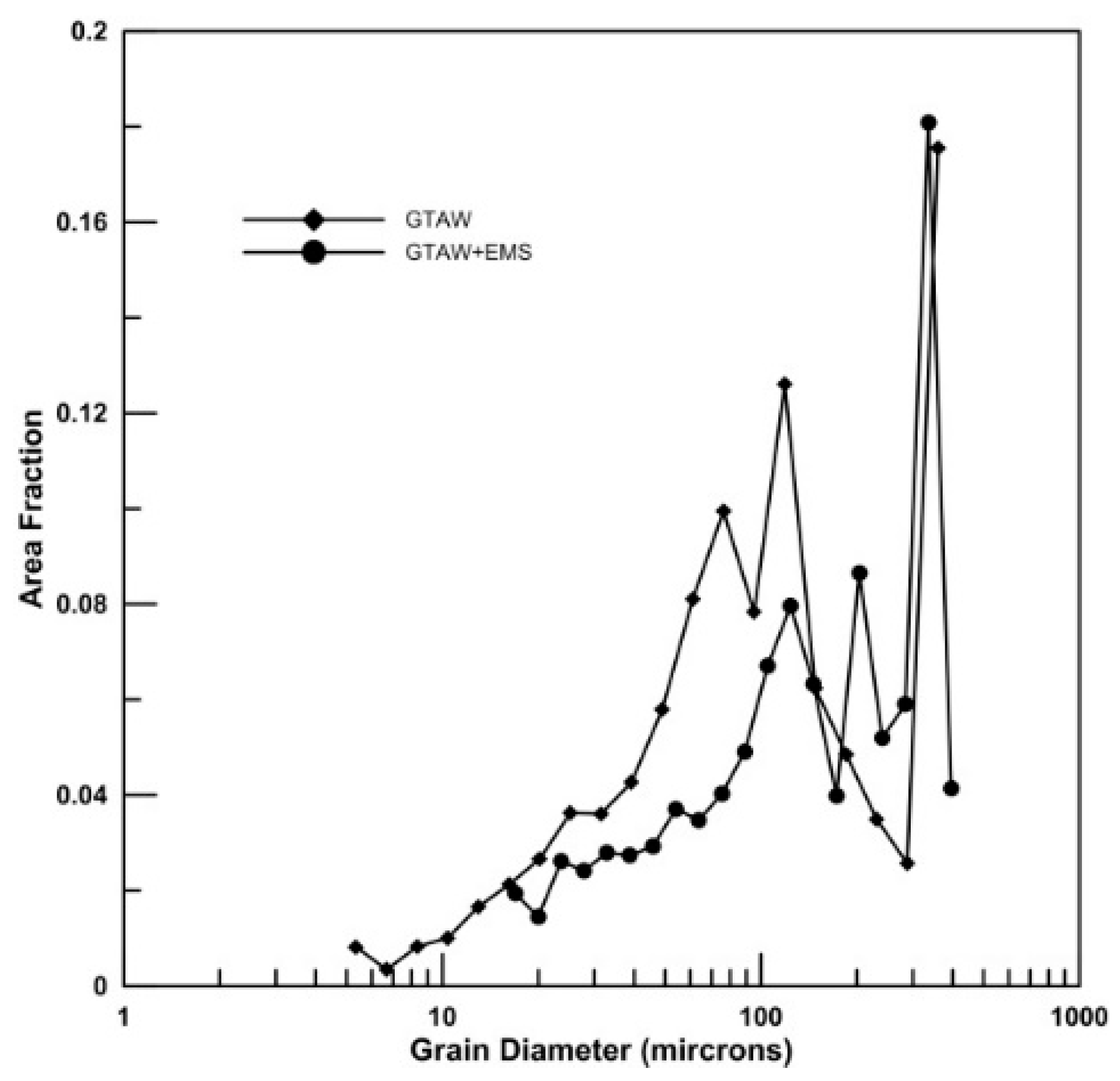

The FN, which is predicted by WRC-1992, is about 14~16 and 24 for the welds and the base metals, respectively. This is similar to the measured FN for the welds, about ten on average, as depicted in

Figure 2. However, the FN for the base metals by WRC-1992 is significantly different from that by FERITSCOPE

® MP30. This difference should result from the microstructural distinction between them. This is because the basis of FERITSCOPE

® MP30 for FN measurement is the magnetic field that the microstructural homogeneity can easily affect. In the welds, the microstructure is relatively homogenous with the small ferrites and austenites.

Although the FN, which is measured by the FERITSCOPE

® MP30, is almost the same for both the GTAW and GTAW+EMS welds, as shown in

Figure 2, EBSD results demonstrate that the ferrite content varies with the depth of the welds which have distinct dilutions due to the groove design and EMS effects. As stated above, the magnetic field is the basis of FERITSCOPE

® MP30. The distance/location is also a critical point for accurate FN measurement by the FERITSCOPE

® MP30.

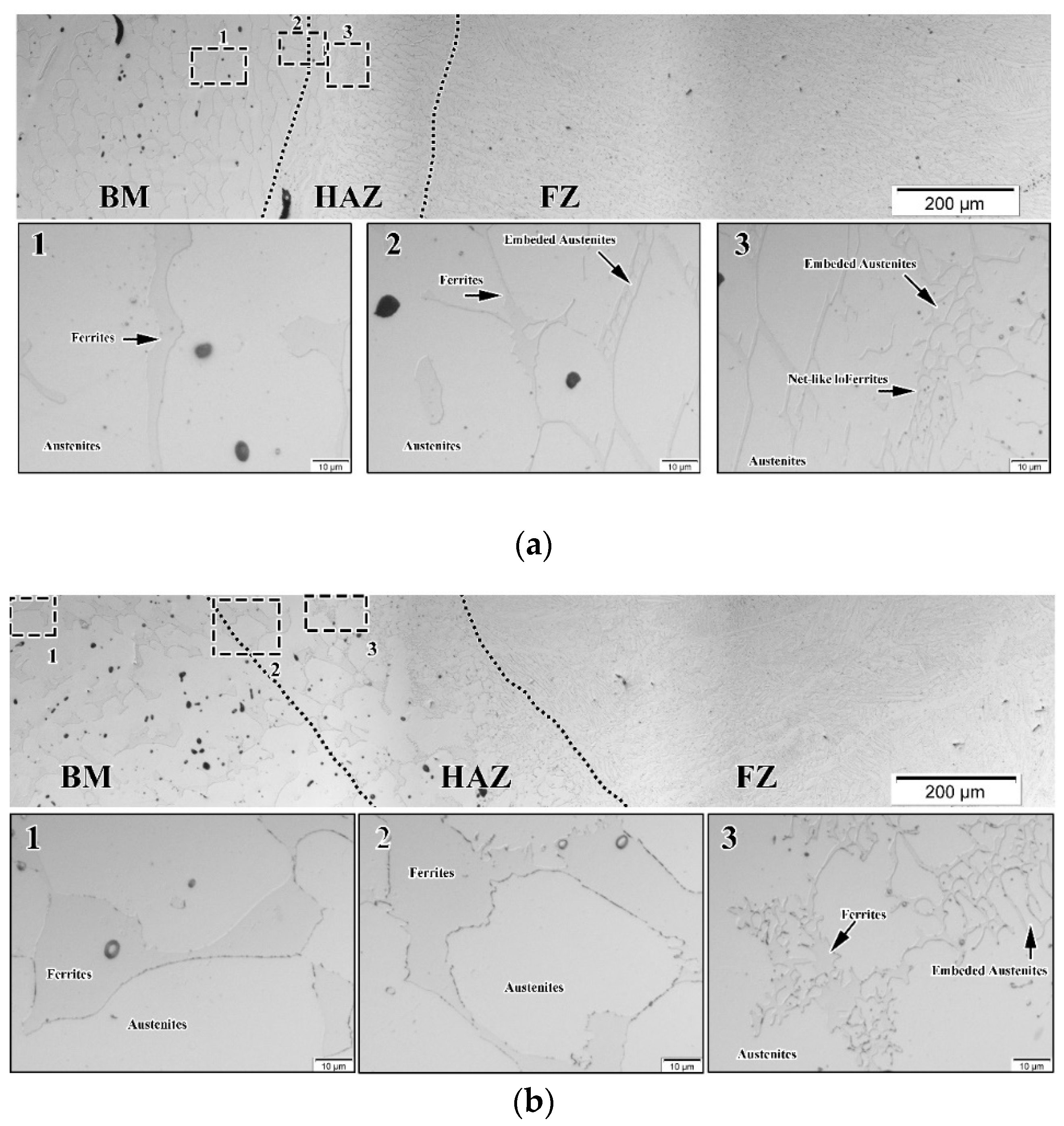

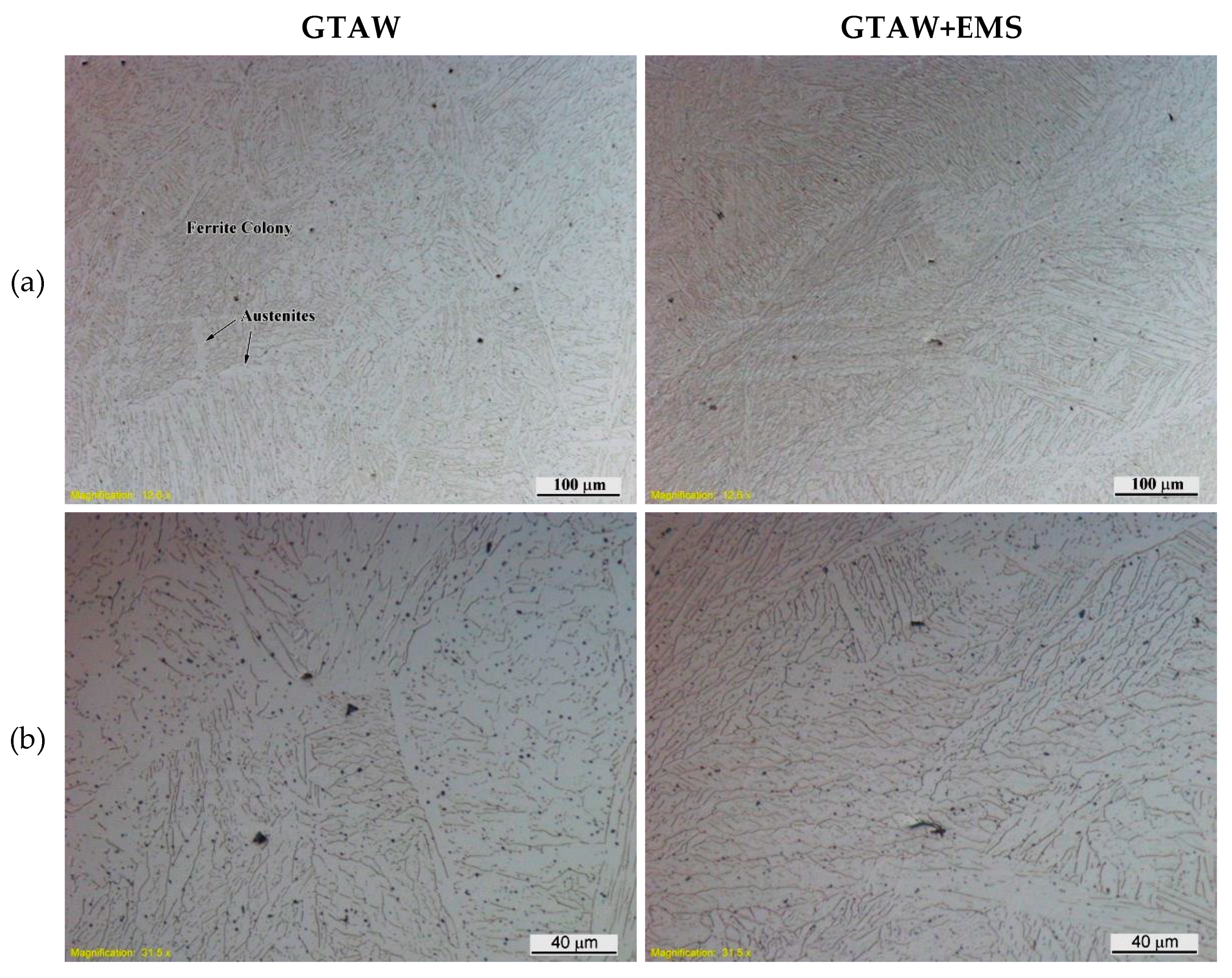

The HAZ microstructure of the GTAW+EMS weldment,

Figure 4b, shows that the ferrite boundaries and the embedded austenitic phases are both less winding and smaller, respectively, than that of the GTAW weldment,

Figure 4a. As demonstrated by Lippold’s study [

20], the faster the cooling rate of the weld bead is, the more the stable ferrites could form.

Figure 5a also depicts that the HAZ of the GTAW+EMS weldments have a lower peak temperature and a faster cooling rate than that of the GTAW weldments. This could be the reason why the ferrites embedded with smaller austenitic phases in the HAZ of the GTAW+EMS weldments.

Many studies indicated that ferrites could become harder owing to the occurrence of spinodal decomposition by thermal aging [

1]. When the spinodal decomposition occurs, the ferrites start to decompose into nano-meter scale Fe-rich (α–domains) phases, Cr-rich (α’–domains) phases, and G-phases [

1,

21,

22]. With the formation of these phases, the ferrites become brittle and increase in hardness. It is thought that the increase of the hardness of the ferrites in HAZs could result from the spinodal decomposition.

The hardness increase of the ferrites in the HAZ of this study is assumed to be as a result of the mechanism of spinodal decomposition that was induced by welding heat.

According to the prediction by WRC-1992 and the measurement by the FERITSCOPE

® MP30, the solidification of welds should be Type F. This is saying that the weld microstructure is fully ferritic at the end of solidification. When the weld cools below the ferrite solvus, austenite form within the microstructure, usually first at the ferrite grain boundaries [

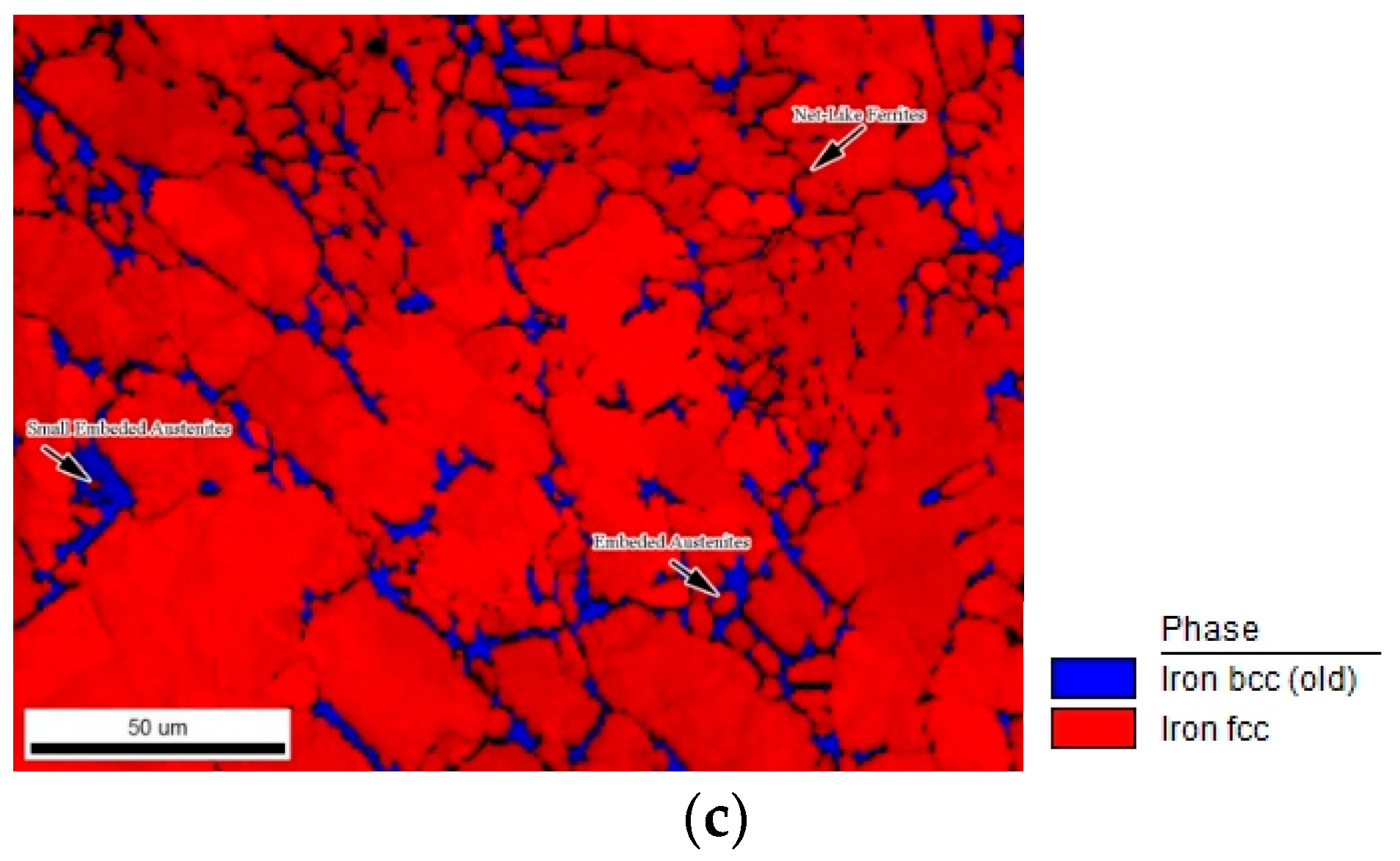

20]. The microstructure of both the GTAW and GTAW+EMS welds, as shown in

Figure 8, is a mixture of the ferrite colonies and austenites. Of them, the microstructure of the GTAW weld is very consistent with the solidification mode, as predicted, while that of the GTAW+EMS weld is not.

Figure 5b presents the temperature profiles of the welds. The temperature profile of the GTAW weld is almost the same as that of the GTAW+EMS weld. With a similar temperature profile, the microstructure of these two welds should be alike. However, their microstructure is entirely different from each other, as presented in

Figure 8. This means that the temperature profiles of the welds,

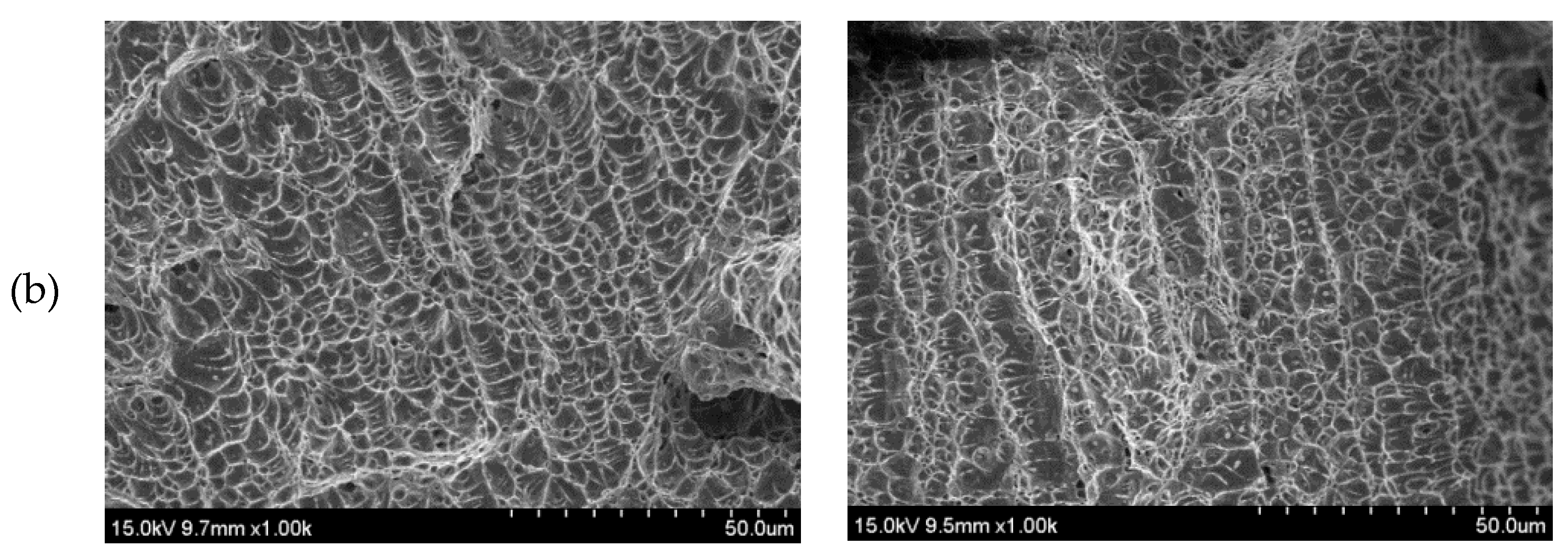

Figure 5b, cannot reflect the microstructural changes, which could be induced by the temperature gradient reduction and the direction change of the steepest temperature gradient by the EMS. In this study, it is conjectured that EMS could alter the dendritic orientations to prompt the formation of dense and intersecting dendrites on the fracture surface of GTAW+EMS welds, as displayed in

Figure 15.

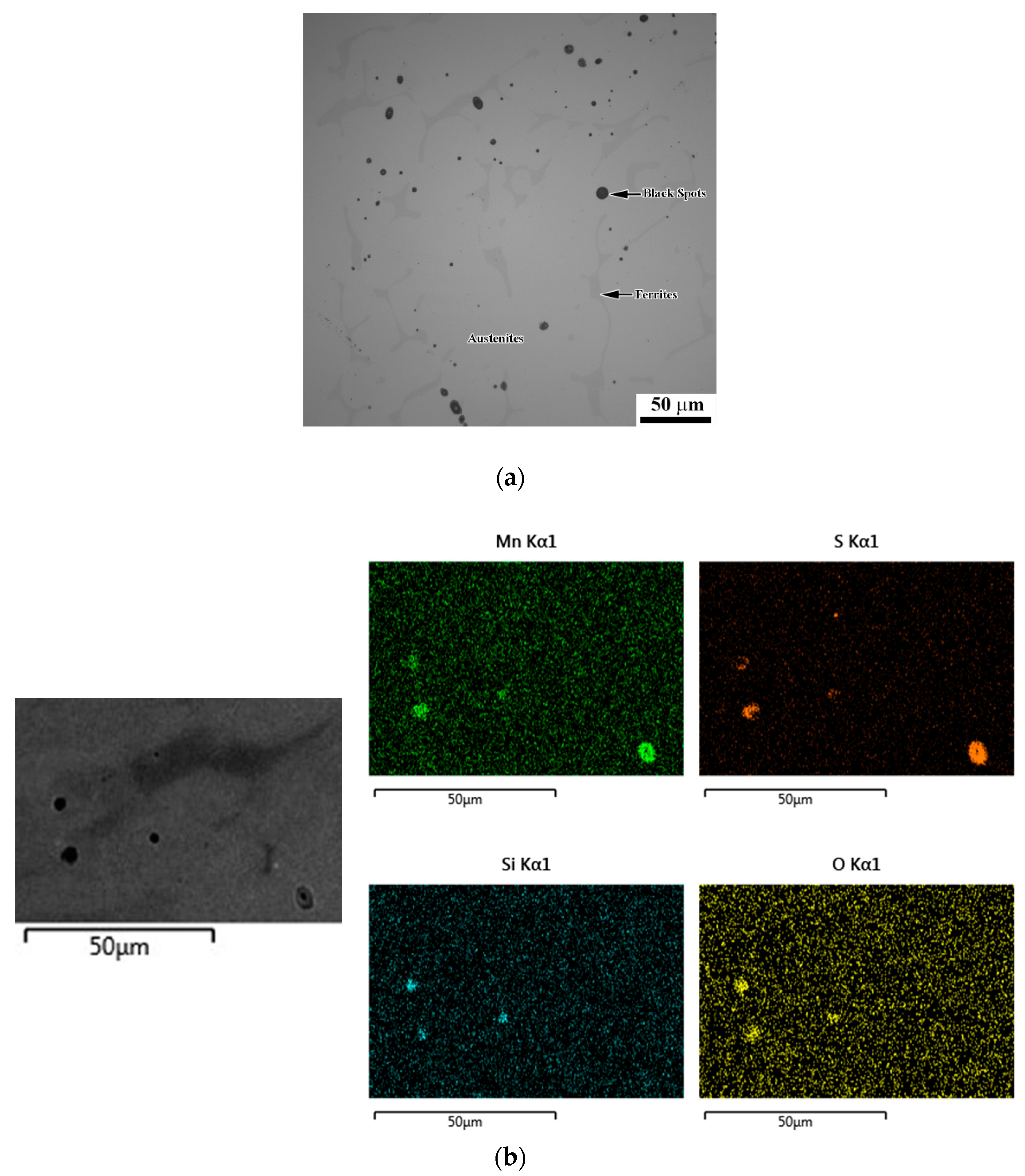

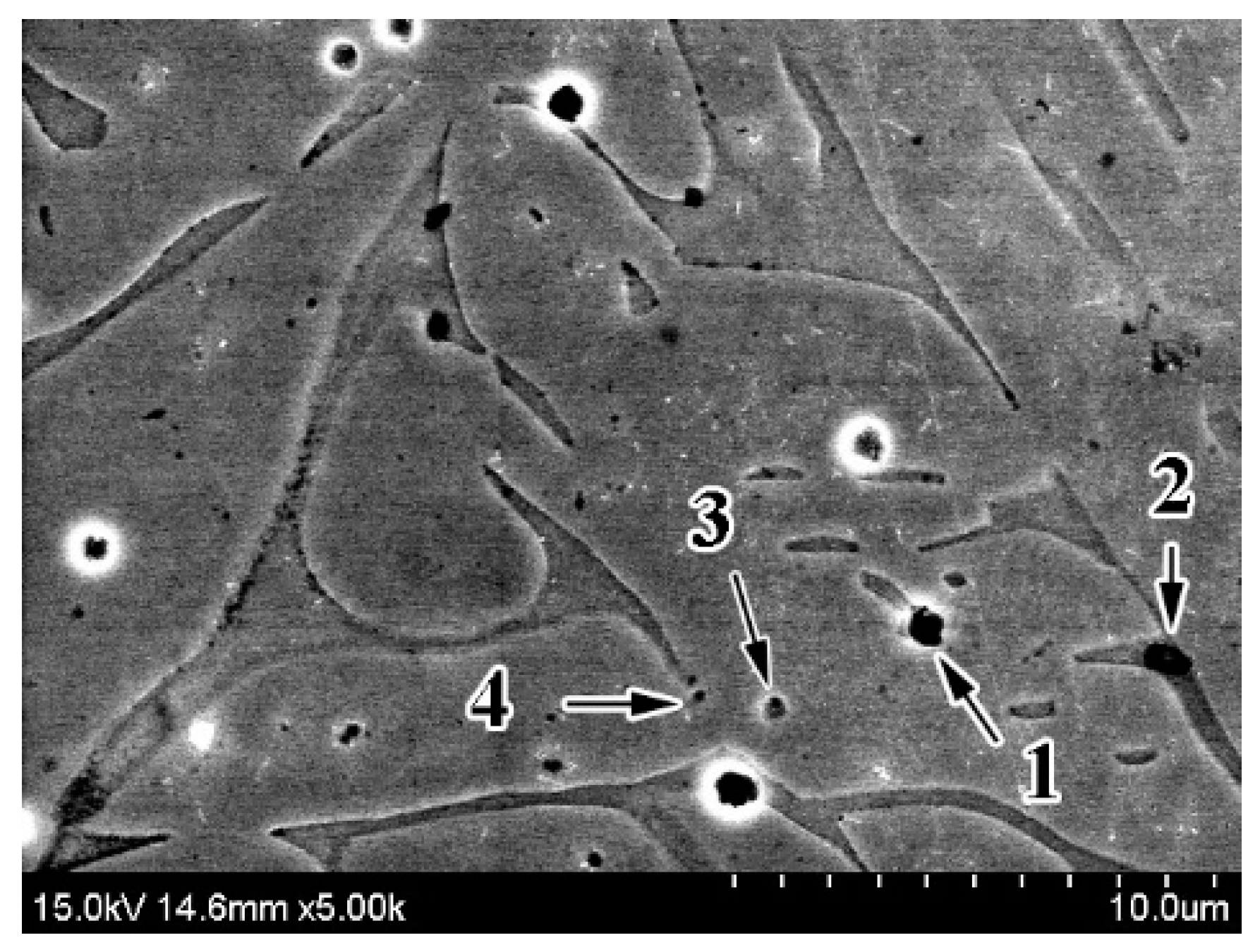

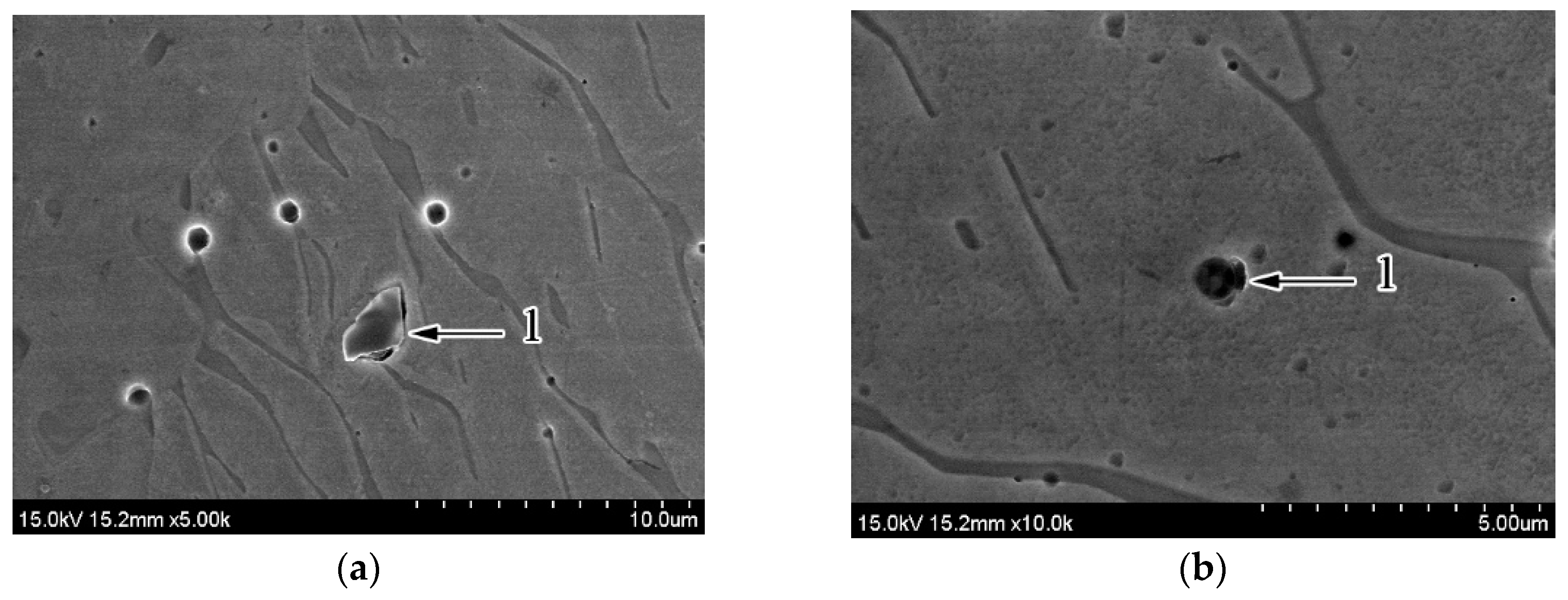

The number of black particles revealed in

Figure 7a,b is affected by dilution and EMS. They increase with increasing dilution, but decrease with the influence of EMS. According to the results of the compositional analysis,

Figure 11 and

Figure 12, most of them are oxides and could come from the base metals.

From the number variation of oxides in the cap and the middle areas, it is inferred that EMS could stir the welding pool to prompt the oxide to float on the surface of the welds. With the lower dilution, EMS could effectively reduce the oxides and impurities and improve the mechanical properties of the welds as a consequence.

The higher hardness of the GTAW weld could be accounted for by the previous microstructural observations of more precipitates and smaller grains in the weld that were induced by the higher dilution from the base metals. In the root, the higher dilution also resulted in more ferrites. These ferrites were further subjected to the subsequent welding heat, prompting the spinodal decomposition of the ferrites with an entailed increase of the hardness of the weld root. On similar reasoning, the lowest hardness of the cap could result from the least extent of exposure to welding heat that the ferrites in the cap region suffered. Therefore, the hardness variations in the welds are determined by the position of the weld and the dilution reduction due to the groove design and the EMS application.

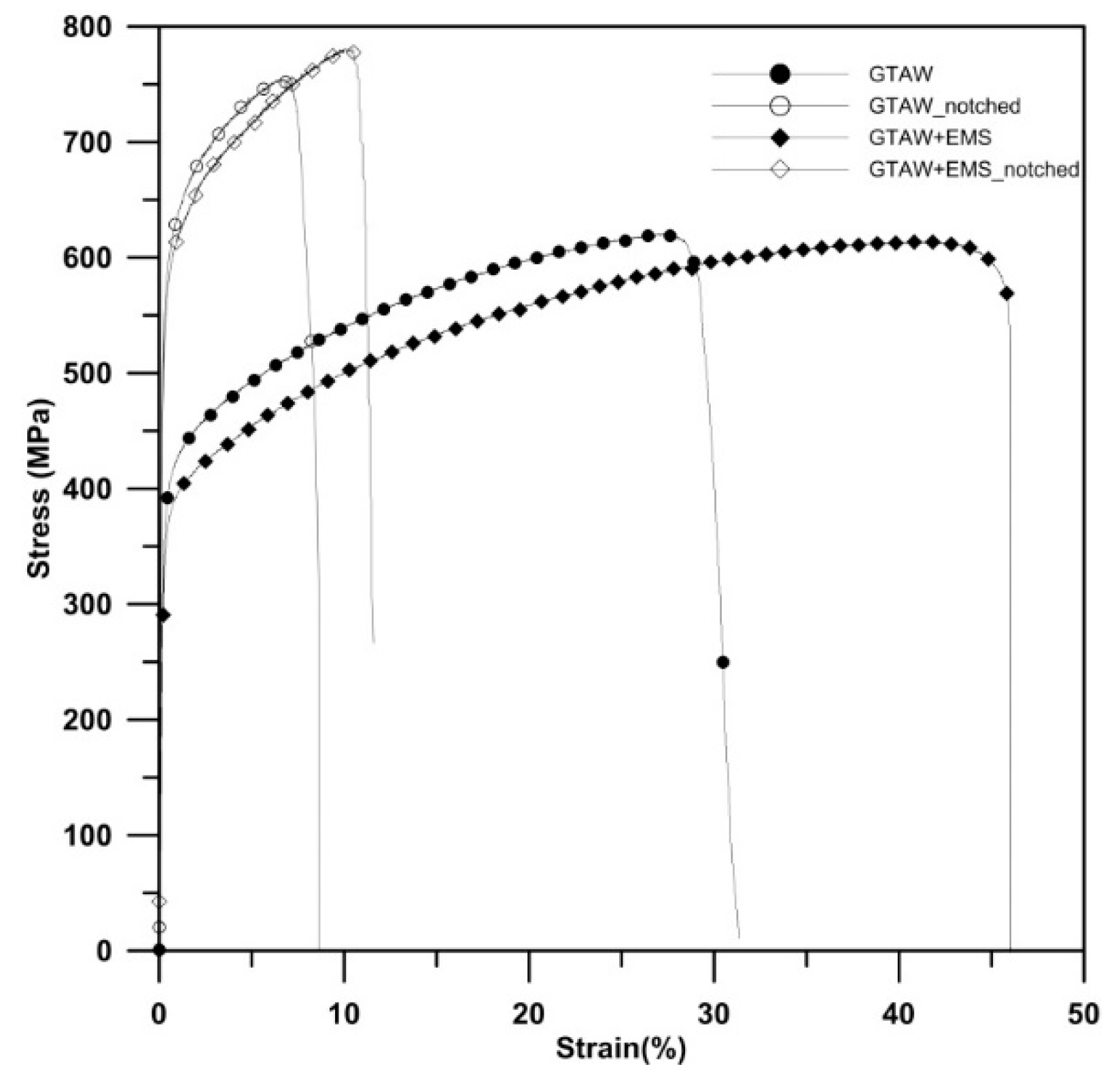

It has been indicated previously that the GTAW weld with more precipitates and small grains is harder than the GTAW+EMS weld. The more precipitates and grain boundaries in the welds, the more resistance to dislocation movements there will be. This is the reason why the notched tensile tests and the standard tensile tests all show that the GTAW weld has a higher Young’s modulus and yield strength than the GTAW+EMS weld.

According to the EBSD results of

Figure 16, the higher elongation of the GTAW+EMS weld could be accounted for by the deformation of austenites. The observations indicate that fewer precipitates and grain boundaries exist to obstruct the dislocation movement in the GTAW+EMS weld. It is further inferred that the intersecting dendrites in the GTAW+EMS weld could also prompt the deformation of austenites. With an increase of strain, the tensile stress of the GTAW+EMS weld rises due to the mechanism of strain hardening.