Influence of Heat Treatment on Microstructures and Mechanical Properties of NiCuCrMoTiAlNb Nickel-Based Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

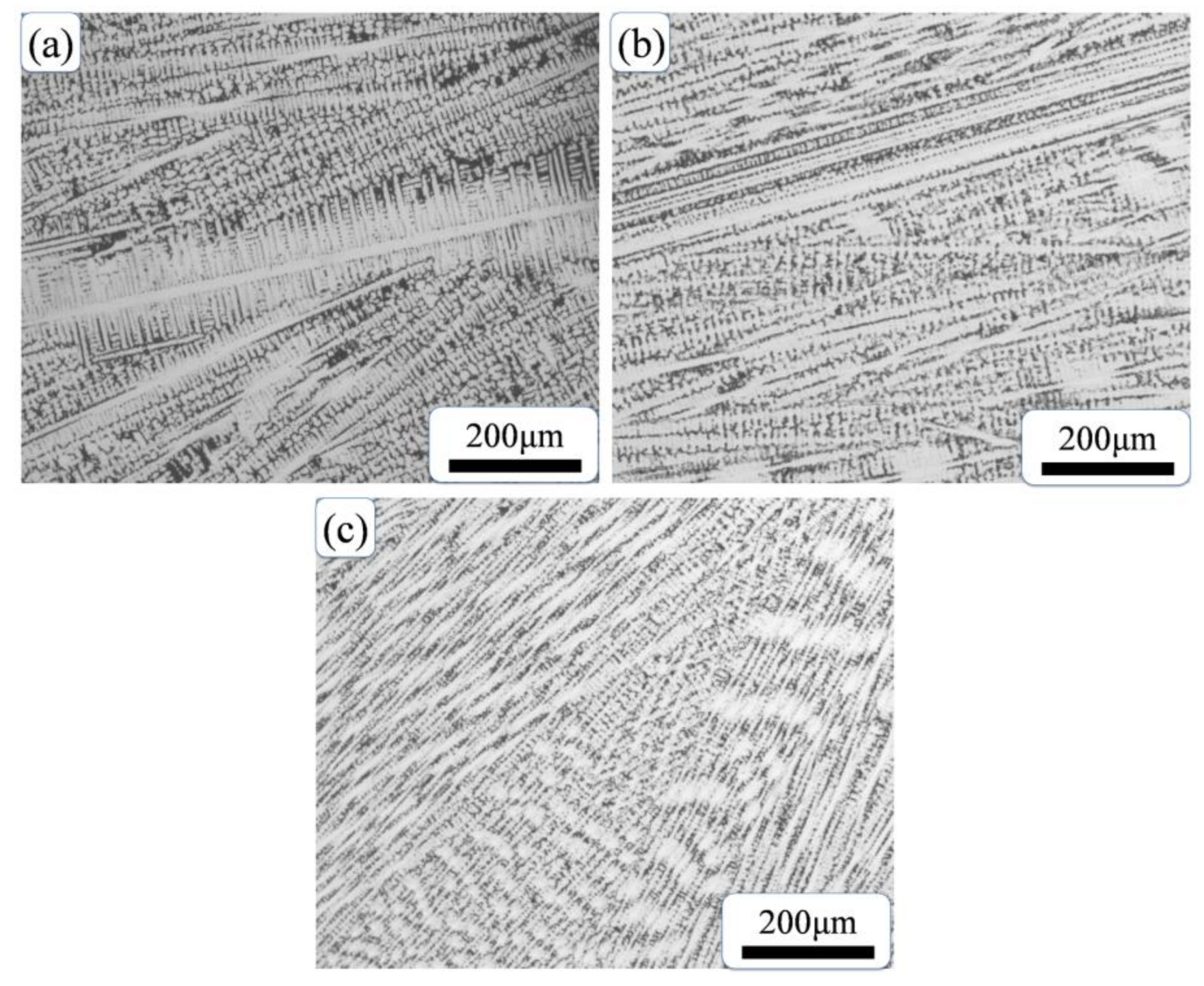

3.1. Optical Microstructure of As-Cast Nickel-Based Alloys

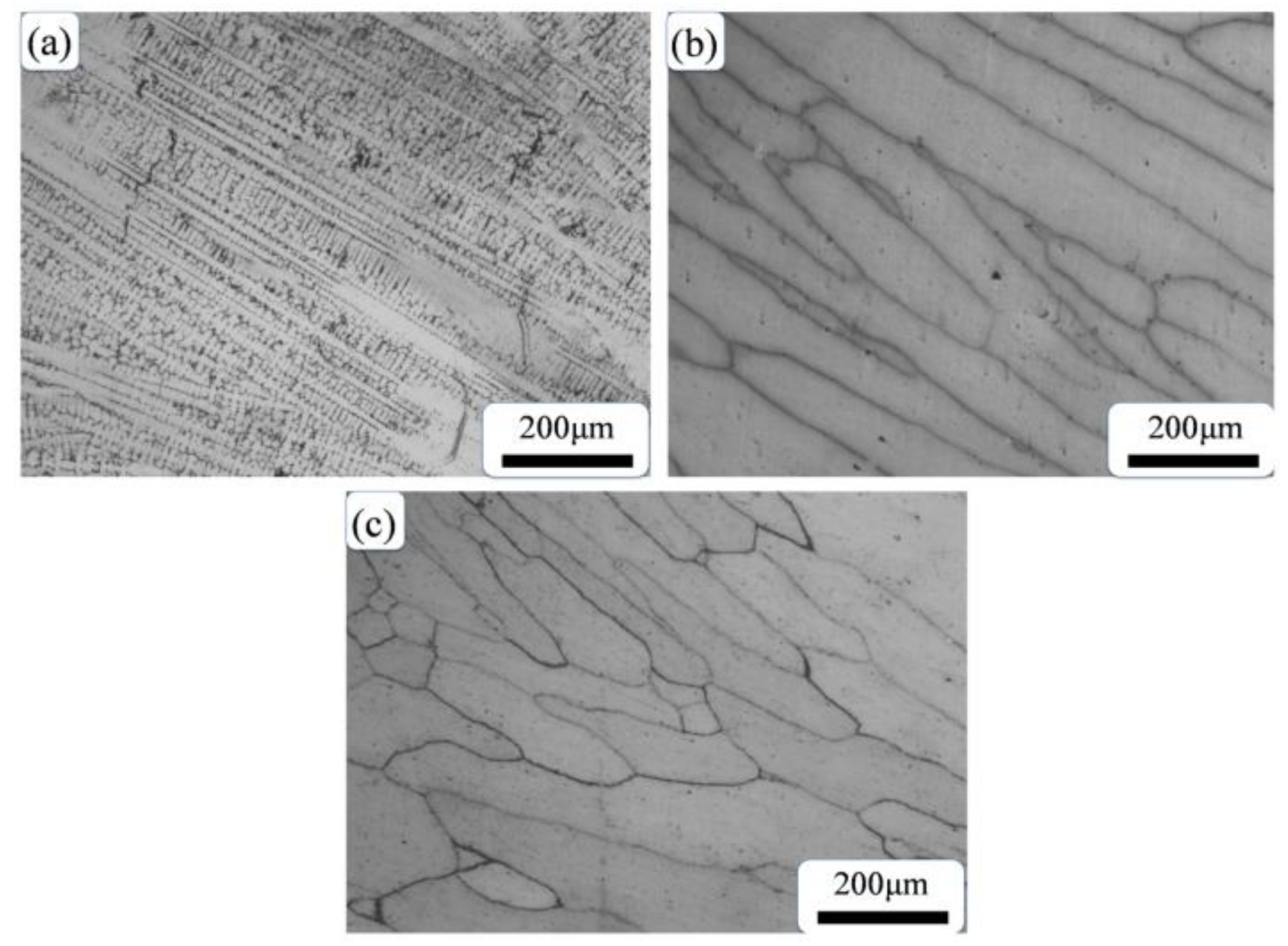

3.2. Optical Microstructure of Heat-Treated Nickel-Based Alloys

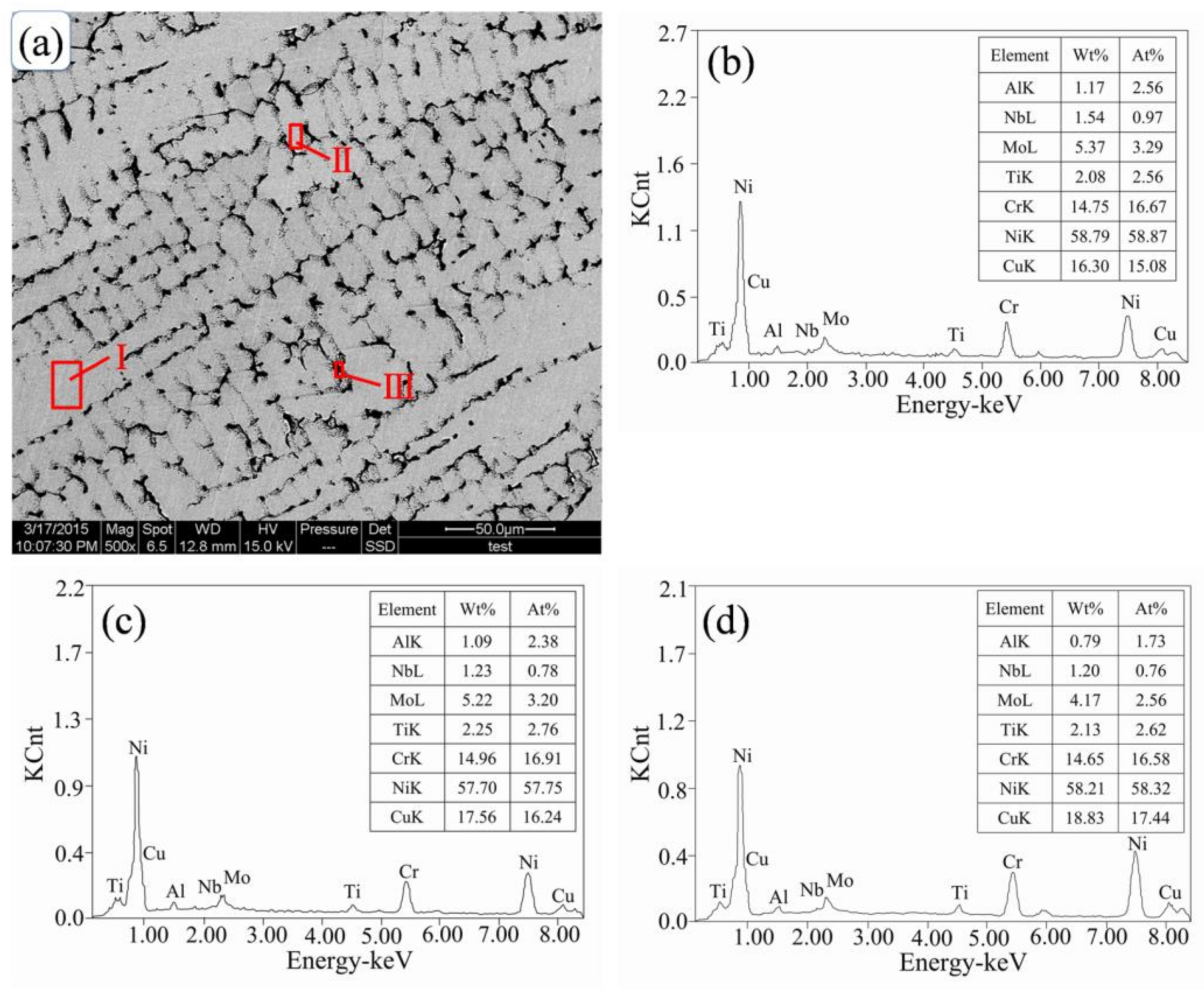

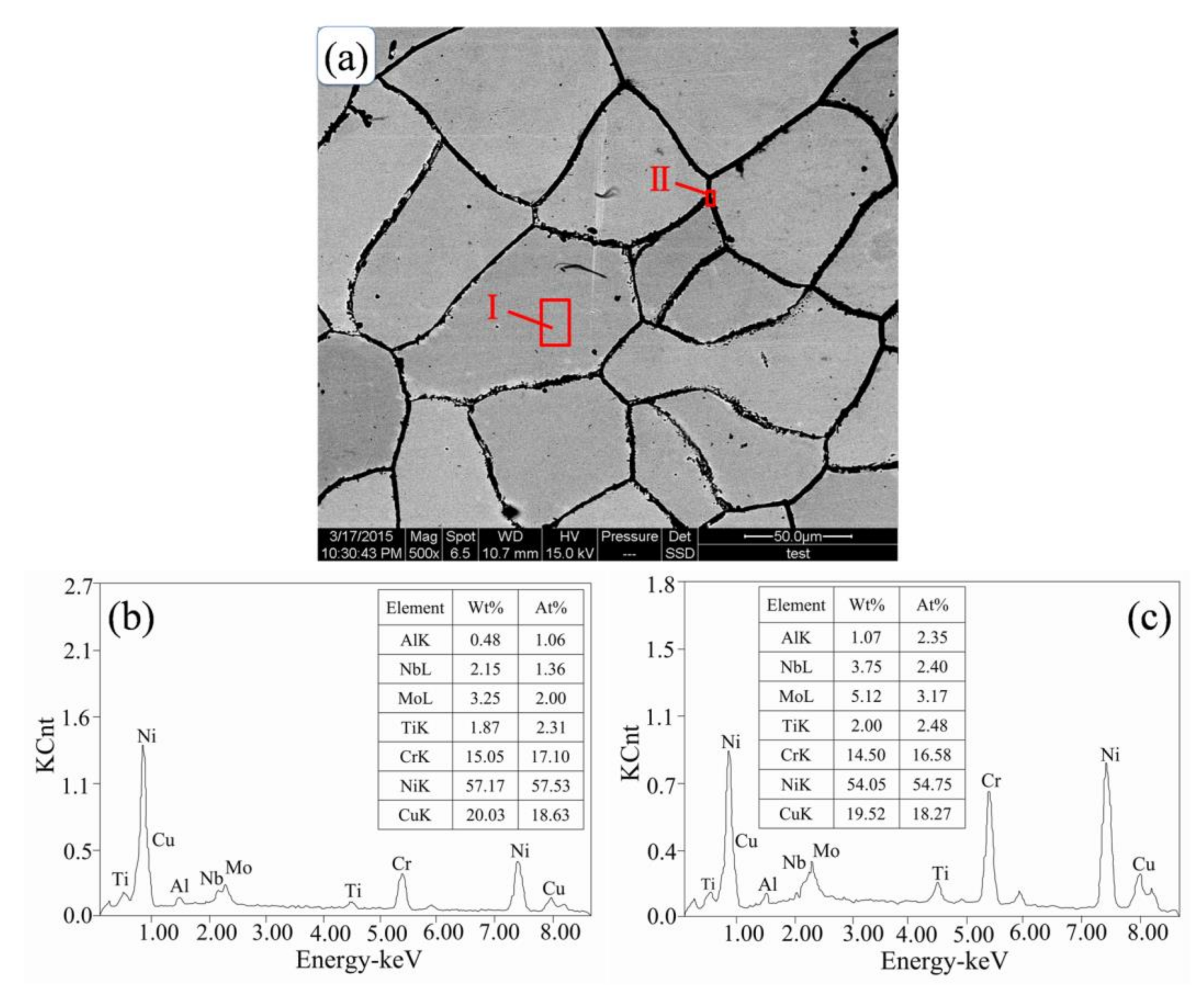

3.3. SEM and EDS Analysis of Heat-Treated Nickel-Based Alloys

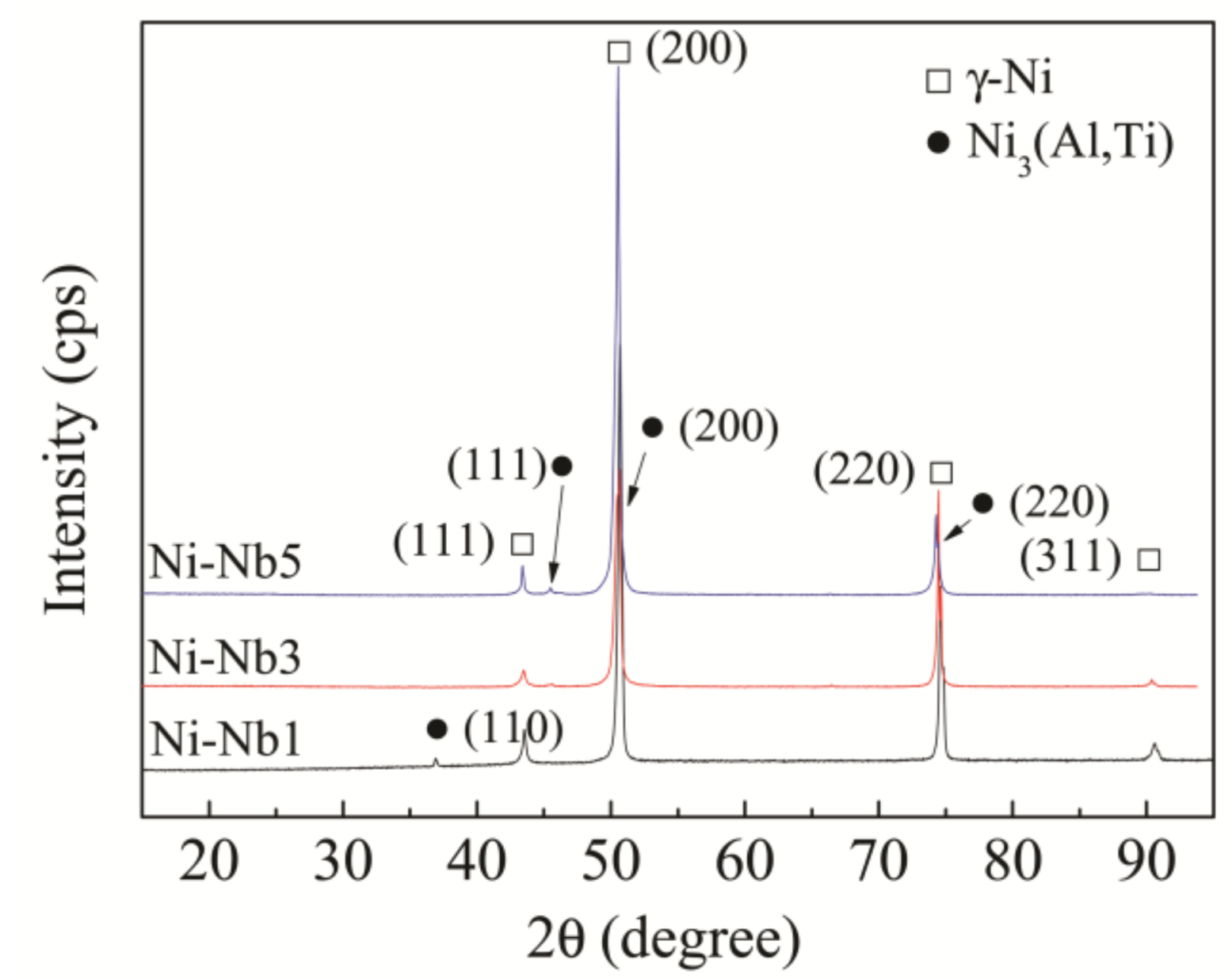

3.4. XRD Analysis of Heat-Treated Nickel-Based Alloys

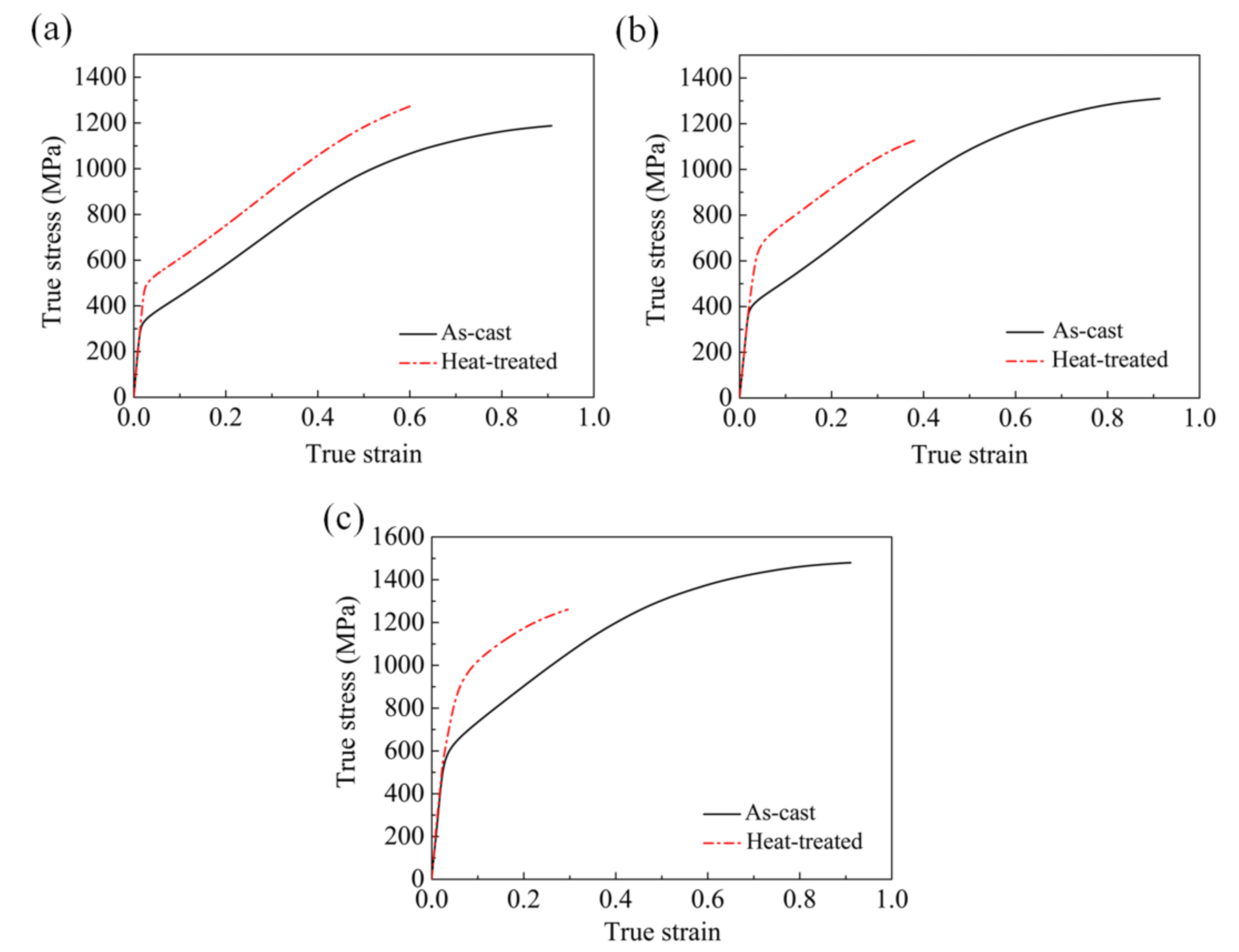

3.5. Mechanical Properties of Nickel-Based Alloys

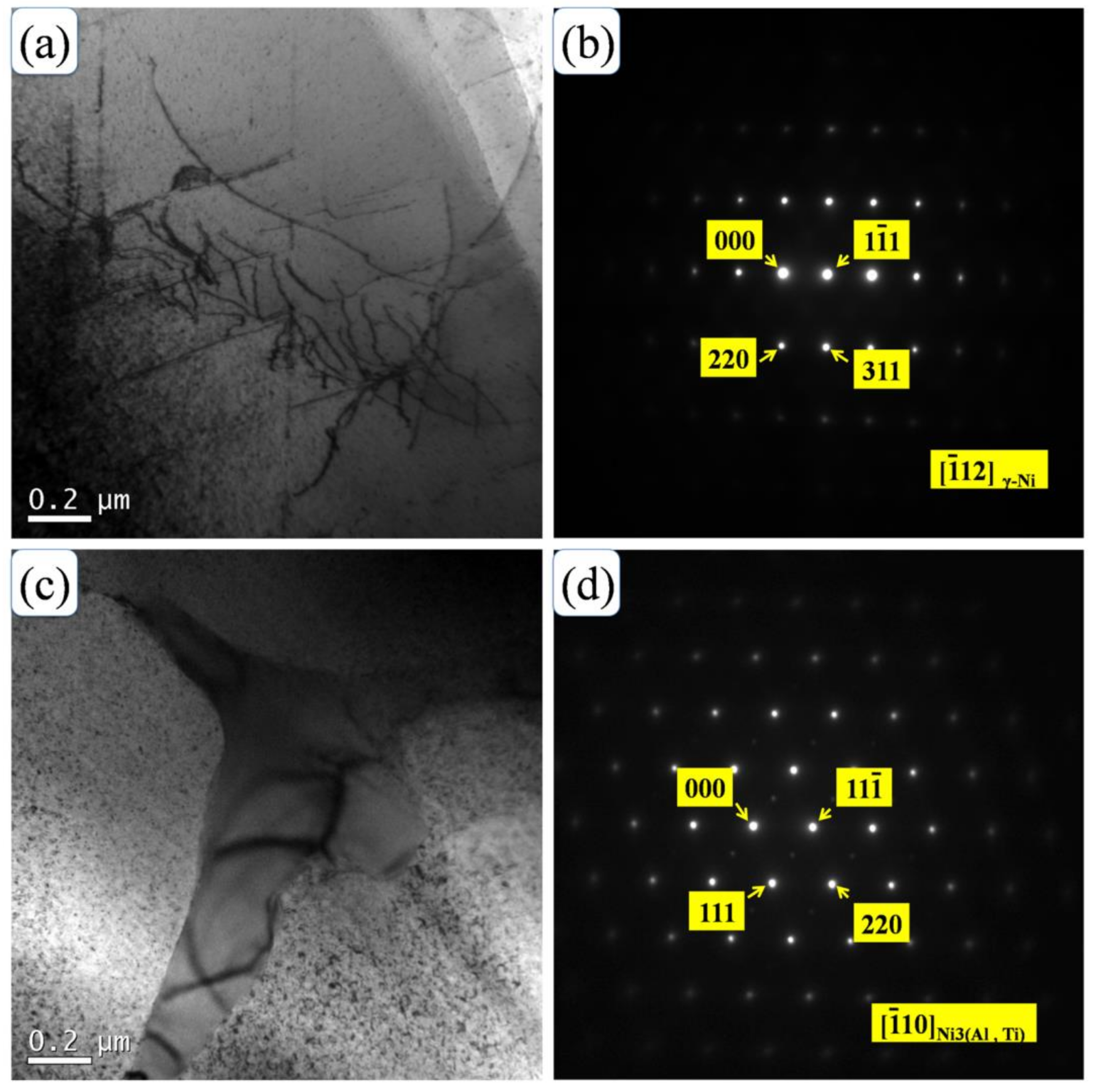

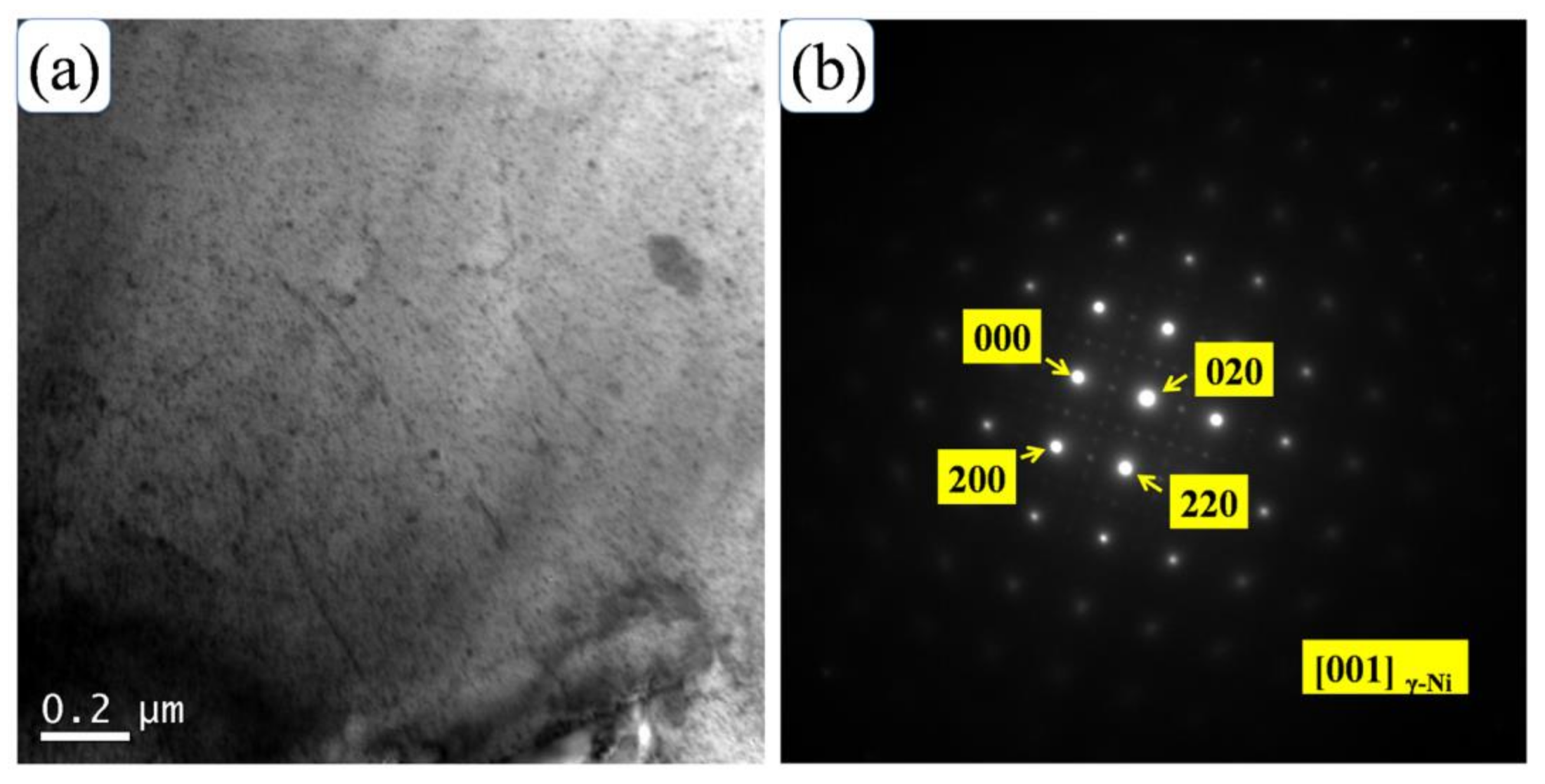

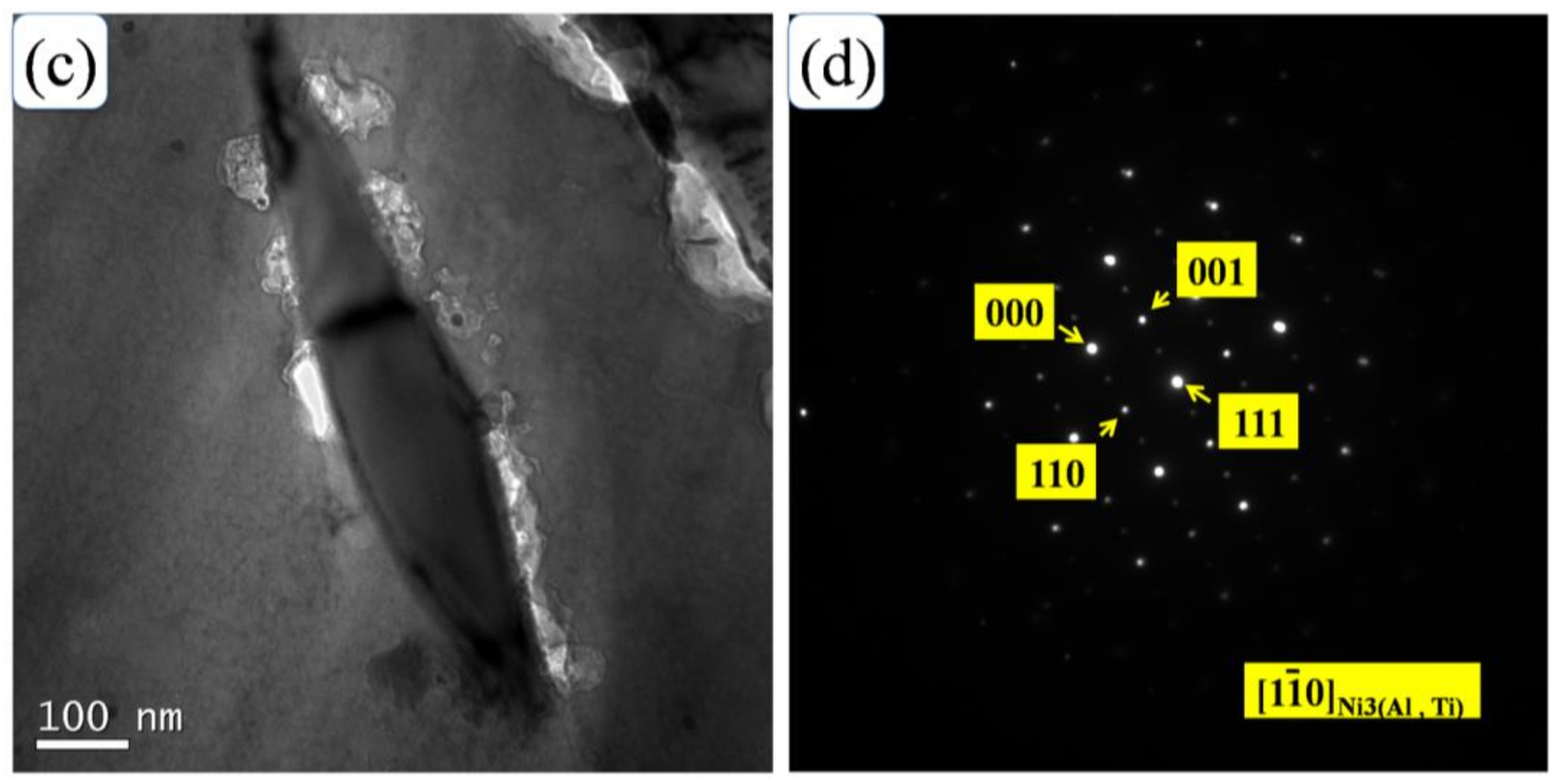

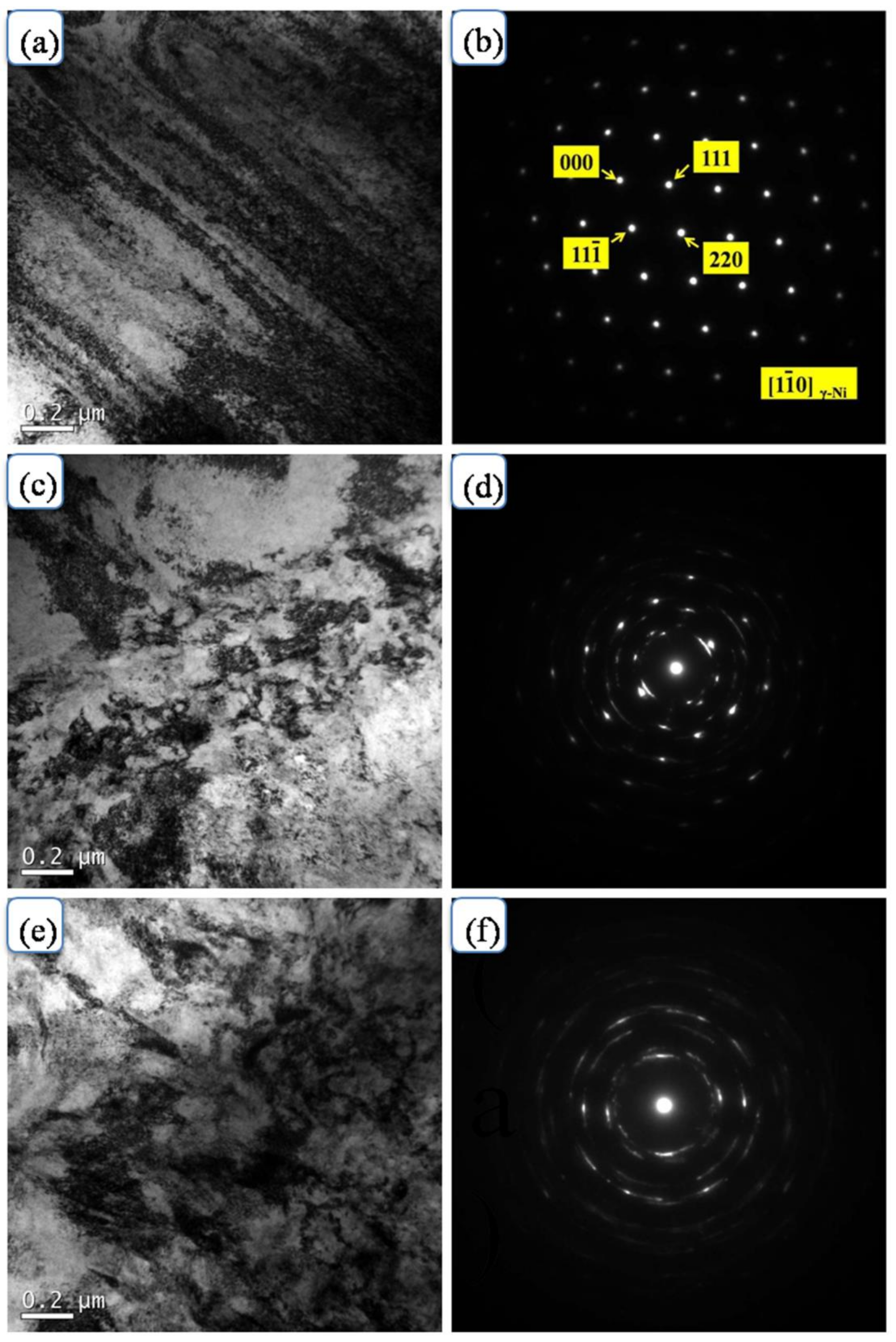

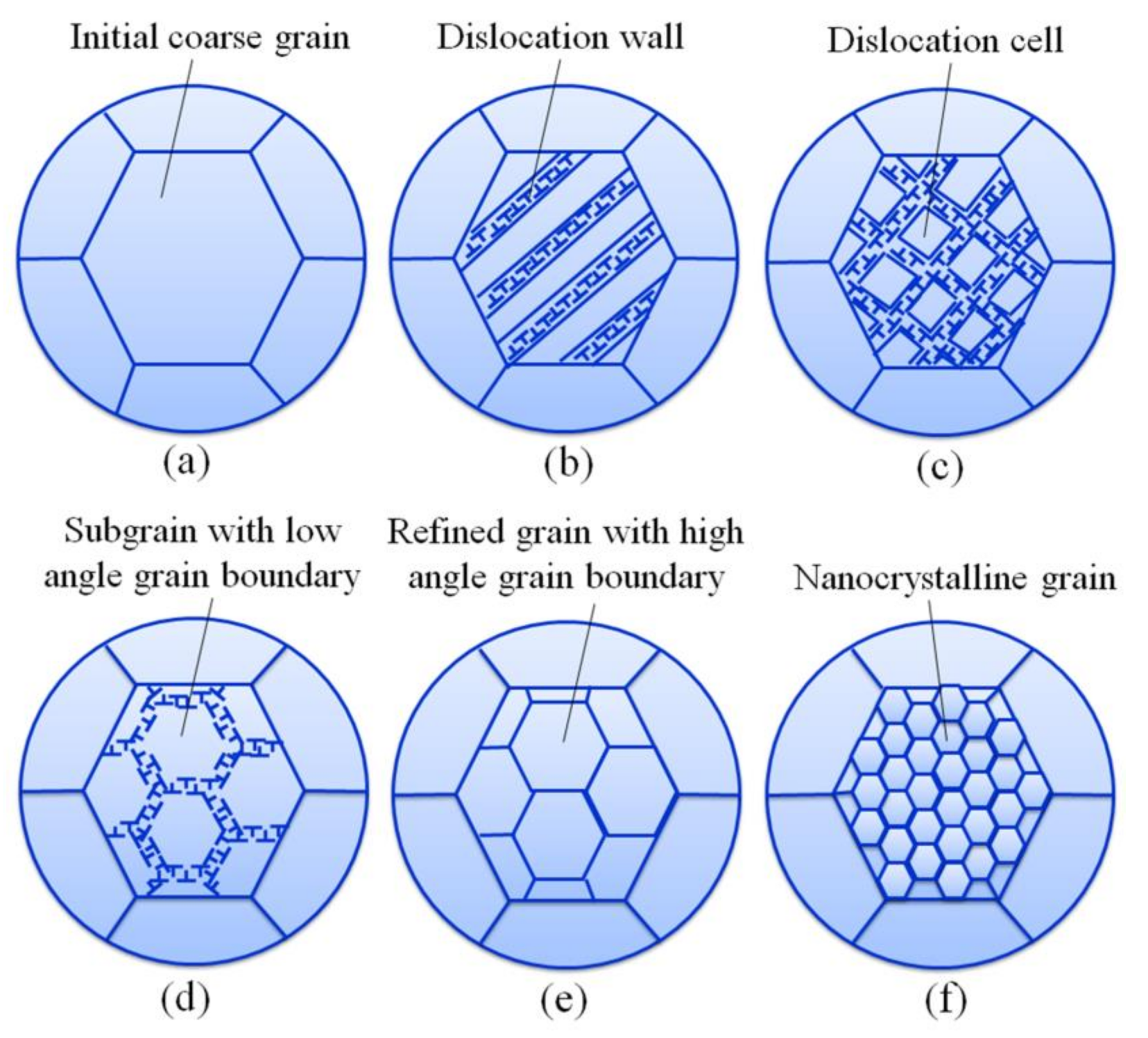

3.6. Plastic Deformation Mechanism of As-Cast and Heat-Treated Ni-Nb5 Samples

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tao, J.; Chen, L.B.; Jiang, F.; Cai, H.P.; Sun, J. Microstructural evolution and mechanical properties of a nickel-based superalloy through long-term service. Mater. Sci. Eng. A 2016, 656, 184–189. [Google Scholar]

- Prasad, K.; Sarkar, R.; Ghosal, P.; Kumar, V. Simultaneous creep-fatigue damage accumulation of forged turbine disc of in 718 superalloy. Mater. Sci. Eng. A 2013, 572, 1–7. [Google Scholar] [CrossRef]

- Zhang, S.H.; Zhang, H.Y.; Cheng, M. Tensile deformation and fracture characteristics of delta-processed Inconel 718 alloy at elevated temperature. Mater. Sci. Eng. A 2011, 528, 6253–6258. [Google Scholar] [CrossRef]

- Mostafaei, A.; Behnamian, Y.; Krimer, Y.L.; Stevens, E.L.; Luo, J.L.; Chmielus, M. Effect of solutionizing and aging on the microstructure and mechanical properties of powder bed binder jet printed nickel-based superalloy 625. Mater. Des. 2016, 111, 482–491. [Google Scholar] [CrossRef]

- Sui, F.L.; Xua, L.X.; Chen, L.Q.; Liu, X.H. Processing map for hot working of Inconel 718 alloy. J. Mater. Process. Technol. 2011, 211, 433–440. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Zhang, S.H.; Cheng, M.; Li, Z.X. Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy. Mater. Charact. 2010, 61, 49–53. [Google Scholar] [CrossRef]

- Lee, W.S.; Lin, C.F.; Chen, T.H.; Chen, H.W. Dynamic mechanal behaviour and dislocation substructure evolution of Inconel 718 over wide temperature range. Mater. Sci. Eng. A 2011, 528, 6279–6286. [Google Scholar] [CrossRef]

- Thomas, A.; El-Wahabi, M.; Cabrera, J.M.; Prado, J.M. High temperature deformation of Inconel 718. J. Mater. Process. Technol. 2006, 177, 469–472. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, K.K.; Li, H.B.; Chen, J.; Chen, X.M.; Wen, D.X. New constitutive model for high-temperature deformation behavior of inconel 718 superalloy. Mater. Des. 2015, 74, 108–118. [Google Scholar] [CrossRef]

- Qin, L.; Pei, Y.; Li, S.; Zhao, X.; Gong, S.; Xu, H. Effect of thermal stability of γ′ phase on the recrystallization behaviors of Ni-based single crystal superalloys. Mater. Des. 2017, 130, 69–82. [Google Scholar] [CrossRef]

- Marsh, C.; Depinoy, S.; Kaoumi, D. Effect of heat treatment on the temperature dependence of the fracture behavior of X-750 alloy. Mater. Sci. Eng. A 2016, 677, 474–484. [Google Scholar] [CrossRef]

- Xie, J.; Tian, S.; Zhou, X.; Yu, X.; Wang, W. Influence of heat treatment regimes on microstructure and creep properties of FGH95 nickel base superalloy. Mater. Sci. Eng. A 2012, 538, 306–314. [Google Scholar] [CrossRef]

- Lu, Y.L.; Liu, J.X.; Li, X.K.; Liang, J.P.; Li, Z.J.; Wu, G.Y.; Zhou, X.T. Hot deformation behavior of Hastelly C276 superalloy. Trans. Nonferrous Met. Soc. China 2012, 22, s84–s88. [Google Scholar] [CrossRef]

- Li, K.K.; Chen, M.S.; Lin, Y.C.; Yuan, W.Q. Microstructural evolution of an aged Ni-based superalloy under two-stage hot compression with different strain rates. Mater. Des. 2016, 111, 344–352. [Google Scholar] [CrossRef]

- Lia, F.; Fua, R.; Yina, F.; Fenga, D.; Wang, H.Z.; Tiana, Z.L.; Dub, G.; Feng, Y. Impact of solution heat treatment on microstructure and creep behavior of a novel cast & wrought FGH4096 turbine disk alloy. Mater. Sci. Eng. A 2017, 696, 273–282. [Google Scholar]

- He, D.G.; Lin, Y.C.; Chen, M.S.; Chen, J.; Wen, D.X.; Chen, X.M. Effect of pre-treatment on hot deformation behavior and processing map of an aged nickel-based superalloy. J. Alloys Compd. 2015, 649, 1075–1084. [Google Scholar] [CrossRef]

- Azadia, M.; Marboutb, A.; Safarlooa, S.; Azadib, M.; Shariata, M.; Rizi, M.H. Effects of solutioning and ageing treatments on properties of Inconel-713C nickel-based superalloy under creep loading. Mater. Sci. Eng. A 2018, 711, 195–204. [Google Scholar] [CrossRef]

- Unocic, R.R.; Zhou, N.; Kovarik, L.; Shen, C.; Wang, Y.; Mills, M.J. Dislocation decorrelation and relationship to deformation microtwins during creep of a γ′ precipitate strengthened Ni-based superalloy. Acta Mater. 2011, 59, 7325–7339. [Google Scholar] [CrossRef]

- Qiu, C.L.; Hua, X.; Mei, J.F.; Paul Andrews, P.; Voice, W. Influence of heat treatment on microstructure and tensile behavior of a hot isostatically pressed nickel-based superalloy. J. Alloys Compd. 2013, 578, 454–464. [Google Scholar] [CrossRef]

- Özgür Özgün; Yılmaz, R.; Gülsoy, H.Ö.; Fındık, F. The effect of aging treatment on the fracture toughness and impact strength of injection molded Ni-625 superalloy parts. Mater. Charact. 2015, 108, 8–15. [Google Scholar]

- Pröbstle, M.; Neumeier, S.; Feldner, P.; Rettig, R.; Helmer, H.E.; Singer, R.F.; Göken, M. Improved creep strength of nickel-base superalloys by optimized γ/γ′ partitioning behavior of solid solution strengthening elements. Mater. Sci. Eng. A 2016, 676, 411–420. [Google Scholar] [CrossRef]

- Cao, G.H.; Sun, T.Y.; Wang, C.H.; Li, X.; Liu, M.; Zhang, Z.X. Investigations of γ′, γ″ and δ precipitates in heat-treated inconel 718 alloy fabricated by selective laser melting. Mater. Charact. 2018, 136, 398–406. [Google Scholar] [CrossRef]

- You, X.; Tan, Y.; Zhao, L.; You, Q.; Wang, Y.; Ye, F. Effect of solution heat treatment on microstructure and electrochemical behavior of electron beam smelted inconel 718 superalloy. J. Alloys Compd. 2018, 741, 792–803. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.; He, D.G.; Chen, M.S.; Liu, G.Q. Effects of pre-treatments on mechanical properties and fracture mechanism of a nickel-based superalloy. Mater. Sci. Eng. A 2016, 679, 401–409. [Google Scholar] [CrossRef]

- Souza, G.R.X.D.; Gabriel, S.B.; Dille, J.; Santos, D.S.D.; Almeida, L.H.D. Work hardening and aging contribution on the mechanical properties of x-750 nickel-based superalloy. Mater. Sci. Eng. A 2013, 564, 102–106. [Google Scholar] [CrossRef]

- Li, C.; Yuan, Z.; Fan, Y.; He, S.; Xuan, W.; Li, X. Microstructure and mechanical properties of a Ni-based superalloy after heat treatment in a steady magnetic field. J. Mater. Process. Technol. 2017, 246, 176–184. [Google Scholar] [CrossRef]

- Rahimi, S.; King, M.; Dumont, C. Stress relaxation behaviour in IN718 nickel based superalloy during ageing heat treatments. Mater. Sci. Eng. A 2017, 708, 563–573. [Google Scholar] [CrossRef]

- Mignanelli, P.M.; Jones, N.G.; Perkins, K.M.; Hardy, M.C.; Stone, H.J. Microstructural evolution of a delta containing nickel-base superalloy during heat treatment and isothermal forging. Mater. Sci. Eng. A 2015, 621, 265–271. [Google Scholar] [CrossRef]

- Wen, D.X.; Lin, Y.C.; Chen, J.; Deng, J.; Chen, X.M.; Zhang, J.L.; He, M. Effects of initial aging time on processing map and microstructures of a nickel-based superalloy. Mater. Sci. Eng. A 2015, 620, 319–332. [Google Scholar]

- Zhang, P.; Yuan, Y.; Yan, J.B.; Wang, J.C.; Song, X.L.; Yang, G.X. Morphological evolution of γ′ precipitates in superalloy M4706 during thermal aging. Mater. Lett. 2018, 211, 107–109. [Google Scholar] [CrossRef]

- Ha, J.W.; Seong, B.S.; Jeong, H.W.; Choi, Y.S.; Kang, N. Effects of the aging temperature and stress relaxation conditions on γ′ precipitation in inconel x-750. J. Nucl. Mater. 2015, 457, 362–368. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L.; Huang, T.; Li, Y.; Jie, Z.; Zhang, J. Investigation on remelting solution heat treatment for nickel-based single crystal superalloys. Scr. Mater. 2017, 136, 74–77. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Sun, D.; Zhang, Y.Q.; Zhu, X.M.; Wang, M.; Zhao, C.Z. Plastic deformation mechanisms of NiCuCrMoTiAlNb Ni-based alloys at cryogenic temperature. Mater. Sci. Eng. A 2016, 664, 135–145. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Zhang, Y.Q.; Zhu, X.M.; Sun, D.; Wang, M.; Zhao, C.Z. Physical mechanisms of nanocrystallization of a novel Ni-based alloy under uniaxial compression at cryogenic temperature. Mater. Charact. 2016, 116, 18–23. [Google Scholar] [CrossRef]

- Cui, L.; Yu, J.; Liu, J.; Jin, T.; Sun, X. The creep deformation mechanisms of a newly designed nickel-base superalloy. Mater. Sci. Eng. A 2018, 710, 309–317. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Sun, D.; Zhang, Y.; Yan, B. Influence of Heat Treatment on Microstructures and Mechanical Properties of NiCuCrMoTiAlNb Nickel-Based Alloy. Metals 2018, 8, 217. https://doi.org/10.3390/met8040217

Jiang S, Sun D, Zhang Y, Yan B. Influence of Heat Treatment on Microstructures and Mechanical Properties of NiCuCrMoTiAlNb Nickel-Based Alloy. Metals. 2018; 8(4):217. https://doi.org/10.3390/met8040217

Chicago/Turabian StyleJiang, Shuyong, Dong Sun, Yanqiu Zhang, and Bingyao Yan. 2018. "Influence of Heat Treatment on Microstructures and Mechanical Properties of NiCuCrMoTiAlNb Nickel-Based Alloy" Metals 8, no. 4: 217. https://doi.org/10.3390/met8040217