Misorientation-Dependent Twinning Induced Hardening and Texture Evolution of TWIP Steel Sheet in Plastic Deformation Process

Abstract

:1. Introduction

2. Experiments and Characterization

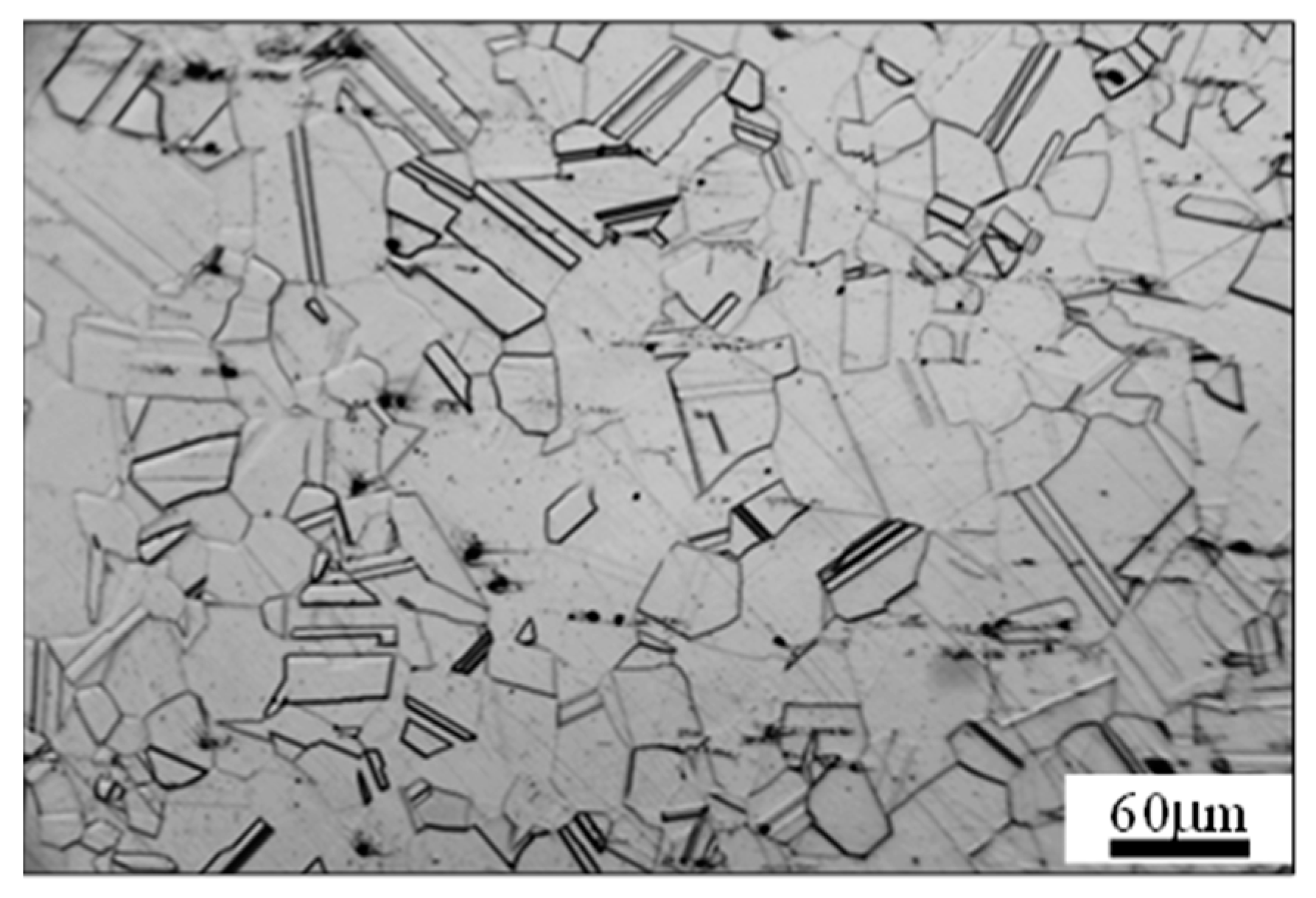

2.1. Material and Experimental Procedure

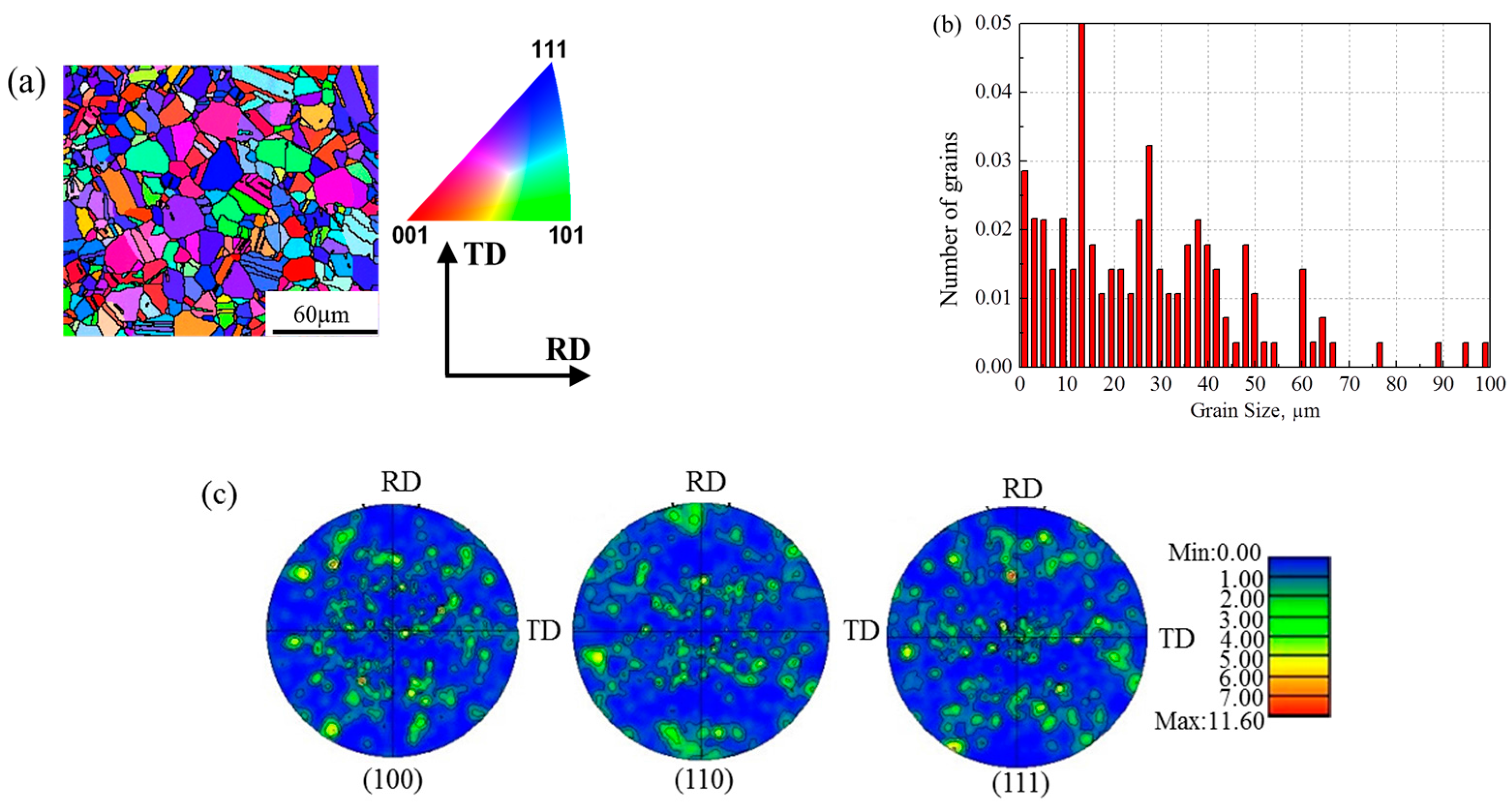

2.2. Results

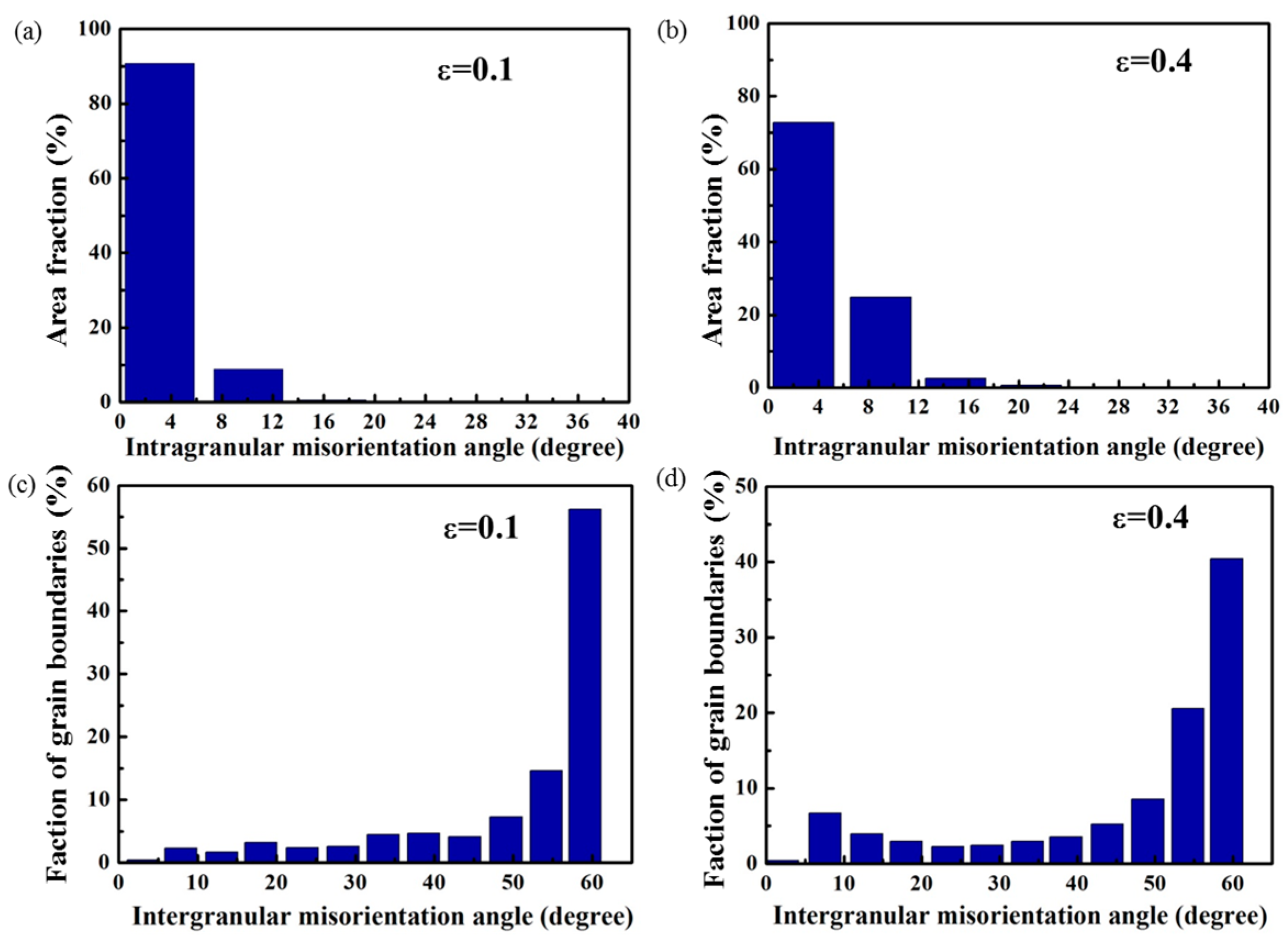

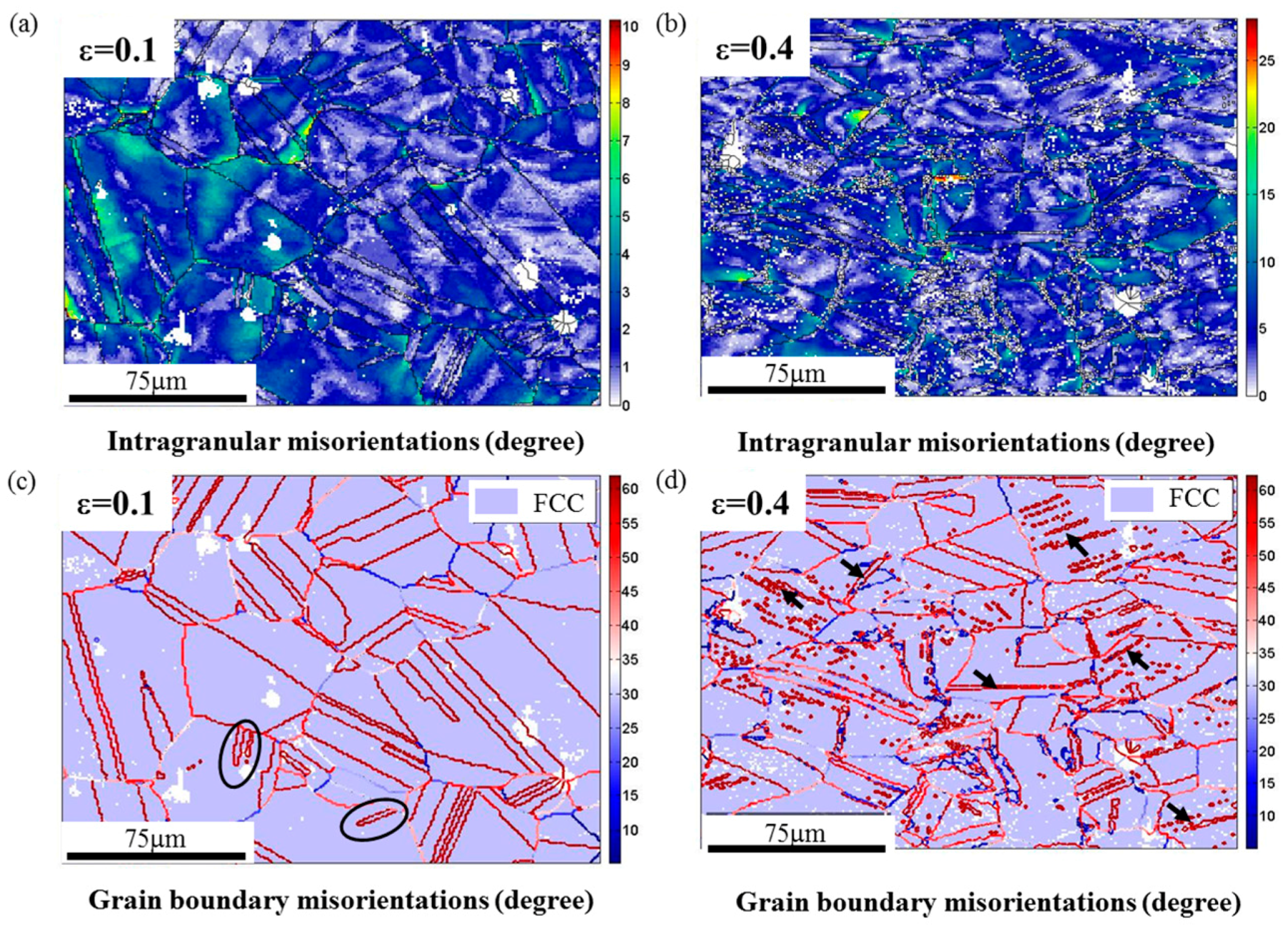

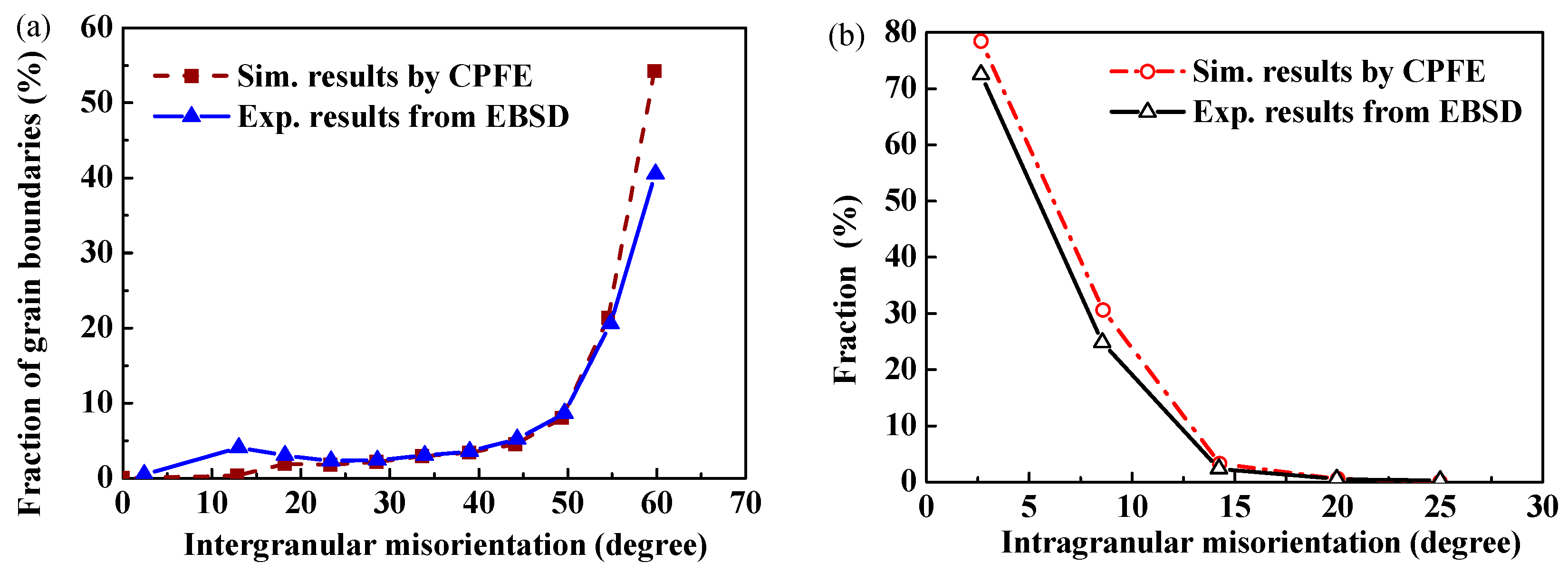

2.2.1. Misorientation-Dependent Twinning Characteristics

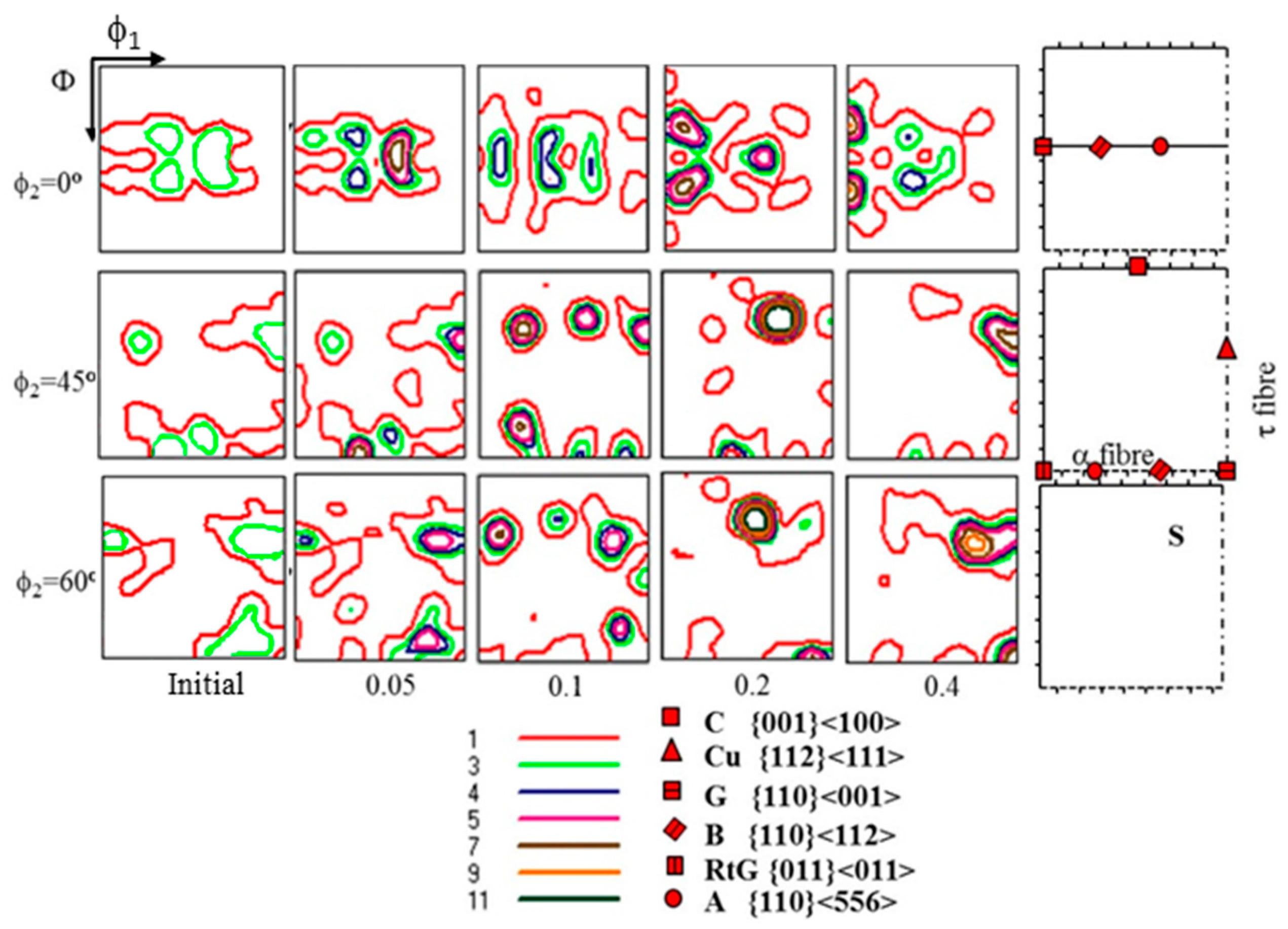

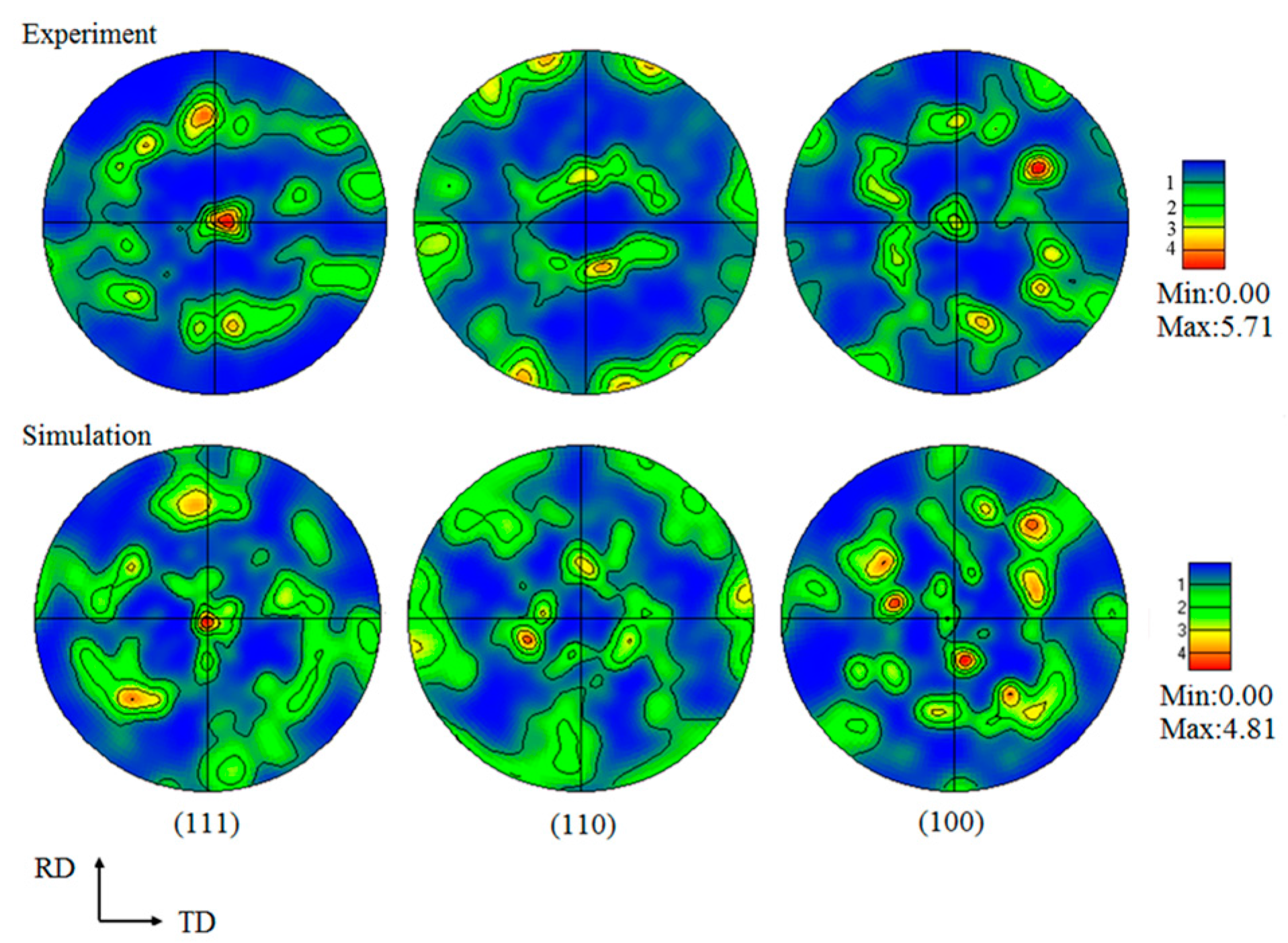

2.2.2. Crystallographic Texture Evolution

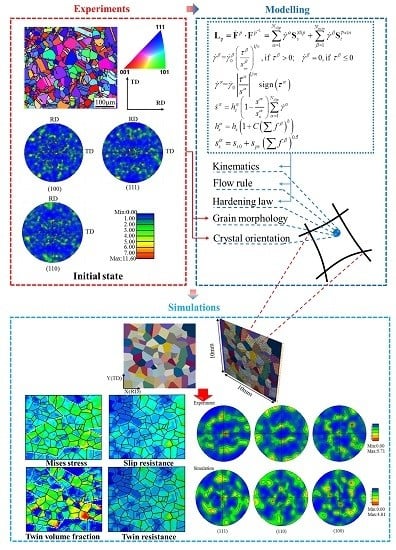

3. Microstructure-Based CPFE Modeling

3.1. Crystal Plasticity Model Including Slip and Twinning

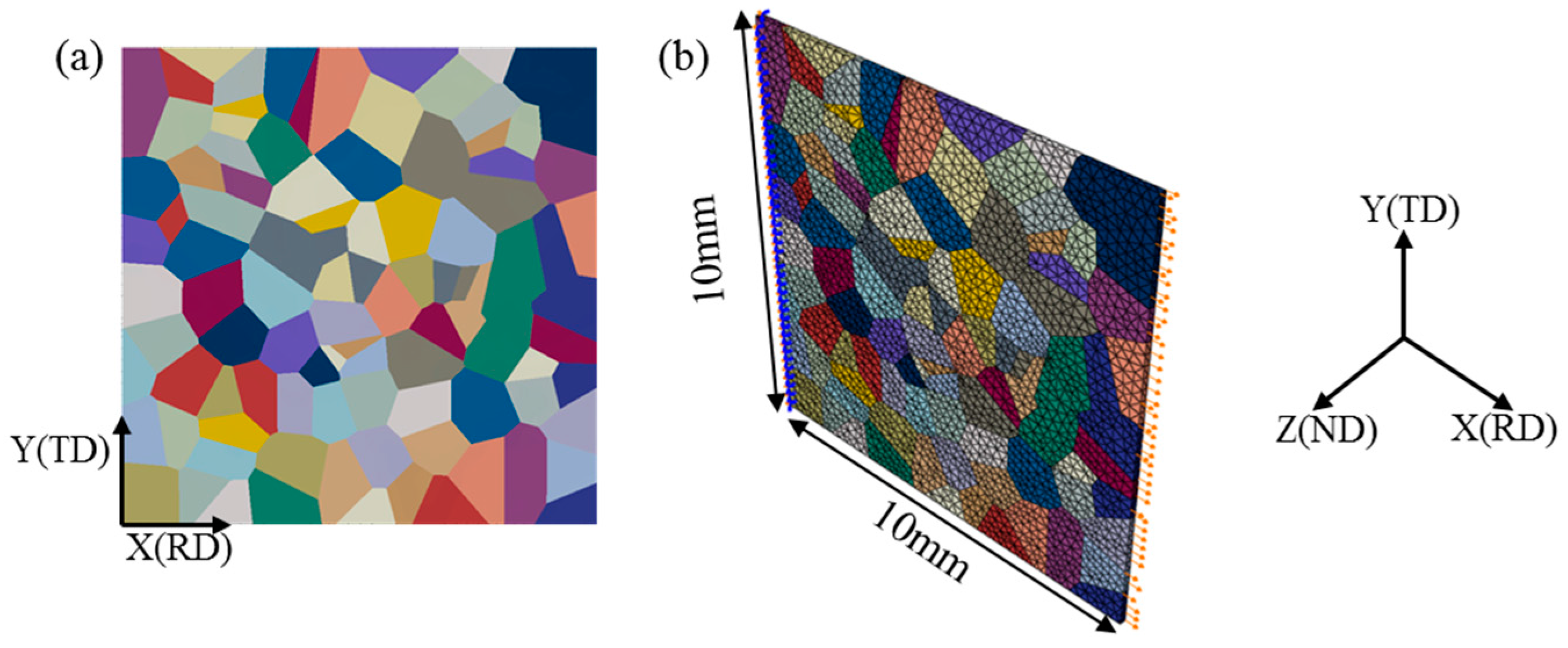

3.2. Establishment of Virtual Polycrystalline Microstructure

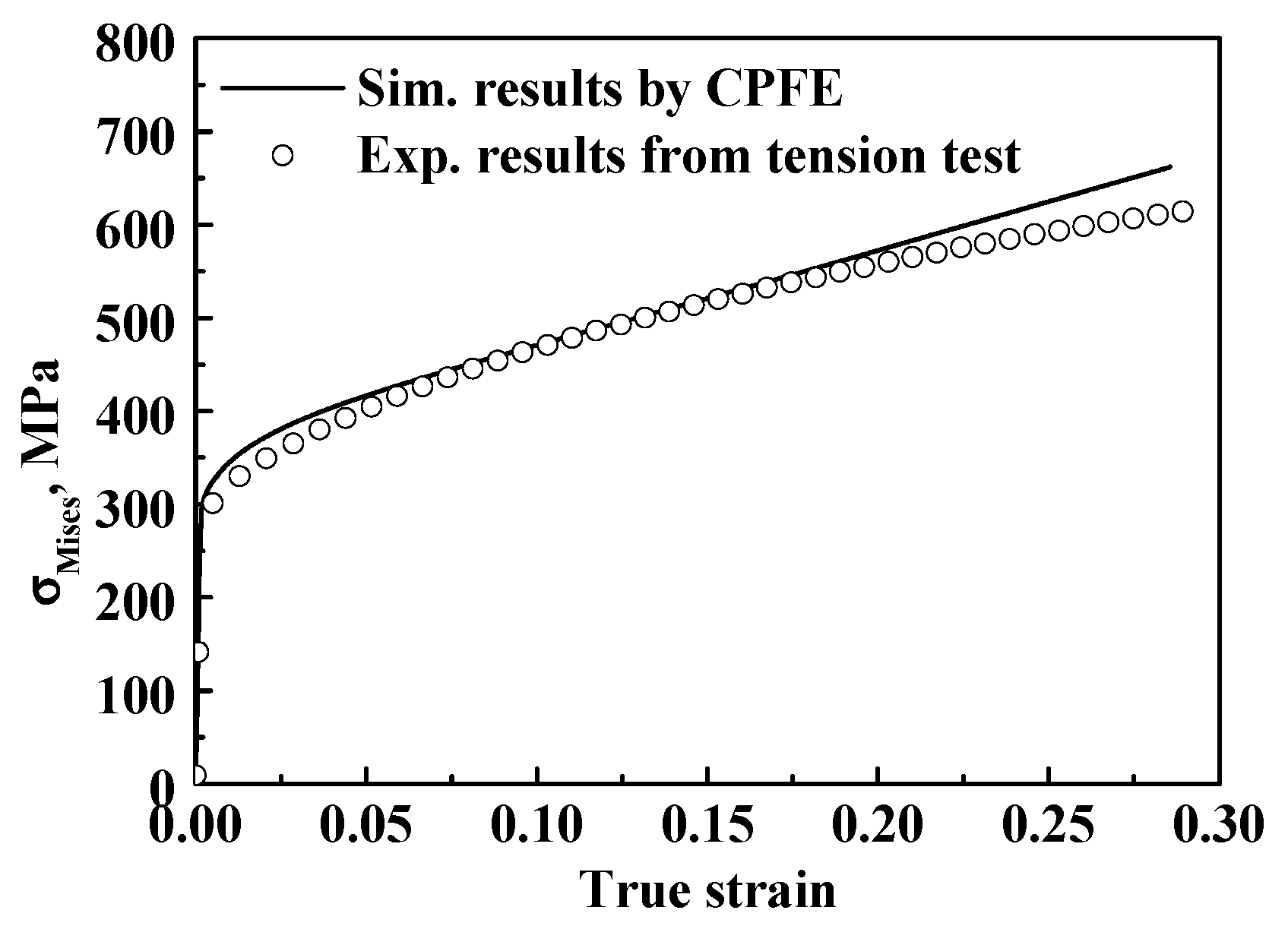

3.3. Evaluation of the CPFE Model

4. Simulation and Discussion

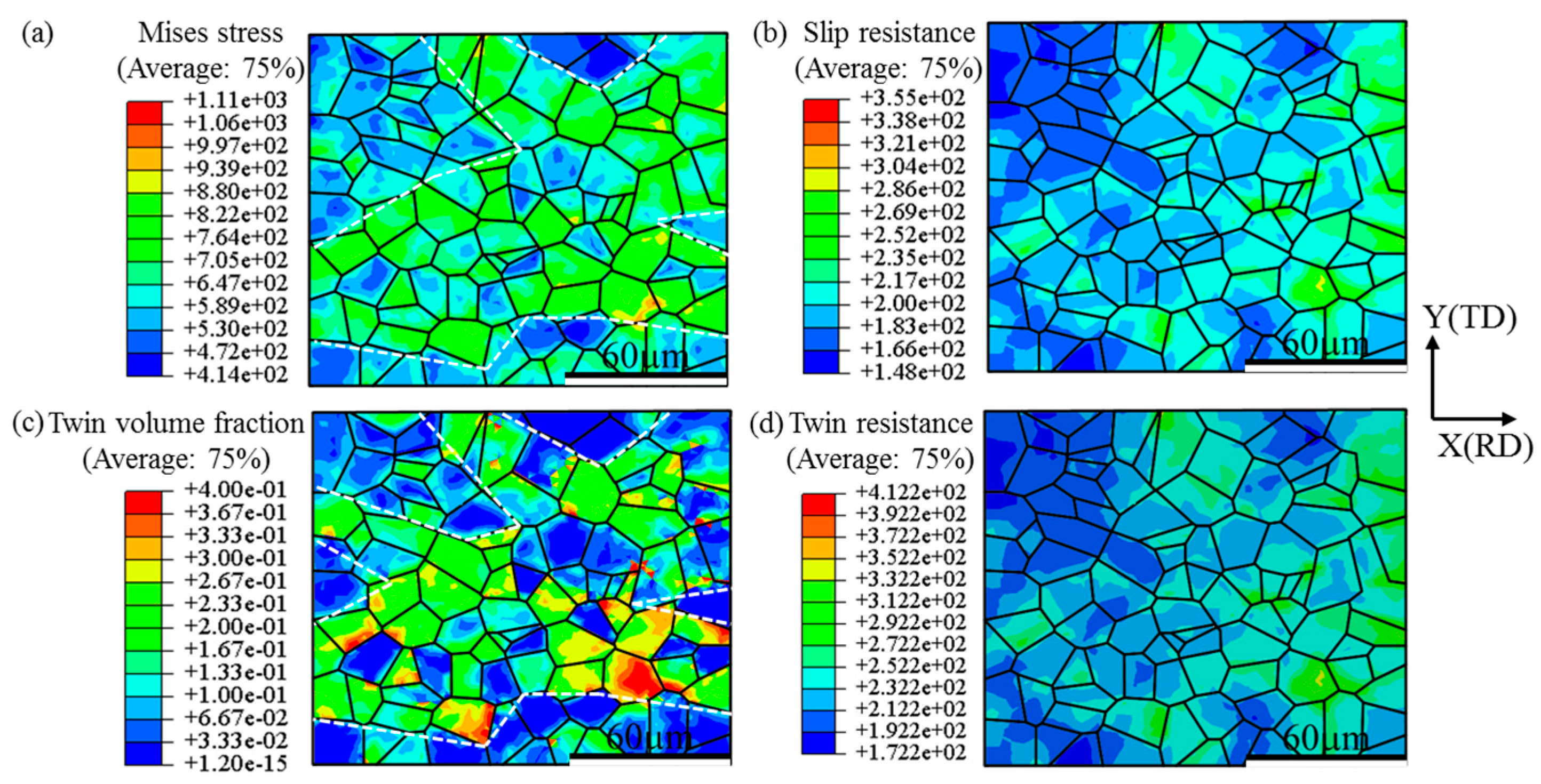

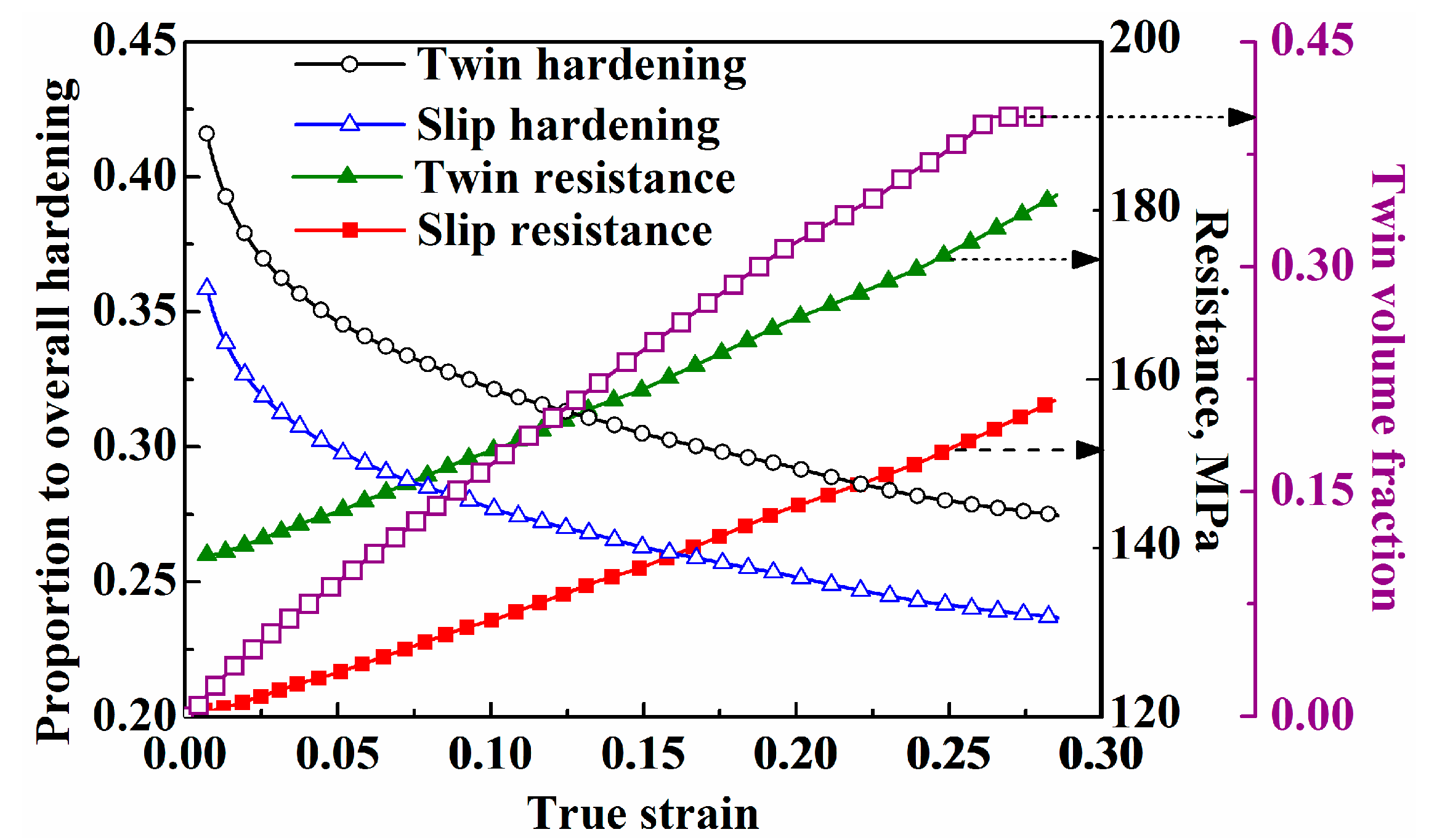

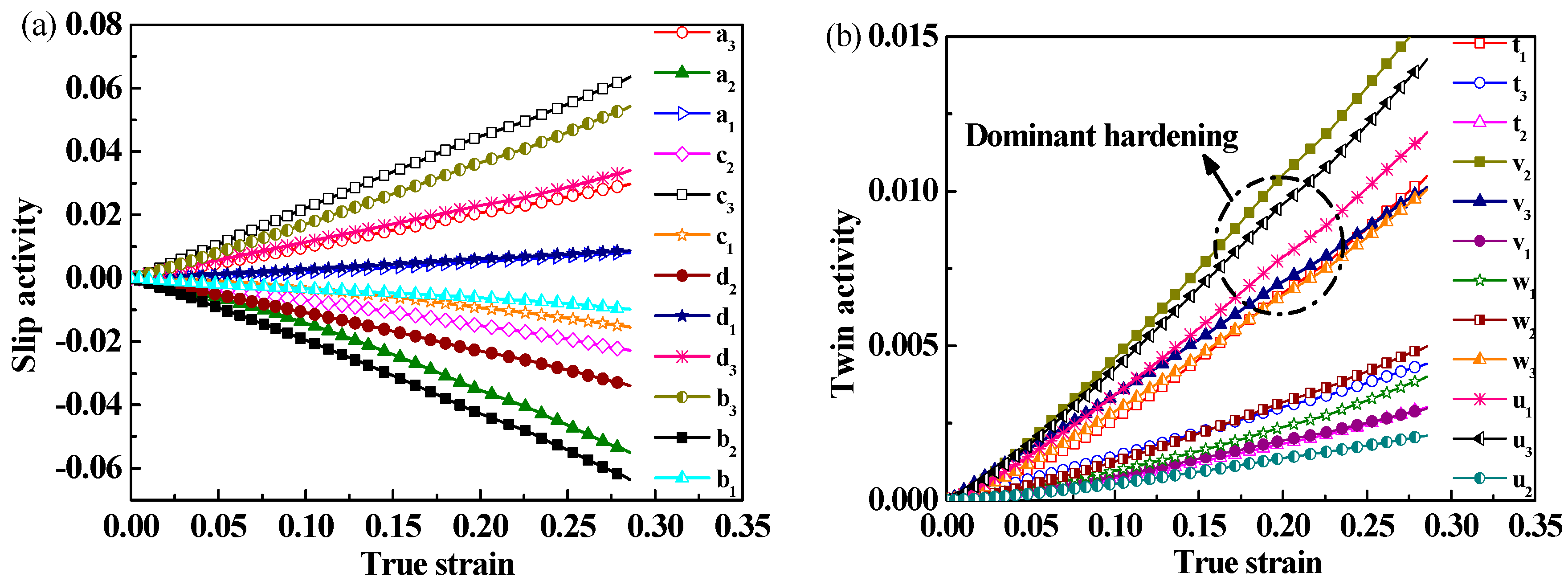

4.1. Effect of Twinning on Hardening Evolution

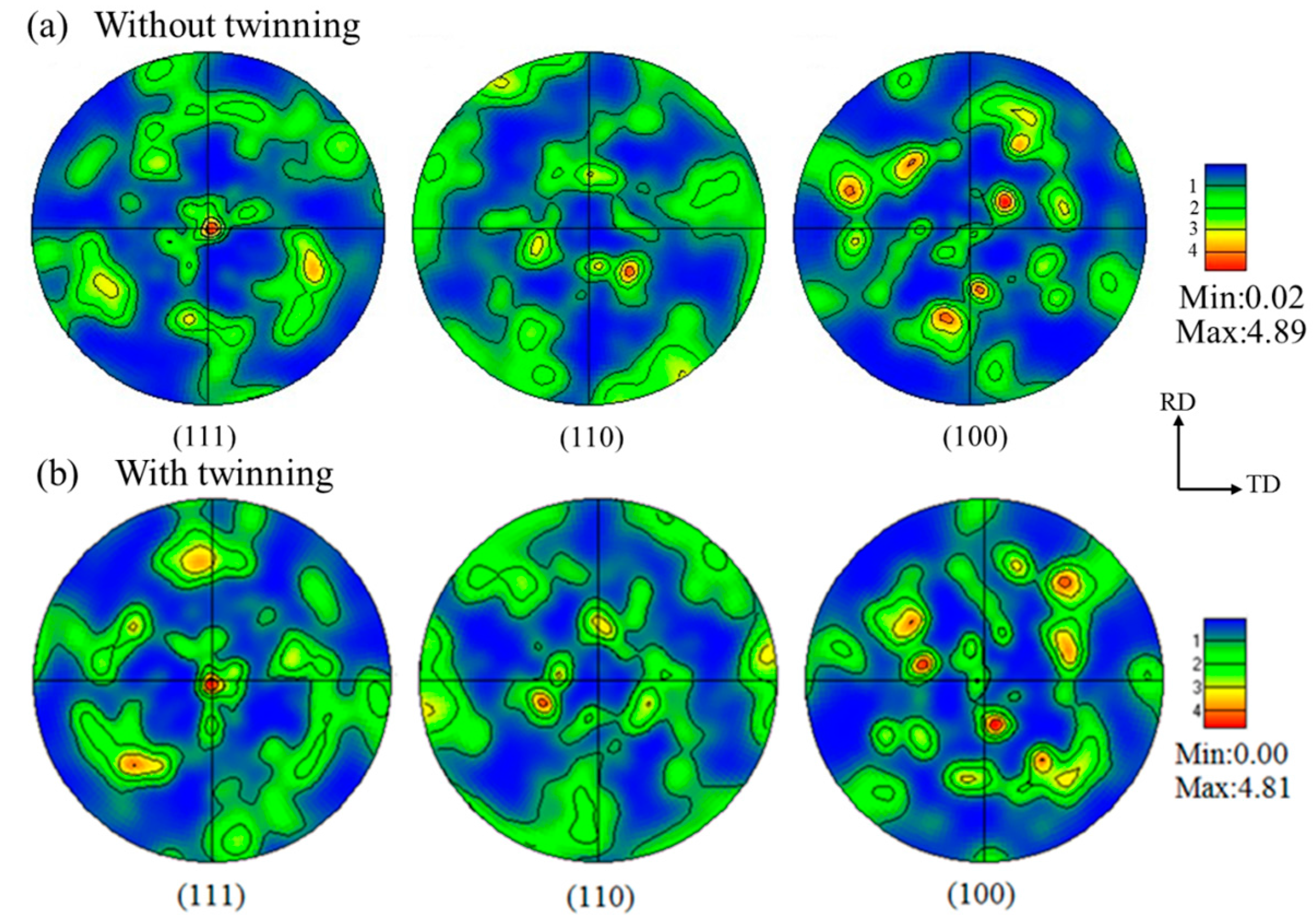

4.2. Effect of Twinning on Crystal Orientation

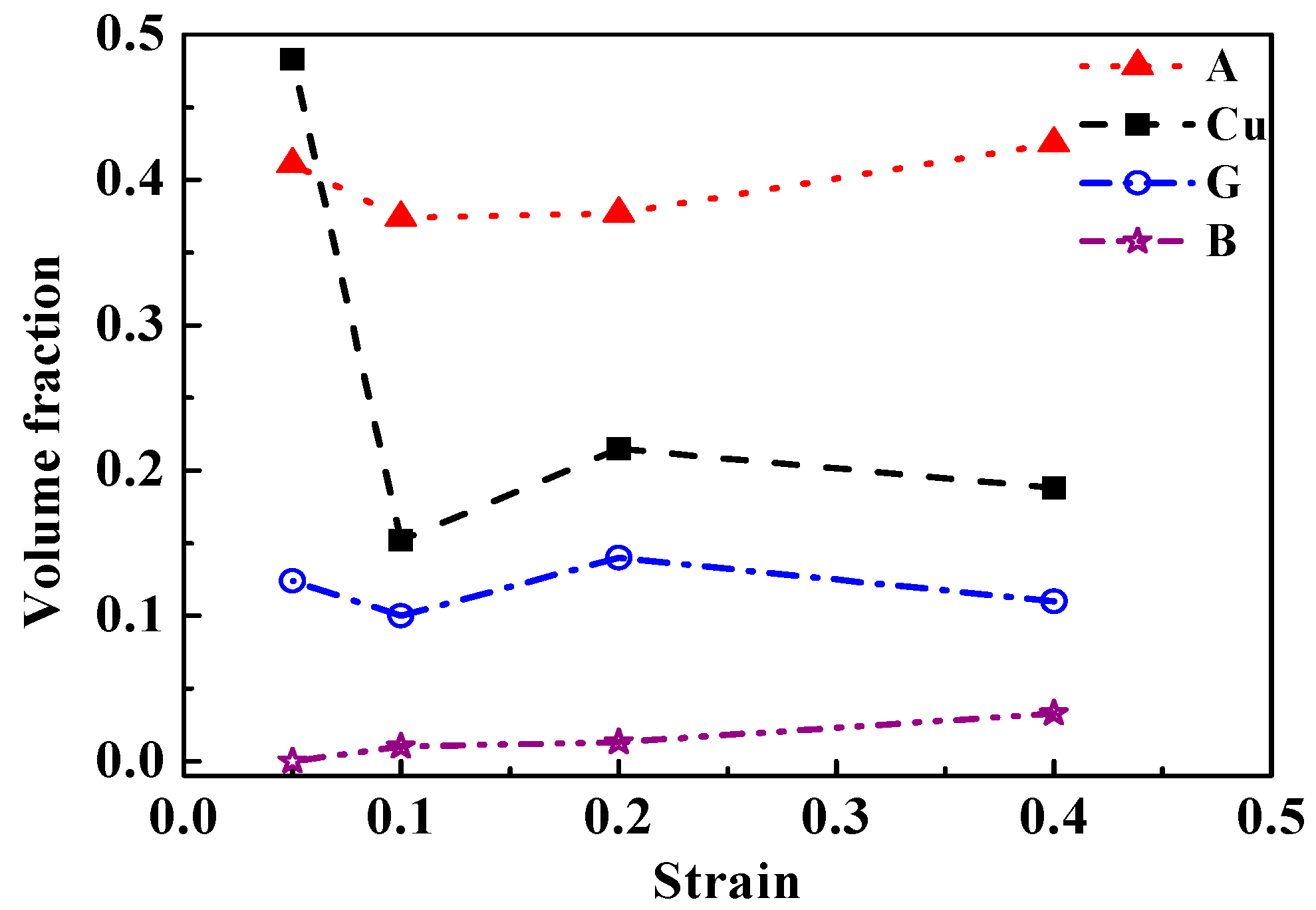

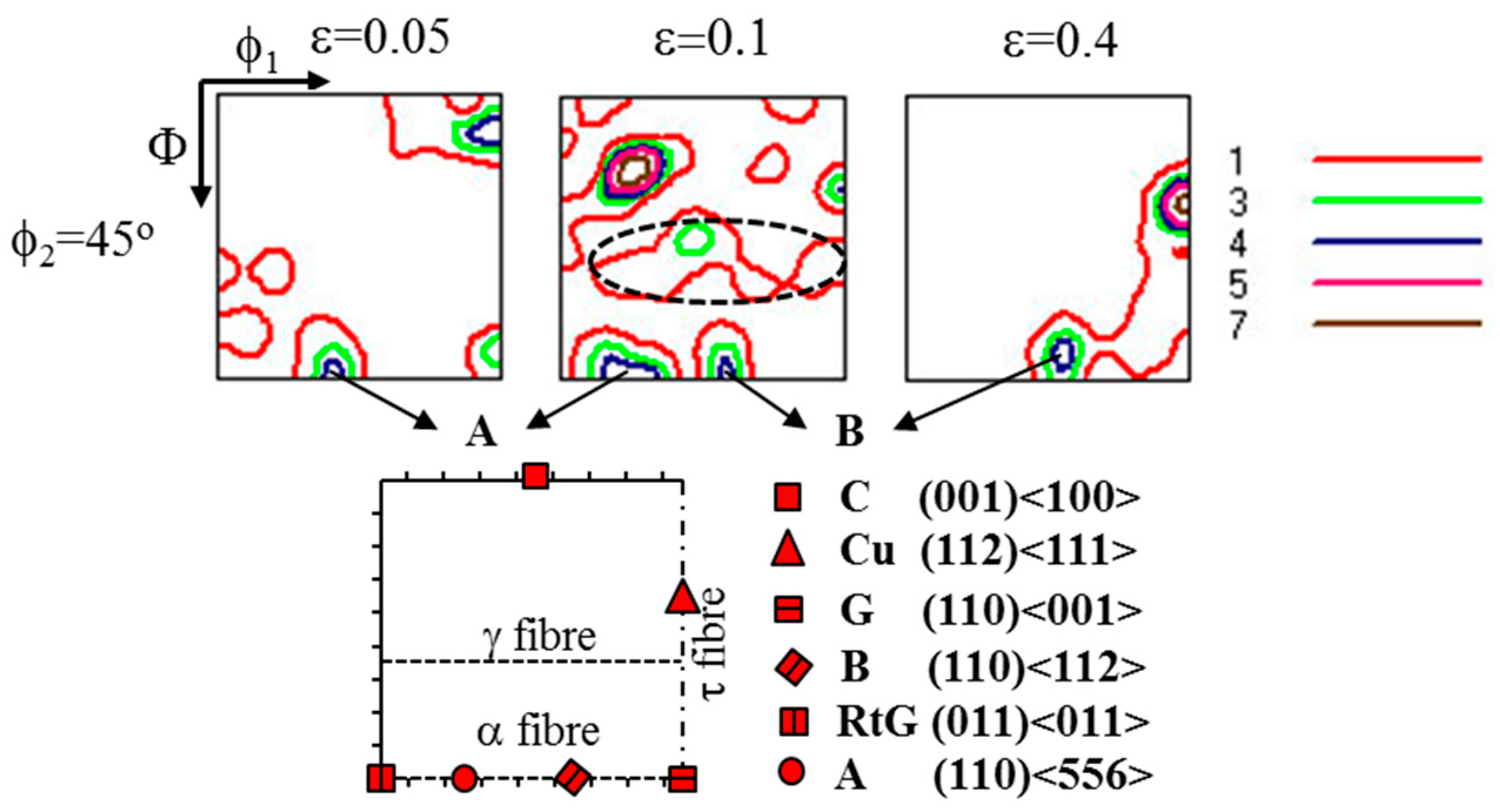

4.3. Evolution of Texture Components

5. Conclusions

- The formation of HAGBs detected by intergranular misorientation distribution could promote the deformation twin lamella nucleation for a FCC-type TWIP steel in uniaxial tensile deformation.

- Twinning promotes the crystal orientation rotation but has less impact on the intensity of crystal distribution compared with no twinning effect. Furthermore, the texture components including the Goss, S and A orientations show a stable volume fraction, while the Cu orientation shifted towards Brass orientation.

- The strain hardening of the studied TWIP steel is dominated by the combined influences of dynamic Hall–Petch effect at the initiation of deformation twinning and texture hardening when the twin volume fraction reaches the saturated value.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Han, H.N.; Oh, C.S.; Kim, G.; Kwon, O. Design method for TRIP-aided multiphase steel based on a microstructure-based modelling for transformation-induced plasticity and mechanically induced martensitic transformation. Mater. Sci. Eng. A 2009, 499, 462–468. [Google Scholar] [CrossRef]

- Patterson, E.E.; Field, D.P.; Zhang, Y. Characterization of twin boundaries in an Fe-17.5Mn-0.56C twinning induced plasticity steel. Mater. Charact. 2013, 85, 100–110. [Google Scholar] [CrossRef]

- Huang, B.X.; Wang, X.D.; Rong, Y.H.; Wang, L.; Jin, L. Mechanical behavior and martensitic transformation of an Fe-Mn-Si-Al-Nb alloy. Mater. Sci. Eng. A 2006, 438–440, 306–311. [Google Scholar] [CrossRef]

- Jiménez, J.A.; Frommeyer, G. Analysis of the microstructure evolution during tensile testing at room temperature of high-manganese austenitic steel. Mater. Charact. 2010, 61, 221–226. [Google Scholar] [CrossRef]

- Kowalska, J.; Ratuszek, W.; Witkowska, M.; Zielińska-Lipiec, A.; Tokarski, T. Microstructure and texture characteristics of the metastable Fe-21Mn-3Si-3Al alloy after cold deformation. J. Alloys Compd. 2015, 643, S39–S45. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.W.; Kim, N.J. Fe-Al-Mn-C lightweight structural alloys: a review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 014205. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.Y.; Guo, N.; Fu, M.W.; Wang, S.W. Modeling of slip, twinning and transformation induced plastic deformation for TWIP steel based on crystal plasticity. Int. J. Plast. 2016, 76, 186–212. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Grässel, O.; Krüger, L.; Frommeyer, G.; Meyer, L.W. High strength Fe-Mn-(Al,Si) TRIP/TWIP steels development-properties-application. Int. J. Plast. 2000, 16, 1391–1409. [Google Scholar] [CrossRef]

- Cooman, B.C.D.; Estrin, Y.; Kim, S.K. Twinning-Induced Plasticity (TWIP) Steels. Acta Mater. 2017. [Google Scholar] [CrossRef]

- Yu, H.Y. Strain-hardening behaviors of TRIP-assisted steels during plastic deformation. Mater. Sci. Eng. A 2008, 479, 333–338. [Google Scholar] [CrossRef]

- Knezevic, M.; Capolungo, L.; Tomé, C.N.; Lebensohn, R.A.; Alexander, D.J.; Mihaila, B.; McCabe, R.J. Anisotropic stress-strain response and microstructure evolution of textured α-uranium. Acta Mater. 2012, 60, 702–715. [Google Scholar] [CrossRef]

- Kaschner, G.C.; Tomé, C.N.; McCabe, R.J.; Misra, A.; Vogel, S.C.; Brown, D.W. Exploring the dislocation/twin interactions in zirconium. Mater. Sci. Eng. A 2007, 463, 122–127. [Google Scholar] [CrossRef]

- Basinski, Z.S.; Szczerba, M.S.; Niewczas, M.; Embury, J.D.; Basinski, S.J. Transformation of slip dislocations during twinning of copper-aluminum alloy crystals. Metall. Res. Technol. 1997, 94, 1037–1044. [Google Scholar] [CrossRef]

- Cooman, B.C.D.; Kim, J.; Lee, S. Heterogeneous deformation in twinning-induced plasticity steel. Scr. Mater. 2012, 66, 986–991. [Google Scholar] [CrossRef]

- Friedman, P.A.; Liao, K.-C.; Pan, J.; Barlat, F. Texture development and hardening characteristics of steel sheets under plane-strain compression. J. Mater. Eng. Perform. 1999, 8, 225–235. [Google Scholar] [CrossRef]

- Sun, C.Y.; Wang, B.; Politis, D.J.; Wang, L.L.; Cai, Y.; Guo, X.R.; Guo, N. Prediction of earing in TWIP steel sheets based on coupled twinning crystal plasticity model. Int. J. Adv. Manuf. Technol. 2017, 89, 3037–3047. [Google Scholar] [CrossRef]

- Renard, K.; Jacques, P.J. On the relationship between work hardening and twinning rate in TWIP steels. Mater. Sci. Eng. A 2012, 542, 8–14. [Google Scholar] [CrossRef]

- Steinmetz, D.R.; Jäpel, T.; Wietbrock, B.; Eisenlohr, P.; Gutierrez-Urrutia, I.; Saeed-Akbari, A.; Hickel, T.; Roters, F.; Raabe, D. Revealing the strain-hardening behavior of twinning-induced plasticity steels: Theory, simulations, experiments. Acta Mater. 2013, 61, 494–510. [Google Scholar] [CrossRef]

- Barbier, D.; Gey, N.; Allain, S.; Bozzolo, N.; Humbert, M. Analysis of the tensile behavior of a TWIP steel based on the texture and microstructure evolutions. Mater. Sci. Eng. A 2009, 500, 196–206. [Google Scholar] [CrossRef]

- Souza, F.M.; Padilha, A.F.; Gutierrez-Urruti, I.; Raabe, D. Texture evolution in the Fe-30.5Mn-8.0Al-1.2C and Fe-30.5Mn-2.1Al-1.2C steels upon cold rolling. Rem Rev. Esc. Minas 2016, 69, 59–65. [Google Scholar] [CrossRef]

- Wu, Y.; Tang, D.; Jiang, H.; Mi, Z.; Jing, H. Texture and microstructure evolution during tensile testing of TWIP steels with diverse stacking fault energy. Acta Metall. Sin. 2013, 26, 713–720. [Google Scholar] [CrossRef]

- Saleh, A.A.; Pereloma, E.V.; Gazder, A.A. Microstructure and texture evolution in a twinning-induced-plasticity steel during uniaxial tension. Acta Mater. 2013, 61, 2671–2691. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent viscoplastic model: prediction of rolling textures of anisotropic polycrystals. Mater. Sci. Eng. A 1994, 175, 71–82. [Google Scholar] [CrossRef]

- Tomé, C.; Lebensohn, R.; Kocks, U. A model for texture development dominated by deformation twinning: application to zirconium alloys. Acta Metall. Mater. 1991, 39, 2667–2680. [Google Scholar] [CrossRef]

- Kalidindi, S.R. Incorporation of deformation twinning in crystal plasticity models. J. Mech. Phys. Solids 1998, 46, 267–290. [Google Scholar] [CrossRef]

- Prakash, A.; Hochrainer, T.; Reisacher, E.; Riedel, H. Twinning Models in Self-Consistent Texture Simulations of TWIP Steels. Steel Res. Int. 2008, 79, 645–652. [Google Scholar] [CrossRef]

- Tari, V.; Rollett, A.D.; Kadiri, H.E.; Beladi, H.; Oppedal, A.L.; King, R.L. The effect of deformation twinning on stress localization in a three dimensional TWIP steel microstructure. Model. Simul. Mater. Sci. Eng. 2015, 23, 045010. [Google Scholar] [CrossRef]

- Gu, C.F.; Hoffman, M.; Toth, L.S.; Zhang, Y.D. Grain size dependent texture evolution in severely rolled pure copper. Mater. Charact. 2015, 101, 180–188. [Google Scholar] [CrossRef]

- Lee, M.G.; Kim, S.J.; Han, H.N. Crystal plasticity finite element modeling of mechanically induced martensitic transformation (MIMT) in metastable austenite. Int. J. Plast. 2010, 26, 688–710. [Google Scholar] [CrossRef]

- Sheikh, H.; Ebrahimi, R.; Bagherpour, E. Crystal plasticity finite element modeling of crystallographic textures in simple shear extrusion (SSE) process. Mater. Des. 2016, 109, 289–299. [Google Scholar] [CrossRef]

- Dancette, S.; Delannay, L.; Renard, K.; Melchior, M.A.; Jacques, P.J. Crystal plasticity modeling of texture development and hardening in TWIP steels. Acta Mater. 2012, 60, 2135–2145. [Google Scholar] [CrossRef]

- Roach, M.D.; Wright, S.I. Investigations of twin boundary fatigue cracking in nickel and nitrogen-stabilized cold-worked austenitic stainless steels. Mater. Sci. Eng. A 2014, 607, 611–620. [Google Scholar] [CrossRef]

- Cao, S.Q.; Zhang, J.X.; Wu, J.S.; Chen, J.G. Effects of GBCD on cold work embrittlement of high strength interstitial free steels. Mater. Des. 2006, 27, 53–57. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I. Modelling twinning evolution during plastic deformation in hexagonal close-packed metals. Mater. Des. 2015, 83, 327–343. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; McCabe, R.J.; Tomé, C.N. Effect of microstructure on the nucleation of deformation twins in polycrystalline high-purity magnesium: A multi-scale modeling study. J. Mech. Phys. Solids 2011, 59, 988–1003. [Google Scholar] [CrossRef]

- Tóth, L.S.; Estrin, Y.; Lapovok, R.; Gu, C. A model of grain fragmentation based on lattice curvature. Acta Mater. 2010, 58, 1782–1794. [Google Scholar] [CrossRef]

- Takayama, Y.; Szpunar, J.A.; Kato, H. Analysis of Intragranular Misorientation related to deformation in an Al-Mg-Mn Alloy. Mater. Sci. Forum 2005, 495–497, 1049–1054. [Google Scholar] [CrossRef]

- Agnoli, A.; Bernacki, M.; Logé, R. Selective growth of low stored energy grains during δ, sub-solvus annealing in the inconel 718 nickel-based superalloy. Metall. Mater. Trans. A 2015, 46, 4405–4421. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.Y.; Bacroix, B.; Réglé, H. Effect of deformation mode and grain orientation on misorientation development in a body-centered cubic steel. Acta Mater. 2007, 55, 4935–4946. [Google Scholar] [CrossRef]

- Bunge, H.J. Texture Analysis in Materials Science; Butterworths: London, UK, 1982. [Google Scholar]

- Vercammen, S.; Blanpain, B.; Cooman, B.C. D.; Wollants, P. Cold rolling behaviour of an austenitic Fe-30Mn-3Al-3Si TWIP-steel: the importance of deformation twinning. Acta Mater. 2004, 52, 2005–2012. [Google Scholar] [CrossRef]

- Bracke, L.; Verbeken, K.; Kestens, L.; Penning, J. Microstructure and texture evolution during cold rolling and annealing of a high Mn TWIP steel. Acta Mater. 2009, 57, 1512–1524. [Google Scholar] [CrossRef]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy fcc alloys that form deformation twins. Metall. Mater. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- Hirsch, J.; Lücke, K.; Hatherly, M. Mechanism of deformation and development of rolling textures in polycrystalline f.c.c. Metals-III. The influence of slip inhomogeneities and twinning. Acta Metall. 1988, 36, 2905–2927. [Google Scholar] [CrossRef]

- Leffers, T.; Ray, R.K. The brass-type texture and its deviation from the copper-type texture. Prog. Mater. Sci. 2009, 54, 351–396. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Bronkhorst, C.A.; Anand, L. Crystallographic texture evolution in bulk deformation processing of FCC metals. J. Mech. Phys. Solids 1992, 40, 537–569. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.; Needleman, A. An analysis of nonuniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Kalidindi, S.R. Modeling anisotropic strain hardening and deformation textures in low stacking fault energy fcc metals. Int. J. Plast. 2001, 17, 837–860. [Google Scholar] [CrossRef]

- Salem, A.; Kalidindi, S.; Semiatin, S. Strain hardening due to deformation twinning in α-titanium: Constitutive relations and crystal-plasticity modeling. Acta Mater. 2005, 53, 3495–3502. [Google Scholar] [CrossRef]

- Quey, R.; Dawson, P.R.; Barbe, F. Large-scale 3D random polycrystals for the finite element method: Generation, meshing and remeshing. Comput. Methods Appl. Eng. 2011, 200, 1729–1745. [Google Scholar] [CrossRef]

- Ardeljan, M.; McCabe, R.J.; Beyerlein, I.J.; Knezevic, M. Explicit incorporation of deformation twins into crystal plasticity finite element models. Comput. Method Appl. Eng. 2015, 295, 396–413. [Google Scholar] [CrossRef]

- Knezevic, M.; Drach, B.; Ardeljan, M.; Beyerlein, I.J. Three dimensional predictions of grain scale plasticity and grain boundaries using crystal plasticity finite element models. Comput. Method Appl. Eng. 2014, 277, 239–259. [Google Scholar] [CrossRef]

- Sun, C.Y.; Guo, X.R.; Guo, N.; Yang, J.; Huang, J. Investigation of plastic deformation behavior on coupling twinning of polycrystal twip steel. Acta Metall. Sin. 2015, 51, 1507–1515. [Google Scholar]

- Pierce, D.T.; Nowag, K.; Montagne, A.; Jimenez, J.A.; Wittig, J.E.; Ghisleni, R. Single crystal elastic constants of high-manganese transformation- and twinning-induced plasticity steels determined by a new method utilizing nanoindentation. Mater. Sci. Eng. A 2013, 578, 134–139. [Google Scholar] [CrossRef]

- Gebhardt, T.; Music, D.; Kossmann, D.; Ekholm, M.; Abrikosov, I.A.; Vitos, L.; Schneider, J.M. Elastic properties of FCC FeeMneX (X ¼ Al, Si) alloys studied by theory and experiment. Acta Mater. 2011, 59, 3145–3155. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture analysis with MTEX—Free and open source software toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Li, L.; Shen, L.M.; Proust, G. A texture-based representative volume element crystal plasticity model for predicting Bauschinger effect during cyclic loading. Mater. Sci. Eng. A 2014, 608, 174–183. [Google Scholar] [CrossRef]

- Wu, P.D.; Guo, X.Q.; Qiao, H. A constitutive model of twin nucleation, propagation and growth in magnesium crystals. Mater. Sci. Eng. A 2015, 625, 140–145. [Google Scholar] [CrossRef]

- Qiao, H.; Barnett, M.R.; Wu, P.D. Modeling of twin formation, propagation and growth in a Mg single crystal based on crystal plasticity finite element method. Int. J. Plast. 2016, 86, 70–92. [Google Scholar] [CrossRef]

- Li, H.; Yang, H.; Lu, R.D.; Fu, M.W. Coupled modeling of anisotropy variation and damage evolution for high strength steel tubular materials. Int. J. Mech. Sci. 2016, 105, 41–57. [Google Scholar] [CrossRef]

- Haase, C.; Kühbach, M.; Barrales-Mora, L.A.; Wong, S.L.; Roters, F.; Molodov, D.A.; Gottstein, G. Recrystallization behavior of a high-manganese steel: Experiments and simulations. Acta Mater. 2015, 100, 155–168. [Google Scholar] [CrossRef]

| C | Mn | Si | Al | S | P | Ti | Fe |

|---|---|---|---|---|---|---|---|

| 0.11 | 30.5 | 2.88 | 2.34 | 0.013 | 0.007 | ≤0.01 | Bal. |

| Initial hardening rate of slip system (MPa) | 180 |

| Saturated value of slip resistance without twinning (MPa) | 300 |

| Hardening index of twinning b | 2 |

| Hardening coefficient of twinning C | 10 |

| Effect of Hall–Petch mechanism (MPa) | 300 |

| Initial slip resistance (MPa) | 120 |

| Initial twinning resistance (MPa) | 139.2 |

| Elastic constant C11 (GPa) | 198 |

| Elastic constant C12 (GPa) | 125 |

| Elastic constant C44 (GPa) | 122 |

| Rate sensitivity coefficient m | 0.02 |

| Reference shear rate (s−1) | 0.001 |

| Deformation Mechanism | Symbol | Plane | Direction | Symbol | Plane | Direction |

|---|---|---|---|---|---|---|

| Slip systems | a1 | b1 | ||||

| a2 | b2 | |||||

| a3 | b3 | |||||

| c1 | d1 | |||||

| c2 | d2 | |||||

| c3 | d3 | |||||

| Twinning systems | t1 | u1 | ||||

| t2 | u2 | |||||

| t3 | u3 | |||||

| v1 | w1 | |||||

| v2 | w2 | |||||

| v3 | w3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, N.; Sun, C.; Fu, M.; Han, M. Misorientation-Dependent Twinning Induced Hardening and Texture Evolution of TWIP Steel Sheet in Plastic Deformation Process. Metals 2017, 7, 348. https://doi.org/10.3390/met7090348

Guo N, Sun C, Fu M, Han M. Misorientation-Dependent Twinning Induced Hardening and Texture Evolution of TWIP Steel Sheet in Plastic Deformation Process. Metals. 2017; 7(9):348. https://doi.org/10.3390/met7090348

Chicago/Turabian StyleGuo, Ning, Chaoyang Sun, Mingwang Fu, and Mingchuan Han. 2017. "Misorientation-Dependent Twinning Induced Hardening and Texture Evolution of TWIP Steel Sheet in Plastic Deformation Process" Metals 7, no. 9: 348. https://doi.org/10.3390/met7090348