Deformation Behavior and Microstructure Evolution of NiTiCu Shape Memory Alloy Subjected to Plastic Deformation at High Temperatures

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

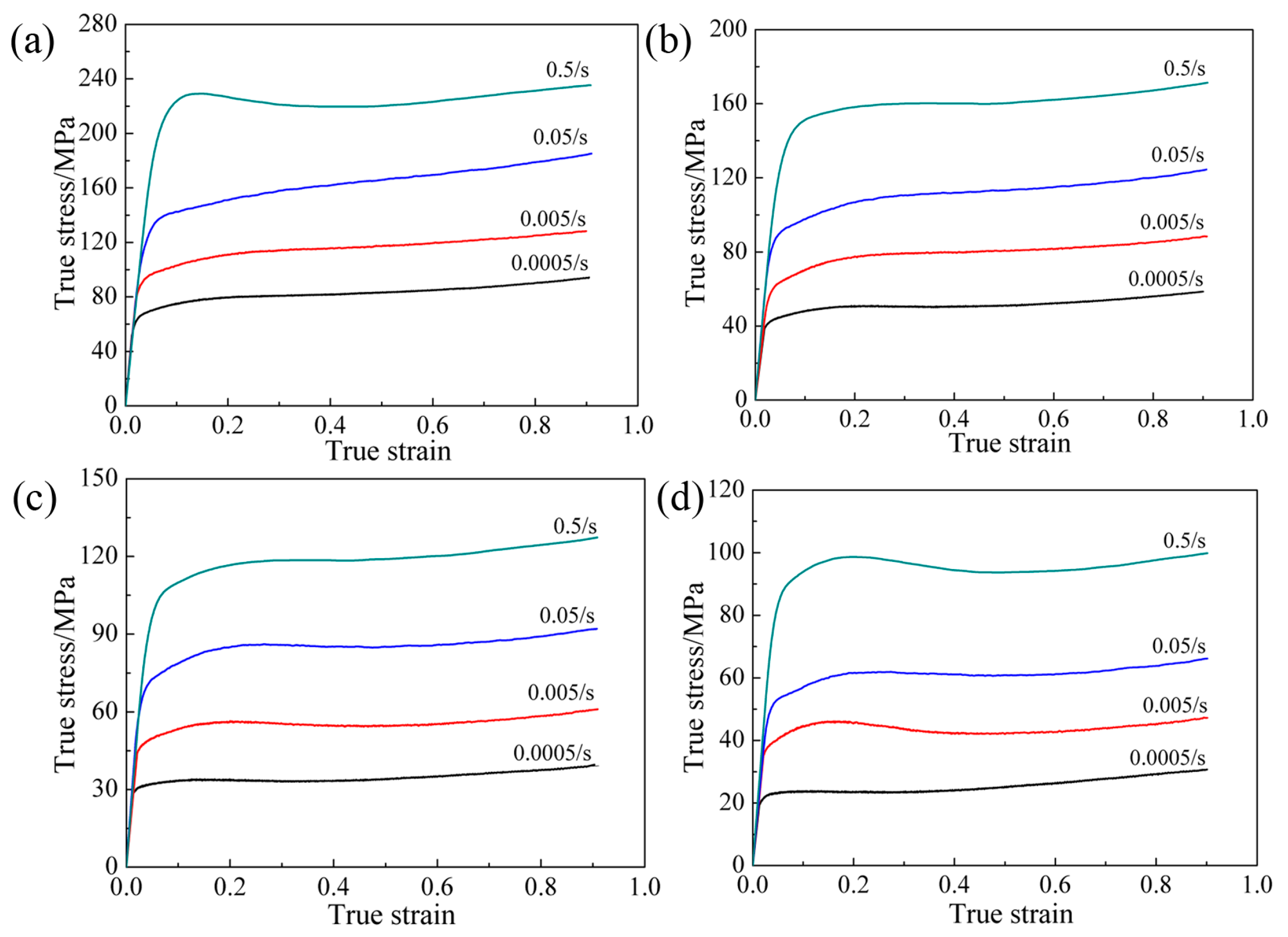

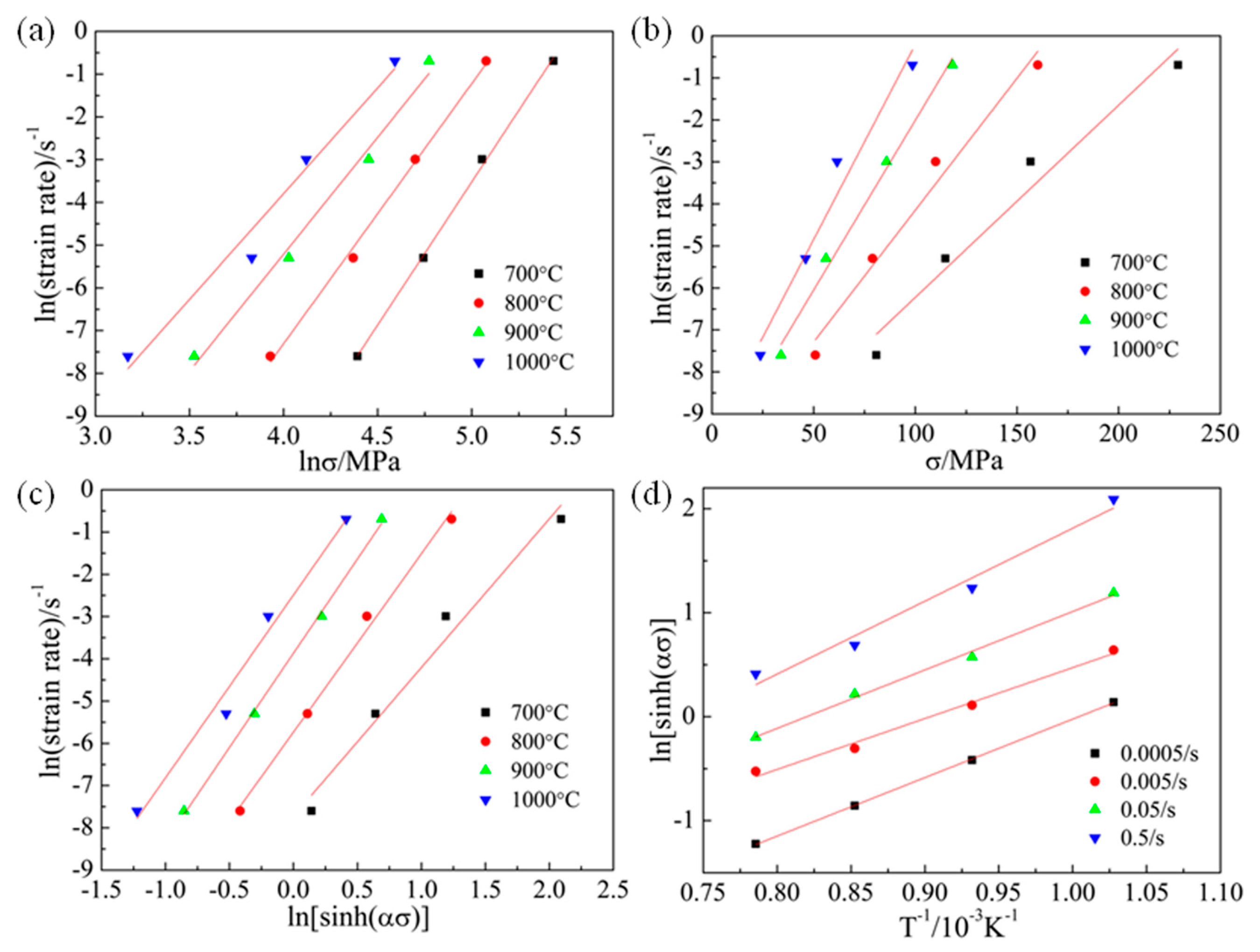

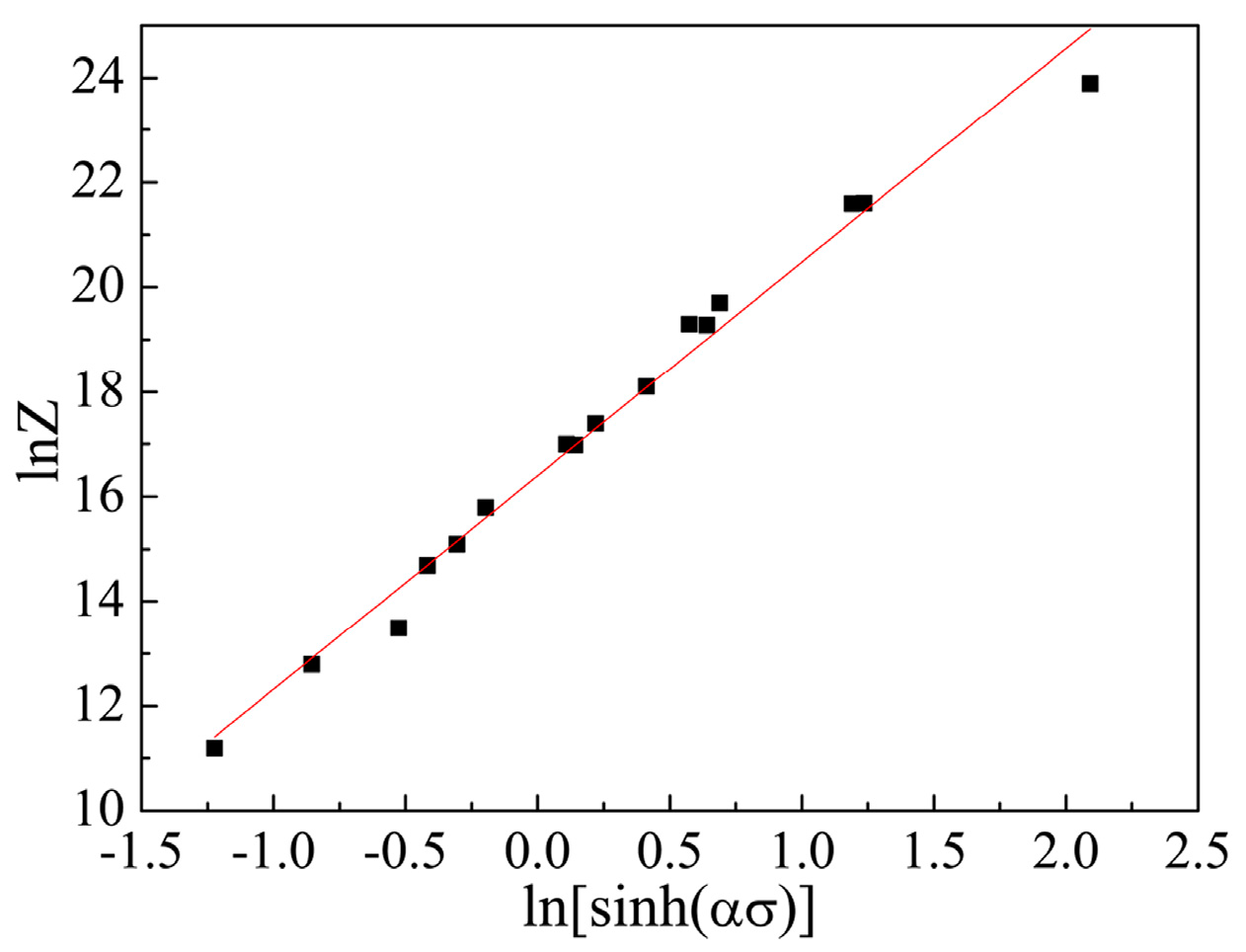

3.1. Deformation Behavior of NiTiCu SMA

3.2. Microstructural Evolution of NiTiCu SMA

4. Conclusions

- (1)

- The constitutive equation of NiTiCu SMA based on the Zener-Hollomon parameter was established in order to describe the flow characteristic of NiTiCu SMA. The results show that the flow stress of NiTiCu SMA depends on the strain rates. Depending on temperatures, DRV or DRX are the main mechanisms for the plastic deformation of NiTiCu SMA at elevated temperatures.

- (2)

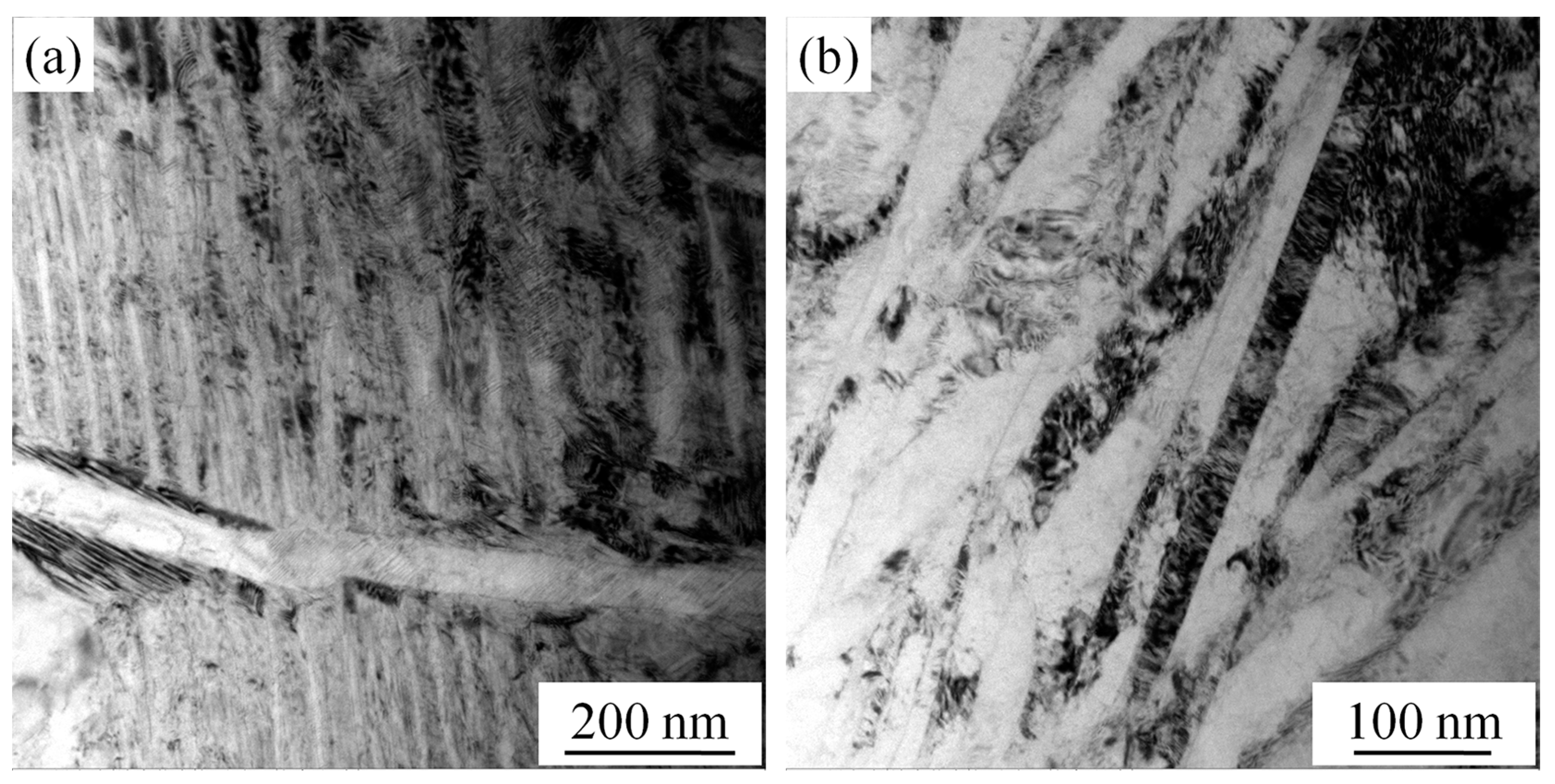

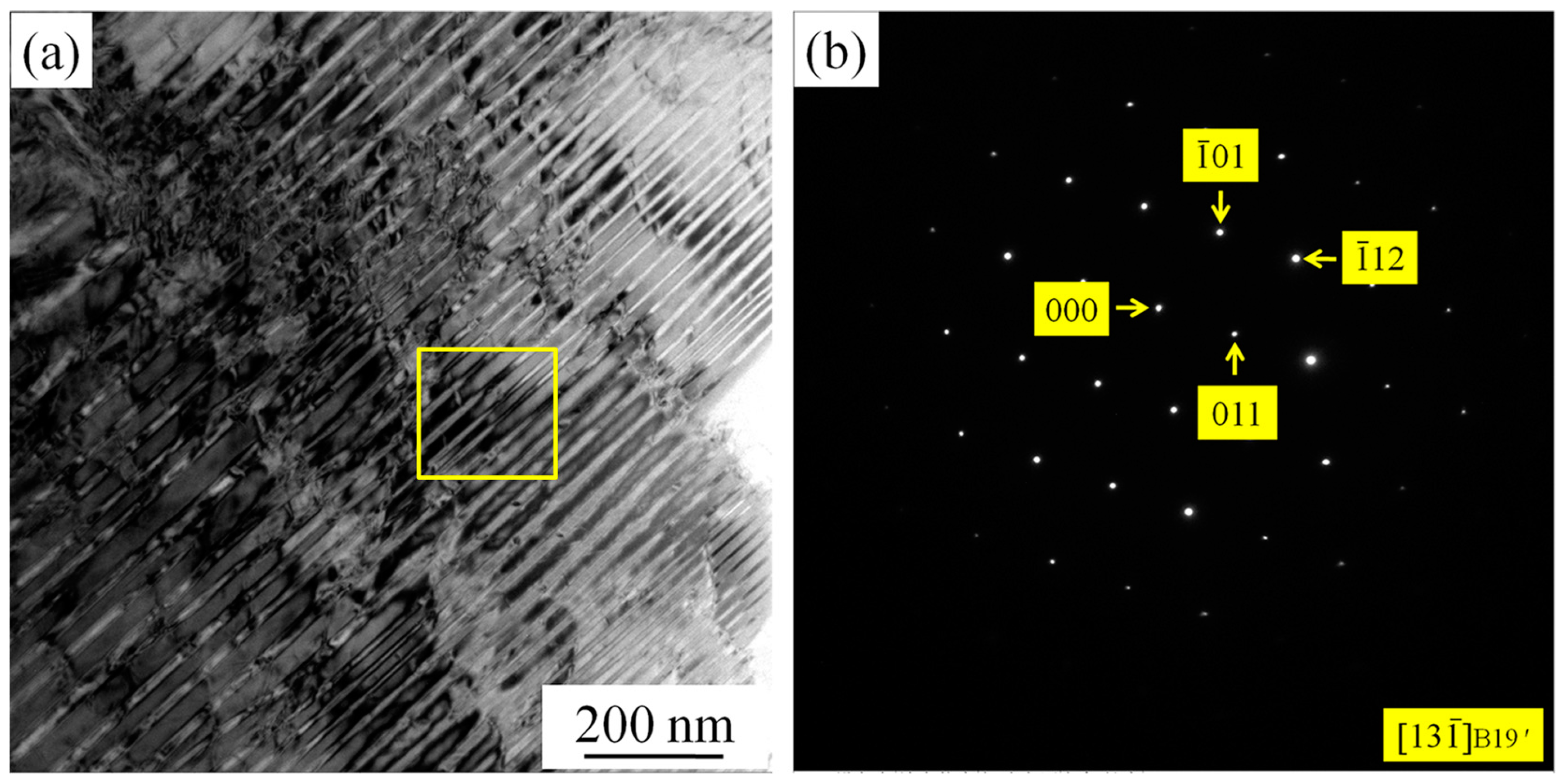

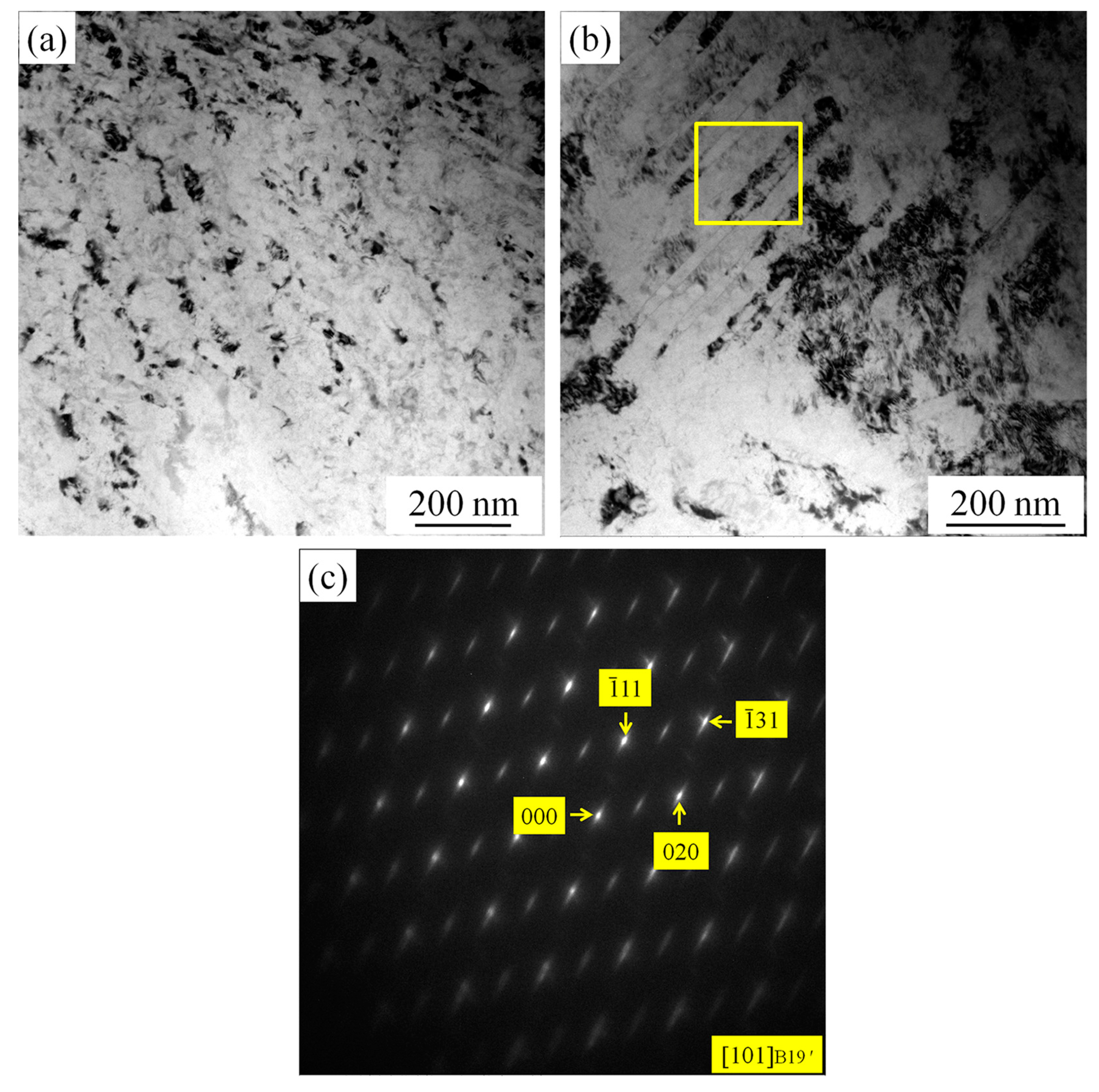

- The microstructures resulting from DRV or DRX have a significant influence on the substructures in the martensite phase of the NiTiCu SMA sample at room temperature. Dislocations become the dominant substructures of martensite in the NiTiCu SMA specimen undergoing compression at 700 °C. Martensite twins are dominant in the NiTiCu SMA specimen undergoing compression at 800 and 900 °C. Martensite twins are not observed in the NiTiCu SMA specimen undergoing compression at 1000 °C.

- (3)

- Dislocation substructures resulting from DRV, such as dislocation cells and subgrain boundaries, are able to suppress the formation of martensite twins in the martensite laths of NiTiCu SMA. The size of dynamic recrystallized grains has an effect on the formation of martensite twins. Martensite twins are not easily formed in larger dynamic recrystallized grain, since the constraint of the grain boundaries plays a weak role. However, in smaller dynamic recrystallized grain, martensite twins are induced in order to accommodate the occurrence of the transformation from austenite phase to martensite phase.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Basu, R.; Eskandari, M.; Upadhayay, L.; Mohtadi-Bonab, M.A.; Szpunar, J.A. A systematic investigation on the role of microstructure on phase transformation behavior in Ni–Ti–Fe shape memory alloys. J. Alloys Compd. 2015, 645, 213–222. [Google Scholar] [CrossRef]

- Choi, E.; Hong, H.K.; Kim, H.S.; Chung, Y.S. Hysteretic behavior of NiTi and NiTiNb SMA wires under recovery or pre-stressing stress. J. Alloys Compd. 2013, 577S, S444–S447. [Google Scholar] [CrossRef]

- Wang, M.J.; Jiang, M.Y.; Liao, G.Y.; Guo, S.; Zhao, X.Q. Martensitic transformation involved mechanical behaviors and wide hysteresis of NiTiNb shape memory alloys. Prog. Natl. Sci. Mater. Int. 2012, 22, 130–138. [Google Scholar] [CrossRef]

- Nespoli, A.; Passaretti, F.; Villa, E. Phase transition and mechanical damping properties: A DMTA study of NiTiCu shape memory alloys. Intermetallics 2013, 32, 394–400. [Google Scholar] [CrossRef]

- Basu, R.; Mohtadi-Bonab, M.A.; Wang, X.; Eskandari, M.; Szpunar, J.A. Role of microstructure on phase transformation behavior in Ni-Ti-Fe shape memory alloys during thermal cycling. J. Alloys Compd. 2015, 652, 459–469. [Google Scholar] [CrossRef]

- Choudhary, N.; Kaur, D. Shape memory alloy thin films and heterostructures for MEMS applications: A review. Sens. Actuators A 2016, 242, 162–181. [Google Scholar] [CrossRef]

- Kaur, N.; Kaur, D. NiTiCu/AlN/NiTiCu shape memory thin film heterostructures for vibration damping in MEMS. J. Alloys Compd. 2014, 590, 116–124. [Google Scholar] [CrossRef]

- Kotil, T.; Sehitoglu, H.; Maier, H.J.; Chumlyakov, Y.I. Transformation and detwinning induced electrical resistance variations in NiTiCu. Mater. Sci. Eng. A 2003, 359, 280–289. [Google Scholar] [CrossRef]

- Saikrishna, C.N.; Ramaiah, K.V.; Bhaumik, S.K. Effects of thermo-mechanical cycling on the strain response of Ni–Ti–Cu shape memory alloy wire actuator. Mater. Sci. Eng. A 2006, 428, 217–224. [Google Scholar] [CrossRef]

- Nespoli, A.; Villa, E.; Besseghini, S. Characterization of the martensitic transformation in Ni50-xTi50Cux alloys through pure thermal measurements. J. Alloys Compd. 2011, 509, 644–647. [Google Scholar] [CrossRef]

- Colombo, S.; Cannizzo, C.; Gariboldi, F.; Airoldi, G. Electrical resistance and deformation during the stress-assisted two-way memory effect in Ni45Ti50Cu5 alloy. J. Alloys Compd. 2006, 422, 313–320. [Google Scholar] [CrossRef]

- Sharifi, E.M.; Karimzadeh, F.; Kermanpur, A. The effect of cold rolling and annealing on microstructure and tensile properties of the nanostructured Ni50Ti50 shape memory alloy. Mater. Sci. Eng. A 2014, 607, 33–37. [Google Scholar] [CrossRef]

- Tadayyon, G.; Guo, Y.; Mazinani, M.; Zebarjad, S.M.; Tiernan, P.; Tofail, S.A.M.; Biggs, M.J.P. Effect of different stages of deformation on the microstructure evolution of Ti-rich NiTi shape memory alloy. Mater. Charact. 2017, 125, 51–66. [Google Scholar] [CrossRef]

- Yeom, J.T.; Kim, J.H.; Hong, J.K.; Kim, S.W.; Park, C.H.; Nam, T.H.; Lee, K.Y. Hot forging design of as-cast NiTi shape memory alloy. Mater. Res. Bull. 2014, 58, 234–238. [Google Scholar] [CrossRef]

- Sehitoglu, H.; Karaman, I.; Zhang, X.; Hong, K.; Chumlyakov, Y.; Kireeva, I. Deformation of NiTiCu shape memory single crystals in compression. Metall. Mater. Trans. A 2001, 32A, 477–489. [Google Scholar] [CrossRef]

- Morakabati, M.; Kheirandish, S.; Aboutalebi, M.; Taheri, A.K.; Abbasi, S.M. The effect of Cu addition on the hot deformation behavior of NiTi shape memory alloys. J. Alloys Compd. 2010, 499, 57–62. [Google Scholar] [CrossRef]

- Morakabati, M.; Aboutalebi, M.; Kheirandish, S.; Taheri, A.K.; Abbasi, S.M. Hot tensile properties and microstructural evolution of as cast NiTi and NiTiCu shape memory alloys. Mater. Des. 2011, 32, 406–413. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Parsa, M.H. Hot deformation and dynamic recrystallization of NiTi intermetallic compound. J. Alloys Compd. 2014, 614, 56–59. [Google Scholar] [CrossRef]

- Yin, X.Q.; Park, C.H.; Li, Y.F.; Ye, W.J.; Zuo, Y.T.; Lee, S.W.; Yeom, J.T.; Mi, X.J. Mechanism of continuous dynamic recrystallization in a 50Ti-47Ni-3Fe shape memory alloy during hot compressive deformation. J. Alloys Compd. 2017, 693, 426–431. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Zhang, Y.Q.; Zhao, Y.N. Dynamic recovery and dynamic recrystallization of NiTi shape memory alloy under hot compression deformation. Trans. Nonferrous Met. Soc. China 2013, 23, 140–147. [Google Scholar] [CrossRef]

- Etaati, A.; Dehghani, K. A study on hot deformation behavior of Ni-42.5Ti-7.5Cu alloy. Mater. Chem. Phys. 2013, 140, 208–215. [Google Scholar] [CrossRef] [Green Version]

- Shamsolhodaei, A.; Zarei-hanzaki, A.; Ghambari, M.; Moemeni, S. The high temperature flow behavior modeling of NiTi shape memory alloy employing phenomenological and physical based constitutive models: A comparative study. Intermetallics 2014, 53, 140–149. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Zhang, Y.Q.; Zhao, Y.N.; Tang, M.; Yi, W.L. Constitutive behavior of Ni-Ti shape memory alloy under hot compression. J. Cent. South Univ. 2013, 20, 24–29. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Jiang, S.Y.; Zhao, Y.N.; Liu, S.W. Constitutive equation and processing map of equiatomic NiTi shape memory alloy under hot plastic deformation. Trans. Nonferrous Met. Soc. China 2016, 26, 2152–2161. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Chen, C.; Hu, L.; Zhu, X. Hot workability of a NiTiCu shape memory alloy with acicular martensite phase based on processing maps. Intermetallics 2017, 86, 94–103. [Google Scholar] [CrossRef]

| /s−1 | ln | T/K | |||

|---|---|---|---|---|---|

| 973 | 1073 | 1173 | 1273 | ||

| 0.0005 | −7.6009 | 80.878 | 50.8828 | 33.95 | 23.8579 |

| 0.005 | −5.2983 | 114.8027 | 79.0071 | 56.1214 | 46.1041 |

| 0.05 | −2.9957 | 156.7221 | 109.9611 | 85.8336 | 61.5655 |

| 0.5 | −0.6931 | 229.1717 | 160.2669 | 118.3127 | 98.6517 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Sun, D.; Zhang, Y.; Hu, L. Deformation Behavior and Microstructure Evolution of NiTiCu Shape Memory Alloy Subjected to Plastic Deformation at High Temperatures. Metals 2017, 7, 294. https://doi.org/10.3390/met7080294

Jiang S, Sun D, Zhang Y, Hu L. Deformation Behavior and Microstructure Evolution of NiTiCu Shape Memory Alloy Subjected to Plastic Deformation at High Temperatures. Metals. 2017; 7(8):294. https://doi.org/10.3390/met7080294

Chicago/Turabian StyleJiang, Shuyong, Dong Sun, Yanqiu Zhang, and Li Hu. 2017. "Deformation Behavior and Microstructure Evolution of NiTiCu Shape Memory Alloy Subjected to Plastic Deformation at High Temperatures" Metals 7, no. 8: 294. https://doi.org/10.3390/met7080294