Infrared Dissimilar Joining of Ti50Ni50 and 316L Stainless Steel with Copper Barrier Layer in between Two Silver-Based Fillers

Abstract

:1. Introduction

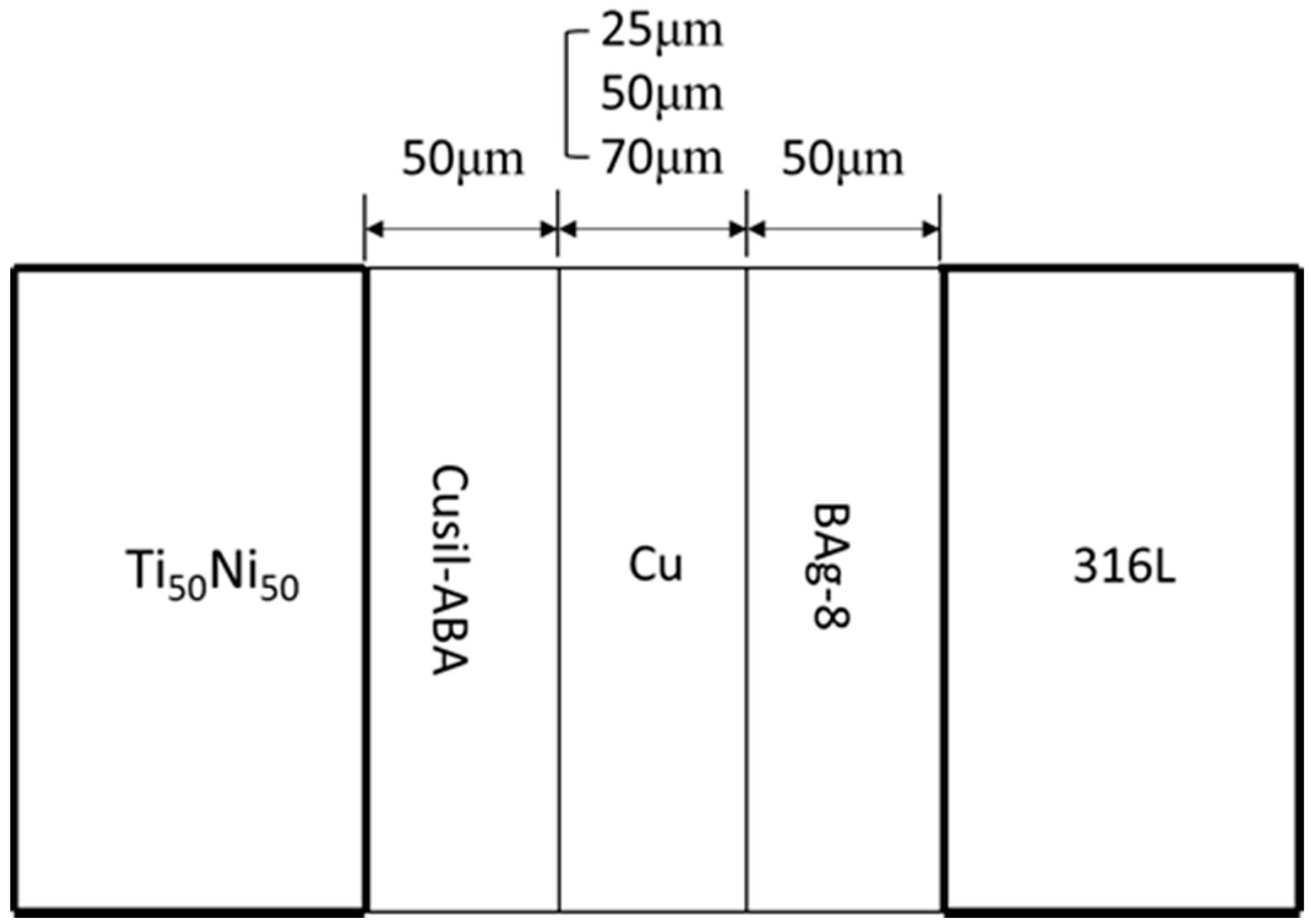

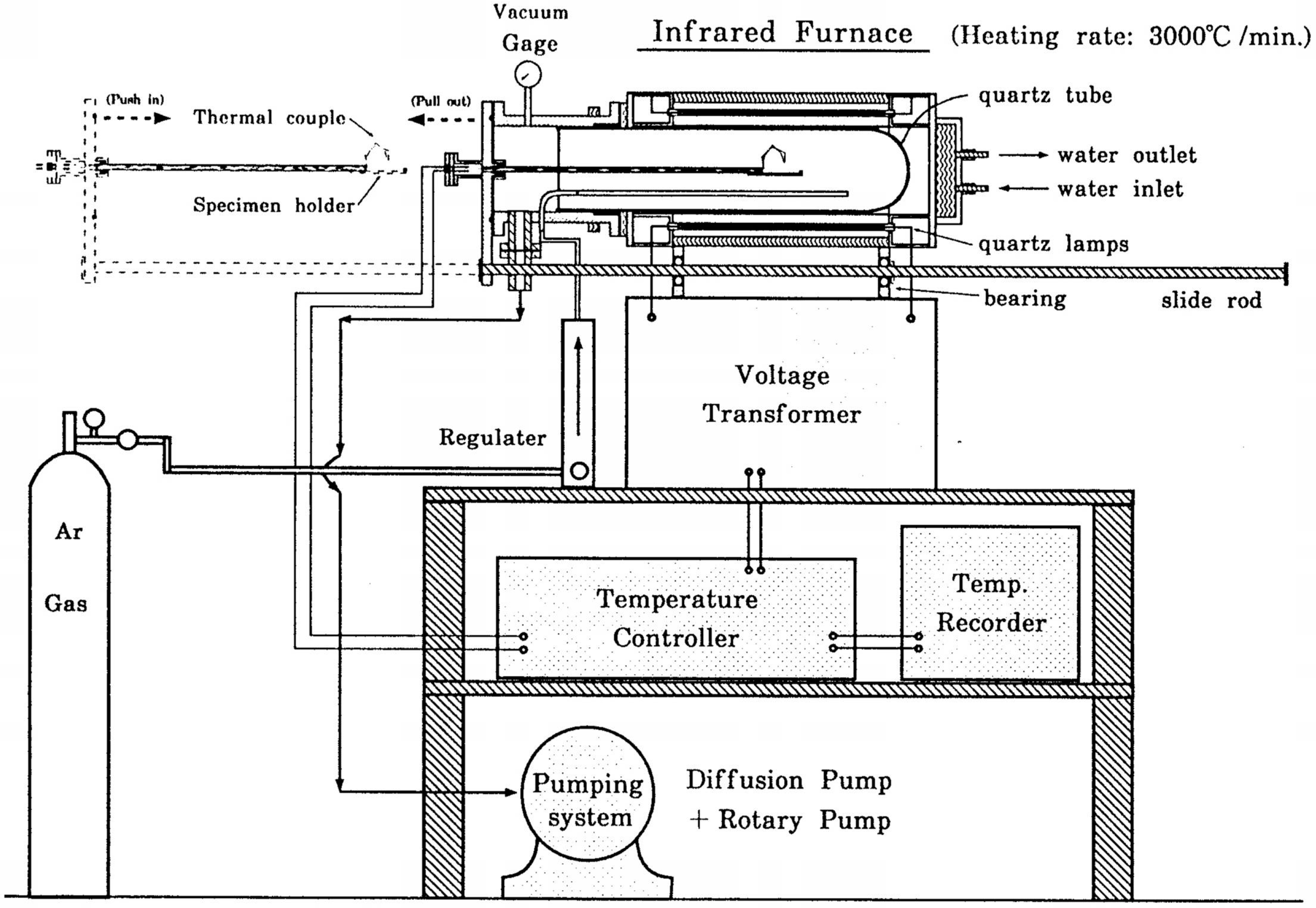

2. Materials Used and Experimental Procedure

3. Experimental Results and Discussion

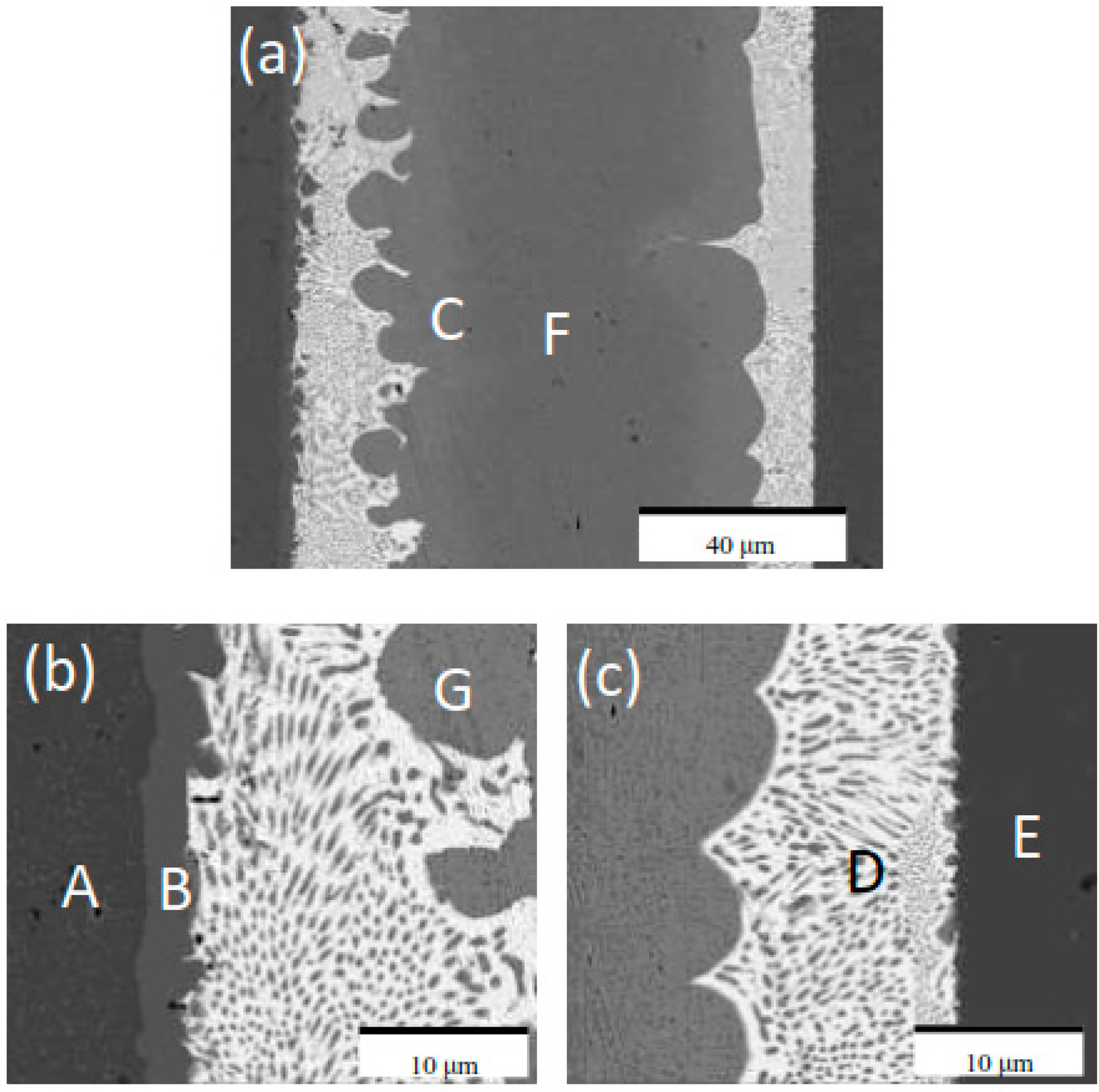

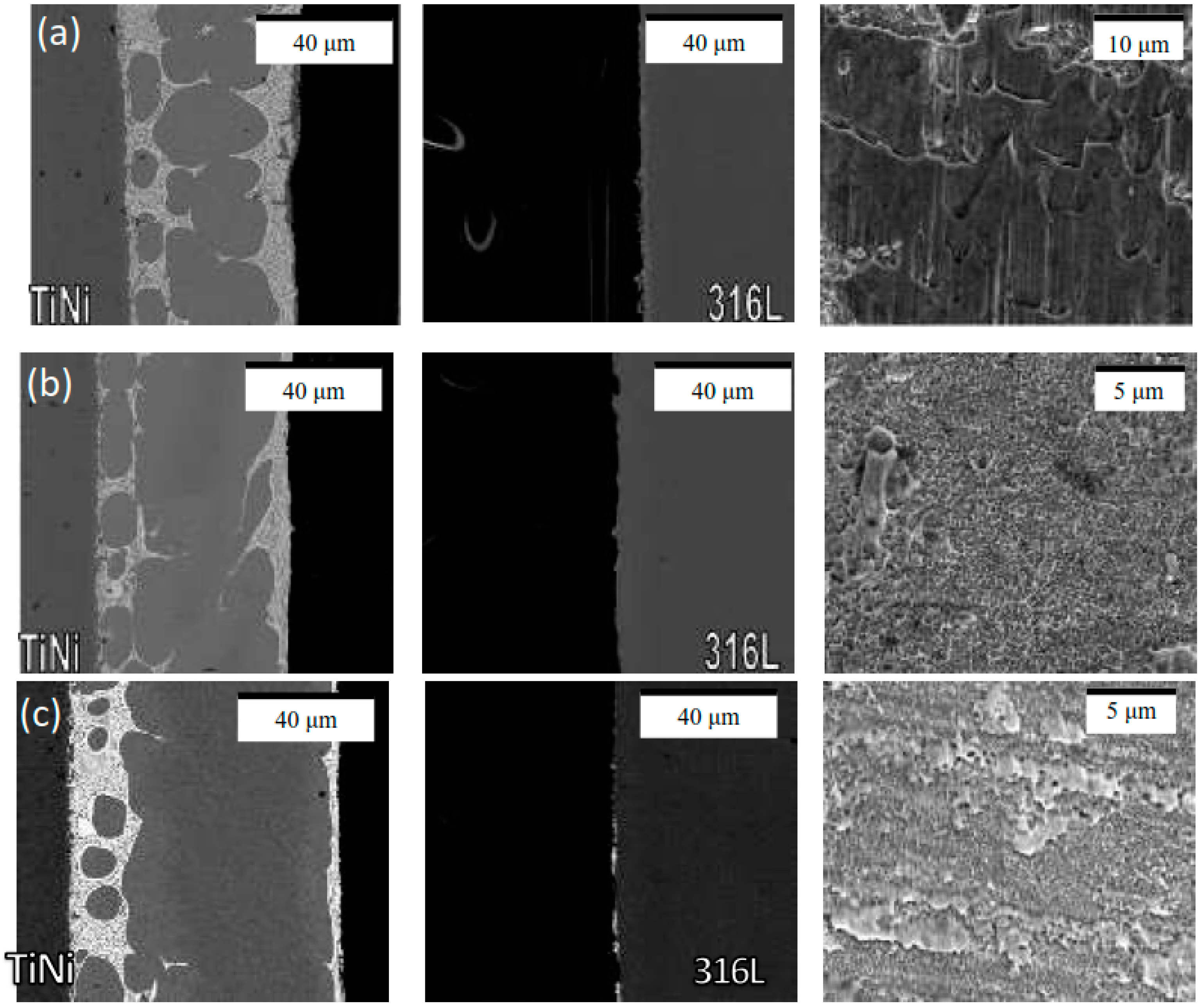

3.1. Microstructures of Brazed Joints

3.2. Microstructures of the Brazed Joints

3.3. The Shear Strengths of Brazed Joints

4. Conclusions

- The Cu foil serves as a barrier layer at thicknesses of 70 μm and 50 μm, and it successfully isolates the interfacial reaction between Ti and Fe at the 316L SS substrate side. In contrast, the Cu foil with 25 μm in thickness is completely dissolved into the braze melt during brazing and fails to be a barrier layer.

- A layer of (CuxNi1−x)2Ti intermetallic is formed at the Ti50Ni50 substrate side, and the Cu interlayer is dissolved into the Cusil-ABA melt to from a few proeutectic Cu particles for all specimens. For the 316L SS substrate side, no interfacial layer is observed and (Ag, Cu) eutectic dominates the brazed joint for 70 μm/50 μm Cu foil. However, an interfacial Ti(Fe, Ni) intermetallic layer and (Fe, Cr)-rich layer are formed in the brazed joint with the 25 μm Cu layer.

- The joint with the 50 μm Cu barrier layer demonstrates the best average shear strengths of 354 MPa and 349 MPa for samples brazed at 820 °C and 850 °C, respectively. All specimens are fractured along the interface between the BAg-8 braze and 316L SS side. Cracks are initiated/propagated in (Ag, Cu) eutectic for the 70 μm and 50 μm thickness Cu foils and at the interfacial Ti(Fe, Ni) reaction layer for the 25 μm foil. The formation of a brittle Ti(Fe, Ni) intermetallic layer deteriorates the bonding strength of the joint.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Funakubo, H. Shape Memory Alloys; Gordon & Breach Science: New York, NY, USA, 1987. [Google Scholar]

- Otsuka, K.; Kakeshita, T. Science and technology of shape-memory alloys: New developments. MRS Bull. 2002, 27, 91–100. [Google Scholar] [CrossRef]

- Braun, S.; Sandstrom, N.; Stemme, G.; Wijngaart, W. Wafer-scale manufacturing of bulk shape-memory-alloy microactuators based on adhesive bonding of titanium-nickel sheets to structured silicon wafers. J. Microelectromech. Syst. 2009, 18, 1309–1317. [Google Scholar] [CrossRef]

- Tomozawa, M.; Kim, H.Y.; Miyazaki, S. Shape memory behavior and internal structure of Ti-Ni-Cu shape memory alloy thin films and their application for microactuators. Acta Mater. 2009, 57, 441–452. [Google Scholar]

- Smith, W.F. Structure and Properties of Engineering Alloys; McGraw-Hill: New York, NY, USA, 1993; pp. 312–316. [Google Scholar]

- Shiue, R.K.; Chen, C.P.; Wu, S.K. Infrared brazing Ti50Ni50 shape memory alloy and 316L stainless steel with two sliver-based fillers. Metall. Mater. Trans. A 2015, 46, 2364–2371. [Google Scholar] [CrossRef]

- Kumar, A.; Ganesh, P.; Kaul, R.; Sindal, B.K. New brazing recipe for ductile niobium-316L stainless steel joints. Weld. J. 2015, 94, 241–249. [Google Scholar]

- Laik, A.; Shirzadi, A.A.; Sharma, G.; Tewari, R.; Jayakumar, T.; Dey, G.K. Microstructure and interfacial reactions during vacuum brazing of stainless steel to titanium using Ag-28 pct Cu alloy. Metall. Mater. Trans. A 2015, 46, 771–782. [Google Scholar]

- Lee, M.K.; Park, J.J.; Lee, J.G.; Rhee, C.K. Phase-dependent corrosion of titanium-to-stainless steel joints brazed by Ag–Cu eutectic alloy filler and Ag interlayer. J. Nucl. Mater. 2013, 439, 168–173. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Brazing of titanium to steel with different filler metals: Analysis and comparison. J. Mater. Sci. 2010, 45, 4332–4338. [Google Scholar] [CrossRef]

- Lee, M.K.; Lee, J.G.; Lee, J.K.; Hong, S.M.; Lee, S.H.; Park, J.J.; Kim, J.W.; Rhee, C.K. Formation of interfacial brittle phases sigma phase and IMC in hybrid titanium-to-stainless steel joint. Trans. Nonferrous Met. Soc. China 2011, 21, 7–11. [Google Scholar] [CrossRef]

- Liu, C.C.; Ou, C.L.; Shiue, R.K. The microstructural observation and wettability study of brazing Ti-6Al-4V and 304 stainless steel using three braze alloys. J. Mater. Sci. 2002, 37, 2225–2235. [Google Scholar] [CrossRef]

- Morizono, Y.; Mizobata, A. Explosive coating of Ag-Cu filler alloy on metal substrates and its effect on subsequent brazing process. ISIJ Int. 2010, 50, 1200–1204. [Google Scholar] [CrossRef]

- Lee, J.G.; Hong, S.J.; Lee, M.K.; Rhee, C.K. High strength bonding of titanium to stainless steel using an Ag interlayer. J. Nucl. Mater. 2009, 395, 145–149. [Google Scholar] [CrossRef]

- Kamat, G.R. Solid-state diffusion welding of nickel to stainless steel. Weld. J. 1988, 67, 44–46. [Google Scholar]

- He, P.; Zhang, J.H.; Zhou, R.L.; Li, X.Q. Diffusion bonding technology of a titanium alloy to a stainless steel web with a Ni interlayer. Mater. Charact. 1999, 43, 287–292. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chan, C.H.; Huang, C.S. Infrared brazing Ti-6Al-4V and 17-4 PH stainless steel with a nickel barrier layer. Metall. Mater. Trans. A 2006, 37, 2207–2217. [Google Scholar] [CrossRef]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. Binary Alloy Phase Diagrams. In ASM Metal Handbook; ASM International: Geauga County, OH, USA, 1992; Volume 3, pp. 2–168. [Google Scholar]

- Villars, P.; Prince, A.; Okamoto, H. Handbook of Ternary Alloy Phase Diagrams; ASM International: Geauga County, OH, USA, 1995. [Google Scholar]

- Yang, S.H. The Study of Infrared Brazing Ti50Ni50 SMA and 316L Stainless Steel/Inconel 600; Department of Mechanical Engineering, National Taiwan University: Taipei, Taiwan, 2015; pp. 5–35. [Google Scholar]

- Lee, S.J.; Wu, S.K.; Lin, R.Y. Infrared joining of TiAl intermetallics using Ti-15Cu-15Ni foil—Part I the microstructure morphologies of joint interfaces. Acta Mater. 1998, 46, 1283–1295. [Google Scholar] [CrossRef]

- Shiue, R.K.; Chen, Y.H.; Wu, S.K. Infrared brazing Ti50Ni50 and invar using Ag-based filler foils. Metall. Mater. Trans. A 2013, 44, 4454–4460. [Google Scholar] [CrossRef]

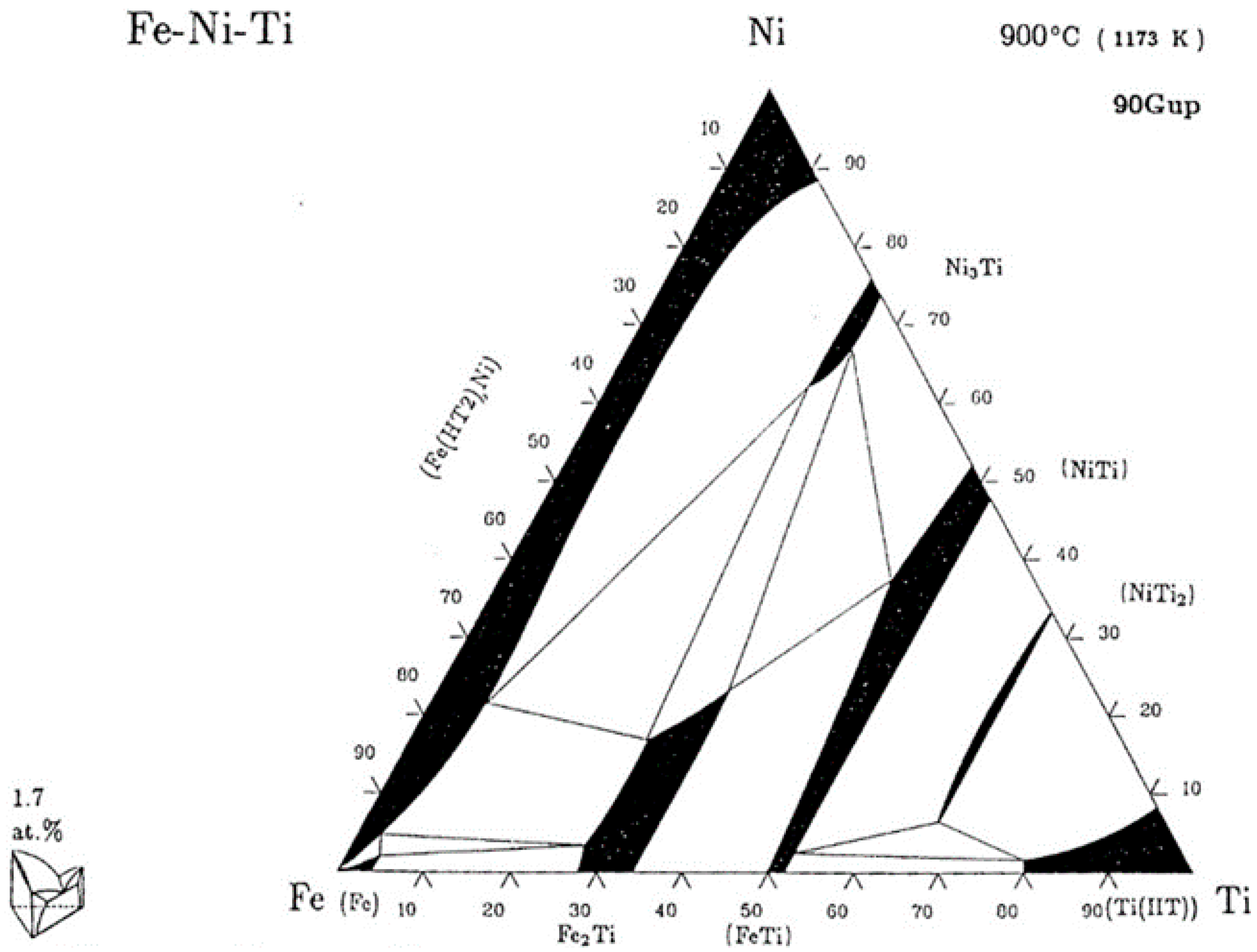

- Loo, F.; Vrolijk, J.; Bastin, G. Phase relations and diffusion paths in the Ti-Ni-Fe system at 900 °C. J. Less-Common Met. 1981, 77, 121–130. [Google Scholar]

| Braze Foil | Cusil-ABA | BAg-8 | Copper |

|---|---|---|---|

| Chemical composition | 63Ag-35.25Cu-1.75Ti (wt %) | 72Ag-28Cu (wt %) | 99.95% purity (wt %) |

| Solidus temperature | 780 °C | 780 °C | 1083 °C |

| Liquidus temperature | 815 °C | 780 °C | 1083 °C |

| at % | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Ti | 49.8 | 30.7 | 3.9 | - | - | - | 2.5 |

| Cu | - | 51.6 | 90.5 | 47.2 | - | 100 | 89.3 |

| Ni | 50.2 | 17.7 | - | - | 10.8 | - | - |

| Fe | - | - | - | - | 68.1 | - | - |

| Ag | - | - | 5.6 | 52.8 | - | - | 8.2 |

| Cr | - | - | - | - | 21.1 | - | - |

| Phase | Ti50Ni50 | (CuxNi1−x)2Ti | Cu-rich | Ag-Cu eutectic | 316L | Cu | Cu-rich |

| at % | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Ti | 50.2 | 31.6 | 2.2 | 40.0 | 9.9 | - | 50.1 |

| Cu | - | 49.8 | 92.6 | 4.8 | - | - | 46.4 |

| Ni | 49.8 | 18.6 | - | 12.7 | 3.3 | 10.5 | 3.5 |

| Fe | - | - | - | 37.0 | 56.1 | 69.1 | - |

| Ag | - | - | 5.2 | 2.9 | 9.1 | - | - |

| Cr | - | - | - | 2.6 | 21.6 | 20.4 | - |

| Phase | Ti50Ni50 | (CuxNi1−x)2Ti | Cu-rich | Ti(Fe, Ni) | (Fe, Cr)-rich | 316L | TiCu |

| at % | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Ti | 49.7 | 30.6 | - | - | - | 4.5 |

| Cu | - | 48.6 | 100 | 27.7 | - | 90.4 |

| Ni | 50.3 | 20.8 | - | - | 13.1 | - |

| Fe | - | - | - | - | 68.9 | - |

| Ag | - | - | - | 72.3 | - | 5.1 |

| Cr | - | - | - | - | 18.0 | - |

| Phase | Ti50Ni50 | (CuxNi1−x)2Ti | Cu | Ag-Cu eutectic | 316L | Cu-rich |

| Filler Metal | Brazing Temperature | Brazing Time | Copper Foil Thickness | Average Shear Strength |

|---|---|---|---|---|

| Cusil-ABA/Cu foil/BAg-8 | 820 °C | 300 s | 25 μm | 140 ± 3 MPa |

| 50 μm | 354 ± 35 MPa | |||

| 70 μm | 292 ± 37 MPa | |||

| 850 °C | 300 s | 25 μm | 236 ± 38 MPa | |

| 50 μm | 349 ± 21 MPa | |||

| 70 μm | 211 ± 39 MPa | |||

| Cusil-ABA * | 870 °C | 300 s | - | 66 ± 15 MPa |

| Ticusil * | 950 °C | 60 s | - | 237 ± 16 MPa |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shiue, R.-K.; Wu, S.-K.; Yang, S.-H.; Liu, C.-K. Infrared Dissimilar Joining of Ti50Ni50 and 316L Stainless Steel with Copper Barrier Layer in between Two Silver-Based Fillers. Metals 2017, 7, 276. https://doi.org/10.3390/met7070276

Shiue R-K, Wu S-K, Yang S-H, Liu C-K. Infrared Dissimilar Joining of Ti50Ni50 and 316L Stainless Steel with Copper Barrier Layer in between Two Silver-Based Fillers. Metals. 2017; 7(7):276. https://doi.org/10.3390/met7070276

Chicago/Turabian StyleShiue, Ren-Kae, Shyi-Kaan Wu, Sheng-Hao Yang, and Chun-Kai Liu. 2017. "Infrared Dissimilar Joining of Ti50Ni50 and 316L Stainless Steel with Copper Barrier Layer in between Two Silver-Based Fillers" Metals 7, no. 7: 276. https://doi.org/10.3390/met7070276