Feature Size Effect on Formability of Multilayer Metal Composite Sheets under Microscale Laser Flexible Forming

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

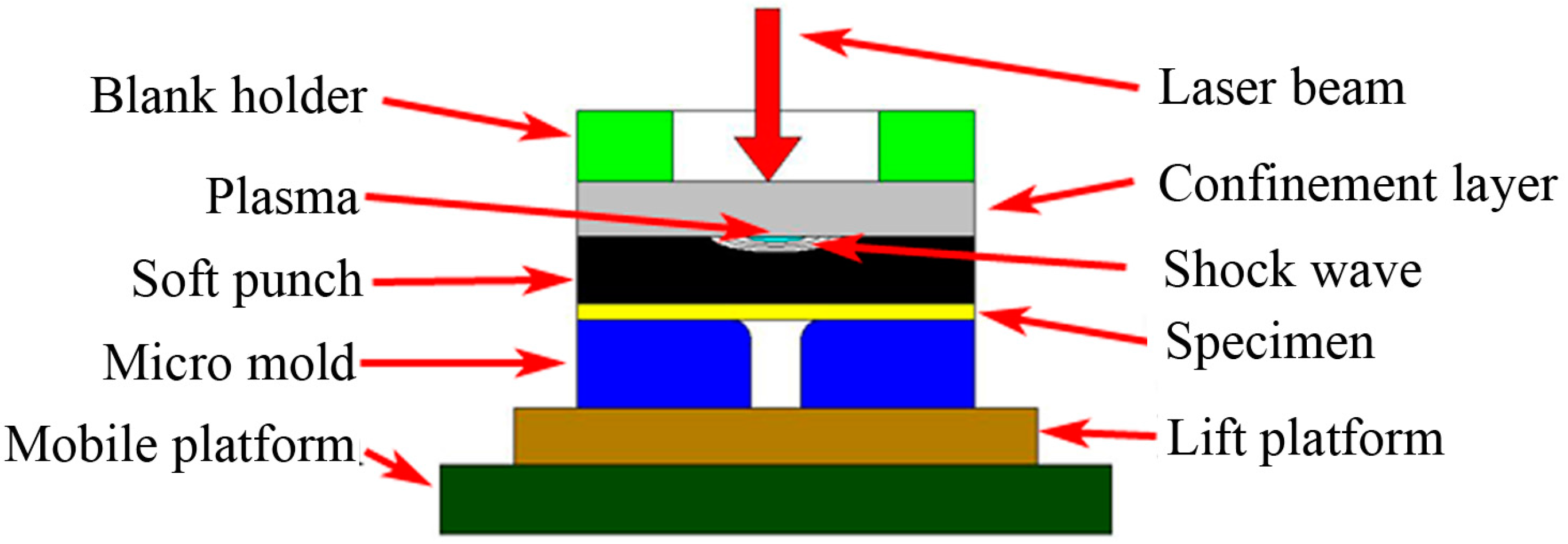

2.2. Experiment Appliance and Principle

2.3. Experiment Procedure

3. Results and Discussion

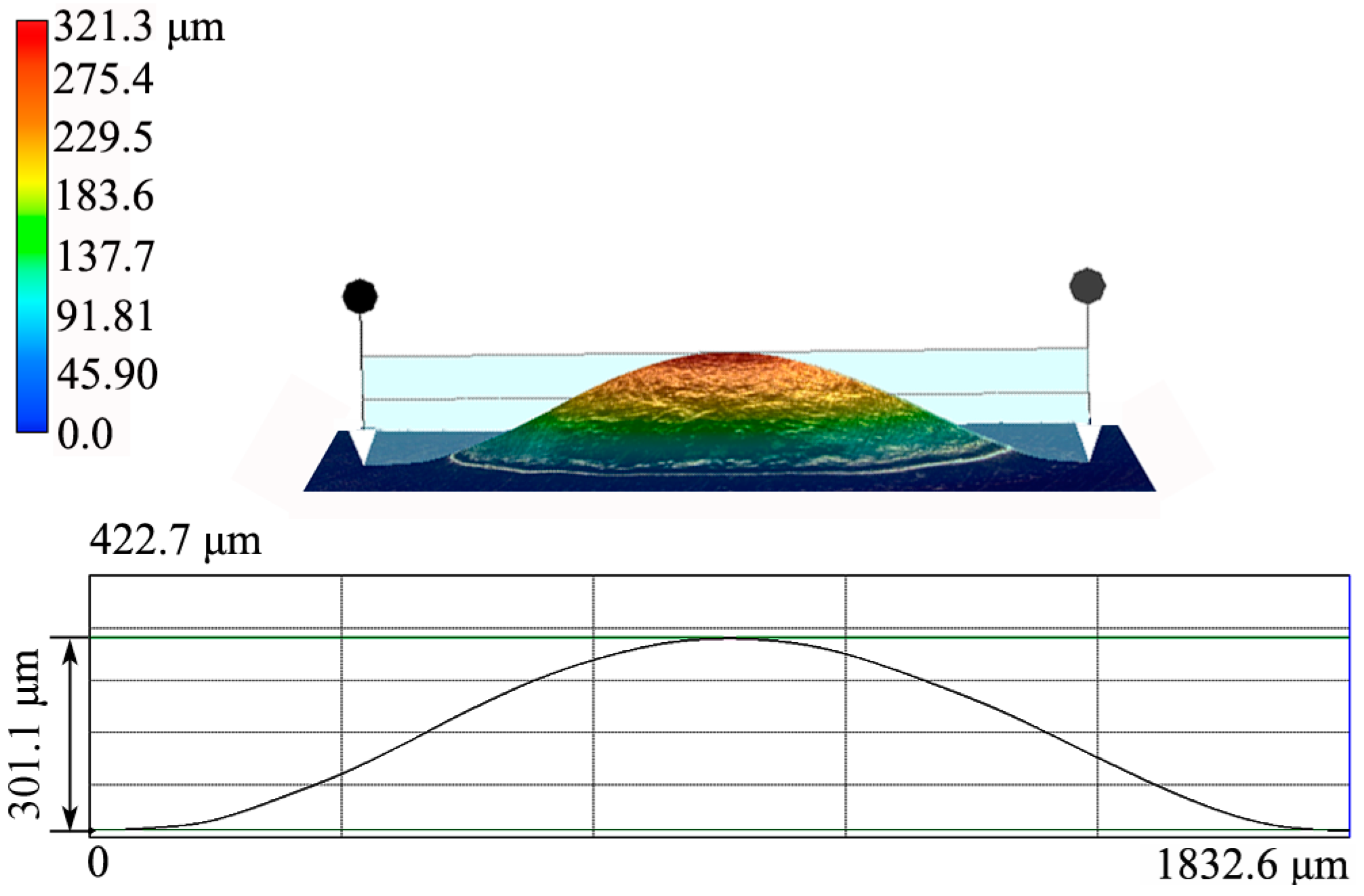

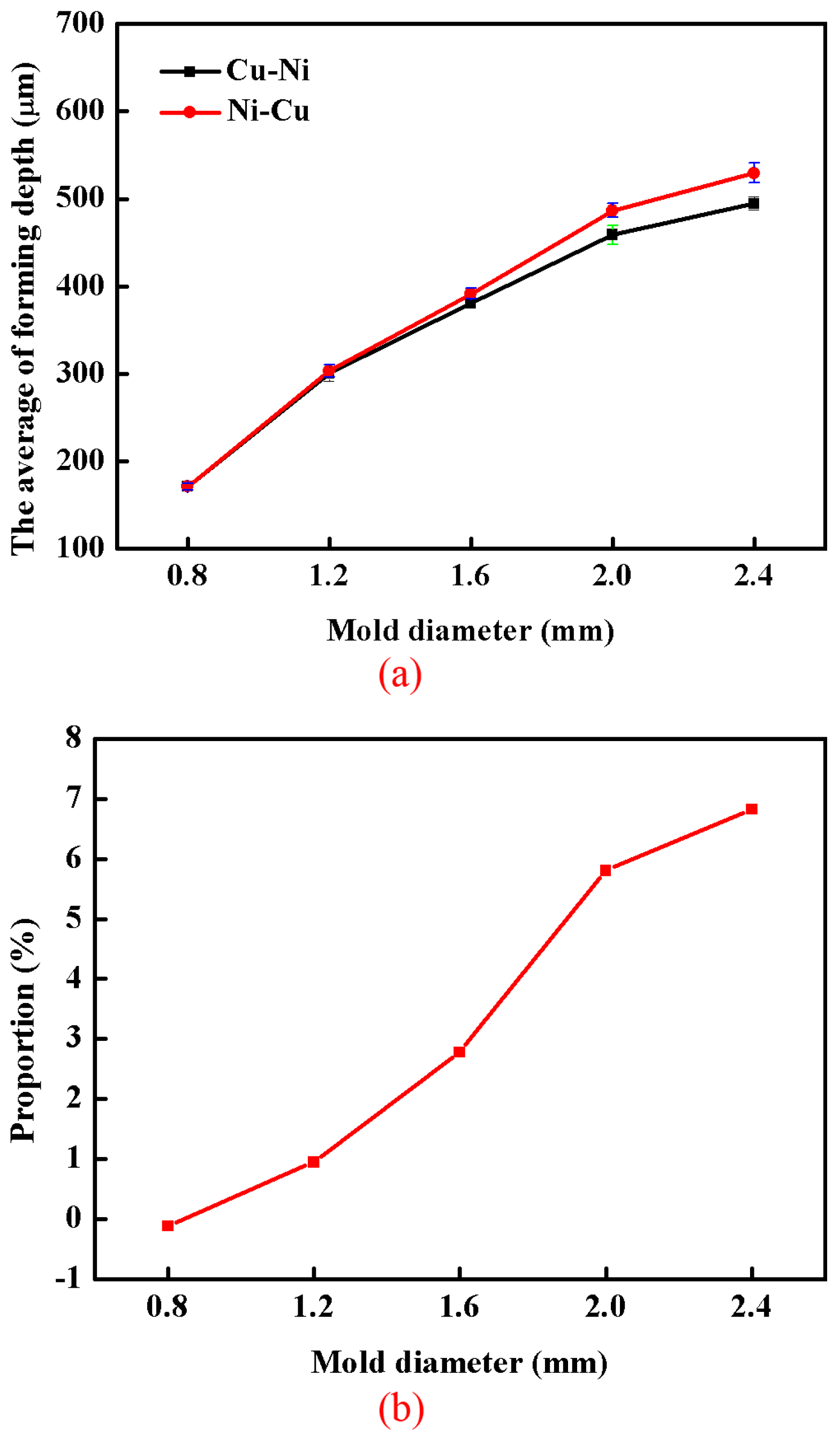

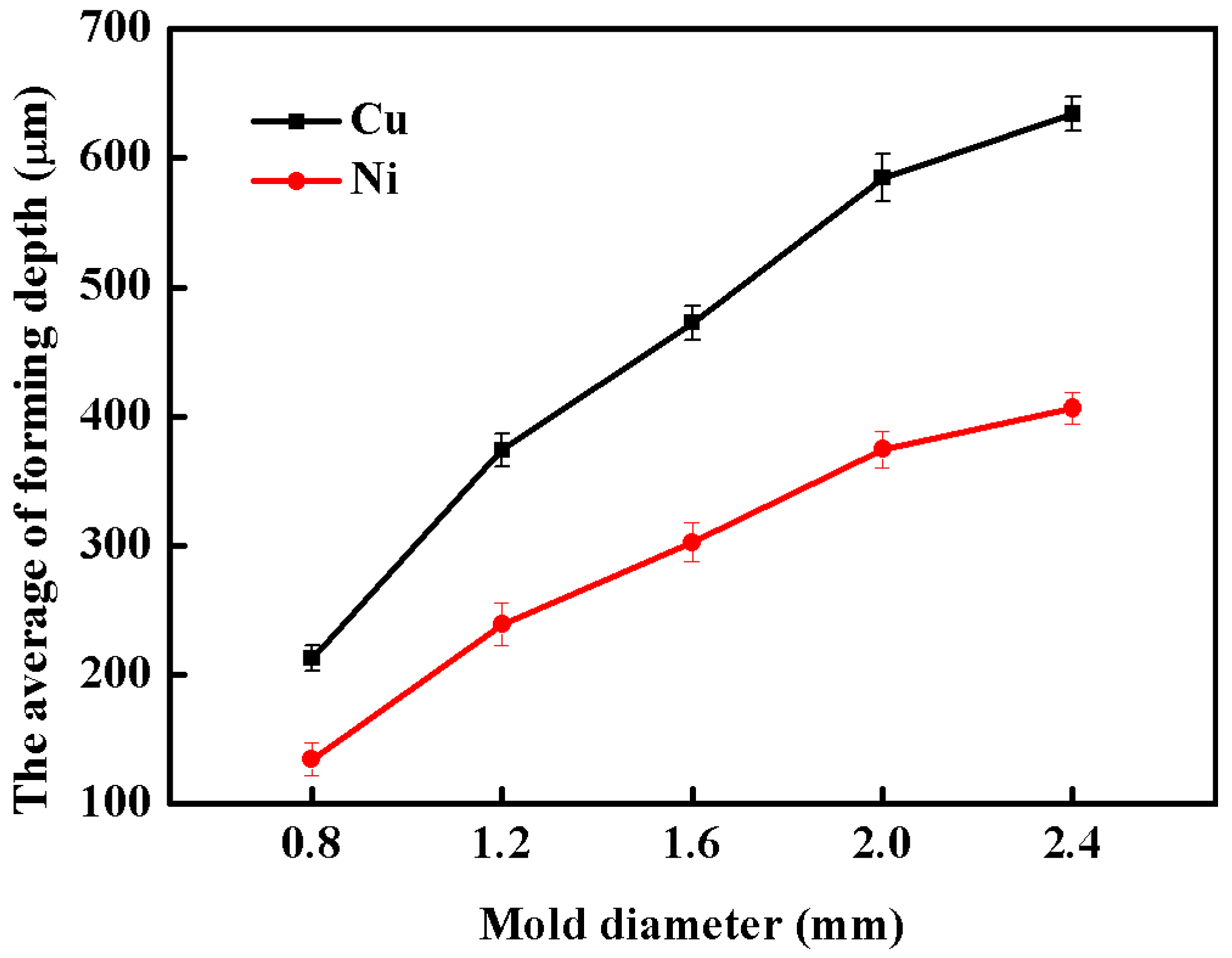

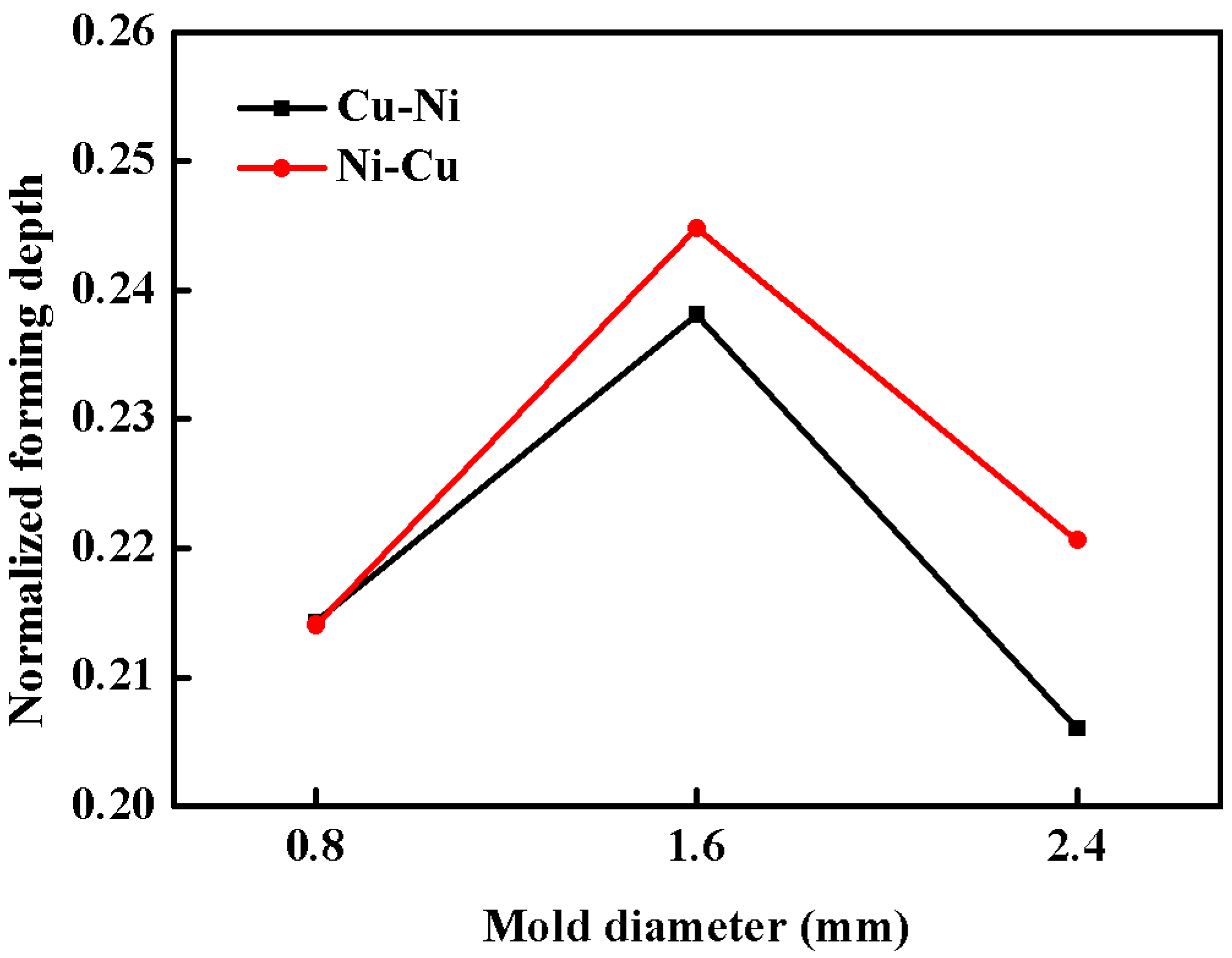

3.1. Feature Size Effect on Forming Depth

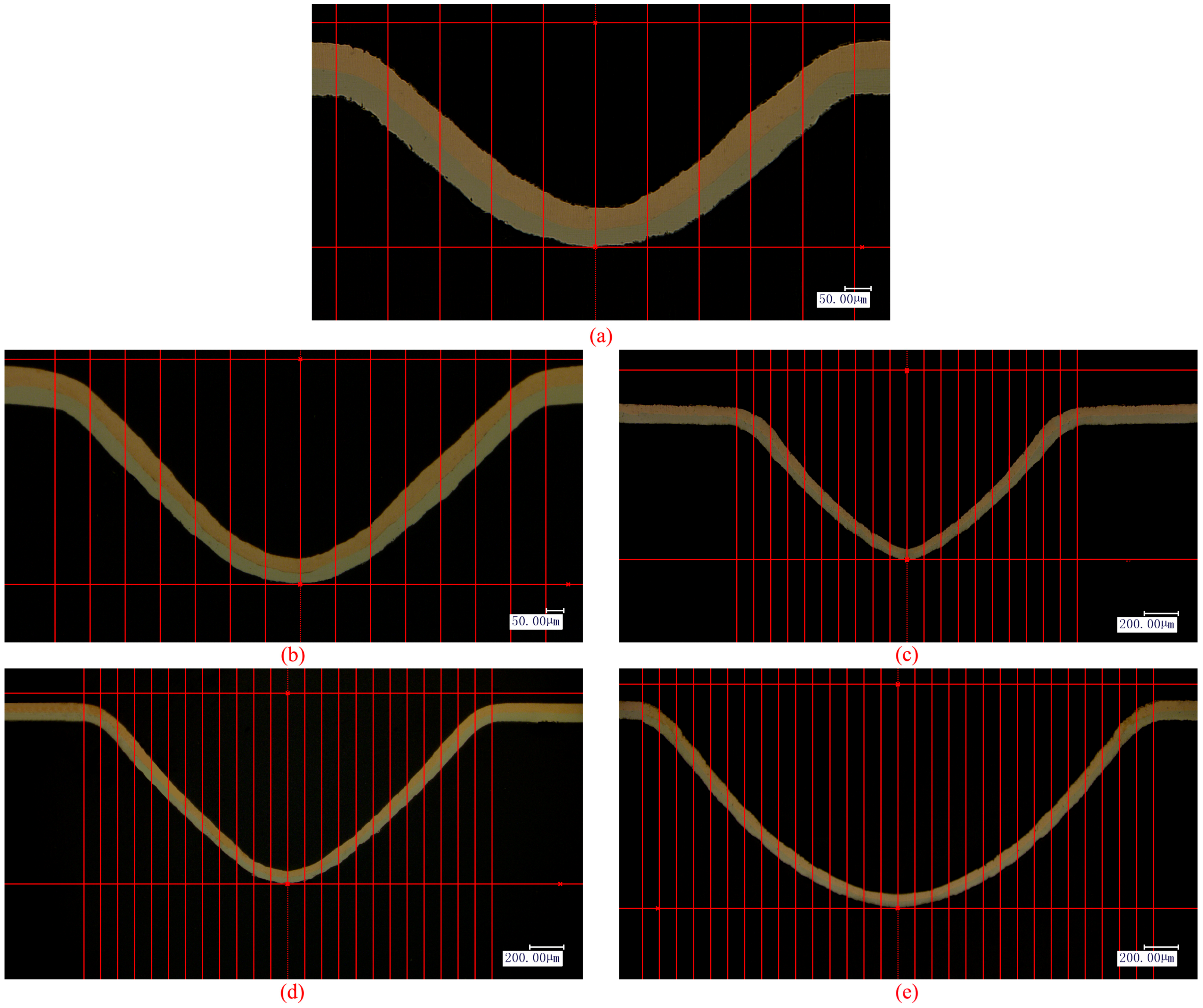

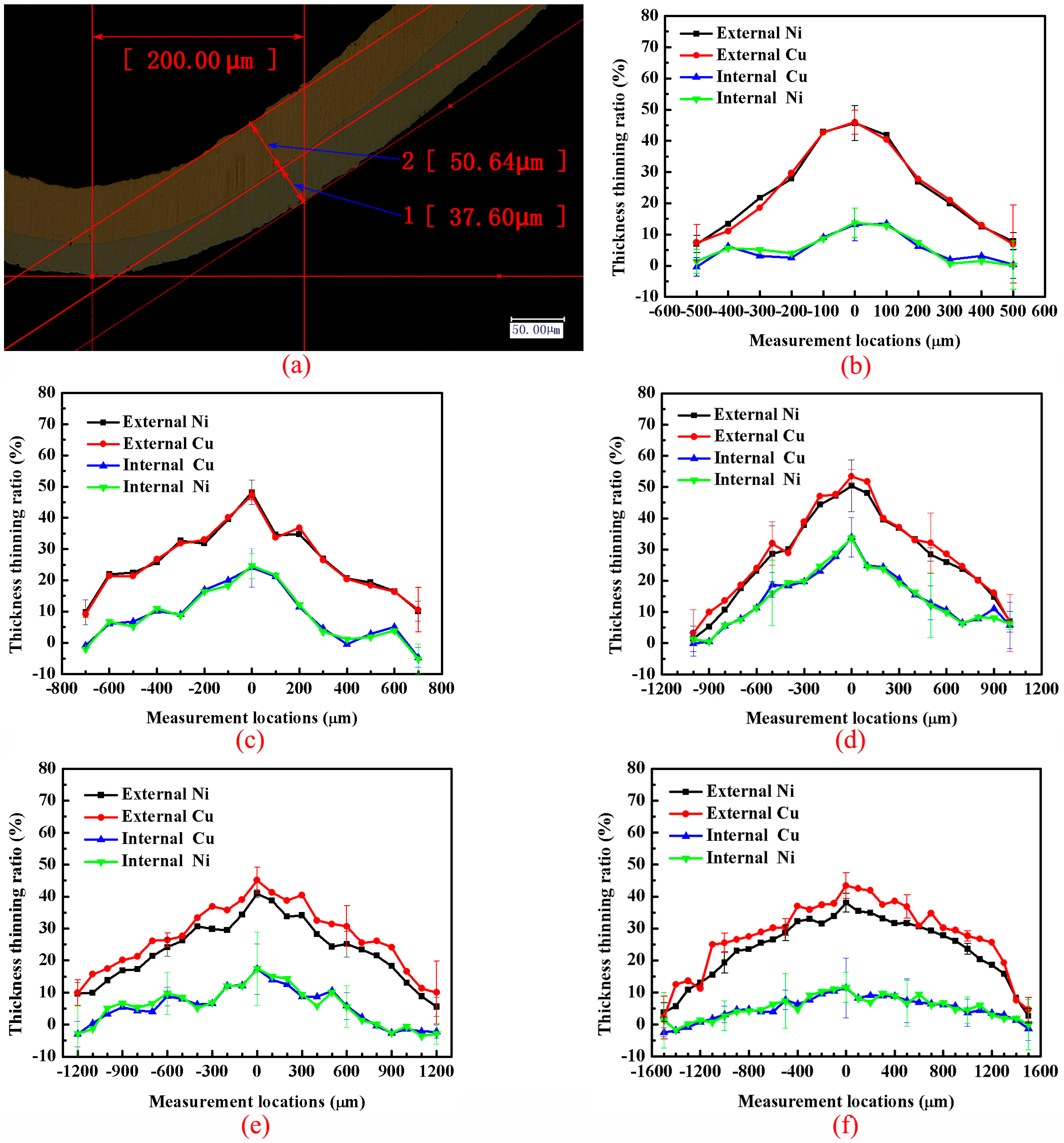

3.2. Feature Size Effect on Thickness Thinning

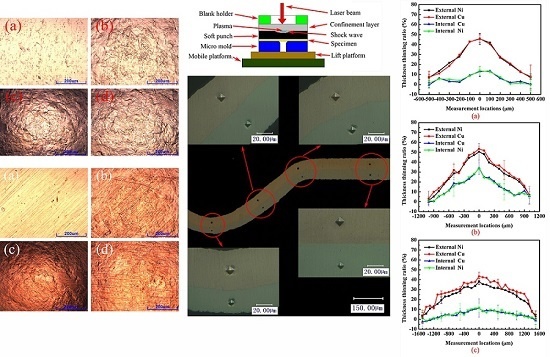

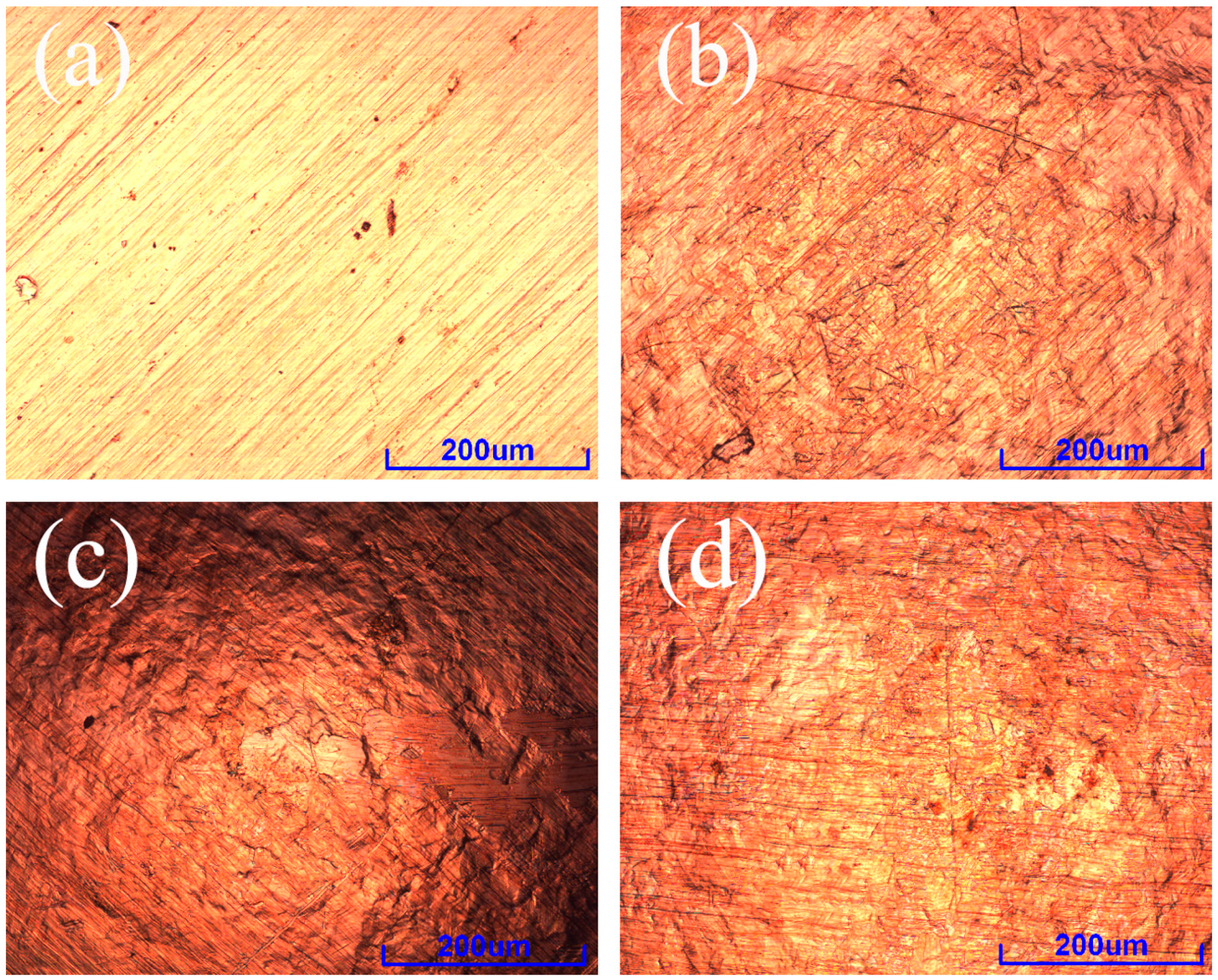

3.3. Feature Size Effect on Surface Quality

3.4. Feature Size Effect on Micro-Hardness Distribution

4. Conclusions

- (1)

- With feature size increasing, forming depth increased. Meanwhile, with feature size increasing, the thickness thinning ratio and surface roughness first increased then decreased.

- (2)

- The difference degree of forming depth and surface roughness between the two different layer stacking sequences increased with increasing feature size. The forming depth and surface roughness of Ni-Cu formed components were larger than Cu-Ni.

- (3)

- The thickness thinning ratio of the external layer was much larger than the internal layer. As feature size increased, the effect of layer stacking sequence on the thickness thinning behavior became increasingly obvious. The difference degree of thickness thinning ratio of the external layer between Cu-Ni and Ni-Cu increased with increasing feature size, and the thickness thinning ratio of the external layer was larger when copper was set as the external layer rather than nickel. The variation law between the thickness thinning ratio of the entire sheet and the feature size was the same as the external layer.

- (4)

- The distribution of micro-hardness was similar to thickness thinning, but it seemed that the difference degree of micro-hardness between two different layer stacking sequences was not considerably influenced by feature size.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vollertsen, F.; Biermann, D.; Hansen, H.N.; Jawahir, I.S.; Kuzman, K. Size effects in manufacturing of metallic components. CIRP Ann. Manuf. Technol. 2009, 58, 566–587. [Google Scholar] [CrossRef]

- Gau, J.T.; Principe, C.; Wang, J. An experimental study on size effects on flow stress and formability of aluminm and brass for microforming. J. Mater. Process. Technol. 2007, 184, 42–46. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W. Experimental and simulation based study on micro-scaled sheet metal deformation behavior in microembossing process. Mater. Sci. Eng. A 2012, 556, 60–67. [Google Scholar] [CrossRef]

- Hu, Y.X.; Li, K.M.; Qi, C.J.; Yao, Z.Q.; Grandhi, R.V. Size effect on indentation depth of oxygen-free high purity copper induced by laser shock processing. Trans. Nonferr. Met. Soc. China 2012, 22, 573–578. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, X.C.; Shan, D.B.; Guo, B.; Langdon, T.G. Effect of grain size and specimen dimensions on micro-forming of high purity aluminum. Mater. Sci. Eng. A 2015, 646, 207–217. [Google Scholar] [CrossRef]

- Wang, X.; Qian, Q.; Shen, Z.B.; Li, J.W.; Zhang, H.F.; Liu, H.X. Numerical simulation of flexible micro-bending processes with consideration of grain structure. Comput. Mater. Sci. 2015, 110, 134–143. [Google Scholar] [CrossRef]

- Chen, F.K.; Tsai, J.W. A study of size effect in micro-forming with micro-hardness tests. J. Mater. Process. Technol. 2006, 177, 146–149. [Google Scholar] [CrossRef]

- Gao, H.; Cheng, G.J. 3D microscale laser dynamic forming: Multiscale modeling and experimental validation. J. Appl. Phys. 2011, 109, 103511. [Google Scholar] [CrossRef]

- Parasiz, S.A.; Kinsey, B.L.; Mahayatsanun, N.; Cao, J. Effect of specimen size andgrain size on deformation in microextrusion. J. Manuf. Process. 2011, 13, 153–159. [Google Scholar] [CrossRef]

- Parasiz, S.A.; VanBenthysen, R.; Kinsey, B.L. Deformation size effects due to specimen and grain size in microbending. J. Manuf. Sci. Eng. 2010, 132, 011018. [Google Scholar] [CrossRef]

- Molotnikov, A.; Lapovok, R.; Gu, C.F.; Davies, C.H.J.; Estrin, Y. Size effects in micro cup drawing. Mater. Sci. Eng. A 2012, 550, 312–319. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Y.J.; Shen, Z.B.; Gu, Y.X.; Zhang, D.; Qiu, T.B.; Liu, H.X. Size effects on formability in microscale laser dynamic forming of copper sheet. J. Mater. Process. Technol. 2015, 220, 173–183. [Google Scholar] [CrossRef]

- Wang, C.J.; Shan, D.B.; Zhou, J.; Guo, B.; Sun, L.N. Size effects of the cavity dimension on the microforming ability during coining process. J. Mater. Process. Technol. 2007, 187–188, 256–259. [Google Scholar] [CrossRef]

- Mahabunphachai, S.; Koç, M. Investigation of size effects on material behavior of thin sheet metals using hydraulic bulge testing at micro/meso-scales. Int. J. Mach. Tools Manuf. 2008, 48, 1014–1029. [Google Scholar] [CrossRef]

- Justinger, H.; Hirt, G. Estimation of grain size and grain orientation influence in microforming processes by Taylor factor considerations. J. Mater. Process. Technol. 2009, 209, 2111–2121. [Google Scholar] [CrossRef]

- Parasiz, S.A.; Kinsey, B.; Krishnan, N.; Cao, J.; Li, M. Investigation of deformation size effects during microextrusion. J. Manuf. Sci. Eng. 2007, 129, 690–697. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.; Shan, D.B.; Li, B.S. Study of size effects on deformation behavior and formability in micro metal forming of Ti foil. In Proceedings of the ASME 2012 International Manufacturing Science and Engineering Conference (MSEC), Note Dame, IN, USA, 4–8 June 2012; pp. 263–268. [Google Scholar]

- Fu, M.W.; Yang, B.; Chan, W.L. Experimental and simulation studies of micro blanking and deep drawing compound process using copper sheet. J. Mater. Process. Technol. 2013, 213, 101–110. [Google Scholar] [CrossRef]

- Liu, H.X.; Sun, X.Q.; Shen, Z.B.; Li, C.; Sha, C.F.; Li, L.Y.; Gao, S.; Ma, Y.J.; Wang, X. The size effect on deformation behavior in microscale laser shock flexible drawing. Opt. Laser Technol. 2016, 86, 93–102. [Google Scholar] [CrossRef]

- He, P.; Yue, X.; Zhang, J.H. Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mater. Sci. Eng. A 2008, 486, 171–176. [Google Scholar] [CrossRef]

- Lee, J.E.; Bae, D.H.; Chung, W.S.; Kim, K.H.; Lee, J.H.; Cho, Y.R. Effects of annealing on the mechanical and interface properties of stainless steel/aluminum/copper clad-metal sheets. J. Mater. Process. Technol. 2007, 187–188, 546–549. [Google Scholar] [CrossRef]

- Dehghani, F.; Salimi, M. Analytical and experimental analysis of the formability of copper-stainless-steel 304L clad metal sheets in deep drawing. Int. J. Adv. Manuf. Technol. 2016, 82, 163–177. [Google Scholar] [CrossRef]

- Syn, C.K.; Lesuer, D.R.; Sherby, O.D. Enhancing tensile ductility of a particulate-reinforced aluminum metal matrix composite by lamination with Mg-9%Li alloy. Mater. Sci. Eng. A 1996, 206, 201–207. [Google Scholar] [CrossRef]

- Manesh, D.H.; Shahabi, H.S. Effective parameters on bonding strength of roll bonded Al/St/Al multilayer. J. Alloys Compd. 2009, 476, 292–299. [Google Scholar] [CrossRef]

- Oya, T.; Tiesler, N.; Kawanishi, S.; Yanagimoto, J.; Koseki, T. Experimental and numerical analysis of multilayered steel sheets upon bending. J. Mater. Process. Technol. 2010, 210, 1926–1933. [Google Scholar] [CrossRef]

- Tsukamoto, H. Impact compressive behavior of deep-drawn cups consisting of aluminum/duralumin multi-layered graded structures. Mater. Sci. Eng. B 2015, 198, 25–34. [Google Scholar] [CrossRef]

- Sun, T.; Liang, J.; Guo, X.; Ren, M.D.; Wang, L.Z. Optical Measurement of Forming Limit and Formability of Cu/Al Clad Metals. J. Mater. Eng. Perform. 2015, 24, 1426–1433. [Google Scholar] [CrossRef]

- Karajibani, E.; Fazli, A.; Hashemi, R. Numerical and experimental study of formability in deep drawing of two-layer metallic sheets. Int. J. Adv. Manuf. Technol. 2015, 80, 113–121. [Google Scholar] [CrossRef]

- Li, C.; Chi, C.Z.; Lin, P.; Zhang, H.; Liang, W. Deformation behavior and interface microstructure evolution of Al/Mg/Al multilayer composite sheets during deep drawing. Mater. Des. 2015, 77, 15–24. [Google Scholar] [CrossRef]

- Afshin, E.; Kadkhodayan, M. An experimental investigation into the warm deep-drawing process on laminated sheets under various grain sizes. Mater. Des. 2015, 87, 25–35. [Google Scholar] [CrossRef]

- Kadkhodayan, M.; Afshin, E. Thinning behavior of laminated sheets metal in warm deep-drawing process under various grain sizes. In Proceedings of the 12th International Conference on Numerical Methods in Industrial Forming Processes, Troyes, France, 4–7 July 2016; Volume 80, p. 15001. [Google Scholar]

- Eslami, A.H.; Zebarjad, S.M.; Moshksar, M.M. Study on mechanical and magnetic properties of Cu/Ni multilayer composite fabricated by accumulative roll bonding process. Mater. Sci. Technol. 2013, 29, 1000–1005. [Google Scholar] [CrossRef]

- Bae, G.; Xiong, Y.; Kumar, S.; Kang, K.; Lee, C. General aspects of interface bonding in kinetic sprayed coatings. Acta Mater. 2008, 56, 4858–4868. [Google Scholar] [CrossRef]

- Urbikain, G.; Perez, J.M.; López de Lacalle, L.N.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1–14. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, Y.K.; Cai, L. Laser shock forming on coated metal sheets characterized by ultrahigh-strain-rate plastic deformation. J. Appl. Phys. 2002, 91, 5501–5503. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; López de Lacalle, L.N. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Wang, X.; Du, D.Z.; Zhang, H.; Shen, Z.B.; Liu, H.; Zhou, J.Z.; Liu, H.X.; Hu, Y.; Gu, C.X. Investigation of microscale laser dynamic flexible forming process—Simulation and experiments. Int. J. Mach. Tools Manuf. 2013, 67, 8–17. [Google Scholar] [CrossRef]

- Bagherzadeh, S.; Mirnia, M.J.; Dariani, M.B. Numerical and experimental investigations of hydro-mechanical deep drawing process of laminated aluminum/steel sheets. J. Manuf. Process. 2015, 18, 131–140. [Google Scholar] [CrossRef]

- Atrian, A.; Fereshteh-Saniee, F. Deep drawing process of steel/brass laminated sheets. Composites Part B 2013, 47, 75–81. [Google Scholar] [CrossRef]

- Morovvati, M.R.; Mollaei-Dariani, B.; Asadian-Ardakani, M.H. A theoretical, numerical, and experimental investigation of plastic wrinkling of circular two-layer sheet metal in the deep drawing. J. Mater. Process. Technol. 2010, 210, 1738–1747. [Google Scholar] [CrossRef]

- Yilamu, K.; Hino, R.; Hamasaki, H.; Yoshida, F. Air bending and springback of stainless steel clad aluminum sheet. J. Mater. Process. Technol. 2010, 210, 272–278. [Google Scholar] [CrossRef]

- Mori, T.; Kurimoto, S. Press-formability of stainless steel and aluminum clad sheet. J. Mater. Process. Technol. 1996, 56, 242–253. [Google Scholar] [CrossRef]

- Liu, H.X.; Hu, Y.; Wang, X.; Shen, Z.B.; Li, P.; Gu, C.X.; Liu, H.; Du, D.Z.; Guo, C. Grain refinement progress of pure titanium during laser shock forming (LSF) and mechanical property characterizations with nanoindentation. Mater. Sci. Eng. A 2013, 564, 13–21. [Google Scholar] [CrossRef]

| Material | Yield Strength (MPa) | Young’s Modulus (GPa) | Poison’s Ratio | Strain Hardening Exponent |

|---|---|---|---|---|

| Copper | 90.0 | 124 | 0.34 | 0.310 |

| Nickel | 163.0 | 207 | 0.31 | 0.330 |

| Parameters | Wave Length | Pulse Width | Single Pulse Energy | Spot Diameter | Energy Stability |

|---|---|---|---|---|---|

| Value | 1064 nm | 8 ns | 80–1800 mJ | 3 mm | <±1% |

| Mold 1 | Mold 2 | Mold 3 | Mold 4 | Mold 5 | |

|---|---|---|---|---|---|

| Diameter (mm) | 0.8 | 1.2 | 1.6 | 2.0 | 2.4 |

| Fillet radius (mm) | 0.10 | 0.15 | 0.20 | 0.25 | 0.30 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, W.; Gau, J.-T.; Shen, Z.; Ma, Y.; Zhang, G.; Wang, X. Feature Size Effect on Formability of Multilayer Metal Composite Sheets under Microscale Laser Flexible Forming. Metals 2017, 7, 275. https://doi.org/10.3390/met7070275

Liu H, Zhang W, Gau J-T, Shen Z, Ma Y, Zhang G, Wang X. Feature Size Effect on Formability of Multilayer Metal Composite Sheets under Microscale Laser Flexible Forming. Metals. 2017; 7(7):275. https://doi.org/10.3390/met7070275

Chicago/Turabian StyleLiu, Huixia, Wenhao Zhang, Jenn-Terng Gau, Zongbao Shen, Youjuan Ma, Guoce Zhang, and Xiao Wang. 2017. "Feature Size Effect on Formability of Multilayer Metal Composite Sheets under Microscale Laser Flexible Forming" Metals 7, no. 7: 275. https://doi.org/10.3390/met7070275