Robotic Nd:YAG Fiber Laser Welding of Ti-6Al-4V Alloy

Abstract

:1. Introduction

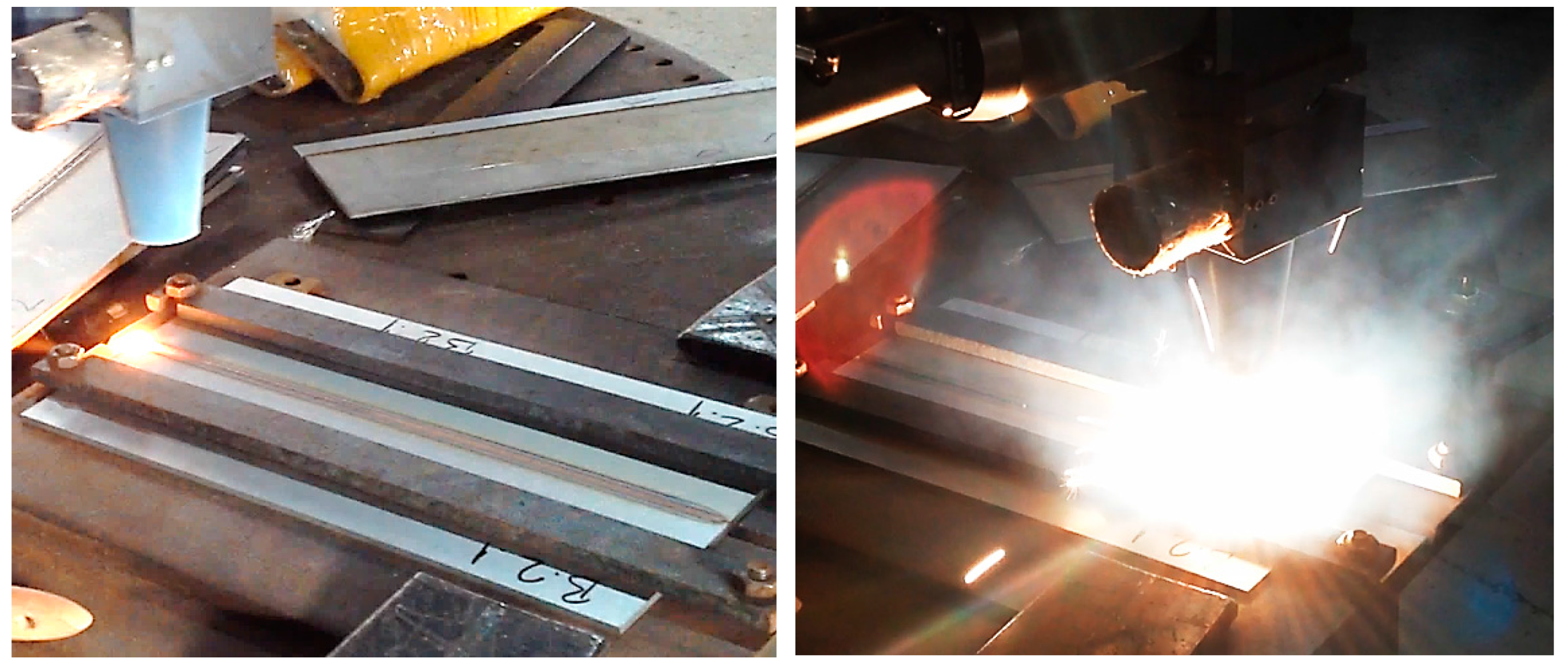

2. Experimental Studies

2.1. Material and Welding Process

2.2. Mechanical Tests and Characterization of Microstructure

3. Results and Discussion

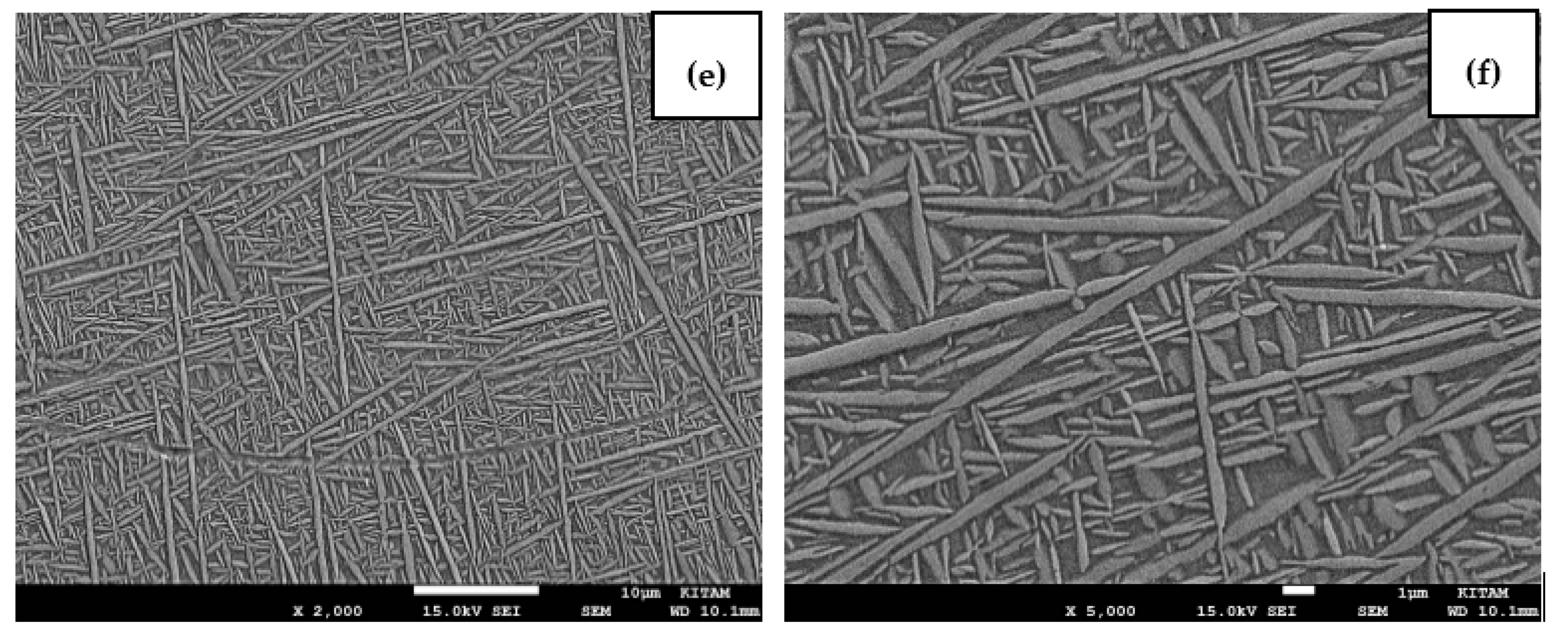

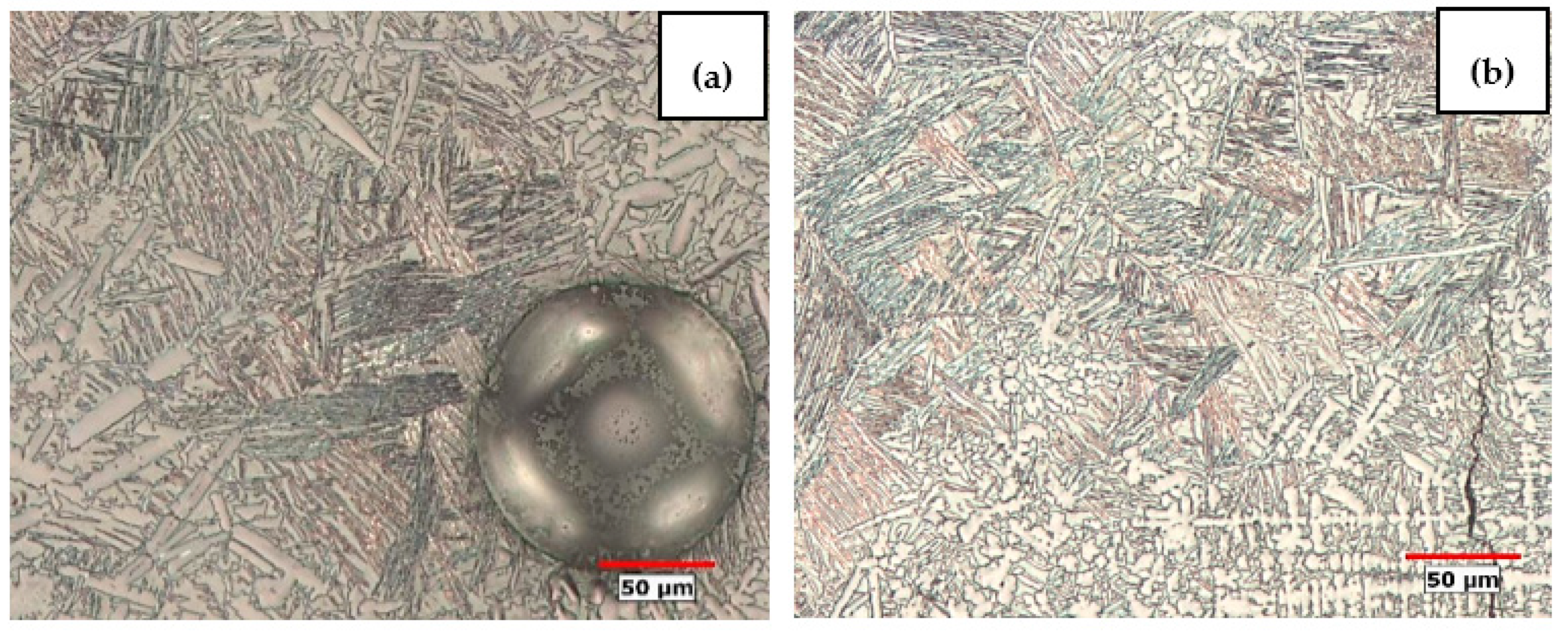

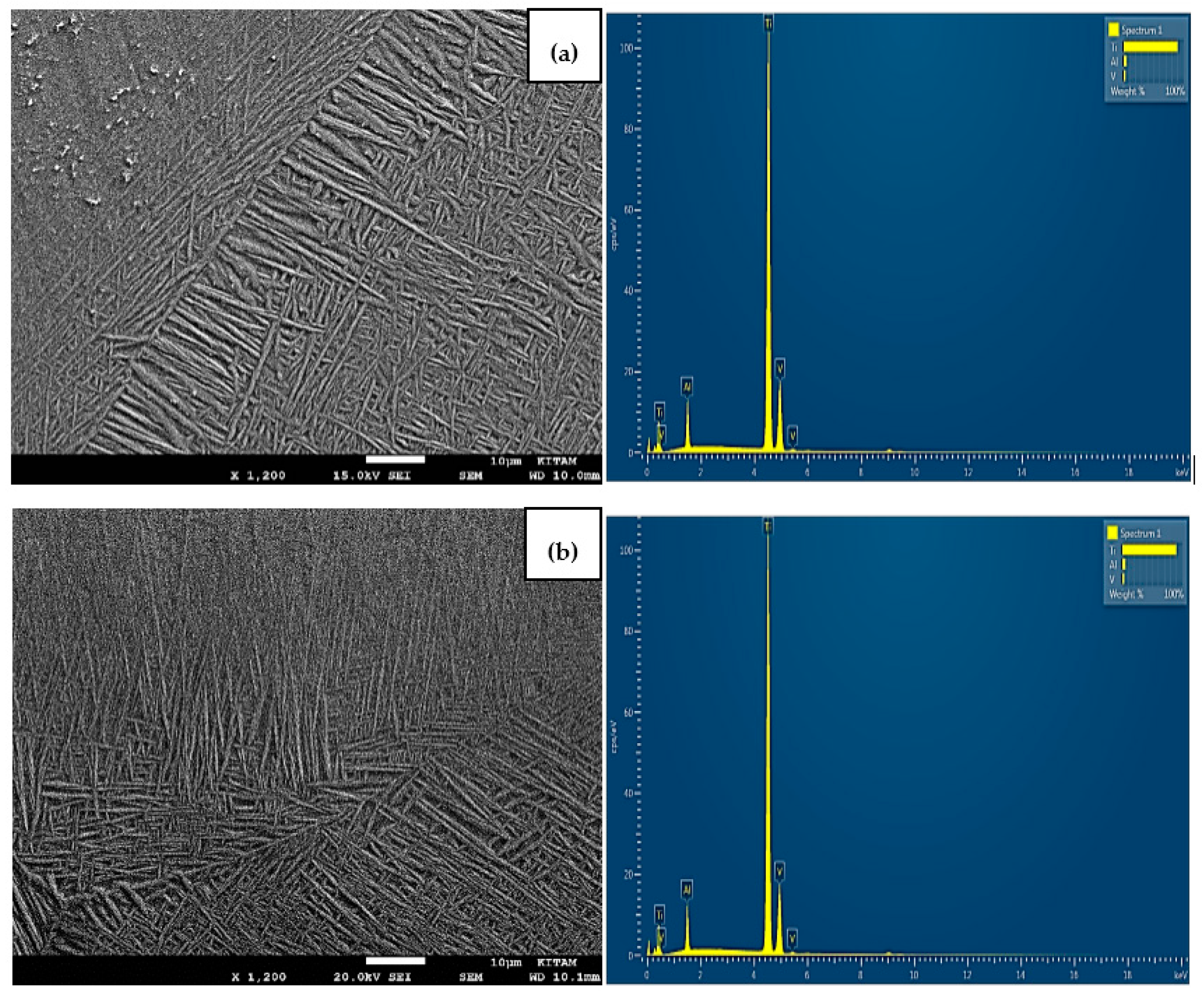

3.1. Macro and Microstructural Examinations

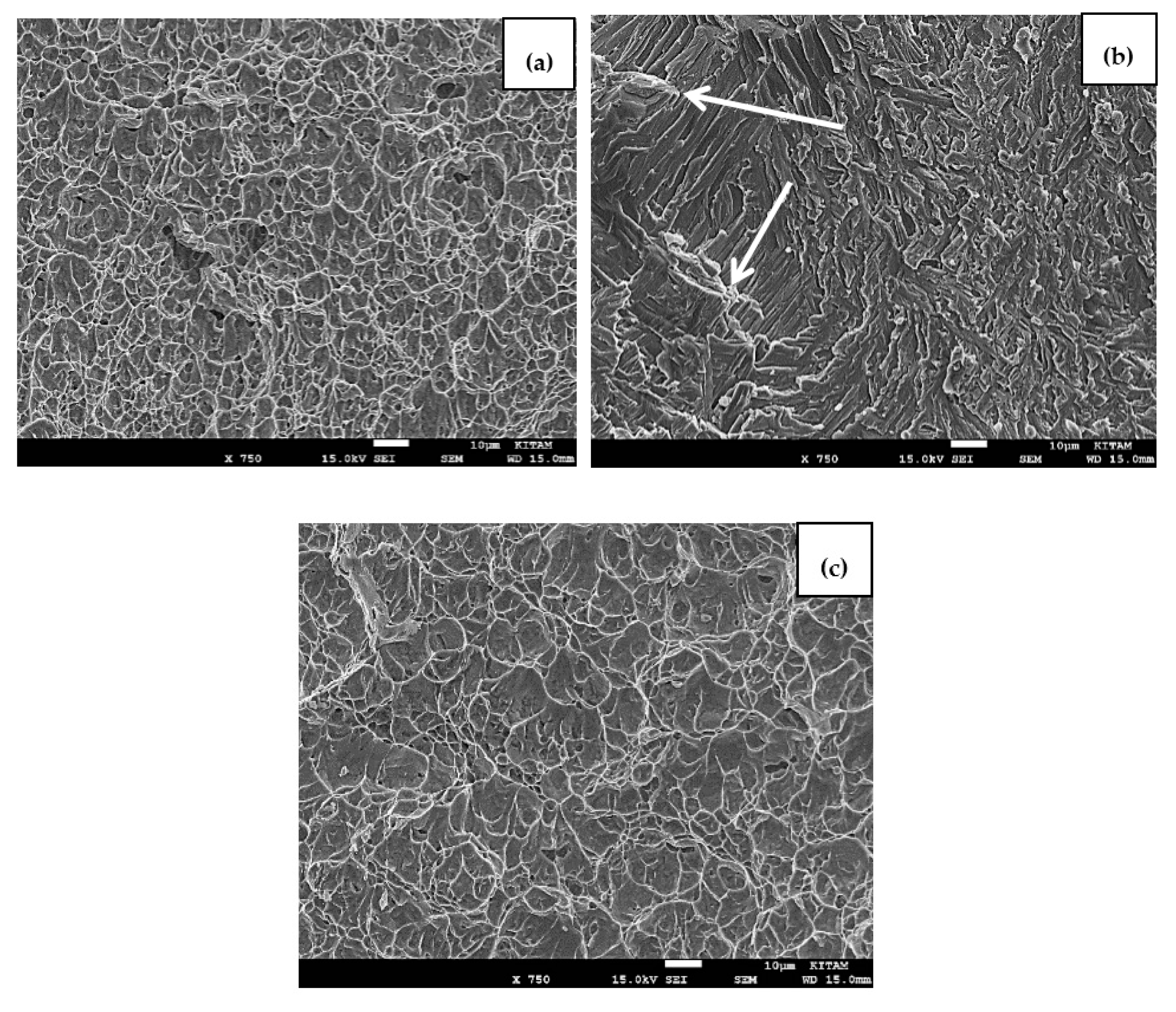

3.2. Tensile Test

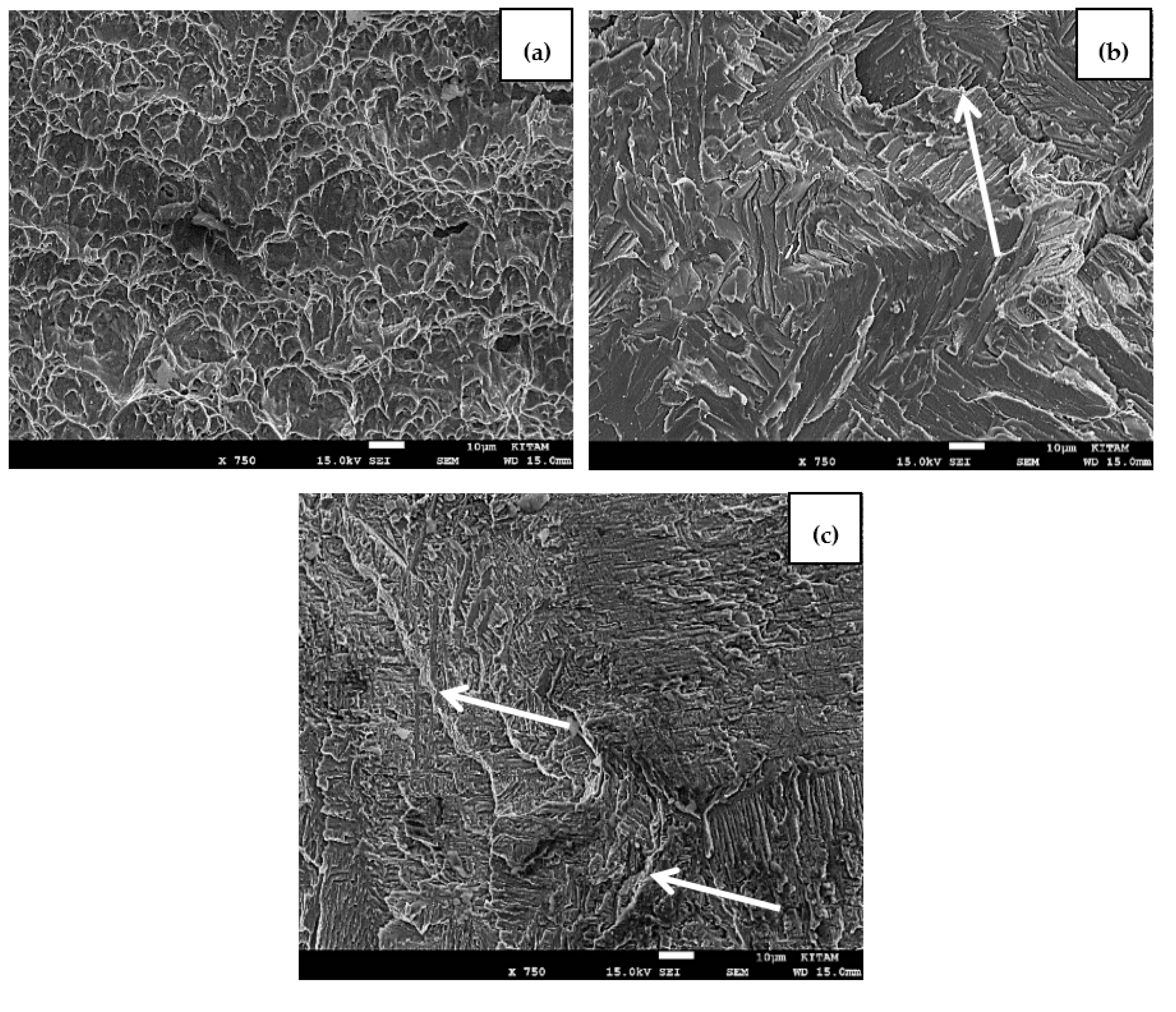

3.3. Charpy V-Notch Impact Test

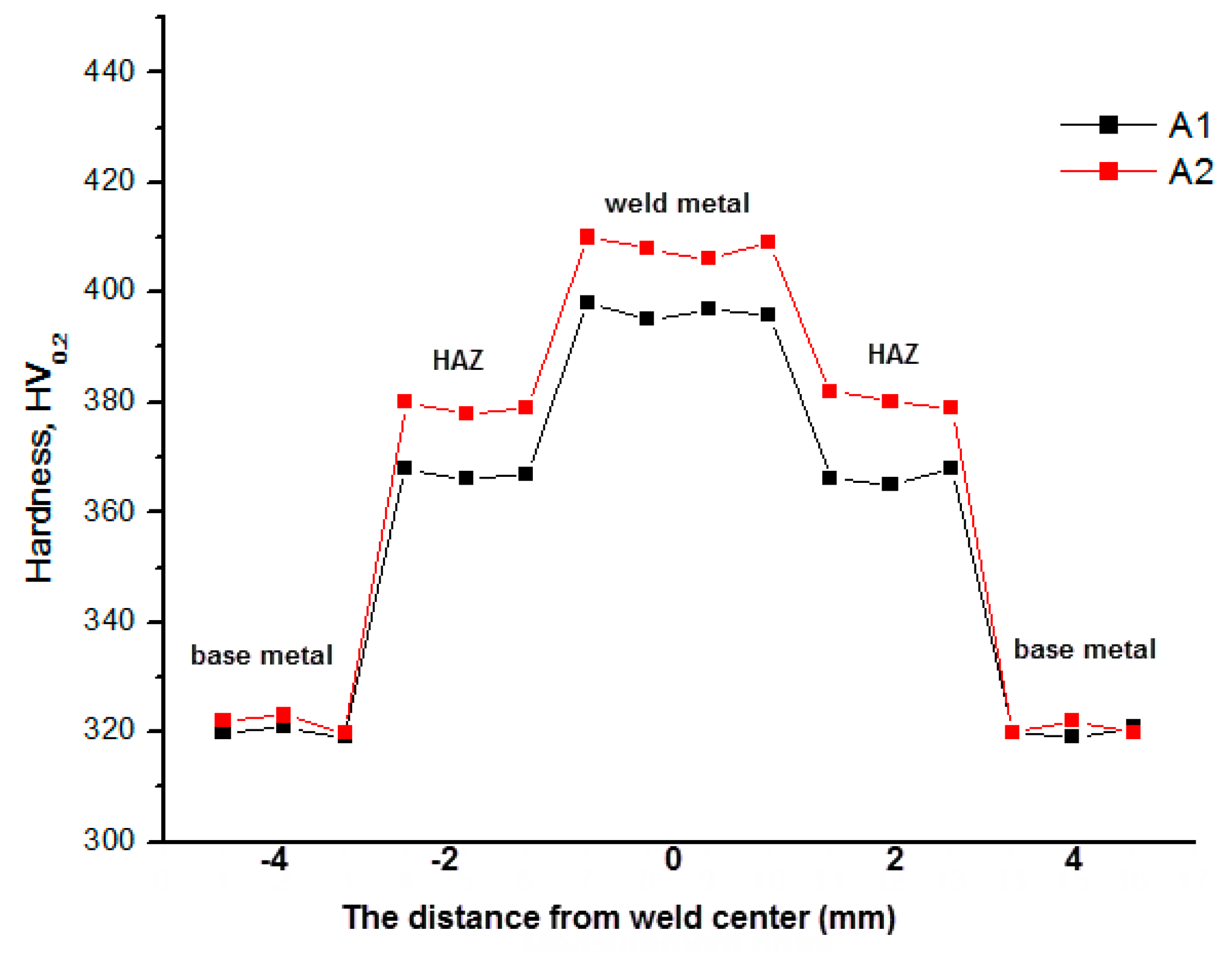

3.4. Microhardness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Donachie, M.J. Titanium: A Technical Guide; ASM International: Geauga County, OH, USA, 2000. [Google Scholar]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Cao, X.; Jahazi, M. Effect of welding speed on butt joint quality of Ti–6Al–4V alloy welded using a high-power Nd:YAG laser. Opt. Lasers Eng. 2009, 47, 1231–1241. [Google Scholar] [CrossRef]

- Yıldız, A.; Kaya, Y.; Kahraman, N. Joint properties and microstructure of diffusion-bonded grade 2 titanium to AISI 430 ferritic stainless steel using pure Ni interlayer. Int. J. Adv. Manuf. Technol. 2016, 86, 1287–1298. [Google Scholar] [CrossRef]

- Akman, E.; Demir, A.; Canel, T.; Sınmazçelik, T. Laser welding of Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2009, 209, 3705–3713. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Jing, L.; Zhang, J.X. A comparative study of pulsed Nd:YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 559, 14–21. [Google Scholar] [CrossRef]

- Balasubramanian, T.S.; Balakrishnan, M.; Balasubramanian, V.; Manickam, M.M. Influence of welding processes on microstructure, tensile and impact properties of Ti-6Al-4V alloy joints. Trans. Nonferr. Met. Soc. China 2011, 6, 1253–1262. [Google Scholar] [CrossRef]

- Murthy, K.K.; Sundaresan, S. Phase transformations in a welded near-α titanium alloy as a function of weld cooling rate and post-weld heat treatment conditions. J. Mater. Sci. 1998, 33, 817–826. [Google Scholar] [CrossRef]

- Köse, C.; Kaçar, R. The effect of preheat & post weld heat treatment on the laser weldability of AISI 420 martensitic stainless steel. Mater. Des. 2014, 64, 221–226. [Google Scholar]

- Köse, C. Weldability of 5754 aluminum alloy using a pulsed Nd:YAG micro scale laser. Mater. Test 2016, 58, 963–969. [Google Scholar] [CrossRef]

- Köse, C. An investigation of the surface characterization of laser surface remelted and laser beam welded AISI 316L stainless steel. Int. J. Electrochem. Sci. 2016, 11, 3542–3554. [Google Scholar] [CrossRef]

- Köse, C.; Kaçar, R. In vitro bioactivity and corrosion properties of laser beam welded medical grade AISI 316L stainless steel in simulated body fluid. Int. J. Electrochem. Sci. 2016, 11, 2762–2777. [Google Scholar] [CrossRef]

- Li, C.; Li, B.; Wu, Z.; Qui, X.; Ye, B.; Wang, A. Stitch welding of Ti–6Al–4V titanium alloy by fiber laser. Trans. Nonferr. Met. Soc. China 2017, 27, 91–101. [Google Scholar] [CrossRef]

- Caiazzo, F.; Cardaropoli, F.; Alfieri, V.; Sergi, V.; Argenio, P.; Barbieri, G. Disk-laser welding of Ti-6Al-4V titanium alloy plates in T-joint configuration. Procedia Eng. 2017, 183, 219–226. [Google Scholar] [CrossRef]

- Chang, B.; Yuan, Z.; Pu, H.; Li, H.; Cheng, H.; Du, D.; Shan, J. A comparative study on the laser welding of Ti6Al4V alloy sheets in flat and horizontal positions. Appl. Sci. 2017, 7, 376. [Google Scholar] [CrossRef]

- Taskin, M.; Caligulu, U.; Turkmen, M. X-ray tests of AISI 430 and 304 stainless steels and AISI 1010 low carbon steel welded by CO2 laser beam welding. Mater. Test. 2011, 53, 741–747. [Google Scholar] [CrossRef]

- Quintino, L.; Costa, A.; Miranda, R.; Yapp, D.; Kumar, V.; Kong, C.J. Welding with high power fiber lasers—A preliminary study. Mater. Des. 2007, 28, 1231–1237. [Google Scholar] [CrossRef]

- Fu, P.; Mao, Z.; Zuo, C.; Wang, Y.; Wang, C. Microstructures and fatigue properties of electron beam welds with beam oscillation for heavy section TC4-DT alloy. Chin. J. Aeronaut. 2014, 4, 1015–1021. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Campanelli, S.L. Ytterbium fiber laser welding of Ti6Al4V alloy. J. Manuf. Process 2015, 20, 250–256. [Google Scholar] [CrossRef]

- Wang, S.H.; Wei, M.D.; Tsay, L.W. Tensile properties of LBW welds in Ti–6Al–4V alloy at evaluated temperatures below 450 °C. Mater. Lett. 2003, 57, 1815–1823. [Google Scholar] [CrossRef]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α+β titanium alloys. Mater. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X. Investigation on the microstructure and mechanical properties of Ti–6Al–4V alloy joints with electron beam welding. Mater. Des. 2012, 36, 663–670. [Google Scholar] [CrossRef]

- Kabir, A.S.H.; Cao, X.; Medraj, M.; Wanjara, P.; Cuddy, J.; Birur, A. Effect of welding speed and defocusing distance on the quality of laser welded Ti-6Al-4V. In Proceedings of the Materials Science and Technology (MS&T) Conference, Houston, TX, USA, 17–21 October 2010; pp. 2787–2797. [Google Scholar]

- Sundaresan, S.; Ram, G.D.J.; Reddy, G.M. Microstructural refinement of weld fusion zones in a–b titanium alloys using pulsed current welding. Mater. Sci. Eng. A 1999, 262, 88–100. [Google Scholar] [CrossRef]

- Li, X.; Xie, J.; Zhou, Y. Effects of oxygen contamination in the argon shielding gas in laser welding of commercially pure titanium thin sheet. J. Mater. Sci. 2005, 40, 3437–3443. [Google Scholar]

- Barreda, J.L.; Santamaria, F.; Azpiroz, X.; Irisarri, A.M.; Varona, J.M. Electron beam welded high thickness Ti6Al4V plates using filler metal of similar and different composition to the base plate. Vacuum 2001, 62, 143–150. [Google Scholar] [CrossRef]

- Yunk, W.K.C.; Ralph, B.; Lee, W.B.; Fenn, R. An investigation into welding parameters affecting the tensile properties of titanium welds. J. Mater. Process. Technol. 1997, 63, 759–764. [Google Scholar] [CrossRef]

- Tsay, L.W.; Tsay, C.Y. The effect of microstructures on the fatigue crack growth in Ti-6AI-4V laser welds. Int. J. Fatigue 1997, 19, 713–720. [Google Scholar] [CrossRef]

- Mehdi, B.; Badji, R.; Ji, V.; Allili, B.; Deschaux-Beaume, F.; Soulie, F. Microstructure and residual stresses in Ti-6Al-4V alloy pulsed and unpulsed TIG welds. J. Mater. Process. Technol. 2016, 231, 441–448. [Google Scholar] [CrossRef]

- Kabir, A.S.H.; Cao, X.; Gholipour, J.; Wanjara, P.; Cuddy, J.; Birur, A.; Medraj, M. Effect of postweld heat treatment on microstructure, hardness, and tensile properties of laser-welded Ti-6Al-4V. Metall. Mater. Trans. A 2012, 43, 4171–4184. [Google Scholar] [CrossRef]

- Caiazzo, F.; Curcio, F.; Daurelio, G.; Minutolo, F.M.C. Ti6Al4V sheets lap and butt joints carried out by CO2 laser: Mechanical and morphological characterization. J. Mater. Process. Technol. 2004, 149, 546–552. [Google Scholar] [CrossRef]

| C% | Al | V | Fe | N | O | H | Ti |

|---|---|---|---|---|---|---|---|

| 0.010 | 6.02 | 4.14 | 0.098 | 0.007 | 0.12 | 0.0020 | Balance |

| Sample | Laser Power (W) | Travel Speed (mm/s) | Shielding Gas | Gas Pressure (bar) | Focal Length (mm) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|---|

| A1 | 1500 | 6 | He | 1 | 190 | 0.25 |

| A2 | 1500 | 9 | He | 1 | 190 | 0.16 |

| Sample | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Fracture Location |

|---|---|---|---|---|

| A | 1057 | 965 | 18.5 | - |

| A1 | 830 | 720 | 8.5 | HAZ |

| A2 | 840 | 724 | 8 | Weld metal |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Köse, C.; Karaca, E. Robotic Nd:YAG Fiber Laser Welding of Ti-6Al-4V Alloy. Metals 2017, 7, 221. https://doi.org/10.3390/met7060221

Köse C, Karaca E. Robotic Nd:YAG Fiber Laser Welding of Ti-6Al-4V Alloy. Metals. 2017; 7(6):221. https://doi.org/10.3390/met7060221

Chicago/Turabian StyleKöse, Ceyhun, and Engin Karaca. 2017. "Robotic Nd:YAG Fiber Laser Welding of Ti-6Al-4V Alloy" Metals 7, no. 6: 221. https://doi.org/10.3390/met7060221