A Non-Destructive Technique for the On-Line Quality Control of Green and Baked Anodes †

Abstract

:1. Introduction

2. Methodology

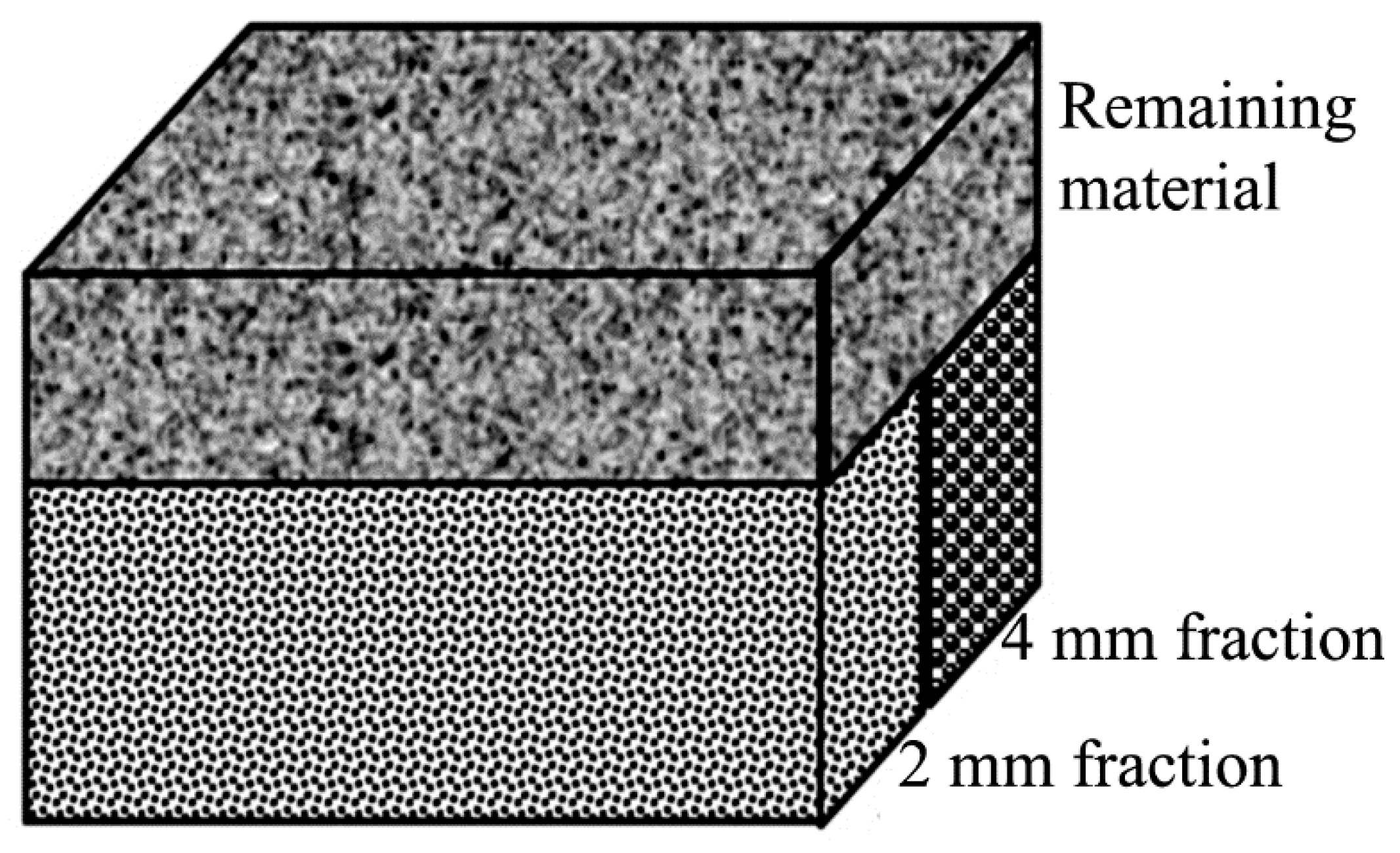

2.1. Fabrication of Anodes in the Laboratory

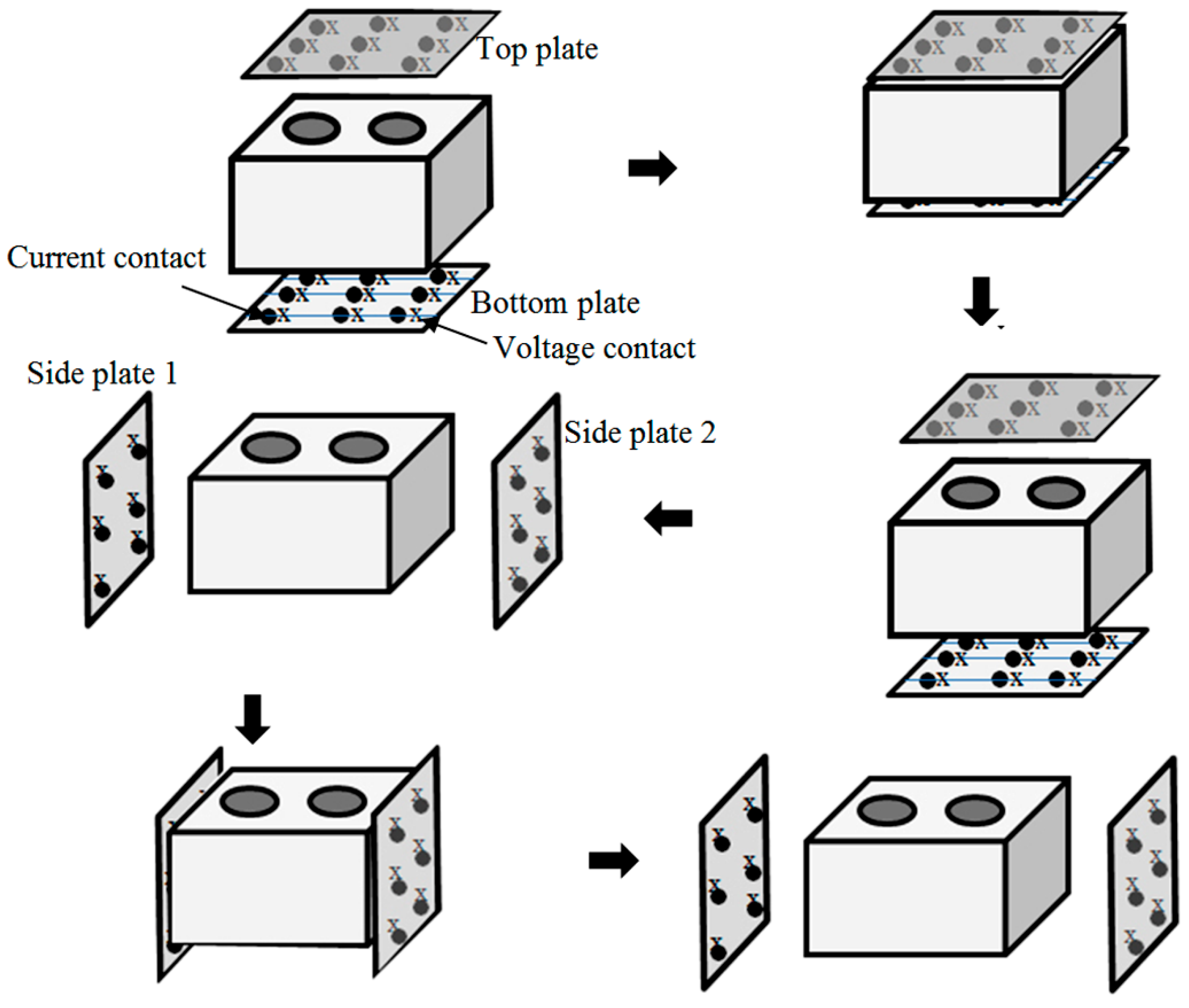

2.2. Measurement of Electrical Resistivity

2.3. Analysis of Tomography Results

2.4. Comparison of Electrical Resistivity and Tomography Results

3. Results and Discussion

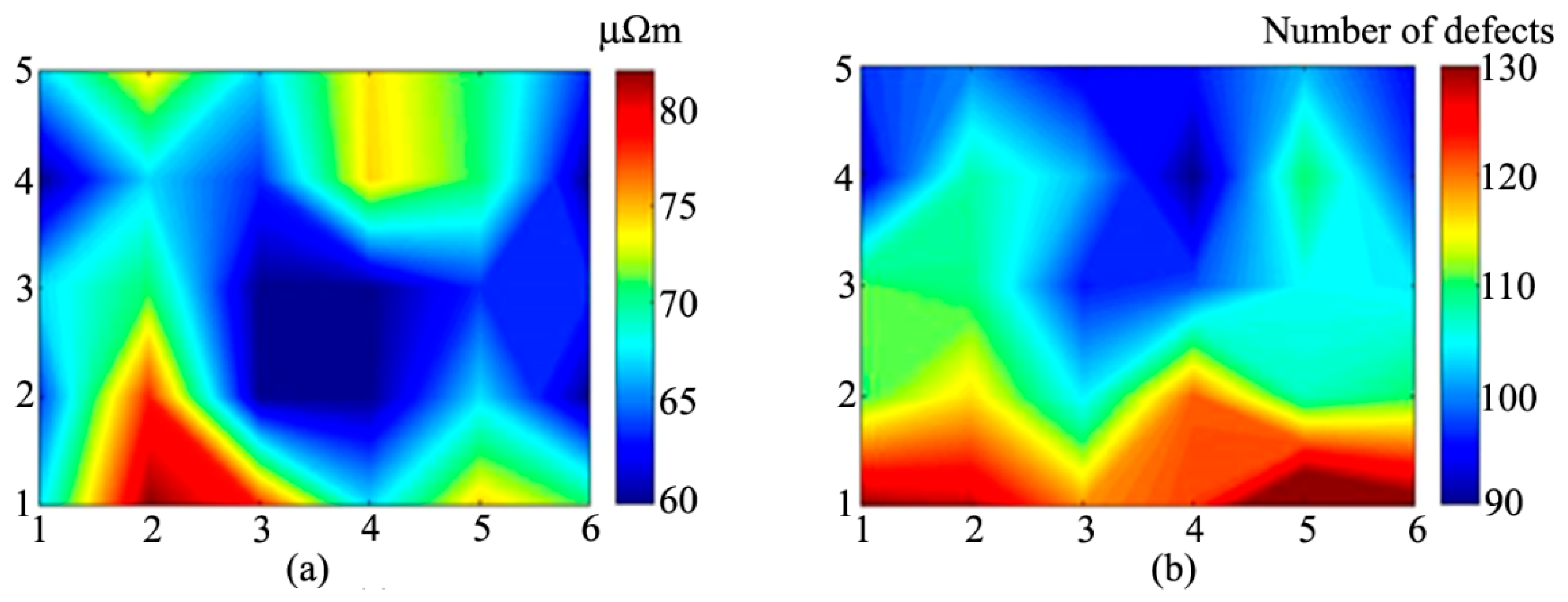

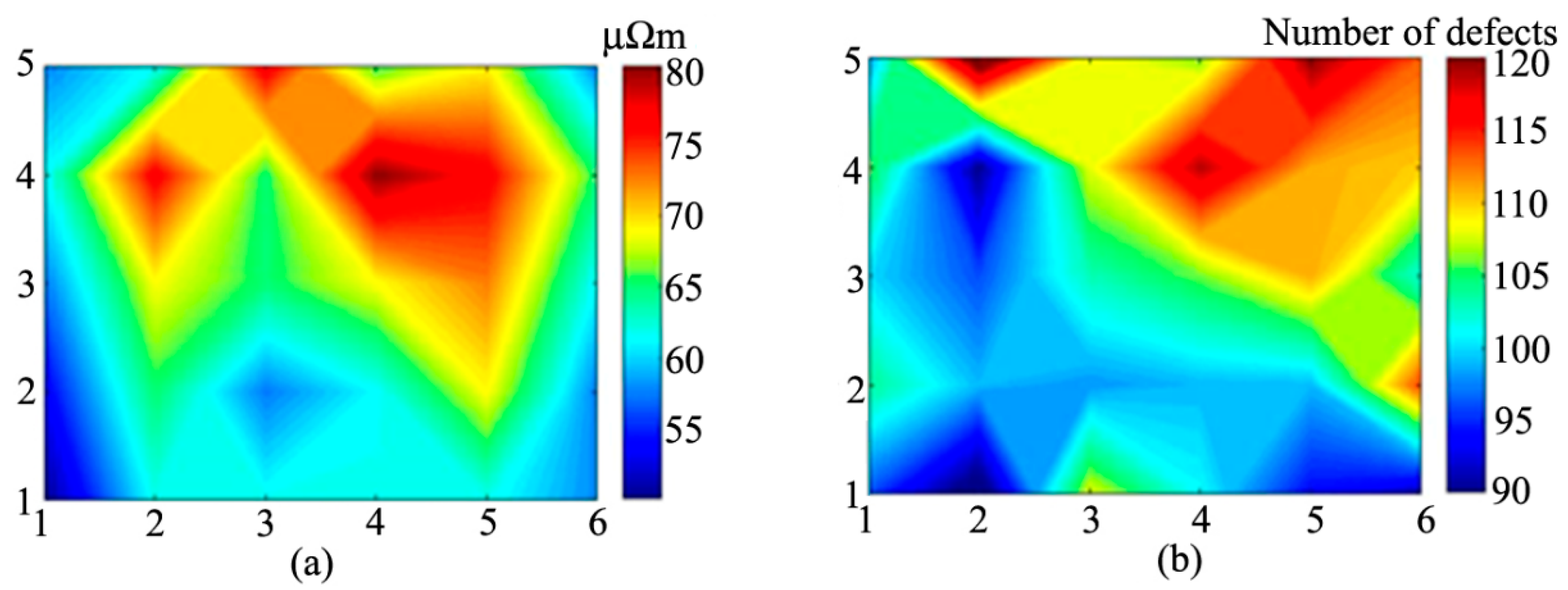

3.1. Analysis of the Electrical Resistivity Measurement

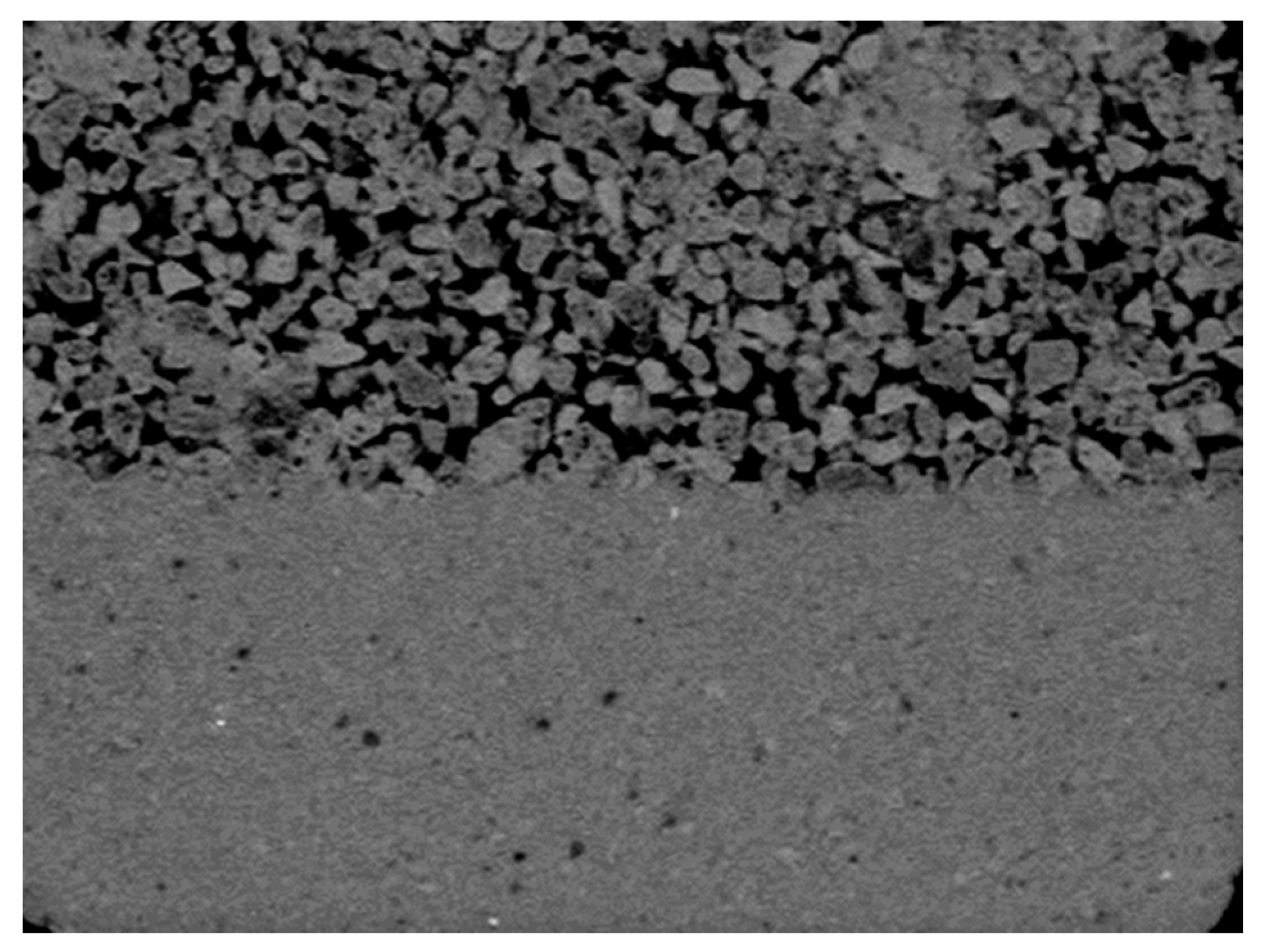

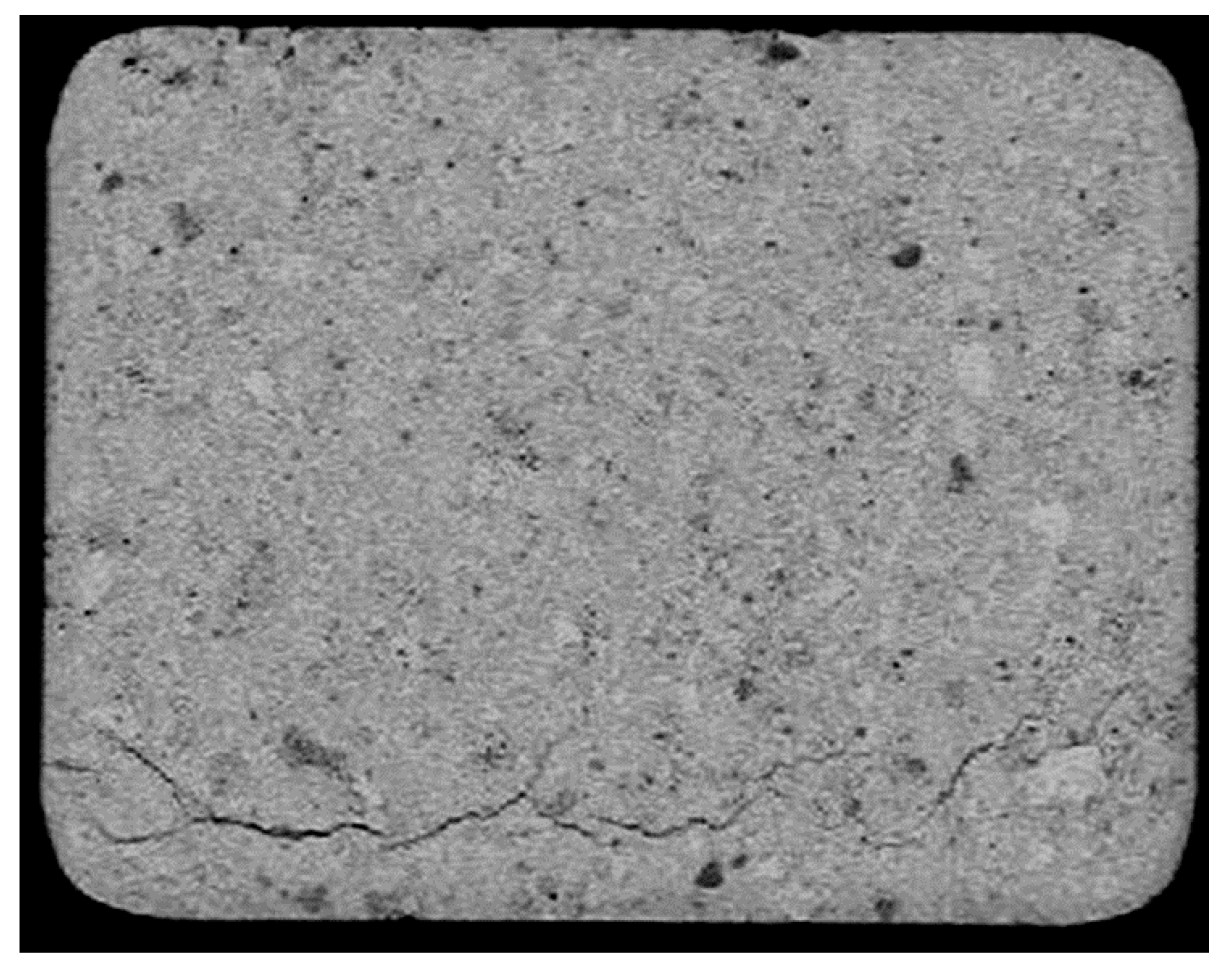

3.2. Tomographic Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hulse, K.L. Anode Manufacture: Raw Materials, Formulation and Processing Parameters, 1st ed.; Calligraphy Sierre: Sierre, Switzerland, 2000. [Google Scholar]

- Meier, M.W. Cracking Behaviour of Anodes; R & D Carbon Ltd.: Sierre, Switzerland, 1996. [Google Scholar]

- Charette, A.; Kocaefe, Y. Le Carbone Dans L’industrie de L’aluminium; Les Presses de L’aluminium: Chicoutimi, QC, Canada, 2012. [Google Scholar]

- Carboni, M. Application of eddy currents to the inspection of fatigue-corroded railway axles. In Proceedings of the 18th World Conference on Nondestructive Testing, Dublan, South Africa, 16–20 April 2012. [Google Scholar]

- Haldemann, P.R.; Fawzi, E.P. Method and Apparatus for Non-Destructively Detecting Flaws in a Carbon Anode. U.S. Patent 5,473,248, 5 Decmber 1995. [Google Scholar]

- Audet, D.; Parent, L. System and Method to Forecast the Electrical Conductivity of Anodes for Aluminum Production Before Baking. U.S. Patent 7,576,534, 18 August 2009. [Google Scholar]

- Boubaker, M.B.; Picard, D.; Duchesne, C.; Tessier, J.; Alamdari, H.; Fafard, M. The potential of acousto-ultrasonic techniques for inspection of baked carbon anodes. Metals 2016, 6, 151. [Google Scholar] [CrossRef]

- NDT Ressources Center. Available online: https://www.nde-ed.org/index_flash.htm (accessed on 5 June 2016).

- Amrani, S.; Kocaefe, D.; Kocaefe, Y.; Morais, B.; Blaney, G. Effect of Heating Rate on the Crack Formation during Baking in Carbon Anodes Used in Aluminum Industry. In Proceedings of the Light Metals, TMS 2014, San Diego, CA, USA, 16–20 February 2014; pp. 175–1180. [Google Scholar]

- Amrani, S. Impact de la Préparation Des Anodes Crues et des Conditions de Cuisson Sur La Fissuration Dans Des Anodes Denses, Ph.D. Thesis, University of Quebec at Chicoutimi, Chicoutimi, QC, Canada, 2015. [Google Scholar]

- Yu, N.; Perrin, S.; Miya, K. Eddy current data for characterizing less volumetric stress corrosion cracking in nonmagnetic materials. Mater. Lett. 2007, 61, 827–829. [Google Scholar]

- He, Y.; Luo, F.; Pan, M.; Weng, F.; Hu, X.; Gao, J.; Liu, B. Pulsed eddy current technique for defect detection in aircraft riveted structures. NDT & E Int. 2010, 43, 176–181. [Google Scholar]

- Matsui, T.; Park, S.G.; Park, M.K.; Matsuura, S. Relationship between electrical resistivity and physical properties of rocks. In Proceedings of the GeoEng2000, An International Conference on Geotechnical & Geological Engineering, Melbourne, Australia, 19–24 November 2000. [Google Scholar]

- Schueler, R.; Joshi, S.P.; Schulte, K. Damage detection in CFRP by electrical conductivity mapping. Compos. Sci. Technol. 2001, 61, 921–930. [Google Scholar] [CrossRef]

- Karhunen, K.; Seppanen, A.; Lehikoinen, A.; Kaipio, J.P. Electrical Resistance Tomography imaging of concrete. Cem. Concr. Res. 2010, 40, 137–145. [Google Scholar]

- Lataste, J.F.; Sirieix, C.; Denys, B.; Frappa, M. Electrical resistivity measurement applied to cracking assessment on reinforced concrete structures in civil engineering. NDT & E Int. 2003, 36, 383–394. [Google Scholar]

- Seger, E.J. Method and Means for Measuring Electrode Resistance. U.S. Patent US3735253, 22 May 1973. [Google Scholar]

- Chollier-Brym, M.-J.; Laroche, D.; Alexandre, A.; Landry, M.; Simard, C.; Simard, L.; Ringuette, D. New method for representative measurement of anode electrical resistance. In Proceedings of the Light Metals, TMS 2012, Orlando, FL, USA, 11–15 March 2012; pp. 1299–1302. [Google Scholar]

- Leonard, G.; Guerard, S.; Laroche, D.; Arnaud, J.-C.; Gourmaud, S.; Gagnon, M.; Chollier-Brym, M.-J.; Perron, Y. Anode electrical measurements: Learning and industrial on-line measurement equipment development. In Proceedings of the Light Metals, TMS 2014, San Diego, CA, USA, 16–20 February 2014; pp. 1269–1274. [Google Scholar]

- Kocaefe, D.; Kocaefe, Y.; Bhattacharyay, D. Measurement of anode electrical resistivity for quality control in aluminium industry. In Proceedings of the Conference of Metallurgists (COM) 2014, Vancouver, BC, Canada, 28 September–1 October 2014. [Google Scholar]

- Kocaefe, Y.; Kocaefe, D.; Bhattacharyay, D. Quality control via electrical resistivity measurement of industrial anodes. In Proceedings of the Light Metals, TMS 2015, Orlando, FL, USA, 15–19 March 2015; pp. 1097–1102. [Google Scholar]

| Anode | Material | Coarse (16 mm − 4 mm +), g | Medium (4 mm − 1 mm +), g | Fines (1 mm −), g |

|---|---|---|---|---|

| Anode 1 | Fresh coke | 0.72X | 0.72Y | 0.72Z |

| Butt | 0.25X | 0.25Y | 0.25Z | |

| Rejects | 0.03X | 0.03Y | 0.03Z | |

| Fresh coke + Butt + Rejects | X | Y | Z | |

| Anode 2 | Fresh coke | 0.72X − 0.25Y | 0.72Y + 0.25Y | 0.72Z |

| Butt | 0.25X + 0.25Y | 0.25Y − 0.25Y = 0 | 0.25Z | |

| Rejects | 0.03X | 0.03Y | 0.03Z | |

| Fresh coke + Butt + Rejects | X | Y | Z | |

| Anode 3 | Fresh coke | 0.72X | 0.72Y | 0.72Z |

| Butt | 0.25X | 0.25Y | 0.25Z | |

| Rejects | 0.03X | 0.03Y | 0.03Z | |

| Fresh coke + Butt + Rejects | X | Y | Z |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benzaoui, A.; Kocaefe, D.; Bhattacharyay, D.; Kocaefe, Y. A Non-Destructive Technique for the On-Line Quality Control of Green and Baked Anodes †. Metals 2017, 7, 128. https://doi.org/10.3390/met7040128

Benzaoui A, Kocaefe D, Bhattacharyay D, Kocaefe Y. A Non-Destructive Technique for the On-Line Quality Control of Green and Baked Anodes †. Metals. 2017; 7(4):128. https://doi.org/10.3390/met7040128

Chicago/Turabian StyleBenzaoui, Abderrahmane, Duygu Kocaefe, Dipankar Bhattacharyay, and Yasar Kocaefe. 2017. "A Non-Destructive Technique for the On-Line Quality Control of Green and Baked Anodes †" Metals 7, no. 4: 128. https://doi.org/10.3390/met7040128