Effect of Welding Heat Input on the Microstructure and Toughness in Simulated CGHAZ of 800 MPa-Grade Steel for Hydropower Penstocks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Weld CGHAZ Simulation and the Onset and End Temperatures for Transformation Determination

2.3. Mechanical Properties

2.4. Microstructural Characterization

3. Results

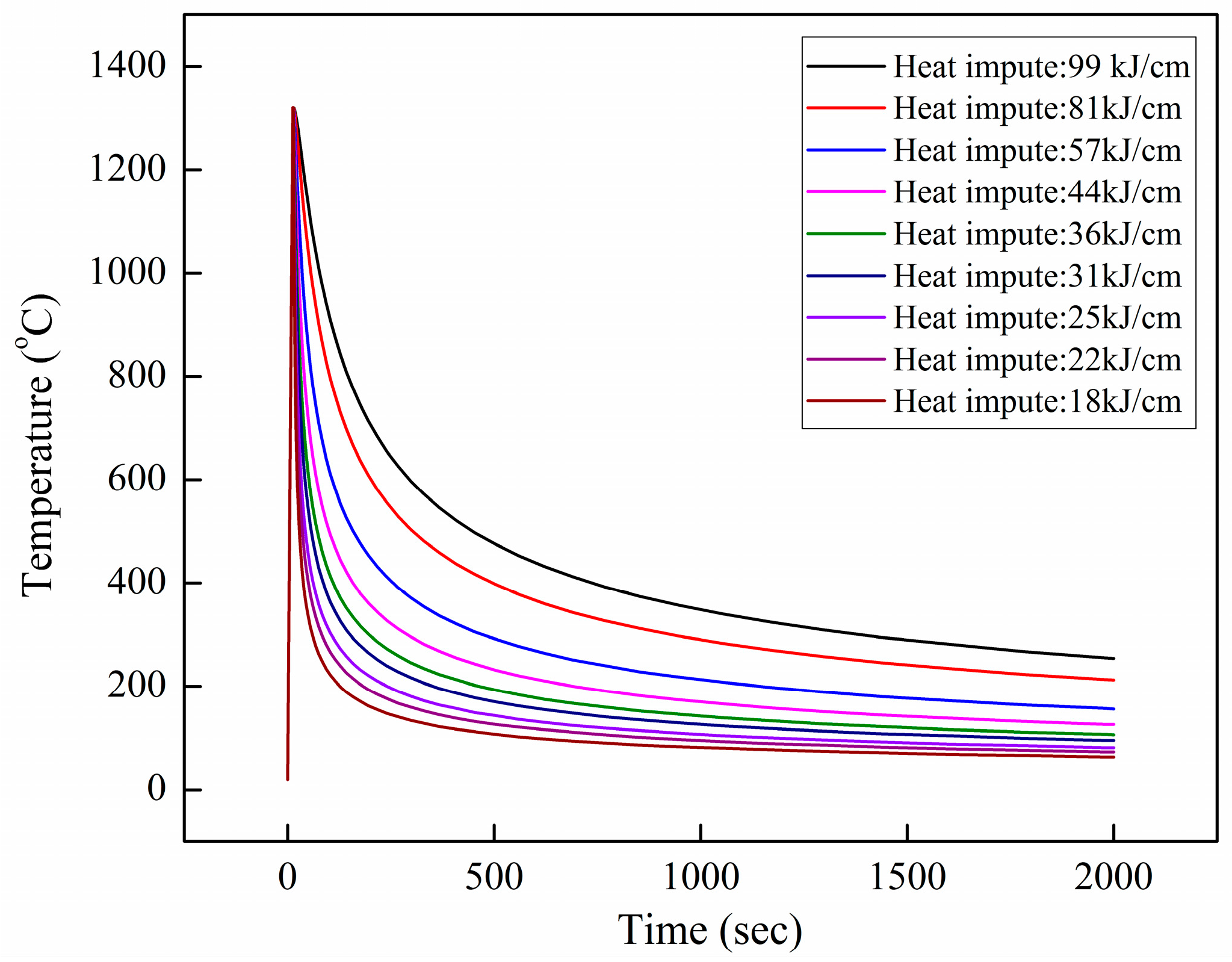

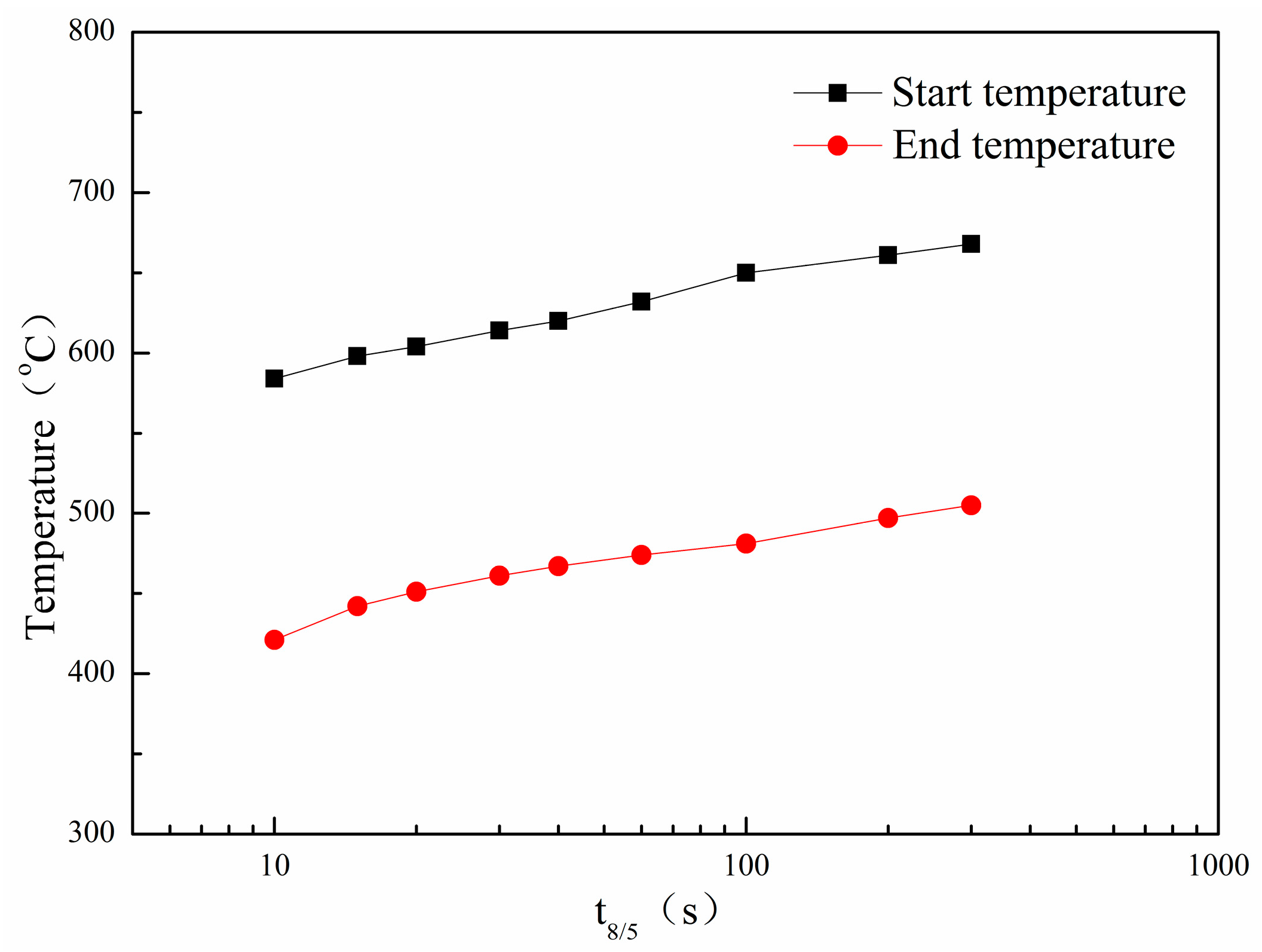

3.1. Continuous Cooling Transformation Occurring in the Simulated CGHAZ

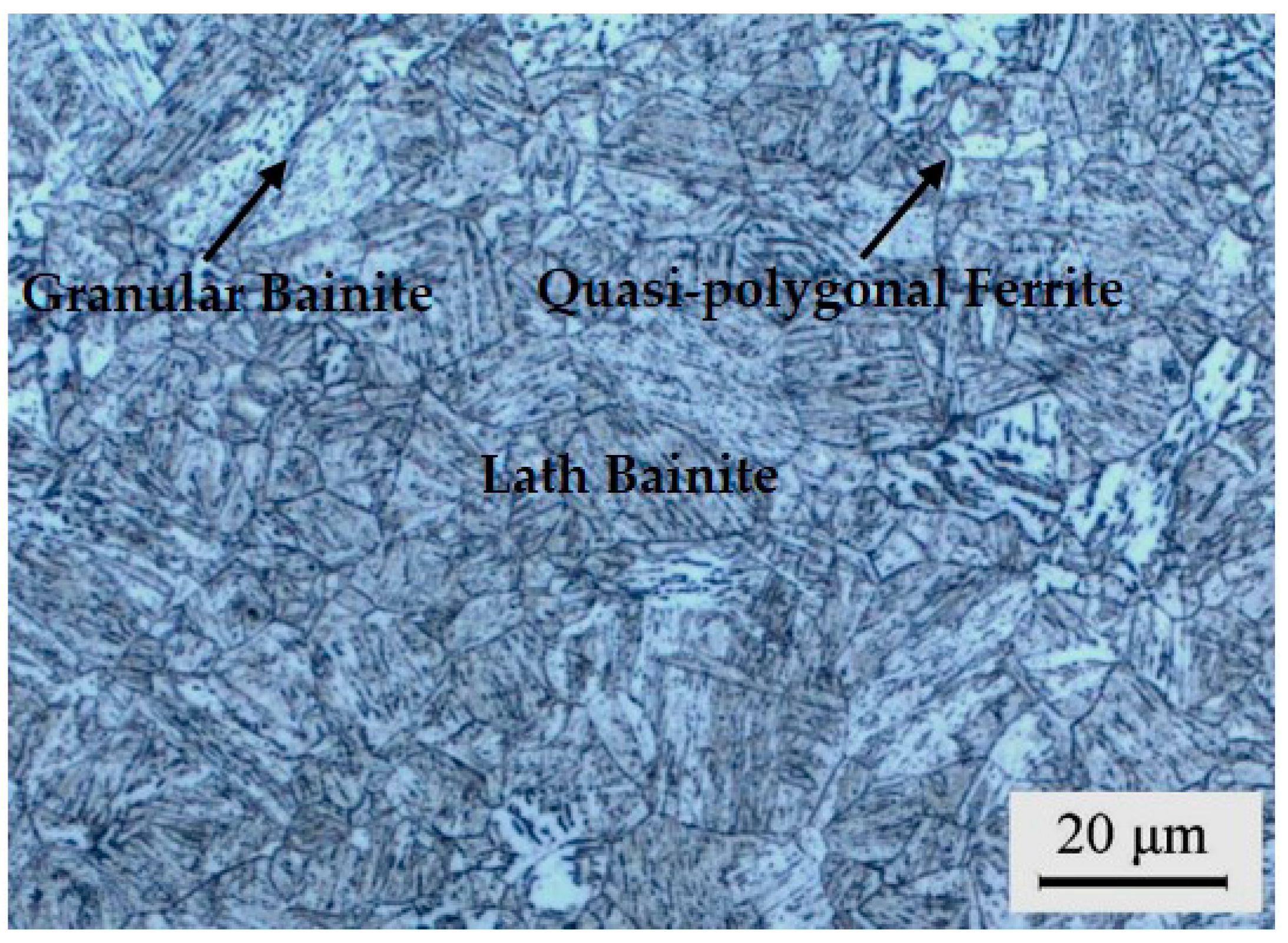

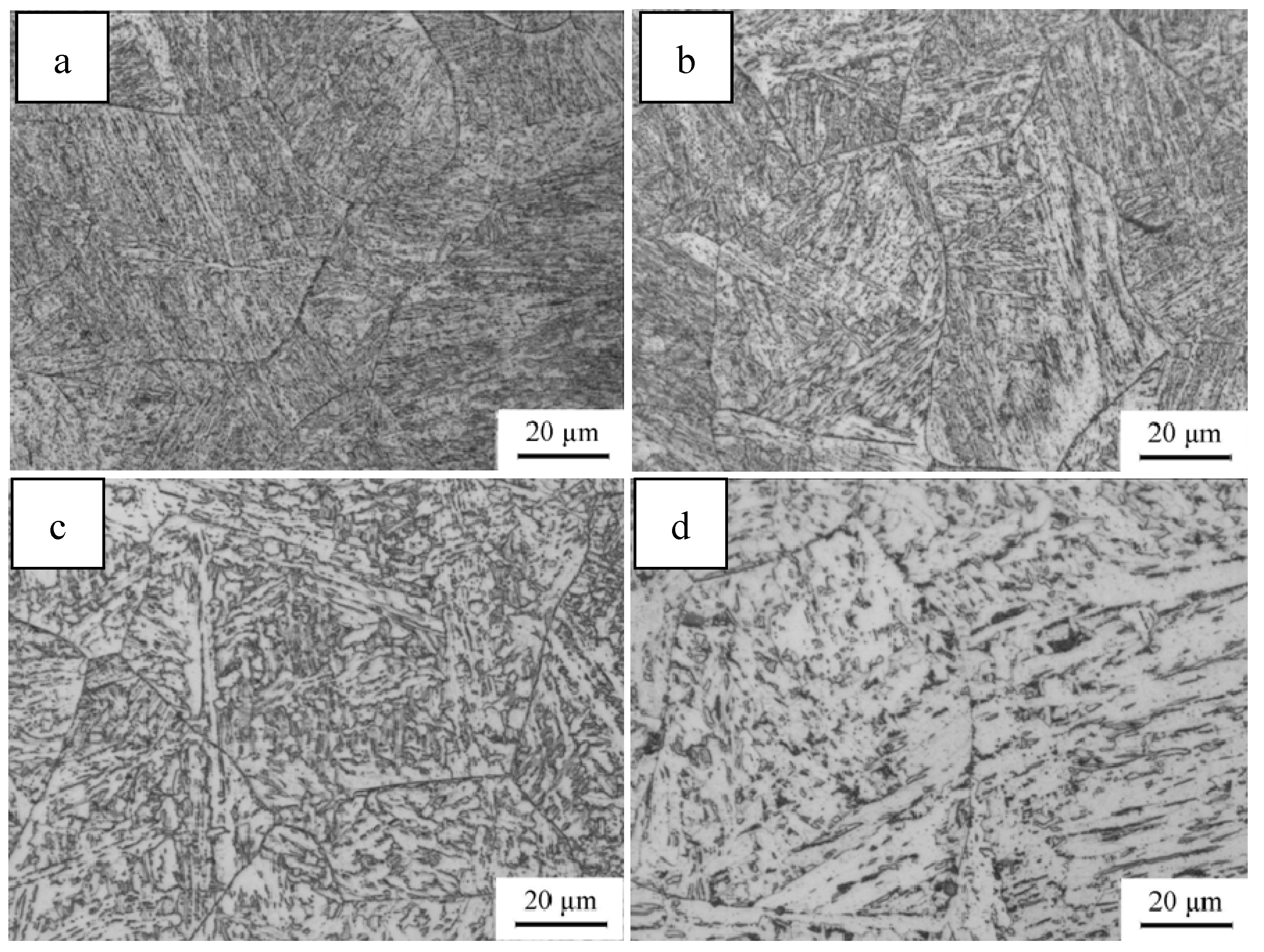

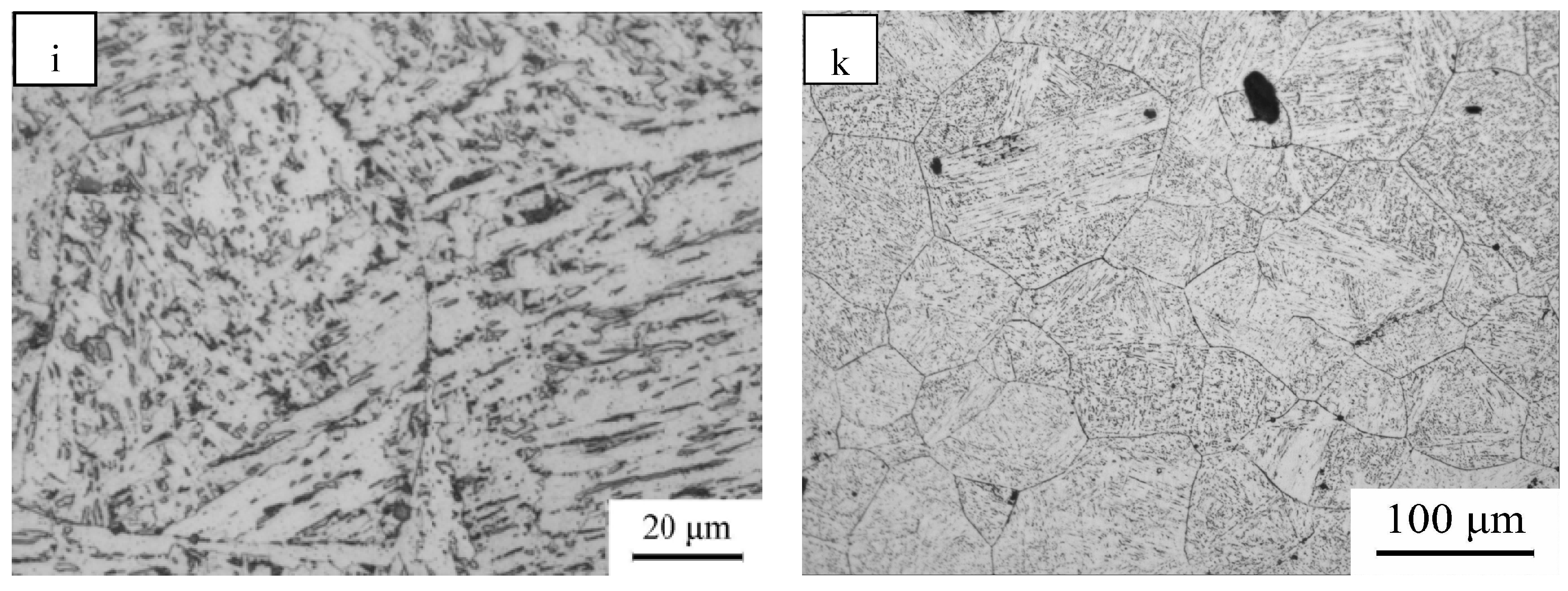

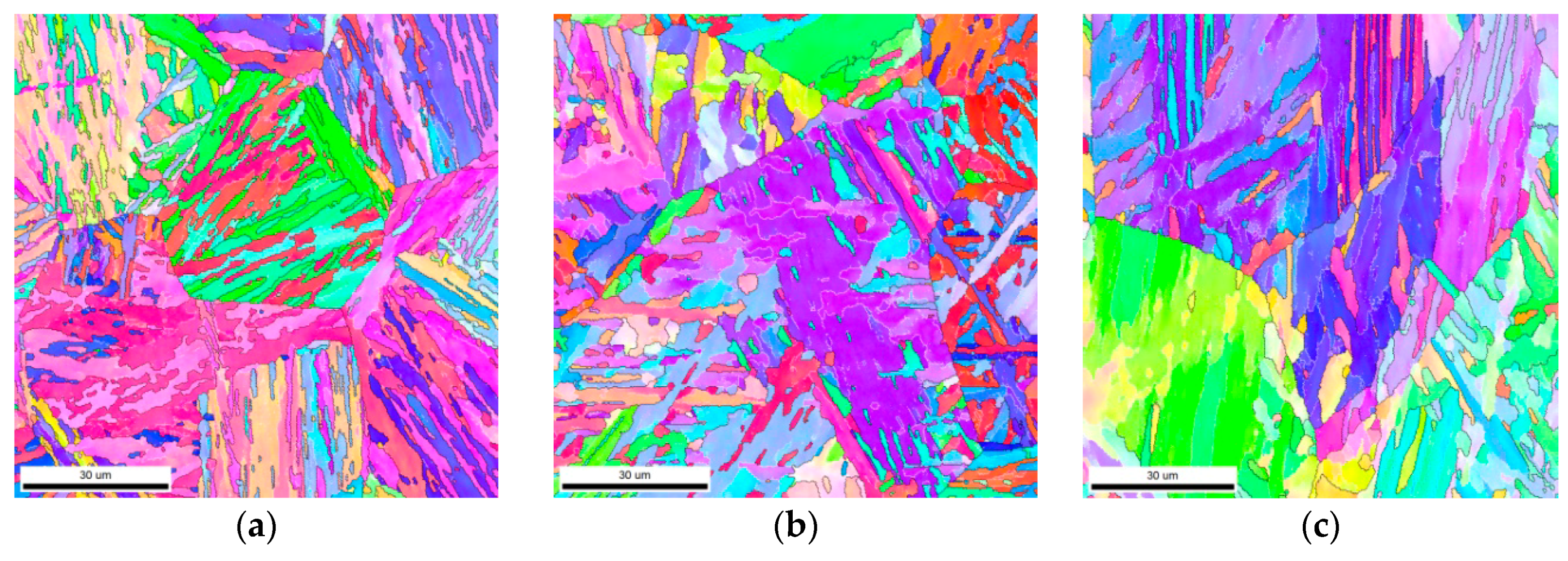

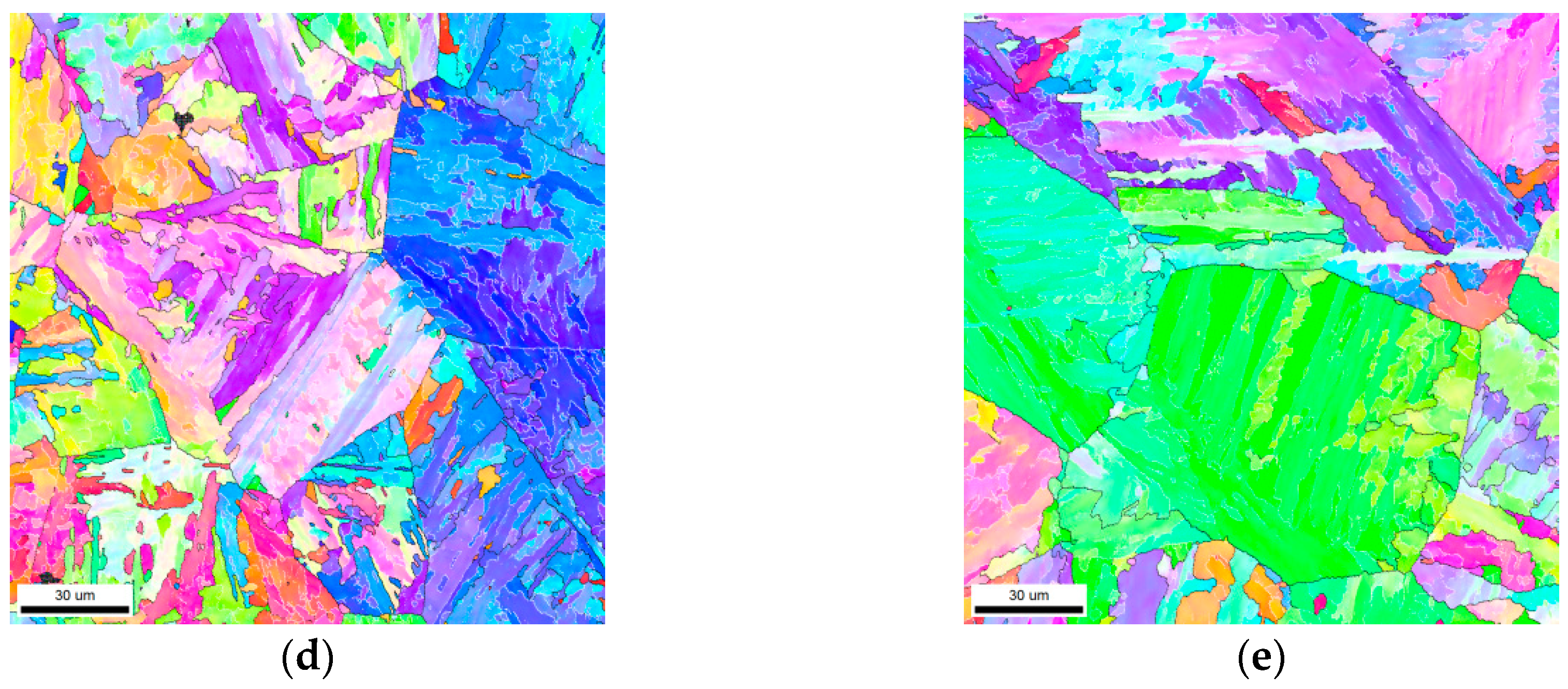

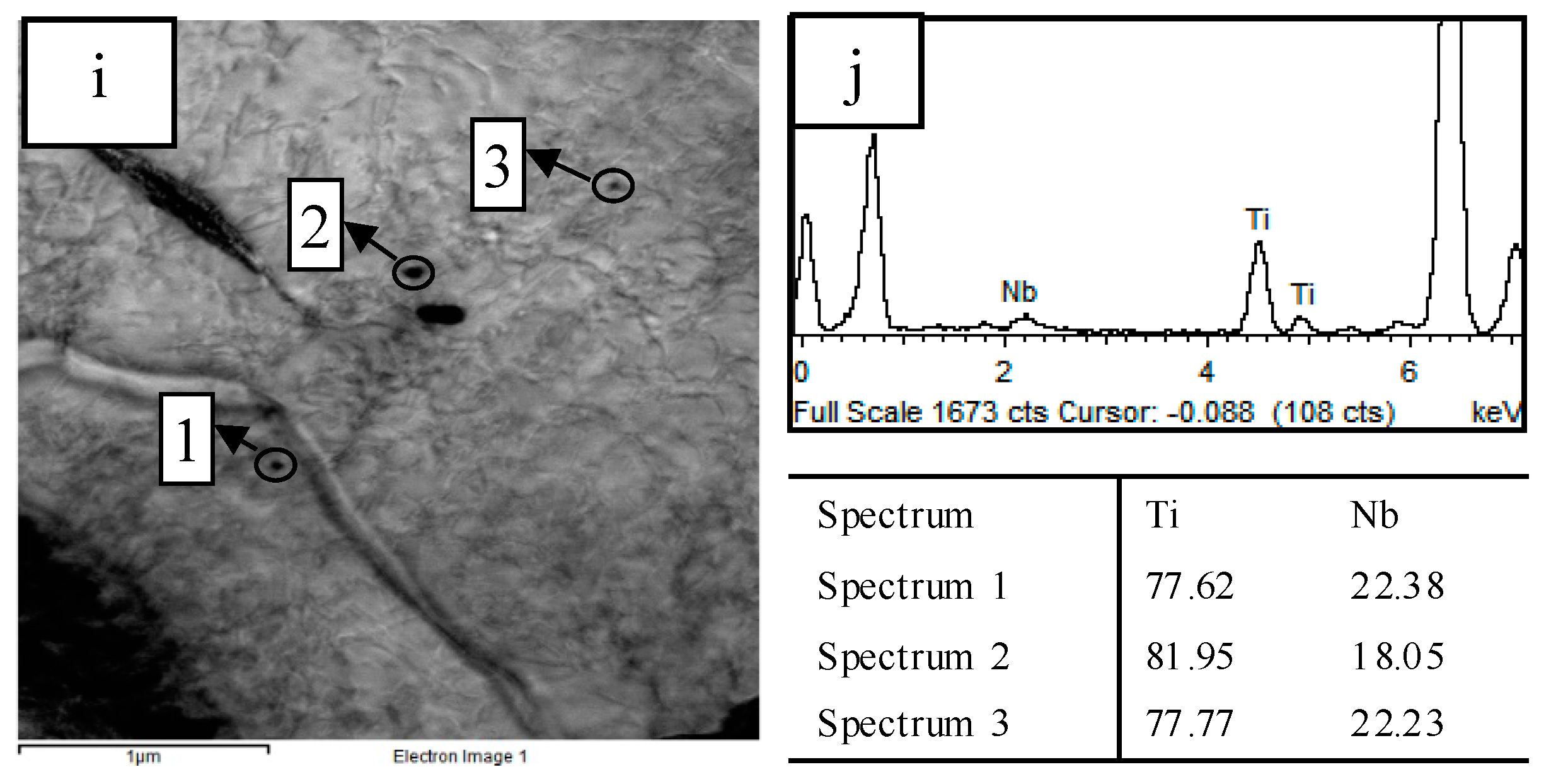

3.2. Microstructure of Simulatied CGHAZ

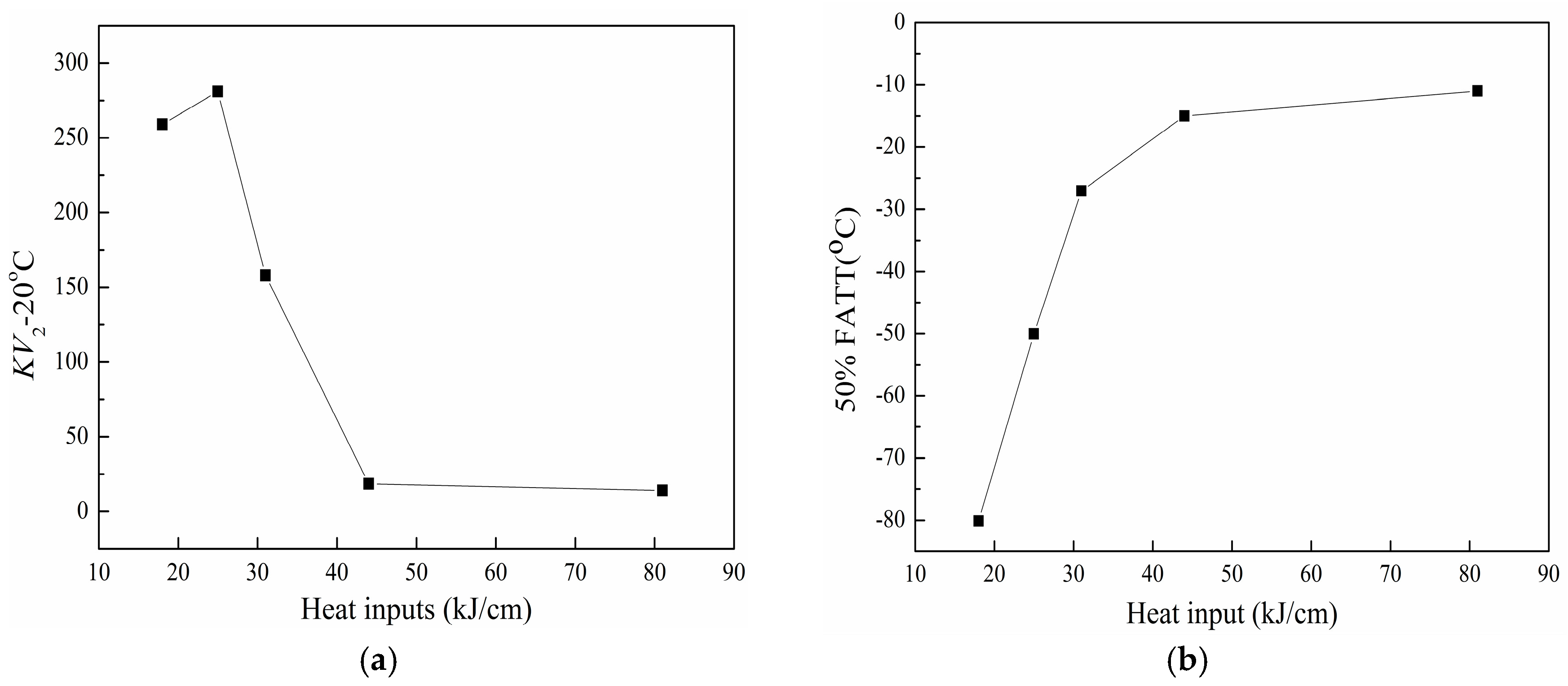

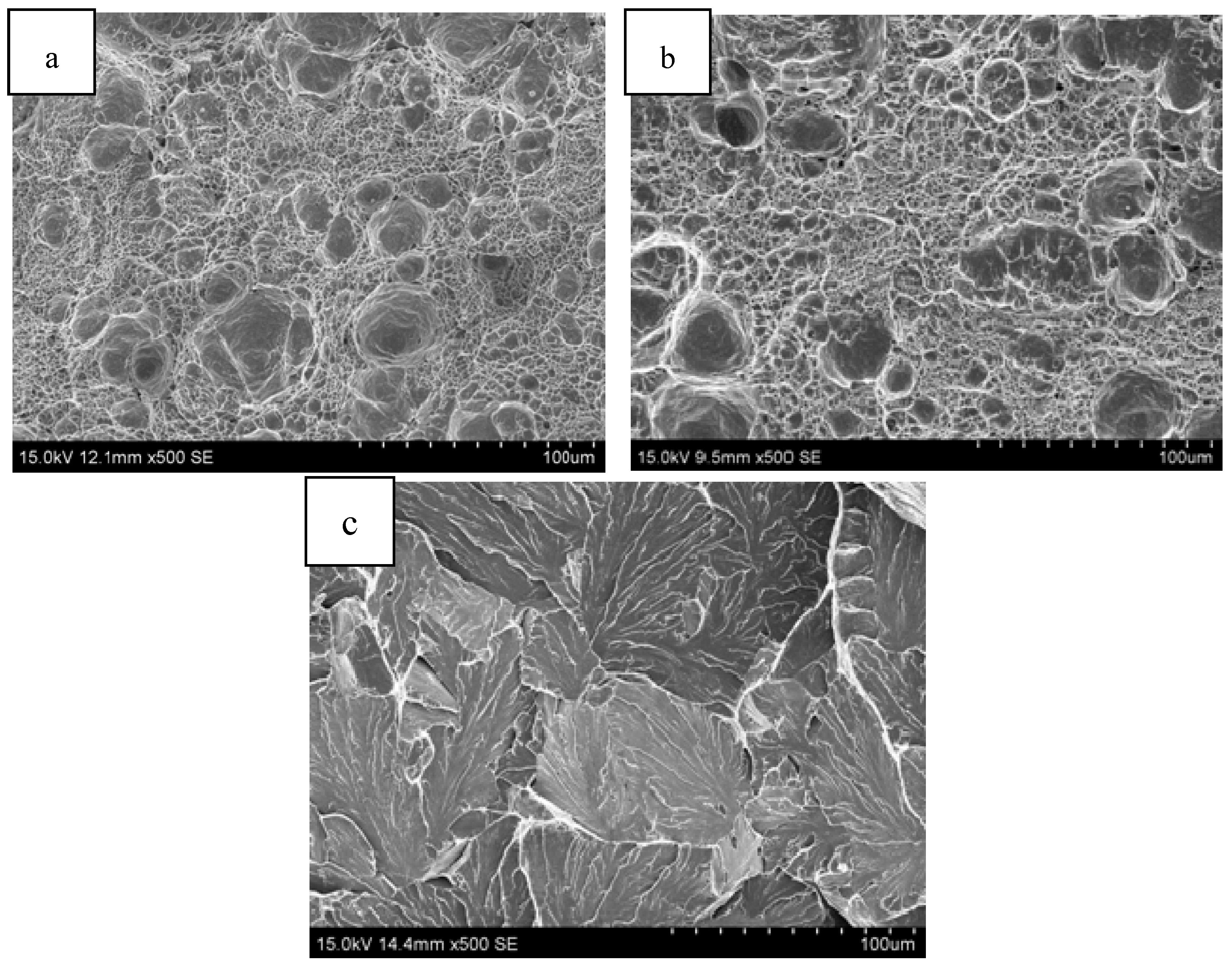

3.3. Mechanical Properties of the Simulated CGHAZ

4. Discussion

4.1. Effect of Heat Input on the Simulated CGHAZ Microstructure

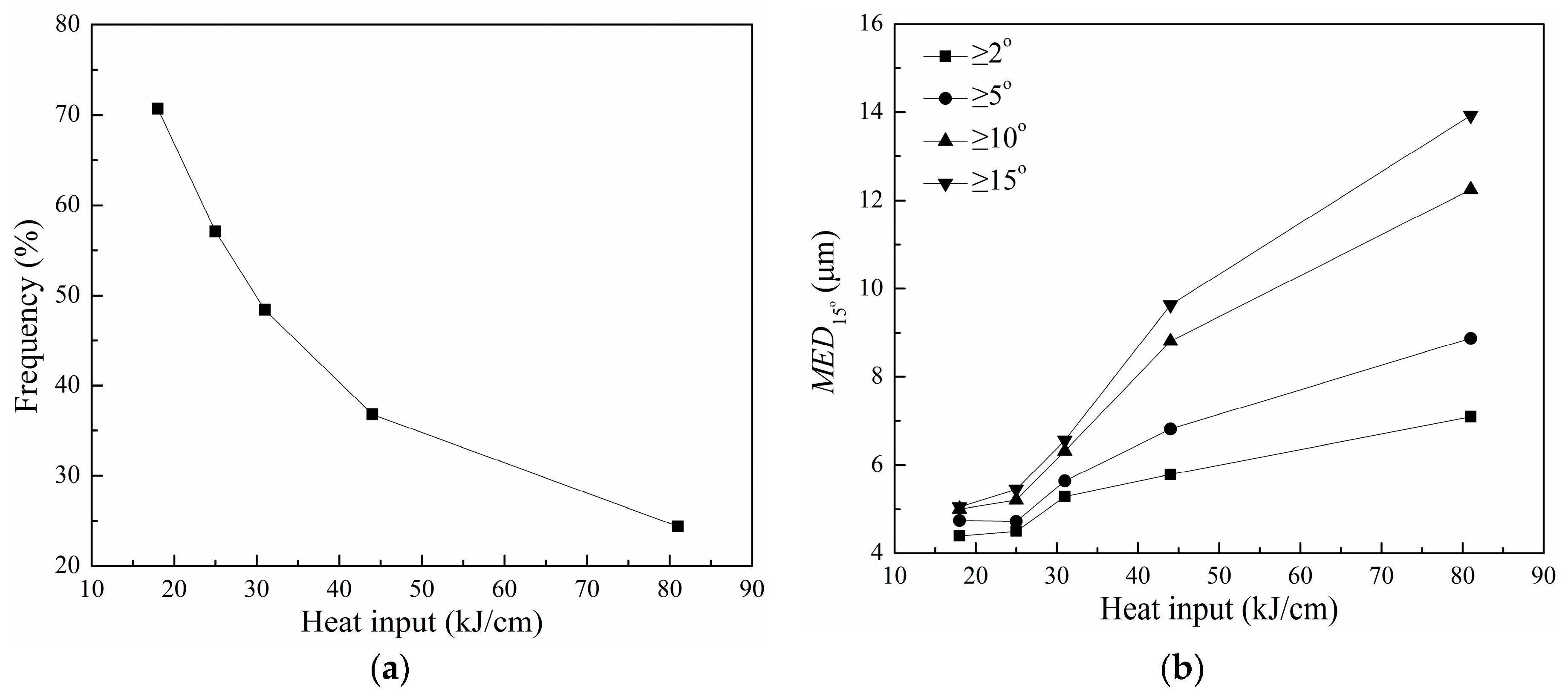

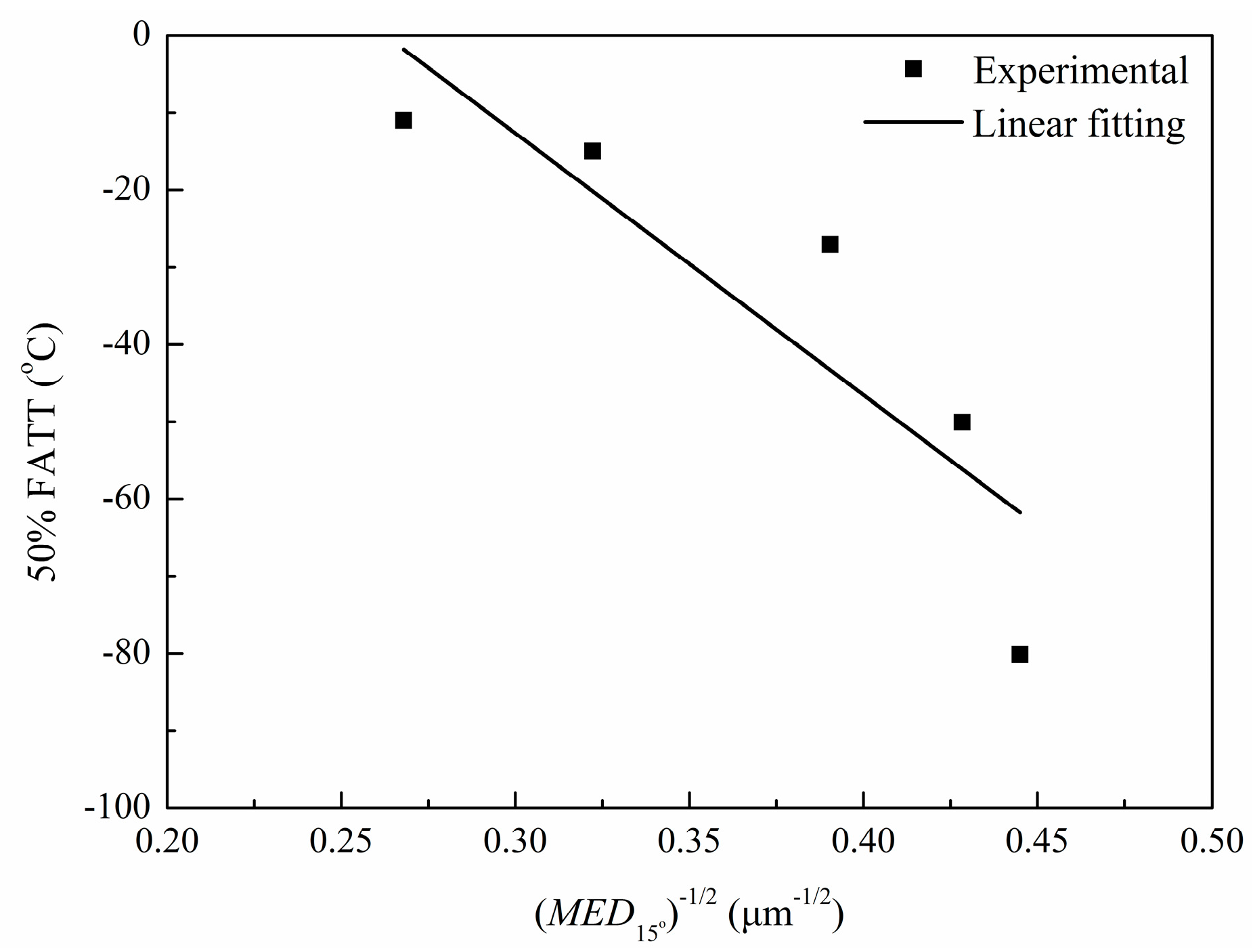

4.2. Effect of Effective Grain Size on 50% FATT of the Simulated CGHAZ

5. Conclusions

- The impact toughness at −20 °C and the hardness of the simulated CGHAZ decrease with increasing heat input. When the input increases from 18 to 81 kJ/cm, the 50% FATT increases from −80 °C to −11 °C.

- At 18 kJ/cm, the microstructures are composed of lath bainite and granular bainite; lath bainite decreases with increasing heat input. The increase in the 50% FATT results mainly from an increase in the austenite grain size and effective grain size, and a decrease in lath bainite and the fraction of HAGBs (misorientation: ≥15°).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guo, A.; Misra, R.D.K.; Liu, J.; Chen, L.; He, X.; Jansto, S.J. An analysis of the microstructure of the heat-affected zone of an ultra-low carbon and niobium-bearing acicular ferrite steel using EBSD and its relationship to mechanical properties. Mater. Sci. Eng. A 2010, 527, 6440–6448. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Wang, J.-J.; Gao, C.-R. Effect of welding heat input on microstructures and toughness in simulated CGHAZ of V–N high strength steel. Mater. Sci. Eng. A 2013, 577, 161–168. [Google Scholar] [CrossRef]

- Shanmugam, S.; Ramisetti, N.K.; Misra, R.D.K.; Hartmann, J.; Jansto, S.G. Microstructure and high strength-toughness combination of a new 700 MPa Nb-microalloyed pipeline steel. Mater. Sci. Eng. A 2008, 478, 26–37. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Analysis of microstructural variation and mechanical behaviors in submerged arc welded joint of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2012, 558, 592–601. [Google Scholar] [CrossRef]

- Easterling, K. Cracking and fracture in welds. In Introduction to the Physical Metallurgy of Welding, 2nd ed.; Butterworth-Heinemann: Woburn, MA, USA, 1992; Chapter 4; pp. 191–260. [Google Scholar]

- Kumar, S.; Nath, S.K.; Kumar, V. Continuous cooling transformation behavior in the weld coarse grained heat affected zone and mechanical properties of Nb-microalloyed and HY85 steels. Mater. Des. 2016, 90, 177–184. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Gourgues, A.F.; Besson, J.; Sturel, T.; Pineau, A. Mechanisms and modeling of cleavage fracture in simulated heat-affected zone microstructures of a high-strength low alloy steel. Metall. Mater. Trans. A 2004, 35, 1039–1053. [Google Scholar] [CrossRef]

- Guo, B.; Fan, L.; Wang, Q.; Fu, Z.; Wang, Q.; Zhang, F. The Role of the Bainitic Packet in Control of Impact Toughness in a Simulated CGHAZ of X90 Pipeline Steel. Metals 2016, 6, 256. [Google Scholar] [CrossRef]

- Kumar, S.; Nath, S.K. Effect of heat input on impact toughness in transition temperature region of weld CGHAZ of a HY 85 steel. J. Mater. Process. Technol. 2016, 236, 216–224. [Google Scholar] [CrossRef]

- Cao, R.; Li, J.; Liu, D.S.; Ma, J.Y.; Chen, J.H. Micromechanism of Decrease of Impact Toughness in Coarse-Grain Heat-Affected Zone of HSLA Steel with Increasing Welding Heat Input. Metall. Mater. Trans. A 2015, 46, 2999–3014. [Google Scholar] [CrossRef]

- Hwang, B.; Kim, Y.G.; Lee, S.; Kim, Y.M.; Kim, N.J.; Yoo, J.Y. Effective grain size and charpy impact properties of high-toughness X70 pipeline steels. Metall. Mater. Trans. A 2005, 36, 2107–2114. [Google Scholar] [CrossRef]

- Díaz-Fuentes, M.; Iza-Mendia, A.; Gutiérrez, I. Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Study of their toughness behavior. Metall. Mater. Trans. A 2003, 34, 2505–2516. [Google Scholar] [CrossRef]

- Gutiérrez, I. Effect of microstructure on the impact toughness of Nb-microalloyed steel: Generalisation of existing relations from ferrite-pearlite to high strength microstructures. Mater. Sci. Eng. A 2013, 571, 57–67. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Gourgues, A.F.; Pineau, A. Austenite to bainite phase transformation in the heat-affected zone of a high strength low alloy steel. Acta Mater. 2004, 52, 2337–2348. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Iza-Mendia, A.; Gutierrez, I. Generalization of the existing relations between microstructure and yield stress from ferrite-pearlite to high strength steels. Mater. Sci. Eng.-Struct. Mater. Prop. Microstruct. Process. 2013, 561, 40–51. [Google Scholar] [CrossRef]

- Liu, F.; Sommer, F.; Bos, C.; Mittemeijer, E.J. Analysis of solid state phase transformation kinetics: Models and recipes. Int. Mater. Rev. 2007, 52, 193–212. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.; Sommer, F.; Mittemeijer, E.J. Isothermal austenite-ferrite transformation of Fe-0.04 at % C alloy: Dilatometric measurement and kinetic analysis. Acta Mater. 2008, 56, 3833–3842. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Zhang, H.Q.; Liu, W.M.; Hou, H. Effects of Nb on microstructure and continuous cooling transformation of coarse grain heat-affected zone in 610 MPa class high-strength low-alloy structural steels. Mater. Sci. Eng. A 2009, 499, 182–186. [Google Scholar] [CrossRef]

- Takahashi, M. Recent progress: Kinetics of the bainite transformation in steels. Curr. Opin. Solid State Mater. Sci. 2004, 8, 213–217. [Google Scholar] [CrossRef]

| C | Mn | Si | Cu | Ni + Cr + Mo | Nb + V + Ti | B |

|---|---|---|---|---|---|---|

| 0.09 | 1.50 | 0.30 | 0.20 | 1.15 | 0.083 | 0.0011 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Q.; Wang, T.; Shi, Z.; Wang, Q.; Wang, Q.; Zhang, F. Effect of Welding Heat Input on the Microstructure and Toughness in Simulated CGHAZ of 800 MPa-Grade Steel for Hydropower Penstocks. Metals 2017, 7, 115. https://doi.org/10.3390/met7040115

Ding Q, Wang T, Shi Z, Wang Q, Wang Q, Zhang F. Effect of Welding Heat Input on the Microstructure and Toughness in Simulated CGHAZ of 800 MPa-Grade Steel for Hydropower Penstocks. Metals. 2017; 7(4):115. https://doi.org/10.3390/met7040115

Chicago/Turabian StyleDing, Qingfeng, Tiansheng Wang, Zhongran Shi, Qian Wang, Qingfeng Wang, and Fucheng Zhang. 2017. "Effect of Welding Heat Input on the Microstructure and Toughness in Simulated CGHAZ of 800 MPa-Grade Steel for Hydropower Penstocks" Metals 7, no. 4: 115. https://doi.org/10.3390/met7040115