Modeling the Constitutive Relationship of Al–0.62Mg–0.73Si Alloy Based on Artificial Neural Network

Abstract

:1. Introduction

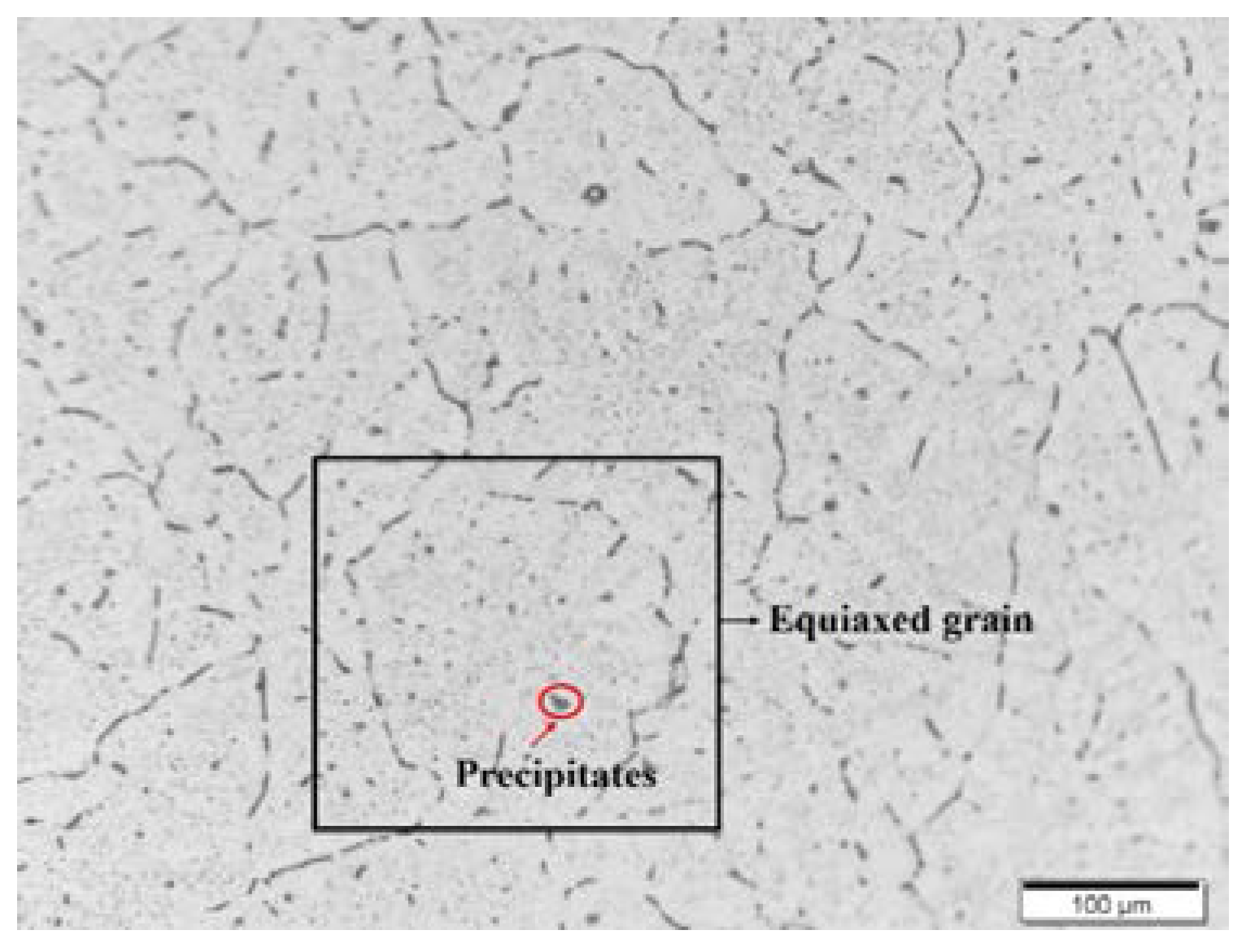

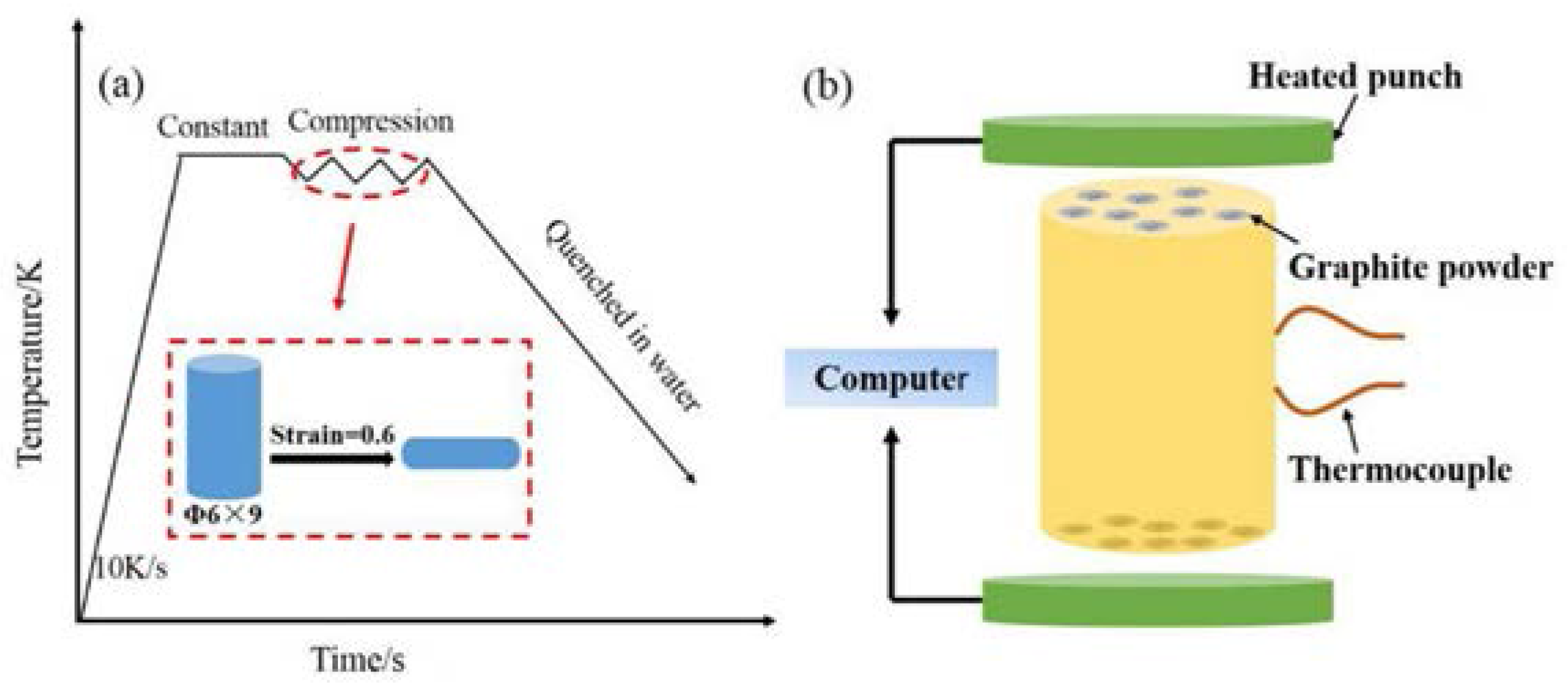

2. Materials and Methods

3. Results and Discussion

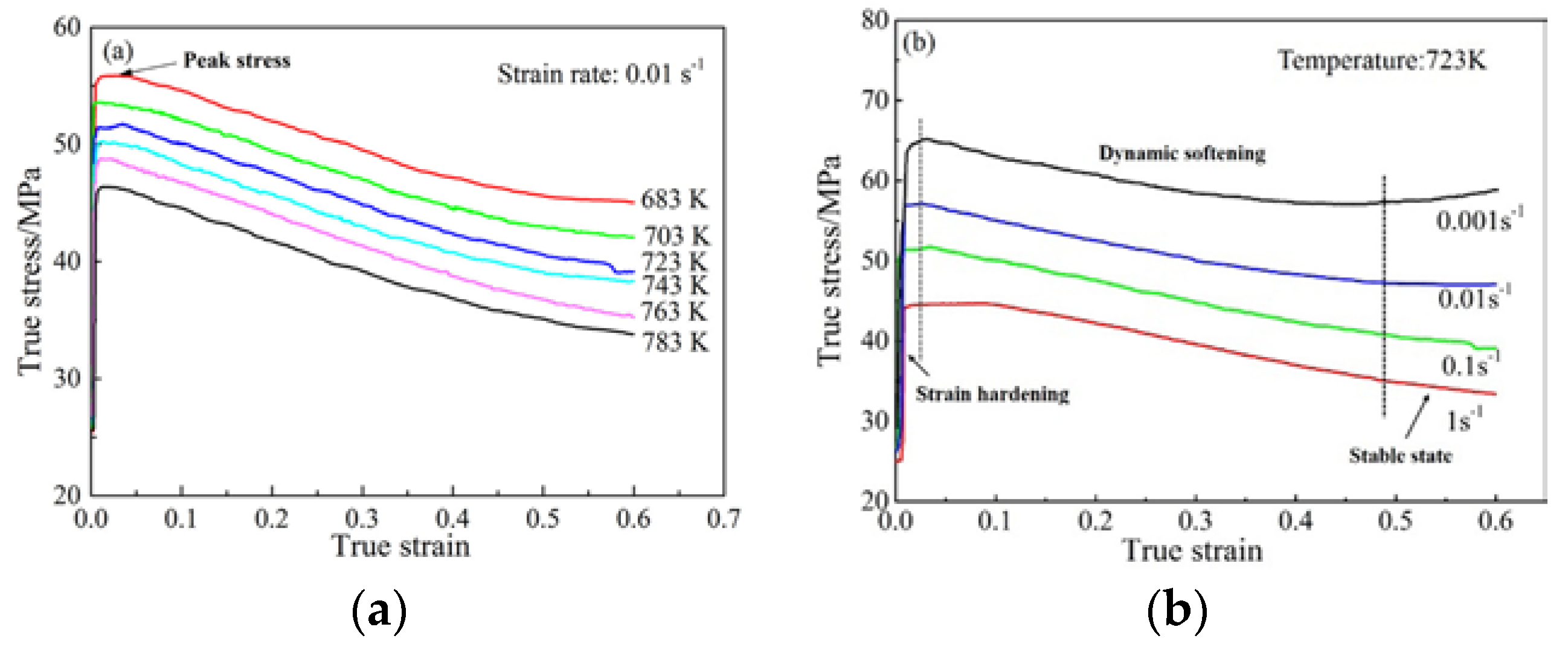

3.1. Flow Behavior

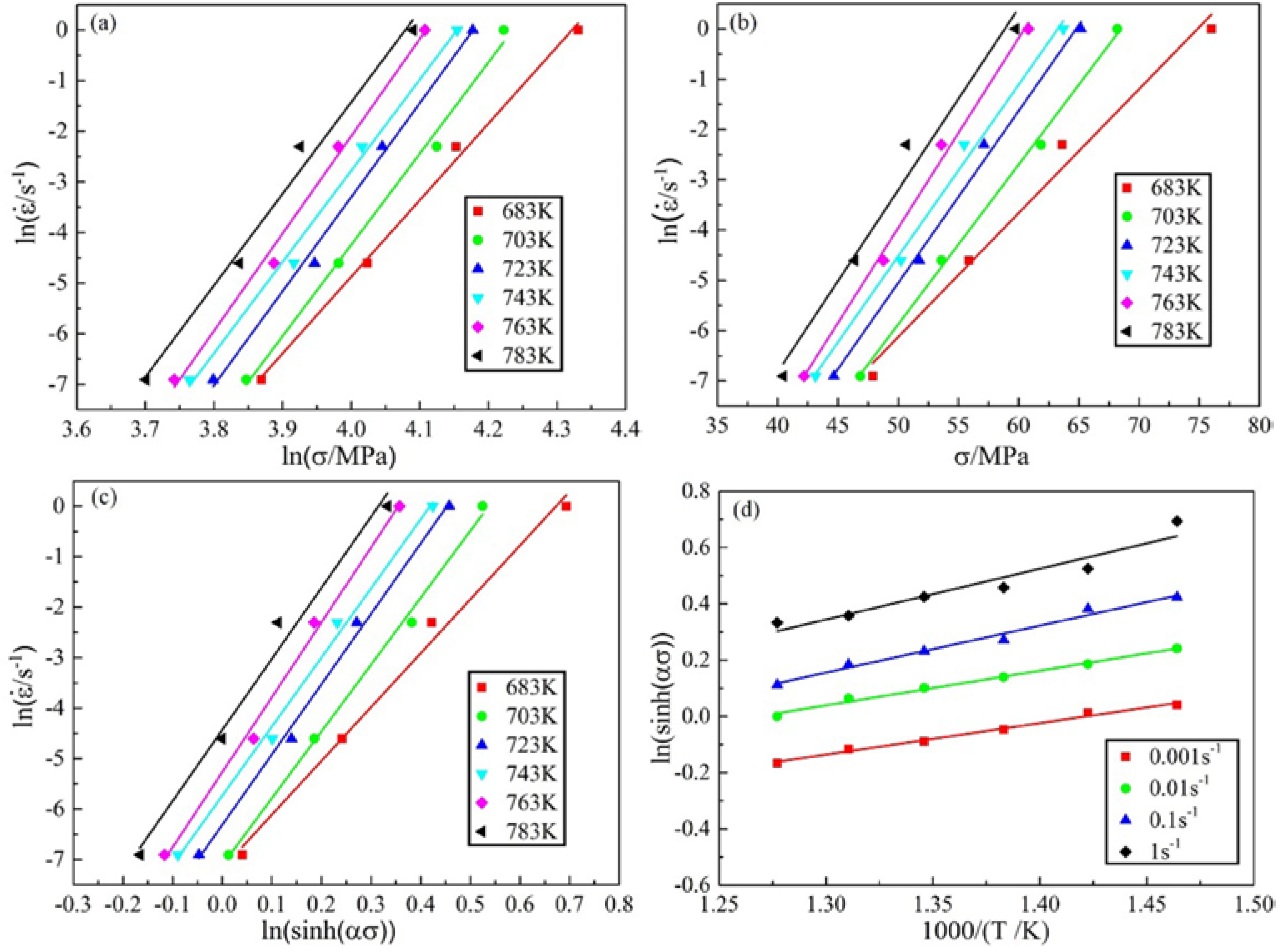

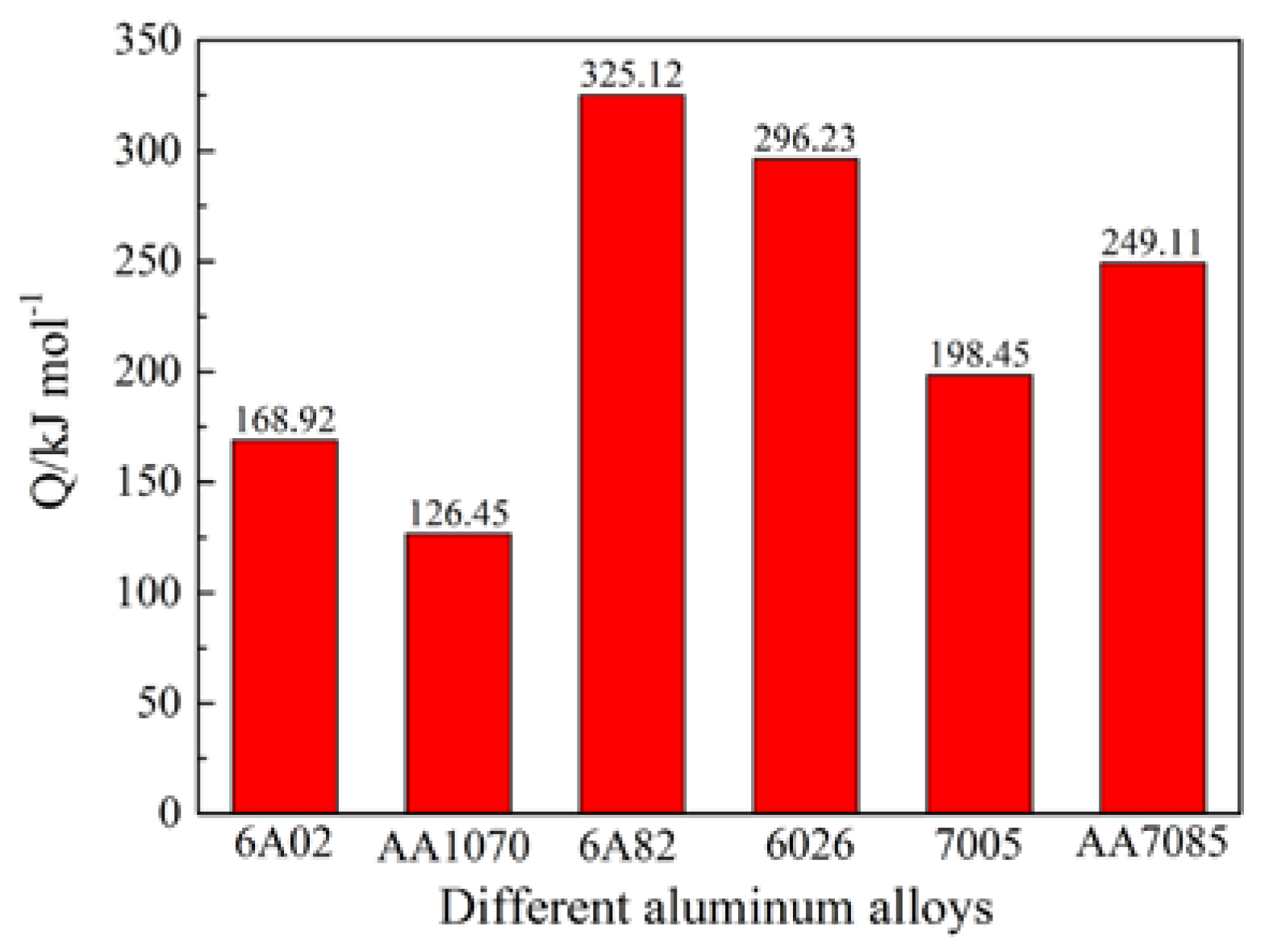

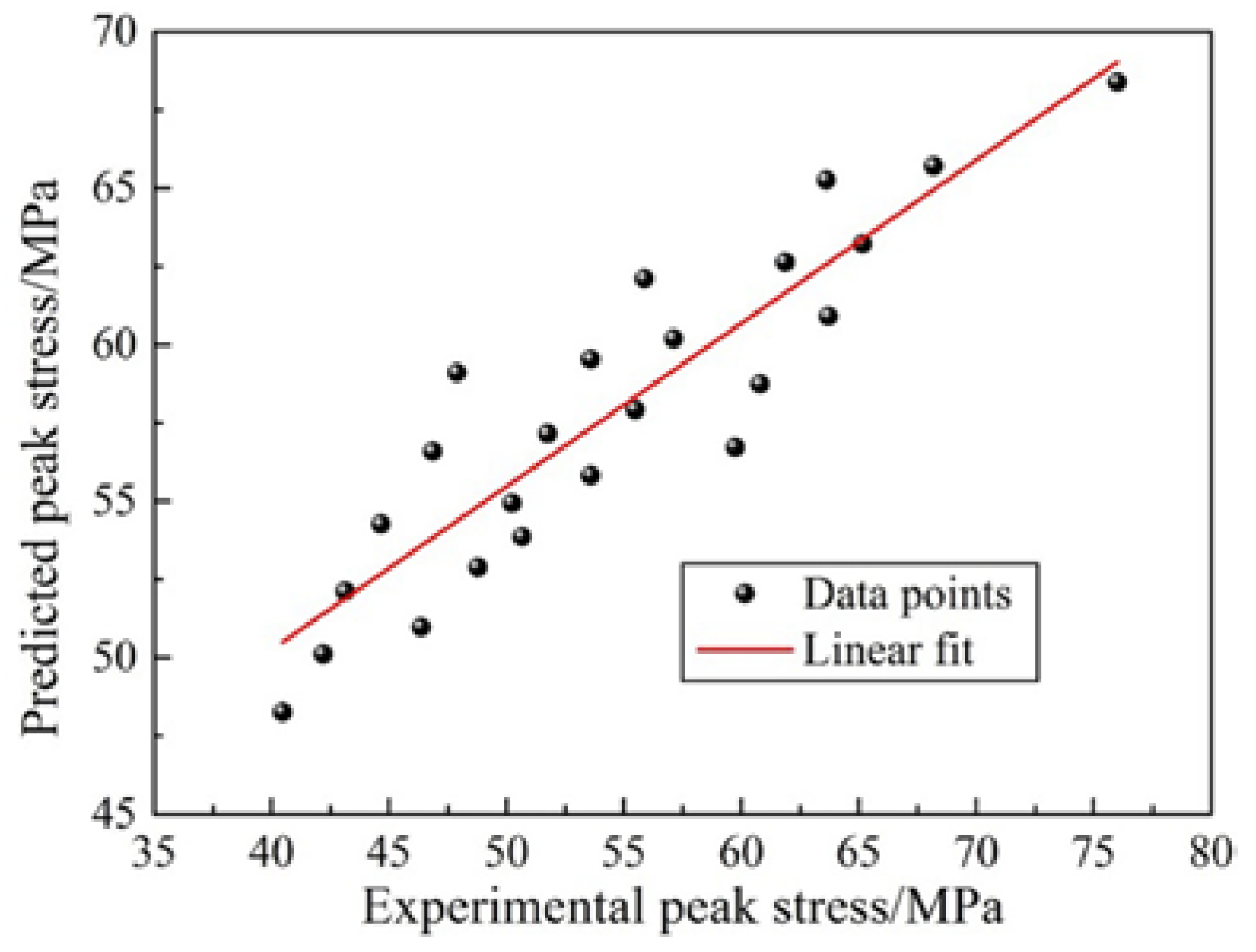

3.2. Arrhenius-Type Constitutive Model

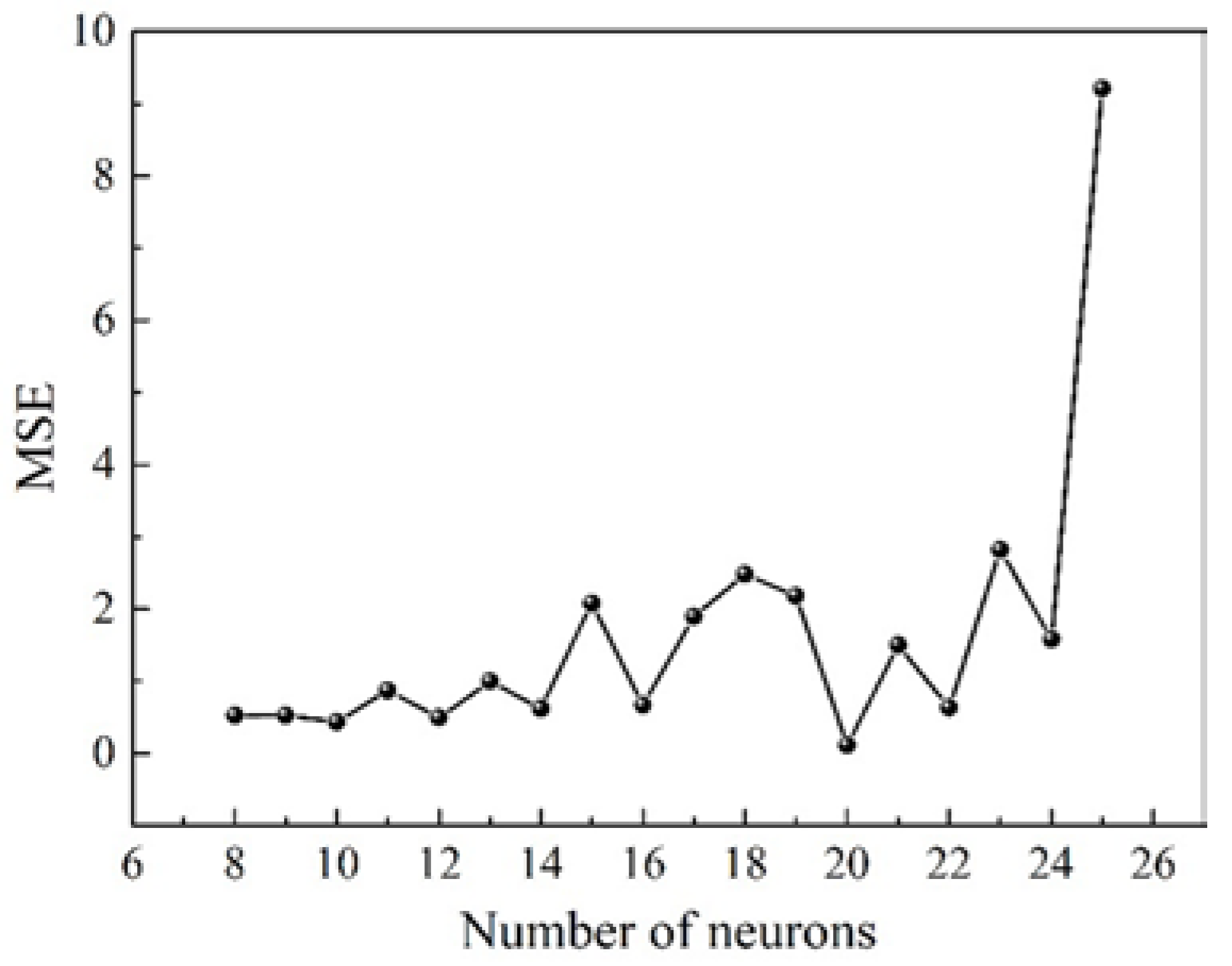

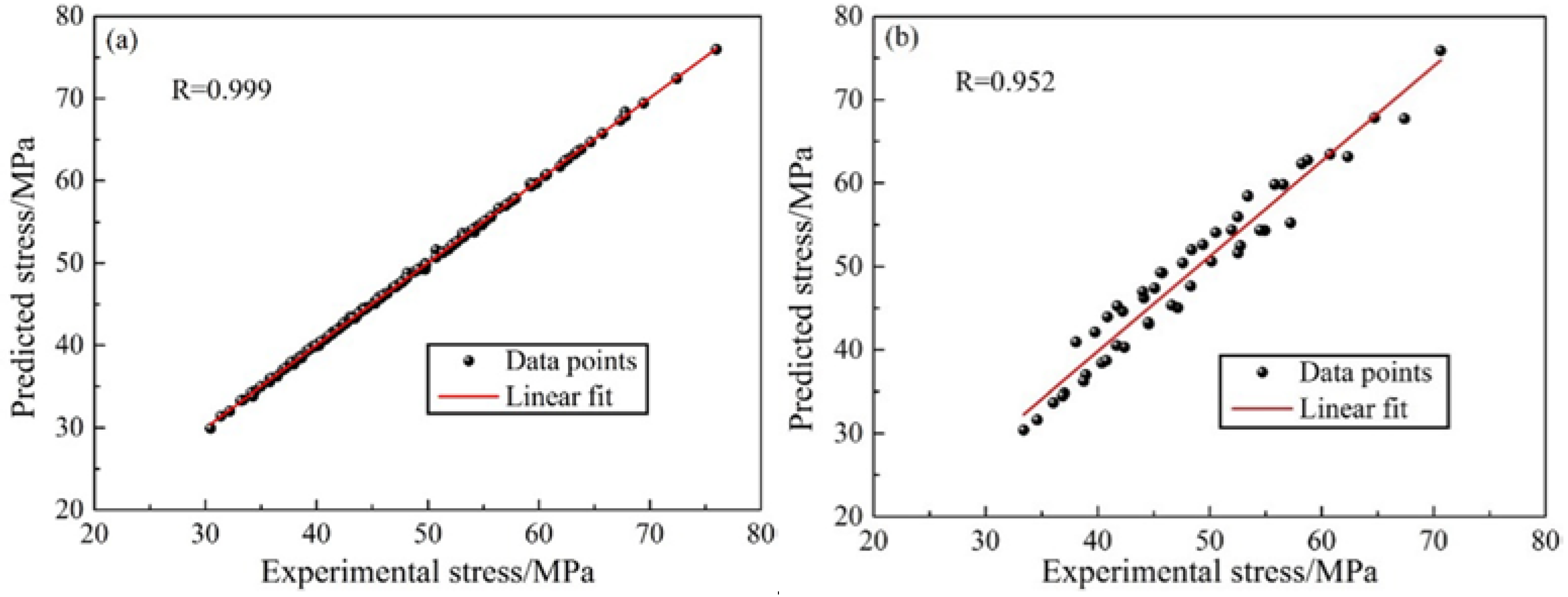

3.3. Artificial Neural Network Modeling

3.4. Evaluation of Arrhenius-Type Constitutive Model and BP Neural Network

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Deng, Y.; Yin, Z.M.; Huang, J.W. Hot deformation behavior and microstructural evolution of homogenized 7050 aluminum alloy during compression at elevated temperature. Mater. Sci. Eng. A 2011, 528, 1780–1786. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.X.; Yuan, D.; Peng, D.S. Hot deformation behavior of the new Al-Mg-Si-Cu aluminum alloy during compression at elevated temperatures. Mater. Charact. 2007, 58, 168–173. [Google Scholar] [CrossRef]

- Quan, G.Z.; Mao, Y.P.; Li, G.S.; Lv, W.Q.; Wang, Y.; Zhou, J. A characterization for the dynamic recrystallization kinetics of as-extruded 7075 aluminum alloy based on true stress–strain curves. Comp. Mater. Sci. 2012, 55, 65–72. [Google Scholar] [CrossRef]

- Shakiba, M.; Parson, N.; Chen, X.-G. Modeling the effects of Cu content and deformation variables on high-temperature flow behavior of dilute Al-Fe-Si using an artificial neural network. Materials 2016, 9, 536. [Google Scholar] [CrossRef]

- Sun, Y.; Hu, L.; Ren, J. Modeling the constitutive relationship of powder metallurgy Ti-47Al-2Nb-2Cr alloy 400 during hot deformation. JMEPG 2015, 24, 1313–1321. [Google Scholar] [CrossRef]

- EI Mehtedi, M.; Gabrielli, F.; Spigarelli, S. Hot workability in process modeling of a bearing steel by using combined constitutive equations and dynamic material model. Mater. Des. 2014, 53, 398–404. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, K.K.; Li, H.B.; Chen, J.; Chen, X.M.; Wen, D.X. New constitutive model for high-temperature deformation behavior of inconel 718 superalloy. Mater. Des. 2015, 74, 108–118. [Google Scholar] [CrossRef]

- Ji, G.L.; Li, Q.; Ding, K.Y.; Yang, L.; Li, L. A physically-based constitutive model for high temperature deformation of Cu-0.36Cr-0.03Zr alloy. J. Alloy. Compd. 2015, 648, 397–407. [Google Scholar] [CrossRef]

- Sarebanzadeh, M.; Mahmudi, R.; Roumina, R. Constitutive analysis and processing map of an extruded Mg-3Gd-1Zn alloy under hot shear deformation. Mater. Sci. Eng. A 2015, 637, 155–161. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, L.X.; Deng, T.Q.; Ye, L. Hot deformation behavior and processing map of as-cast AZ61 magnesium alloy. Mater. Sci. Eng. A 2013, 559, 528–533. [Google Scholar] [CrossRef]

- Deng, T.Q.; Ye, L.; Sun, H.F.; Hu, L.X.; Yuan, S.J. Development of flow stress model for hot deformation of Ti-47%Al alloy. Trans. Nonferr. Met. Soc. China 2012, 21, 308–314. [Google Scholar] [CrossRef]

- Khamei, A.A.; Dehghani, K. Effects of strain rate and temperature on hot tensile deformation of severe plastic deformed 6061 aluminum alloy. Mater. Sci. Eng. A 2015, 627, 1–9. [Google Scholar] [CrossRef]

- Han, Y.; Qiao, G.J.; Sun, J.P.; Zou, D.N. A comparative study on constitutive relationship of as-cast 904L austenitic stainless steel during hot deformation based on Arrhenius-type and artificial neural network models. Comput. Mater. Sci. 2013, 67, 93–103. [Google Scholar] [CrossRef]

- Li, B.; Pan, Q.L.; Yin, Z.M. Microstructural evolution and constitutive relationship of Al-Zn-Mg alloy containing small amount of Sc and Zr during hot deformation based on Arrhenius-type and artificial neural network models. J. Alloy. Compd. 2014, 584, 406–416. [Google Scholar] [CrossRef]

- Ji, G.L.; Li, F.G.; Li, Q.H.; Li, H.Q.; Li, Z. Prediction of the hot deformation behavior for Aermet100 steel using an artificial neural network. Comput. Mater. Sci. 2010, 48, 626–632. [Google Scholar] [CrossRef]

- Li, H.Y.; Wang, X.F.; Wei, D.D.; Hu, J.D.; Li, Y.H. A comparative study on modified Zerilli-Armstrong, Arrhenius-type and artificial neural network models to predict high-temperature deformation behavior in T24 steel. Mater. Sci. Eng. A 2012, 536, 216–222. [Google Scholar] [CrossRef]

- Quan, G.Z.; Lv, W.Q.; Mao, Y.P.; Zhang, Y.W.; Zhou, J. Prediction of flow stress in a wide temperature range involving phase transformation for as-cast Ti-6Al-2Zr-1Mo-1V alloy by artificial neural network. Mater. Des. 2013, 50, 51–61. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Khalesian, A.R.; Abedi, H.R. Artificial neural network modeling to predict the hot deformation behavior of an A356 aluminum alloy. Mater. Des. 2013, 49, 386–391. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Wu, X.L.; Gao, K.Y.; Wang, W.; Nie, Z.R. Hot deformation behavior and constitutive equation of a new type Al-Zn-Mg-Er-Zr alloy during isothermal compression. Mater. Sci. Eng. A 2016, 651, 415–424. [Google Scholar] [CrossRef]

- Zhou, P.; Ma, Q.X.; Luo, J.B. Hot deformation behavior of as-cast 30Cr2Ni4MoV steel using processing maps. Metals 2017, 7. [Google Scholar] [CrossRef]

- Xiang, S.; Liu, D.Y.; Zhu, R.H.; Li, J.F.; Chen, Y.L.; Zhang, X.H. Hot deformation behavior and microstructure evolution of 1460 Al–Li alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 3855–3864. [Google Scholar] [CrossRef]

- Rezaei Ashtiani, H.R.; Parsa, M.H.; Bisadi, H. Constitutive equations for elevated temperature flow behavior of commercial purity aluminum. Mater. Sci. Eng. A 2012, 545, 61–67. [Google Scholar] [CrossRef]

- Yang, Q.; Yang, D.; Zhang, Z.; Cao, L.; Wu, X.; Huang, G.; Liu, Q. Flow behavior and microstructure evolution of 6A82 aluminium alloy with high copper content during hot compression deformation at elevated temperatures. Trans. Nonferrous Met. Soc. China 2016, 26, 649–657. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J. Hot deformation behavior and constitutive modeling of homogenized 6026 aluminum alloy. Mater. Des. 2015, 74, 25–35. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W. Constitutive analysis of homogenized 7005 aluminum alloy at evaluated temperature for extrusion process. Mater. Des. 2015, 66, 129–136. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, H.; Li, D.; Zhang, Z.; Huang, G.; Liu, Q. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature. Mater. Sci. Eng. A 2014, 596, 176–182. [Google Scholar] [CrossRef]

- Hollomon, J.H.; Zener, C. Problems in fracture of metals. J. Appl. Phys. 1946, 82, 82–90. [Google Scholar] [CrossRef]

- Zhao, J.W.; Ding, H.; Zhao, W.J.; Huang, M.L.; Wei, D.B.; Jiang, Z.Y. Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network. Comput. Mater. Sci. 2014, 92, 47–56. [Google Scholar] [CrossRef]

| Element | Mg | Si | Fe | Mn | Cu | Ni | Ti | Zn | Al |

|---|---|---|---|---|---|---|---|---|---|

| Wt % | 0.62 | 0.73 | <0.05 | <0.05 | <0.01 | <0.01 | <0.01 | <0.01 | Bal |

| Strain Rate/s−1 | Flow Stress/MPa | |||||

|---|---|---|---|---|---|---|

| 683 K | 703 K | 723 K | 743 K | 763 K | 783 K | |

| 0.001 | 47.90 | 46.86 | 44.66 | 43.13 | 42.19 | 40.47 |

| 0.01 | 55.88 | 53.60 | 51.76 | 50.23 | 48.78 | 46.37 |

| 0.1 | 63.62 | 61.86 | 57.12 | 55.48 | 53.59 | 50.67 |

| 1 | 76.00 | 68.19 | 65.17 | 63.71 | 60.80 | 59.74 |

| Input-Hidden Layer Activation Function | Hidden-Output Layer Activation Function | Mean Square Error (MSE) |

|---|---|---|

| tansig | tansig | 0.222 |

| tansig | purelin | 0.113 |

| tansig | logsig | 0.289 |

| purelin | tansig | 0.139 |

| purelin | purelin | 1.862 |

| purelin | logsig | 0.167 |

| logsig | tansig | 0.732 |

| logsig | purelin | 0.491 |

| logsig | logsig | 1.094 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Yan, S.; Sun, Y.; Chen, H. Modeling the Constitutive Relationship of Al–0.62Mg–0.73Si Alloy Based on Artificial Neural Network. Metals 2017, 7, 114. https://doi.org/10.3390/met7040114

Han Y, Yan S, Sun Y, Chen H. Modeling the Constitutive Relationship of Al–0.62Mg–0.73Si Alloy Based on Artificial Neural Network. Metals. 2017; 7(4):114. https://doi.org/10.3390/met7040114

Chicago/Turabian StyleHan, Ying, Shun Yan, Yu Sun, and Hua Chen. 2017. "Modeling the Constitutive Relationship of Al–0.62Mg–0.73Si Alloy Based on Artificial Neural Network" Metals 7, no. 4: 114. https://doi.org/10.3390/met7040114