1. Introduction

Aluminum is produced according to the reaction described in Equation (1) [

1]:

Carbon anodes serve as the carbon source on the left-hand side of the equation. The carbon anodes are produced from calcined petroleum coke, with coal tar pitch as the binder. The aluminum industry always strives to improve the production of carbon anodes in order to improve cell stability and lifetime of the anodes. As the anodes are consumed, they need to be changed every 22–28 days. Anode change is part of the routine work in a potroom, and causes temporary instability in each individual cell. This instability includes freezing of electrolyte onto the surface of the cold new anode, and during the time it takes for the electrolyte to melt, no current is drawn by this anode. This in turn causes increased current to be drawn by the remaining anodes. Hence, the introduction of a cold anode will affect both the current load of all the anodes in the cell and the thermal balance of the cell. Anode change will also cause instability in the flow of electrolyte within the cell, and in turn the flow of alumina towards the anodes. Good anode quality is crucial to maintain stable operation, and it is of great interest to optimize the lifetime of the anodes [

1]. High density, low specific electrical resistivity, low impurity level, low permeability, and low air and CO

2 reactivity are all parameters that characterize a high-quality anode. The optimization of carbon anodes relies on many different production parameters, such as mixing temperature, baking level, coke and pitch quality, aggregate composition, etc. The optimum baking level and mixing temperature are dependent on the coke and pitch qualities used [

2].

The Mettler softening point of the pitch is commonly used as a standard guideline for the selection of the proper mixing temperature between coke, pitch, and butts. Most commonly, the mixing temperature is set approximately 50 °C above the Mettler softening point [

3]. However, studies using the sessile drop technique show that an even higher temperature may be needed to optimize the wetting angle between the coke and the pitch, and that the wetting angle between coke and pitch is dependent on both the pitch itself and the coke substrate [

4,

5]. Wilkening [

2,

6] has suggested using mixing temperatures as high as 350 °C in order to improve anode density, specific electrical resistivity (SER), and strength.

A large part of the porosity in anodes is mostly a result of the mixing and vibroforming processes; however, increased porosity can be introduced during the baking process. This type of porosity can be reduced by good baking process control. During the heating part of the baking process, the pitch binder is carbonized to pitch-coke, with release of approximately 1/3 of the pitch matter as volatiles [

7]. During the volatilization and carbonization processes of pitch, more porosity is introduced to the anodes. This porosity is inevitable, but excess porosity can be avoided by good baking furnace design with good temperature control, low Δ

T throughout the furnace, and by using a slow heating rate [

8,

9]. A target baking temperature also needs to be found, as overbaking can cause desulfurization and hence increased microporosity in the anode [

9]. Jentoftsen et al. [

10] suggested that underbaked anodes caused lower anodic current efficiency in the potroom.

Many have studied the effect of production parameters on the final properties of anodes. Azari et al. [

11] studied the effect of a wide range of mixing temperatures (158 °C, 168 °C, 178 °C, and 188 °C) and mixing time (6 min, 10 min, 15 min, and 20 min) on a pitch with a Mettler softening point at 109 °C. They found an optimum mixing temperature at 178 °C and a mixing time of 10 min in their laboratory setup. With this mixing temperature and time, they achieved the highest baked apparent density, the lowest air permeability, and the lowest surface area (measured using the Brunauer-Emmett-Teller (BET) method). With a higher mixing temperature, the anode properties became poorer, and they argued that this was because the viscosity of the pitch became so low that the pitch penetrated very small pores of the coke. They argue that it might make the amount of pitch insufficient to fill the voids between coke particles. At lower mixing temperatures, the viscosity of the pitch was increasingly higher, resulting in agglomeration of the fine particles without penetration of the pitch into open pores.

Air reactivity of cokes and air reactivity of baked anodes have been studied extensively over the years. The results are not unambiguous, and this is likely due to the many coke calcination temperatures studied, the different types of cokes, and if the cokes have been calcined in an industrial calciner or in a laboratory environment [

12]. The results of air reactivity on cokes are not always directly transferrable to baked anode properties. Belitskus [

12] studied the effect of coke calcination temperature and anode baking temperature on the crystallite height,

Lc, of the coke, the baked apparent density, specific electrical resistivity, and air reactivity. The crystallite height of the cokes calcined at three different temperatures (1150 °C, 1250 °C, and 1350 °C) increased linearly with calcination temperature. It was found that the apparent density of the anode increased with increasing baking temperature. The effect was higher for the anodes baked at the highest baking temperature, produced from coke with lowest calcination temperature. SER decreased with increasing baking temperature for all the coke calcination temperatures used. Air reactivity of the anodes also decreased with increasing baking temperature and with increasing coke calcination temperature.

The fact that

Lc increases with increasing calcination temperature of cokes was also found by Boero [

13]. He also found that air reactivity decreased as

Lc increased. It was also suggested that the surface area of the coke could affect air reactivity, but Boero argued that this effect is difficult to measure, since the surface area would change over time when the cokes react with air.

Dreyer, Samanos, and Vogt [

14] studied two different cokes—one high in sulfur and one low in sulfur—and the final properties of baked carbon anodes. The two cokes were calcined at a high and a low level, and four pilot-scale anodes were produced. The sulfur content of the low-sulfur coke was found to be constant over the course of the baking temperature, and no desulfurization was observed. For the high-sulfur coke, desulfurization was observed, and a rapid drop in sulfur content appeared. When studying various properties of the anodes, they found that the coefficient of thermal expansion (CTE) was little affected by baking temperature for the low sulfur content anode. However, for the higher sulfur content anode, a rapid drop in CTE was found when the baking temperature exceeded the threshold for desulfurization. CO

2 reactivity was not significantly affected by baking temperature, although the higher sulfur anodes were slightly more affected by baking temperature with respect to CO

2 reactivity. This was attributed to desulfurization. SER decreased with increasing baking temperature, but SER was not affected by desulfurization.

The aim of this paper is to study the effect of two mixing temperatures and three baking levels on the resulting quality of six pilot-scale anodes, using the statistical tool called factorial design. The coke is a single source coke of a relatively low impurity level and constant calcination temperature. No butts were added, and the type and level of pitch was the same for all experiments. Impurity levels may therefore be assumed to be constant, and effects of calcination level of the coke on pitch wetting can be neglected. Thus, mixing temperature and baking level are the only parameters varied in the experiments, selected in order to minimize the complex interdependencies of material and process parameters on anode properties. The experiments were performed in accordance with 22 full factorial designs in order to identify how and if the mixing temperatures and baking levels affect the density, SER, air permeability, CTE, air reactivity, and CO2 reactivity, and whether there are possible interaction effects.

3. Results

Table 3,

Table 4 and

Table 5 show the anode production parameters with corresponding raw data physical properties for the three factorial design setups demonstrated in

Table 1. The 2

2 factorial design setup is indicated with main factors A (mixing temperature) and B (baking level), and standard notation −1 indicating low levels and +1 indicating high levels.

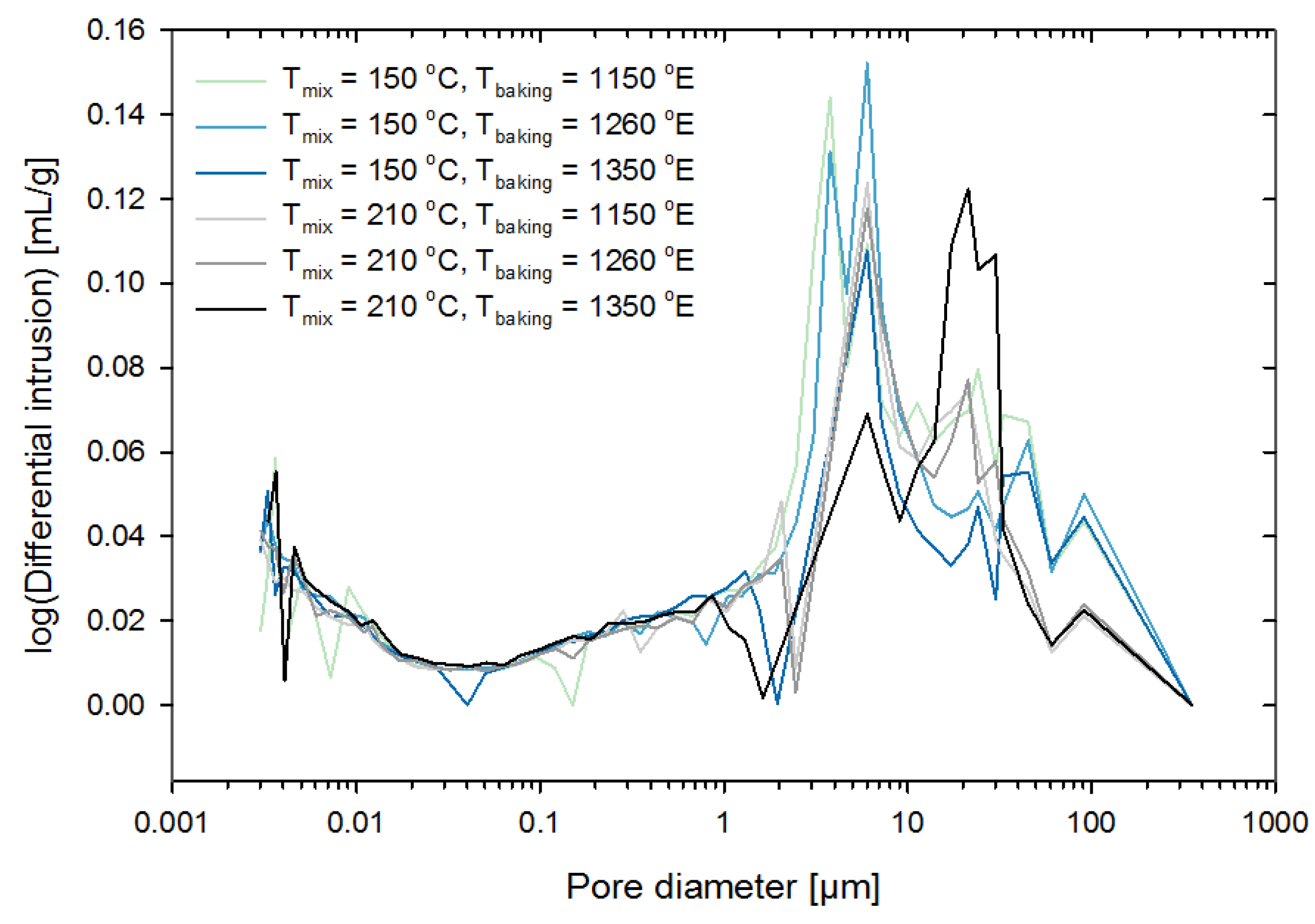

Figure 1 shows the pore size distribution of the pilot scale anodes, as found by Hg porosimetry. The peaks that appear at about 4–7 μm are pores that are likely to appear due to porosity between fines. Peaks between 20–30 μm correspond to calcining pores, appearing when volatiles are being released from pitch during baking and larger pores between fines. The peaks at about 100 μm are inhomogeneity pore that appear due to the non-ideal low mixing temperature. These peaks are much more evident for the low mixing temperature anodes, compared with the high mixing temperature anodes. It is not apparent why the two parallels of the high mixing, high baked anode show a much larger peak at 20–30 μm than the other anode samples. The increase in porosity observed at pore sizes below 0.01 μm is most likely due to crushing of the anode samples at the high pressure imposed on the samples.

Figure 2 shows the visual effect of mixing temperature on the porosity in the anodes. This difference in porosity affects air permeability and SER directly, as shown in

Table 4 and

Figure 3.

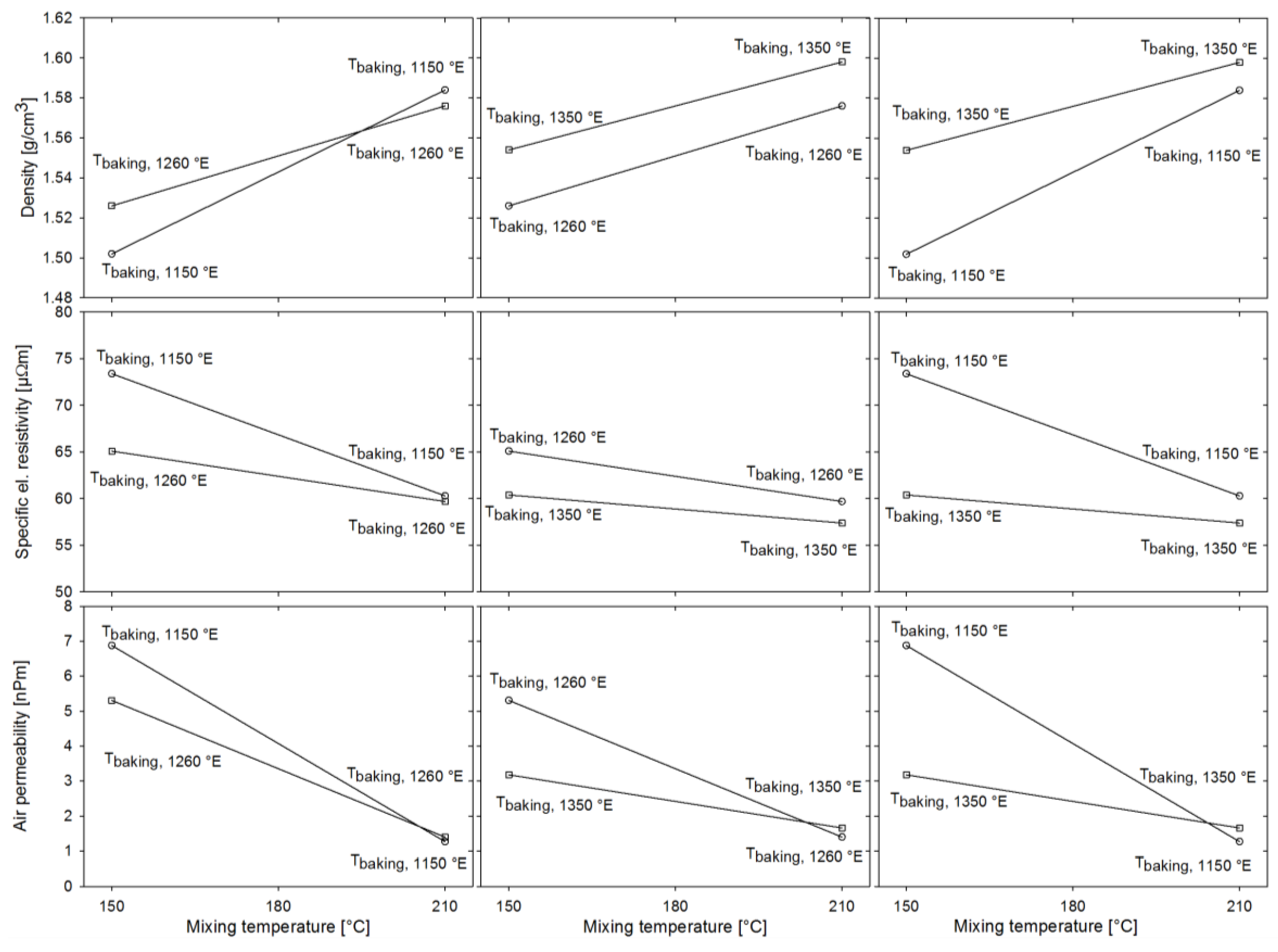

Figure 3 shows the effect of mixing temperature and baking level on the physical parameters density, SER, and air permeability.

Figure 4 shows the effect of mixing temperature and baking temperature on the coefficient of thermal expansion, CO

2 reactivity, and air reactivity. The left column shows underbaking vs. target baking, the middle column shows target baking vs. overbaking, and the right column shows underbaking vs. overbaking.

A steep slope between low and high level of mixing temperature indicates a high effect of mixing temperature on the physical properties. Density, air permeability, and CO

2 reactivity show a steep slope between low and high mixing temperature. Density increases and air permeability decreases with higher mixing temperature. SER also decreases somewhat with higher mixing temperature, but is also affected by baking level, and this is in accordance with literature [

12,

14]. Both the decrease in air permeability and SER can be related to the increase in density. A higher mixing temperature is clearly beneficial in terms of density, air permeability, and SER.

A large difference between the two lines in each window in

Figure 3 and

Figure 4 indicates a large effect of baking level on the physical properties. In

Figure 3, the difference in physical properties between high and low baking levels is not significant, except when comparing underbaking and overbaking. This is especially true at the low mixing temperature level, indicating that low mixing and low baking level give a particularly poor quality anode as expected, with low density, high SER, and high air permeability.

In

Figure 4, a fairly large difference is observed between the graphs of CO

2 and air reactivity, indicating a high influence of baking temperature on these physical properties. CO

2 reactivity increases with higher baking temperature, and intuitively this could be argued to be due to some release of sulfur from the coke structure during baking, as described in literature [

9]. Sulfur is a known inhibitor of CO

2 reactivity, as it forms inactive metal–sulfur complexes with metal catalysts [

19]. However, it was also observed in

Figure 4 that density of the anodes generally increased with increasing baking level, including the overbaked anodes, and the coke used in this work is a low sulfur coke (<1%, found by X-Ray Fluorescence (XRF), ISO 12980:2000 and reported in [

20]). Low-sulfur cokes have shown low “puffing” effect and little release of sulfur at baking levels relevant to the levels used in this study [

14,

19]. This also implies that it is plausible that little sulfur is released during the baking of these pilot anodes, since desulfurization would cause increased microporosity in the coke structure and lower the final density of the anode. Hg porosimetry also shows little change in microporosity during the increase in baking temperature, so it is convincing that little desulfurization takes place. CO

2 reactivity decreases with higher mixing temperature, indicating a covariance between CO

2 reactivity and anode density.

The effect of main factors A and B—namely, mixing temperature and baking level—can be calculated using Equation 2.

Table 6,

Table 7 and

Table 8 show the calculated effects of main factors A and B and the interaction effect AB for the three factorial design setups demonstrated in

Table 1. When investigating

Table 6,

Table 7 and

Table 8, it is clear that mixing temperature is a factor that determines the output density to a much larger degree than the baking temperature. Additionally, the interaction effect is rather small between mixing and baking temperature. However, for SER, both mixing temperature and baking level affect the output property. The interaction effect is also rather high. Mixing temperature is important in controlling the density, as seen visually in

Figure 2. A higher baking level is beneficial for the SER, supporting the argument that little sulfur is released from the coke structure because desulfurization would cause increased microstructure. Increased microstructure would lower the SER. This is also in accordance with literature [

12,

14]. Air permeability is also strongly affected by mixing temperature, and a higher mixing temperature decreases the permeability.

No significant difference is seen between the high and low baking and mixing temperatures for coefficient of thermal expansion. CTE is clearly not affected by either mixing temperature or baking level, even though the anodes show fairly large effects of the production parameters on the other properties of this study, density in particular. This suggests that CTE is a raw material property, mainly the coke. This is also in accordance with what Dreyer, Samanos, and Vogt [

14] found for anodes made from low-sulfur coke.

Both mixing temperature and baking level affect the CO

2 reactivity. However, the interaction effect is rather low. A higher mixing temperature lowers the CO

2 reactivity, while a higher baking level increases the CO

2 reactivity. The density of the anodes increases with both increasing mixing and baking temperature as illustrated in

Figure 3. In

Figure 2, the lower mixing temperature gives larger and more pores compared to when using a higher mixing temperature, and these findings are further confirmed quantitatively in

Figure 1. A large open porosity will increase CO

2 reactivity due to an increased exposed surface area. Azari et al. [

11] found an increase in BET surface area as the density decreased, and it is reasonable to believe that similar results would have been found here if BET had been performed. At the same binder level, the higher mixing temperature will lower the viscosity of the pitch and hence spread the binder better and thinner between and within coke particles. This leads to higher density and more homogeneous anodes [

11].

Air reactivity is strongly affected by baking temperature, especially when comparing the overbaked pilot anodes to the anodes baked at 1150 °E and 1260 °E, as shown in

Figure 4 and

Table 7 and

Table 8. However, for the target baking case, the mixing temperature also appears to have a slight impact on the air reactivity. Air reactivity decreases significantly for the overbaked pilot anodes compared to the target baking and underbaked case, regardless of mixing temperature. This is most likely due to the baking level in the overbaked case being higher than the calcination temperature of the coke used. According to Hydro Aluminium, a typical calcination temperature for the coke used is 1240–1280 °E [

21]. During further calcination of the coke in the anodes, the graphite structure changes as described by Oberlin [

22]. The crystallite height grows larger during calcination from 700–1300 °C, and

Lc is highest at the highest calcination temperature. It is reasonable to assume that a change in graphite crystallite structure can affect the air reactivity due to ordering of the graphite structure giving fewer active sites available for reaction between air and carbon. Another explanation can be that with higher baking temperature, some metal complexes may be released from the coke structure upon heating. Vanadium is a known metal air burn catalyst, as it destabilizes the carbon ring structure of the surrounding carbons [

23]. However, no proof is given in the present work that vanadium or other metal complexes are actually released during the baking process. Since the mixing temperature did not affect the air reactivity significantly, this indicates that other factors such as increased graphitization of the anode coke or metal impurity concentration are more important than porosity and exposed surface area.

Pareto charts [

15] created from the absolute values of effects A, B, and interaction effect AB are shown in

Figure 5. The Pareto chart helps visualize which effects are most important for each physical property underlining the discussion above.