Effect of Cobalt on Microstructure and Wear Resistance of Ni-Based Alloy Coating Fabricated by Laser Cladding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Microstructure Observation

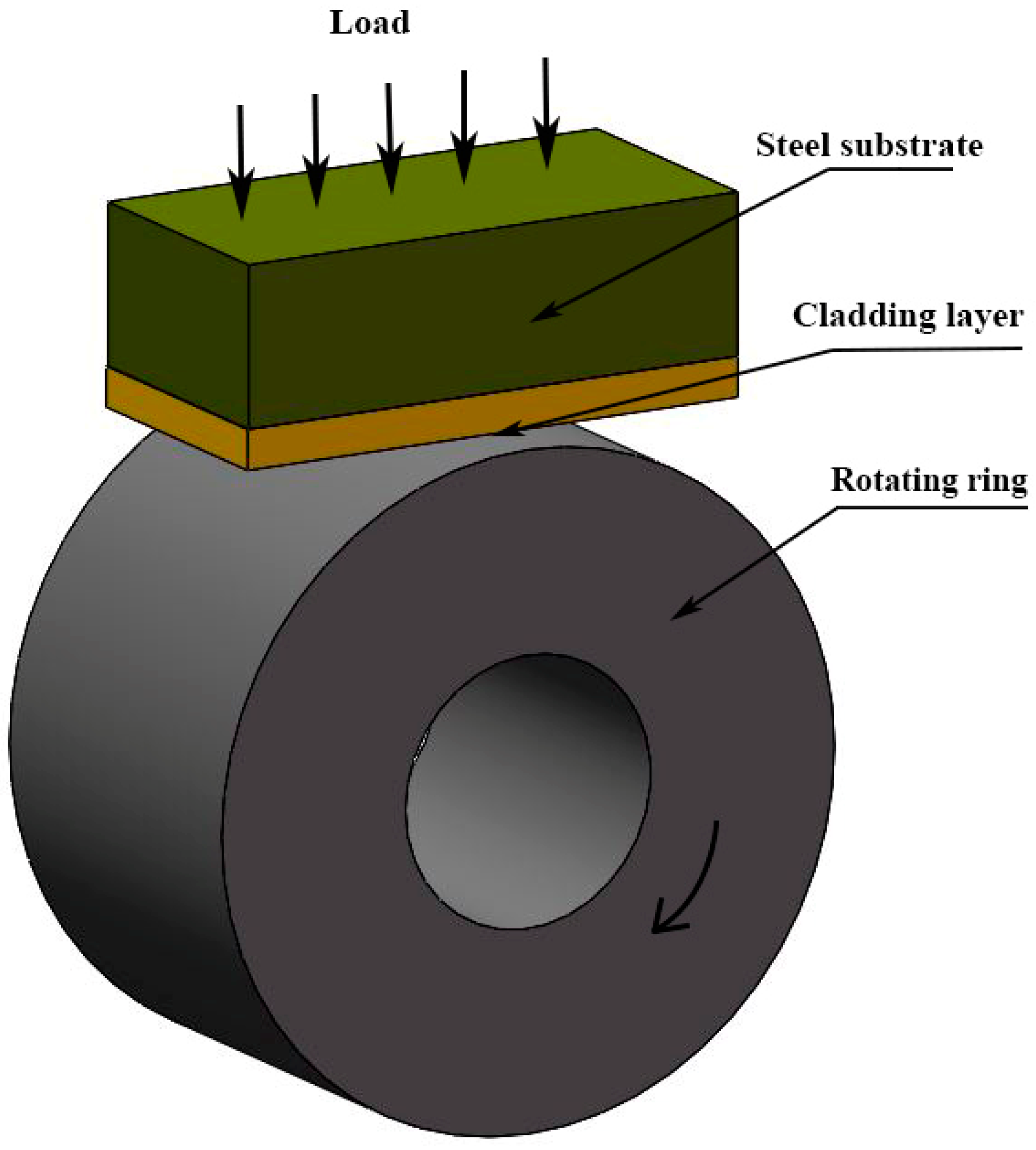

2.3. Microhardness and Wear Resistance Tests

3. Results and Discussion

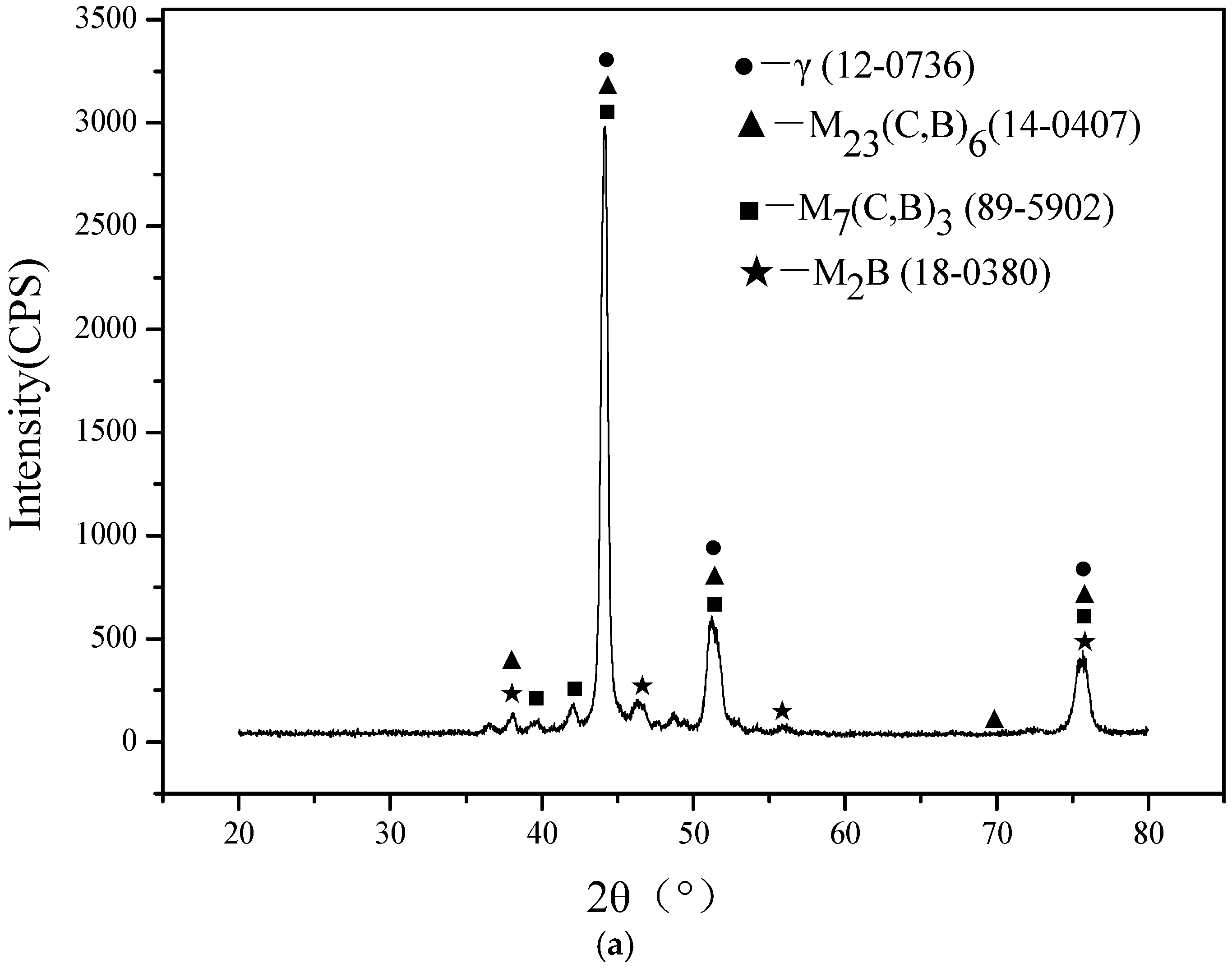

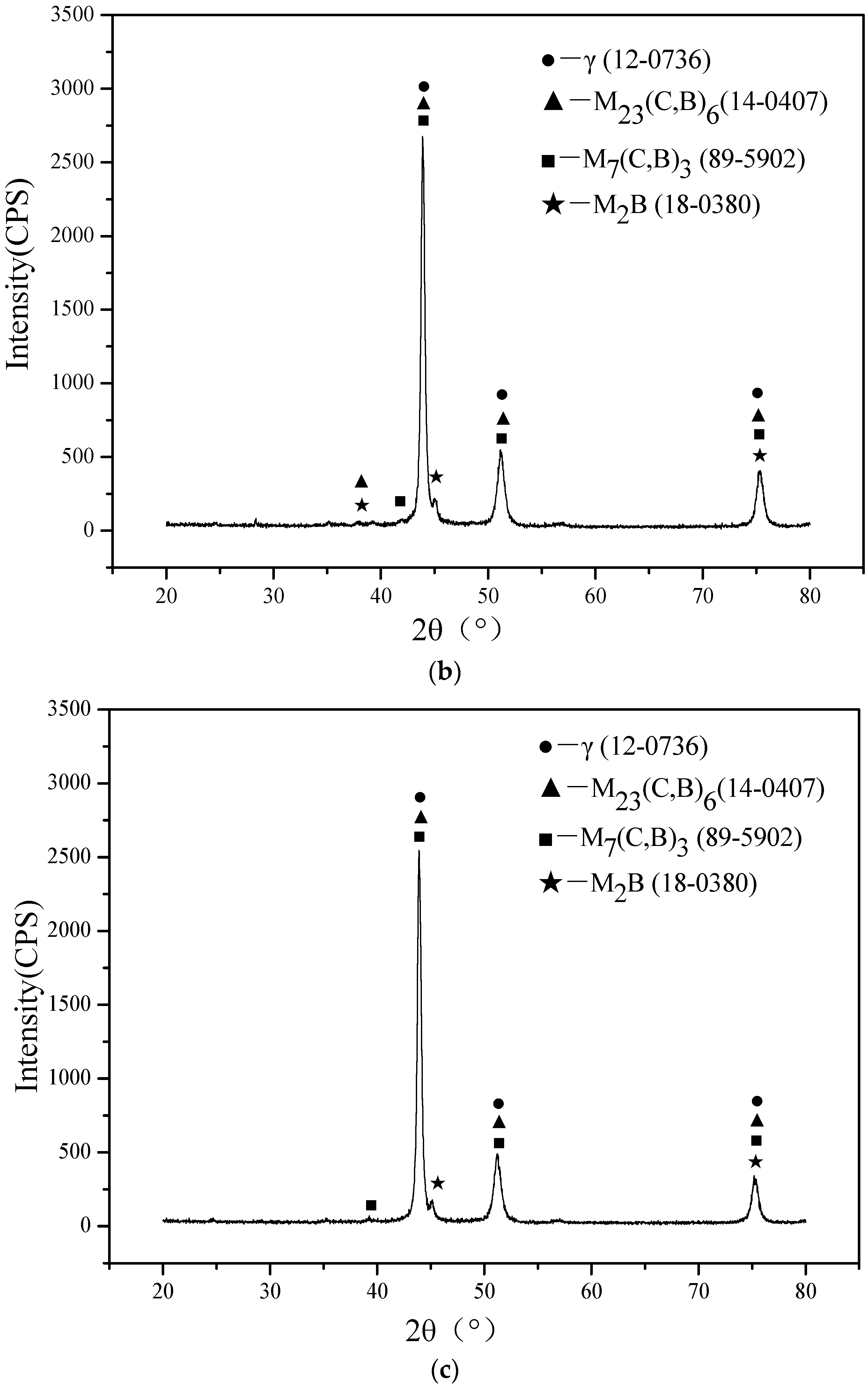

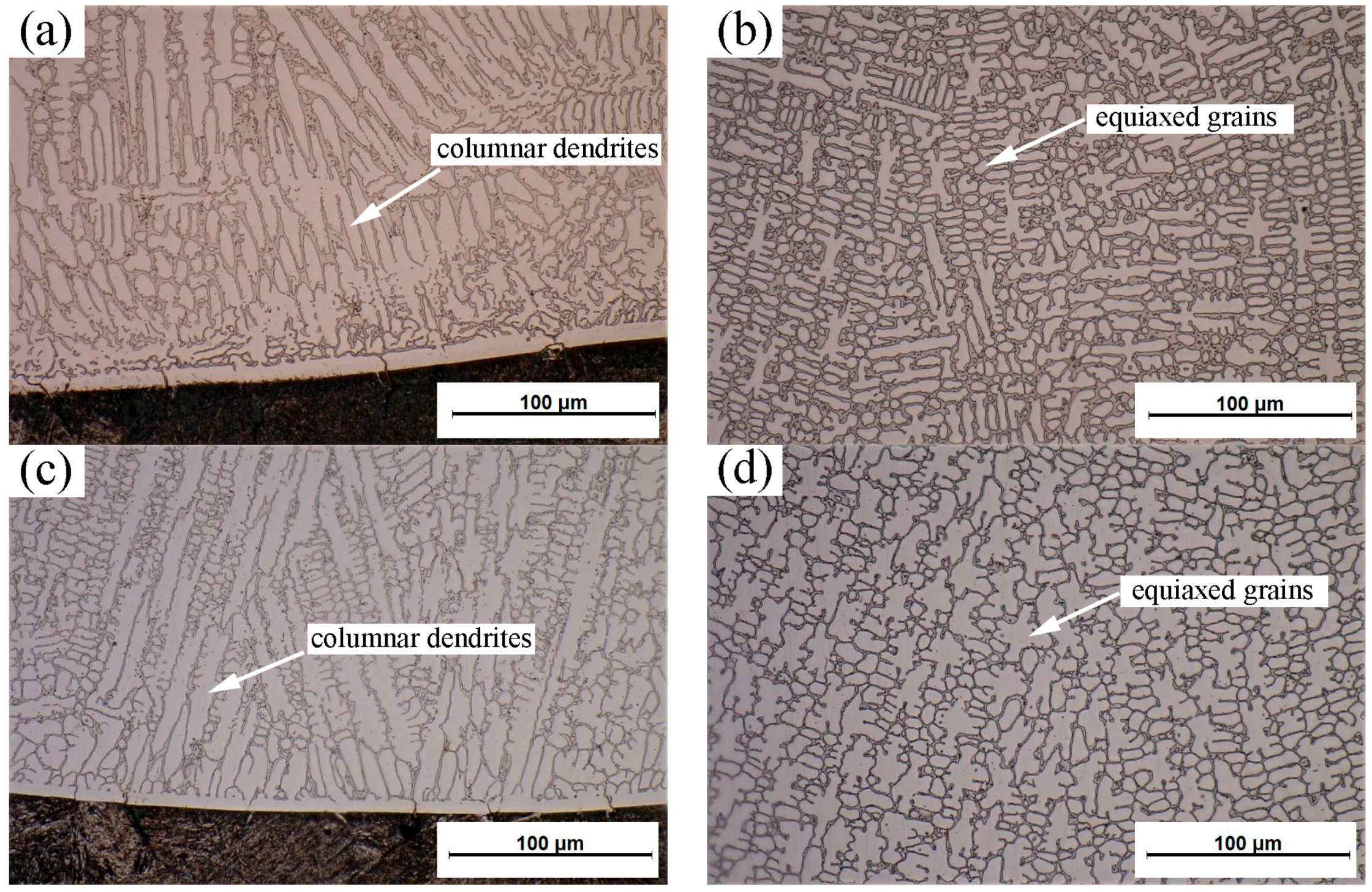

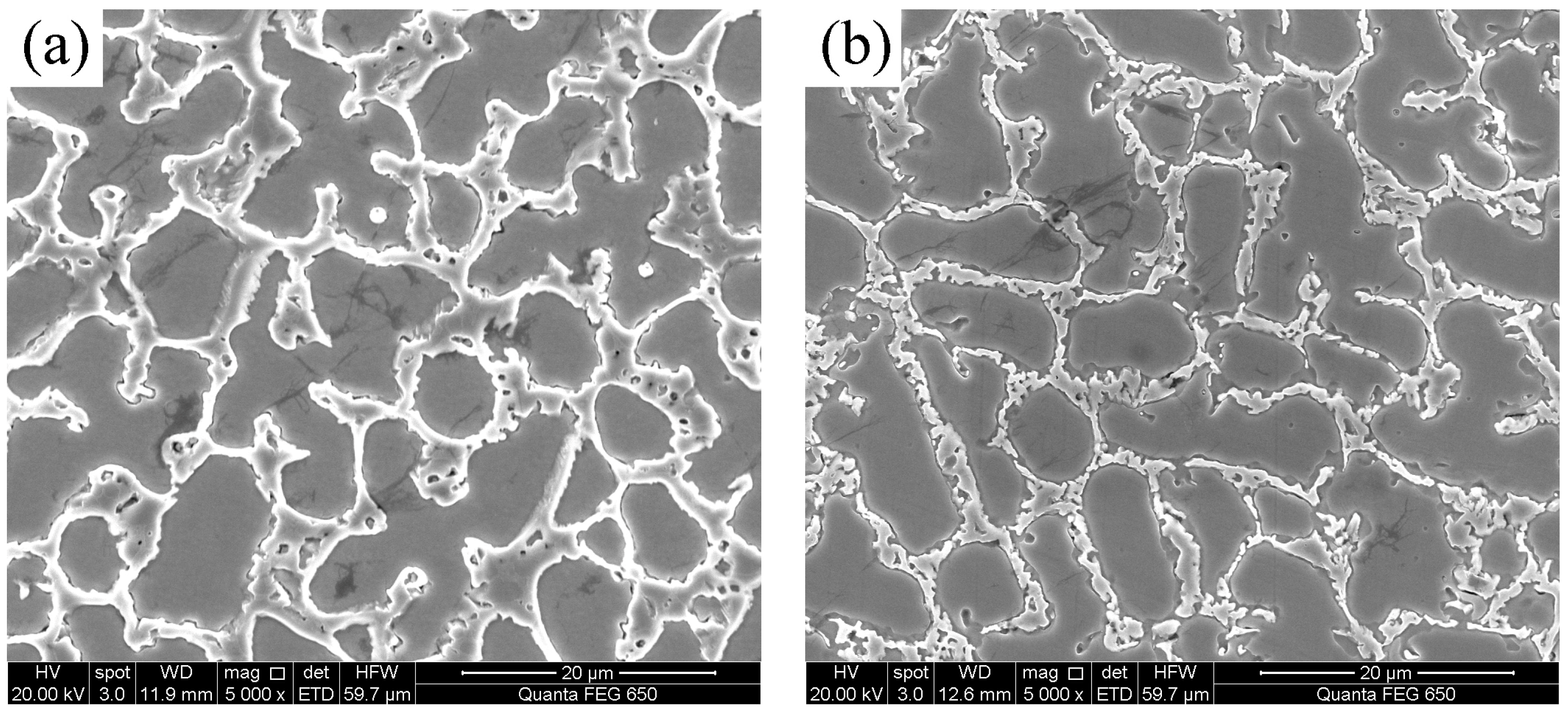

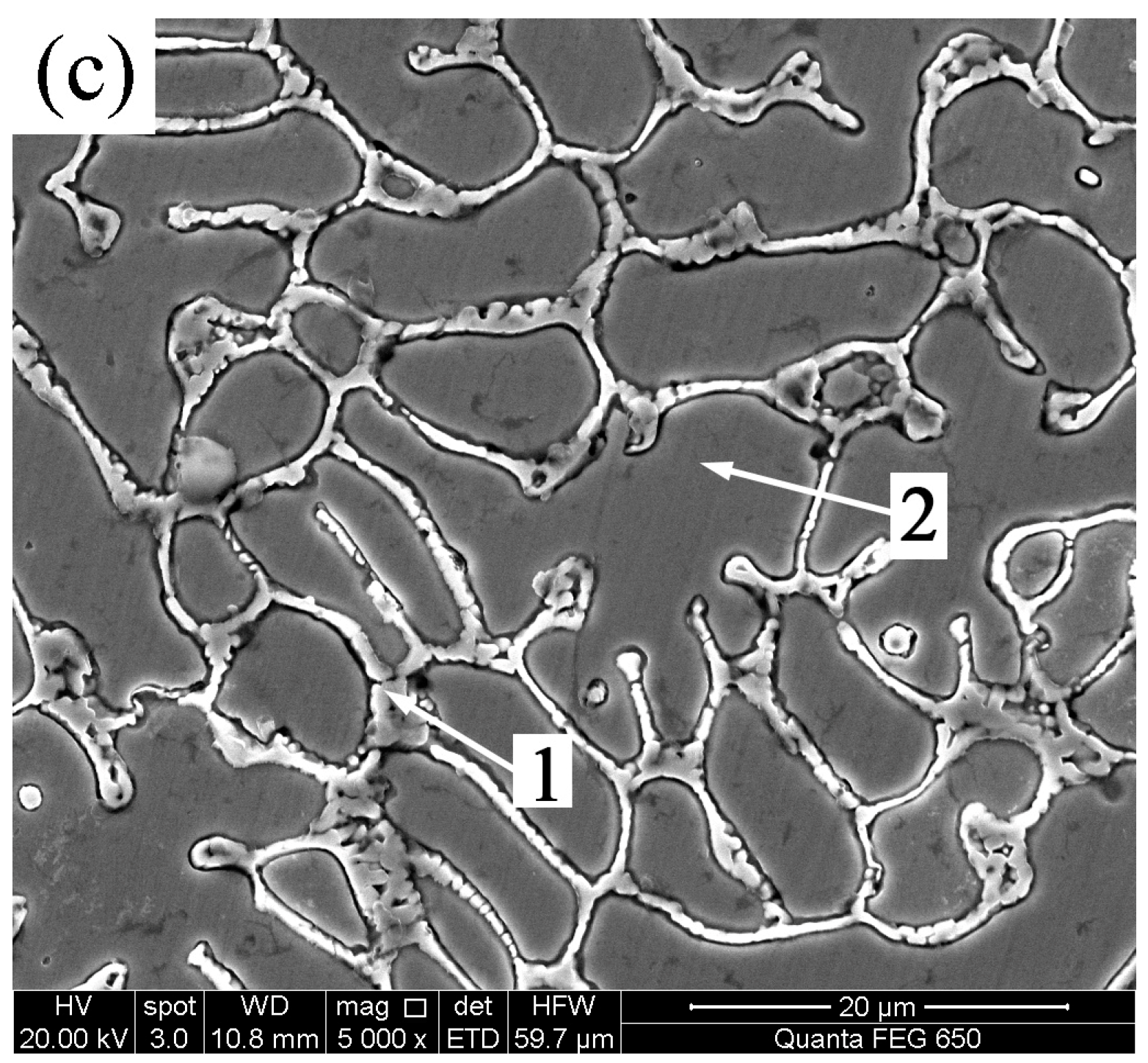

3.1. Phase and Microstructure

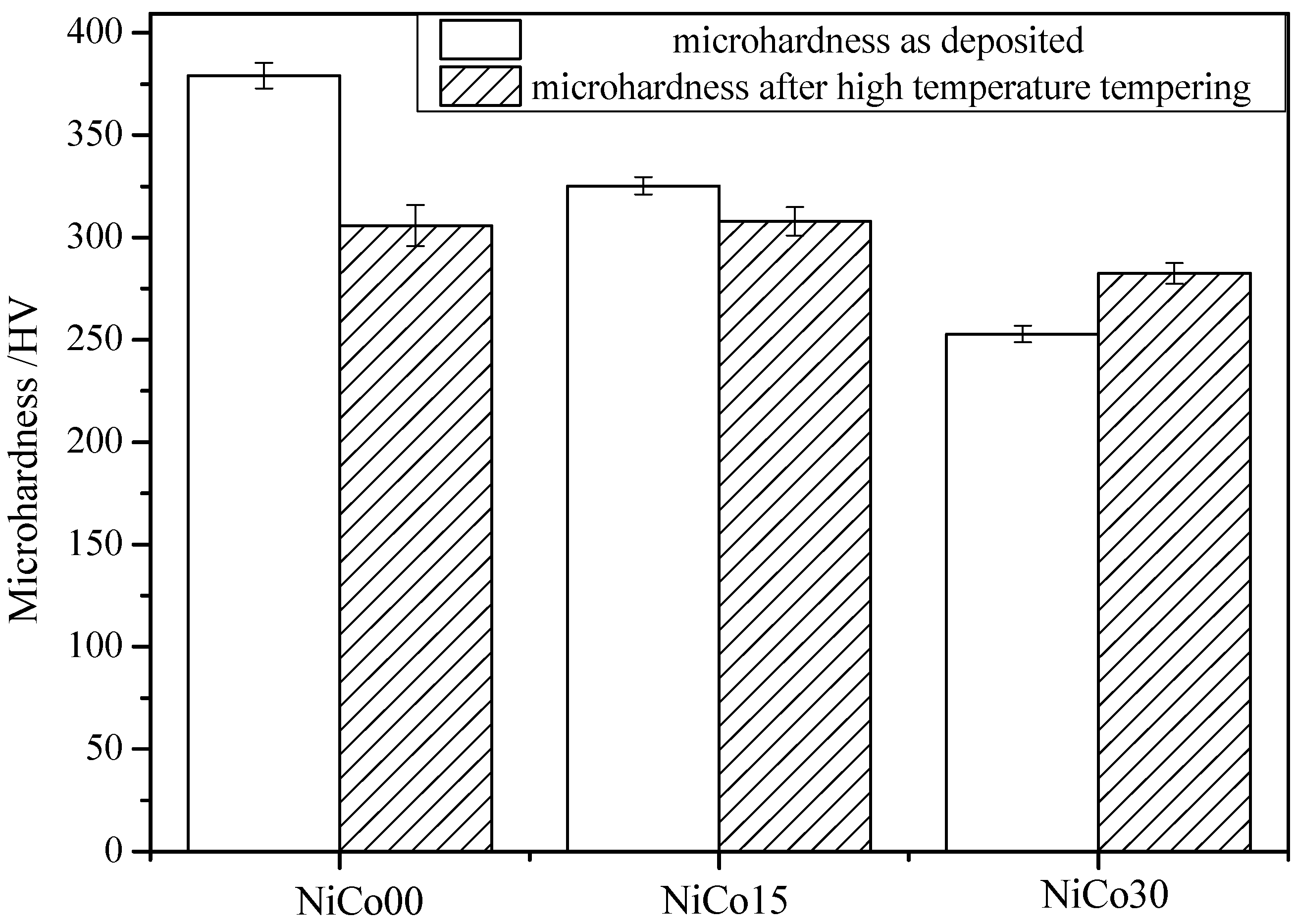

3.2. Microhardness

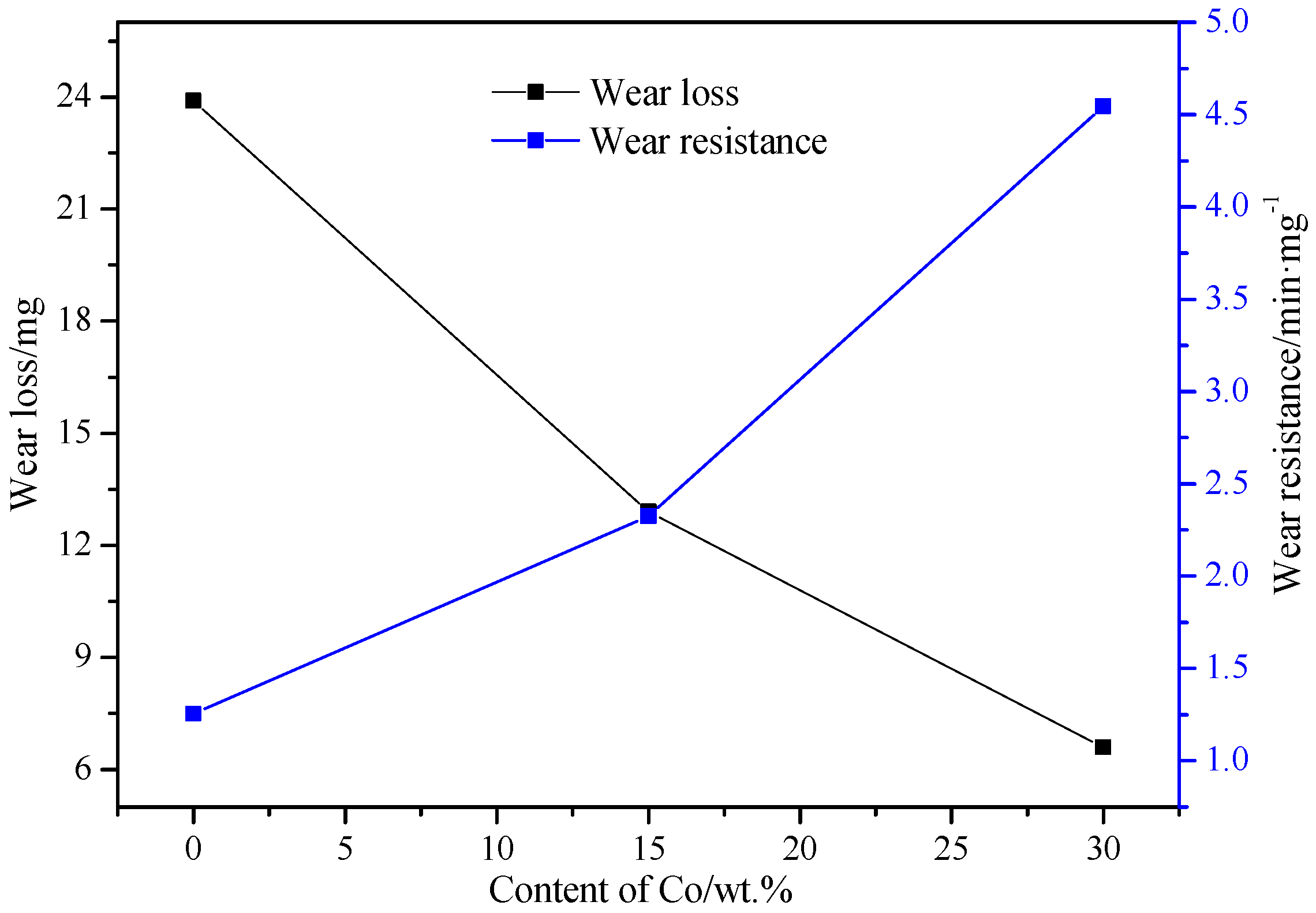

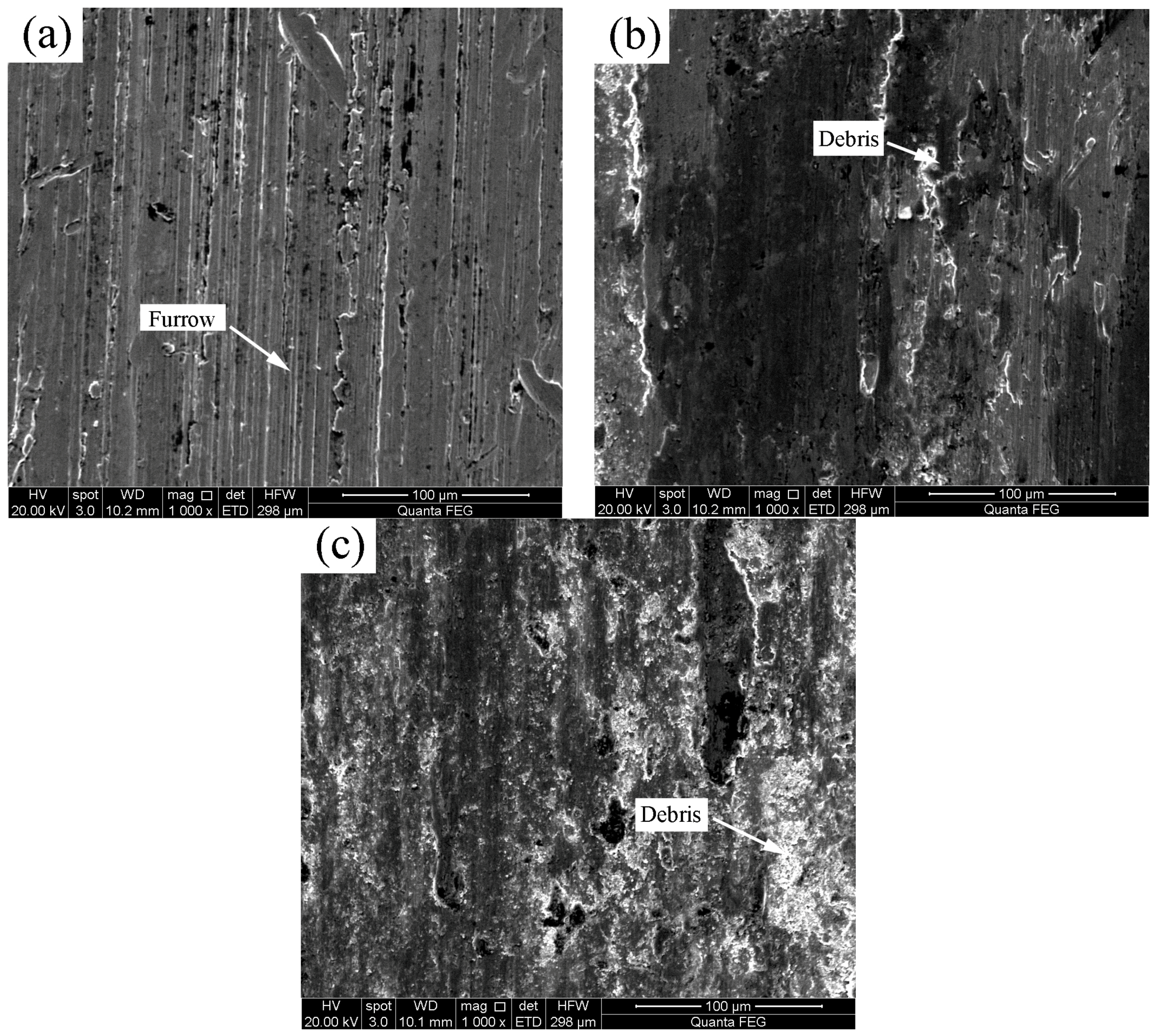

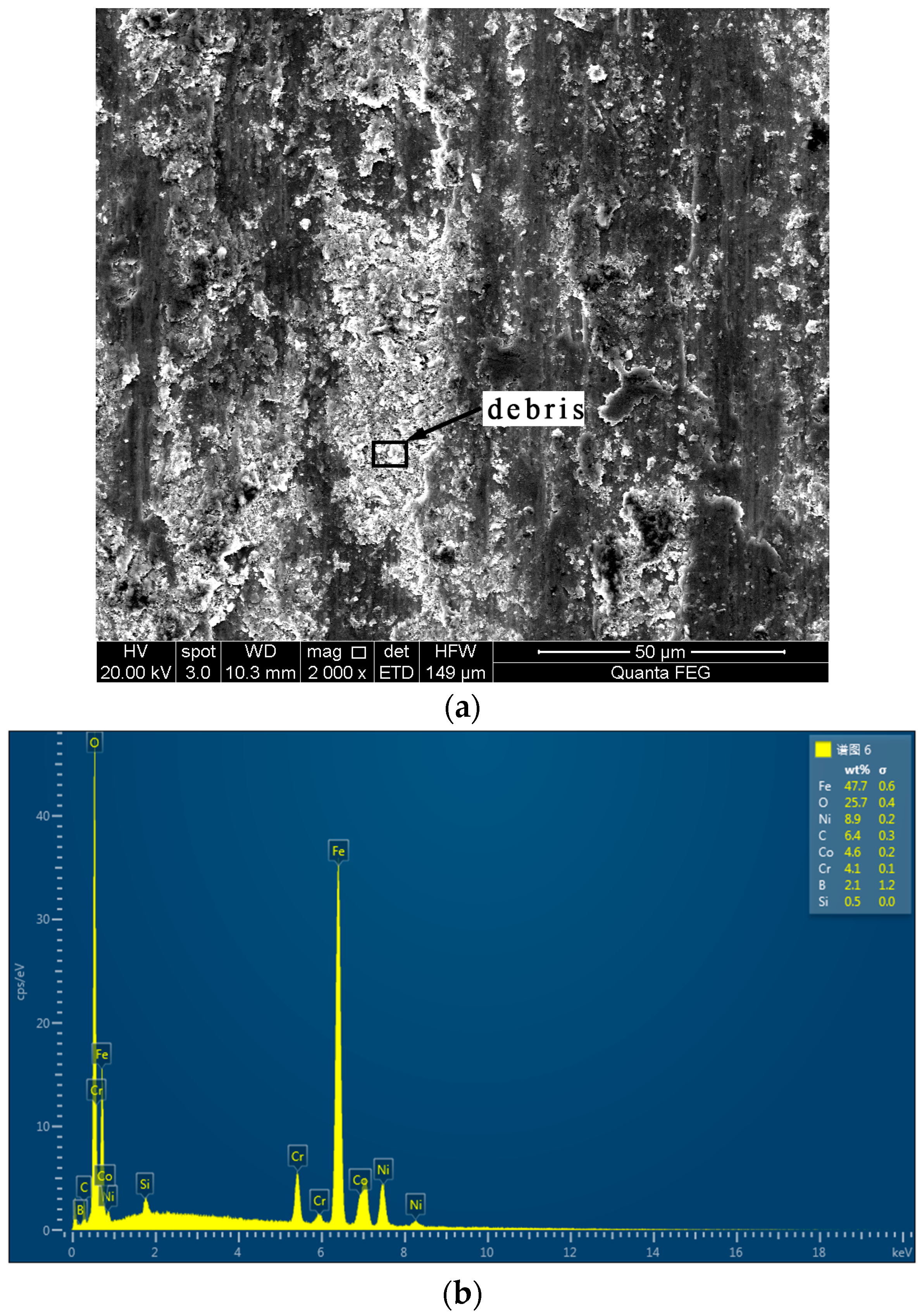

3.3. Wear Resistance

4. Conclusions

- (1)

- The phases of cladding layers with different Co contents include γ, M7(C, B)3, M23(C, B)6, and M2B, where M is Cr and Fe. The amount of M7(C, B)3, M23(C, B)6, and M2B decreases gradually with the increase of the Co content.

- (2)

- Good metallurgical bondings have been achieved between the substrates and the cladding layers. The microstructure of cladding layers are mainly composed of dendrites and eutectic structures. The width of eutectic structures decreases with the increase of the Co content.

- (3)

- The microhardness of the cladding layer decreases, but the wear resistance increases with the increase of Co content. The wear resistance of the NiCo30 coating is about 3.6 times that of the NiCo00 coating. The wear mechanism of the cladding layer is changed from abrasive wear to adhesive wear with the increase of Co content.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, Y.; Guo, Y.; Lu, B.; Xu, M.; Xu, J. Microstructure and properties of the interface area in the laser cladded Ni based coatings on the 1Cr10Mo1NiWVNbN steel. Metals 2017, 7, 175. [Google Scholar] [CrossRef]

- Farahmand, P.; Kovacevic, R. An experimental-numerical investigation of heat distribution and stress field in single- and multi-track laser cladding by a high-power direct diode laser. Opt. Laser Technol. 2014, 63, 154–168. [Google Scholar] [CrossRef]

- Corbin, S.F.; Toyserkani, E.; Khajepour, A. Cladding of an Fe-aluminide coating on mild steel using pulsed laser assisted powder deposition. Mater. Sci. Eng. 2003, 354, 48–57. [Google Scholar] [CrossRef]

- Wu, F.; Chen, T.; Wang, H.; Liu, D. Effect of Mo on Microstructures and wear properties of in situ synthesized Ti(C,N)/Ni-based composite coatings by laser cladding. Materials 2017, 10, 1047. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, C.; Xu, L.; Xiao, H.; Zheng, L. Microstructure and mechanical properties of the hot-rolled Mg–Y–Nd–Zr alloy. J. Mater. Res. 2013, 28, 1386–1393. [Google Scholar] [CrossRef]

- Xie, M.-X.; Zhang, L.-J.; Zhang, G.-F.; Zhang, J.-X.; Bi, Z.-Y.; Li, P.-C. Microstructure and mechanical properties of CP-Ti/X65 bimetallic sheets fabricated by explosive welding and hot rolling. Mater. Des. 2015, 87, 181–197. [Google Scholar] [CrossRef]

- Azevedo, T.F.; Dos Santos, C.R.; De Souza, R.E.A.; Tentardini, E.K.; Griza, S. Failure analysis of the repair procedure of an ore compactor roll. Eng. Fail. Anal. 2013, 31, 195–202. [Google Scholar] [CrossRef]

- Ray, A.; Arora, K.S.; Lester, S.; Shome, M. Laser cladding of continuous caster lateral rolls: Microstructure, wear and corrosion characterisation and on-field performance evaluation. J. Mater. Process. Technol. 2014, 214, 1566–1575. [Google Scholar] [CrossRef]

- Sampath, S.; Neiser, R.A.; Herman, H.; Kirkland, J.P.; Elam, W.T. A structural investigation of a plasma sprayed Ni-Cr based alloy coating. J. Mater. Res. 1993, 8, 78–86. [Google Scholar] [CrossRef]

- Cooke, K.; Oliver, G.; Buchanan, V.; Palmer, N. Optimisation of the electric wire arc-spraying process for improved wear resistance of sugar mill roller shells. Surf. Coat. Technol. 2007, 202, 185–188. [Google Scholar] [CrossRef]

- Birger, E.M.; Moskvitin, G.V.; Polyakov, A.N.; Arkhipov, V.E. Industrial laser cladding: Current state and future. Weld. Int. 2011, 25, 234–243. [Google Scholar] [CrossRef]

- Lin, Y.; Lei, Y.; Fu, H.; Lin, J. Mechanical properties and toughening mechanism of TiB2/NiTi reinforced titanium matrix composite coating by laser cladding. Mater. Des. 2015, 80, 82–88. [Google Scholar] [CrossRef]

- Simunovic, K.; Saric, T.; Simunovic, G. Different approaches to the investigation and testing of the Ni-based self-fluxing alloy coatings—A review. Part 1: General facts, wear and corrosion investigations. Tribol. Trans. 2014, 57, 955–979. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Yue, T. The pseudo-eutectic microstructure and enhanced properties in laser-cladded hypereutectic Ti-20% Si coatings. Metals 2017, 7, 33. [Google Scholar] [CrossRef]

- Paatsch, W. Energy turnaround—A challenge for surface technology. Trans. IMF 2016, 94, 228–230. [Google Scholar] [CrossRef]

- He, H.; Zhang, T.; Ma, M.; Liu, W. Microstructure and wear resistance of laser cladding particulate reinforced Fe-based composite coating on railway steel. J. Laser Appl. 2017, 29, 22503. [Google Scholar] [CrossRef]

- Gao, W.; Zhao, S.; Liu, F.; Wang, Y.; Zhou, C.; Lin, X. Effect of defocus manner on laser cladding of Fe-based alloy powder. Surf. Coat. Technol. 2014, 248, 54–62. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Qian, S.; Yu, Q.; Dong, C. Microstructure and wear resistance of laser-clad (Co, Ni) 61.2B26.2Si7.8Ta4.8 coatings. Metals 2017, 7, 419. [Google Scholar] [CrossRef]

- Lewis, S.R.; Lewis, R.; Fletcher, D.I. Assessment of laser cladding as an option for repairing/enhancing rails. Wear 2015, 330–331, 581–591. [Google Scholar] [CrossRef]

- Lin, C.-M. Parameter optimization of laser cladding process and resulting microstructure for the repair of tenon on steam turbine blade. Vacuum 2015, 115, 117–123. [Google Scholar] [CrossRef]

- Angelastro, A.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D.; Ferrara, S. A methodology for optimization of the direct laser metal deposition process. Key Eng. Mater. 2011, 473, 75–82. [Google Scholar] [CrossRef]

- Xu, J.S.; Zhang, X.C.; Xuan, F.Z.; Wang, Z.D.; Tu, S.T. Microstructure and sliding wear resistance of laser cladded WC/Ni composite coatings with different contents of WC particle. J. Mater. Eng. Perform. 2011, 21, 1904–1911. [Google Scholar] [CrossRef]

- Paul, C.P.; Mishra, S.K.; Tiwari, P.; Kukreja, L.M. Solid-particle erosion behaviour of WC/Ni composite clad layers with different contents of WC particles. Opt. Laser Technol. 2013, 50, 155–162. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.M. Microstructure and wear resistance of a laser clad TiC reinforced nickel aluminides matrix composite coating. Mater. Sci. Eng. 2004, 368, 80–87. [Google Scholar] [CrossRef]

- Ma, Q.; Li, Y.; Wang, J.; Liu, K. Investigation on cored-eutectic structure in Ni60/WC composite coatings fabricated by wide-band laser cladding. J. Alloys Compd. 2015, 645, 151–157. [Google Scholar] [CrossRef]

- Lei, Y.; Sun, R.; Lei, J.; Tang, Y.; Niu, W. A new theoretical model for high power laser clad TiC/NiCrBSiC composite coatings on Ti6Al4V alloys. Opt. Lasers Eng. 2010, 48, 899–905. [Google Scholar] [CrossRef]

- Zhang, G.Y.; Wang, C.L.; Gao, Y. Mechanism of rare earth CeO2 on the Ni-based laser cladding layer of 6063 Al surface. Rare Met. Mater. Eng. 2016, 45, 1002–1006. [Google Scholar]

- Ma, Q.; Li, Y.; Wang, J. Effects of Ti addition on microstructure homogenization and wear resistance of wide-band laser clad Ni60/WC composite coatings. Int. J. Refract. Met. Hard Mater. 2017, 64, 225–233. [Google Scholar]

- Guo, H.M.; Wang, Q.; Wang, W.J.; Guo, J.; Liu, Q.Y.; Zhu, M.H. Investigation on wear and damage performance of laser cladding Co-based alloy on single wheel or rail material. Wear 2015, 328–329, 329–337. [Google Scholar] [CrossRef]

- Clare, A.T.; Oyelola, O.; Abioye, T.E.; Farayibi, P.K. Laser cladding of rail steel with Co–Cr. Surf. Eng. 2013, 29, 731–736. [Google Scholar] [CrossRef]

- Bartkowski, D.; Kinal, G. Microstructure and wear resistance of Stellite-6/WC MMC coatings produced by laser cladding using Yb:YAG disk laser. Int. J. Refract. Met. Hard Mater. 2016, 58, 157–164. [Google Scholar] [CrossRef]

- Gao, L.; Bian, X.; Tian, Y.; Fu, C. Effect of Co on microstructure and interfacial properties of Fe-based laser cladding. J. Iron Steel Res. Int. 2009, 16, 84–88. [Google Scholar] [CrossRef]

- Wang, K.; Chang, B.; Chen, J.; Fu, H.; Lin, Y.; Lei, Y. Effect of molybdenum on the microstructures and properties of stainless steel coatings by laser cladding. Appl. Sci. 2017, 7, 1065. [Google Scholar] [CrossRef]

- Wang, K.M.; Fu, H.G.; Li, Y.L.; Lei, Y.P.; Wei, S.Z.; Su, Z.Q. Effect of power on microstructure and properties of laser cladding NiCrBSi composite coating. Trans. IMF 2017, 95, 328–336. [Google Scholar]

- Kou, S. Welding Metallurgy; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Gäumann, M.; Bezençon, C.; Canalis, P.; Kurz, W. Single-crystal laser deposition of superalloys: Processing-microstructure maps. Acta Mater. 2001, 49, 1051–1062. [Google Scholar] [CrossRef]

- Chang, L.M.; An, M.Z.; Guo, H.F.; Shi, S.Y. Microstructure and properties of Ni–Co/nano-Al2O3 composite coatings by pulse reversal current electrodeposition. Appl. Surf. Sci. 2006, 253, 2132–2137. [Google Scholar] [CrossRef]

- Li, Y.M.; Liu, H.J.; Liu, J.; An, B.; Hao, Y. Effect of Co on as-cast structure and properties of K4169 superalloy. Foundry Technol. 2010, 31, 280–283. [Google Scholar]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Chakraborty, G.; Kumar, N.; Das, C.R.; Albert, S.K.; Bhaduri, A.K.; Dash, S.; Tyagi, A.K. Study on microstructure and wear properties of different nickel base hardfacing alloys deposited on austenitic stainless steel. Surf. Coat. Technol. 2014, 244, 180–188. [Google Scholar] [CrossRef]

- Fernández, M.R.; García, A.; Cuetos, J.M.; González, R.; Noriega, A.; Cadenas, M. Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC. Wear 2015, 324–325, 80–89. [Google Scholar] [CrossRef]

| Wear Ring | Ring Diameter (mm) | Rotating Speed (r/min) | Load (N) | Time (min) | Experiment Temperature (°C) |

|---|---|---|---|---|---|

| GCr15 Steel | 45 | 200 | 300 | 30 | 20 |

| Point | Chemical Composition (wt. %) | ||||||

|---|---|---|---|---|---|---|---|

| Cr | C | Co | B | Si | Fe | Ni | |

| Point 1 | 29.955 | 6.512 | 23.583 | 0.930 | 0.579 | 0.979 | 36.564 |

| Point 2 | 15.329 | 0.922 | 34.026 | 0.471 | 0.556 | 1.659 | 47.847 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Chang, B.; Lei, Y.; Fu, H.; Lin, Y. Effect of Cobalt on Microstructure and Wear Resistance of Ni-Based Alloy Coating Fabricated by Laser Cladding. Metals 2017, 7, 551. https://doi.org/10.3390/met7120551

Wang K, Chang B, Lei Y, Fu H, Lin Y. Effect of Cobalt on Microstructure and Wear Resistance of Ni-Based Alloy Coating Fabricated by Laser Cladding. Metals. 2017; 7(12):551. https://doi.org/10.3390/met7120551

Chicago/Turabian StyleWang, Kaiming, Baohua Chang, Yongping Lei, Hanguang Fu, and Yinghua Lin. 2017. "Effect of Cobalt on Microstructure and Wear Resistance of Ni-Based Alloy Coating Fabricated by Laser Cladding" Metals 7, no. 12: 551. https://doi.org/10.3390/met7120551