Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds

Abstract

:1. Introduction

1.1. Context

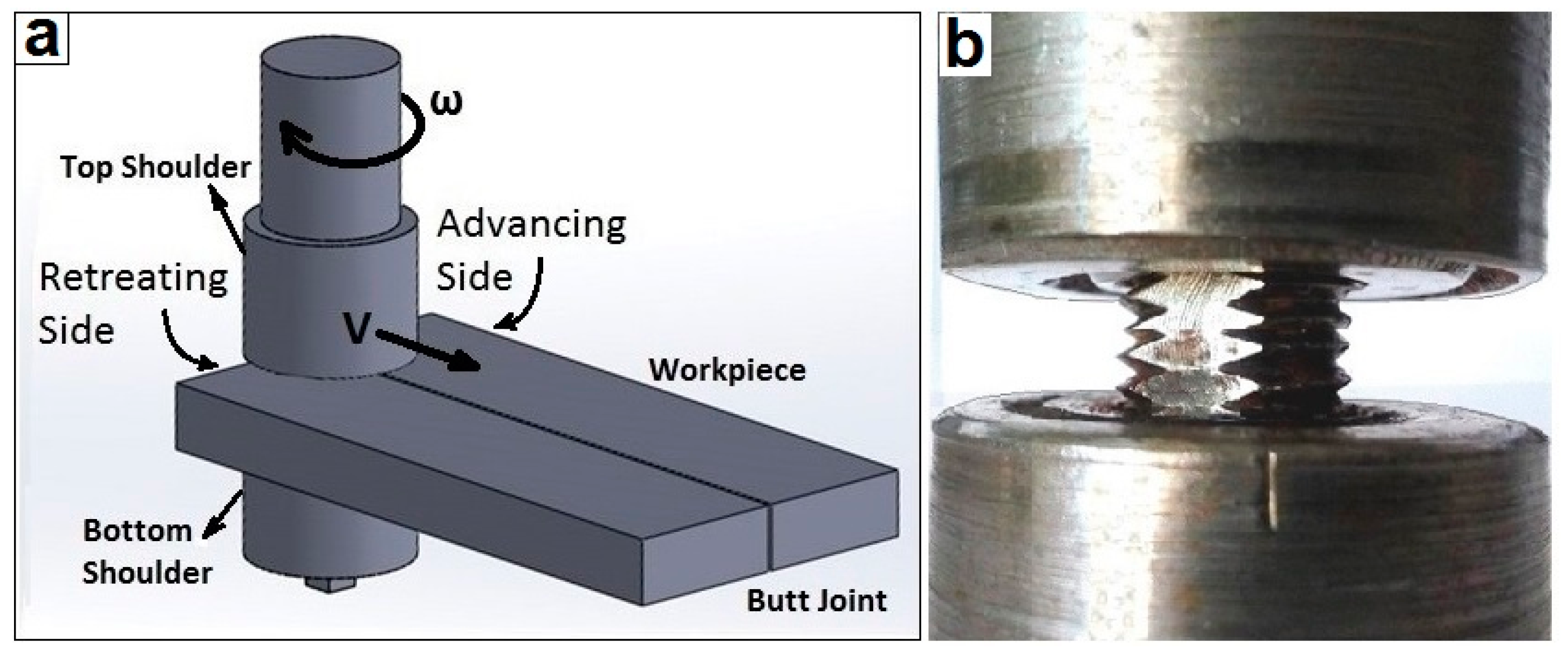

1.2. Background to Friction Stir Welding

1.3. Characteristics of Aluminium 6082-T6 in BFSW

1.4. Visualising the Cross Section of BFSW Welds

1.4.1. Zones within the Weld

1.4.2. Metallography

1.5. Issues with the Metallography of Aluminium Alloys

2. Materials and Methods

2.1. Purpose

2.2. Approach

2.3. Experimental Welding Process

2.4. Metallography and Etchants

- NaOH is used to reveal grain structure. Likewise, HF.

- H3PO4 dissolves the Al2O3 oxide layer.

- CH3COOH is used to dilute the solution and reduce pitting attack. CH3COOH also has a positive effect in delineation of fine features (e.g., in stirring zone).

- Duration of immersion.

- Increasing the temperature up to 70 °C during etching.

- Immersion in ultrasonic bath can improve the uniform etching and also help remove the oxide layer. However, in our case, conventional immersion was used for all etchants.

3. Results

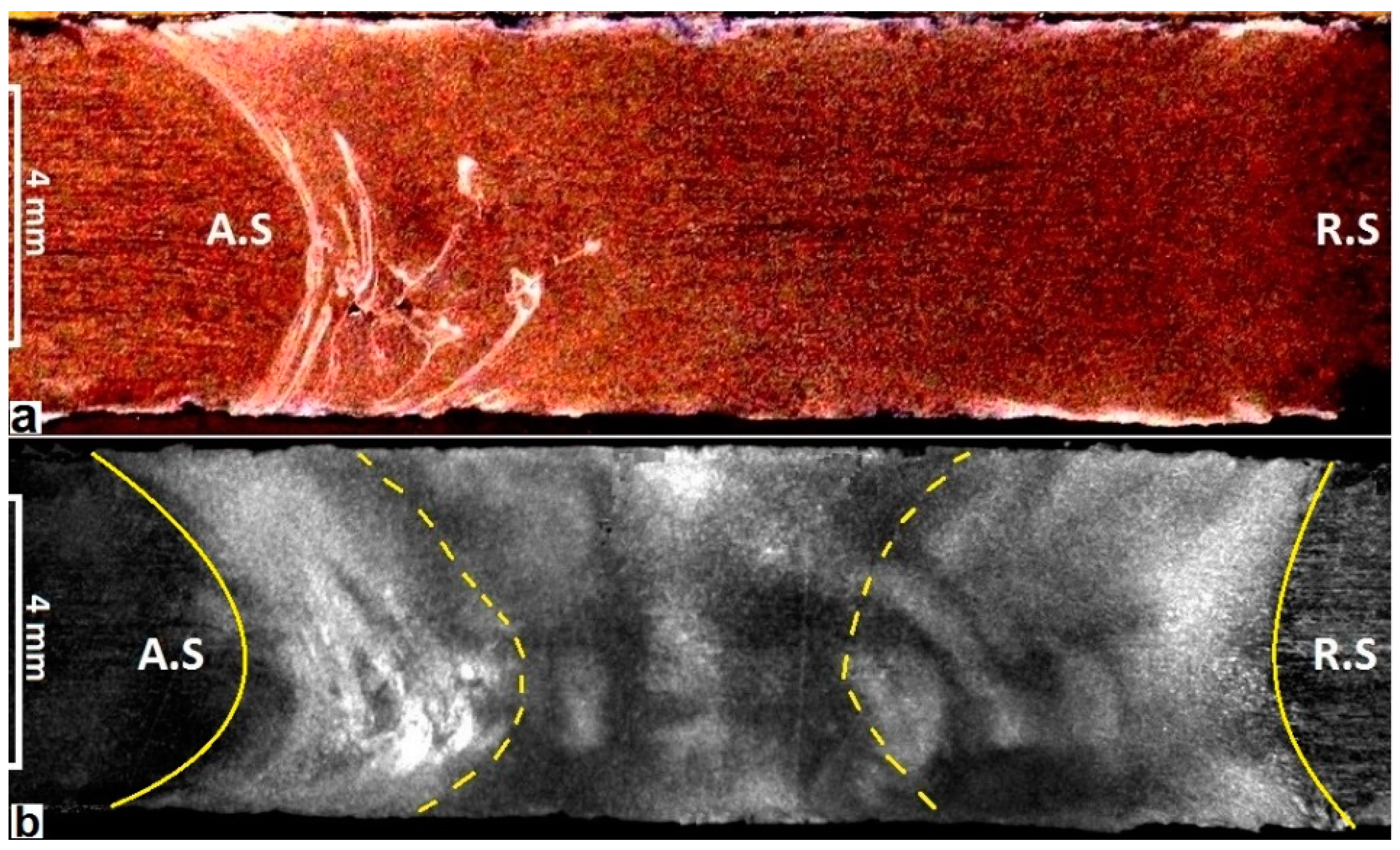

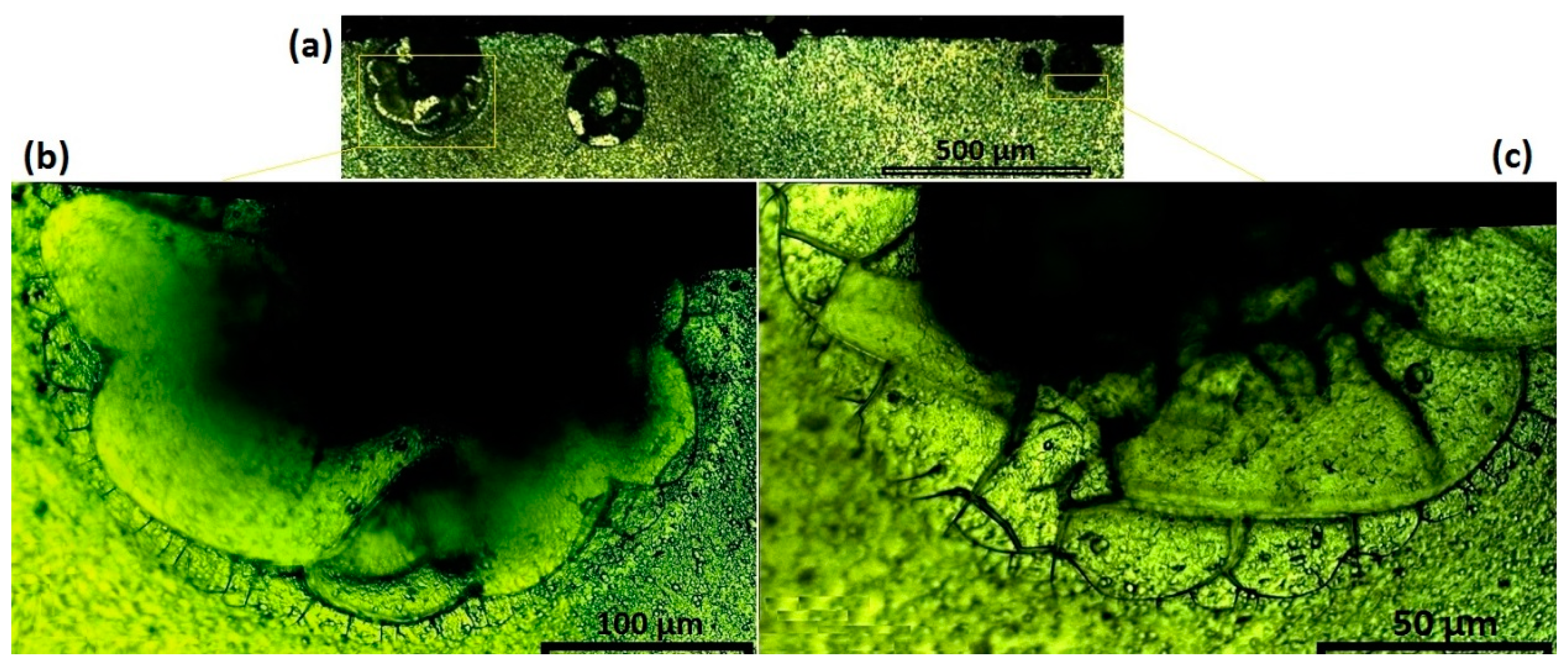

3.1. Macrostructure

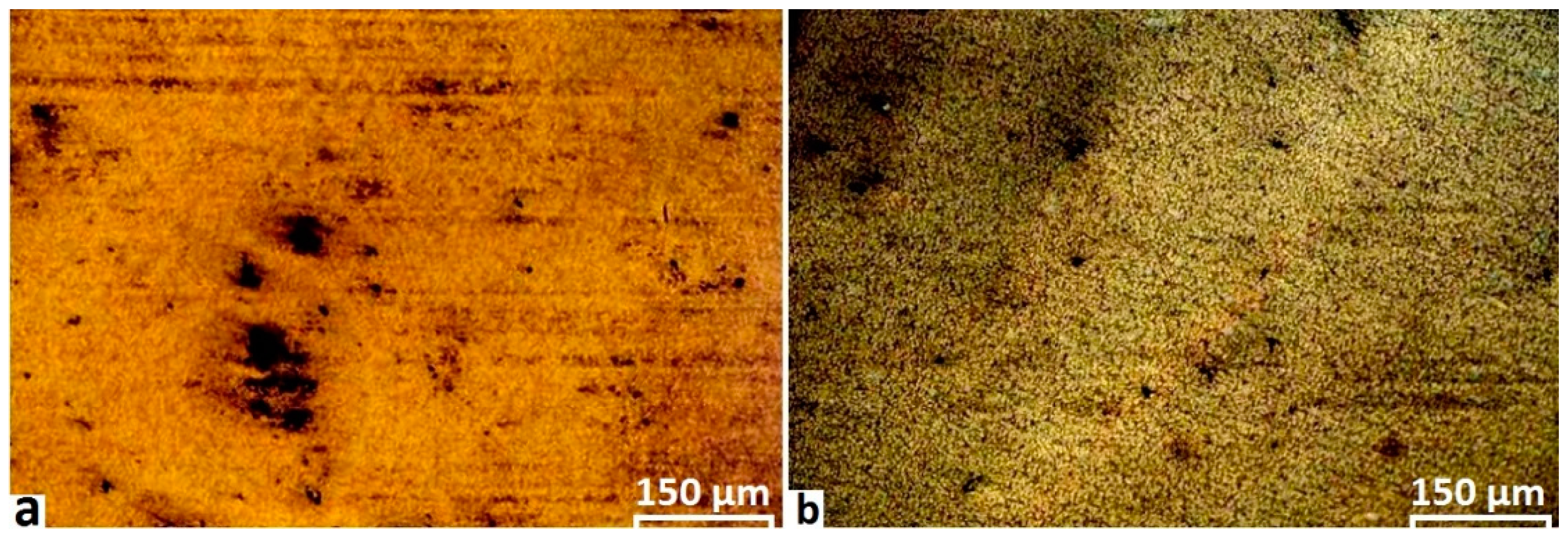

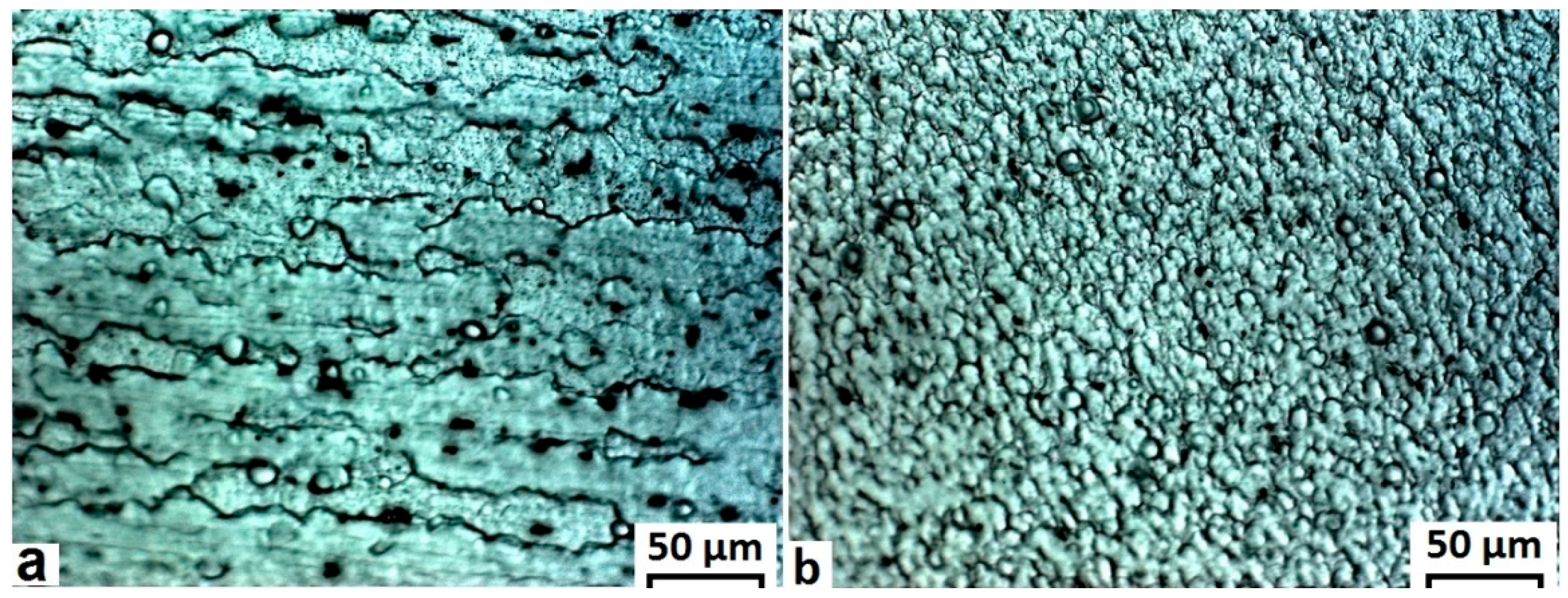

3.2. Microstructure

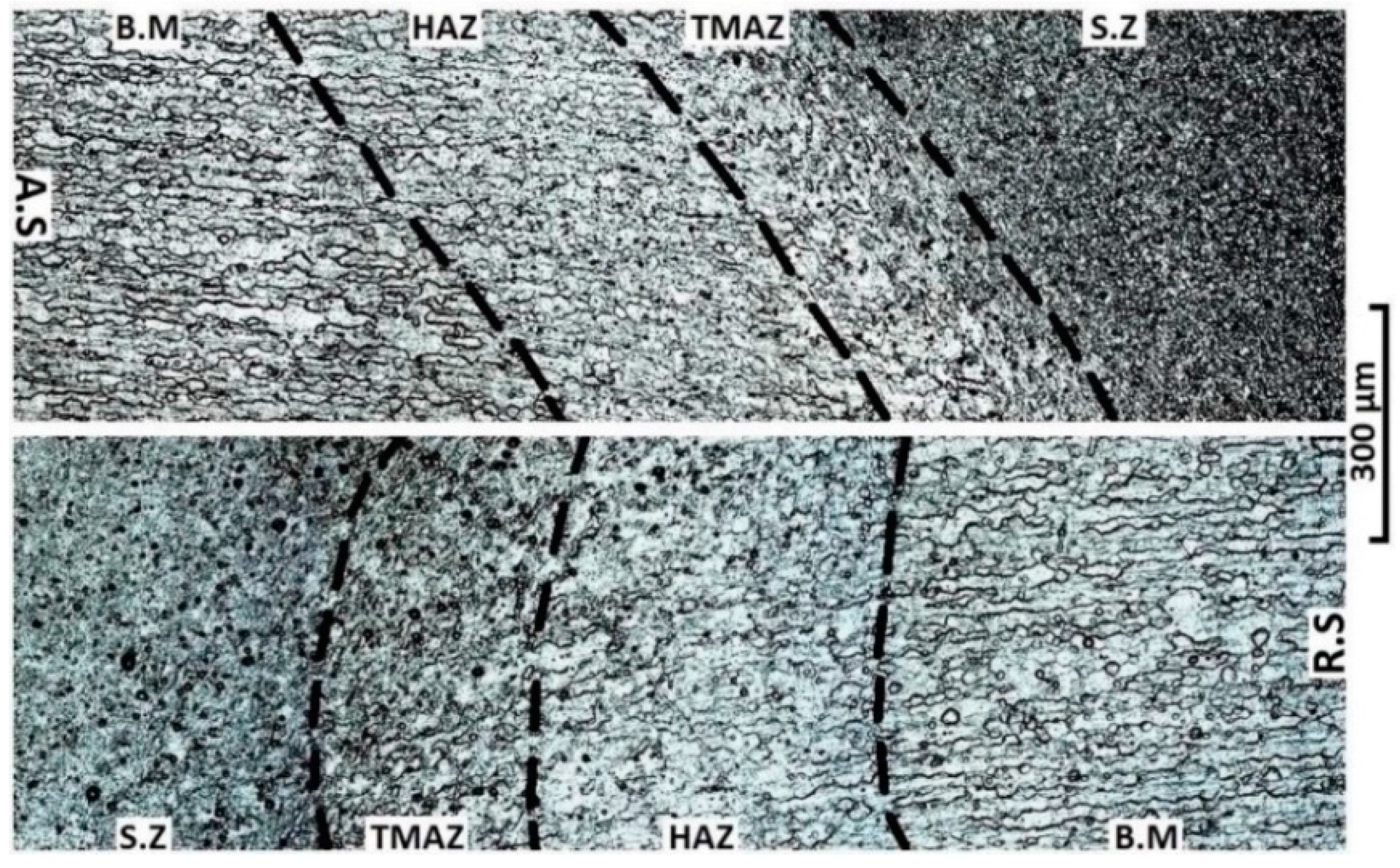

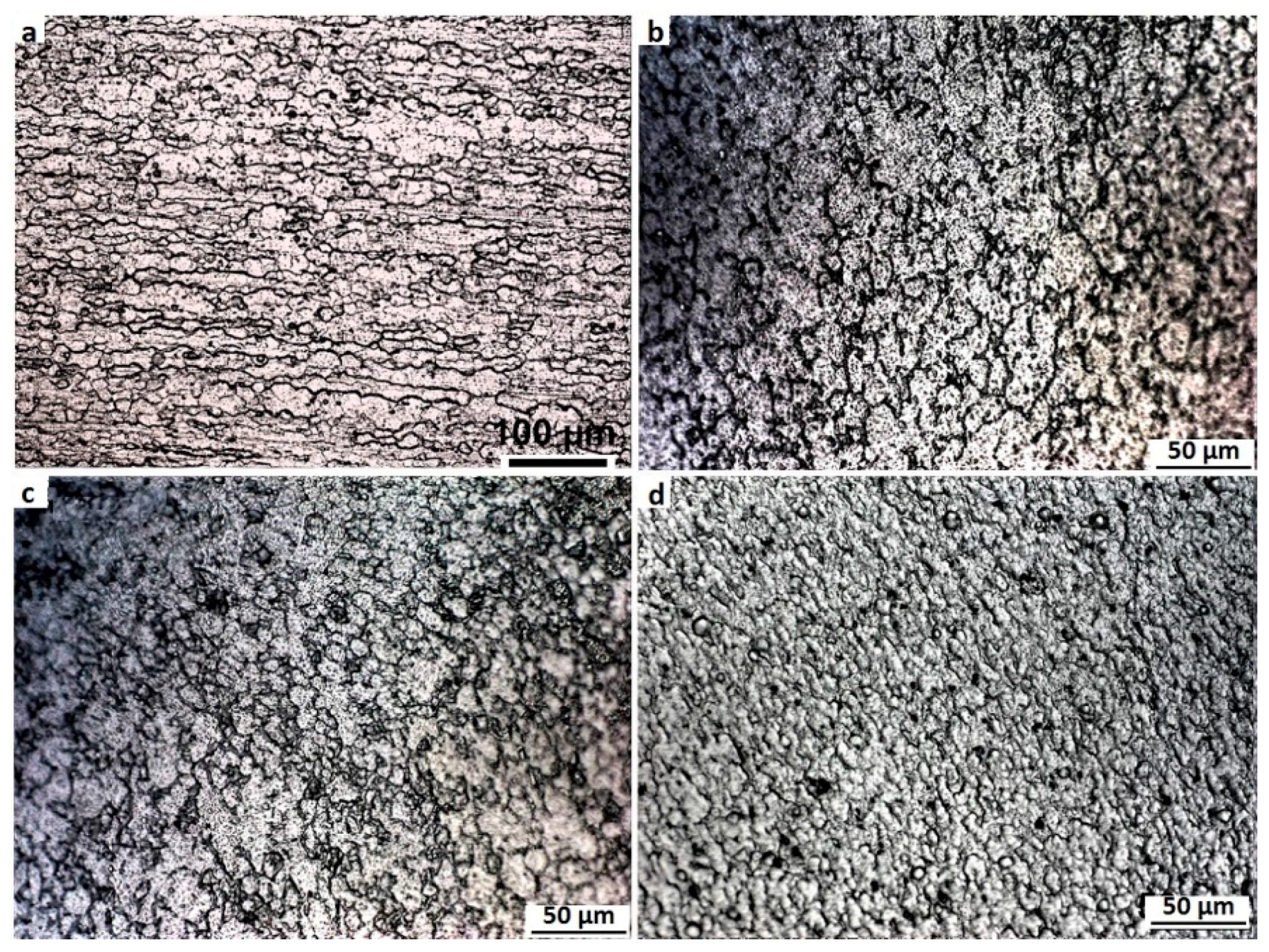

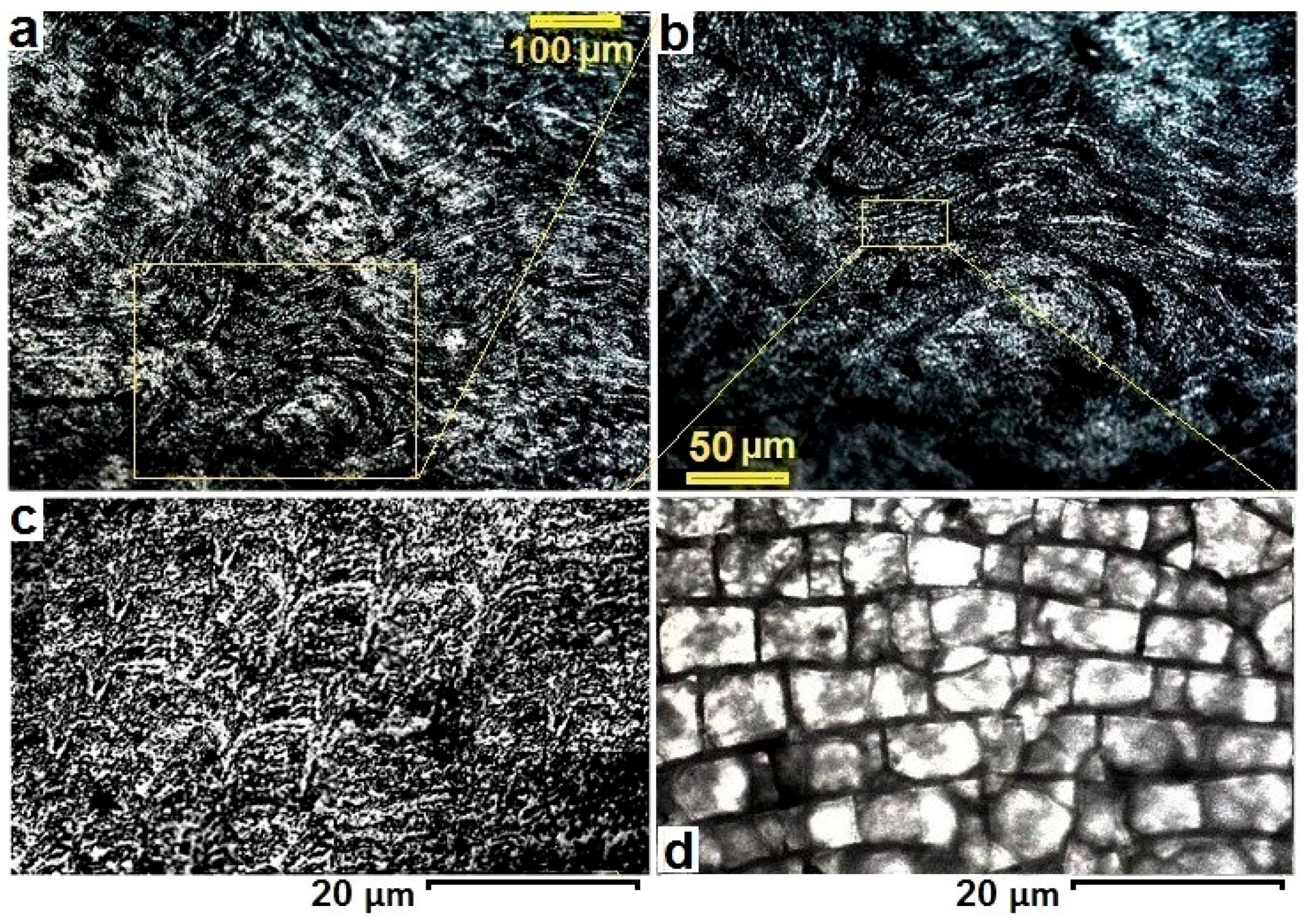

3.3. Grain Boundaries

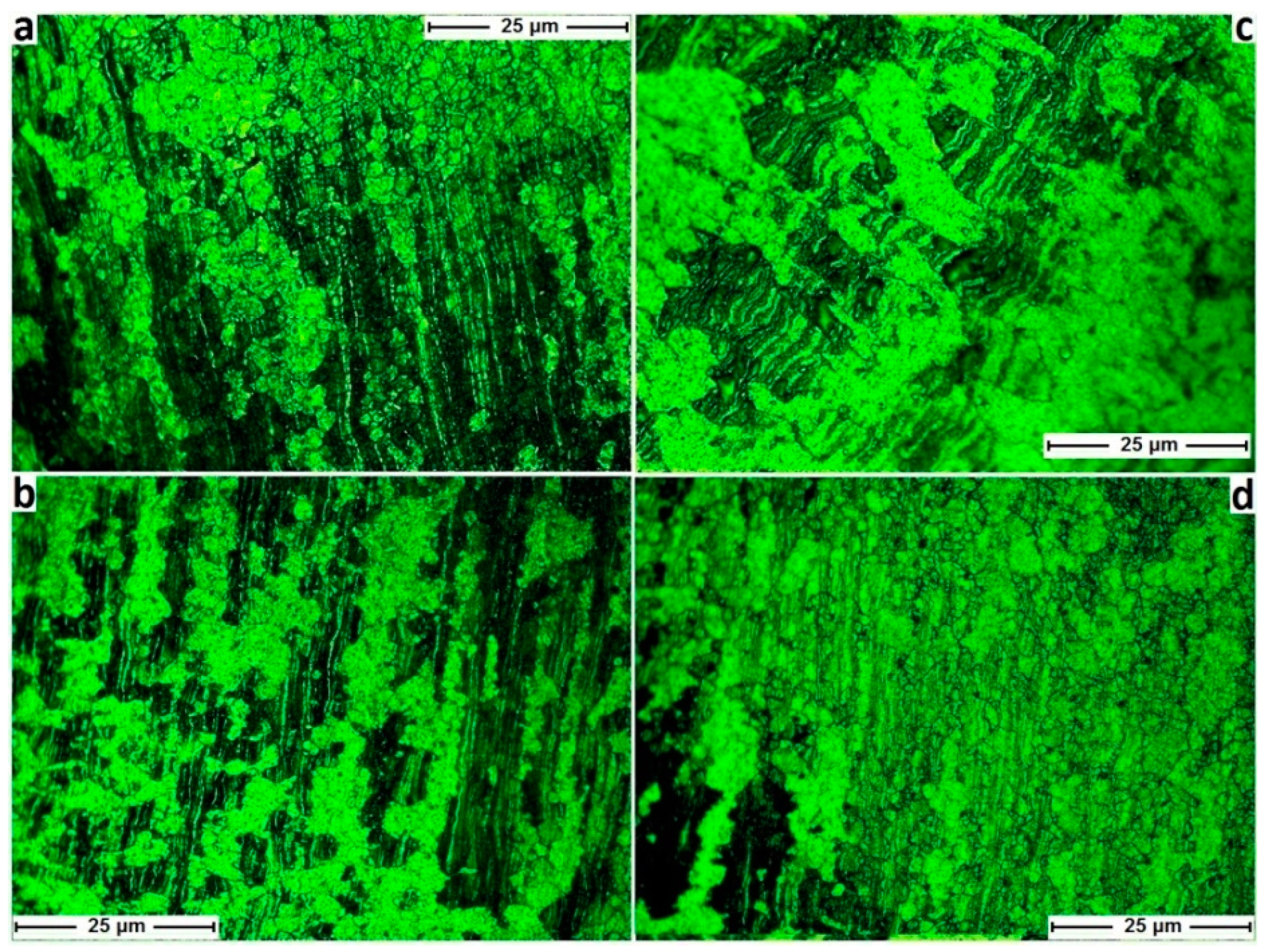

3.4. Morphological Flow of Grains (Thermomechanical Distortion, Fragmentation, and Recrystallization)

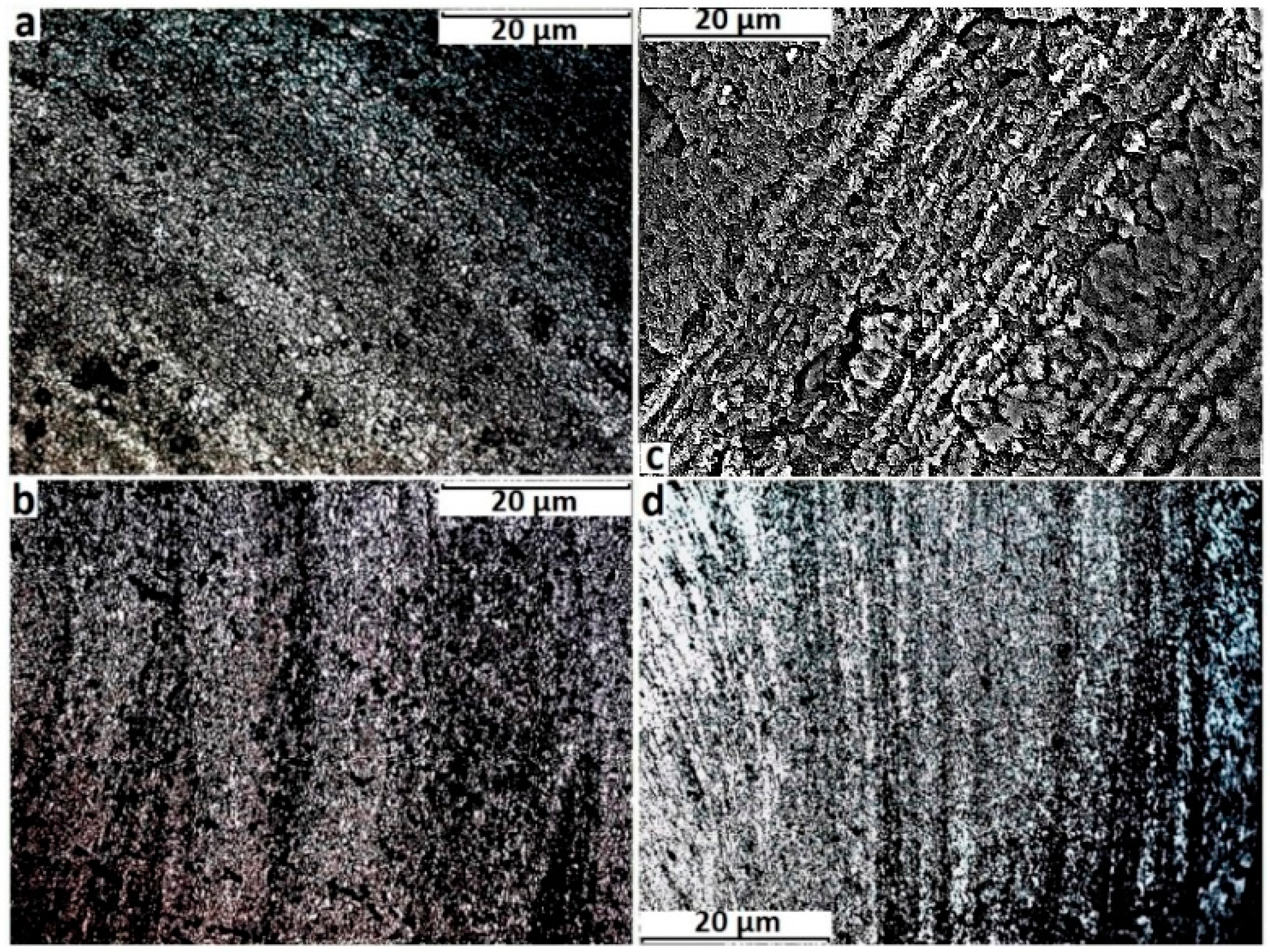

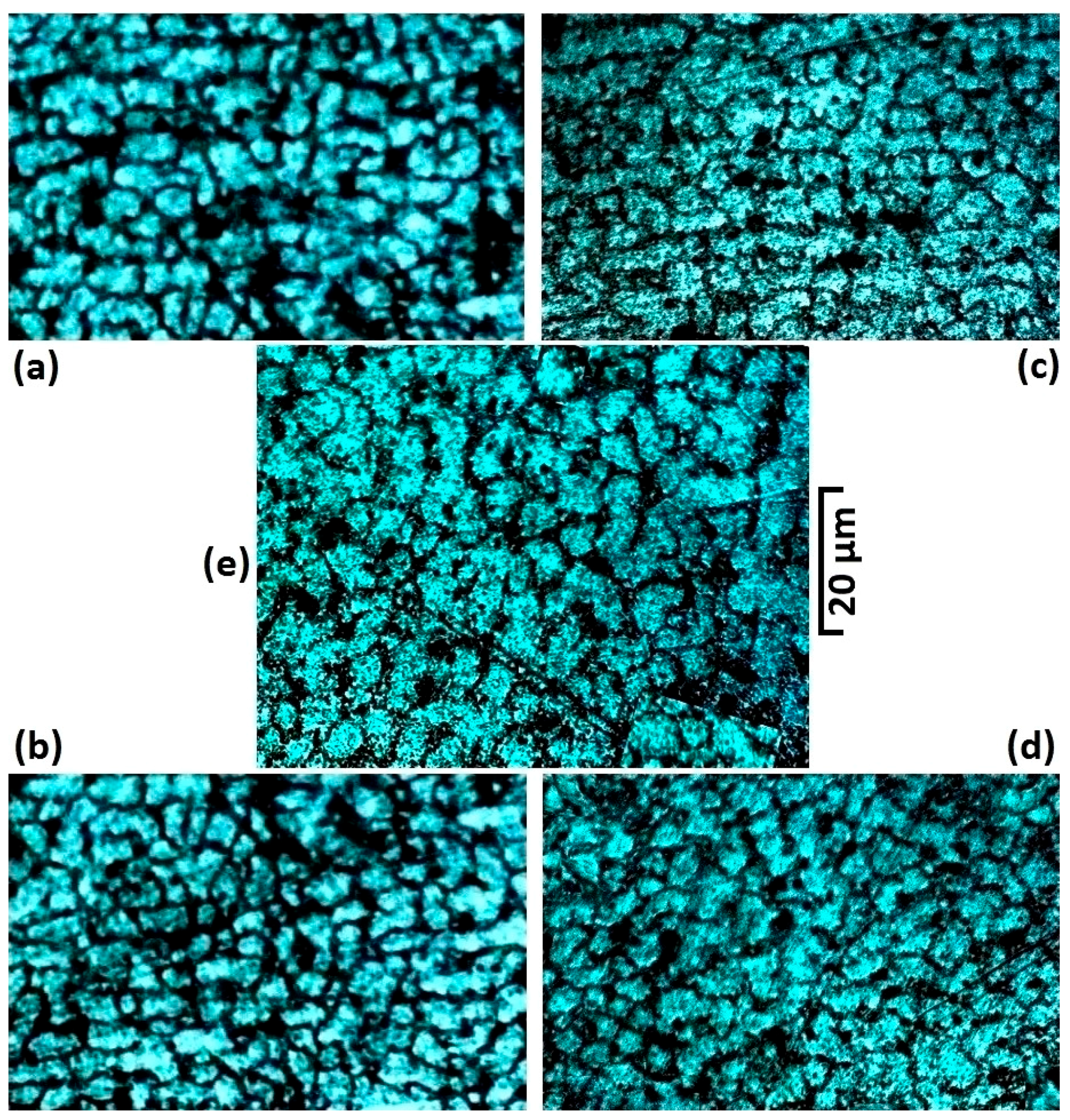

3.5. High Magnification Observations: Microflow Patterns, Polycrystalline Grain Distribution

3.6. Coherent Interfaces

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Martin, J.; Wei, S. Friction stir welding technology for marine applications. In Friction Stir Welding and Processing Viii; Springer: Berlin, Germany, 2015; pp. 219–226. [Google Scholar]

- Thomas, W.; Nicholas, E. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Thomas, W.; Wiesner, C. In Recent developments of FSW technologies: Evaluation of root defects, composite refractory tools for steel joining and one-pass welding of thick sections using self-reacting bobbin tools, Trends in Welding Research. In Proceedings of the 8th International Conference, Callaway Gardens Resort, Pine Mountain, GA, USA, 1–6 June 2008; p. 25. [Google Scholar]

- Thomas, W.; Wiesner, C.; Marks, D.; Staines, D. Conventional and bobbin friction stir welding of 12% chromium alloy steel using composite refractory tool materials. Sci. Technol. Weld. Join. 2009, 14, 247–253. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Ahmed, M.; Martin, J.P.; Perrett, J.G.; Wynne, B.P. The Use of Bobbin Tools for Friction Stir Welding of Aluminium Alloys; Materials Science Forum; Trans Tech Publ: Stafa-Zurich, Switzerland, 2010; pp. 1179–1184. [Google Scholar]

- Chen, J.; Fujii, H.; Sun, Y.; Morisada, Y.; Ueji, R. Fine grained Mg–3Al–1Zn alloy with randomized texture in the double-sided friction stir welded joints. Mater. Sci. Eng. A 2013, 580, 83–91. [Google Scholar] [CrossRef]

- Moreira, P.; De Jesus, A.; Ribeiro, A.; De Castro, P. Fatigue crack growth in friction stir welds of 6082-T6 and 6061-T6 aluminium alloys: A comparison. Theor. Appl. Fract. Mech. 2008, 50, 81–91. [Google Scholar] [CrossRef]

- Moreira, P.; Santos, T.; Tavares, S.; Richter-Trummer, V.; Vilaça, P.; De Castro, P. Mechanical and metallurgical characterization of friction stir welding joints of AA6061-T6 with AA6082-T6. Mater. Des. 2009, 30, 180–187. [Google Scholar] [CrossRef]

- Sued, M.K. Fixed Bobbin Friction Stir Welding of Marine Grade Aluminium. Ph.D. Thesis, University of Canterbury, Christchurch, New Zealand, 2015. [Google Scholar]

- Adamowski, J.; Szkodo, M. Friction stir welds (FSW) of aluminium alloy AW6082-T6. J. Achiev. Mater. Manuf. Eng. 2007, 20, 403–406. [Google Scholar]

- Scialpi, A.; De Filippis, L.; Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater. Des. 2007, 28, 1124–1129. [Google Scholar] [CrossRef]

- De Giorgi, M.; Scialpi, A.; Panella, F.; De Filippis, L. Effect of shoulder geometry on residual stress and fatigue properties of AA6082 FSW joints. J. Mech. Sci. Technol. 2009, 23, 26–35. [Google Scholar] [CrossRef]

- Gopi, S.; Manonmani, K. Microstructure and mechanical properties of friction stir welded 6082-T6 aluminium alloy. Aust. J. Mech. Eng. 2013, 11, 131–138. [Google Scholar] [CrossRef]

- Nandan, R.; Roy, G.; Lienert, T.; Debroy, T. Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater. 2007, 55, 883–895. [Google Scholar] [CrossRef]

- Sued, M.; Pons, D.; Lavroff, J.; Wong, E.-H. Design features for bobbin friction stir welding tools: Development of a conceptual model linking the underlying physics to the production process. Mater. Des. (1980–2015) 2014, 54, 632–643. [Google Scholar] [CrossRef]

- Sued, M.K.; Pons, D.J. Dynamic interaction between machine, tool, and substrate in bobbin friction stir welding. Int. J. Manuf. Eng. 2016, 2016, 14. [Google Scholar] [CrossRef]

- Sharma, M.; Singh, A.; Singh, P.; Pathak, K.; Agnihotri, G. Experimental investigation of the effect of die angle on extrusion process using plasticine. Exp. Tech. 2011, 35, 38–44. [Google Scholar] [CrossRef]

- Neumann, T.; Zettler, R.; Vilaca, P.; Dos Santos, J.; Quintino, L. Analysis of self-reacting friction stir welds in a 2024-T351 alloy. Frict. Stir Weld. Process. IV 2007, 55–72. [Google Scholar]

- Dai, Q.; Wang, X.; Hou, Z.; Wu, J.; Shi, Q. Microcavities accompanying a zigzag line in friction stir welded A6082-T6 alloy joint. Sci. Technol. Weld. Join. 2015, 20, 68–74. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Sasabe, S.; Matsumoto, T. Mechanical properties of A6082 welded joints with Nd–YAG laser. Weld. Int. 2012, 26, 351–359. [Google Scholar] [CrossRef]

- Aginagalde, A.; Gomez, X.; Galdos, L.; García, C. Heat treatment selection and forming strategies for 6082 aluminum alloy. J. Eng. Mater. Technol. 2009, 131, 044501. [Google Scholar] [CrossRef]

- Mohamed, A.; Samuel, F. A review on the heat treatment of Al-Si-Cu/Mg casting alloys. In Heat Treatment-Conventional and Novel Applications; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Svensson, L.-E.; Karlsson, L.; Larsson, H.; Karlsson, B.; Fazzini, M.; Karlsson, J. Microstructure and mechanical properties of friction stir welded aluminium alloys with special reference to AA 5083 and AA 6082. Sci. Technol. Weld. Join. 2000, 5, 285–296. [Google Scholar] [CrossRef]

- Esmaily, M.; Mortazavi, N.; Osikowicz, W.; Hindsefelt, H.; Svensson, J.; Halvarsson, M.; Martin, J.; Johansson, L. Bobbin and conventional friction stir welding of thick extruded AA6005-T6 profiles. Mater. Des. 2016, 108, 114–125. [Google Scholar] [CrossRef]

- Hilgert, J.; Schmidt, H.; Dos Santos, J.; Huber, N. Thermal models for bobbin tool friction stir welding. J. Mater. Process. Technol. 2011, 211, 197–204. [Google Scholar] [CrossRef]

- Hilgert, J.; dos Santos, J.F.; Huber, N. Investigation of the material shear layer in bobbin tool friction stir welding. Frict. Stir Weld. Process. VI 2011, 187–193. [Google Scholar]

- Hejazi, I.; Mirsalehi, S.E. Effect of pin penetration depth on double-sided friction stir welded joints of AA6061-T913 alloy. Trans. Nonferr. Metals Soc. China 2016, 26, 676–683. [Google Scholar] [CrossRef]

- Heurtier, P.; Jones, M.; Desrayaud, C.; Driver, J.H.; Montheillet, F.; Allehaux, D. Mechanical and thermal modelling of friction stir welding. J. Mater. Process. Technol. 2006, 171, 348–357. [Google Scholar] [CrossRef]

- Shen, J.; Wang, F.; Suhuddin, U.F.; Hu, S.; Li, W.; Dos Santos, J.F. Crystallographic texture in bobbin tool friction-stir-welded aluminum. Metall. Mater. Trans. A 2015, 46, 2809–2813. [Google Scholar] [CrossRef]

- Mrówka-Nowotnik, G.; Sieniawski, J. Influence of heat treatment on the microstructure and mechanical properties of 6005 and 6082 aluminium alloys. J. Mater. Process. Technol. 2005, 162, 367–372. [Google Scholar] [CrossRef]

- Panagopoulos, C.; Georgiou, E.; Gavras, A. Corrosion and wear of 6082 aluminum alloy. Tribol. Int. 2009, 42, 886–889. [Google Scholar] [CrossRef]

- Birol, Y.; Seracettin, A. Cooling slope casting to produce EN AW 6082 forging stock for manufacture of suspension components. Trans. Nonferr. Met. Soc. China 2014, 24, 1674–1682. [Google Scholar] [CrossRef]

- Xu, H.; Tang, H.; Liu, Z.; Xie, M.; Jiao, J. Microstructure and mechanical properties of 6082 aluminum alloy joints welded by MIG. Hot Work. Technol. 2010, 1, 042. [Google Scholar]

- Frigaard, Ø.; Grong, Ø.; Midling, O. A process model for friction stir welding of age hardening aluminum alloys. Metall. Mater. Trans. A 2001, 32, 1189–1200. [Google Scholar] [CrossRef]

- Vander Voort, G.; Manilova, E.P. Metallographic Etching of Aluminum and Its Alloys. Available online: http://www.georgevandervoort.com/metallography/specific/aluminum/20001307-metallographic-etching-of-aluminum-and-its-alloys.html (accessed on 10 October 2017).

- Vander Voort, G.F.; Lampman, S.R.; Sanders, B.R.; Anton, G.J.; Polakowski, C.; Kinson, J.; Muldoon, K.; Henry, S.D.; Scott, W.W., Jr. Asm Handbook; ASM International: Material Park, OH, USA, 2001. [Google Scholar]

- Myhr, O.; Klokkehaug, S.; Grong, O.; Fjær, H.; Kluken, A. Modeling of microstructure evolution, residual stresses and distortions in 6082-T6 aluminum weldments. Weld. J. 1998, 77, 286–292. [Google Scholar]

- Airod, A. Fundamental Analysis of the Deformation Behaviour of 5083 and 6082 Aluminium Alloys. Ph.D. Thesis, Ghent University, Gent, Belgium, 2006. [Google Scholar]

- Zipperian, D.C. Metallographic Handbook; Chief Technical Officier PACE Technologies: Tucson, AZ, USA, 2011. [Google Scholar]

- Sued, M.; Pons, D.; Lavroff, J. Compression Ratio Effects in Bobbin Friction Stir Welding. In Proceedings of the 10th International Friction Stir Welding Symposium, Beijing, China, 20–22 May 2014; pp. 1–19. [Google Scholar]

- Sued, M.; Tamadon, A.; Pons, D. Material flow visualization in bobbin friction stir welding by analogue model. In Proceedings of Mechanical Engineering Research Day 2017; Centre for Advanced Research on Energy: Melaka, Malaysia, 2017; pp. 368–369. [Google Scholar]

- Schneider, J.; Chen, P.; Nunes, A.C., Jr. Formation of oxides in the interior of friction stir welds. In Proceedings of the 11th International Friction Stir Welding Symposium, Cambridge, UK, 17–19 May 2016. [Google Scholar]

- Schneider, J.; Nunes, A.C., Jr. Origins of Line Defects in Self-Reacting Friction Stir Welds and Their Impact on Weld Quality. 2016. Available online: https://ntrs.nasa.gov/search.jsp?R=20160011068 (accessed on 1 January 2016).

- Kah, P.; Rajan, R.; Martikainen, J.; Suoranta, R. Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 2015, 10, 26. [Google Scholar] [CrossRef]

| Chemical Element | % Present |

|---|---|

| Silicon (Si) | (0.70–1.30) |

| Magnesium (Mg) | (0.60–1.20) |

| Manganese (Mn) | (0.40–1.00) |

| Iron (Fe) | (0.0–0.50) |

| Chromium (Cr) | (0.0–0.25) |

| Zinc (Zn) | (0.0–0.20) |

| Titanium (Ti) | (0.0–0.10) |

| Copper (Cu) | (0.0–0.10) |

| Other (Each) | (0.0–0.05) |

| Other (total) | (0.0–0.15) |

| Aluminium (Al) | Balance |

| Parameter | Value |

|---|---|

| DShoulder (mm) | 21 |

| DPin (mm) | 7 |

| DShoulder/DPin | 3 |

| Plate Thickness (mm) | 6 |

| Compression Ratio | 3.75% |

| Spindle rotational speed ω (rpm) | 600 |

| Feed rate V (mm/min) | 400 |

| Thread Pitch (mm) | 1.75 |

| Number of Threads | 4 |

| Name of Etchant | Etching Type | Pre-Etching | Etchant Composition |

|---|---|---|---|

| A | General Macrostructure | - | 30.0 g NaOH + 100 mL ethanol (3 min, 50 °C) |

| B | General Macrostructure | - | 2.5 mL HF + 2.5 mL HCl + 95 mL H2O (30 s, 50 °C) |

| C | General Microstructure | - | 0.5 g (NH4)2MoO4 + 3.0 g NH4Cl + 1 mL HF + 18 mL HNO3 + 80 mL H2O (90 s, 70 °C) |

| D | G.B Microstructure | 20 g NaOH + 80 mL H2O (20 s, 50 °C), | Etchant C (60 s, 70 °C) |

| E | HAZ Microstructure | 20 g NaOH + 80 mL H2O (20 s, 50 °C), then: 30 mL H3PO4 + 70 mL ethanol (20 s, 50 °C) | 10 g CrO3 + 2 g Na2SO4 + 10 mL HNO3 + 10 mL CH3COOH + 1 mL HF + 80 mL H2O (60 s, 70 °C) |

| F | TMAZ Microstructure | 20 g NaOH + 80 mL H2O (20 s, 50 °C), then: 30 mL H3PO4 + 70 mL ethanol (20 s, 50 °C) | Etchant E (60 s, 70 °C), then: 15 mL CH3COOH + 85 mL H2O (15 s, 70 °C), then: 15 mL H3PO4 + 85 mL H2O (15 s, 70 °C), |

| G | S.Z Microstructure | 20 g NaOH + 80 mL H2O (40 s, 50 °C) | 10 mL HCl + 40 mL HNO3 + 2.5 mL HF + 12 g CrO3 + 10 mL CH3COOH + 50 mL H2O (60 s, 70 °C), then: 20 mL CH3COOH + 80 mL H2O (20 s, 70 °C), then: 20 mL H3PO4 + 80 mL H2O (20 s, 70 °C), |

| H | Micro-flow Patterns | - | 2 mL HF + 2 mL HBF4 + 10 mL HNO3 + 20 mL CH3COOH + 33 mL H2O + 33 mL ethanol (90 s, 70 °C) |

| I | Polycrystalline Structure | 20 g NaOH + 80 mL ethanol (20 s, 50 °C), then: 20 mL H3PO4 + 80 mL ethanol (20 s, 50 °C) | 2 mL HF + 2 mL HBF4 + 5 mL HNO3 + 30 mL CH3COOH + 60 mL ethanol (90 s, 70 °C) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds. Metals 2017, 7, 423. https://doi.org/10.3390/met7100423

Tamadon A, Pons DJ, Sued K, Clucas D. Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds. Metals. 2017; 7(10):423. https://doi.org/10.3390/met7100423

Chicago/Turabian StyleTamadon, Abbas, Dirk J. Pons, Kamil Sued, and Don Clucas. 2017. "Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds" Metals 7, no. 10: 423. https://doi.org/10.3390/met7100423