Effect of Microstructure on Fracture Toughness and Fatigue Crack Growth Behavior of Ti17 Alloy

Abstract

:1. Introduction

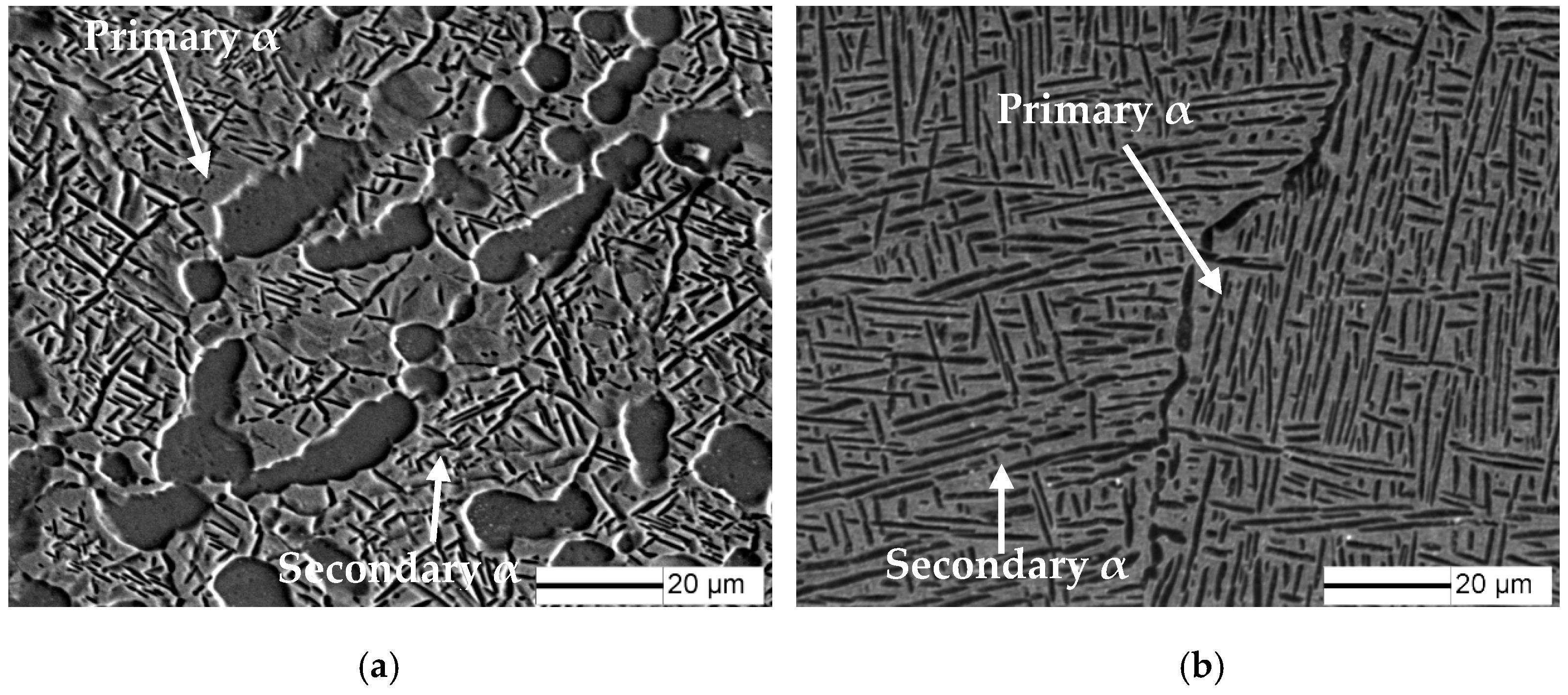

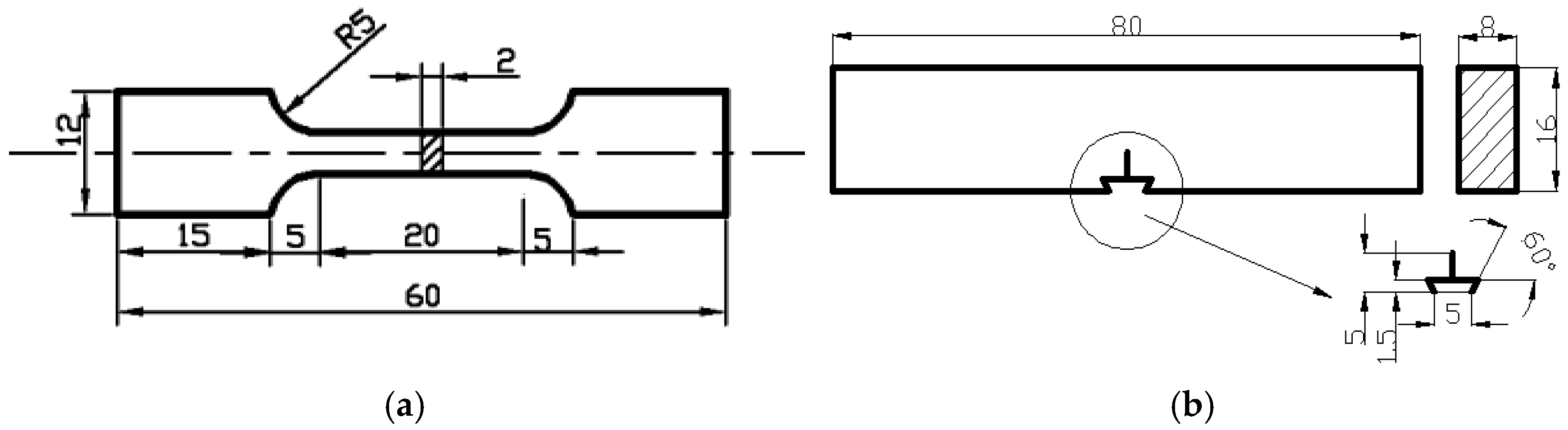

2. Materials and Methods

3. Results and Discussion

3.1. Tensile Properties

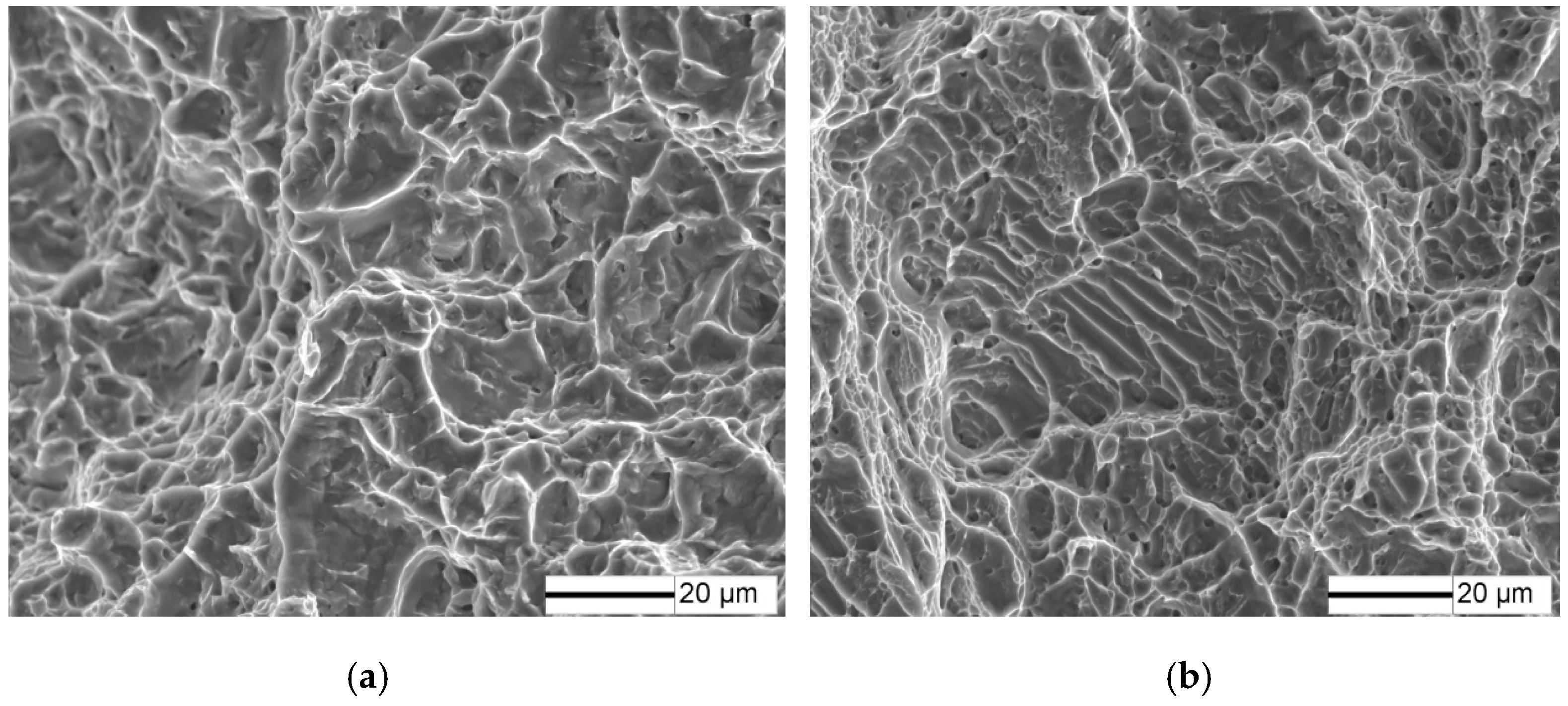

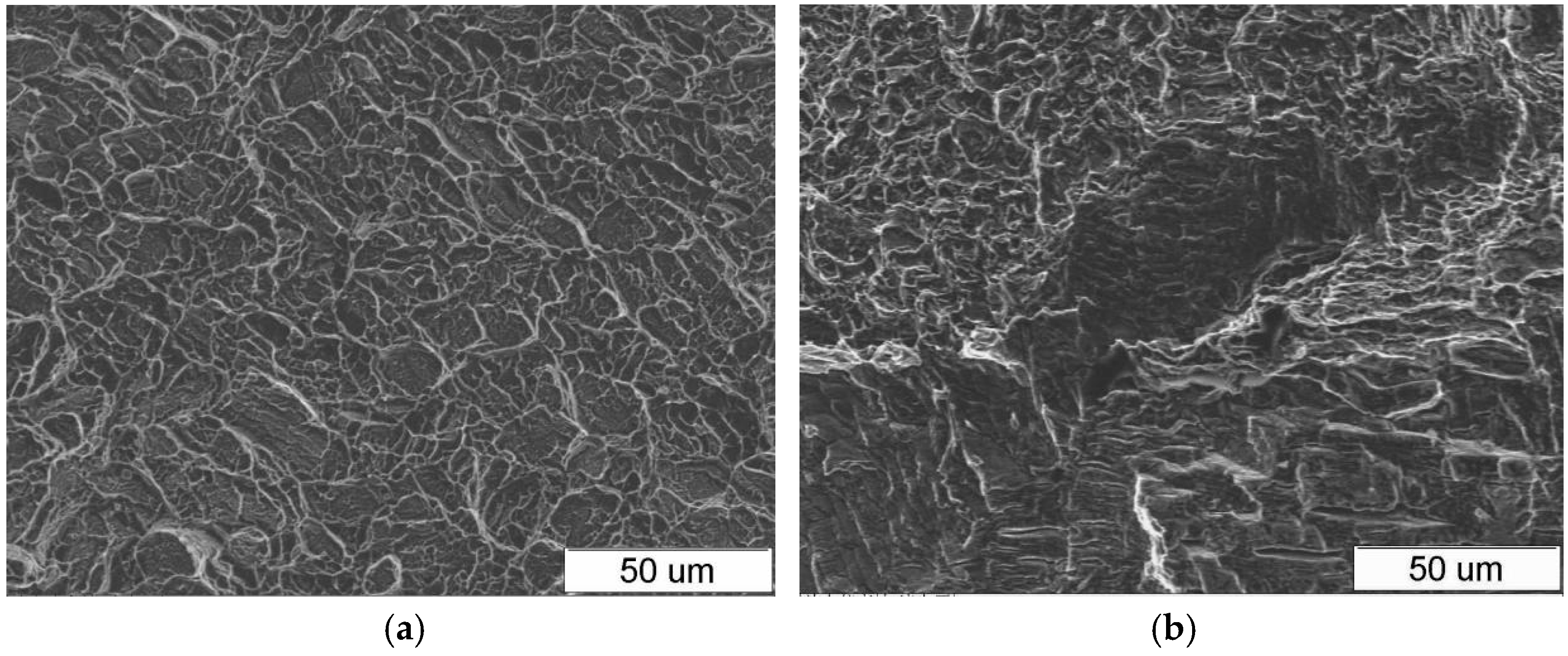

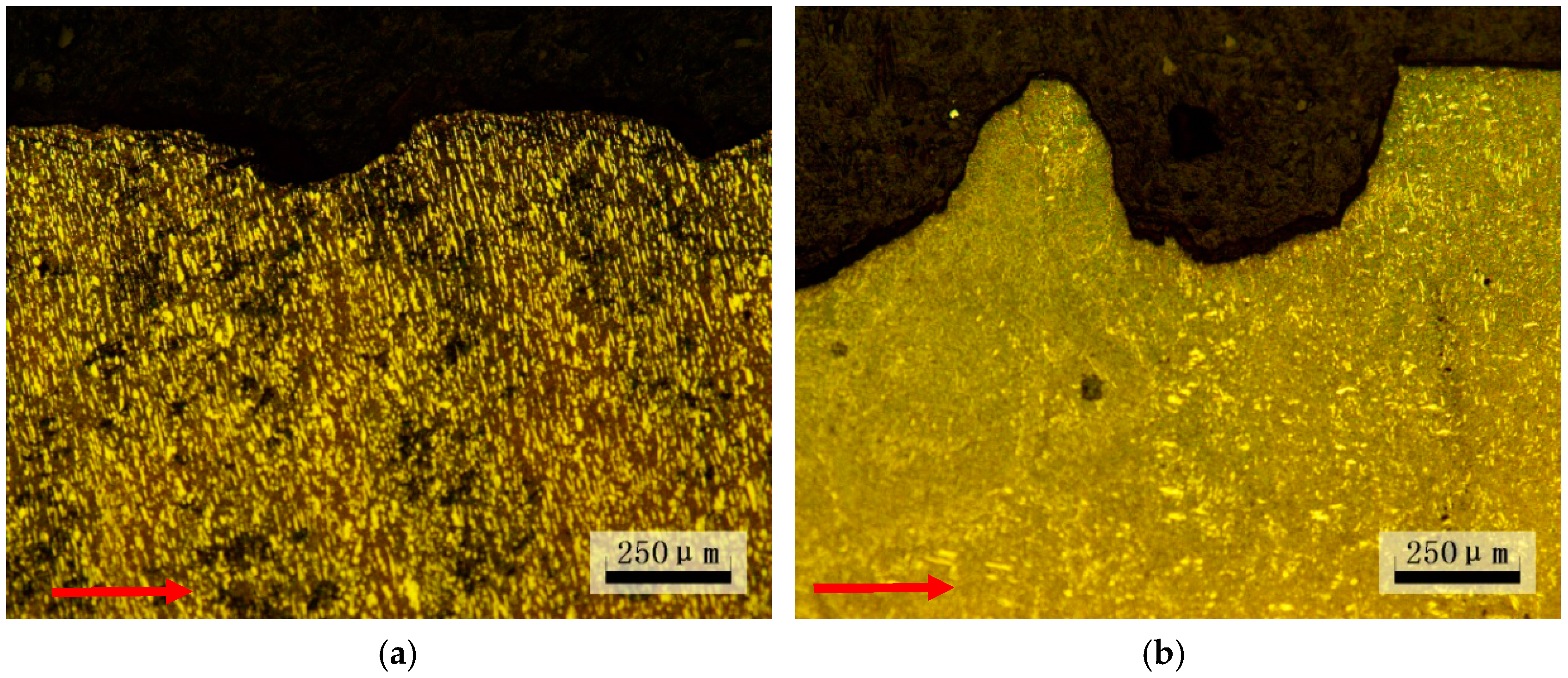

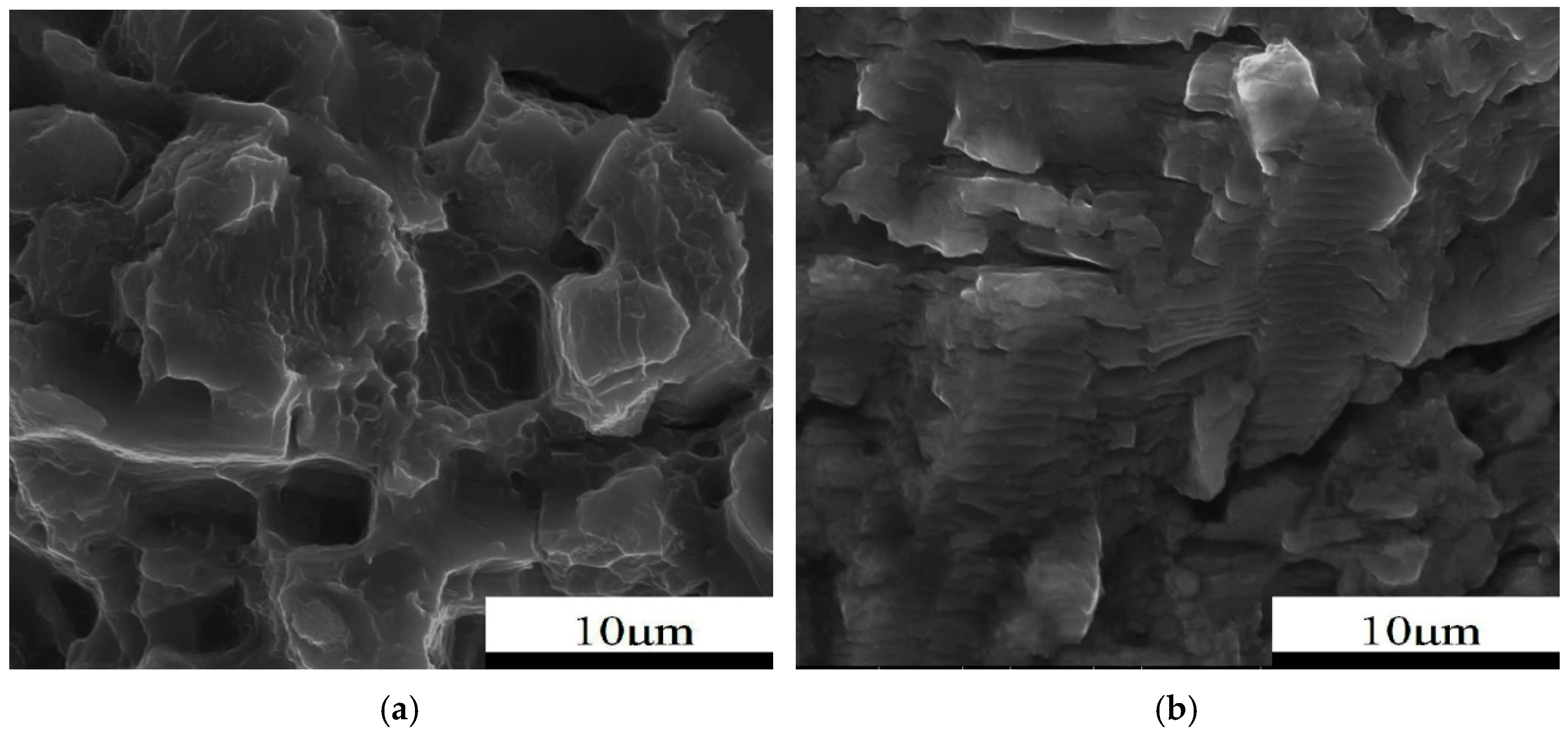

3.2. Fracture Toughness

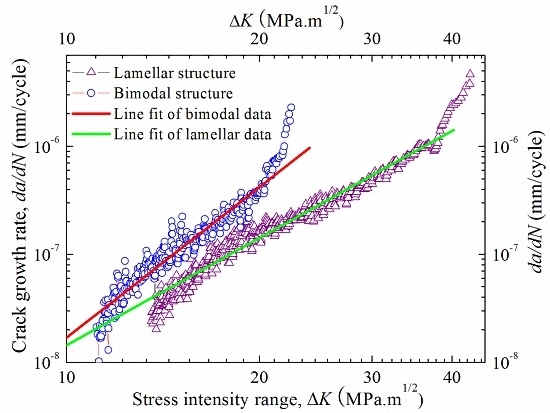

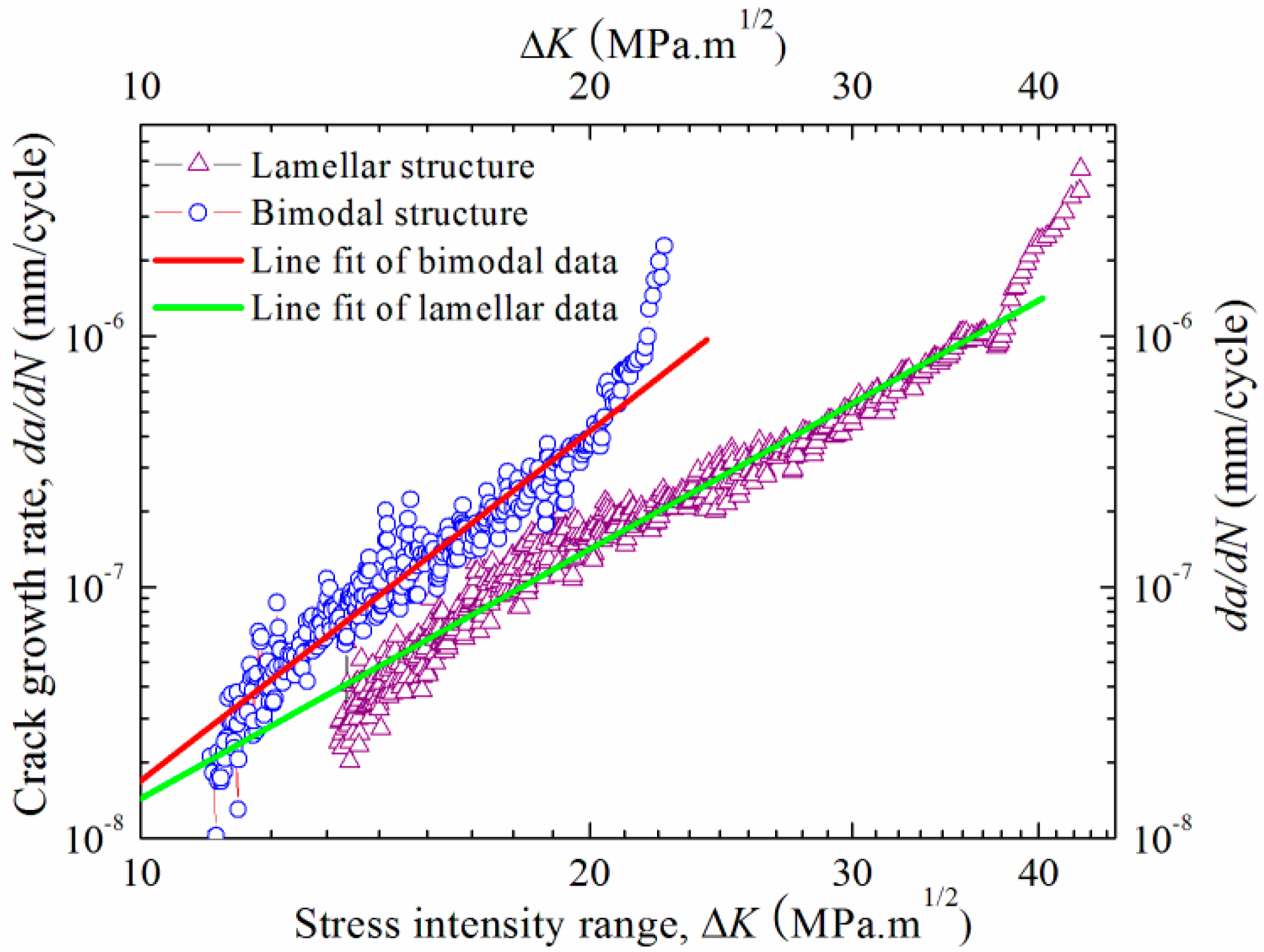

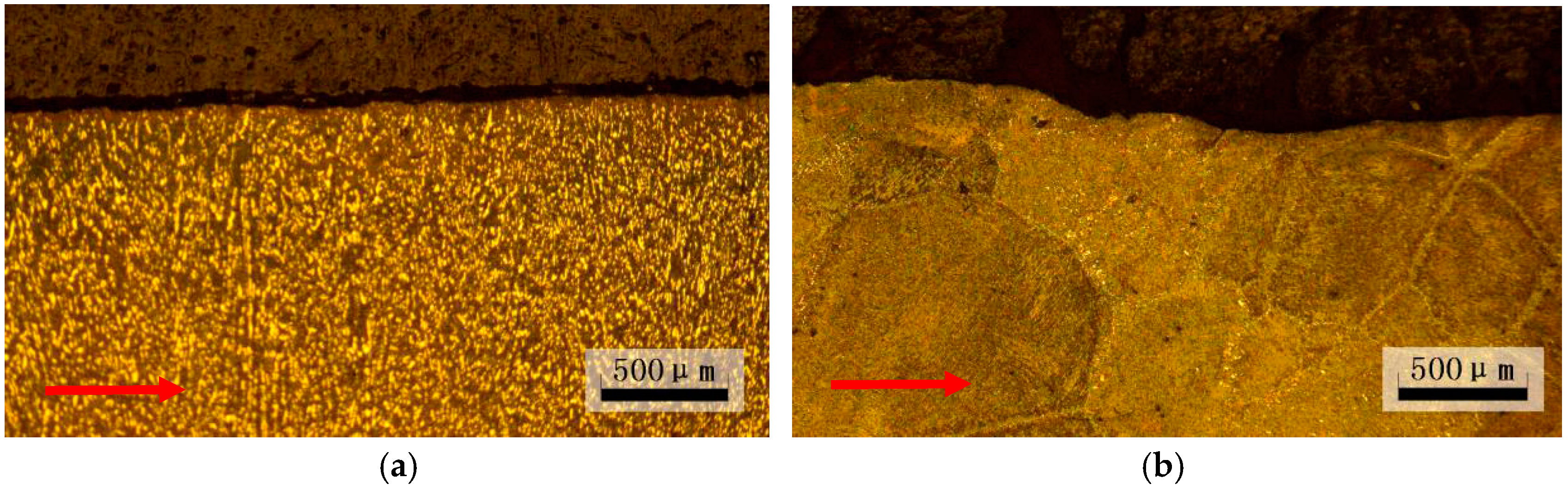

3.3. Fatigue Crack Growth Behavior

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| α | Hexagonal phase in titanium alloys |

| β | Body-centered cubic phase in titanium alloys |

| Tβ | Beta-transus temperature |

| a | Crack length |

| C, m | Parameters of the Paris-Erdogan equation |

| da/dN | Fatigue crack growth rate |

| ΔK | Cyclic stress intensity factor |

| N | Number of cycles |

References

- Elrod, C.W. Review of Titanium Application in Gas Turbine Engines. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; pp. 649–656.

- Nalla, R.K.; Boyce, B.L.; Campbell, J.P.; Peters, J.O.; Ritchie, R.O. Influence of Microstructure on High-Cycle Fatigue of Ti-6Al-4V: Bimodal vs. Lamellar Structures. Metall. Mater. Trans. A 2002, 33, 899–917. [Google Scholar] [CrossRef]

- Verdhan, N.; Bhende, D.D.; Kapoor, R.; Chakravartty, J.K. Effect of microstructure on the fatigue crack growth behaviour of a near-α Ti alloy. Int. J. Fatigue 2015, 74, 46–54. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Krüger, L.; Grundmann, N.; Trubitz, P. Influence of Microstructure and Stress Ratio on Fatigue Crack Growth in a Ti-6-22-22-S alloy. Mater. Today Proc. 2015, 2, 205–211. [Google Scholar] [CrossRef]

- Li, W.Y.; Ma, T.; Yang, S. Microstructure Evolution and Mechanical Properties of Linear Friction Welded Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti17) Titanium Alloy Joints. Adv. Eng. Mater. 2010, 12, 35–43. [Google Scholar] [CrossRef]

- Shi, X.H.; Zeng, W.D.; Zhao, Q.Y. The effects of lamellar features on the fracture toughness of Ti17 titanium alloy. Mater. Sci. Eng. A 2015, 636, 543–550. [Google Scholar] [CrossRef]

- Cadario, A.; Alfredsson, B. Fatigue growth of short cracks in Ti17: Experiments and simulations. Eng. Fract. Mech. 2007, 74, 2293–2310. [Google Scholar] [CrossRef]

- García, A.M.M. BLISK Fabrication by Linear Friction Welding; INTECH Open Access Publisher: Rijeka, Croatia, 2011. [Google Scholar]

- Kumar, B.V.R.R. A Review on Blisk Technology. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 1353–1358. [Google Scholar]

- Luo, J.; Li, L.; Li, M.Q. The flow behavior and processing maps during the isothermal compression of Ti17 alloy. Mater. Sci. Eng. A 2014, 606, 165–174. [Google Scholar] [CrossRef]

- Wang, T.; Guo, H.Z.; Tan, L.J.; Yao, Z.K.; Zhao, Y.; Liu, P.H. Beta grain growth behaviour of TG6 and Ti17 titanium alloys. Mater. Sci. Eng. A 2011, 528, 6375–6380. [Google Scholar] [CrossRef]

- Teixeira, J.D.C.; Appolaire, B.; Aeby-Gautier, E.; Denis, S.; Cailletaud, G.; Späth, N. Transformation kinetics and microstructures of Ti17 titanium alloy during continuous cooling. Mater. Sci. Eng. A 2007, 448, 135–145. [Google Scholar] [CrossRef] [Green Version]

- Tarín, P.; Fernández, A.L.; Simón, A.G.; Badía, J.M.; Piris, N.M. Transformations in the Ti-5Al-2Sn-2Zr-4Mo-4Cr (Ti-17) alloy and mechanical and microstructural characteristics. Mater. Sci. Eng. A 2006, 438–440, 364–368. [Google Scholar] [CrossRef]

- Xu, J.W.; Zeng, W.D.; Zhao, Y.W.; Jia, Z.Q.; Sun, X. Effect of globularization behavior of the lamellar alpha on tensile properties of Ti-17 alloy. J. Alloy. Compd. 2016, 673, 86–92. [Google Scholar] [CrossRef]

- Moshier, M.A.; Nicholas, T.; Hillberry, B.M. Load history effects on fatigue crack growth threshold for Ti-6Al-4V and Ti-17 titanium alloys. Int. J. Fatigue 2001, 23, 253–258. [Google Scholar] [CrossRef]

- Gungor, M.N.; Ucok, I.; Kramer, L.S.; Dong, H.; Martin, N.R.; Tack, W.T. Microstructure and mechanical properties of highly deformed Ti-6Al-4V. Mater. Sci. Eng. A 2005, 410–411, 369–374. [Google Scholar] [CrossRef]

- Chandravanshi, V.K.; Bhattacharjee, A.; Kamat, S.V.; Nandy, T.K. Influence of thermomechanical processing and heat treatment on microstructure, tensile properties and fracture toughness of Ti-1100-0.1B alloy. J. Alloy. Compd. 2014, 589, 336–345. [Google Scholar] [CrossRef]

- Xue, Y.L.; Li, S.M.; Zhong, H.; Fu, H.Z. Characterization of fracture toughness and toughening mechanisms in Laves phase Cr2Nb based alloys. Mater. Sci. Eng. A 2015, 638, 340–347. [Google Scholar] [CrossRef]

- Shi, X.H.; Zeng, W.D.; Zhao, Q.Y. The effect of surface oxidation behavior on the fracture toughness of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy. J. Alloy. Compd. 2015, 647, 740–749. [Google Scholar] [CrossRef]

- Stephens, R.R.; Stephenst, R.I.; Veitt, A.L.; Albertson, T.P. Fatigue crack growth of Ti-62222 titanium alloy under constant amplitude and minitwist flight spectra at 25 °C and 175 °C. Int. J. Fatigue 1997, 19, 301–308. [Google Scholar] [CrossRef]

| Element | Al | Sn | Zr | Mo | Cr | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. % | 5.01 | 1.98 | 2.02 | 4.15 | 4.33 | 0.30 | 0.05 | 0.05 | 0.0125 | 0.09 | Balance |

| Specimens | US/MPa | YS/MPa | A/% | CTOD/µm |

|---|---|---|---|---|

| Bimodal structure | 1220 | 1165 | 13 | 12 |

| Lamellar structure | 1205 | 1150 | 9.8 | 68 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, R.; Ji, Y.; Wang, S.; Liu, S. Effect of Microstructure on Fracture Toughness and Fatigue Crack Growth Behavior of Ti17 Alloy. Metals 2016, 6, 186. https://doi.org/10.3390/met6080186

Liang R, Ji Y, Wang S, Liu S. Effect of Microstructure on Fracture Toughness and Fatigue Crack Growth Behavior of Ti17 Alloy. Metals. 2016; 6(8):186. https://doi.org/10.3390/met6080186

Chicago/Turabian StyleLiang, Rong, Yingping Ji, Shijie Wang, and Shuzhen Liu. 2016. "Effect of Microstructure on Fracture Toughness and Fatigue Crack Growth Behavior of Ti17 Alloy" Metals 6, no. 8: 186. https://doi.org/10.3390/met6080186