Metallographic Index-Based Quantification of the Homogenization State in Extrudable Aluminum Alloys

Abstract

:1. Introduction

2. Materials and Methods

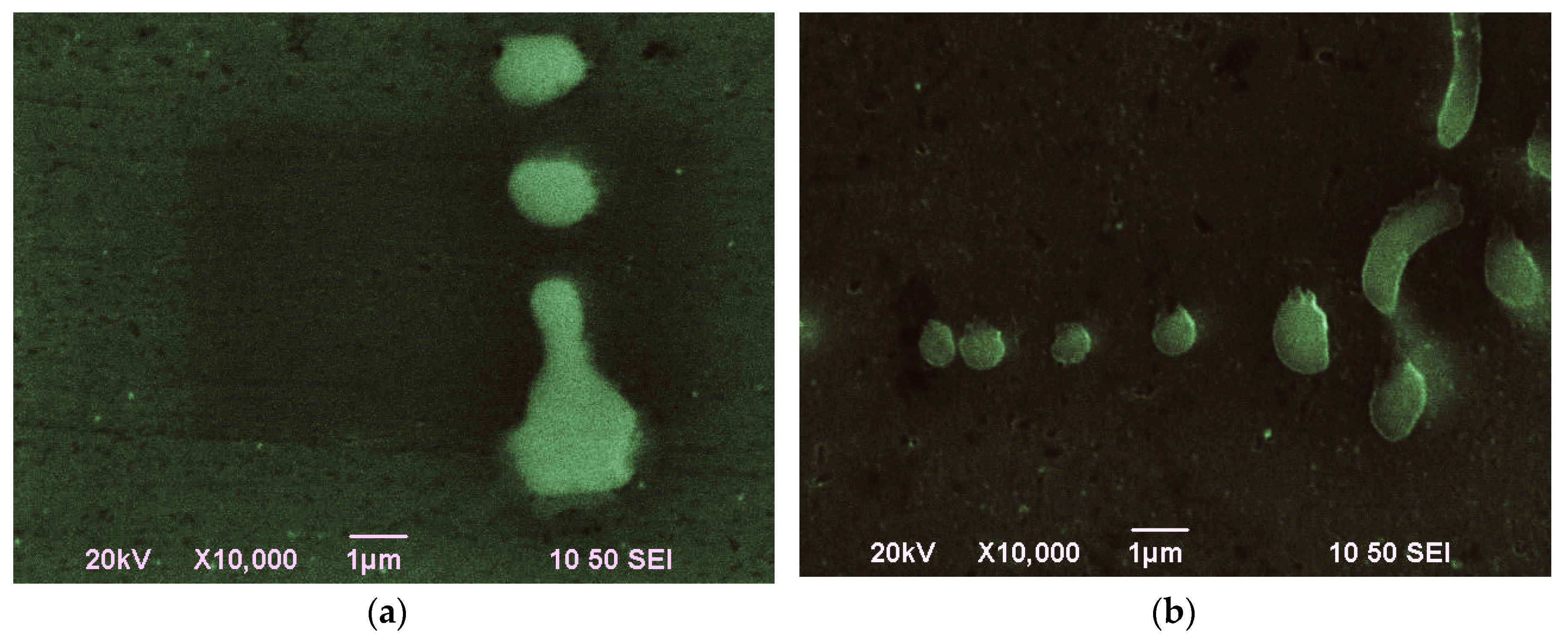

3. Results and Discussion

4. Conclusions

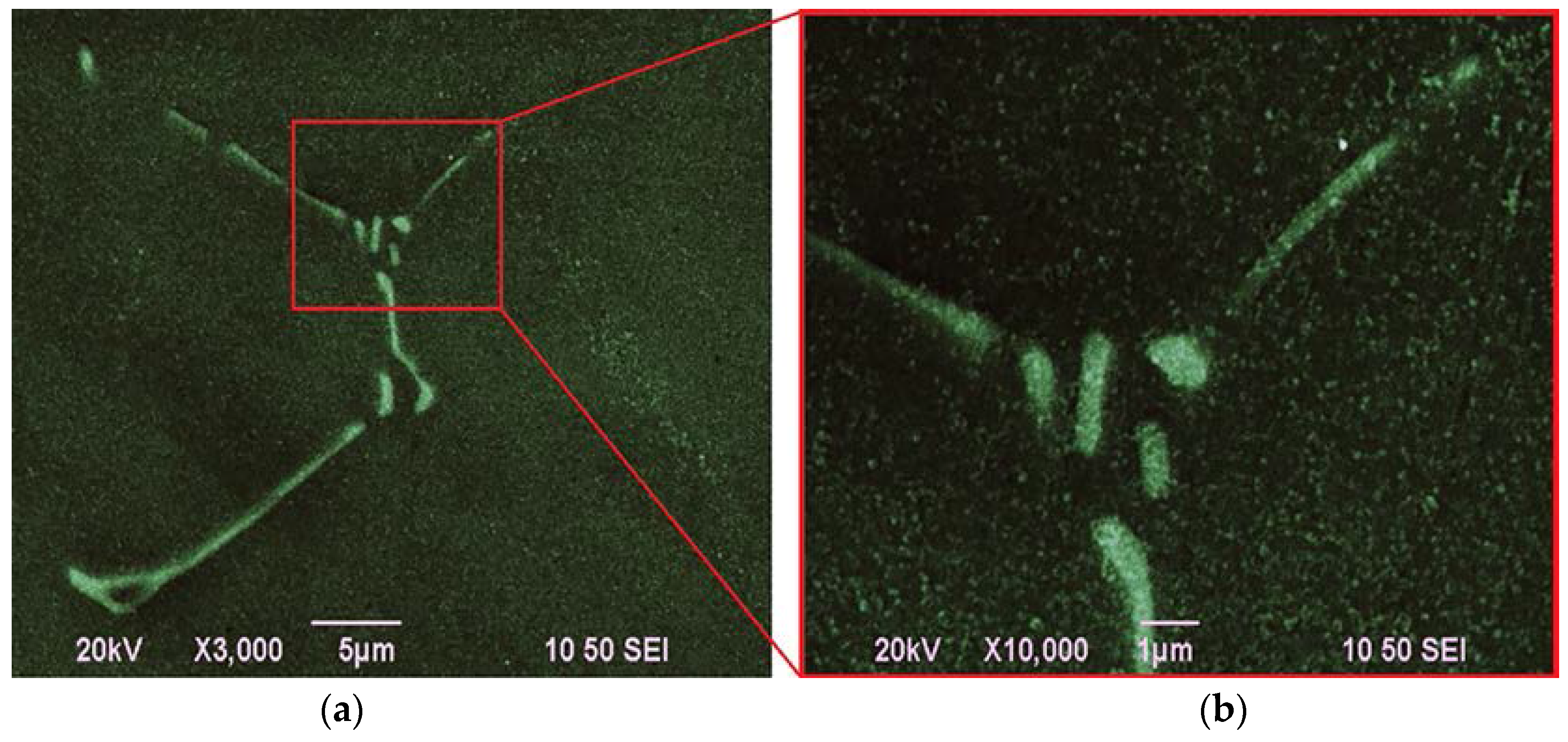

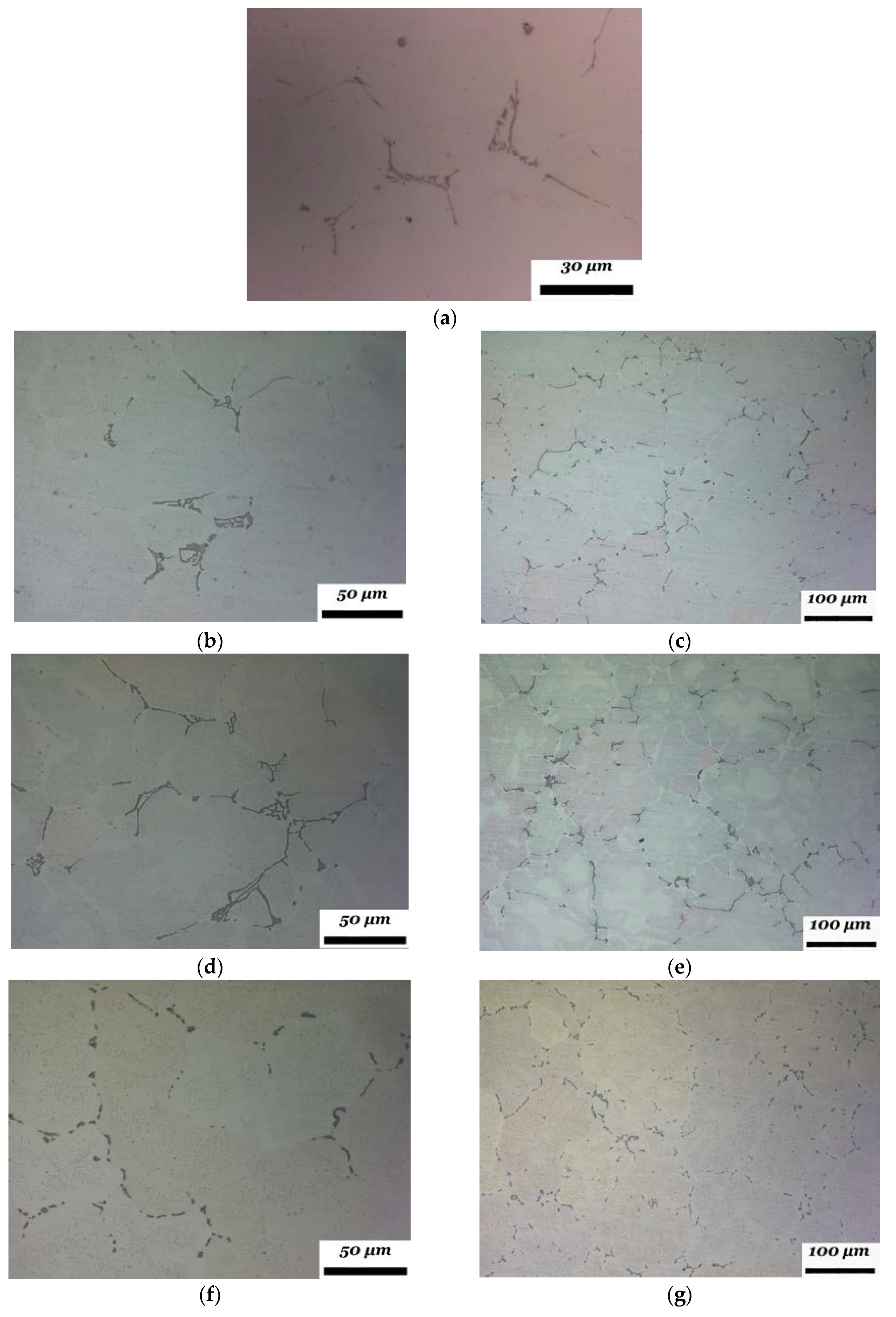

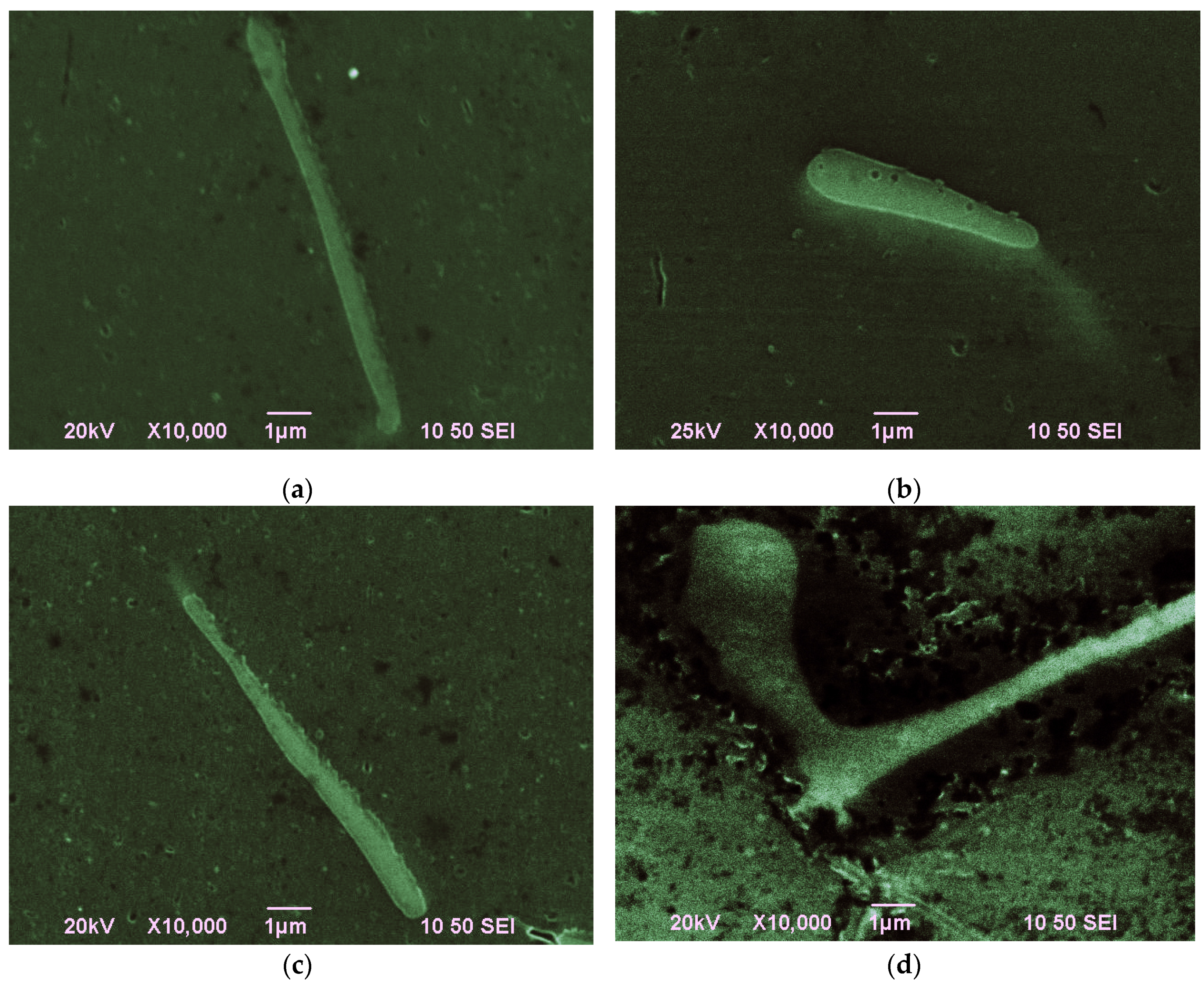

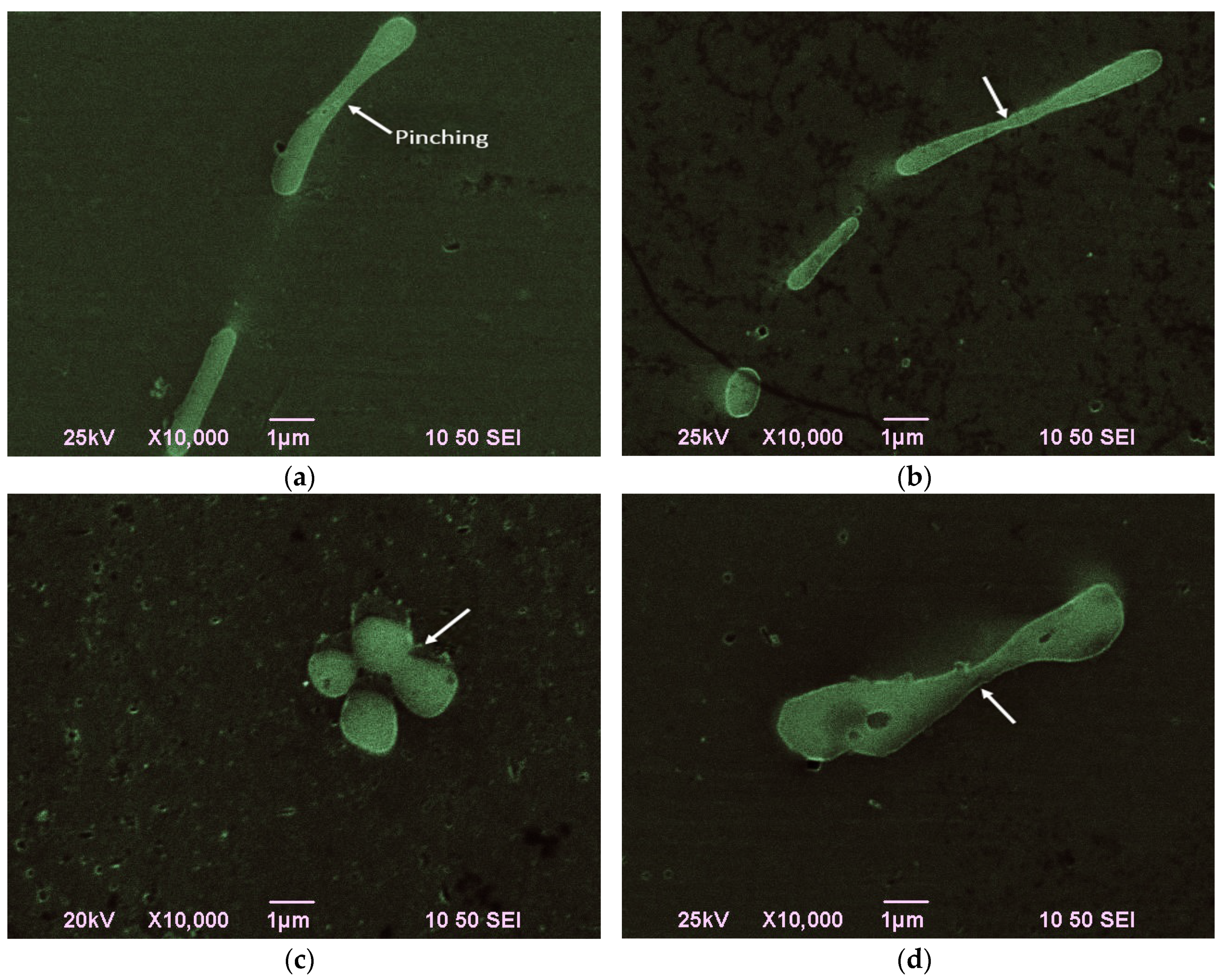

- The α-AlFeSi particles, after the completion of the β to α-AlFeSi transformation undergo morphological changes leading to spheroidization. This process can be divided in three stages: (1) rounding of edges, (2) particle pinching, and (3) necklace formation.

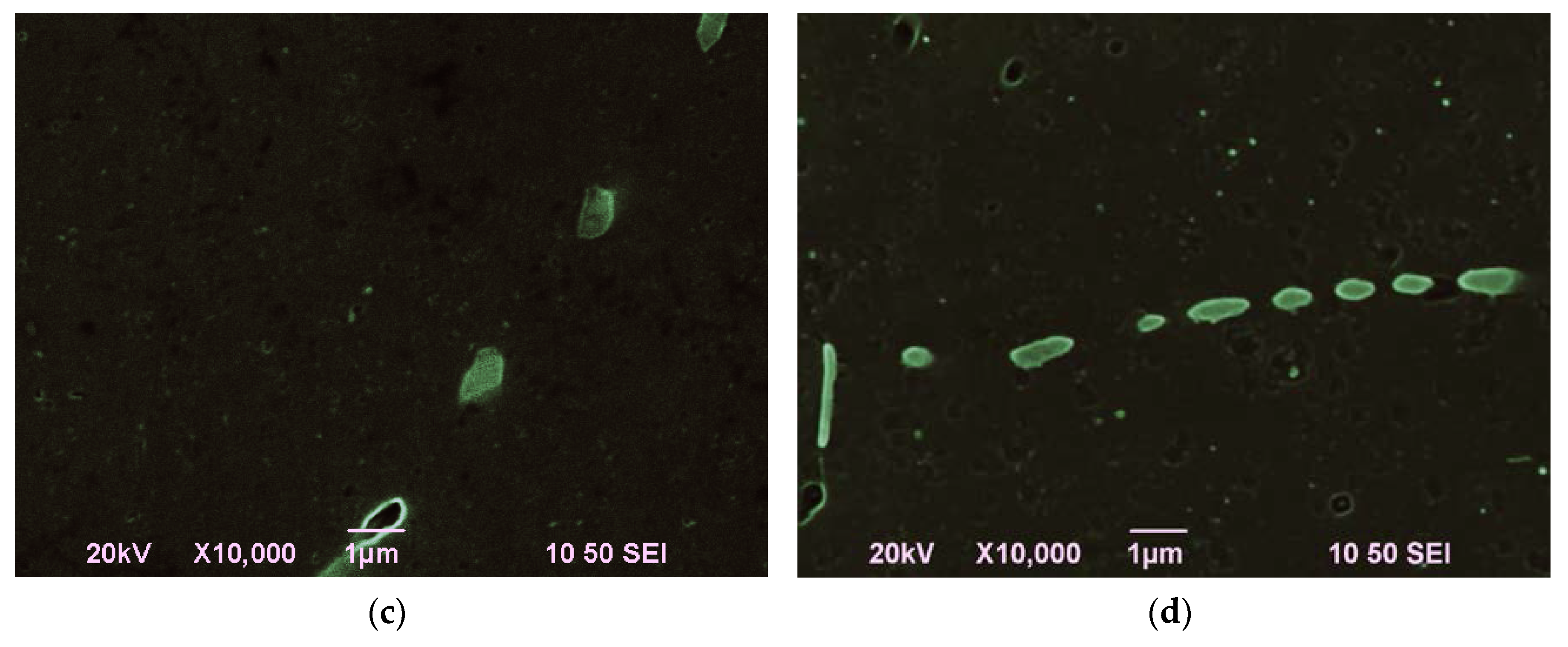

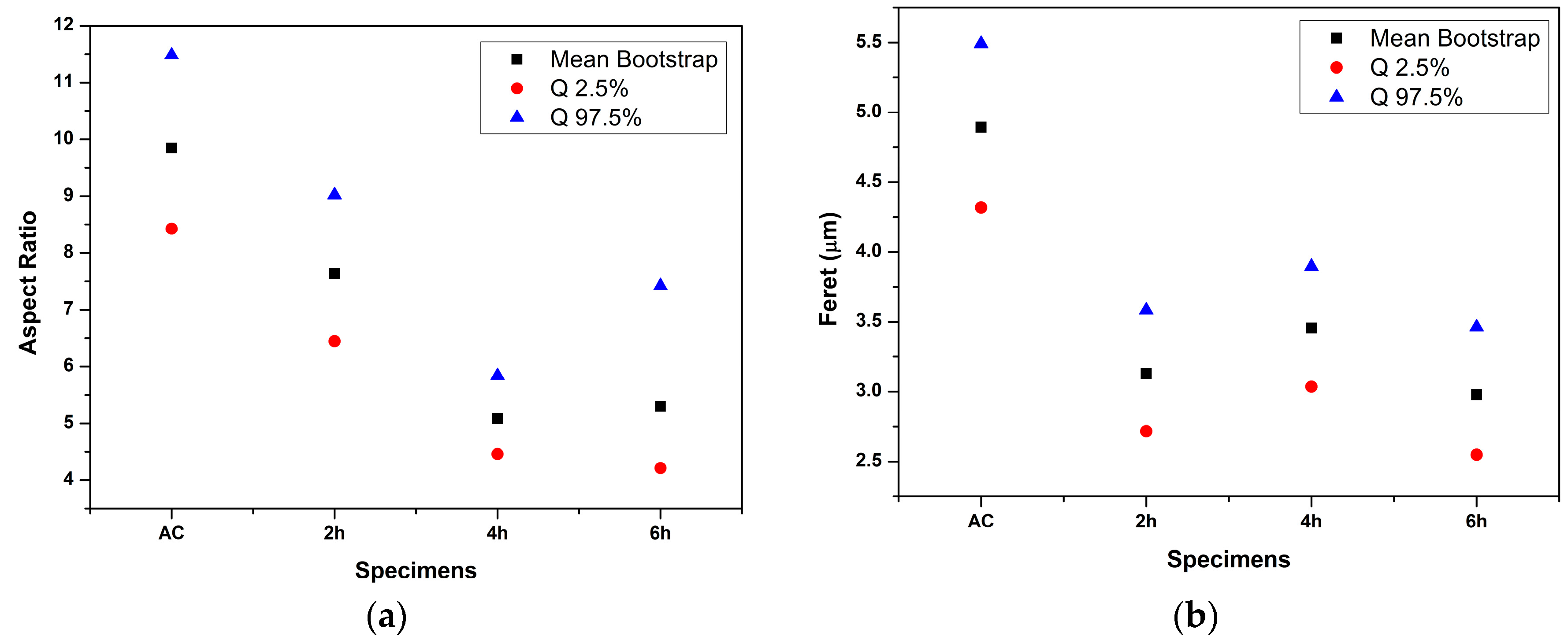

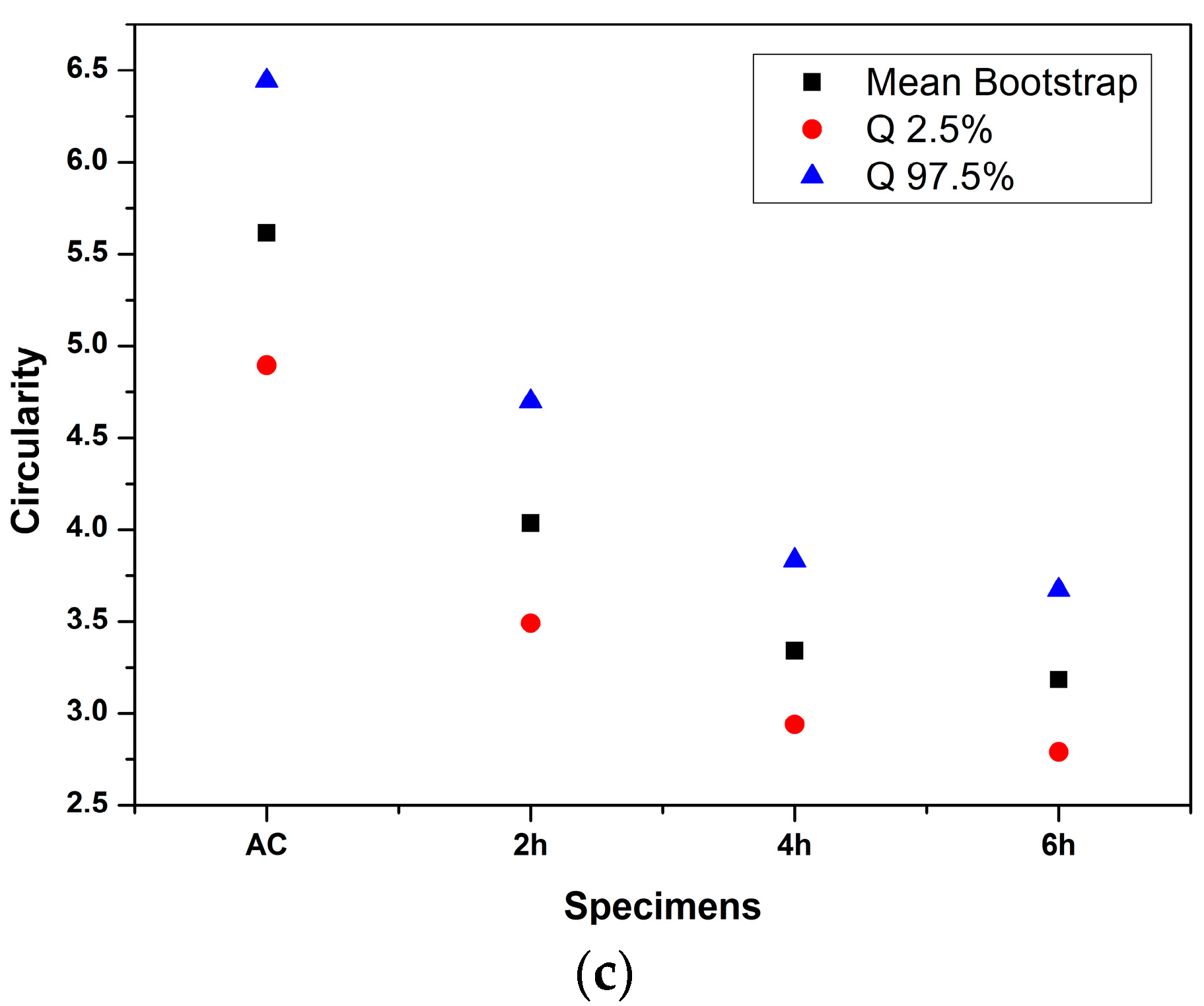

- The evolution of the morphological changes can be described quantitatively by the use of indices, such as aspect ratio, feret and circularity, which are sensitive to homogenization process parameters, such as the homogenization time.

- The circularity index exhibited the most consistent variation with homogenization time. The lowest value of the circularity index (more circular particles) coincided with the metallographic observation for necklace formation. Shorter homogenization times resulted in intermediate stages involving rounding of edges or particle pinching.

- The method requires the measurement of a large number of particles and the implementation of a statistical analysis in order to be credible.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sheppard, T. Extrusion of Aluminum Alloys; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1999. [Google Scholar]

- Xie, F.Y.; Kraft, T.; Zuo, Y.; Moon, C.H.; Chang, Y.A. Microstructure and microsegregation in Al-rich Al-Cu-Mg alloys. Acta Mater. 1999, 47, 489–500. [Google Scholar] [CrossRef]

- Robinson, J.S. Influence of retrogression and reaging on fracture toughness of 7010 aluminum alloy. Mater. Sci. Tech. Ser. 2003, 19, 1697–1701. [Google Scholar] [CrossRef]

- Rokhlin, L.L.; Dobatkina, T.V.; Bochvar, N.R.; Lysova, E.V. Investigation of phase equilibria in alloys of the Al-Zn-Mg-Cu-Zr-Sc system. J. Alloy. Compd. 2004, 367, 10–16. [Google Scholar] [CrossRef]

- Liu, Y.L.; Kang, S.B. The solidification process of Al-Mg-Si alloy. J. Mater. Sci. 1997, 32, 1443–1447. [Google Scholar] [CrossRef]

- Saha, P.K. Aluminum Extrusion Technology; ASM International: Metals Park, OH, USA, 2000. [Google Scholar]

- Mukhopadhyay, P. Alloy designation, processing and use of AA6xxx series aluminum alloys. ISRN Metall. 2012. [Google Scholar] [CrossRef]

- Birol, Y. The effect of homogenization practice on the microstructure of AA6063 billets. J. Mater. Process. Technol. 2004, 148, 250–258. [Google Scholar] [CrossRef]

- Cai, M.; Rodson, J.D.; Lorimer, G.W.; Parson, N.C. Simulation of the casting and Homogenization of two 6xxx Series Alloys. Mater. Sci. Forum 2002, 396, 209–214. [Google Scholar] [CrossRef]

- Usta, M.; Glicksman, M.E.; Wright, R.N. The effect of Heat Treatment on Mg2Si Coarsening in Aluminum 6105 Alloy. Metall. Mater. Trans. A 2004, 35, 435–438. [Google Scholar] [CrossRef]

- Van de Langkruis, J. The effect of thermal treatments on the extrusion behaviour of AlMgSi alloys. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, June 2000. [Google Scholar]

- Kuijpers, N.C.W.; Vermolen, F.J.; Vuik, K.; van der Zwaag, S. A model of the β-AlFeSi to α-Al(FeMn)Si transformation in Al-Mg-Si alloys. Mater. Trans. 2003, 44, 1448–1456. [Google Scholar] [CrossRef]

- Kuijpers, N.C.W.; Vermolen, F.J.; Vuik, C.; Koenis, P.T.G.; Nilsen, K.E.; van der Zwaag, S. The dependence of the β-AlFeSi to α-Al(FeMn)Si transformation kinetics in Al-Mg-Si alloys on the alloying elements. Mater. Sci. Eng. A 2005, 394, 9–19. [Google Scholar] [CrossRef]

- Haidemenopoulos, G.N.; Kamoutsi, H.; Zervaki, A.D. Simulation of the transformation of iron intermetallics during homogenization of 6xx series extrudable aluminum alloys. J. Mater. Process. Technol. 2012, 212, 2255–2260. [Google Scholar] [CrossRef]

- Eivani, A.R.; Ahmed, H.; Zhou, J.; Duszczyk, J. Evolution of Grain Boundary Phases during the Homogenization of AA7020 Aluminum Alloy. Metall. Mater. Trans. A 2009, 40, 717–728. [Google Scholar] [CrossRef]

- Eivani, A.R.; Ahmed, H.; Zhou, J.; Duszczyk, J. Correlation between Electrical Resistivity, Particle Dissolution, Precipitation of Dispersoids, and Recrystallization Behavior of AA7020 Aluminum Alloy. Metall. Mater. Trans. A 2009, 40, 2435–2446. [Google Scholar] [CrossRef]

- Eivani, A.R.; Ahmed, H.; Zhou, J.; Duszczyk, J. Modelling dissolution of low melting point phases during the homogenisation of AA7020 aluminium alloy. Mater. Sci. Technol. 2010, 26, 215–222. [Google Scholar] [CrossRef]

- Robson, J.D.; Prangnell, P.B. Dispersoid precipitation and process modelling in zirconium containing commercial aluminium alloys. Acta Mater. 2001, 49, 599–613. [Google Scholar] [CrossRef]

- Fan, X.; Jiang, D.; Meng, Q.; Zhong, L. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization. Mater. Lett. 2006, 60, 1475–1479. [Google Scholar] [CrossRef]

- Kuijpers, N.C.W.; Tirel, J.; Hanlon, D.N.; van der Zwaag, S. Quantification of the evolution of the 3D intermetallic structure in a 6005A aluminium alloy during a homogenisation treatment. Mater. Charact. 2002, 48, 379–392. [Google Scholar] [CrossRef]

- ASTM Specification F1877 Standard Practice for Characterization of Particles; ASTM International: Philadelphia, PA, USA, 1998. [CrossRef]

- Wayne, D. Applied Nonparametric Statistics, 2nd ed.; Cengage Learning: Andover, UK, 2000; pp. 226–234. [Google Scholar]

- Efron, B.; Tibshirani, R.J. An Introduction to the Bootstrap, 1st ed.; Chapman & Hall/CRC: London, UK, 1993; pp. 1–16. [Google Scholar]

| Chemical Composition (wt. %) | Temperature (°C) | Time (h) | |

|---|---|---|---|

| Al | Bal. | 560 | 2 |

| Mg | 0.38 | ||

| Si | 0.4 | 4 | |

| Fe | 0.2 | 6 | |

| Mn | 0.03 | ||

| Alloy | Number of Images | Number of Particles |

|---|---|---|

| As-cast | 58 | 106 |

| 2 h | 57 | 161 |

| 4 h | 56 | 150 |

| 6 h | 58 | 133 |

| Aspect Ratio | Feret | Circularity |

|---|---|---|

| A ratio of the major to the minor diameter of a particle, where dmax and dmin correspond to the longest and the shortest lines passing through the centroid | The longest caliper length | Circularity is a measure of how closely a particle resembles a circle. It varies from zero to one with a perfect circle having a value of one |

| F | ||

|  |  |

| No. | dmax/μm | dmin/μm | AR | p/μm | A/μm2 | C | F/μm |

|---|---|---|---|---|---|---|---|

| 1 | 3.655 | 0.376 | 9.720 | 8.405 | 1.083 | 5.190 | 3.656 |

| 2 | 3.289 | 0.379 | 8.678 | 7.427 | 0.844 | 5.200 | 3.308 |

| 3 | 1.792 | 0.389 | 4.606 | 4.395 | 0.735 | 2.103 | 1.793 |

| 4 | 1.069 | 0.534 | 2.001 | 2.820 | 0.441 | 1.433 | 1.068 |

| 5 | 1.123 | 0.632 | 1.776 | 3.080 | 0.524 | 1.439 | 1.160 |

| 6 | 0.976 | 0.489 | 1.995 | 2.712 | 0.423 | 1.384 | 1.000 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarafoglou, P.I.; Aristeidakis, J.S.; Tzini, M.-I.T.; Haidemenopoulos, G.N. Metallographic Index-Based Quantification of the Homogenization State in Extrudable Aluminum Alloys. Metals 2016, 6, 121. https://doi.org/10.3390/met6050121

Sarafoglou PI, Aristeidakis JS, Tzini M-IT, Haidemenopoulos GN. Metallographic Index-Based Quantification of the Homogenization State in Extrudable Aluminum Alloys. Metals. 2016; 6(5):121. https://doi.org/10.3390/met6050121

Chicago/Turabian StyleSarafoglou, Panagiota I., John S. Aristeidakis, Maria-Ioanna T. Tzini, and Gregory N. Haidemenopoulos. 2016. "Metallographic Index-Based Quantification of the Homogenization State in Extrudable Aluminum Alloys" Metals 6, no. 5: 121. https://doi.org/10.3390/met6050121