NURBS-Based Collocation Methods for the Structural Analysis of Shells of Revolution

Abstract

:1. Introduction

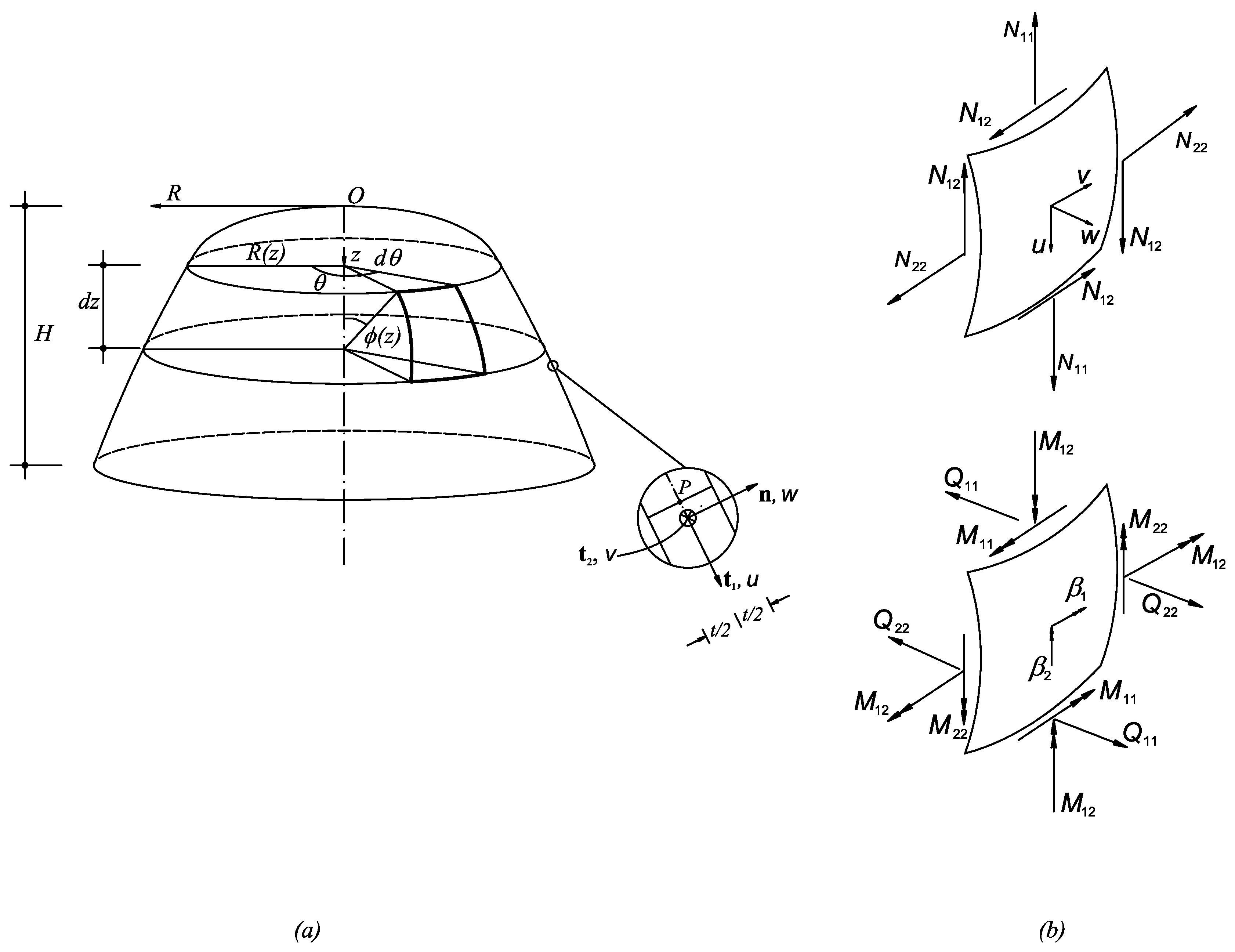

2. Statement of the Problem

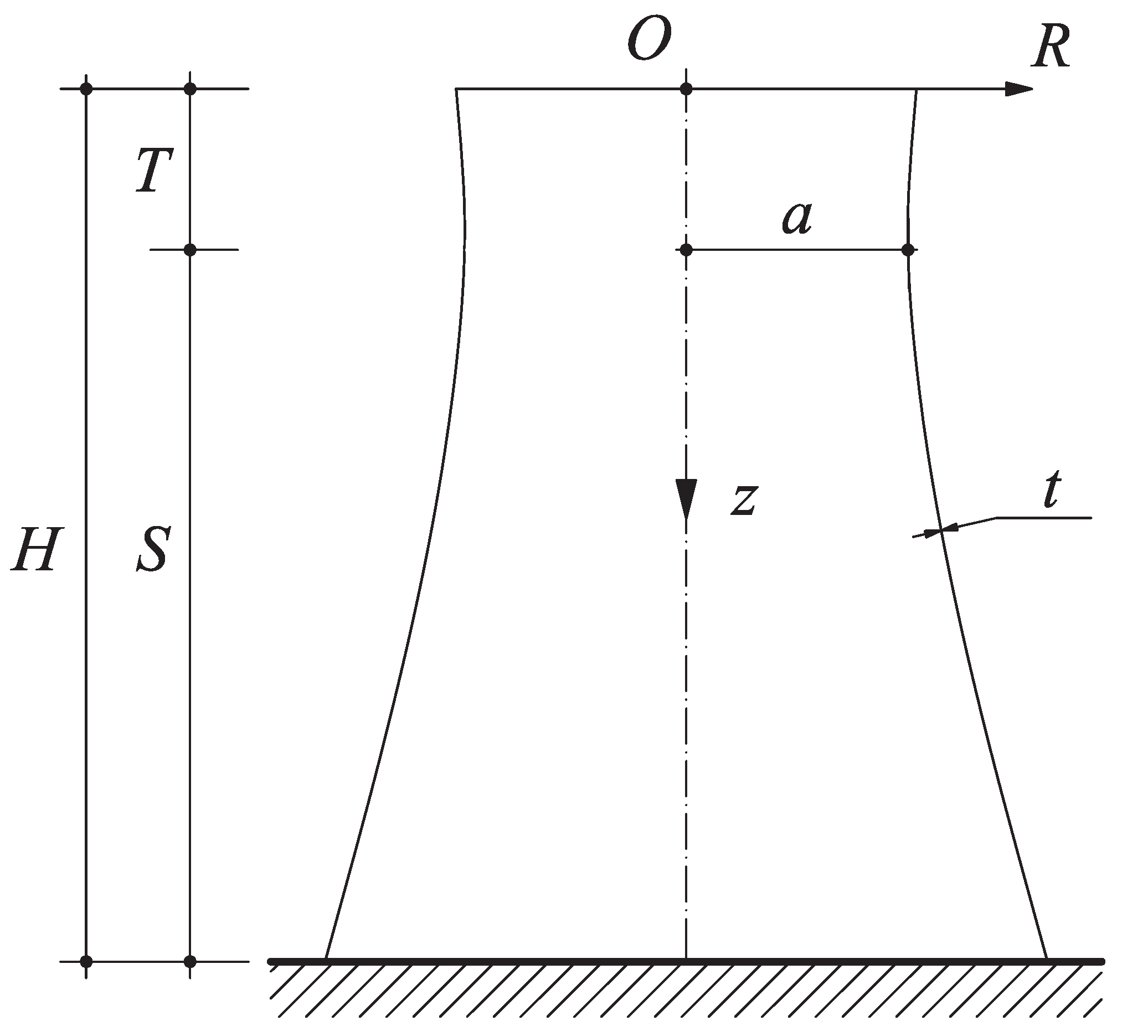

2.1. Geometry

2.2. Displacement Field

2.3. Internal Actions

2.4. Equilibrium

2.4.1. Free Vibration Problem

2.4.2. Static Equilibrium Problem

3. B-Spline Basis Functions

3.1. One Dimensional NURBS Interpolation

4. NURBS-Based Collocation Method

- Free vibration problem

- Static equilibrium problem

- Define NURBS order p, number of control points n, build open knot vector Ξ, build NURBS basis and derivatives;

- Compute collocation points , ;

- Parametrize curvilinear space coordinate as , and relevant geometric quantities, i.e., , , ;

- Collocate above mentioned quantities at collocation points;

- Approximate equilibrium, mass matrix, and boundary conditions operators: , , and , respectively, and applied load distribution , through NURBS interpolants;

- Collocate discrete governing equations, i.e., equilibrium [resp. boundary condition] equations at internal [resp. boundary] collocation points;

- Assemble linear equations, viz. (15)–(16);

- Solve for , ;

- Post-process solution through NURBS interpolation.

5. Numerical Results

5.1. Free Vibration Problems

5.1.1. Asymptotic Analysis of Fundamental Frequency

- Parabolic shape:

- Elliptic shape:with , ;

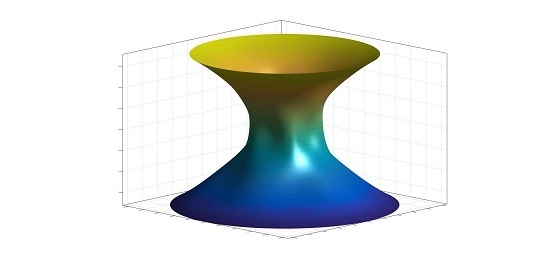

- Hyperbolic shape:with , .

- Parabolic shell:

- Elliptic shell:

- Hyperbolic shell:

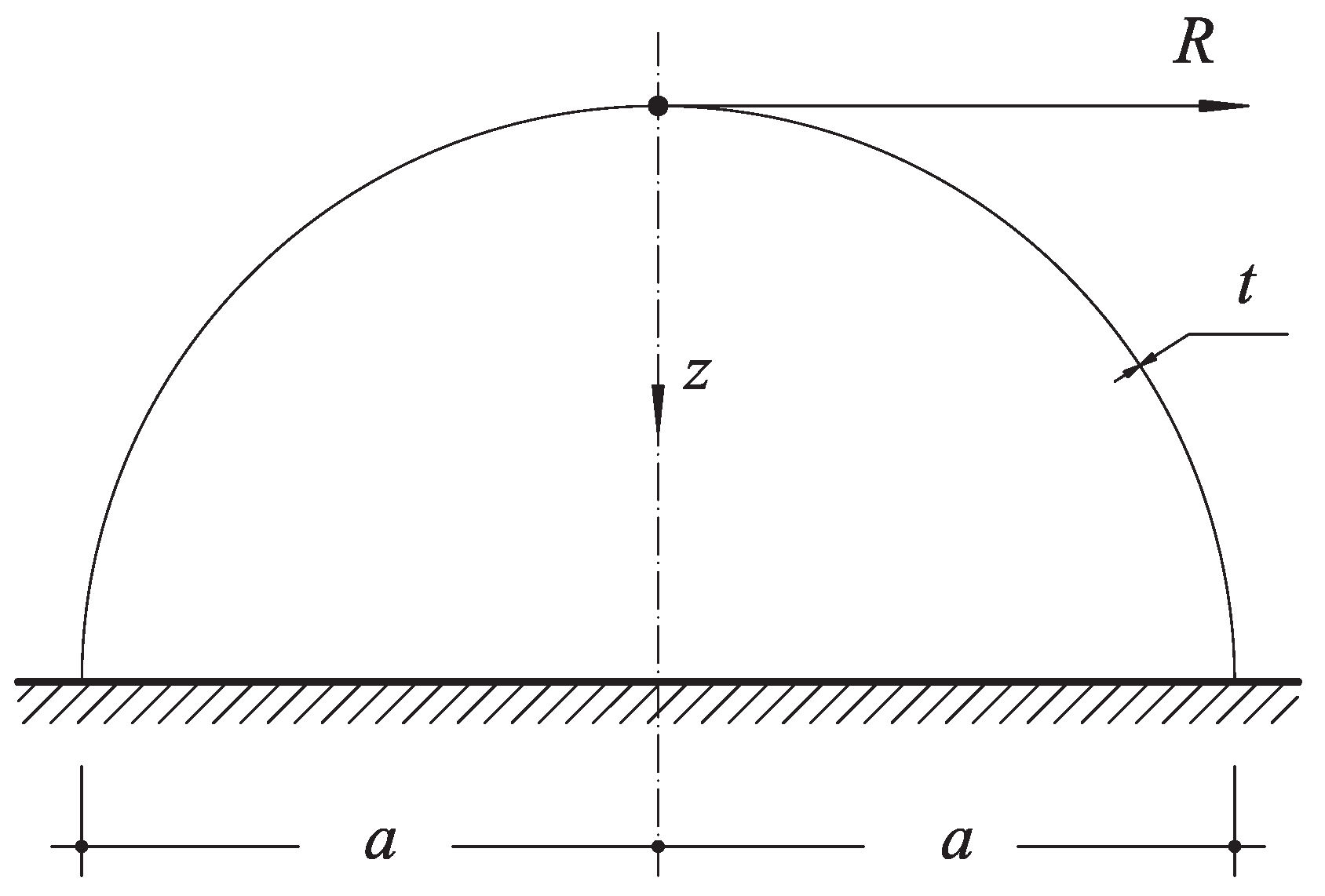

5.1.2. Clamped Hemispherical Shell in Free Vibration

5.1.3. Simply supported circular plate in free vibration

5.2. Static Equilibrium Problems

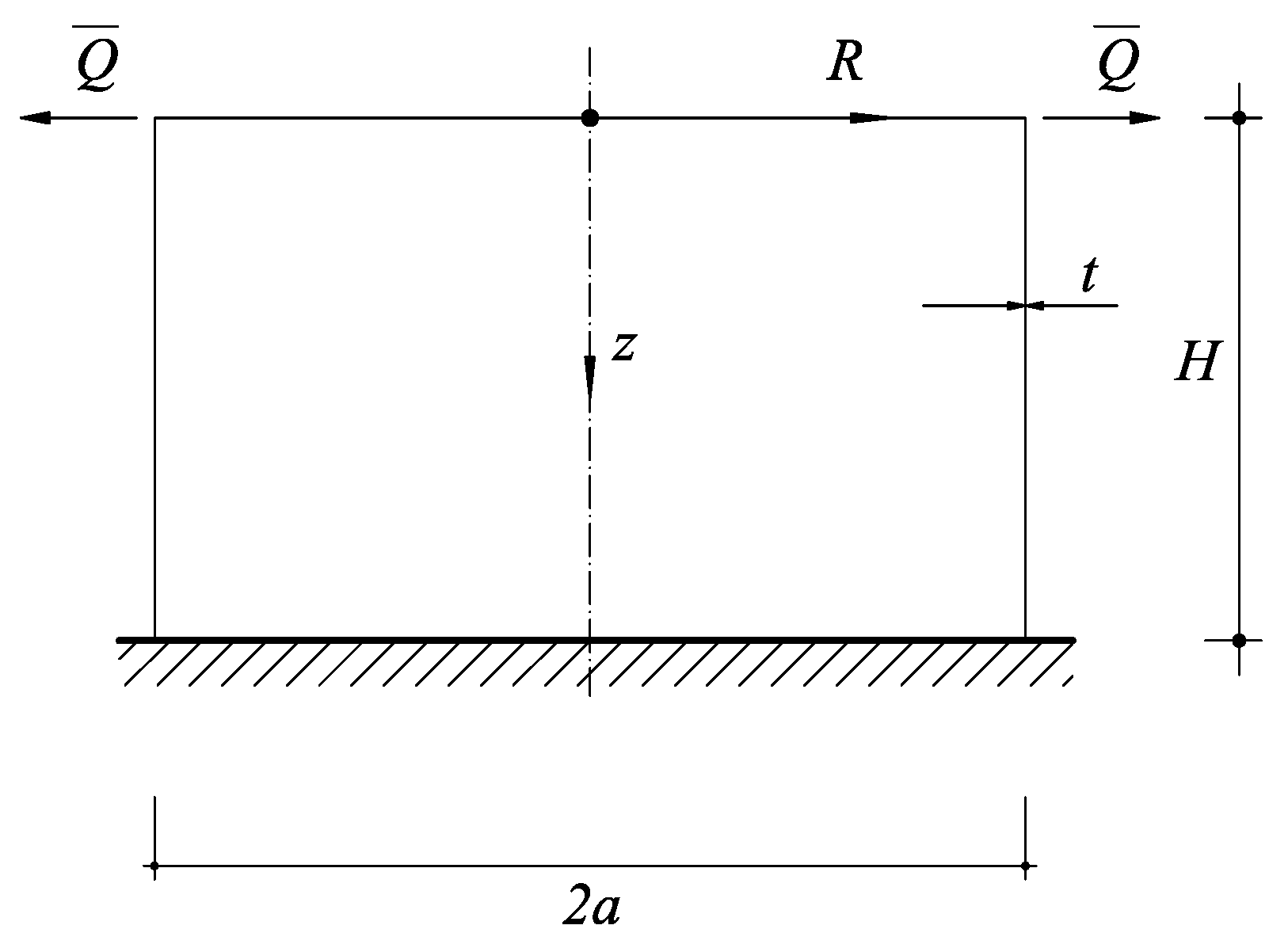

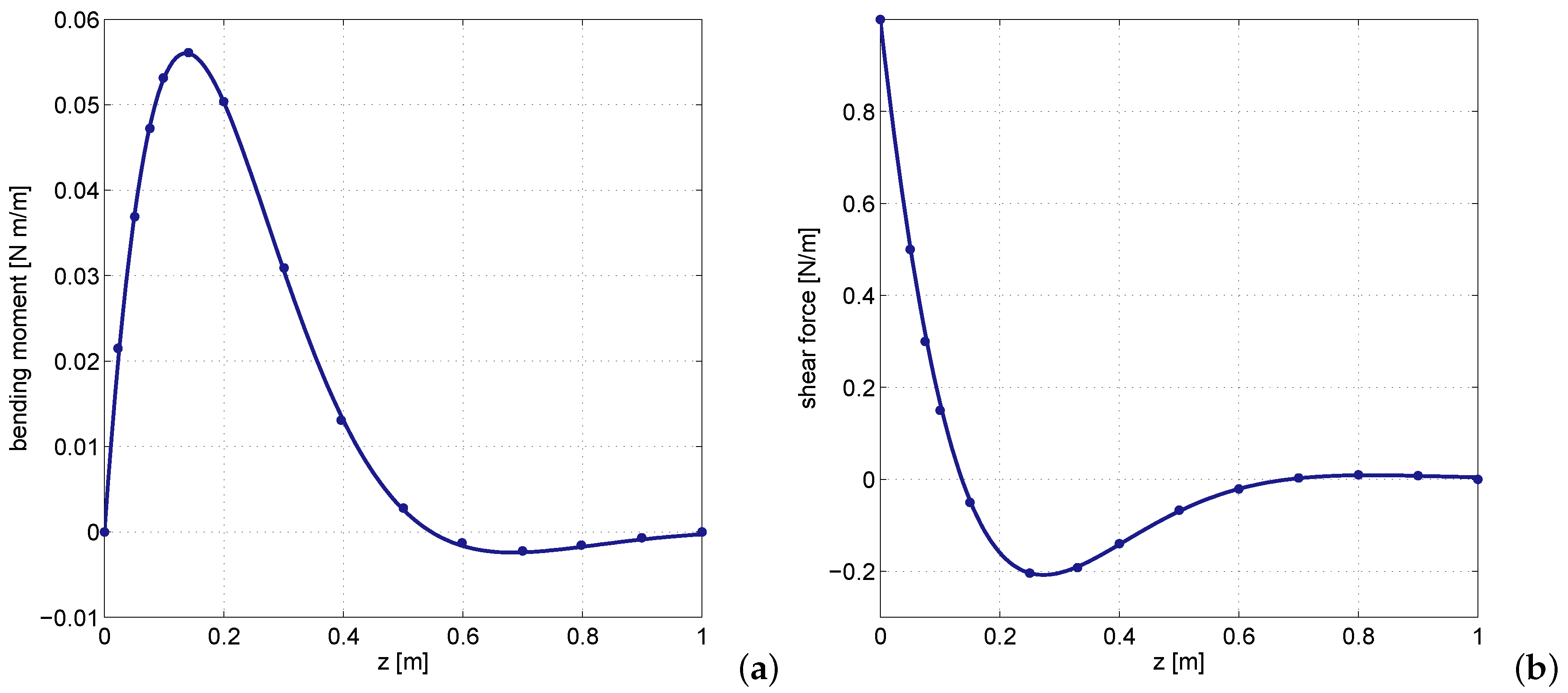

5.2.1. Cantilever Cylindrical Shell under Tip Load

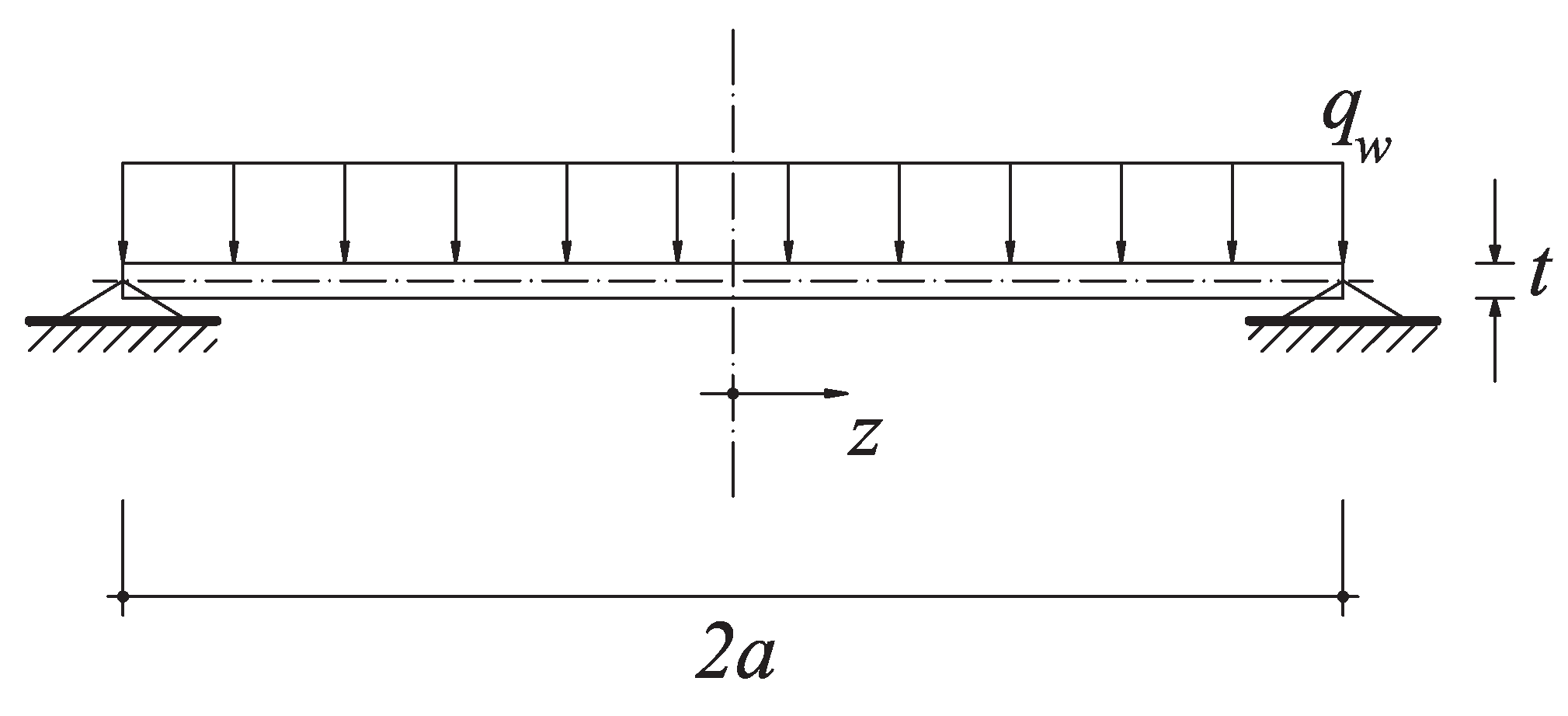

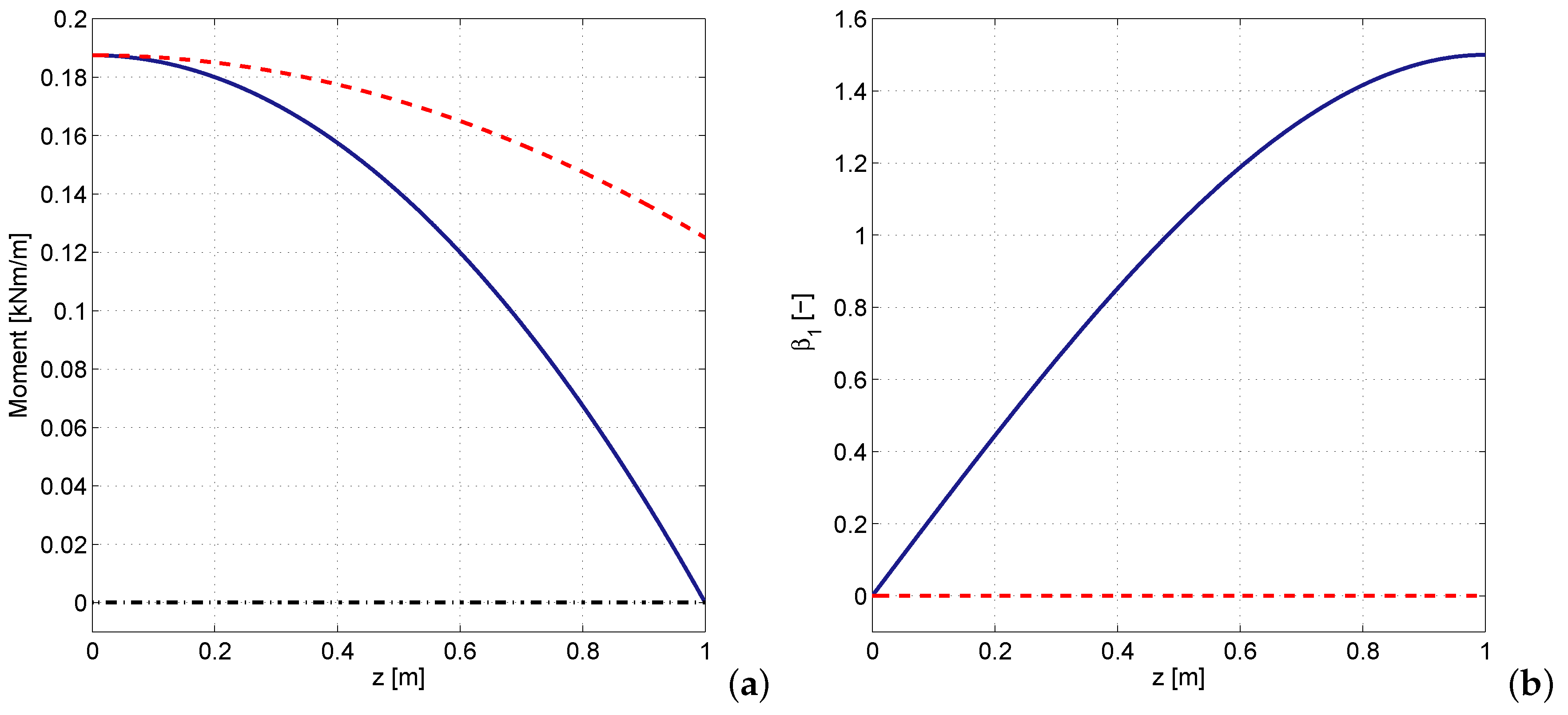

5.2.2. Simply Supported Circular Plate Subject to Uniform Pressure

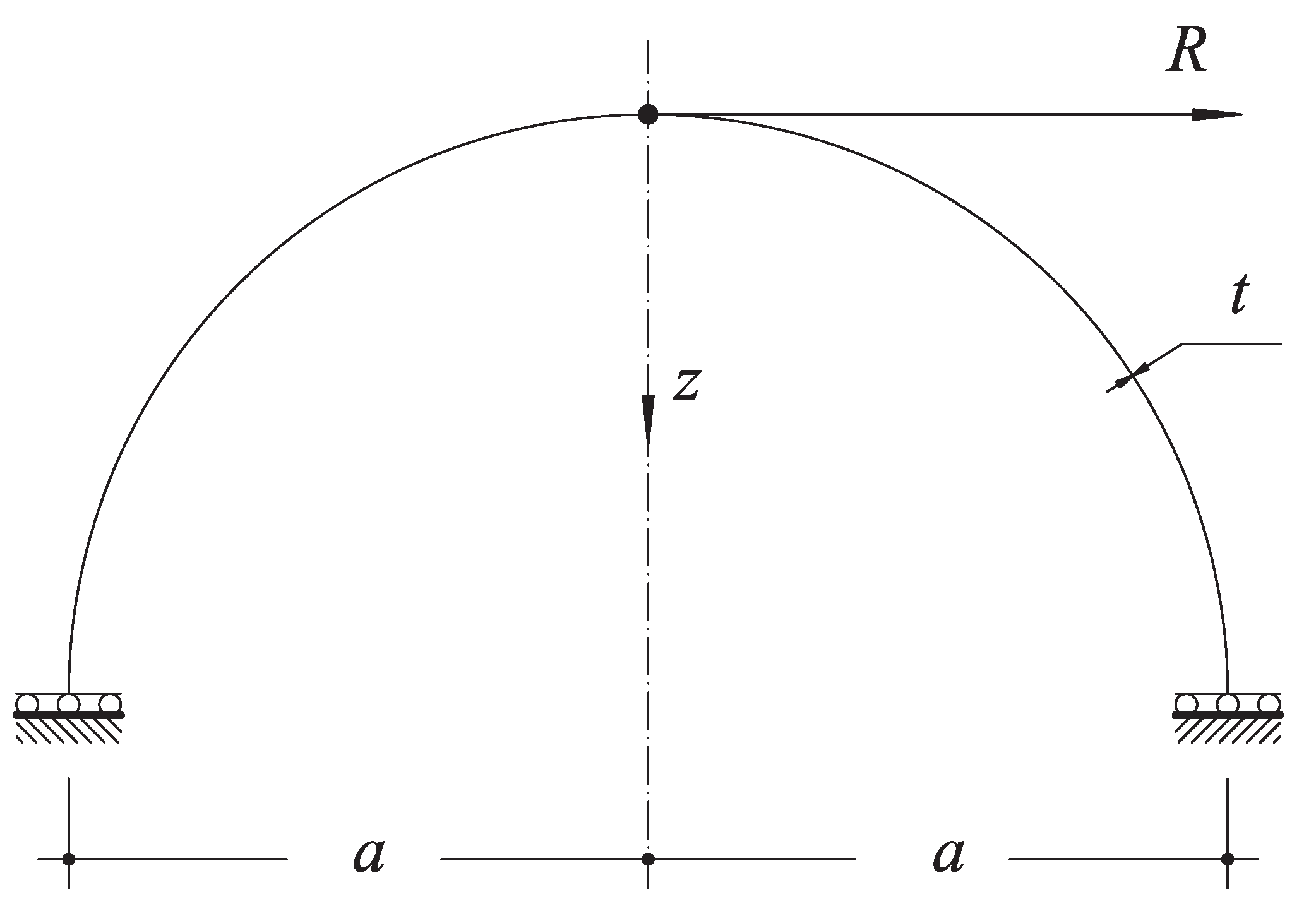

5.2.3. Hemispherical Shell under Uniform Pressure

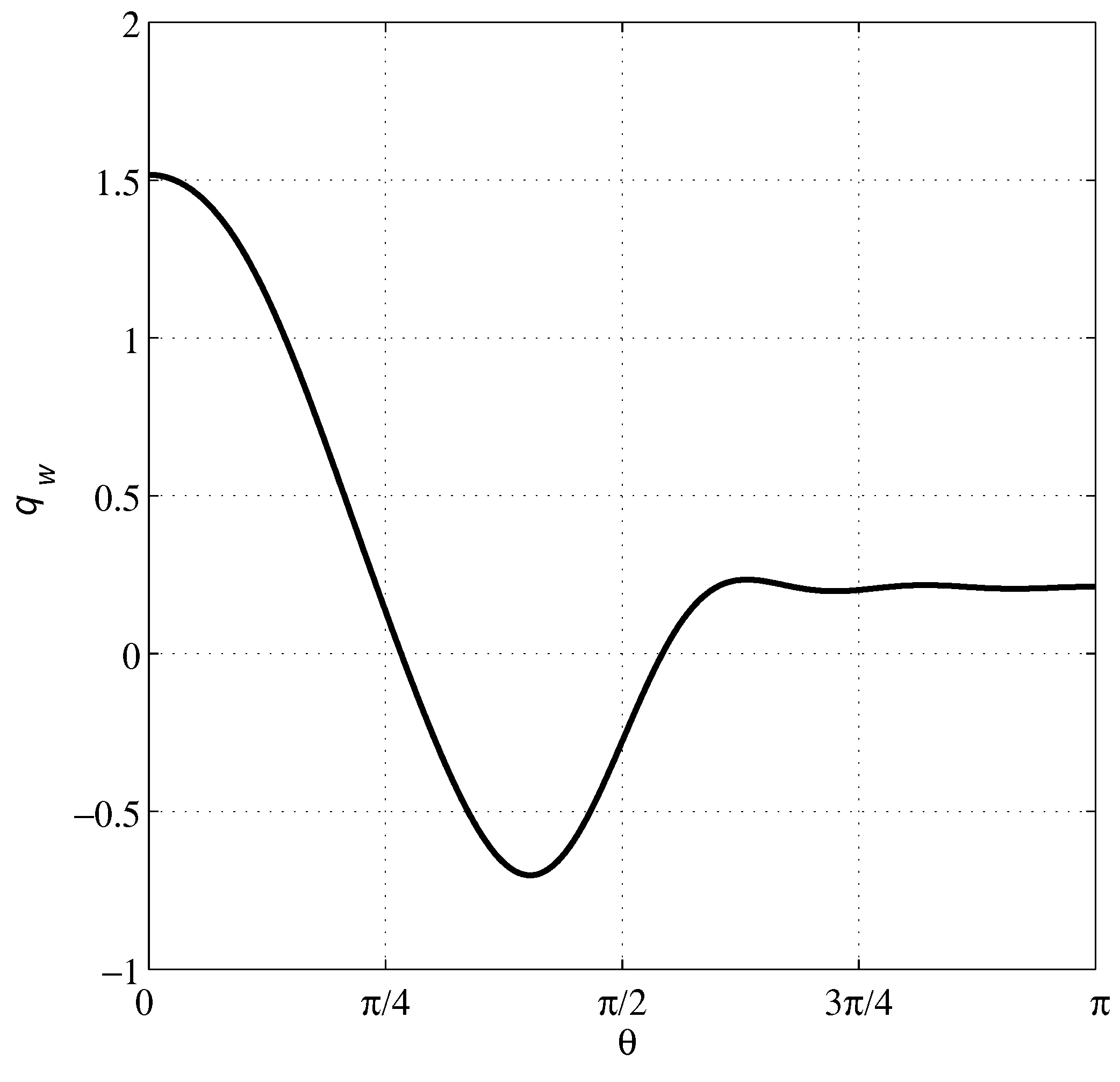

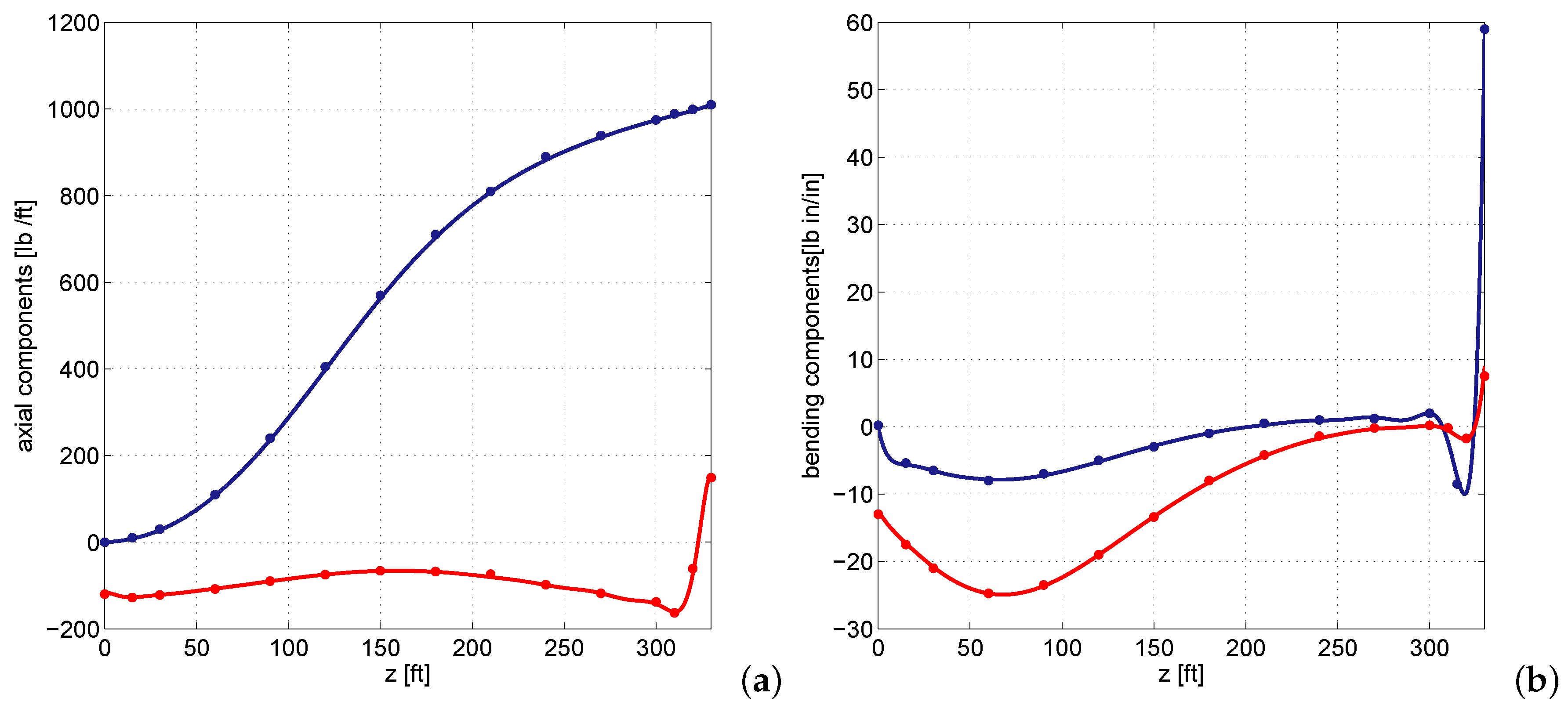

5.2.4. Hyperboloid of Revolution under Wind Load

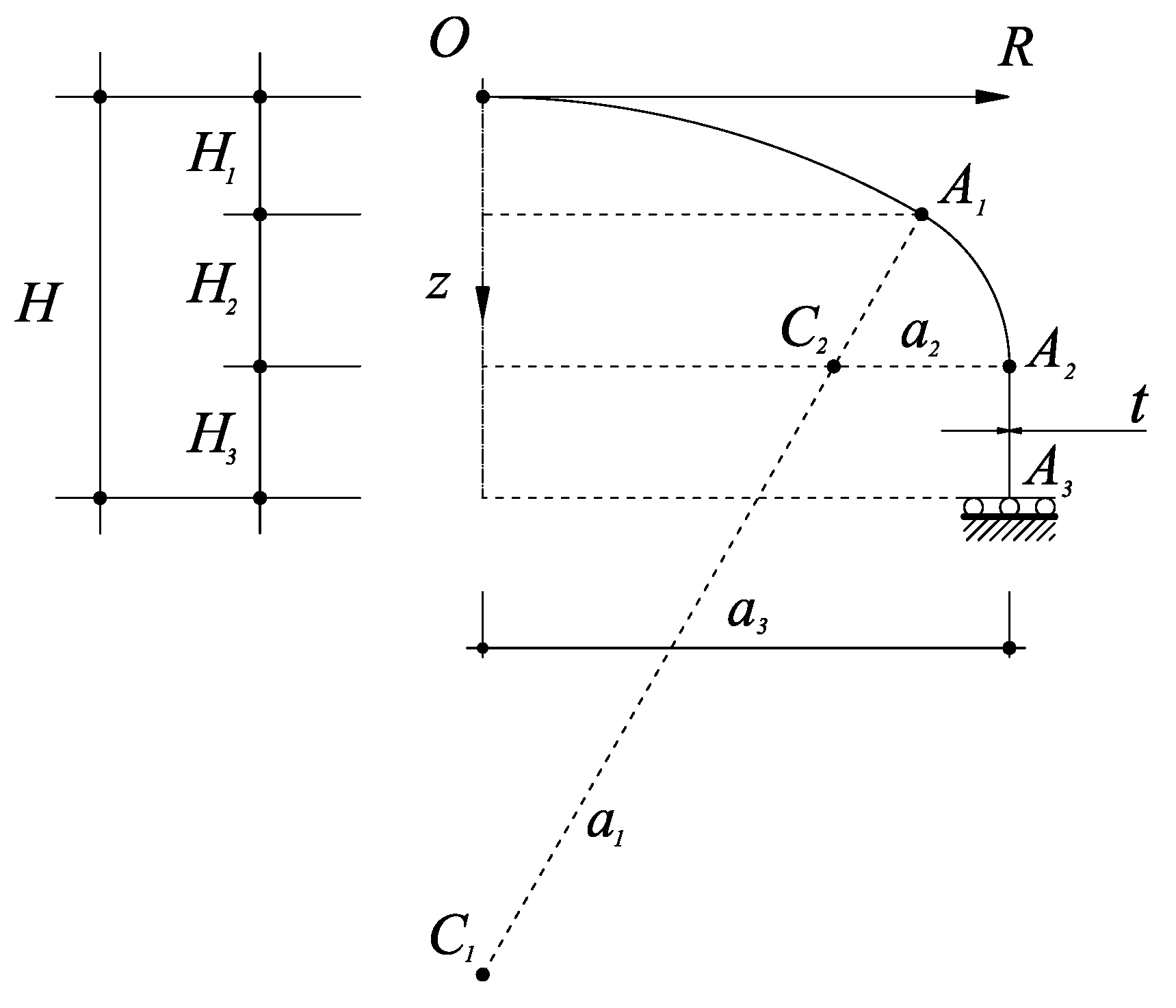

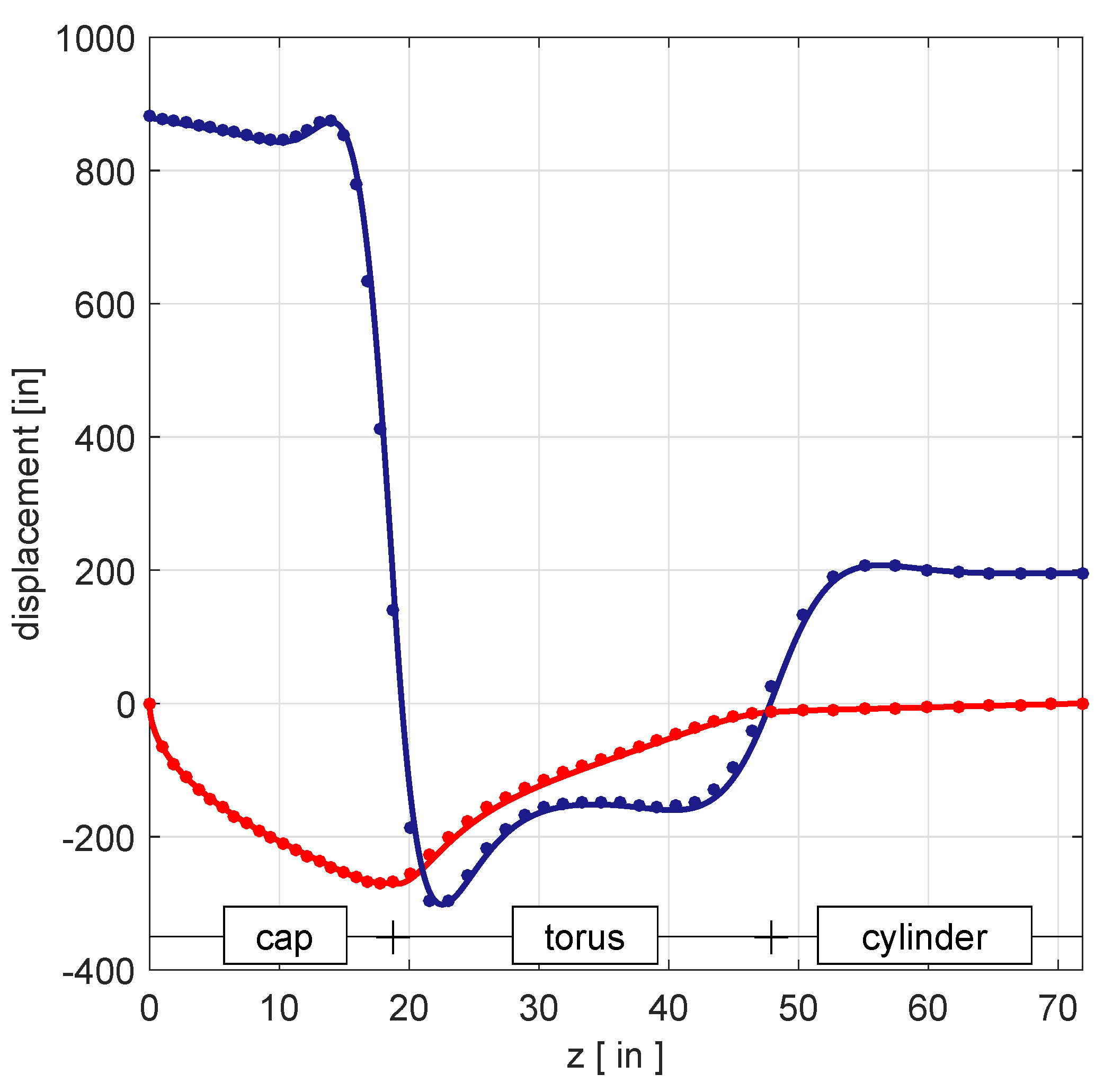

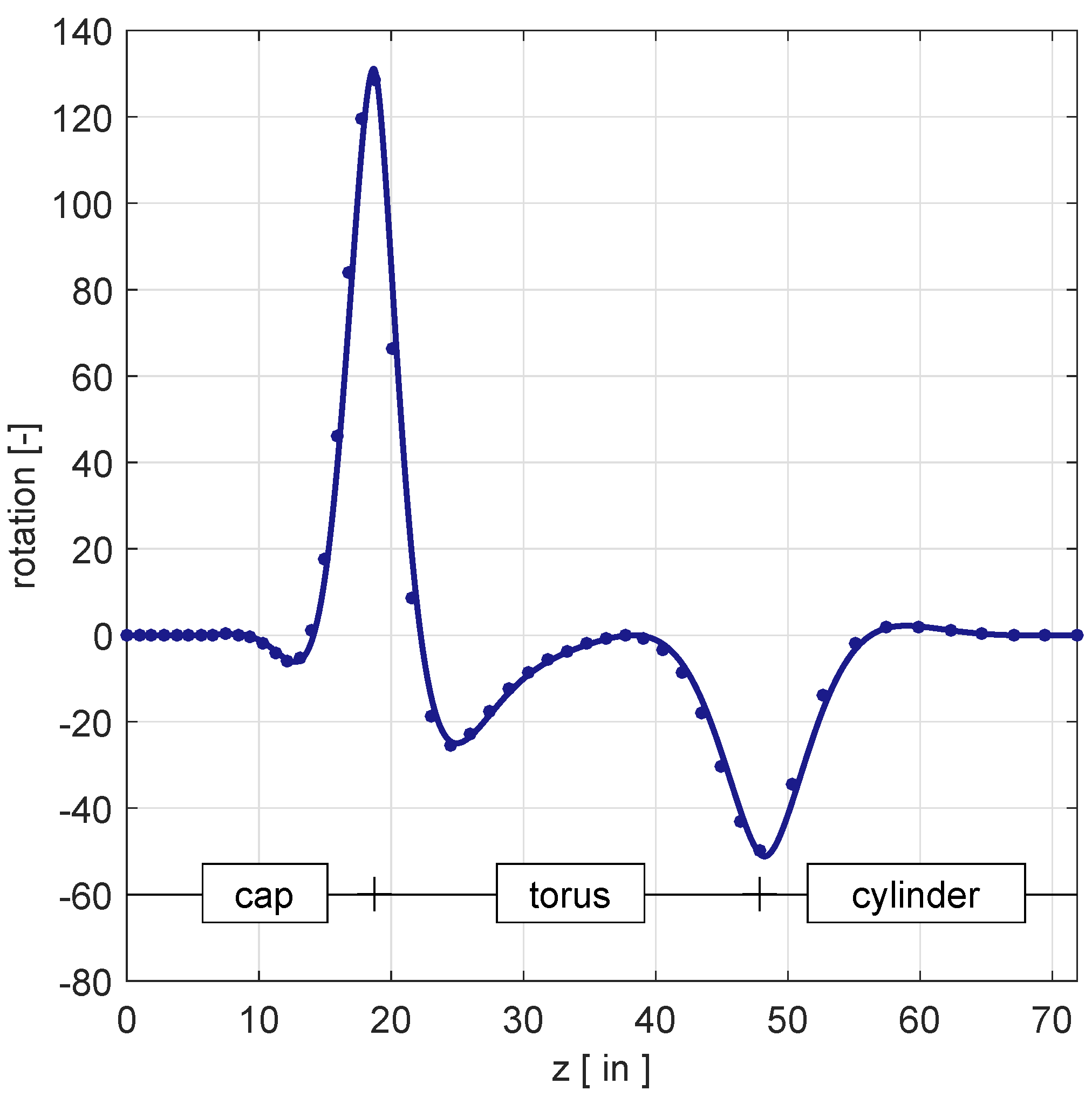

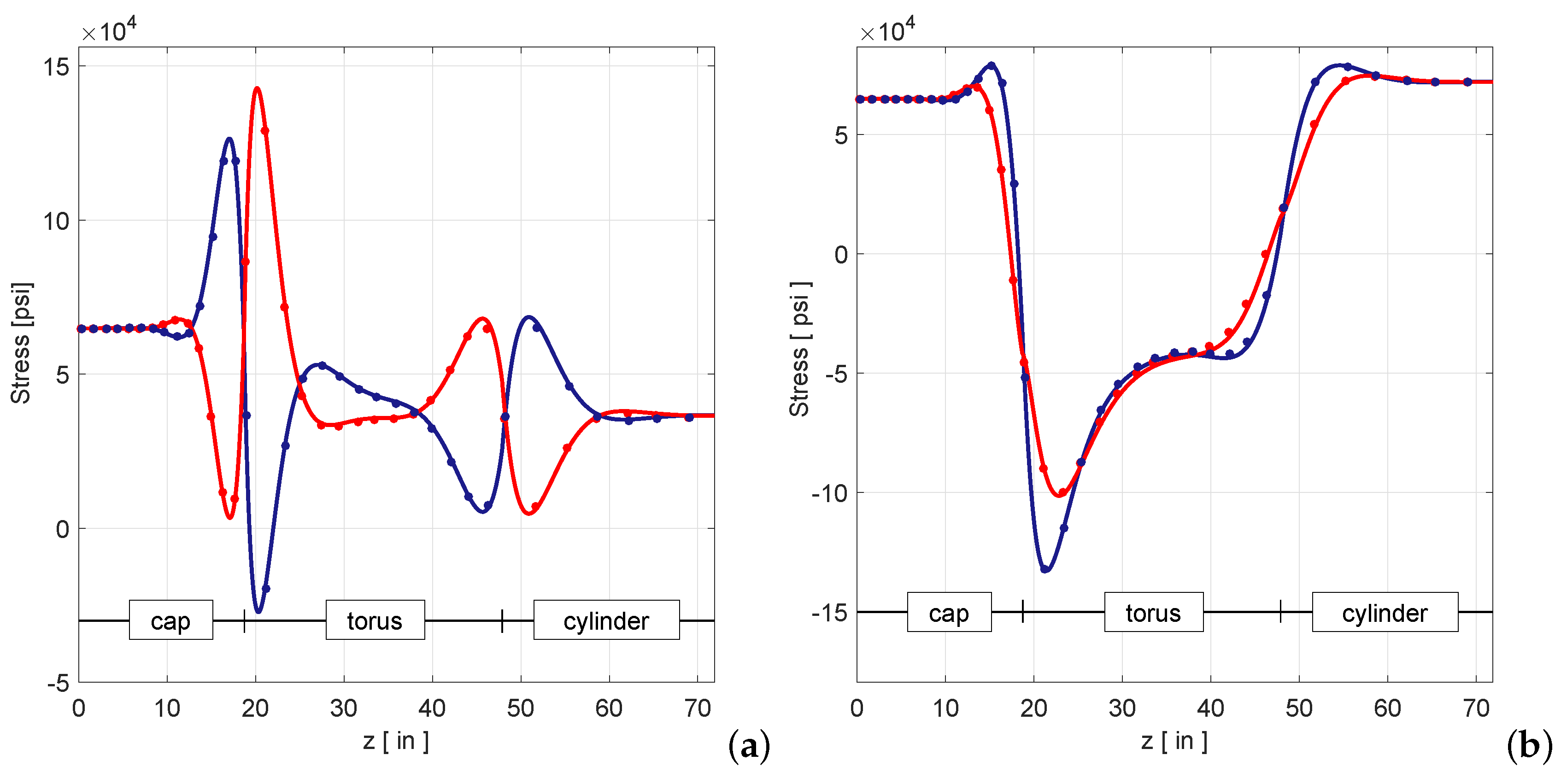

5.2.5. Torispherical tank subject to uniform internal pressure

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Fundamental Relationships for Shells of Revolution

Appendix A.1. Metric Quantities on Shell Mid-Surface

Appendix A.2. Fourier Series Expansions

- Displacements and rotations.with the vectorcollecting the 5 displacement components harmonic amplitudes.In the case of a free vibration problem, harmonic motion is assumed, i.e., the time dependence of is taken as:

- Stress resultants and couples.with the vectorcollecting the 8 stress resultants harmonic amplitudes.

- Strain components.with the vectorordering the 8 strain components harmonic amplitudes.

- Surface loads.with .

Appendix A.3. Strain-Displacement Operator

Appendix A.4. Linear Elastic Constitutive Equation

Appendix B. Equilibrium and Boundary Conditions Operators

Appendix B.1. Equilibrium Operator

Appendix B.2. Boundary Conditions

- Free edge

- Simply supported edge

- Sliding edge

- Clamped edge

References

- Bellman, R. Differential quadrature and long-term integration. J. Math. Anal. Appl. 1971, 34, 235–238. [Google Scholar] [CrossRef]

- Bellman, R.; Kashef, B.G.; Casti, J. Differential quadrature: A technique for the rapid solution of nonlinear partial differential equations. J. Comput. Phys. 1972, 10, 40–52. [Google Scholar] [CrossRef]

- Petersen, I. Convergence of approximate methods of the interpolation type for ordinary differential equations. Izv. Akad. Nauk. SSR 1961, 1, 3–12. [Google Scholar]

- Karpilovskaya, E.B. Convergence of the collocation method. Proc. USSR Acad. Sci. 1963, 151, 766–769. [Google Scholar]

- Vainikko, G. Convergence and stability of the collocation method. Differ. ur-niya 1965, 1, 244–254. [Google Scholar]

- Vainikko, G. The convergence of the collocation method for non-linear differential equations. USSR Comput. Math. Math. Phys. 1966, 6, 47–58. [Google Scholar] [CrossRef]

- Kaspshitskaya, M.F.; Luchka, A.Y. The collocation method. USSR Comput. Math. Math. Phys. 1968, 8, 19–39. [Google Scholar] [CrossRef]

- Schillinger, D.; Evans, J.A.; Reali, A.; Schott, M.; Hughes, T.J.R. Isogeometric collocation: Cost comparison with galerkin methods and extension to adaptive hierarchical nurbs discretizations. Comput. Methods Appl. Mech. Eng. 2013, 267, 170–232. [Google Scholar] [CrossRef]

- Bert, C.W.; Malik, M. Differential quadrature: A powerful new technique for analysis of composite structures. Compos. Struct. 1997, 39, 179–189. [Google Scholar] [CrossRef]

- Mirfakhraei, P.; Redekop, D. Buckling of circular cylindrical shells by the differential quadrature method. Int. J. Press. Vessel. Pip. 1998, 75, 347–353. [Google Scholar] [CrossRef]

- Wu, T.; Liu, G. Axisymmetric bending solution of shells of revolution by the generalized differential quadrature rule. Int. J. Press. Vessel. Pip. 2000, 77, 149–157. [Google Scholar] [CrossRef]

- Wu, T.; Wang, Y.; Liu, G. A generalized differential quadrature rule for bending analysis of cylindrical barrel shells. Comput. Methods Appl. Mech. Eng. 2003, 192, 1629–1647. [Google Scholar] [CrossRef]

- Artioli, E.; Viola, E. Static analysis of shear-deformable shells of revolution via G.D.Q. method. Struct. Eng. Mech. 2005, 19, 459–475. [Google Scholar] [CrossRef]

- Viola, E.; Artioli, E. The G.D.Q. method for the harmonic dynamic analysis of rotational shell structural elements. Struct. Eng. Mech. 2004, 17, 789–817. [Google Scholar] [CrossRef]

- Artioli, E.; Gould, P.L.; Viola, E. A differential quadrature method solution for shear-deformable shells of revolution. Eng. Struct. 2005, 27, 1879–1892. [Google Scholar] [CrossRef]

- Artioli, E.; Viola, E. Free vibration analysis of spherical caps using a G.D.Q. numerical solution. ASME J. Press. Vessel. Technol. 2006, 128, 370–378. [Google Scholar] [CrossRef]

- Bellman, R.; Kashef, B.; Lee, E.; Vasudevan, R. Differential quadrature and splines. Comput. Math. Appl. 1975, 1, 371–376. [Google Scholar] [CrossRef]

- Guo, Q.; Zhong, H. Non-linear vibration analysis of beams by a spline-based differential quadrature method. J. Sound Vib. 2004, 269, 413–420. [Google Scholar] [CrossRef]

- Zhong, H. Spline-based differential quadrature for fourth order differential equations and its application to kirchhoff plates. Appl. Math. Model. 2004, 28, 353–366. [Google Scholar] [CrossRef]

- Huang, D. Analysis of laminated plates and shells by using spline gauss collocation method. Comput. Struct. 1991, 38, 469–473. [Google Scholar] [CrossRef]

- Viswanathan, K.; Lee, S.K. Free vibration of laminated cross-ply plates including shear deformation by spline method. Int. J. Mech. Sci. 2007, 49, 352–363. [Google Scholar] [CrossRef]

- Viswanathan, K.; Navaneethakrishnan, P. Free vibration study of layered cylindrical shells by collocation with splines. J. Sound Vib. 2003, 260, 807–827. [Google Scholar] [CrossRef]

- Viswanathan, K.; Navaneethakrishnan, P. Free vibration of layered truncated conical shell frusta of differently varying thickness by the method of collocation with cubic and quintic splines. Int. J. Solids Struct. 2005, 42, 1129–1150. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Calo, V.M.; Cottrell, J.A.; Evans, J.A.; Hughes, T.J.R.; Lipton, S.; Scott, M.A.; Sederberg, T.W. Isogeometric analysis using t-splines. Comput. Methods Appl. Mech. Eng. 2010, 199, 229–263. [Google Scholar] [CrossRef]

- Cottrell, J.A.; Hughes, T.J.R.; Reali, A. Studies of refinement and continuity in isogeometric structural analysis. Comput. Methods Appl. Mech. Eng. 2007, 196, 4160–4183. [Google Scholar] [CrossRef]

- Cottrell, J.A.; Reali, A.; Bazilevs, Y.; Hughes, T.J.R. Isogeometric analysis of structural vibrations. Comput. Methods Appl. Mech. Eng. 2006, 195, 5257–5296. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Cottrell, J.A.; Bazilevs, Y. Isogeometric analysis: Cad, finite elements, nurbs, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 2005, 194, 4135–4195. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Reali, A.; Sangalli, G. Duality and unified analysis of discrete approximations in structural dynamics and wave propagation: Comparison of p-method finite elements with k-method nurbs. Comput. Methods Appl. Mech. Eng. 2008, 197, 4104–4124. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Reali, A.; Sangalli, G. Efficient quadrature for nurbs-based isogeometric analysis. Comput. Methods Appl. Mech. Eng. 2010, 199, 301–313. [Google Scholar] [CrossRef]

- Auricchio, F.; da Veiga, L.B.; Hughes, T.J.R.; Reali, A.; Sangalli, G. Isogeometric collocation methods. Math. Models Methods Appl. Sci. 2010, 20, 2075–2107. [Google Scholar] [CrossRef]

- Auricchio, F.; da Veiga, L.B.; Hughes, T.J.R.; Reali, A.; Sangalli, G. Isogeometric collocation for elastostatics and explicit dynamics. Comput. Methods Appl. Mech. Eng. 2012, 249–252, 2–14. [Google Scholar] [CrossRef]

- Auricchio, F.; da Veiga, L.B.; Kiendl, J.; Lovadina, C.; Reali, A. Locking-free isogeometric collocation methods for spatial timoshenko rods. Comput. Methods Appl. Mech. Eng. 2013, 263, 113–126. [Google Scholar] [CrossRef]

- Da Veiga, L.B.; Lovadina, C.; Reali, A. Avoiding shear locking for the timoshenko beam problem via isogeometric collocation methods. Comput. Methods Appl. Mech. Eng. 2012, 241–244, 38–51. [Google Scholar] [CrossRef]

- Da Veiga, L.B.; Lovadina, C. An interpolation theory approach to shell eigenvalue problems. Math. Models Methods Appl. Sci. 2008, 18, 2003–2018. [Google Scholar] [CrossRef]

- Finlayson, B.; Scriven, L. The method of weighted residuals—A review. Appl. Mech. Rev. 1966, 19, 735–748. [Google Scholar]

- Farin, G. Curves and Surfaces for Computer Aided Geometric Design; Morgan Kaufman Publishers: San Francisco, CA, USA, 2002. [Google Scholar]

- Gould, P.L. Finite Element Analysis of Shells of Revolution; Pitman Advanced Publishing Program: New York, NY, USA, 1985. [Google Scholar]

- Kraus, H. Thin Elastic Shells; John Wiley & Sons: New York, NY, USA, 1967. [Google Scholar]

- Novozhilov, V.V. Thin Shell Theory; Wolters-Noordhoff: Groningen, The Netherlands, 1970. [Google Scholar]

- Soedel, W. Vibrations of Shells and Plates; Marcel Dekker, Inc.: New York, NY, USA, 2004. [Google Scholar]

- Piegl, L.; Tiller, W. The NURBS Book, 2nd ed.; Springer-Verlag: Berlin Heidelberg Germany, 1997. [Google Scholar]

- Rogers, D. An Introduction to NURBS with Historical Perspective; Morgan Kaufman Publishers: San Francisco, CA, USA, 2001. [Google Scholar]

- Greville, T. On the normalization of the b-splines and the location of the nodes for the case of unequally spaced knots. In Inequalities; Oshida, O., Ed.; Academic Press: New York, NY, USA, 1967. [Google Scholar]

- Bellomo, N. Nonlinear models and problems in applied sciences from differential quadrature to generalized collocation methods. Math. Comput. Model. 1997, 26, 13–34. [Google Scholar] [CrossRef]

- Bellomo, N.; De Angelis, E.; Graziano, L.; Romano, A. Solution of nonlinear problems in applied sciences by generalized collocation methods and mathematica. Comput. Math. Appl. 2001, 41, 1343–1363. [Google Scholar] [CrossRef]

- Johnson, R.W. Higher order b-spline collocation at the greville abscissae. Appl. Numer. Math. 2005, 52, 63–75. [Google Scholar] [CrossRef]

- Artioli, E.; da Veiga, L.B.; Hakula, H.; Lovadina, C. Free vibrations for some koiter shells of revolution. Appl. Math. Lett. 2008, 21, 1245–1248. [Google Scholar] [CrossRef]

- Auricchio, F.; da Veiga, L.B.; Lovadina, C. Remarks on the asymptotic behaviour of Koiter shells. Comput. Struct. 2002, 80, 735–745. [Google Scholar] [CrossRef]

- Da Veiga, L.B.; Lovadina, C. Asymptotics of shell eigenvalue problems. C. R. Math. 2006, 342, 707–710. [Google Scholar] [CrossRef]

- Artioli, E.; da Veiga, L.B.; Hakula, H.; Lovadina, C. On the asymptotic behaviour of shells of revolution in free vibration. Comput. Mech. 2009, 44, 45–60. [Google Scholar] [CrossRef]

- Altman, W.; Neto, E.L. Vibration of thin shells of revolution based on a mixed finite element formulation. Comput. Struct. 1986, 23, 291–303. [Google Scholar] [CrossRef]

- Kunieda, H. Flexural axisymmetric free vibrations of a spherical dome: exact results and approximate solutions. J. Sound Vib. 1984, 92, 1–10. [Google Scholar] [CrossRef]

- Luah, M.H.; Fan, S.C. General free vibration analysis of shells of revolution using the spline finite element method. Comput. Struct. 1989, 33, 1153–1162. [Google Scholar] [CrossRef]

- Kim, J.G.; Kim, Y.Y. Higher-order hybrid-mixed axisymmetric thick shell element for vibration analysis. Int. J. Numer. Meth. Eng. 2001, 51, 241–252. [Google Scholar] [CrossRef]

- Timoshenko, S.; Woinowsky-Krieger, S. Theory of Plates and Shells; Mcgraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Reddy, J.N. Energy and Variational Methods in Applied Mechanics; John Wiley & Sons: New York, NY, USA, 1984. [Google Scholar]

- Kim, J.G.; Kim, Y.Y. A higher-order hybrid-mixed harmonic shell-of-revolution element. Comp. Meth. Appl. Mech. Eng. 2000, 182, 1–16. [Google Scholar]

- Luah, M.H.; Fan, S.C. New spline finite element for analysis of shells of revolution. J. Eng. Mech. ASCE 1990, 116, 709–725. [Google Scholar]

- Basu, P.K.; Gould, P.L. Shore-III: Shell of Revolution Finite Element Program; Washington University: St. Louis, MO, USA, 1977. [Google Scholar]

- Gould, P.L. Analysis of Shells and Plates; Springer-Verlag: New York, NY, USA, 1988. [Google Scholar]

| Parabolic | Slope | Elliptic | Slope | Hyperbolic | Slope | |

|---|---|---|---|---|---|---|

| 104.215276 | 464.007232 | 323.741324 | ||||

| 0.86531 | 0.11402 | 0.54346 | ||||

| 38.483324 | 406.921457 | 173.166457 | ||||

| 0.97565 | 0.07091 | 0.65487 | ||||

| 12.515376 | 375.017756 | 81.474984 | ||||

| 0.953114 | 0.03469 | 0.66104 | ||||

| 4.025786 | 360.333432 | 38.062875 | ||||

| 0.98518 | 0.01484 | 0.66326 | ||||

| 1.289914 | 354.228976 | 17.736469 | ||||

| 0.98857 | 0.00610 | 0.66686 | ||||

| 0.417654 | 351.74876 | 8.211765 |

| Harmonic Number j | Mode Number m | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 0 | ||||||

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| 4 | ||||||

| 5 | ||||||

| Harmonic Number n | Maude Number m | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 0 | ||||||

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| 4 | ||||||

| 5 | ||||||

| z [m] | Theor. [56] | Present | Ref. [57] | |

|---|---|---|---|---|

| [m] | 0.00 | 0.938 | 0.938 | 0.939 |

| 0.25 | 0.868 | 0.868 | 0.868 | |

| 0.50 | 0.668 | 0.668 | 0.668 | |

| 0.75 | 0.364 | 0.364 | 0.364 | |

| 1.00 | 0 | 0 | 0 | |

| 0.00 | 0 | 0 | 0 | |

| 0.25 | 0.551 | 0.551 | 0.551 | |

| 0.50 | 1.031 | 1.031 | 1.031 | |

| 0.75 | 1.371 | 1.371 | 1.371 | |

| 1.00 | 1.500 | 1.500 | 1.500 | |

| [kN m/m] | 0.00 | 0.188 | 0.188 | 0.188 |

| 0.25 | 0.176 | 0.176 | 0.176 | |

| 0.50 | 0.141 | 0.141 | 0.141 | |

| 0.75 | 0.082 | 0.082 | 0.082 | |

| 1.00 | 0 | 0 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Bellis, M.L.; Artioli, E. NURBS-Based Collocation Methods for the Structural Analysis of Shells of Revolution. Metals 2016, 6, 68. https://doi.org/10.3390/met6030068

De Bellis ML, Artioli E. NURBS-Based Collocation Methods for the Structural Analysis of Shells of Revolution. Metals. 2016; 6(3):68. https://doi.org/10.3390/met6030068

Chicago/Turabian StyleDe Bellis, Maria Laura, and Edoardo Artioli. 2016. "NURBS-Based Collocation Methods for the Structural Analysis of Shells of Revolution" Metals 6, no. 3: 68. https://doi.org/10.3390/met6030068