Microstructure and High Temperature Deformation of Extruded Al-12Si-3Cu-Based Alloy

Abstract

:1. Introduction

2. Experimental Section

| Alloy Compositions (wt. %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Element | Si | Fe | Cu | Mg | Ni | Ti | V | Zr | Al |

| DM104 | 12 | 0.3 | 3.2 | 0.9 | 2.0 | 0.1 | 0.1 | 0.1 | Bal. |

3. Results and Discussion

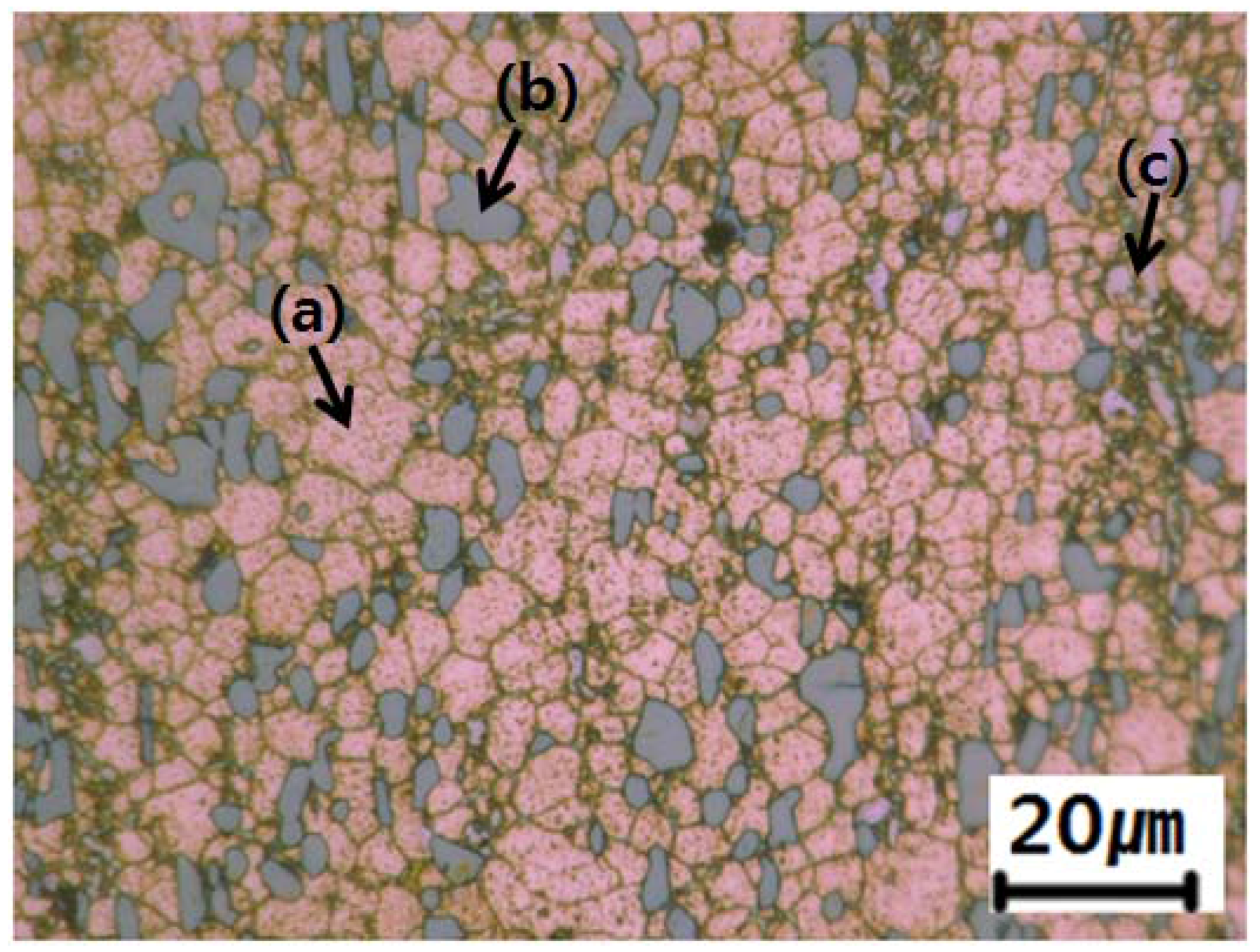

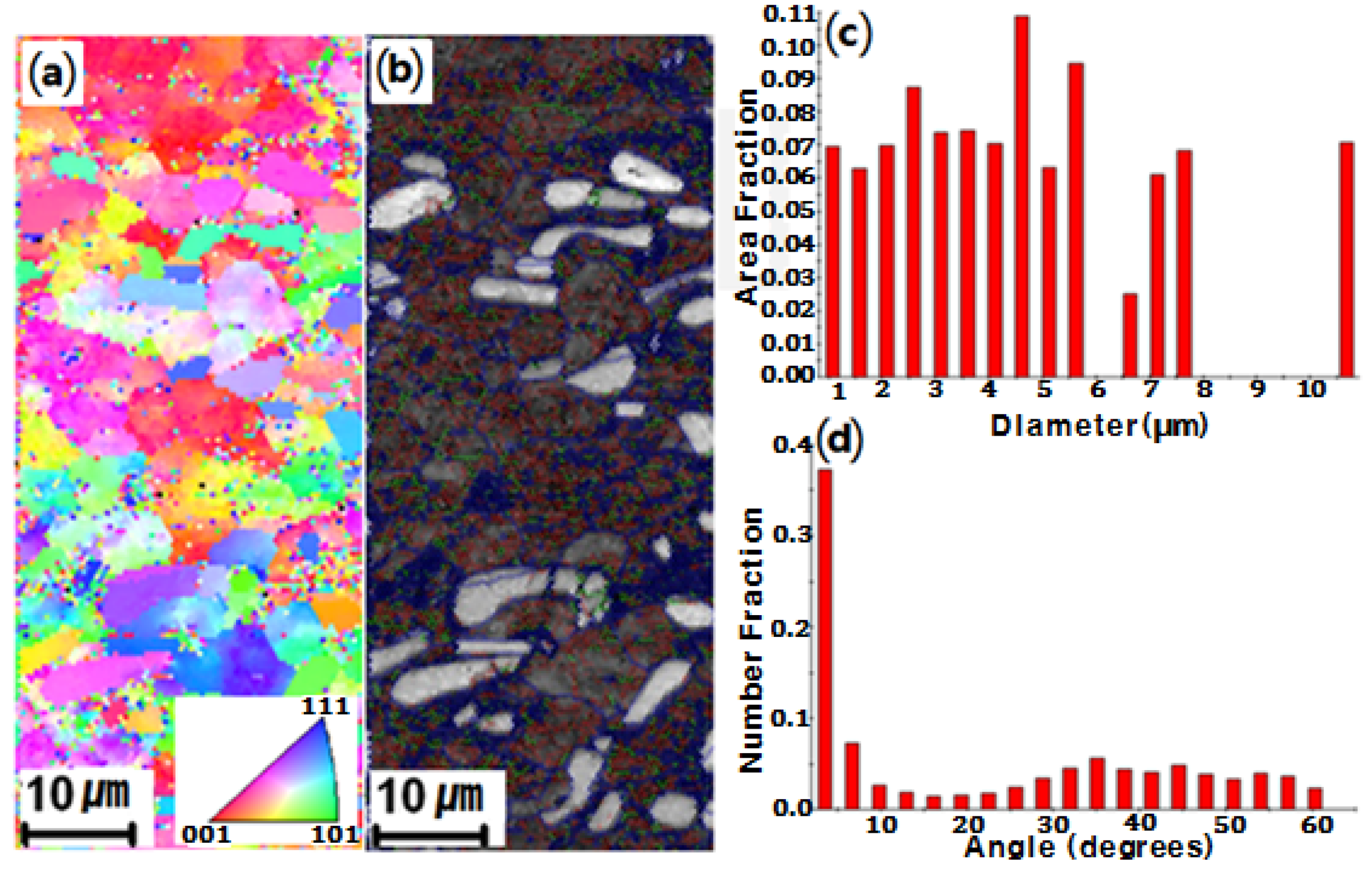

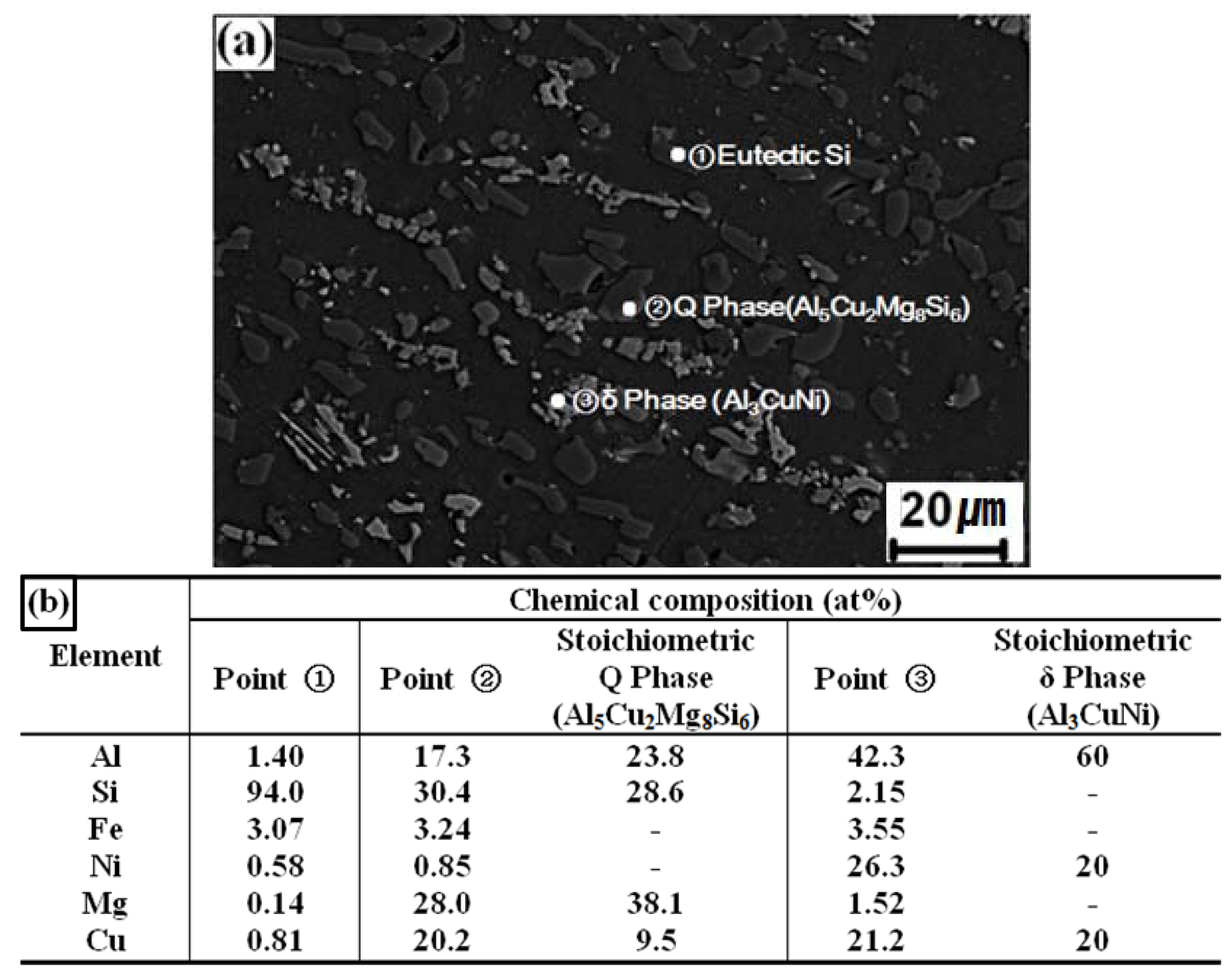

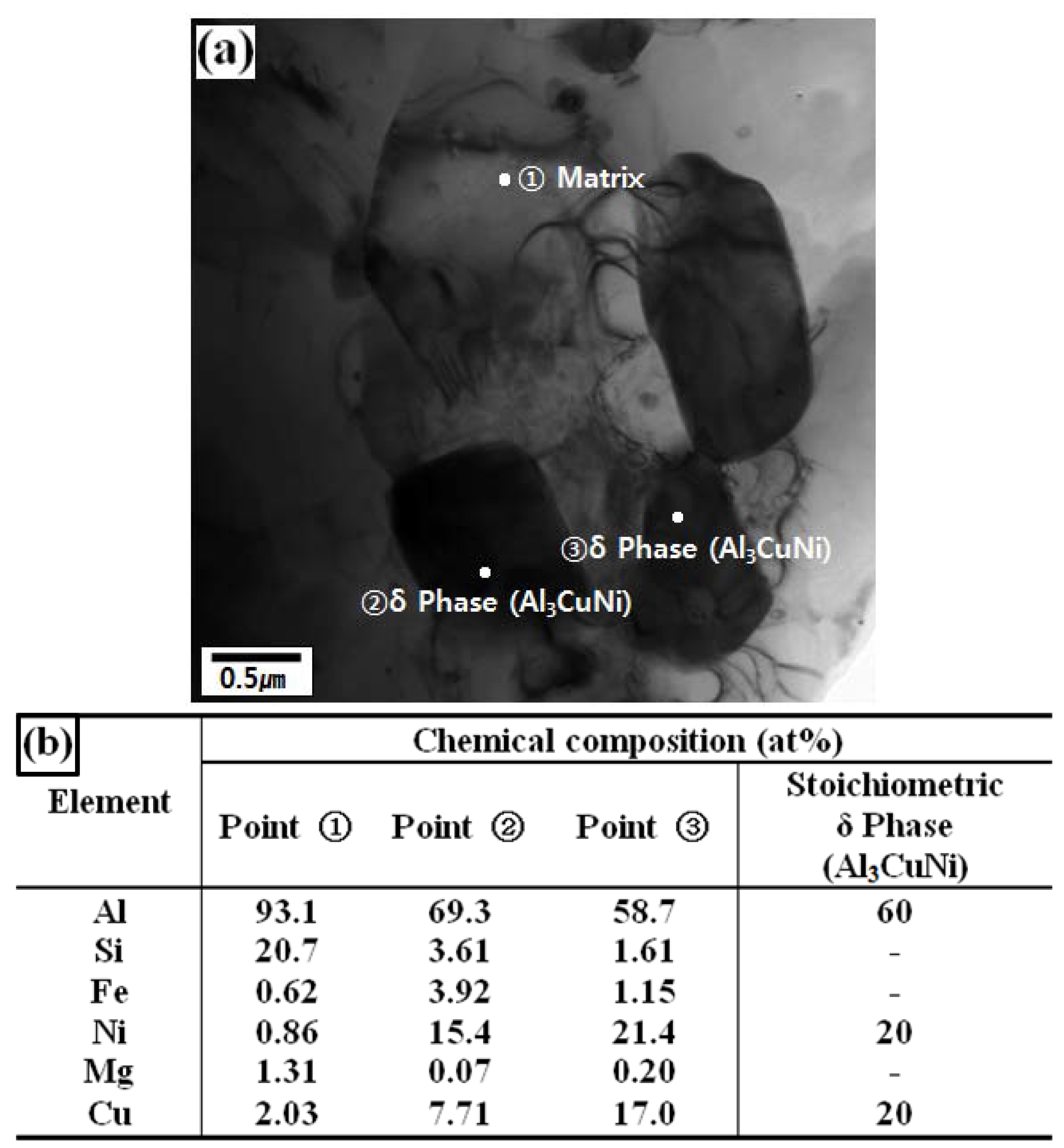

3.1. Microstructure of the As-Received Alloy

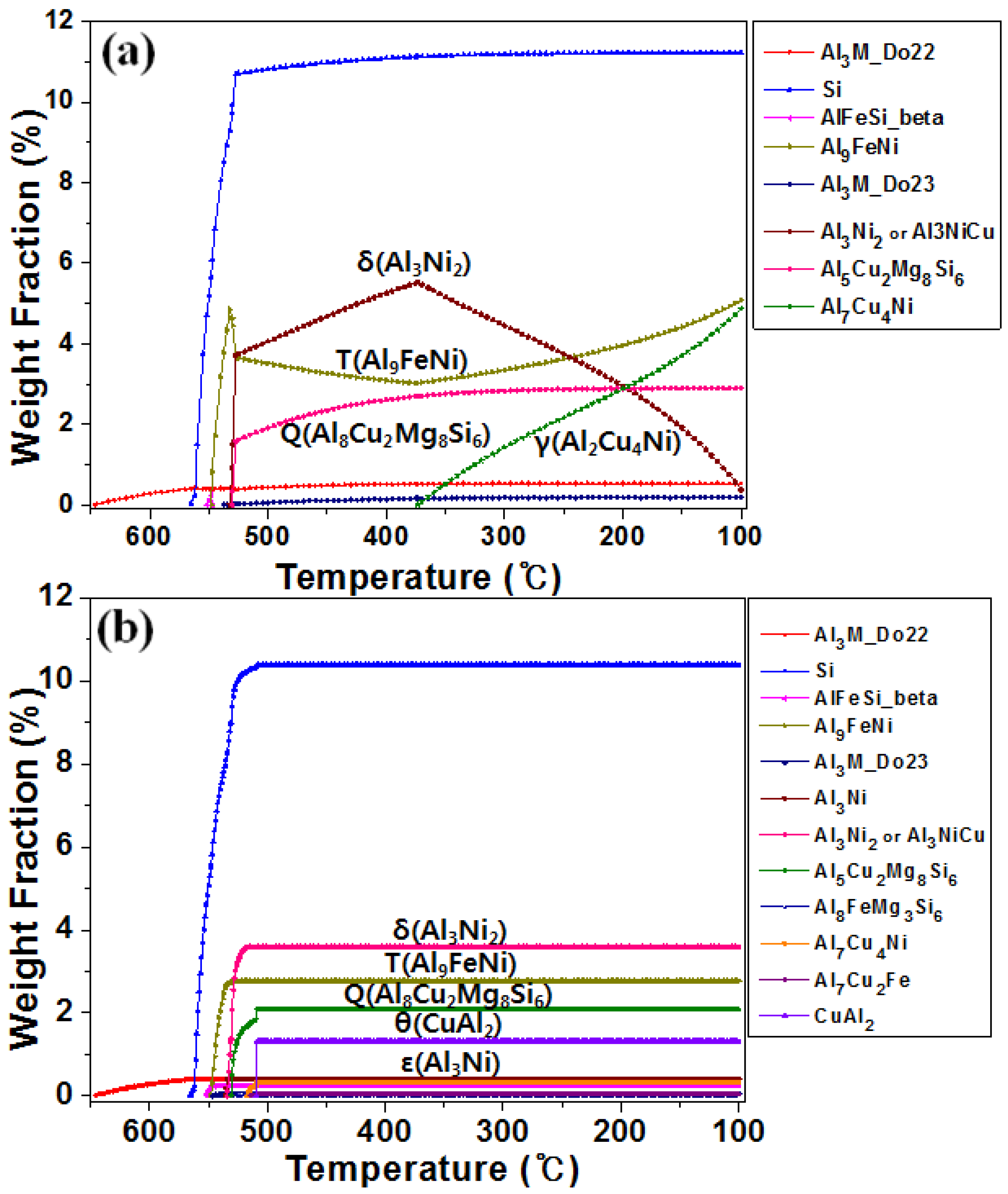

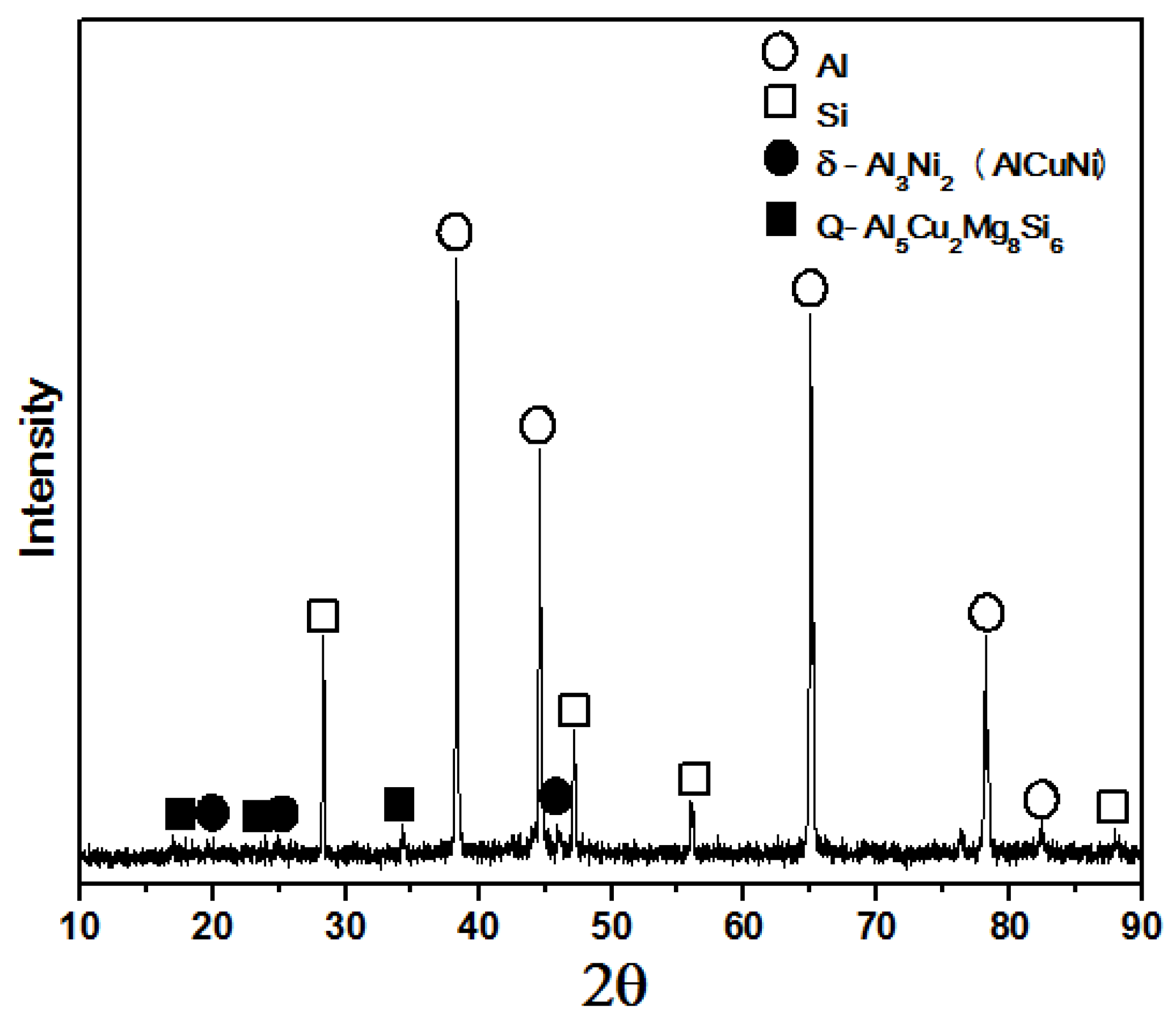

3.2. Phase Analysis

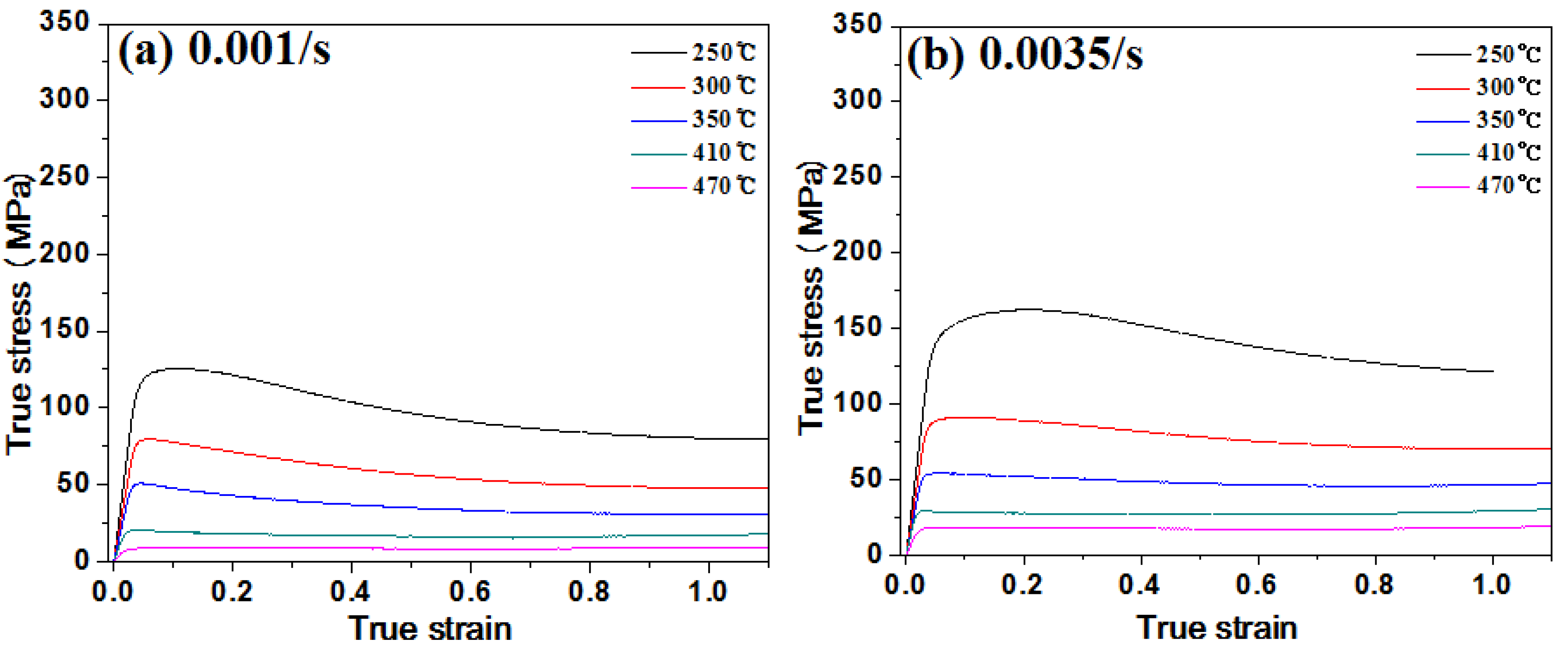

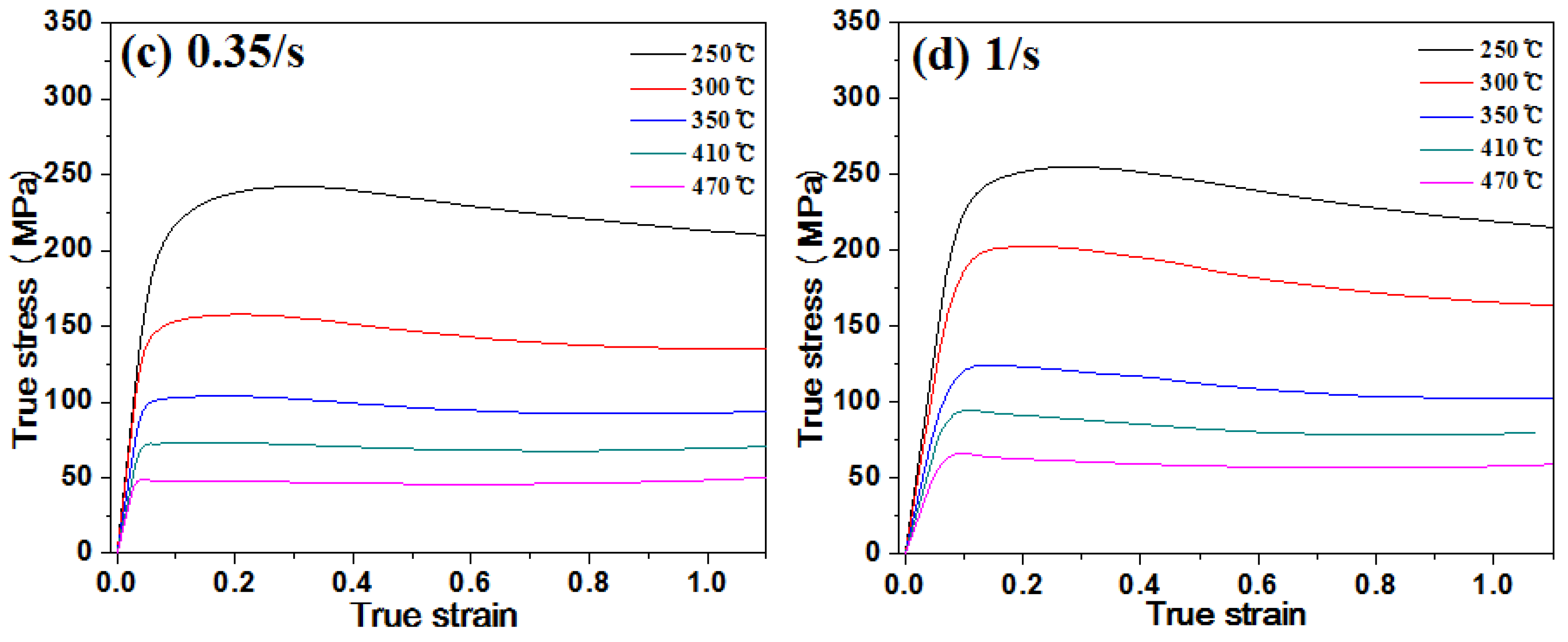

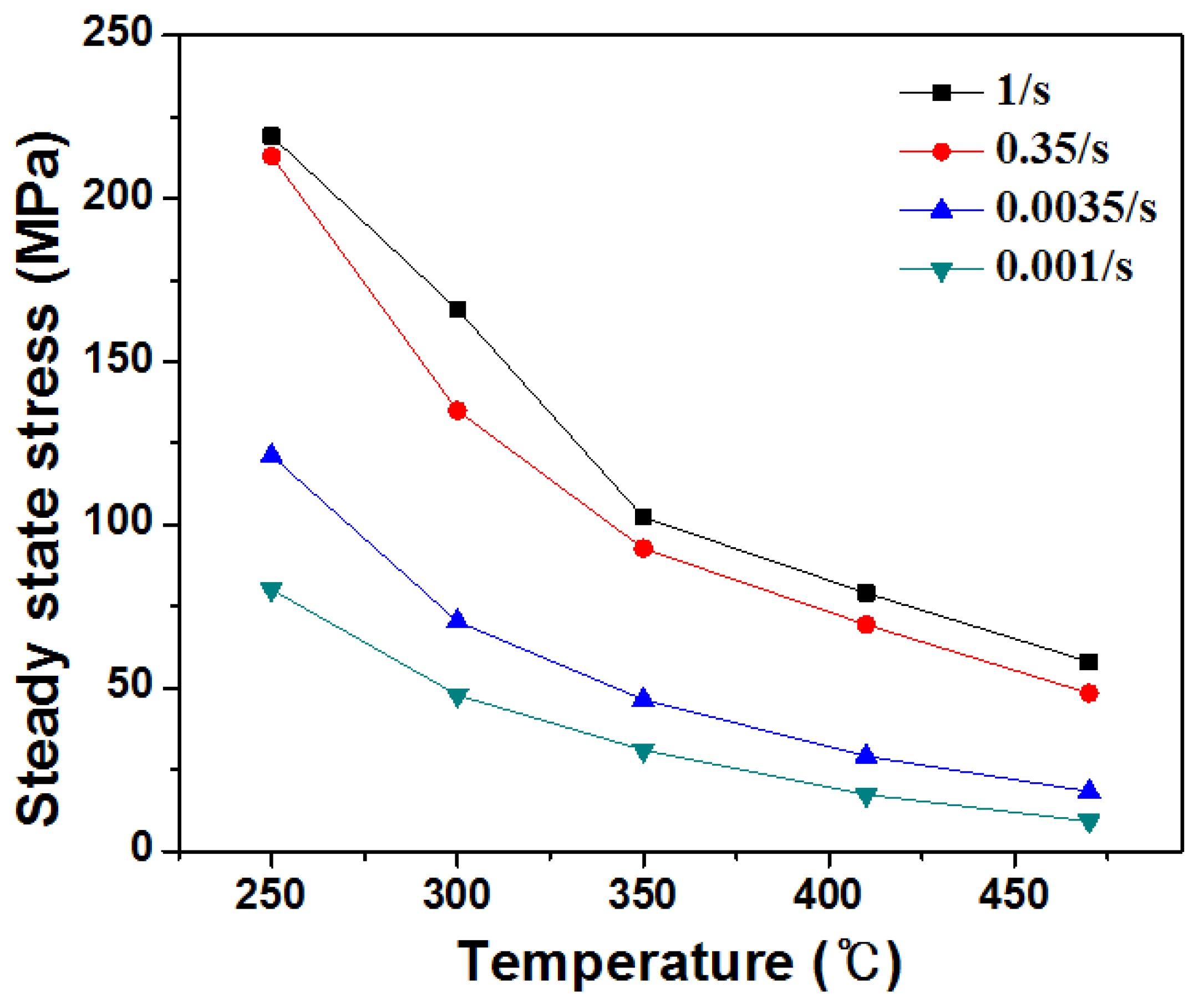

3.3. Compressive Deformation

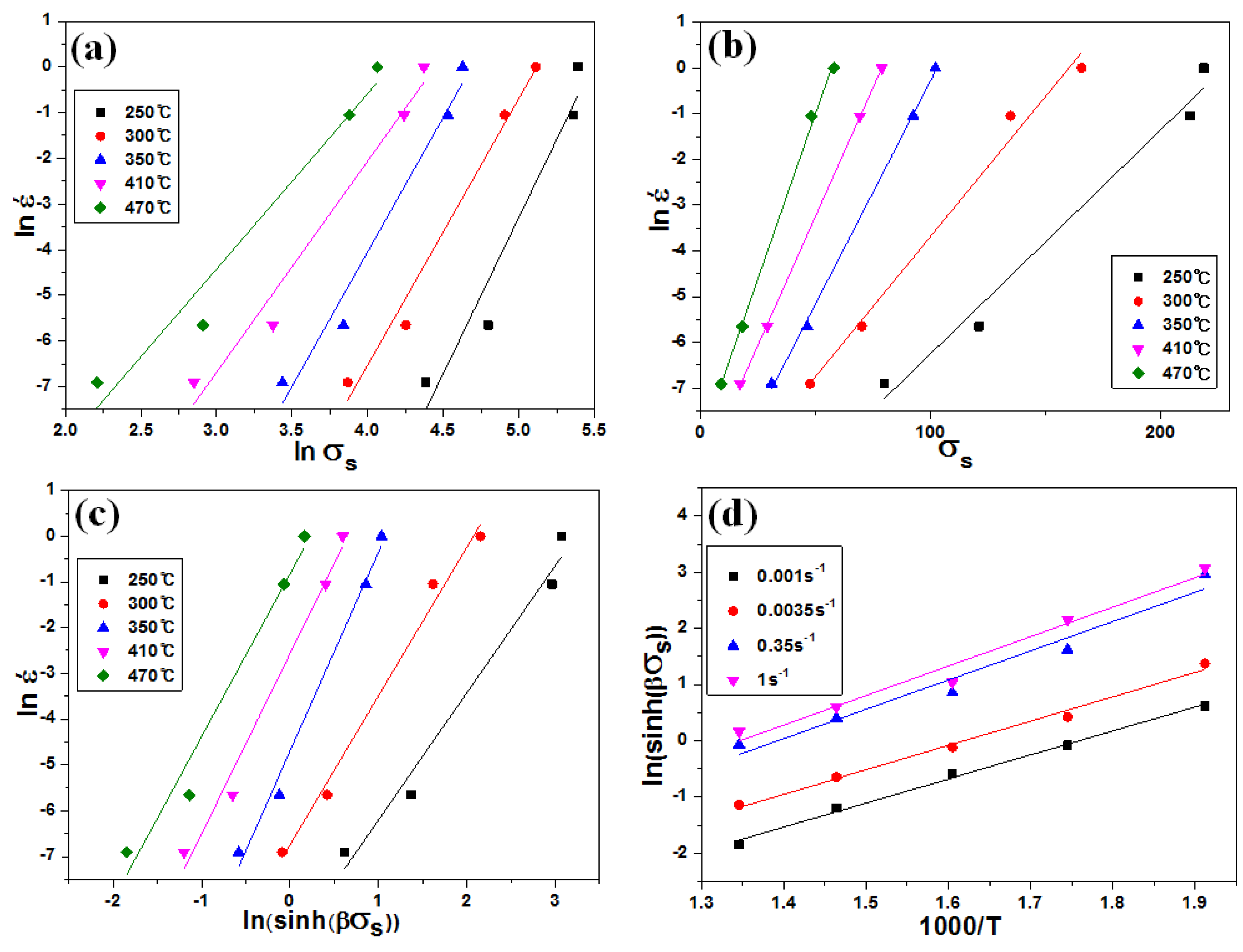

3.4. Constitutive Equations

| Constant | n | α | β | A3 (s−1) | n‘ | Q (kJ/mol) |

|---|---|---|---|---|---|---|

| Value | 5.41 | 0.093 | 0.017 | 5.3 × 109 | 3.57 | 142 |

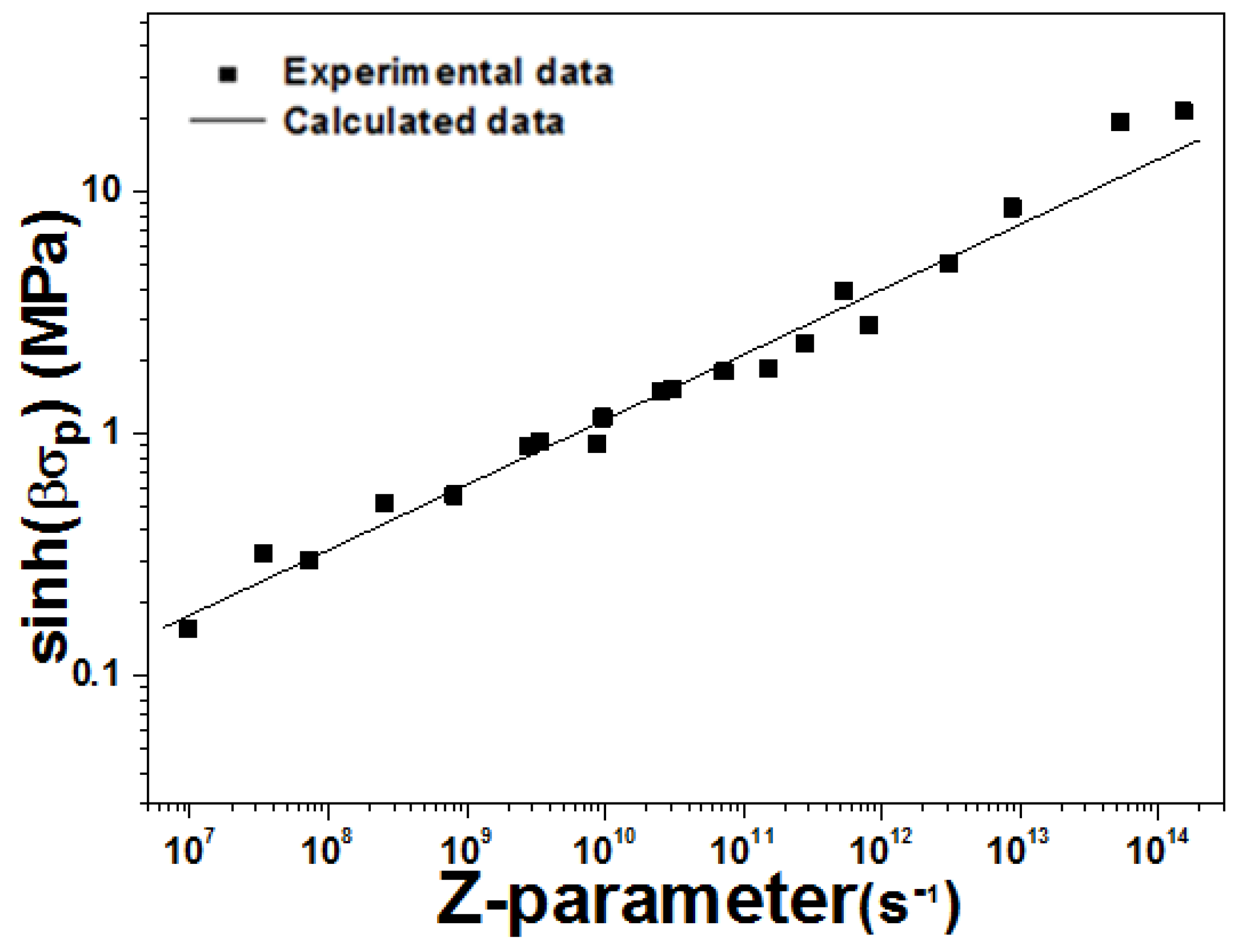

3.5. Zener-Hollomon Parameter

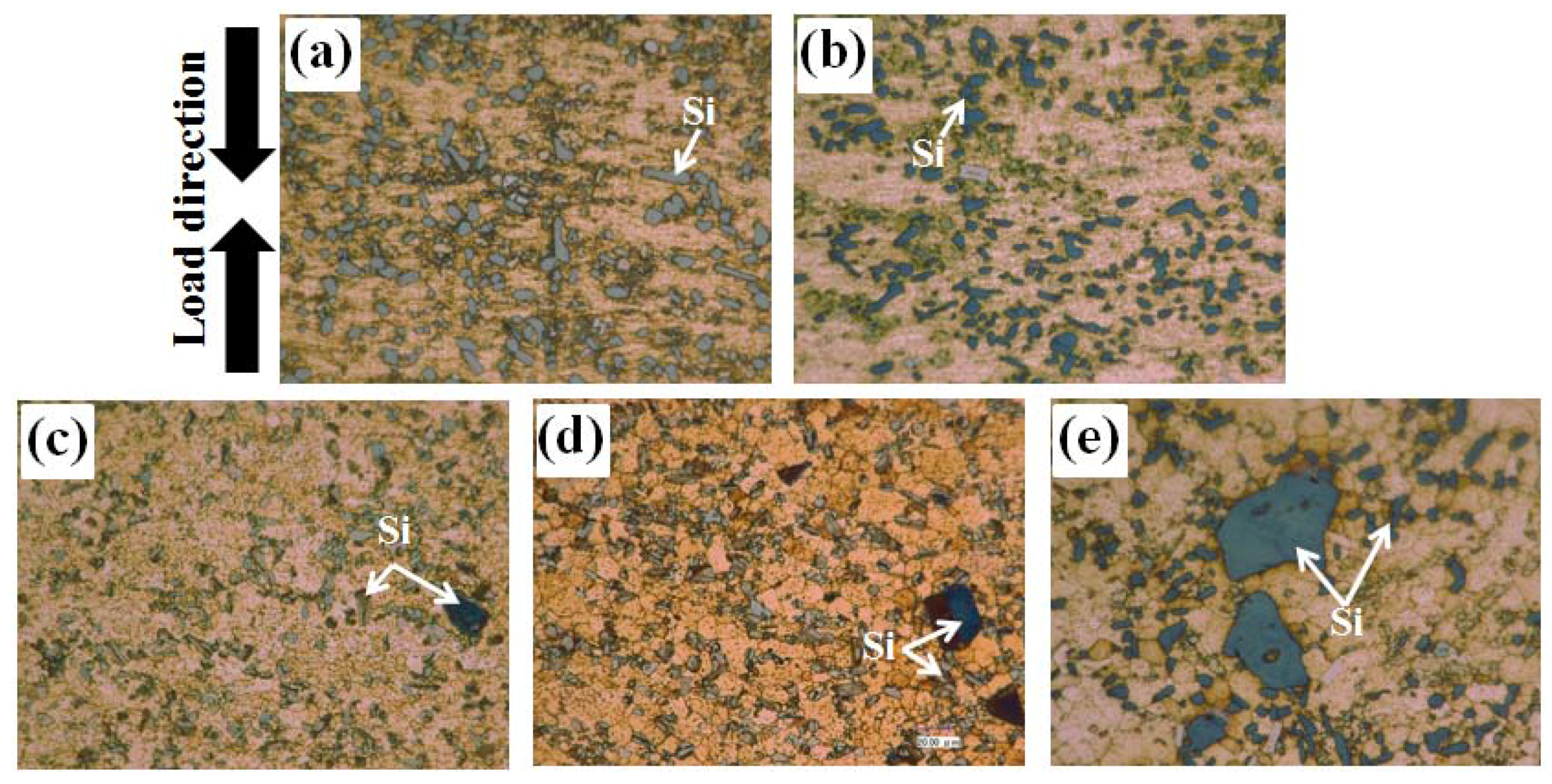

3.6. Microstructure of the Deformed Specimens

| Strain Rate (/s) | Temperature (°C) | ||

|---|---|---|---|

| 350 | 410 | 470 | |

| 1 | 2.9 | 3.2 | 4.1 |

| 0.35 | 3.3 | 3.4 | 4.5 |

| 0.0035 | 4.8 | 5.9 | 6.7 |

| 0.001 | 5.1 | 5.7 | 7.2 |

4. Conclusions

- The as-received alloy had equiaxed grains with a mean grain size of approximately 5 μm, spherical Si particles and fine intermetallic phases including δ(Al3NiCu) and Q(Al5Cu2Mg3Si6).

- EBSD analysis of the as-received alloy showed that the fraction of high-angle boundaries (HABs) was approximately 60%, and the low-angle boundaries (LABs) are distributed mostly as sub-grain boundaries within the HABs.

- The true stress-true strain curves obtained from the compressive tests exhibited steady-state flow after reaching the peak stress.

- The steady-state stress decreased with increasing temperature and decreasing strain rate. A close relationship was observed between the steady-state stress and a constitutive equation for high temperature deformation.

- Fine equiaxed grains and a dislocation structure within the equiaxed grains were observed in the deformed specimens, indicating the occurrence of dynamic recrystallization during high temperature deformation.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Manasijevic, S.; Radisa, R.; Markovic, S.; Acimovic-Pavlovic, Z.; Raic, K. Thermal analysis and microscopic characterization of the piston alloy AlSi13Cu4Ni2Mg. Intermetallics 2011, 19, 486–492. [Google Scholar] [CrossRef]

- Chen, C.-L.; Thomson, R.C. The combined use of EBSD and EDX analyses for the identification of complex intermetallic phases in multicomponent Al-Si piston alloys. J. Alloys Compd. 2010, 490, 293–300. [Google Scholar] [CrossRef]

- Kim, J.; Jang, G.S.; Kim, M.S.; Lee, J.K. Microstructure and compressive deformation of hypereutectic Al-Si-Fe based P/M alloys fabricated by spark plasma sintering. Trans. Nonferrous Met. Soc. China 2014, 24, 2346–2351. [Google Scholar] [CrossRef]

- Park, S.-C.; Kim, M.-S.; Kim, K.-T.; Shin, S.-Y.; Lee, J.-K.; Ryu, K.-H. Compressive Deformation Behavior of Al-10Si-5Fe-1Zr Powder alloys Consolidated by Spark Plasma Sintering Precess. Korean J. Met. Mater. 2011, 49, 853–859. [Google Scholar]

- Sjölander, E.; Seigeddine, S. The heat treatment of Al-Si-Cu-Mg casting alloys. J. Mater. Processs. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Aguilera-luna, I.; Castro-Roman, M.J.; Escobedo-bocardo, J.C.; Garcia-Pastor, F.A.; Herrera-Trejo, M. Effect of cooling rate and Mg content on the Al-Si eutectic for Al-Si-Cu-Mg alloys. Mater. Charact. 2014, 95, 211–218. [Google Scholar] [CrossRef]

- Zamani, M.; Seifeddine, S.; Jarfors, A.E.W. High temperature tensile deformation behavior and failure mechanisms of an Al-Si-Cu-Mg cast alloy—The microstrcutural scale effect. Mater. Des. 2015, 86, 361–370. [Google Scholar]

- Cho, H.S.; Kim, M.S. High Temperature Deformation Behavior of Al-16Si-5Fe based alloys Produced from Rapidly Solidified Powders. J. Korean Inst. Met. Mater. 1999, 37, 1191–1197. [Google Scholar]

- Li, Y.; Yang, Y.; Wu, Y.; Wang, L.; Liu, X. Quantitative comparison of three Ni-containing phases to the elevated-temperature properties of Al-Si piston alloys. Mater. Sci. Eng. A 2010, 527, 7132–7137. [Google Scholar] [CrossRef]

- Wu, Y.; Liao, H.C.; Yang, J.; Zhou, K. Effect of Si content on Dynamic Recrystallization of Al-Si-Mg alloys During Hot Extrusion. J. Mater. Sci. Technol. 2014, 30, 1271–1277. [Google Scholar] [CrossRef]

- Hu, H.E.; Wang, X.; Deng, L. High temperature deformation behavior and optimal hot processing parameters of Al-Si eutectic alloy. Mater. Sci. Eng. 2013, 576, 45–51. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Yuan, D.; Peng, D. Hot deformation behavior of the new Al-Mg-Si-Cu aluminum alloy during compression at elevated temperatures. Mater. Charact. 2007, 58, 168–173. [Google Scholar] [CrossRef]

- Liao, H.; Wu, Y.; Zhou, K.; Yang, J. Hot deformation behavior and processing map of Al-Si-Mg alloys containing different amount of silicon based on Gleebe-3500 hot compression simulation. Mater. Des. 2015, 65, 1091–1099. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, S.-B.; Kim, M.-S. Microstructure and High Temperature Deformation of Extruded Al-12Si-3Cu-Based Alloy. Metals 2016, 6, 32. https://doi.org/10.3390/met6020032

Yu S-B, Kim M-S. Microstructure and High Temperature Deformation of Extruded Al-12Si-3Cu-Based Alloy. Metals. 2016; 6(2):32. https://doi.org/10.3390/met6020032

Chicago/Turabian StyleYu, Seung-Baek, and Mok-Soon Kim. 2016. "Microstructure and High Temperature Deformation of Extruded Al-12Si-3Cu-Based Alloy" Metals 6, no. 2: 32. https://doi.org/10.3390/met6020032