Upsetting Analysis of High-Strength Tubular Specimens with the Taguchi Method

Abstract

:1. Introduction

- development of new parts in a digital environment,

- analyses of technological windows of produced parts,

- stable mass production.

2. Material Properties

3. Modified Upsetting Test

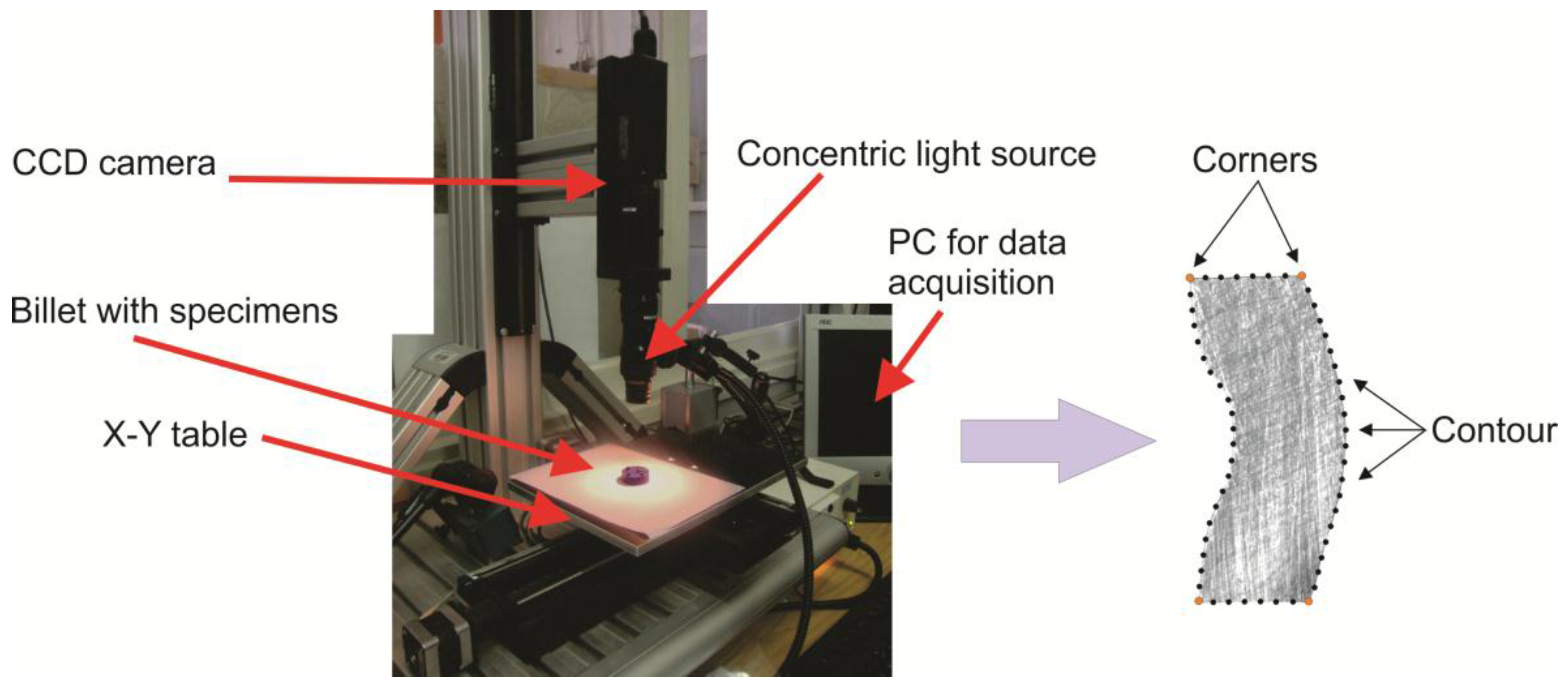

3.1. Experimental Work

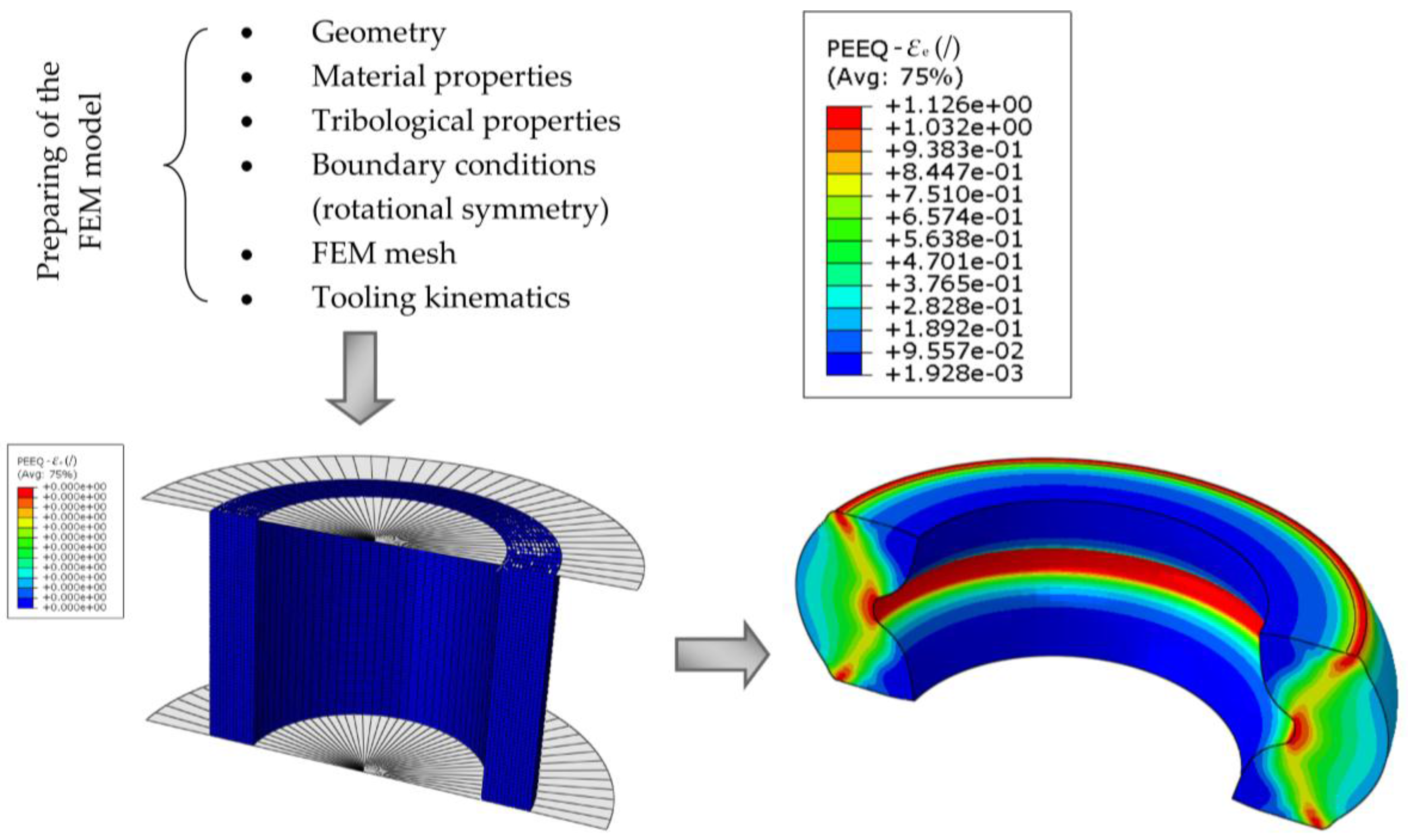

3.2. FEM Model

3.3. Design of Experiments

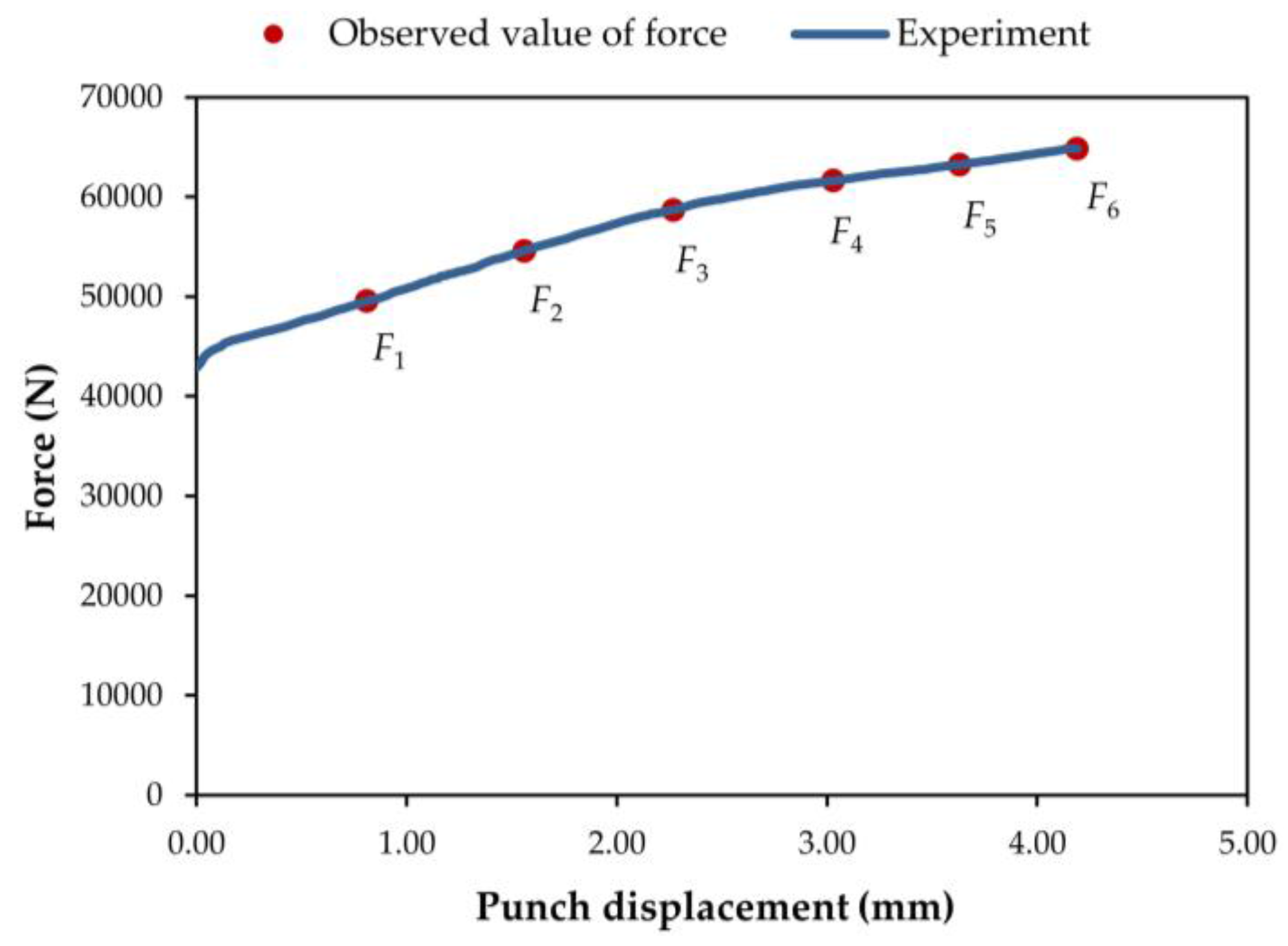

3.4. Selection of Flow Curve Parameters

3.5. Reverse Engineering Analyses

3.5.1. Determination of Impacts on Force Course

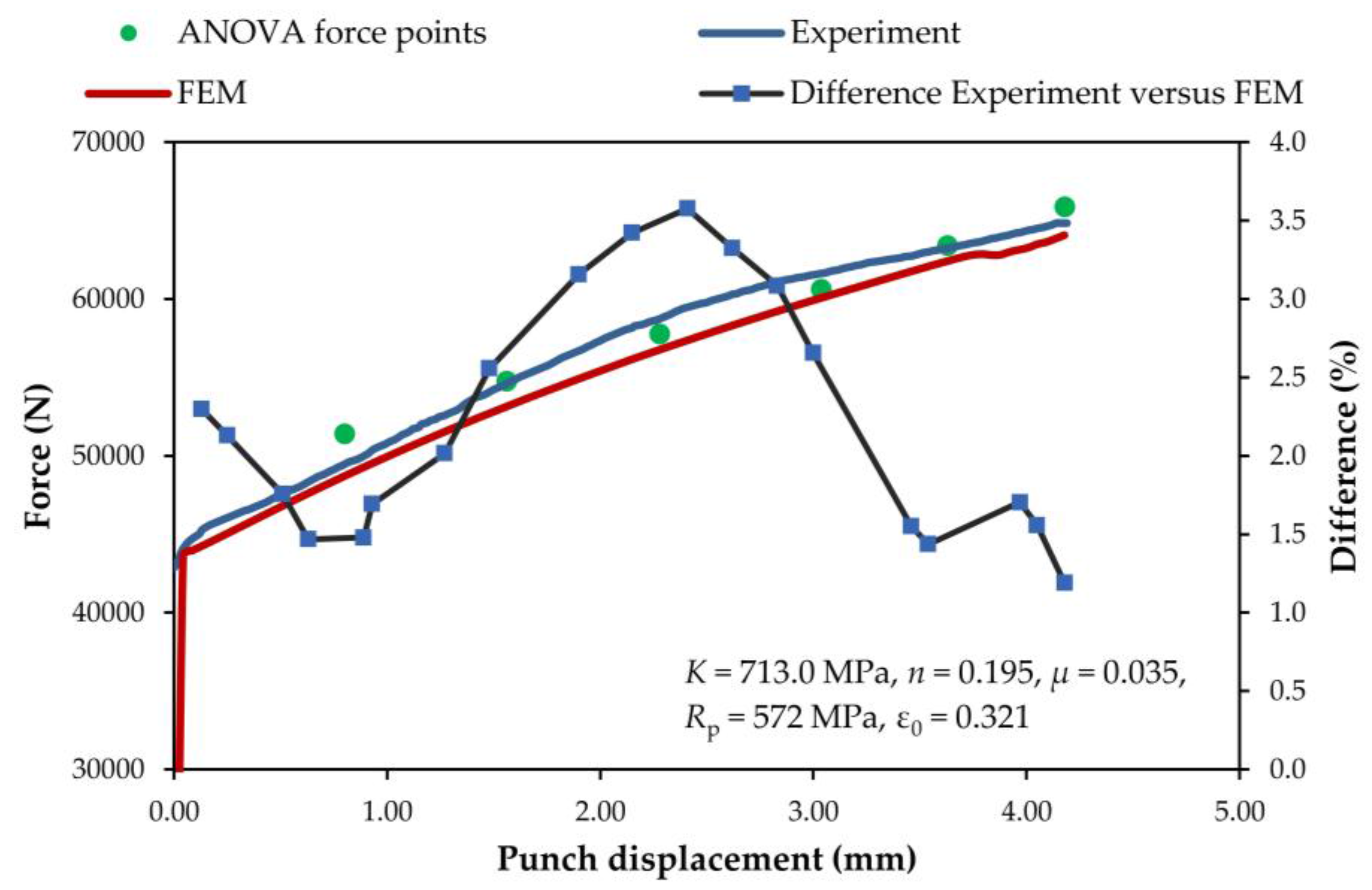

3.5.2. Multi-Parameter Analysis for an Inverse-Engineering Approach

3.6. Comparison of Tube Shaping

4. Conclusions

- 1)

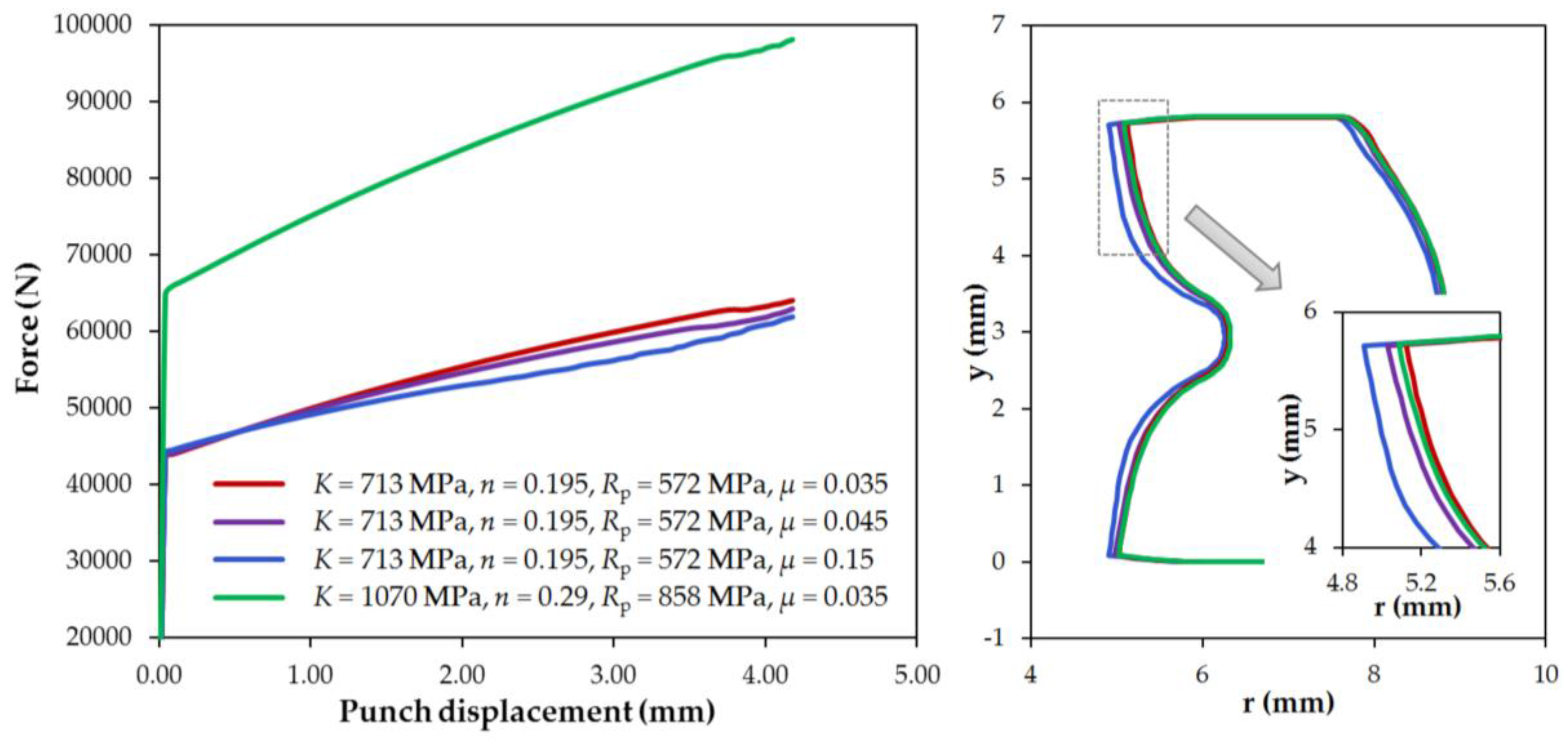

- The forming force versus punch displacement was used for a reverse engineering approach to determine the flow curve parameters since it was found that the variation of material parameters has only a minor role on the specimen shaping.

- 2)

- The optimization approach based on the comparison of experimentally and statistically determined values (Taguchi + ANOVA) of forming force at six upsetting levels delivered the parameters of the material’s flow curve K = 713 MPa, n = 0.195, and ε0 = 0.321 according to Swift’s power law. The friction coefficient μ in this optimization was selected according to the one measured for the PTFE foil. The yield stress of the tube Rp was also determined experimentally.

- 3)

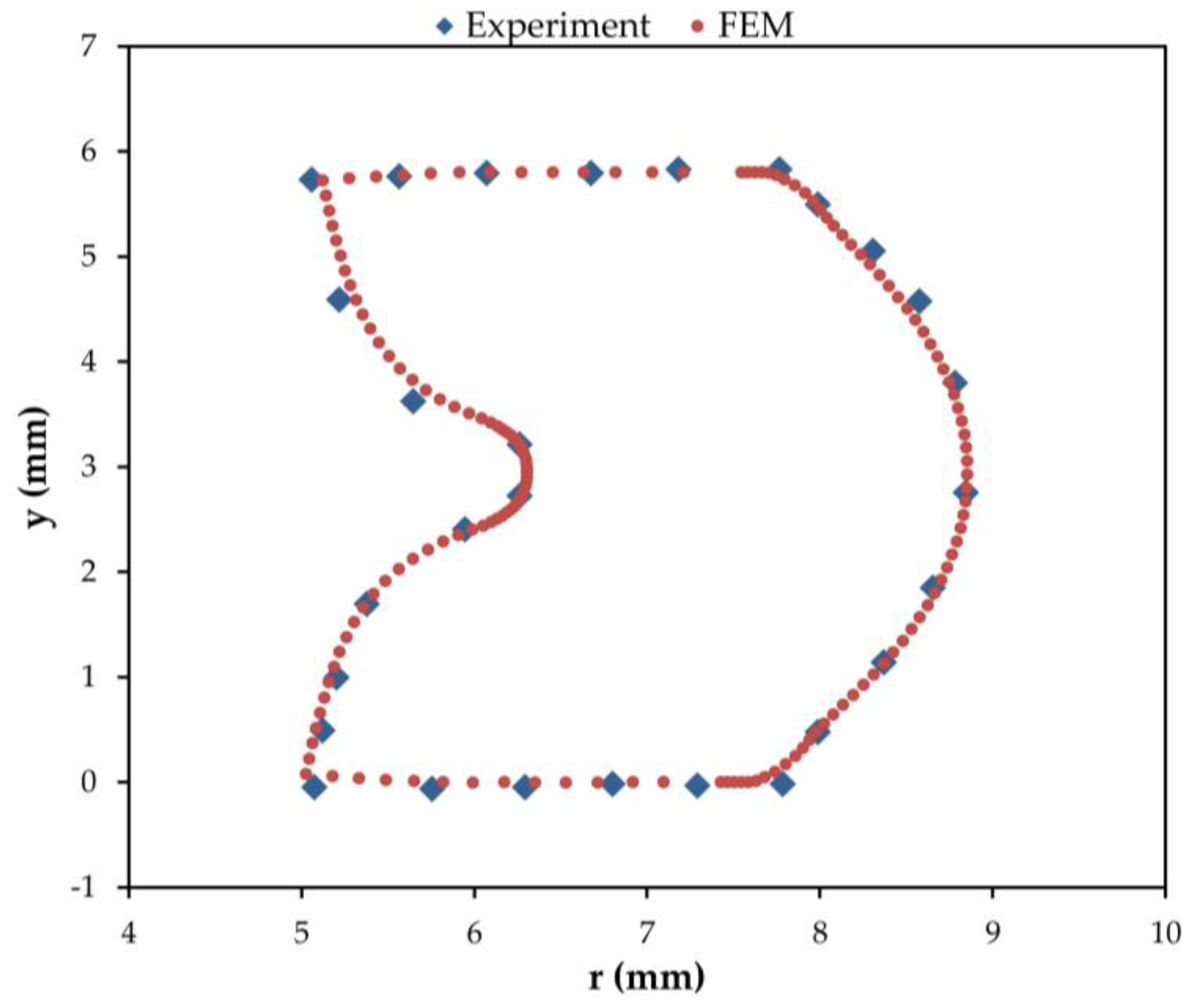

- The comparison of the FEM-predicted force course based on the determined material flow curve and the experimental force course showed that the differences are below 5%.

- 4)

- The comparison of the cross-sectional contours of the upset specimens with the numerically obtained results for the determined flow curve according to Swift’s law showed only minor shape deviations.

- 5)

- Future analyses should focus on the geometrical optimization of the specimens regarding the d0:h0 ratio for various D/t ratios. The presented methodology needs to be further tested regarding its robustness according to all input parameters, such as the level of the flow curve, the value of Rp, and the friction coefficient.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gu, G.; Xia, Y.; Zhou, Q. On the fracture possibility of thin-walled tubes under axial crushing. Thin Walled Struct. 2012, 55, 85–95. [Google Scholar] [CrossRef]

- He, Z.; Yuan, S.; Liu, G.; Wu, J.; Cha, W. Formability testing of AZ31B magnesium alloy tube at elevated temperature. J. Mater. Process. Technol. 2010, 210, 877–884. [Google Scholar] [CrossRef]

- Shim, D.-S.; Kim, K.-P.; Lee, K.-Y. Double-stage forming using critical pre-bending radius in roll bending of pipe with rectangular cross-section. J. Mater. Process. Technol. 2016, 236, 189–203. [Google Scholar] [CrossRef]

- Alves, L.M.; Martins, P.A.F. Forming of thin-walled tubes into toroidal shells. J. Mater. Process. Technol. 2010, 210, 689–695. [Google Scholar] [CrossRef]

- Souissi, N.; Souissi, S.; Niniven, C.L.; Amar, M.B.; Bradai, C.; Elhalouani, F. Optimization of Squeeze Casting Parameters for 2017 A Wrought Al Alloy Using Taguchi Method. Metals 2014, 4, 141–154. [Google Scholar] [CrossRef]

- Zeng, G.; Lai, X.; Yu, Z.; Lin, Z. Numerical Simulation and Sensitivity Analysis of Parameters for Multistand Roll Forming of Channel Section With Outer Edge. J. Iron Steel Res. Int. 2009, 16, 32–37. [Google Scholar] [CrossRef]

- Celentano, D.J.; Rosales, D.A.; Peña, J.A. Simulation and Experimental Validation of Tube Sinking Drawing Processes. Mater. Manuf. Process. 2011, 26, 770–780. [Google Scholar] [CrossRef]

- Brnic, J.; Niu, J.; Canadija, M.; Turkalj, G.; Lanc, D. Behavior of AISI 316L Steel Subjected to Uniaxial State of Stress at Elevated Temperatures. J. Mater. Sci. Technol. 2009, 25, 175–180. [Google Scholar]

- Brnic, J.; Turkalj, G.; Canadija, M.; Lanc, D.; Krscanski, S.; Brcic, M.; Li, Q.; Niu, J. Mechanical Properties, Short Time Creep, and Fatigue of an Austenitic Steel. Materials 2016, 9, 298. [Google Scholar] [CrossRef]

- Vukelic, G.; Brnic, J. Predicted Fracture Behavior of Shaft Steels with Improved Corrosion Resistance. Metals 2016, 6, 40. [Google Scholar] [CrossRef]

- Geiger, M.; Hußnätter, W.; Merklein, M. Specimen for a novel concept of the biaxial tension test. J. Mater. Process. Technol. 2005, 167, 177–183. [Google Scholar] [CrossRef]

- Suttner, S.; Merklein, M. Experimental and numerical investigation of a strain rate controlled hydraulic bulge test of sheet metal. J. Mater. Process. Technol. 2016, 235, 121–133. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, F.; Wan, Q.; Zhang, Z.; Jin, L.; Dong, J. Microstructure and mechanical properties of AZ80 magnesium alloy tube fabricated by hot flow forming. Mater. Des. 2015, 67, 64–71. [Google Scholar] [CrossRef]

- Wang, H.; Bouchard, R.; Eagleson, R.; Martin, P.; Tyson, W. Ring Hoop Tension Test (RHTT): A Test for Transverse Tensile Properties of Tubular Materials. J. Test. Eval. 2002, 30, 382–391. [Google Scholar] [CrossRef]

- Lin, Y.; He, Z.; Yuan, S.; Wu, J. Formability determination of AZ31B tube for IHPF process at elevated temperature. Trans. Nonferr. Met. Soc. China 2011, 21, 851–856. [Google Scholar] [CrossRef]

- Faraji, G.; Hashemi, R.; Mashhadi, M.M.; Dizaji, A.F.; Norouzifard, V. Hydroforming Limits in Metal Bellows Forming Process. Mater. Manuf. Process. 2010, 25, 1413–1417. [Google Scholar] [CrossRef]

- Song, W.-J.; Heo, S.-C.; Ku, T.-W.; Kim, J.; Kang, B.-S. Evaluation of effect of flow stress characteristics of tubular material on forming limit in tube hydroforming process. Int. J. Mach. Tools Manuf. 2010, 50, 753–764. [Google Scholar] [CrossRef]

- Agüero, A.; Pallarés, F.J.; Pallarés, L. Equivalent geometric imperfection definition in steel structures sensitive to lateral torsional buckling due to bending moment. Eng. Struct. 2015, 96, 41–55. [Google Scholar] [CrossRef]

- Liu, N.; Yang, H.; Li, H.; Tao, Z.; Hu, X. An imperfection-based perturbation method for plastic wrinkling prediction in tube bending under multi-die constraints. Int. J. Mech. Sci. 2015, 98, 178–194. [Google Scholar] [CrossRef]

- Liu, N.; Yang, H.; Li, H.; Zhan, M.; Tao, Z.; Hu, X. Modelling of Wrinkling in NC Bending of Thin-walled Tubes with Large Diameters under Multi-die Constraints Using Hybrid Method. Proced. Eng. 2014, 81, 2171–2176. [Google Scholar] [CrossRef]

- Guillow, S.R.; Lu, G.; Grzebieta, R.H. Quasi-static axial compression of thin-walled circular aluminium tubes. Int. J. Mech. Sci. 2001, 43, 2103–2123. [Google Scholar] [CrossRef]

- Peek, R. Wrinkling of tubes in bending from finite strain three-dimensional continuum theory. Int. J. Solids Struct. 2002, 39, 709–723. [Google Scholar] [CrossRef]

- Lee, K.-L.; Pan, W.-F.; Kuo, J.-N. The influence of the diameter-to-thickness ratio on the stability of circular tubes under cyclic bending. Int. J. Solids Struct. 2001, 38, 2401–2413. [Google Scholar] [CrossRef]

- Pirh, T. Določevanje Preoblikovalnih Lastnosti Cevastih Preizkušancev (Determination Forming Properties of Tube Specimens). Master’s Thesis, University of Ljubljana, Ljubljana, Slovenia, May 2010. [Google Scholar]

- Bunge, H.J.; Pöhlandt, K.; Tekkaya, A.E.; Banabic, D. Formability of Metallic Materials: Plastic Anisotropy, Formability Testing, Forming Limits, 1st ed.; Springer-Verlag Berlin Heidelberg: Berlin, Germany, 2000. [Google Scholar]

- Schey, J.A. Tribology in Metalworking: Friction, Lubrication and Wear; American Society for Metals: Metals Park, OH, USA, 1983. [Google Scholar]

- Camacho, A.M.; Veganzones, M.; Claver, J.; Martín, F.; Sevilla, L.; Sebastián, M.Á. Determination of Actual Friction Factors in Metal Forming under Heavy Loaded Regimes Combining Experimental and Numerical Analysis. Materials 2016, 9, 751. [Google Scholar] [CrossRef]

- Sofuoglu, H.; Rasty, J. On the measurement of friction coefficient utilizing the ring compression test. Tribol. Int. 1999, 32, 327–335. [Google Scholar] [CrossRef]

- Pipan, M.; Kos, A.; Herakovic, N. Adaptive Algorithm for the Quality Control of Braided Sleeving. Adv. Mech. Eng. 2014, 6, 1–8. [Google Scholar] [CrossRef]

- Hsia, S.-Y.; Shih, P.-Y. Wear Improvement of Tools in the Cold Forging Process for Long Hex Flange Nuts. Materials 2015, 8, 6640–6657. [Google Scholar] [CrossRef]

- Altan, T.; Ngaile, G.; Shen, G. Cold and Hot Forging: Fundamentals and Applications, 1st ed.; ASM International: Materials Park, OH, USA, 2005; pp. 295–298. [Google Scholar]

- Pepelnjak, T. Analyses of friction coefficients of PTFE foils used for forming applications at elevated temperatures. In Proceedings of the IN-TECH 2015—International Conference on Innovative Technologies, Dubrovnik, Croatia, 9 November 2015; pp. 438–441.

- Abaqus Theory Manual, version 6.14; Software of Dassault Systems; Dassault Simulia Company: Providence, RI, USA, 2016.

- Gronostajski, Z. The constitutive equations for FEM analysis. J. Mater. Process. Technol. 2000, 106, 40–44. [Google Scholar] [CrossRef]

- Lin, J.-C.; Lee, K. Optimization of Bending Process Parameters for Seamless Tubes Using Taguchi Method and Finite Element Method. Adv. Mater. Sci. Eng. 2015, 2015, 8. [Google Scholar] [CrossRef]

- Abedini, A.; Rahimlou, P.; Asiabi, T.; Ahmadi, S.R.; Azdast, T. Effect of flow forming on mechanical properties of high density polyethylene pipes. J. Manuf. Process. 2015, 19, 155–162. [Google Scholar] [CrossRef]

- Gürün, H.; Karaağaç, İ. The Experimental Investigation of Effects of Multiple Parameters on the Formability of the DC01 Sheet Metal. Stroj. Vestn. J. Mech. Eng. 2015, 61, 651–662. [Google Scholar] [CrossRef]

- Steel Tubes for Precision Applications—Technical Delivery Conditions—Part 5: Welded and Cold Sized Square and Rectangular Tubes, British Standard, BS EN 10305-5:2003. Available online: http://www.lincsourcing.fr/admin/bildbank/uploads/Dokument/Body_of_knowledge/British_standard,_steel_tubes_for_precision_applications.pdf (accessed on 15 July 2016).

| Tube Data and Standard | Rp0.2 min (MPa) | Rm (MPa) | At (%) | Rp/Rm |

|---|---|---|---|---|

| Analyzed tubular specimens: D/t = 7 | 572 | 605 | 9.4 | 0.945 |

| Standard (EN 10305-3:2002) | 420 | 490 | 12 | 0.7832–0.9968 |

| Run | K (MPa) | n | μ | Rp (MPa) |

|---|---|---|---|---|

| 1 | 875 | 0.15 | 0.205 | 544 |

| 2 | 800 | 0.29 | 0.025 | 544 |

| 3 | 725 | 0.08 | 0.070 | 544 |

| 4 | 725 | 0.36 | 0.025 | 482 |

| 5 | 875 | 0.08 | 0.160 | 482 |

| 6 | 725 | 0.29 | 0.205 | 420 |

| 7 | 875 | 0.36 | 0.115 | 420 |

| 8 | 950 | 0.36 | 0.160 | 544 |

| 9 | 800 | 0.15 | 0.160 | 420 |

| 10 | 650 | 0.08 | 0.025 | 420 |

| 11 | 875 | 0.22 | 0.025 | 606 |

| 12 | 950 | 0.29 | 0.115 | 482 |

| 13 | 800 | 0.22 | 0.205 | 482 |

| 14 | 950 | 0.15 | 0.025 | 668 |

| 15 | 800 | 0.36 | 0.070 | 606 |

| 16 | 875 | 0.29 | 0.070 | 668 |

| 17 | 725 | 0.22 | 0.160 | 668 |

| 18 | 950 | 0.22 | 0.070 | 420 |

| 19 | 725 | 0.15 | 0.115 | 606 |

| 20 | 650 | 0.15 | 0.070 | 482 |

| 21 | 650 | 0.36 | 0.205 | 668 |

| 22 | 950 | 0.08 | 0.205 | 606 |

| 23 | 800 | 0.08 | 0.115 | 668 |

| 24 | 650 | 0.22 | 0.115 | 544 |

| 25 | 650 | 0.29 | 0.160 | 606 |

| Force | F1 | F2 | F3 | F4 | F5 | F6 |

|---|---|---|---|---|---|---|

| Punch displacement (mm) | 0.81 | 1.56 | 2.27 | 3.03 | 3.63 | 4.19 |

| Run | K (MPa) | n | μ | Rp (MPa) | F1 (N) | F2 (N) | F3 (N) | F4 (N) | F5 (N) | F6 (N) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 875 | 0.15 | 0.205 | 544 | 52,013.9 | 57,667.4 | 61,501.7 | 65,150.2 | 68,172.4 | 71,733.9 |

| 2 | 800 | 0.29 | 0.025 | 544 | 48,070.8 | 54,788.9 | 60,930.7 | 67,063.9 | 71,515.5 | 74,827.8 |

| 3 | 725 | 0.08 | 0.070 | 544 | 49,257.5 | 53,178.2 | 55,837.0 | 57,917.1 | 59,440.7 | 61,846.8 |

| 4 | 725 | 0.36 | 0.025 | 482 | 42,758.1 | 49,079.3 | 55,041.5 | 61,214.0 | 65,854.5 | 69,486.2 |

| 5 | 875 | 0.08 | 0.160 | 482 | 58,019.4 | 62,889.6 | 65,688.6 | 68,557.7 | 70,986.6 | 74,079.4 |

| 6 | 725 | 0.29 | 0.205 | 420 | 38,823.6 | 43,810.6 | 47,659.2 | 51,606.0 | 54,556.6 | 58,316.9 |

| 7 | 875 | 0.36 | 0.115 | 420 | 40,992.9 | 48,051.7 | 53,793.0 | 58,884.1 | 62,920.8 | 67,032.1 |

| 8 | 950 | 0.36 | 0.160 | 544 | 49,854.3 | 56,461.3 | 61,609.5 | 66,960.9 | 71,398.8 | 76,122.9 |

| 9 | 800 | 0.15 | 0.160 | 420 | 45,863.7 | 51,842.5 | 55,513.1 | 59,048.3 | 61,689.6 | 65,109.1 |

| 10 | 650 | 0.08 | 0.025 | 420 | 43,696.8 | 49,466.9 | 53,833.5 | 57,573.6 | 59,947.5 | 61,672.4 |

| 11 | 875 | 0.22 | 0.025 | 606 | 53,589.7 | 60,779.8 | 67,085.8 | 73,115.2 | 77,301.8 | 80,216.2 |

| 12 | 950 | 0.29 | 0.115 | 482 | 47,082.9 | 54,585.2 | 60,388.8 | 65,400.8 | 69,326.3 | 73,664.8 |

| 13 | 800 | 0.22 | 0.205 | 482 | 44,789.6 | 50,128.1 | 54,054.1 | 57,945.9 | 60,952.4 | 64,679.8 |

| 14 | 950 | 0.15 | 0.025 | 668 | 59,841.7 | 67,722.7 | 74,213.1 | 80,042.6 | 83,868.8 | 86,386.5 |

| 15 | 800 | 0.36 | 0.070 | 606 | 52,119.6 | 56,866.0 | 61,004.7 | 64,918.9 | 67,762.6 | 71,292.2 |

| 16 | 875 | 0.29 | 0.070 | 668 | 57,155.3 | 61,971.5 | 66,059.0 | 69,813.1 | 72,621.1 | 76,237.1 |

| 17 | 725 | 0.22 | 0.160 | 668 | 55,097.5 | 57,786.2 | 59,761.4 | 62,460.3 | 64,831.4 | 67,962.0 |

| 18 | 950 | 0.22 | 0.070 | 420 | 47,639.9 | 56,792.6 | 63,388.5 | 68,961.5 | 72,364.8 | 76,387.3 |

| 19 | 725 | 0.15 | 0.115 | 606 | 50,630.8 | 53,535.3 | 55,744.4 | 57,895.8 | 60,194.2 | 62,855.8 |

| 20 | 650 | 0.15 | 0.070 | 482 | 41,969.5 | 45,564.2 | 48,332.2 | 50,705.5 | 52,254.3 | 54,802.9 |

| 21 | 650 | 0.36 | 0.205 | 668 | 55,220.8 | 58,087.2 | 60,476.3 | 63,201.4 | 66,029.6 | 69,445.6 |

| 22 | 950 | 0.08 | 0.205 | 606 | 63,122.5 | 68,155.2 | 71,328.3 | 74,207.3 | 76,963.0 | 80,346.5 |

| 23 | 800 | 0.08 | 0.115 | 668 | 56,356.8 | 59,488.8 | 61,629.4 | 63,646.8 | 65,855.6 | 68,638.0 |

| 24 | 650 | 0.22 | 0.115 | 544 | 45,540.9 | 48,365.2 | 50,623.7 | 52,847.7 | 55,144.8 | 57,802.9 |

| 25 | 650 | 0.29 | 0.160 | 606 | 50,234.4 | 52,973.6 | 55,071.0 | 57,648.8 | 60,236.6 | 63,319.4 |

| Force | Influential Parameter | p-Value | Force | Influential Parameter | p-Value |

|---|---|---|---|---|---|

| F1 | K | <0.0001 | F4 | K | <0.0001 |

| n | 0.0003 | n | 0.6672 | ||

| μ | 0.4553 | μ | 0.0021 | ||

| Rp | <0.0001 | Rp | <0.0001 | ||

| K·n | 0.0091 | K∙n | 0.0033 | ||

| K∙μ | 0.1899 | K∙μ | 0.8832 | ||

| K∙Rp | 0.2535 | K∙Rp | 0.4999 | ||

| n∙μ | 0.3473 | n∙μ | 0.2916 | ||

| n∙Rp | 0.0007 | n∙Rp | 0.0019 | ||

| μ∙Rp | 0.7288 | μ∙Rp | 0.3103 | ||

| F2 | K | <0.0001 | F5 | K | <0.0001 |

| n | 0.0002 | n | 0.4014 | ||

| μ | 0.0496 | μ | 0.0053 | ||

| Rp | <0.0001 | Rp | 0.0009 | ||

| K∙n | 0.0014 | K∙n | 0.0093 | ||

| K∙μ | 0.3163 | K∙μ | 0.8549 | ||

| K∙Rp | 0.5220 | K∙Rp | 0.5320 | ||

| n∙μ | 0.2142 | n∙μ | 0.3447 | ||

| n∙Rp | <0.0001 | n∙Rp | 0.0180 | ||

| μ∙Rp | 0.7476 | μ∙Rp | 0.3900 | ||

| F3 | K | <0.0001 | F6 | K | <0.0001 |

| n | 0.0079 | n | 0.1046 | ||

| μ | 0.0015 | μ | 0.0096 | ||

| Rp | <0.0001 | Rp | 0.0011 | ||

| K∙n | 0.0005 | K∙n | 0.0103 | ||

| K∙μ | 0.5451 | K∙μ | 0.8752 | ||

| K∙Rp | 0.8954 | K∙Rp | 0.5490 | ||

| n∙μ | 0.1529 | n∙μ | 0.3933 | ||

| n∙Rp | <0.0001 | n∙Rp | 0.0178 | ||

| μ∙Rp | 0.3630 | μ∙Rp | 0.3572 |

| Punch Displacement (mm) | Force (N) |

|---|---|

| 0.81 | 49,537 |

| 1.56 | 54,600 |

| 2.27 | 58,687 |

| 3.03 | 61,612 |

| 3.63 | 63,225 |

| 4.19 | 64,838 |

| Number | K (MPa) | n | μ | Rp(MPa) | ε0 |

|---|---|---|---|---|---|

| 1 | 713.0 | 0.195 | 0.035 | 572 | 0.321 |

| 2 | 716.7 | 0.187 | 0.039 | 572 | 0.298 |

| 3 | 710.0 | 0.203 | 0.033 | 572 | 0.343 |

| 4 | 708.4 | 0.199 | 0.031 | 572 | 0.339 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pepelnjak, T.; Šašek, P.; Kudlaček, J. Upsetting Analysis of High-Strength Tubular Specimens with the Taguchi Method. Metals 2016, 6, 257. https://doi.org/10.3390/met6110257

Pepelnjak T, Šašek P, Kudlaček J. Upsetting Analysis of High-Strength Tubular Specimens with the Taguchi Method. Metals. 2016; 6(11):257. https://doi.org/10.3390/met6110257

Chicago/Turabian StylePepelnjak, Tomaž, Patricia Šašek, and Jan Kudlaček. 2016. "Upsetting Analysis of High-Strength Tubular Specimens with the Taguchi Method" Metals 6, no. 11: 257. https://doi.org/10.3390/met6110257