An Evaluation of Mechanical Properties with the Hardness of Building Steel Structural Members for Reuse by NDT

Abstract

:1. Introduction

2. Investigation Overview

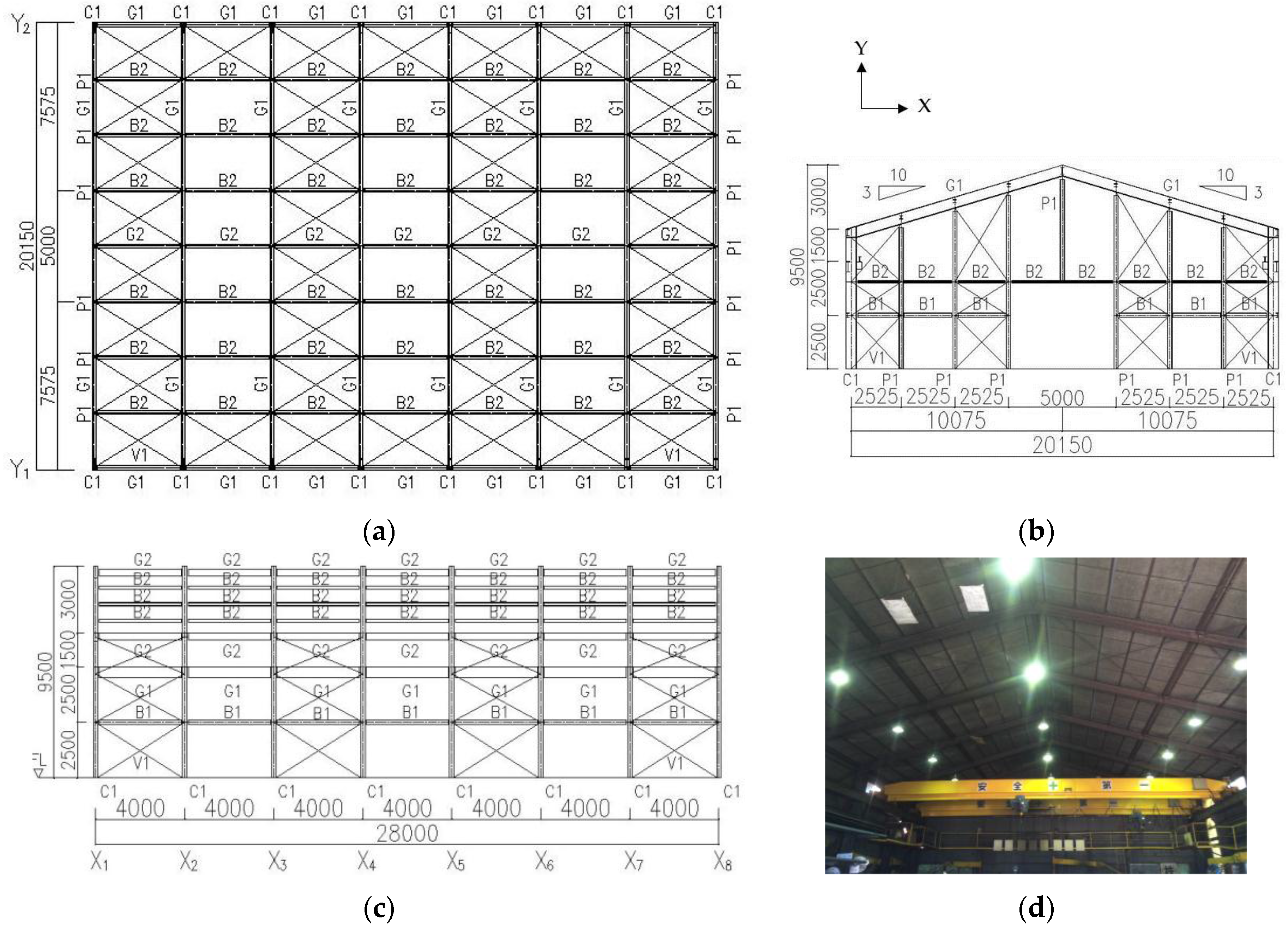

2.1. Target Building

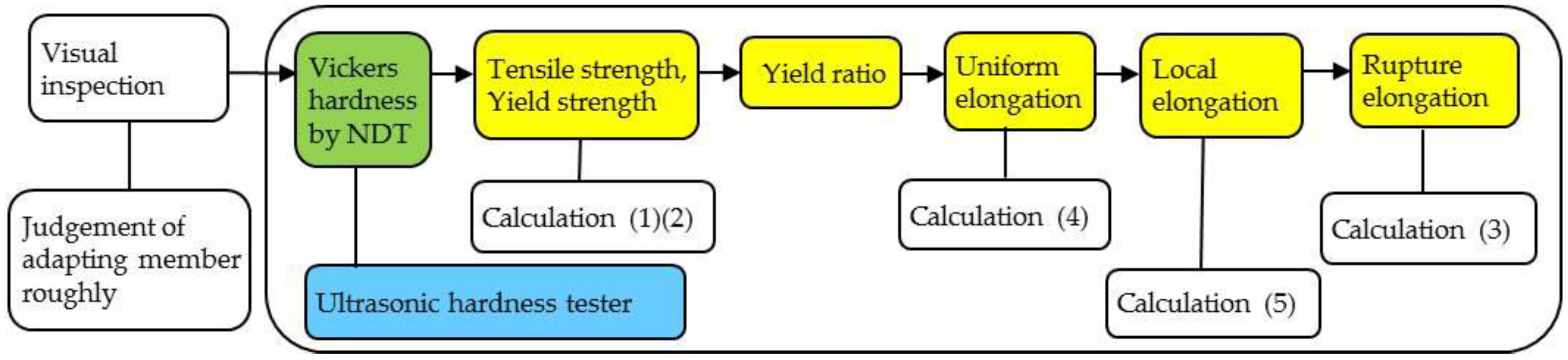

2.2. Flow for Estimating Mechanical Properties

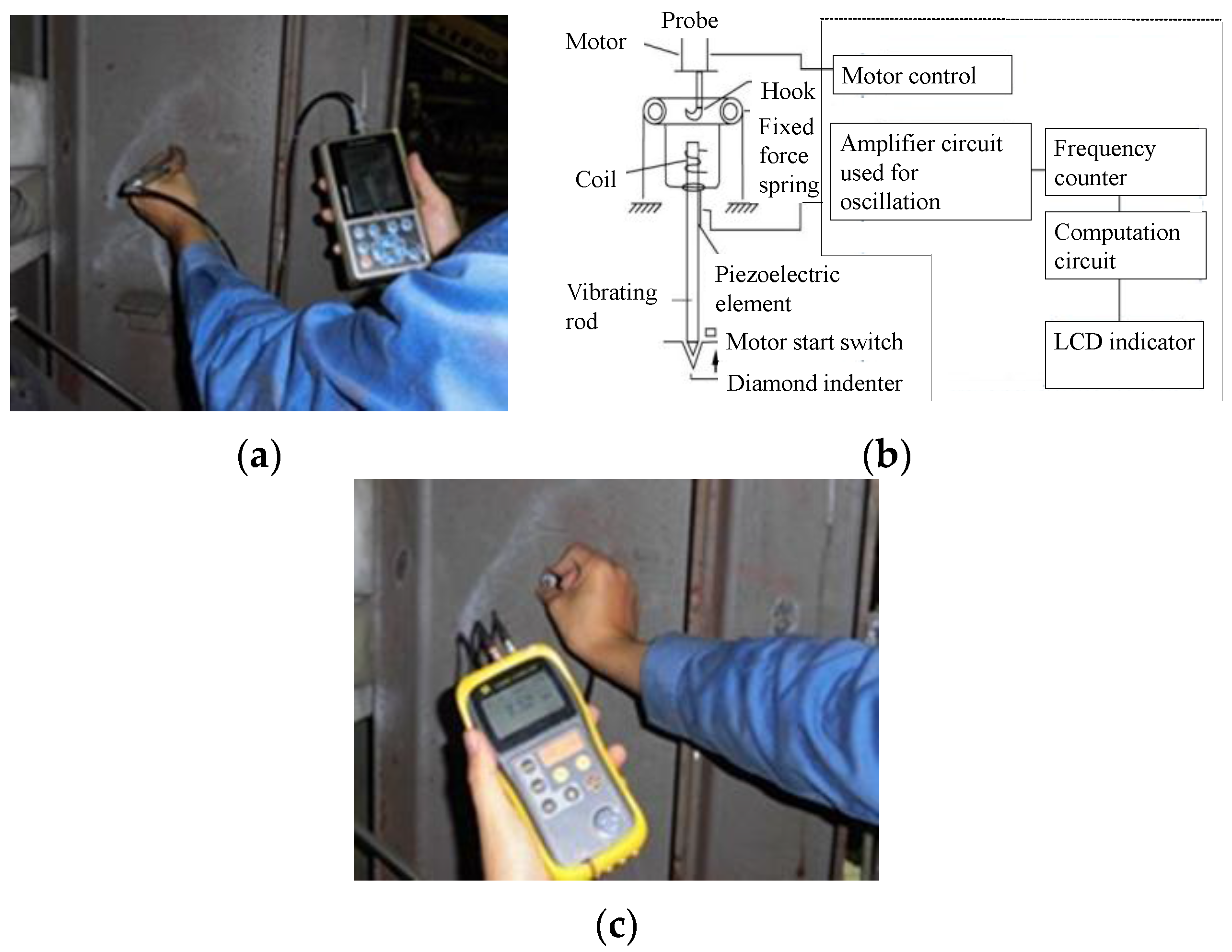

2.3. Non-Destructive Testing Equipment

3. Evaluation of Mechanical Properties

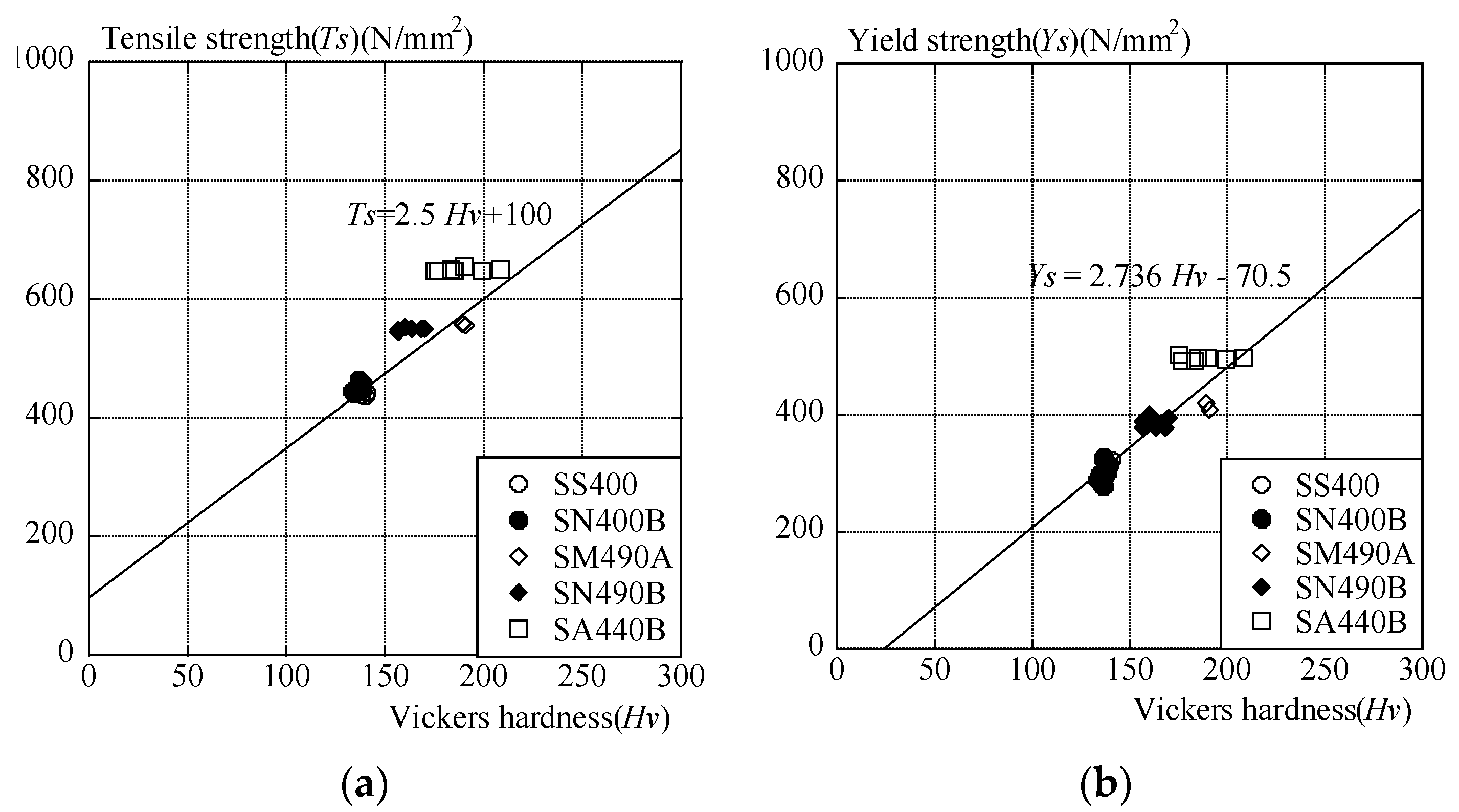

3.1. Tensile Strength and Yield Point or Yield Strength

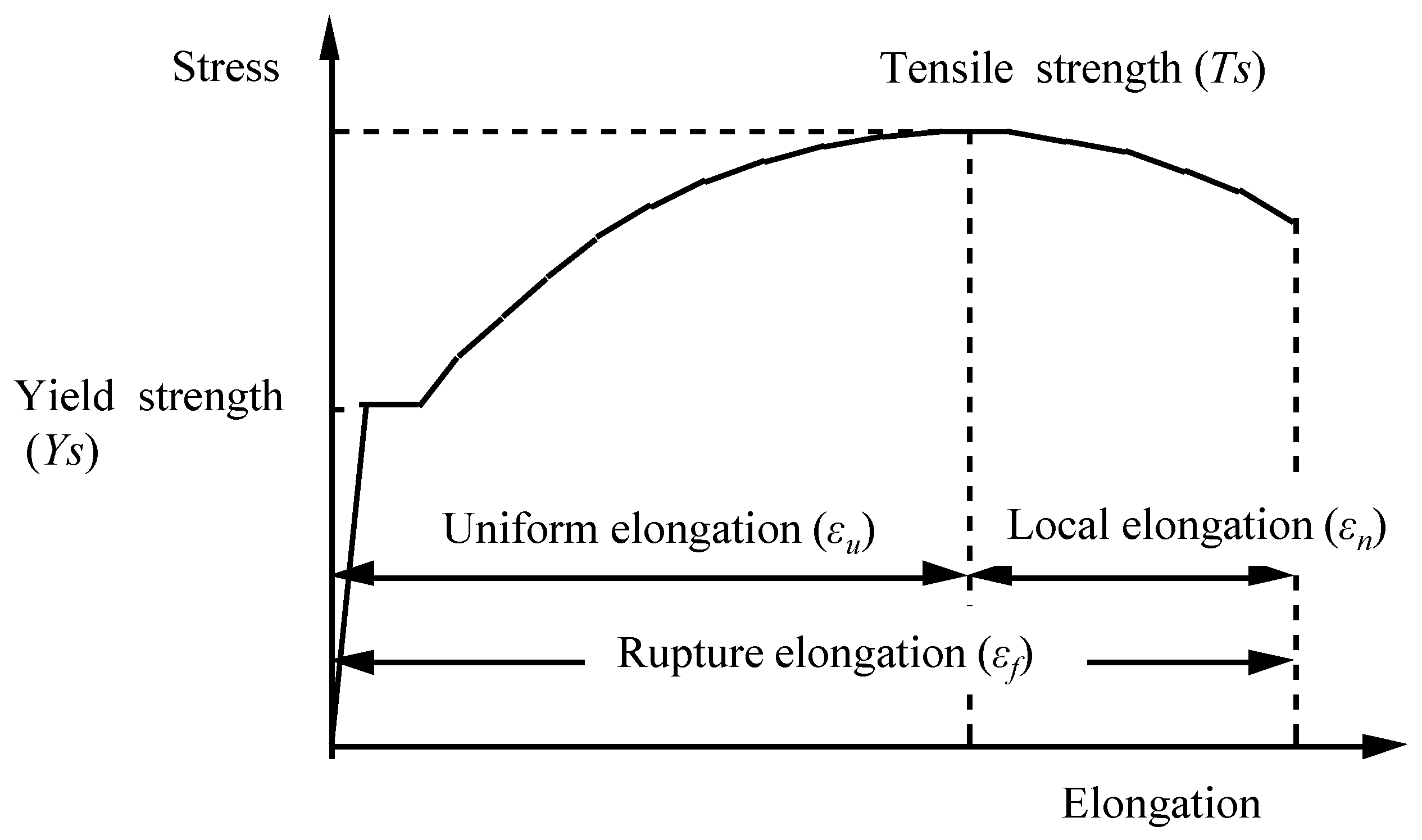

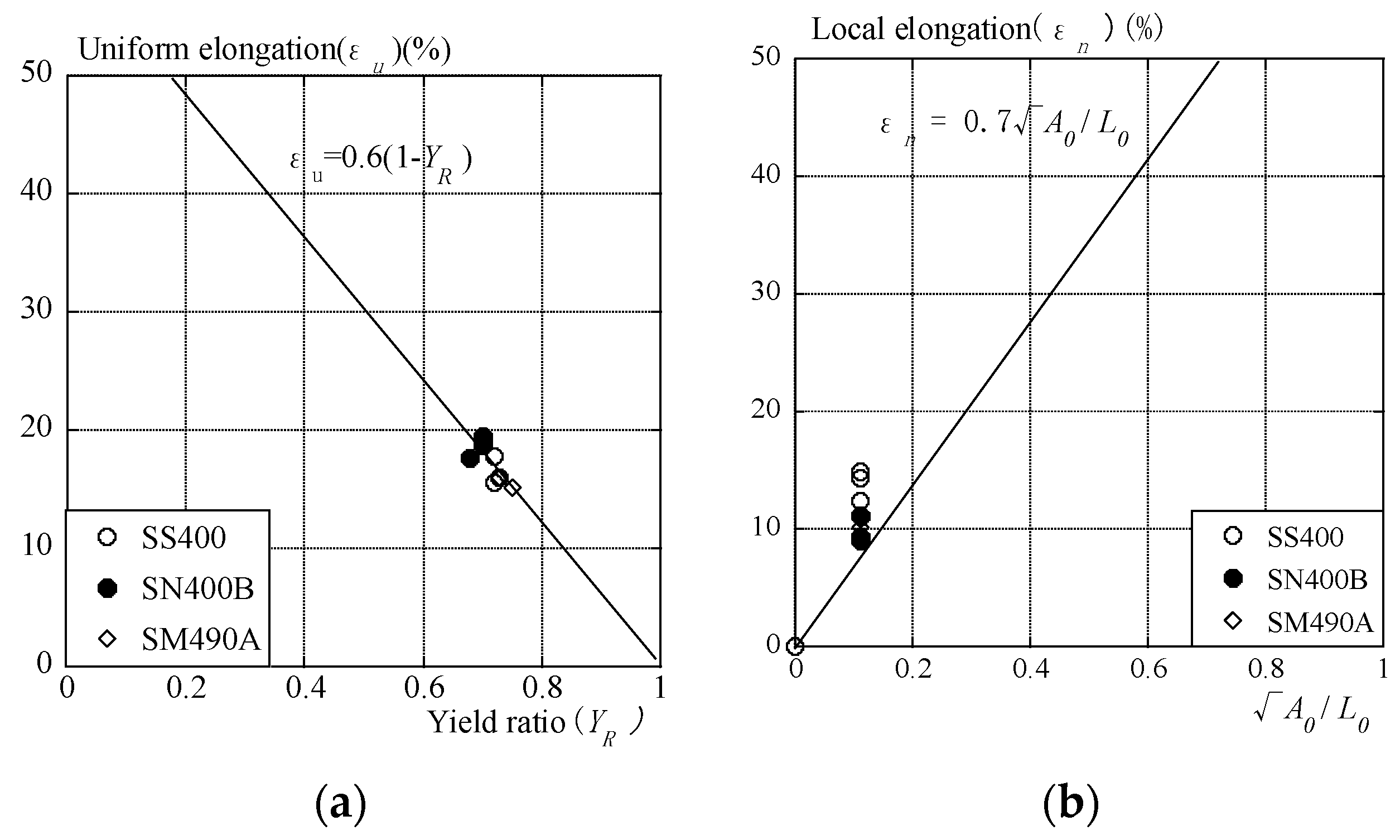

3.2. Rupture Elongation

3.3. Degradation

4. Example of Material Estimation

4.1. Mechanical Properties

4.2. Degradation

5. Conclusions

- (1)

- Based on Vickers hardness found via NDT, this paper proposed a flow for estimating the mechanical properties of the steel structural members. Tensile strength and yield point or yield strength were calculated using Vickers hardness. Uniform elongation and local elongation of the steel structural members were calculated using the yield ratio and plate thickness of the structural members, respectively.

- (2)

- The proposed estimation flow of mechanical properties, e.g., tensile strength, yield point or yield strength, and rupture elongation, was verified applying to a target building steel structure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Japan Meteorological Agency. IPCC Fourth Assessment Report; Ministry of the Environment: Tokyo, Japan, 2007.

- Architectural Institute of Japan. Activity report “architectural approach to global warming (Dec.1997 presidential statement)”. Archit. J. 1998, 113, 90–91. Available online: http://www.aij.or.jp/jpn/archives/971202.htm (accessed on 20 October 2014). [Google Scholar]

- Architectural Institute of Japan. Towards the Architecture for a Global Environment; Shokokusha Publishing Co., Ltd.: Tokyo, Japan, 2002. [Google Scholar]

- Manual for Re-Using Structural Members; Architectural Institute of Japan: Tokyo, Japan, 2009.

- Architectural Institute of Japan. Proposal 2050 Vision, Building-related Measures to Counteract Global Warming Towards Carbon-Neutralization. December 2009. Available online: http://www.aij.or.jp/scripts/request/document/20091222-1e.pdf (accessed on 20 October 2014).

- Fujita, M.; Iwata, M. Reuse system for building steel structures. Struct. Infrastruct. Eng. 2008, 4, 207–220. [Google Scholar] [CrossRef]

- Fujita, M.; Iwata, M. The Reuse Management Model of Building Steel Structures. In Proceedings of the International ECCE Conference Euroinfra 2009, Current State and Challenges for Sustainable Development of Infrastructure, Helsinki, Finland, 15–16 October 2009; pp. 15–16.

- Fujita, M.; Iwata, M. Reuse dismantling and structural performance of reusable members. Struct. Eng. Int. 2008, 18, 230–237. [Google Scholar] [CrossRef]

- Fujita, M.; Iwata, M. Guideline for reusable members of building steel structures and test. In Codes in Structural Engineering Developments and Needs for International Practice; IBASE: Sharm el-Sheikh, Egypt, 2010; pp. 545–552. [Google Scholar]

- Fujita, M. Reuse system of building steel structures—Structural performance of reusable members and practical examples—Novel and non-conventional materials and technologies for sustainability. Key Eng. Mater. 2012, 517, 513–521. [Google Scholar] [CrossRef]

- Iwata, M.; Fujita, M. A damage-controlled structure using buckling-restrained knee braces. Struct. Eng. Int. 2011, 21, 462–470. [Google Scholar] [CrossRef]

- Fujita, M.; Masuda, T. Application of Various NDT Methods for the Evaluation of Building Steel Structures for Reuse. Materials 2014, 7, 7130–7144. [Google Scholar] [CrossRef]

- Aoyagi, R.; Umezu, K. Comparison of ultrasonic-hardness-tester hardness and micro-vickers hardness. Jpn. J. Appl. Phys. 2007, 46, 4558–4560. [Google Scholar] [CrossRef]

- Cahoon, J.R.; Broughton, W.H.; Kutzak, A.R. The determination of yield strength from hardness measurements. Metall. Trans. 1971, 2, 1971–1979. [Google Scholar]

- The Japan Welding Engineering Society. Quality Performance Method of Welding Connections of Building Steel Structures; Technical Report for The Japan Welding Engineering Society: Tokyo, Japan, 2006. [Google Scholar]

- Suzuki, H.; Horikawa, K. On the uniform elongation of structural steels. J. Struct. Eng. 1992, 38A, 979–987. Available online: http://library.jsce.or.jp/jsce/open/00127/1992/38-3-0979.pdf (accessed on 18 October 2016). [Google Scholar]

- Kleesattel, C.; Gladwell, G.M.L. The contact-impedance meter-1. Ultrasonics 1968, 6, 175–180. [Google Scholar] [CrossRef]

- Kleesattel, C.; Gladwell, G.M.L. The contact-impedance meter-3. Ultrasonics 1969, 7, 57–62. [Google Scholar] [CrossRef]

- Bradfield, G. Strength, elasticity and ultrasonics. Ultrasonics 1972, 10, 166–172. [Google Scholar] [CrossRef]

- Szilard, J. Quicker, simpler hardness testing using ultrasonics. Ultrasonics 1984, 22, 174–178. [Google Scholar] [CrossRef]

- Bouda, A.B.; Benchaala, A.; Alem, K. Ultrasonic characterization of materials hardness. Ultrasonics 2000, 38, 224–227. [Google Scholar] [CrossRef]

- JIS Z 2241. Metallic Materials Tensile Testing Method of Test at Room Temperature; Japanese Industrial Standards Committee: Tokyo, Japan, 2011. [Google Scholar]

- ISO 6892-1. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; Japanese Industrial Standards Committee: Tokyo, Japan, 2009. [Google Scholar]

- Kaneya, T. Experiment research of tensile strength, yield point, and Vickers hardness concerning correlation. Synop. Archit. Inst. Jpn. 2006, 6, 989–990. [Google Scholar]

- Iwata, Y.; Ishihara, T.; Mukai, A.; Nishiyama, I.; Aoki, H. Relation between uniform elongation and rupture elongation at coupon tension tests of structural steel. AIJ J. Struct. Constr. Eng. 2013, 78, 223–232. [Google Scholar] [CrossRef]

- The Japan Welding Engineering Society. Weldable High Strength Steel Plates; The Japan Welding Engineering Society: Tokyo, Japan, 2012. [Google Scholar]

- Pavlina, E.J.; van Tyne, C.J. Correlation of Yield Strength and Tensile Strength with Hardness for Steels. J. Mater. Eng. Perform. 2008, 17, 888–893. [Google Scholar] [CrossRef]

- Suzuki, H. A theoretical equation of relationship between uniform elongation and yield ratio of structural steels. J. Constr. Steel 1994, 2, 473–478. [Google Scholar]

- JIS K 5600-8. Testing Methods for Paints—Part 8: Evaluation of Degradation of Coatings; Japanese Industrial Standards Committee: Tokyo, Japan, 2014. [Google Scholar]

- ISO 4628. Paints and Varnishes—Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- ASTM D 714-02. Standard Test Method for Evaluating Degree of Blistering of Paints; American Society for Testing and Materials: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM D 610-01. Standard Method of Evaluating Degree of Rusting on Painted Steel Surfaces; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- JIS G 3192. Dimensions, Mass and Permissible Variations of Hot Rolled Steel Sections; Japanese Industrial Standards Committee: Tokyo, Japan, 2014. [Google Scholar]

- JIS G 3101. Rolled Steels for General Structure; Japanese Industrial Standards Committee: Tokyo, Japan, 2010. [Google Scholar]

- ISO 630. Structural Steels—Plates, Wide Flats, Bars, Sections and Profiles; International Organization for Standardization: Geneva, Switzerland, 1995. [Google Scholar]

- JIS G 0321. Product Analysis and Its Tolerance for Wrought Steel; Japanese Industrial Standards Committee: Tokyo, Japan, 2010. [Google Scholar]

| Location | Mark | Size |

|---|---|---|

| Beam | G1 | H-400 × 200 × 8 × 13 |

| G2 | H-350 × 150 × 6.5 × 9 | |

| Column | C1 | H-350 × 150 × 7 × 11 |

| Sub-beam | B1 | H-200 × 100 × 5.5 × 8 |

| B2 | H-150 × 75 × 5 × 7 | |

| Mid-column | P1 | H-250 × 250 × 9 × 14 |

| Brace | V1 | 1-M20 |

| Purlin | -- | C-100 × 50 × 3.2 |

| Series | Material | Type * | Thickness mm | Yield Strength N/mm2 | Tensile Strength N/mm2 | Uniform Elongation εu (%) | Rupture Elongation εf (%) | Vickers Hardness Hv | Strain Hardening Coefficient | Number Specimen |

|---|---|---|---|---|---|---|---|---|---|---|

| Series_1 | SS400 | 1A | 12 | 313 | 436 | 16 | 31 | 140 | 0.249 | 8 |

| 12 | 315 | 438 | 18 | 30 | 138 | 0.229 | ||||

| 12 | 323 | 442 | 16 | 30 | 141 | 0.236 | ||||

| SN400B | 1A | 12 | 310 | 459 | 18 | 29 | 138 | 0.246 | ||

| 12 | 321 | 459 | 18 | 29 | 137 | 0.248 | ||||

| 12 | 327 | 463 | 19 | 28 | 137 | 0.232 | ||||

| SM490A | 1A | 12 | 419 | 559 | 15 | 26 | 189 | 0.205 | ||

| 12 | 408 | 557 | 16 | 26 | 191 | 0.188 | ||||

| Series_2 | SN400B | 5 | 12 | 279 | 451 | -- | 43 | 137 | -- | 21 |

| 12 | 277 | 449 | -- | 44 | 136 | -- | ||||

| 12 | 288 | 442 | -- | 37 | 134 | -- | ||||

| 12 | 300 | 443 | -- | 44 | 135 | -- | ||||

| 12 | 289 | 445 | -- | 41 | 133 | -- | ||||

| 12 | 301 | 448 | -- | 42 | 138 | -- | ||||

| 12 | 294 | 445 | -- | 43 | 135 | -- | ||||

| SN490B | 5 | 12 | 377 | 550 | -- | 36 | 168 | -- | ||

| 12 | 378 | 545 | -- | 38 | 157 | -- | ||||

| 12 | 388 | 547 | -- | 39 | 157 | -- | ||||

| 12 | 399 | 552 | -- | 36 | 160 | -- | ||||

| 12 | 388 | 550 | -- | 38 | 163 | -- | ||||

| 12 | 378 | 549 | -- | 36 | 163 | -- | ||||

| 12 | 394 | 550 | -- | 38 | 170 | -- | ||||

| SA440B | 1A | 40 | 498 | 657 | -- | 26 | 190 | -- | ||

| 40 | 502 | 647 | -- | 25 | 175 | -- | ||||

| 40 | 495 | 647 | -- | 25 | 199 | -- | ||||

| 40 | 491 | 647 | -- | 26 | 177 | -- | ||||

| 40 | 493 | 651 | -- | 25 | 183 | -- | ||||

| 40 | 496 | 648 | -- | 24 | 185 | -- | ||||

| 40 | 496 | 649 | -- | 24 | 208 | -- |

| Materials Grade | Yield Strength (N/mm2) | Tensile Strength (N/mm2) | Rupture Elongation (%) | ||||

|---|---|---|---|---|---|---|---|

| Lower Limit/Upper Limit | Lower Limit/Upper Limit | Lower Limit | |||||

| 6 ≤ t * < 12 | 12 ≤ t < 16 | t = 16 | 16 < t ≤ 40 | 6 ≤ t ≤ 16 | 16 < t ≤ 50 | ||

| SS400 | 245/-- | 245/-- | 245/-- | 235/-- | 400/510 | 17 | 21 |

| SM400A | 245/-- | 245/-- | 245/-- | 235/-- | 400/510 | 18 | 22 |

| SM400B | 245/-- | 245/-- | 245/-- | 235/-- | 400/510 | 18 | 22 |

| SM400C | 245/-- | 245/-- | 245/-- | 235/-- | 400/510 | 18 | 22 |

| SN400A | 235/-- | 235/-- | 235/-- | 235/-- | 400/510 | 17 | 21 |

| SN400B | 235/-- | 235/355 | 235/355 | 235/355 | 400/510 | 18 | 22 |

| SN400C | -- | -- | 235/355 | 235/355 | 400/510 | 18 | 22 |

| SM490A | 325/-- | 325/-- | 325/-- | 315/-- | 490/610 | 17 | 21 |

| SM490B | 325/-- | 325/-- | 325/-- | 315/-- | 490/610 | 17 | 21 |

| SN490B | 325/-- | 325/445 | 325/445 | 325/445 | 490/610 | 17 | 21 |

| SN490C | -- | -- | 325/445 | 325/445 | 490/610 | 17 | 21 |

| Line | Thickness of Painting (μm) | Mark of Rust | Line | Thickness of Painting (μm) | Mark of Rust |

|---|---|---|---|---|---|

| Y1X1 | 74 | Ri5(S5) | Y2X1 | 65 | Ri5(S5) |

| Y1X2 | 65 | Ri5(S5) | Y2X2 | 74 | Ri5(S5) |

| Y1X3 | 67 | Ri4(S4) | Y2X3 | 80 | Ri4(S4) |

| Y1X4 | 89 | Ri4(S4) | Y2X4 | 72 | Ri4(S4) |

| Y1X6 | 85 | Ri4(S4) | Y2X6 | 95 | Ri4(S4) |

| Y1X7 | 102 | Ri4(S4) | Y2X7 | 99 | Ri4(S4) |

| Y1X8 | 94 | Ri4(S4) | Y2X8 | 86 | Ri4(S4) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fujita, M.; Kuki, K. An Evaluation of Mechanical Properties with the Hardness of Building Steel Structural Members for Reuse by NDT. Metals 2016, 6, 247. https://doi.org/10.3390/met6100247

Fujita M, Kuki K. An Evaluation of Mechanical Properties with the Hardness of Building Steel Structural Members for Reuse by NDT. Metals. 2016; 6(10):247. https://doi.org/10.3390/met6100247

Chicago/Turabian StyleFujita, Masanori, and Keiichi Kuki. 2016. "An Evaluation of Mechanical Properties with the Hardness of Building Steel Structural Members for Reuse by NDT" Metals 6, no. 10: 247. https://doi.org/10.3390/met6100247