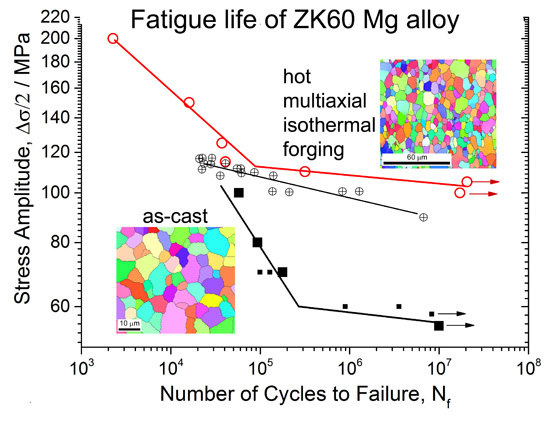

Fatigue Performance of Mg-Zn-Zr Alloy Processed by Hot Severe Plastic Deformation

Abstract

:1. Introduction

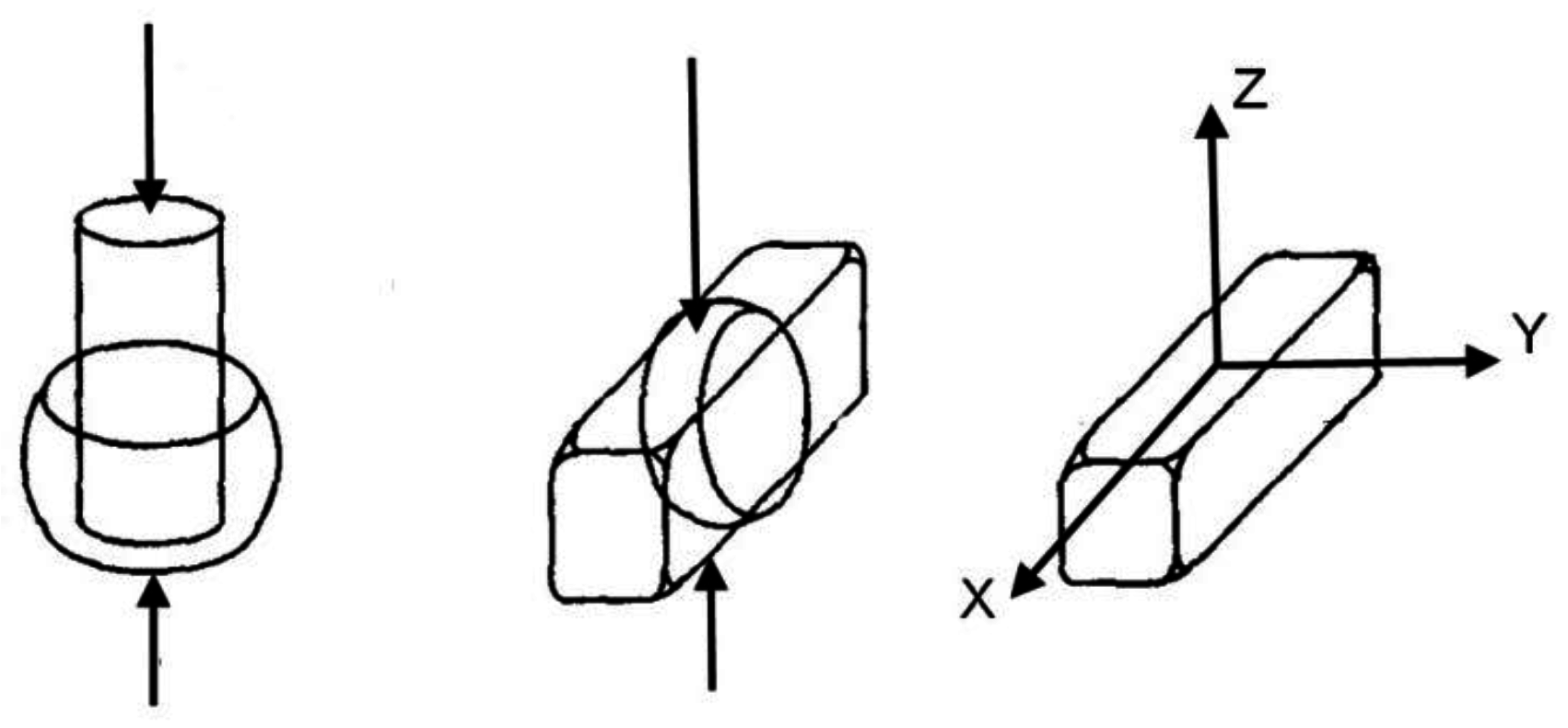

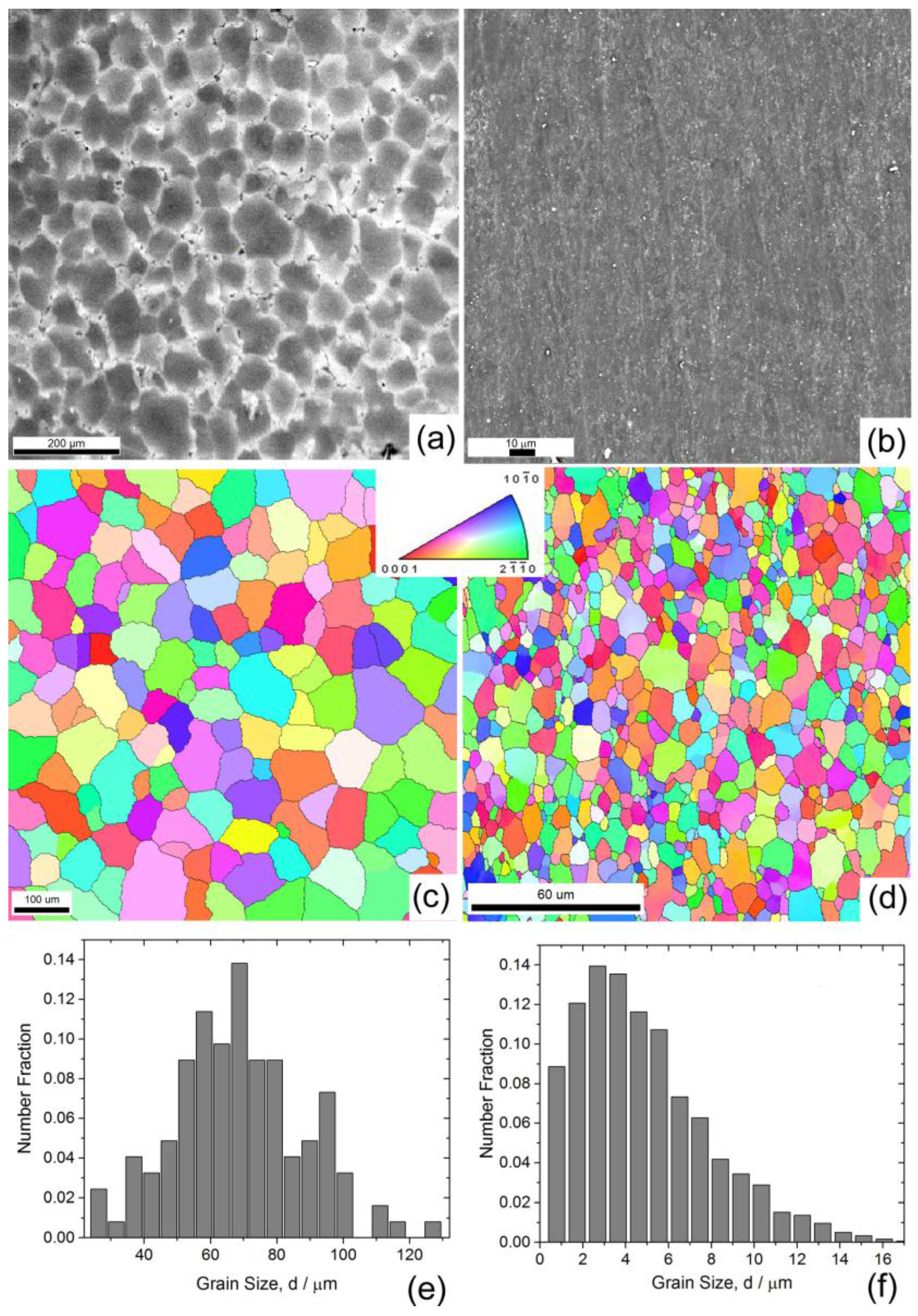

2. Experimental Procedure

2.1. Materials and Preparation

2.2. Microstructure Characterization

2.3. Mechanical Testing

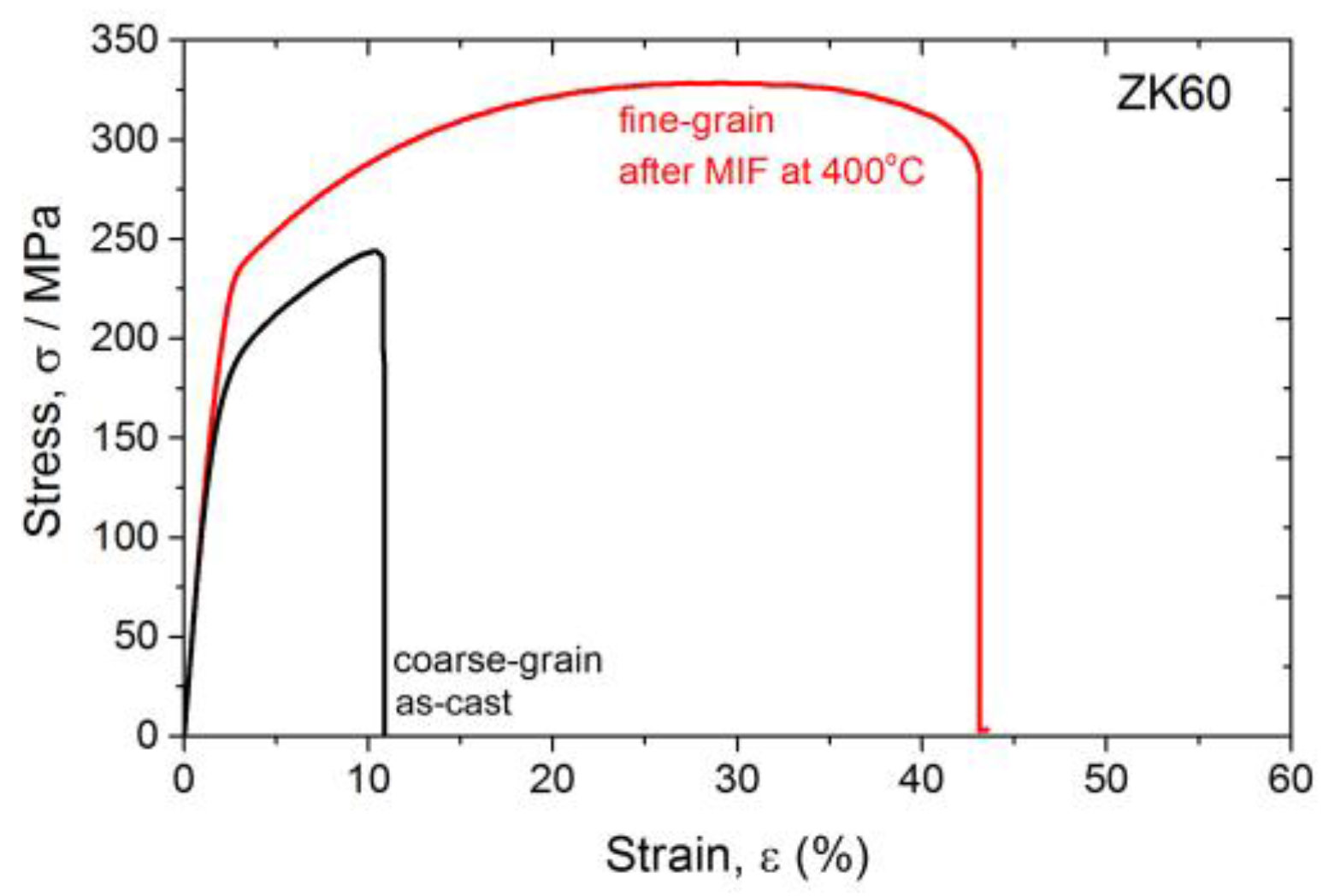

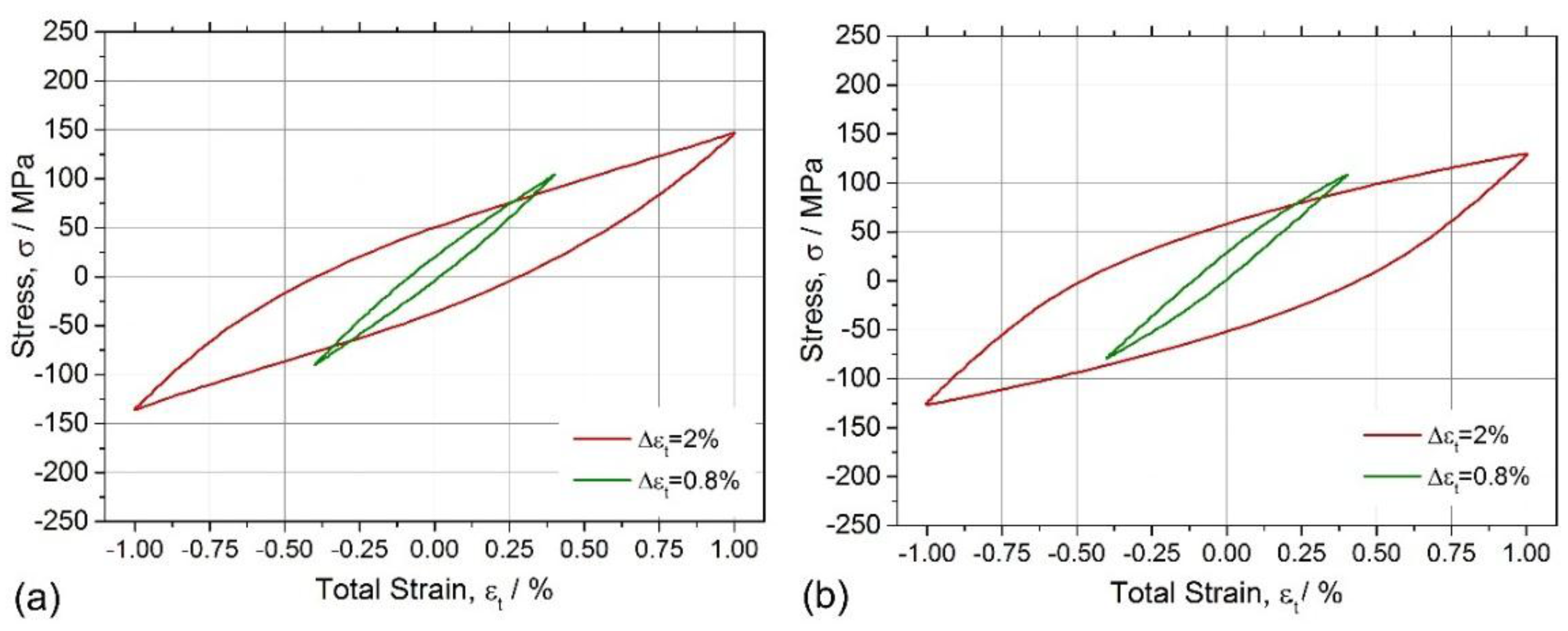

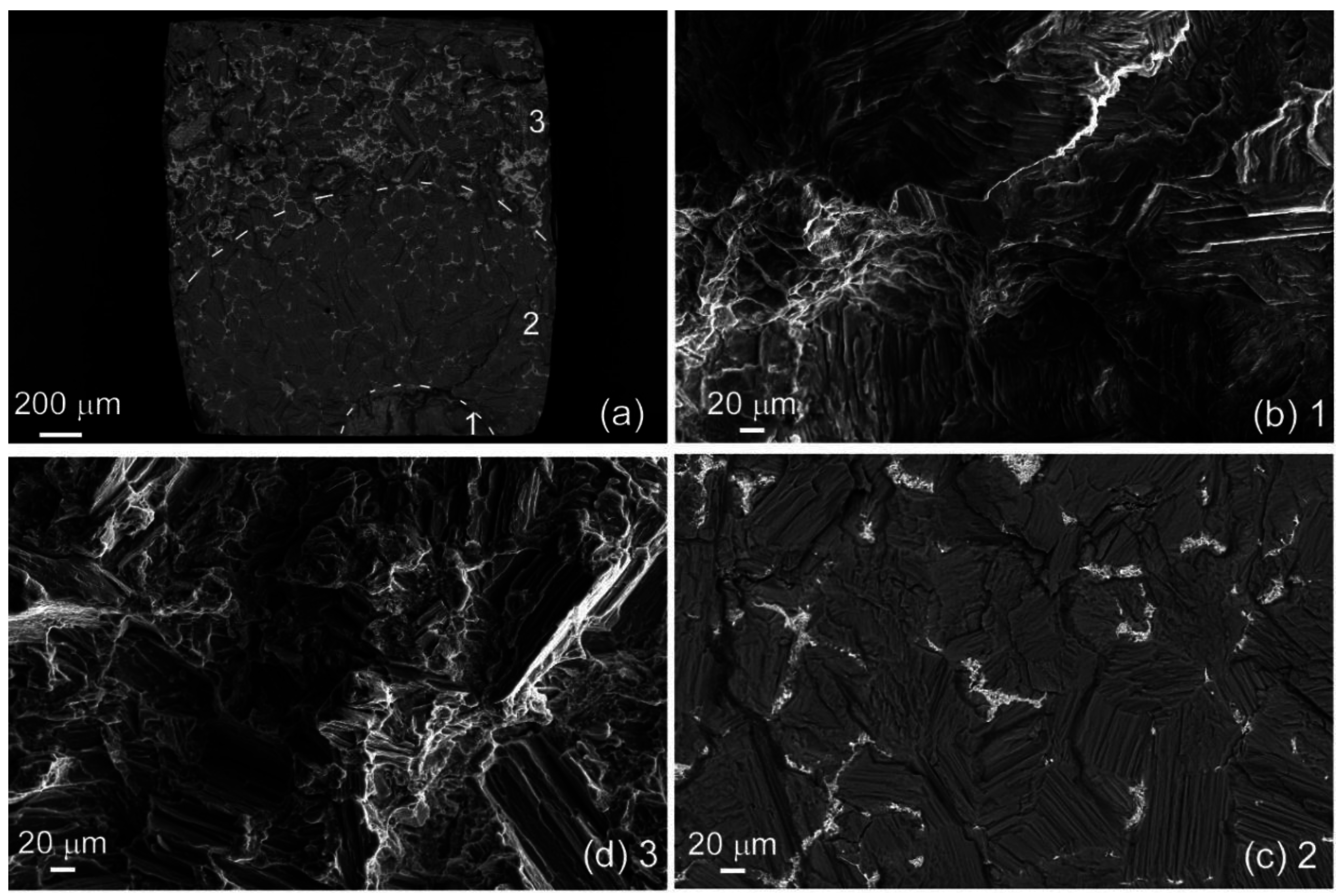

3. Experimental Results and Discussion

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Xiong, Y.; Jiang, Y. Fatigue of ZK60 magnesium alloy under uniaxial loading. Int. J. Fatigue 2014, 64, 74–83. [Google Scholar] [CrossRef]

- Matsuzuki, M.; Horibe, S. Analysis of fatigue damage process in magnesium alloy AZ31. Mater. Sci. Eng. A 2009, 504, 169–174. [Google Scholar] [CrossRef]

- Hasegawa, S.; Tsuchida, Y.; Yano, H.; Matsui, M. Evaluation of low cycle fatigue life in AZ31 magnesium alloy. Int. J. Fatigue 2007, 29, 1839–1845. [Google Scholar] [CrossRef]

- Begum, S.; Chen, D.L.; Xu, S.; Luo, A.A. Low cycle fatigue properties of an extruded AZ31 magnesium alloy. Int. J. Fatigue 2009, 31, 726–735. [Google Scholar] [CrossRef]

- Chen, C.; Liu, T.; Lv, C.; Lu, L.; Luo, D. Study on cyclic deformation behavior of extruded Mg–3Al–1Zn alloy. Mater. Sci. Eng. A 2012, 539, 223–229. [Google Scholar] [CrossRef]

- Lin, X.Z.; Chen, D.L. Strain controlled cyclic deformation behavior of an extruded magnesium alloy. Mater. Sci. Eng. A 2008, 496, 106–113. [Google Scholar] [CrossRef]

- Lee, S.; Wang, H.; Gharghouri, M. Twinning-detwinning behavior during cyclic deformation of magnesium alloy. Metals 2015, 5, 881–890. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Mukai, T.; Yamanoi, M.; Watanabe, H.; Higashi, K. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure. Scr. Mater. 2001, 45, 89–94. [Google Scholar] [CrossRef]

- Agnew, S.R.; Mehrotra, P.; Lillo, T.M.; Stoica, G.M.; Liaw, P.K. Texture evolution of five wrought magnesium alloys during route A equal channel angular extrusion: Experiments and simulations. Acta Mater. 2005, 53, 3135–3146. [Google Scholar] [CrossRef]

- Agnew, S.R.; Horton, J.A.; Lillo, T.M.; Brown, D.W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing. Scr. Mater. 2004, 50, 377–381. [Google Scholar] [CrossRef]

- Zúberová, Z.; Kunz, L.; Lamark, T.T.; Estrin, Y.; Janeček, M. Fatigue and tensile behavior of cast, hot-rolled, and severely plastically deformed AZ31 magnesium alloy. Metall. Mat. Trans. A 2007, 38, 1934–1940. [Google Scholar] [CrossRef]

- Vinogradov, A.; Orlov, D.; Estrin, Y. Improvement of fatigue strength of a Mg–Zn–Zr alloy by integrated extrusion and equal-channel angular pressing. Scr. Mater. 2012, 67, 209–212. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Knauer, E.; Freudenberger, J.; Marr, T.; Kauffmann, A.; Schultz, L. Grain refinement and deformation mechanisms in room temperature severe plastic deformed Mg-Az31. Metals 2013, 3, 283–297. [Google Scholar] [CrossRef]

- Orlov, D.; Raab, G.; Lamark, T.T.; Popov, M.; Estrin, Y. Improvement of mechanical properties of magnesium alloy ZK60 by integrated extrusion and equal channel angular pressing. Acta Mater. 2011, 59, 375–385. [Google Scholar] [CrossRef]

- Estrin, Y.; Yi, S.B.; Brokmeier, H.G.; Zuberova, Z.; Yoon, S.C.; Kim, H.S.; Hellmig, R.J. Microstructure, texture and mechanical properties of the magnesium alloy AZ31 processed by ecap. Int. J. Mater. Res. 2008, 99, 50–55. [Google Scholar] [CrossRef]

- Höppel, H.W.; Zhou, Z.M.; Mughrabi, H.; Valiev, R.Z. Microstructural study of the parameters governing coarsening and cyclic softening in fatigued ultrafine-grained copper. Philos. Mag. A 2002, 82, 1781–1794. [Google Scholar] [CrossRef]

- Höppel, H.W.; Mughrabi, H.; Vinogradov, A. Fatigue Properties of Bulk Nanostructured Materials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009; pp. 481–500. [Google Scholar]

- Agnew, S.R.; Vinogradov, A.Y.; Hashimoto, S.; Weertman, J.R. Overview of fatigue performance of Cu processed by severe plastic deformation. J. Electron. Mater. 1999, 28, 1038–1044. [Google Scholar] [CrossRef]

- Zhu, R.; Wu, Y.J.; Ji, W.Q.; Wang, J.T. Cyclic softening of ultrafine-grained az31 magnesium alloy processed by equal-channel angular pressing. Mater. Lett. 2011, 65, 3593–3596. [Google Scholar] [CrossRef]

- Nugmanov, D.R.; Sitdikov, O.S.; Markushev, M.V. Microstructure evolution in ma14 magnesium alloy under multi-step isothermal forging. Lett. Mater. 2011, 1, 213–216. [Google Scholar]

- Nugmanov, D.R.; Sitdikov, O.S.; Markushev, M.V. About fine-grain structure forming in bulk magnesium alloy ma14 under multidirectional isothermal forging. Bas. Probl. Mater. Sci. 2012, 9, 230–234. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: London, UK, 1991; p. 617. [Google Scholar]

- Estrin, Y.; Vinogradov, A. Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: An overview. Int. J. Fatigue 2010, 32, 898–907. [Google Scholar] [CrossRef]

- Wu, L.; Stoica, G.M.; Liao, H.H.; Agnew, S.R.; Payzant, E.A.; Wang, G.Y.; Fielden, D.E.; Chen, L.; Liaw, P.K. Fatigue-property enhancement of magnesium alloy, AZ31B, through equal-channel-angular pressing. Metall. Mater. Trans. A 2007, 38, 2283–2289. [Google Scholar] [CrossRef]

- Dong, S.; Jiang, Y.; Dong, J.; Wang, F.; Ding, W. Cyclic deformation and fatigue of extruded ZK60 magnesium alloy with aging effects. Mater. Sci. Eng. A 2014, 615, 262–272. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, J.; Jiang, Y.; Li, Q. An experimental study on cyclic deformation and fatigue of extruded ZK60 magnesium alloy. Int. J. Fatigue 2012, 36, 47–58. [Google Scholar] [CrossRef]

- Vinogradov, A.; Orlov, D.; Danyuk, A.; Estrin, Y. Deformation mechanisms underlying tension–compression asymmetry in magnesium alloy ZK60 revealed by acoustic emission monitoring. Mater. Sci. Eng. A 2015, 621, 243–251. [Google Scholar] [CrossRef]

- Vinogradov, A.; Orlov, D.; Danyuk, A.; Estrin, Y. Effect of grain size on the mechanisms of plastic deformation in wrought Mg–Zn–Zr alloy revealed by acoustic emission measurements. Acta Mater. 2013, 61, 2044–2056. [Google Scholar] [CrossRef]

- Wu, L. Mechanical Behavior and the Role of Deformation Twinning in Wrought Magnesium Alloys Investigated Using Neutron and Synchrotron X-ray Diffraction. Doctoral Dissertation, The University of Tennessee, Knoxville, TN, USA, 2009. [Google Scholar]

- Constantinescu, D.M.; Moldovan, P.; Sillekens, W.H.; Sandu, M.; Bojin, D.; Baciu, F.; Apostol, D.A.; Miron, M.C. Static and fatigue properties of magnesium alloys used in automotive industry. Sci. Bull. Automot. Ser. 2009, 19(B), 33–39. [Google Scholar]

- Vinogradov, A. Mechanical properties of ultrafine-grained metals: New challenges and perspectives. Adv. Eng. Mater. 2015. [Google Scholar] [CrossRef]

- Nugmanov, D.R.; Sitdikov, O.S.; Markushev, M.V. Texture and anisotropy of yield strength in multistep isothermally forged Mg-5.8Zn-0.65Zr alloy. IOP Conf. Ser. Mater. Sci. Eng. 2015, 82, 012099. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasilev, E.; Linderov, M.; Nugmanov, D.; Sitdikov, O.; Markushev, M.; Vinogradov, A. Fatigue Performance of Mg-Zn-Zr Alloy Processed by Hot Severe Plastic Deformation. Metals 2015, 5, 2316-2327. https://doi.org/10.3390/met5042316

Vasilev E, Linderov M, Nugmanov D, Sitdikov O, Markushev M, Vinogradov A. Fatigue Performance of Mg-Zn-Zr Alloy Processed by Hot Severe Plastic Deformation. Metals. 2015; 5(4):2316-2327. https://doi.org/10.3390/met5042316

Chicago/Turabian StyleVasilev, Evgeni, Mikhail Linderov, Dayan Nugmanov, Oleg Sitdikov, Mikhail Markushev, and Alexei Vinogradov. 2015. "Fatigue Performance of Mg-Zn-Zr Alloy Processed by Hot Severe Plastic Deformation" Metals 5, no. 4: 2316-2327. https://doi.org/10.3390/met5042316