High Temperature Flow Response Modeling of Ultra-Fine Grained Titanium

Abstract

:1. Introduction

2. Materials and Experimental Procedures

3. Results and Discussion

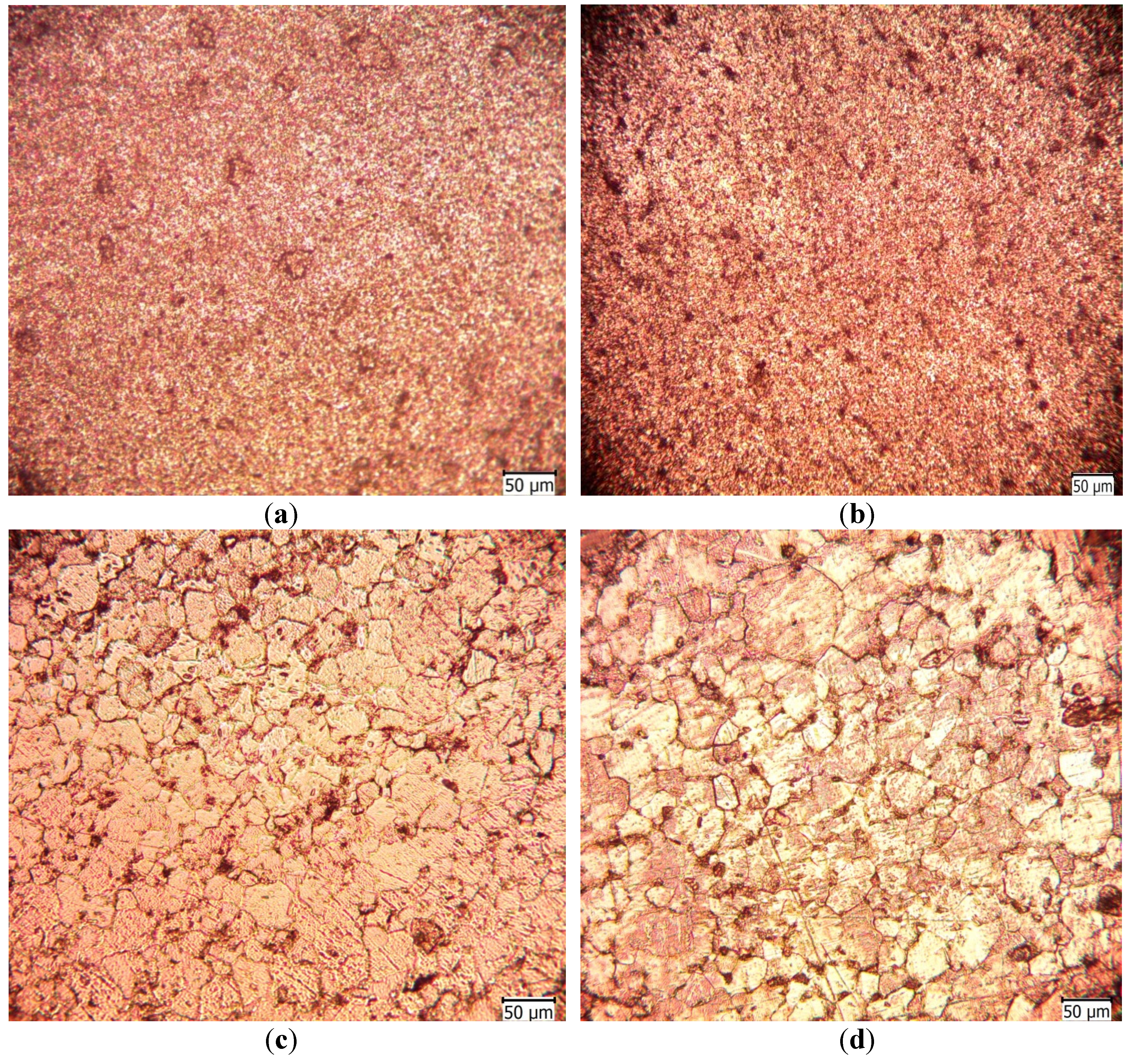

3.1. Effects of Temperature and Deformation Rate on the Microstructural Evolution

3.2. Constitutive Equation for the Modified Johnson-Cook Model

3.3. Calculation of B(T), n(T) and C(ε,T)

| Material Constants | 600 °C | 700 °C | 800 °C | 900 °C |

|---|---|---|---|---|

| B(T), MPa | −60.099 | −11.806 | −1.696 | −1.995 |

| n(T) | 4.311 | 3.251 | 1.319 | 0.123 |

| Strain | 600 °C | 700 °C | 800 °C | 900 °C |

|---|---|---|---|---|

| 0.20 | −0.0201 | −0.013 | 0.0005 | −0.013 |

| 0.40 | 0.0055 | −0.0005 | 0.0016 | −0.0005 |

| 0.60 | 0.015 | −0.0162 | −0.0019 | −0.0162 |

| 0.80 | −0.0029 | −0.0265 | −0.0035 | −0.0265 |

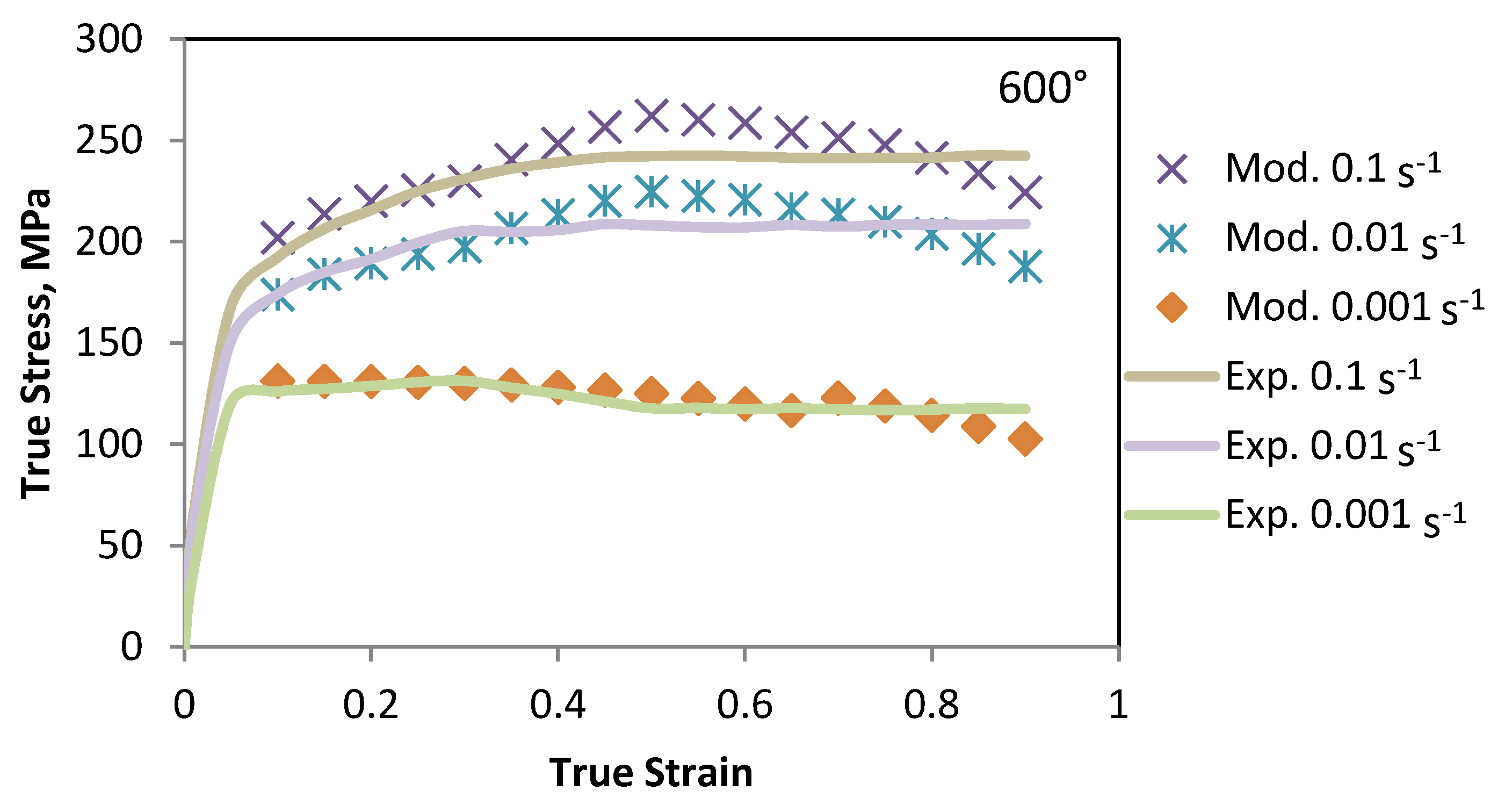

3.4. Prediction of Flow Stress by the Modified Johnson-Cook Modeling

3.5. Extension of the Johnson-Cook Model for Prediction of ECAE Processed Ti with a Corrective Term

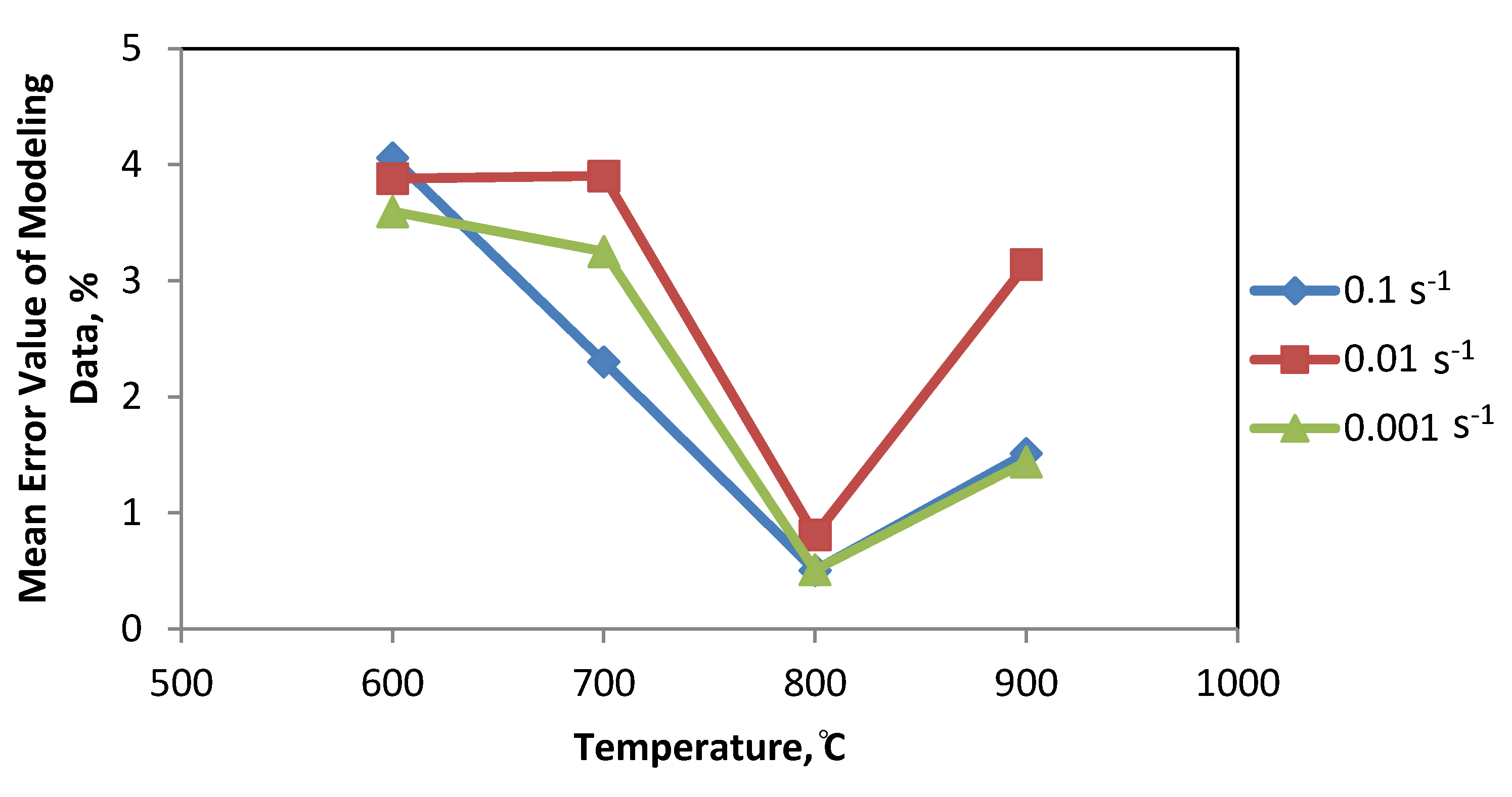

3.6. Verification of the Model

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Stolyarov, V.V.; Zhu, Y.T.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Influence of ECAP routes on the microstructure and properties of pure Ti. Mater. Sci. Eng. A 2001, 299, 59–67. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Fan, Z.; Jiang, H.; Sun, X.; Song, J.; Zhang, X.; Xie, C. Microstructures and mechanical deformation behaviors of ultrafine-grained commercial pure (grade 3) Ti processed by two-step severe plastic deformation. Mater. Sci. Eng. A 2009, 527, 45–51. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Grain refinement and properties of pure Ti processed by warm ECAP and cold rolling. Mater. Sci. Eng. A 2003, 343, 43–50. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Kolobov, Y.R.; Grabovetskaya, G.P.; Stolyarov, V.V.; Girsova, N.V.; Valiev, R.Z. Microstructures and mechanical properties of ultrafine-grained Ti foil processed by equal-channel angular pressing and cold rolling. J. Mater. Res. 2003, 18, 1011–1016. [Google Scholar] [CrossRef]

- Yapici, G.G.; Karaman, I.; Maier, H.J. Mechanical flow anisotropy in severely deformed pure titanium. Mater. Sci. Eng. A 2006, 434, 294–302. [Google Scholar] [CrossRef]

- Sanosh, K.P.; Balakrishnan, A.; Francis, L.; Kim, T.N. Vickers and Knoop Micro-hardness Behavior of Coarse-and Ultrafine-grained Titanium. J. Mater. Sci. Technol. 2010, 26, 904–907. [Google Scholar] [CrossRef]

- Segal, V.M. Engineering and commercialization of equal channel angular extrusion (ECAE). Mater. Sci. Eng. A 2004, 386, 269–276. [Google Scholar] [CrossRef]

- Hoseini, M.; Pourian, M.H.; Bridier, F.; Vali, H.; Szpunar, J.A.; Bocher, P. Thermal stability and annealing behaviour of ultrafine grained commercially pure titanium. Mater. Sci. Eng. A 2012, 532, 58–63. [Google Scholar] [CrossRef]

- Long, F.W.; Jiang, Q.W.; Xiao, L.; Li, X.W. Compressive deformation behaviors of coarse- and ultrafine-grained pure titanium at different temperatures: a comparative study. Mater. Trans. 2011, 52, 1617–1622. [Google Scholar] [CrossRef]

- Meredith, C.S.; Khan, A. The microstructural evolution and thermo-mechanical behavior of UFG Ti processed via equal channel angular pressing. J. Mater. Process. Technol. 2015, 219, 257–270. [Google Scholar] [CrossRef]

- Meredith, C.S.; Khan, A. Texture evolution and anisotropy in the thermo-mechanical response of UFG Ti processed via equal channel angular pressing. Int. J. Plasticity 2012, 30–31, 202–217. [Google Scholar] [CrossRef]

- Zeng, Z.; Jonsson, S.; Zhang, Y. Constitutive equations for pure titanium at elevated temperatures. Mater. Sci. Eng. A 2009, 505, 116–119. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Yang, H.; Li, H.; Ren, N.; Wang, D. Quasi-static tensile behavior and constitutive modeling of large diameter thin-walled commercial pure titanium tube. Mater. Sci. Eng. A 2013, 569, 96–105. [Google Scholar] [CrossRef]

- Tsao, L.C.; Wu, H.Y.; Leong, J.C.; Fang, C.J. Flow stress behavior of commercial pure titanium sheet during warm tensile deformation. Mater. Des. 2012, 34, 179–184. [Google Scholar] [CrossRef]

- Ping, L.; Kemin, X.; Yan, L.; Jianrong, T. Neural network prediction of flow stress of Ti–15–3 alloy under hot compression. J. Mater. Process. Technol. 2004, 148, 235–238. [Google Scholar] [CrossRef]

- Wang, Z.; Qiang, H.; Wang, X.; Wang, G. Constitutive model for a new kind of metastable beta titanium alloy during hot deformation. Trans. Nonferrous Metals Soc. China 2012, 22, 634–641. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547.

- Khan, A.S.; Suh, Y.S.; Kazmi, R. Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys. Int. J. Plasticity 2004, 20, 2233–2248. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Yapici, G.G. Workability characteristics and mechanical behavior modeling of severely deformed pure titanium at high temperatures. Mater. Des. 2014, 53, 749–757. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Yapici, G.G. Hot Deformation Behavior of Ultra-fine Grained Pure Ti. Adv. Mater. Res. 2014, 829, 10–14. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Yapici, G.G. Elevated temperature mechanical behavior of severely deformed pure titanium. J. Mater. Eng. Perform. 2014, 23, 1834–1844. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Purcek, G.; Yapici, G.G.; Karaman, I.; Maier, H.J. Effect of commercial purity levels on the mechanical properties of ultrafine-grained titanium. Mater. Sci. Eng. A 2011, 528, 2303–2308. [Google Scholar] [CrossRef]

- Li, L.X.; Peng, D.S.; Liu, J.A.; Liu, Z.Q. An experiment study of the lubrication behavior of graphite in hot compression tests of Ti-6Al-4V alloy. J. Mater. Process. Technol. 2001, 112, 1–5. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, Q.F.; Xia, Y.C.; Li, L.T. A phenomenological constitutive model for high temperature flow stress prediction of Al-Cu-Mg alloy. Mater. Sci. Eng. A 2012, 534, 654–662. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sajadifar, S.V.; Yapici, G.G. High Temperature Flow Response Modeling of Ultra-Fine Grained Titanium. Metals 2015, 5, 1315-1327. https://doi.org/10.3390/met5031315

Sajadifar SV, Yapici GG. High Temperature Flow Response Modeling of Ultra-Fine Grained Titanium. Metals. 2015; 5(3):1315-1327. https://doi.org/10.3390/met5031315

Chicago/Turabian StyleSajadifar, Seyed Vahid, and Guney Guven Yapici. 2015. "High Temperature Flow Response Modeling of Ultra-Fine Grained Titanium" Metals 5, no. 3: 1315-1327. https://doi.org/10.3390/met5031315