Effect of Milling Time and the Consolidation Process on the Properties of Al Matrix Composites Reinforced with Fe-Based Glassy Particles

Abstract

:1. Introduction

2. Experimental Section

2.1. Raw Materials

2.2. Mechanical Milling

2.3. Consolidation

2.4. Characterization of the Powders and Consolidated Samples

3. Results and Discussion

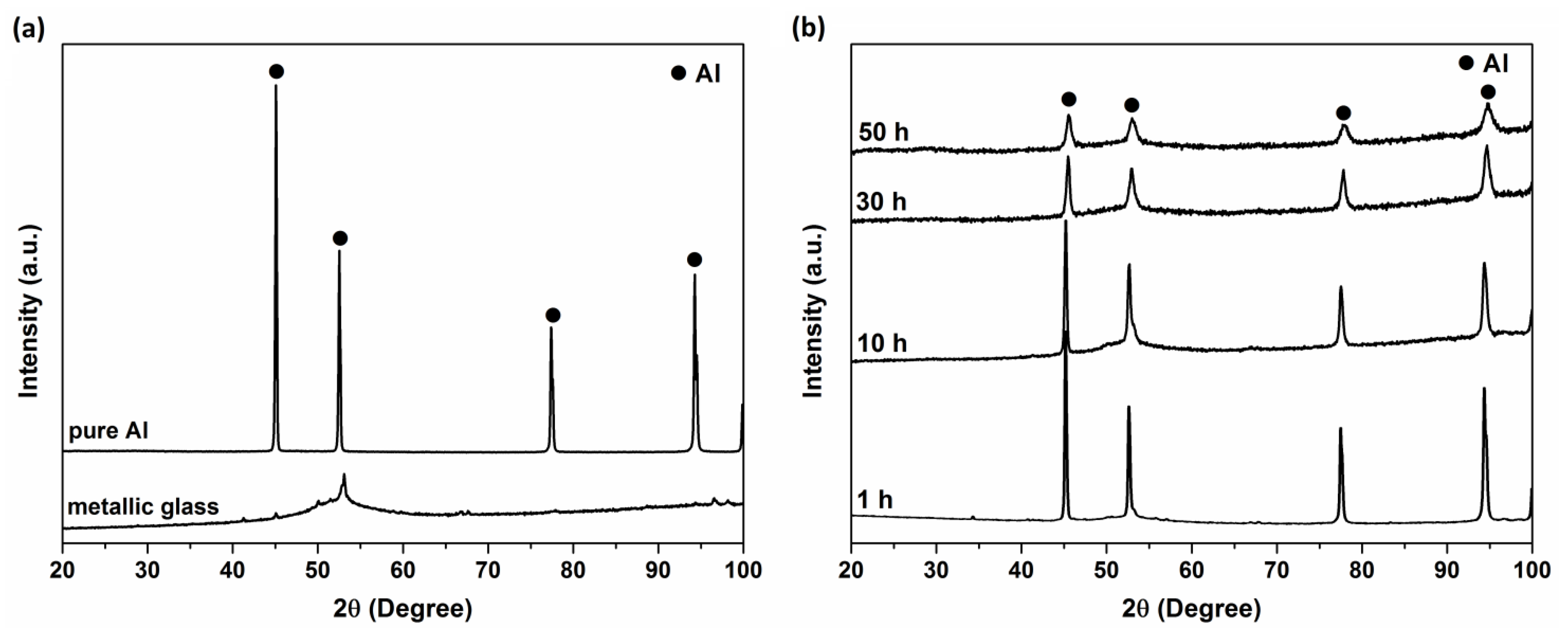

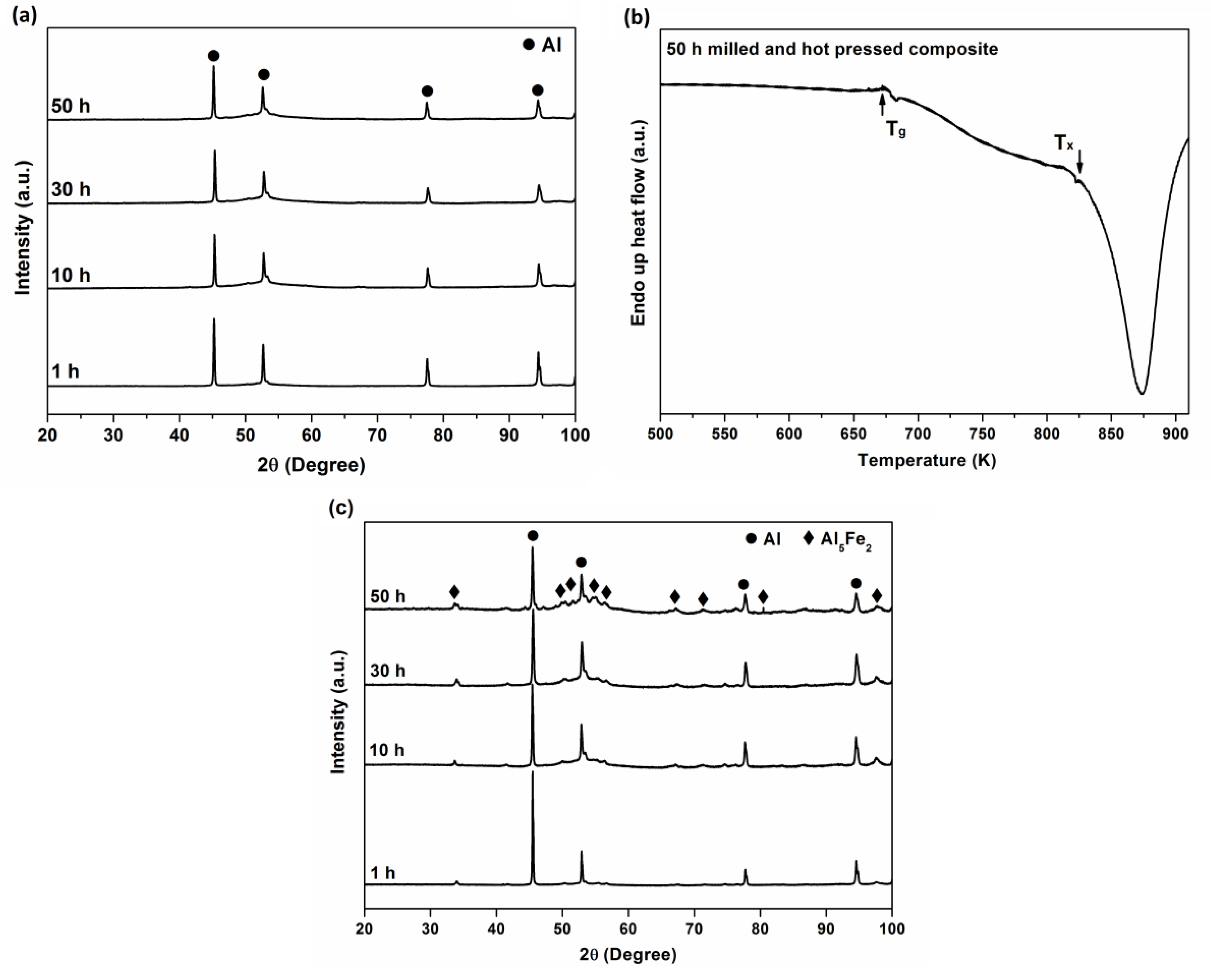

3.1. Processing and Characterization of the Composite Powders

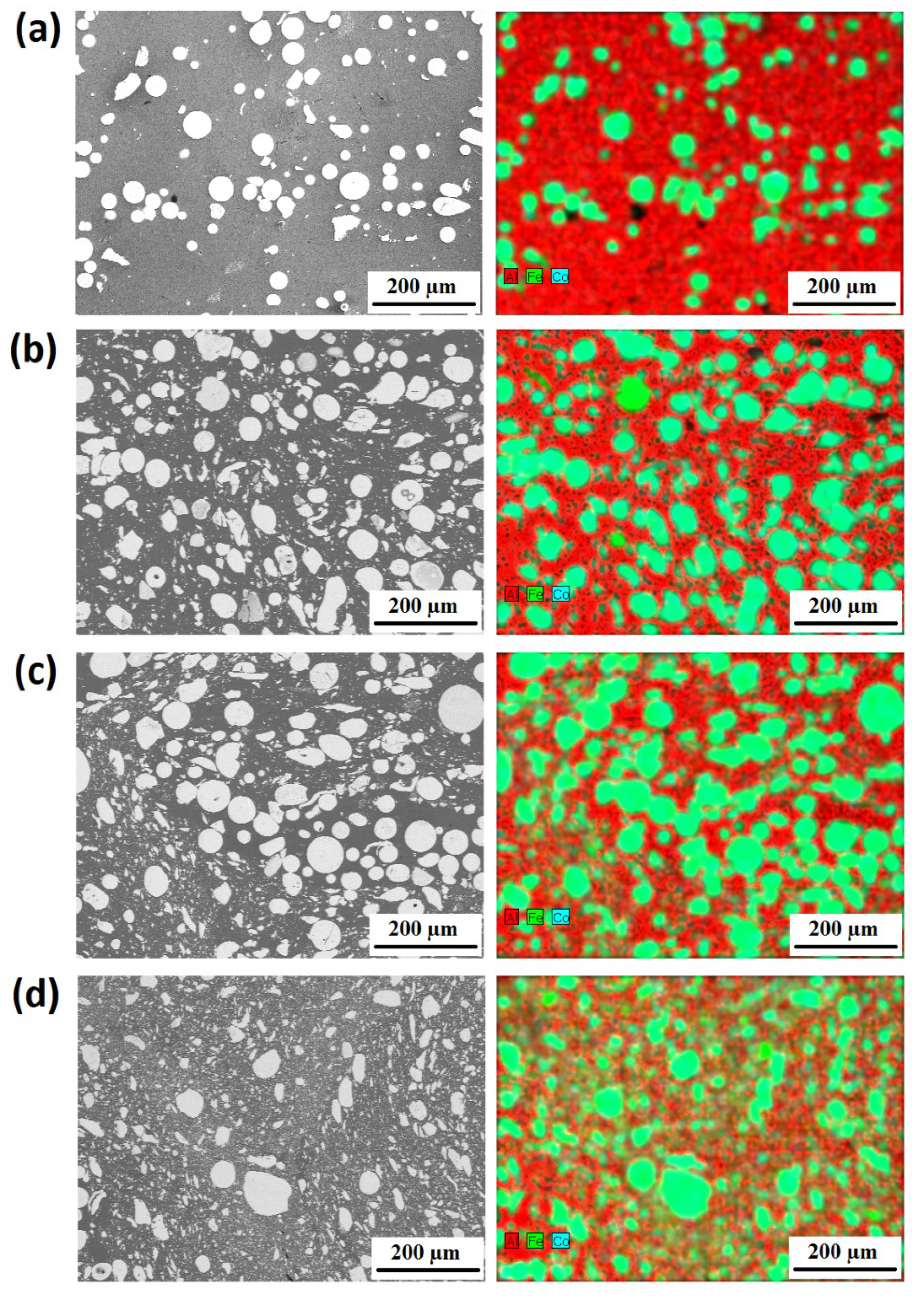

3.2. Characterization of the Consolidated Samples

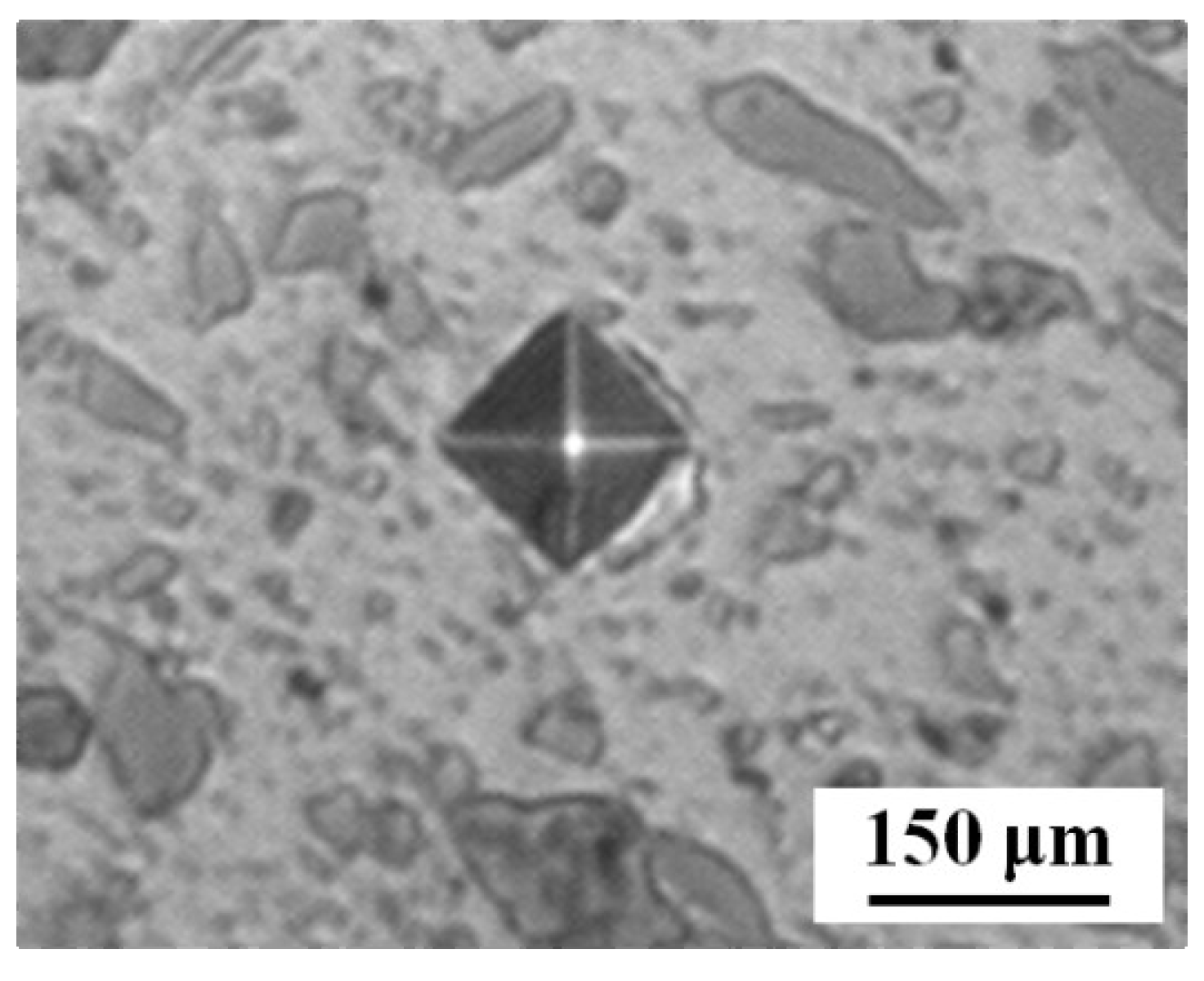

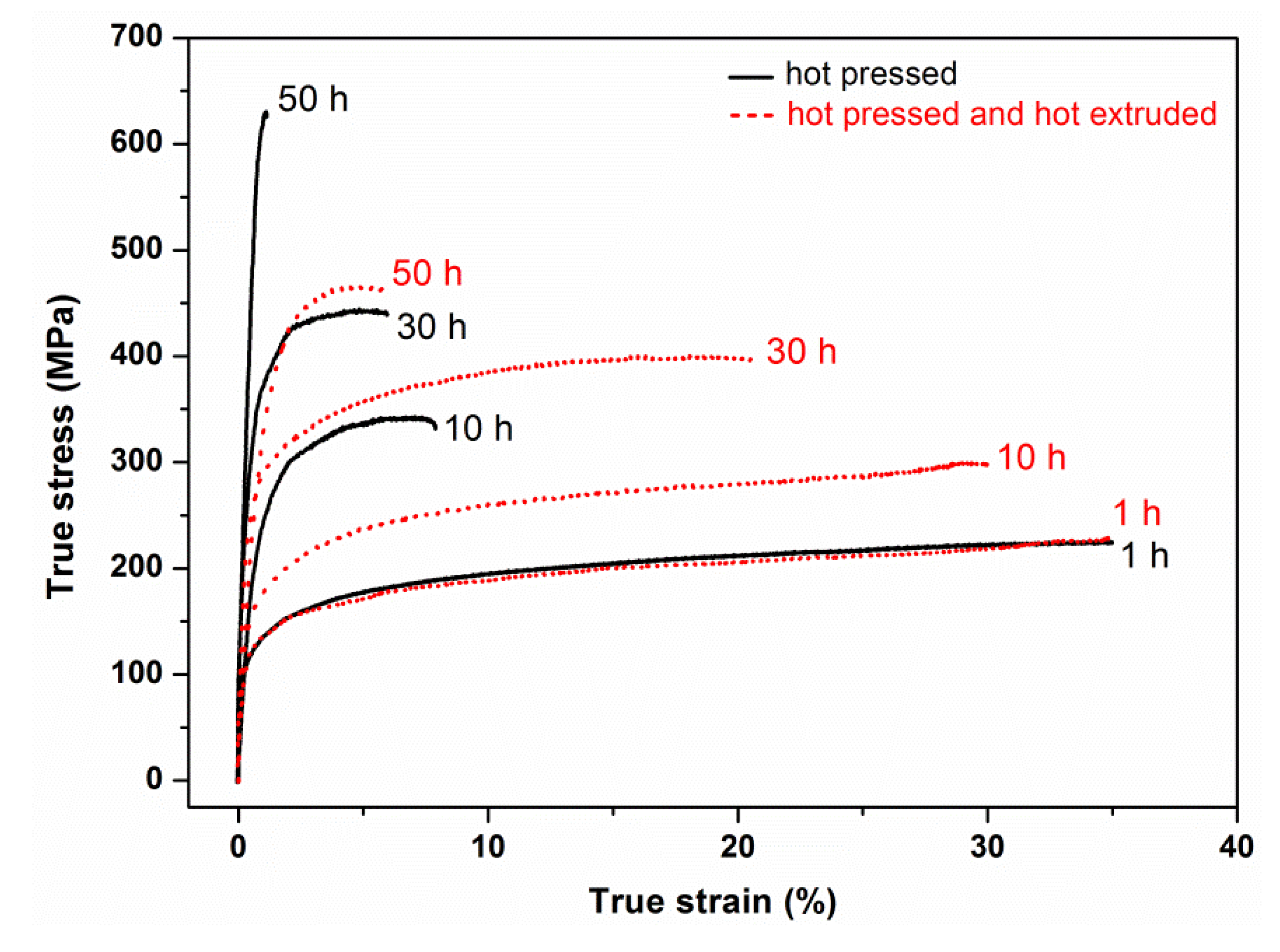

3.3. Mechanical Properties of the Consolidated Samples

| Milling time (h) | Consolidation process | Yield Strength (MPa) | Ultimate Strength (MPa) | Strain at Fracture (%) | Vickers Microhardness (HV) |

|---|---|---|---|---|---|

| 1 | HP | 125 | 220 | 35.0 | 51 ± 2 |

| HP + HE | 125 | 220 | 35.0 | 45 ±2 | |

| 10 | HP | 275 | 340 | 8.5 | 79 ± 5 |

| HP + HE | 180 | 295 | 30.5 | 60 ± 6 | |

| 30 | HP | 350 | 440 | 6.5 | 136 ± 5 |

| HP + HE | 285 | 390 | 21.0 | 101 ± 7 | |

| 50 | HP | 595 | 630 | 1.2 | 155 ± 7 |

| HP + HE | 340 | 470 | 6.5 | 144 ± 11 |

| Milling Time (h) | Average inter-particle distance (µm) | |

|---|---|---|

| Hot pressed composites | Hot pressed and hot extruded composites | |

| 1 | 21 ± 7 | 26 ± 7 |

| 10 | 8 ± 1 | 10 ± 2 |

| 30 | 6 ± 2 | 6 ± 1 |

| 50 | 3 ± 1 | 4 ± 1 |

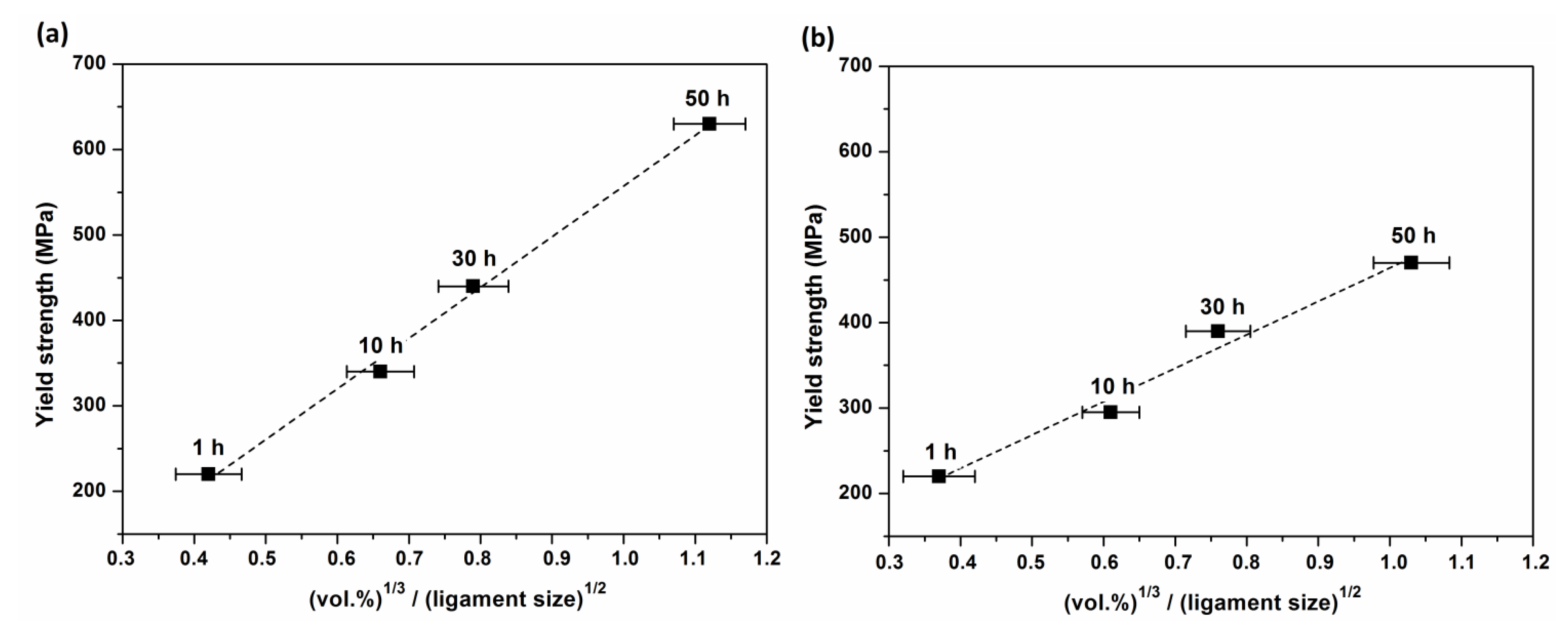

3.4. Evaluation of the Mechanical Behavior by Theoretical Predictions

4. Conclusions

- Milled and hot pressed composites revealed no formation of intermetallic compounds even after milling for 50 h, within the sensitivity of the XRD measurements. Only a small amount of the Al5Fe2 intermetallic compound was observed in the XRD patterns of all milled, hot pressed and hot extruded samples. DSC scans revealed that milling time changes the overall crystallization behavior of the composite powders.

- Ball milling resulted in the decrease of the grain sizes of the Al matrix, in the reduction of the particle size of the glassy reinforcements and in their homogeneous distribution in the Al matrix. This has a positive effect on the hardness and strength of the composites produced by both hot pressing and hot pressing followed by hot extrusion. With increasing the milling time from 1–50 h, the microhardness values of the hot pressed and hot extruded samples increase from 51 ± 2.26–155 ± 6.5 HV and from 45.1 ± 2.24–144 ± 10.5 HV, respectively. With increasing milling time from 1–50 h, the strength of the composites increases remarkably for both consolidation processes, showing a similar tendency as observed for the hardness.

- The ultimate strength of the hot pressed materials increases from 220 MPa for the composite milled for 1 h to 340, 440 and 630 MPa for the composites milled for 10, 30 and 50 h, respectively. The 50-h milled and hot pressed composite exhibits small plastic deformation of 1.2% and a maximum strength of 630 MPa, which is in agreement with the highest Vickers microhardness of 155 ± 6.5 HV among all composites.

- The use of hot extrusion after hot pressing slightly reduces both the strength and hardness of the composites, while raising the plastic deformation ranging between 35 and 6.5%. The 30-h milled, hot pressed and hot extruded composite gives a combination of high strength (390 MPa) and remarkable plasticity (21%).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Epple, M. Biomaterialien und Biomineralisation—Eine Einführung für Naturwissenschaftler, Mediziner und Ingenieure; Springer: Wiesbaden, Germany, 2003. [Google Scholar]

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Miracle, D.B.; Donaldson, S.L. Composites. In ASM Handbook; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Davis, J.R. Aluminum and Aluminum alloys. In ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites; Cambridge University Press: New York, NY, USA, 1993. [Google Scholar]

- Kainer, K.U. Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering; WILEY-VCH: Weinheim, Germany, 2006. [Google Scholar]

- Christman, T.; Needleman, A.; Suresh, S. An experimental and numerical study of deformation in metal-ceramic composites. Acta Metall. 1998, 37, 3029–3050. [Google Scholar] [CrossRef]

- Slipenyuk, A.; Kuprin, V.; Milman, Y.; Goncharuk, V.; Eckert, J. Properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ration. Acta Mater. 2006, 54, 157–166. [Google Scholar] [CrossRef]

- Song, M.S.; Zhang, M.X.; Zhang, S.G.; Huang, B.; Li, L.G. In situ fabrication of TiC particulates locally reinforced aluminum matrix composites by self-propagating reaction during casting. Mater. Sci. Eng. A 2008, 473, 166–171. [Google Scholar] [CrossRef]

- Wang, J.; Yi, D.; Su, X.; Yin, F.; Li, H. Properties of submicron AlN particulate reinforced aluminium matrix composite. Mater. Des. 2009, 30, 78–81. [Google Scholar] [CrossRef]

- Feng, C.F.; Froyen, L. In situ synthesis of Al2O3 and TiB2 particulate mixture reinforced aluminium matrix composites. Scr. Mater. 1997, 36, 467–473. [Google Scholar] [CrossRef]

- Arsenault, R.J. The strengthening of aluminum 6061 by fiber and platelet silicon carbide. Mater. Sci. Eng. A 1984, 64, 171–181. [Google Scholar] [CrossRef]

- Balci, Ö.; Ağaoğulları, D.; Gökçe, H.; Duman, İ.; Öveçoğlu, M.L. Influence of TiB2 particle size on the microstructure and properties of Al matrix composites prepared via mechanical alloying and pressureless sintering. J. Alloys Compd. 2013, 586, S78–S84. [Google Scholar]

- Ibrahim, I.A.; Mohammed, F.A.; Lavernia, E.J. Particulate reinforce metal matrix composites: Review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Sakaliyska, M.; Surreddi, K.B.; Eckert, J. Powder metallurgy of Al-based metal matrix composites reinforced with β-Al3Mg2 intermetallic particles: Analysis and modeling of mechanical properties. Acta Mater. 2009, 57, 4529–4538. [Google Scholar] [CrossRef]

- Inoue, A. Bulk amorphous and nanocrystalline alloys with high functional properties. Mater. Sci. Eng. A 2001, 304–306, 1–10. [Google Scholar]

- Ashby, M.F.; Greer, A.L. Metallic glasses as structural materials. Scr. Mater. 2006, 54, 321–326. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, L.C.; Zhang, W.Y.; Das, J.; Kim, K.B.; Eckert, J. Interfacial reaction during the fabrication of Ni60Nb40 metallic glass particles-reinforced Al based MMCs. Mater. Sci. Eng. A 2007, 444, 206–213. [Google Scholar] [CrossRef]

- Aljerf, M.; Georgarakis, K.; Louzguine-Luzgin, D.; le Moulec, A.; Inoue, A.; Yavari, A.R. Strong and light metal matrix composites with metallic glass particulate reinforcement. Mater. Sci. Eng. A 2012, 532, 325–330. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Aljerf, M.; Li, Y.; Braccini, M.; Yavari, A.R.; Inoue, A. Cu-based metallic glass particle additions to significantly improve overall compressive properties of an Al alloy. Compos. A 2010, 41, 1551–1557. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, J.H.; Park, J.S.; Kim, J.C.; Kim, W.T.; Kim, W.T.; Kim, D.H. Fabrication of Ni–Nb–Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process. Scr. Mater. 2004, 50, 1367–1371. [Google Scholar] [CrossRef]

- Yu, P.; Kim, K.B.; Das, J.; Baier, F.; Xu, W.; Eckert, J. Fabrication and mechanical properties of Ni–Nb metallic glass particle-reinforced Al-based metal matrix composite. Scr. Mater. 2006, 54, 1445–1450. [Google Scholar] [CrossRef]

- Scudino, S.; Surreddi, K.B.; Sager, S.; Sakaliyska, M.; Kim, J.S.; Löser, W.; Eckert, J. Production and mechanical properties of metallic glass-reinforced Al-based metal matrix composites. J. Mater. Sci. 2008, 43, 4518–4526. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Prashanth, K.G.; Bartusch, B.; Surredi, K.B.; Murty, B.S.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Kumar, S.; Scudino, S.; Murty, B.S.; Eckert, J. Fabrication and response of Al70Y16Ni10Co4 glass reinforced metal matrix composites. Mater. Manuf. Processes 2011, 26, 1242–1247. [Google Scholar] [CrossRef]

- Shen, T.D.; Schwarz, R.B. Bulk ferromagnetic glasses prepared by flux melting and water quenching. Appl. Phys. Lett. 1999, 75, 49–51. [Google Scholar] [CrossRef]

- Fujii, H.; Sun, Y.; Inada, K.; Ji, Y.; Yokoyama, Y.; Kimura, H.; Inoue, A. Fabrication of Fe-based metallic glass particle reinforced Al-based composite materials by Friction Stir processing. Mater. Trans. 2011, 52, 1634–1640. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Kaban, I.; Jovari, P.; Waske, A.; Stoica, M.; Bednarcik, J.; Beuneu, B.; Mattern, N.; Eckert, J. Atomic structure and magnetic properties of Fe–Nb–B metallic glasses. J. Alloys Compd. 2014, 586, S189–S193. [Google Scholar] [CrossRef]

- Zheng, R.; Yang, H.; Liu, T.; Ameyama, K.; Ma, C. Microstructure and mechanical properties of aluminum alloy matrix composites reinforced with Fe-based metallic glass particles. Mater. Des. 2014, 53, 512–518. [Google Scholar] [CrossRef]

- Murty, B.S.; Ranganathan, S. Novel materials synthesis by mechanical alloying/milling. Int. Mater. Rev. 1998, 43, 101–141. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Harrigan, W.C., Jr. Commercial processing of metal matrix composites. Mater. Sci. Eng. A 1998, 244, 75–79. [Google Scholar] [CrossRef]

- Surreddi, K.B.; Scudino, S.; Sakaliyska, M.; Prashanth, K.G.; Sordelet, D.J.; Eckert, J. Crystallization behavior and consolidation of gas-atomized Al84Gd6Ni7Co3 glassy powder. J. Alloys Compd. 2010, 491, 137–142. [Google Scholar] [CrossRef]

- Kim, J.Y.; Scudino, S.; Kühn, U.; Kim, B.S.; Lee, M.H.; Eckert, J. Production and characterization of Brass-matrix composites reinforced with Ni59Zr20Ti16Si2Sn3 glassy particles. Metals 2012, 2, 79–94. [Google Scholar] [CrossRef]

- German, R.M. Sintering Theory and Practice; Wiley-Interscience: Weinheim, Germany, 1996. [Google Scholar]

- Prashanth, K.G.; Murty, B.S. Production, kinetic study and properties of Fe-based glass and its composites. Mat. Manuf. Processes 2010, 25, 592–597. [Google Scholar] [CrossRef]

- Keryvin, V.; Hoang, V.H.; Shen, J. Hardness, toughness, brittleness and cracking systems in an iron-based bulk metallic glass by indentation. Intermetallics 2009, 17, 211–217. [Google Scholar] [CrossRef]

- San Marchi, C.; Cao, F.; Kouzeli, M.; Mortensen, A. Quasistatic and dynamic compression of aluminum-oxide particle reinforced pure aluminum. Mater. Sci. Eng. A 2002, 337, 202–211. [Google Scholar] [CrossRef]

- Gurland, J. The fracture strength of sintered tungsten carbide-cobalt alloys in relation to composition and particle spacing. Trans. Metall. Soc. AMIE 1963, 227, 1146–1149. [Google Scholar]

- Chawla, K.K. Composite Materials: Science and Engineering; Springer-Verlag: New York, NY, USA, 1987. [Google Scholar]

- Kim, H.S. On the rule of mixtures for the hardness of particle reinforced composites. Mater. Sci. Eng. A 2000, 289, 30–33. [Google Scholar] [CrossRef]

- Hirth, J.P. Physical Metallurgy; Cahn, R.W., Haasen, P., Eds.; North-Holland: Amstdam, The Netherlands, 1996. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balcı, Ö.; Prashanth, K.G.; Scudino, S.; Ağaoğulları, D.; Duman, İ.; Öveçoğlu, M.L.; Uhlenwinkel, V.; Eckert, J. Effect of Milling Time and the Consolidation Process on the Properties of Al Matrix Composites Reinforced with Fe-Based Glassy Particles. Metals 2015, 5, 669-685. https://doi.org/10.3390/met5020669

Balcı Ö, Prashanth KG, Scudino S, Ağaoğulları D, Duman İ, Öveçoğlu ML, Uhlenwinkel V, Eckert J. Effect of Milling Time and the Consolidation Process on the Properties of Al Matrix Composites Reinforced with Fe-Based Glassy Particles. Metals. 2015; 5(2):669-685. https://doi.org/10.3390/met5020669

Chicago/Turabian StyleBalcı, Özge, Konda Gokuldoss Prashanth, Sergio Scudino, Duygu Ağaoğulları, İsmail Duman, M. Lütfi Öveçoğlu, Volker Uhlenwinkel, and Jürgen Eckert. 2015. "Effect of Milling Time and the Consolidation Process on the Properties of Al Matrix Composites Reinforced with Fe-Based Glassy Particles" Metals 5, no. 2: 669-685. https://doi.org/10.3390/met5020669