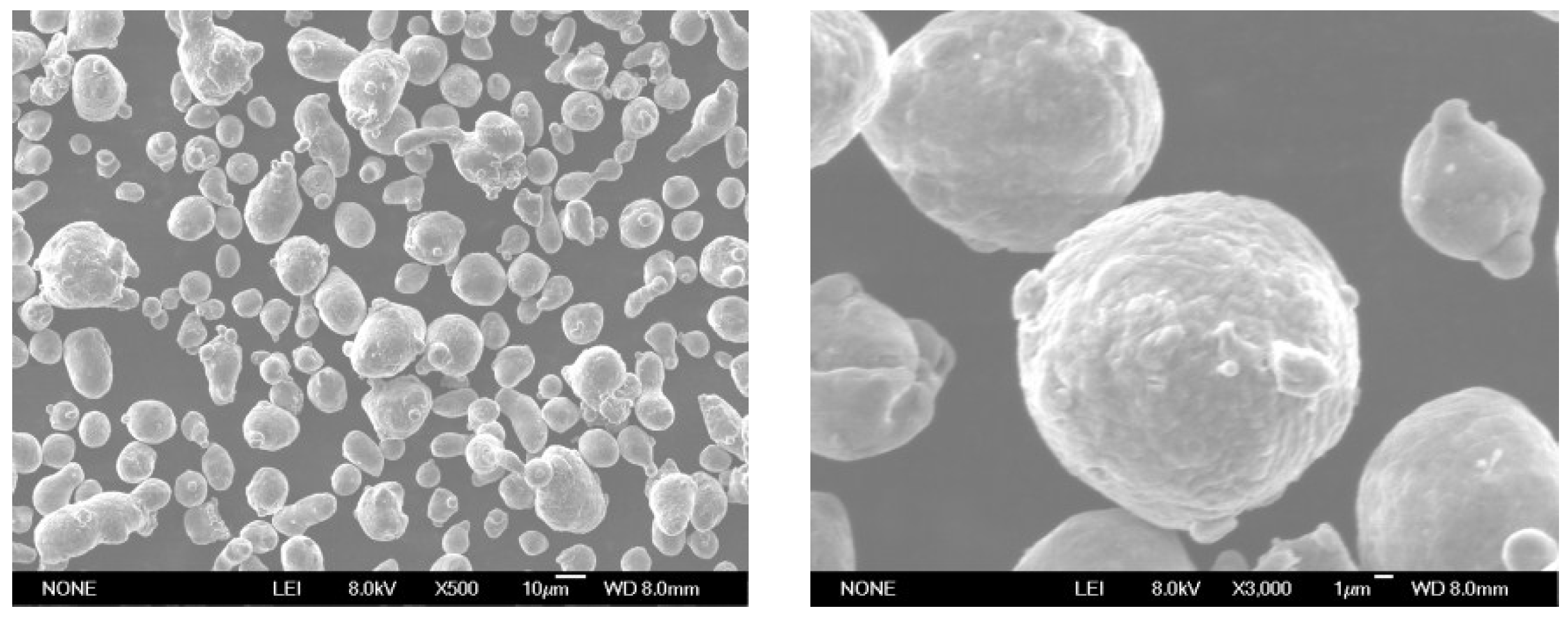

3.1. Microstructural Evolution of the Alloy Powders during Partial Remelting

Figure 3 presents the microstructures of the alloy powders heated at 635 °C for different durations. It shows that the original microstructure of a powder consisted of fine α-Al grains and intergranular eutectics between the grains (shown by arrows in

Figure 3a). The difference between grain boundaries and grain interior within powder is also found in 7075 Al powder [

16,

17]. The amount of the eutectics obviously decreases during the heating from 0 min to 1 min (comparing

Figure 3a,b). The original powders (including many fine α grains) become compact particles without grain boundaries (one powder only contains one grain). Simultaneously, some white particles and globular holes appear (

Figure 3b).

Figure 3.

Micrographs of the alloy powders heated at 635 °C for different durations and then water-quenched. (a) 0 min; (b) 1 min; (c) 2 min; (d) 3 min; (e) 10 min; (f) 30 min.

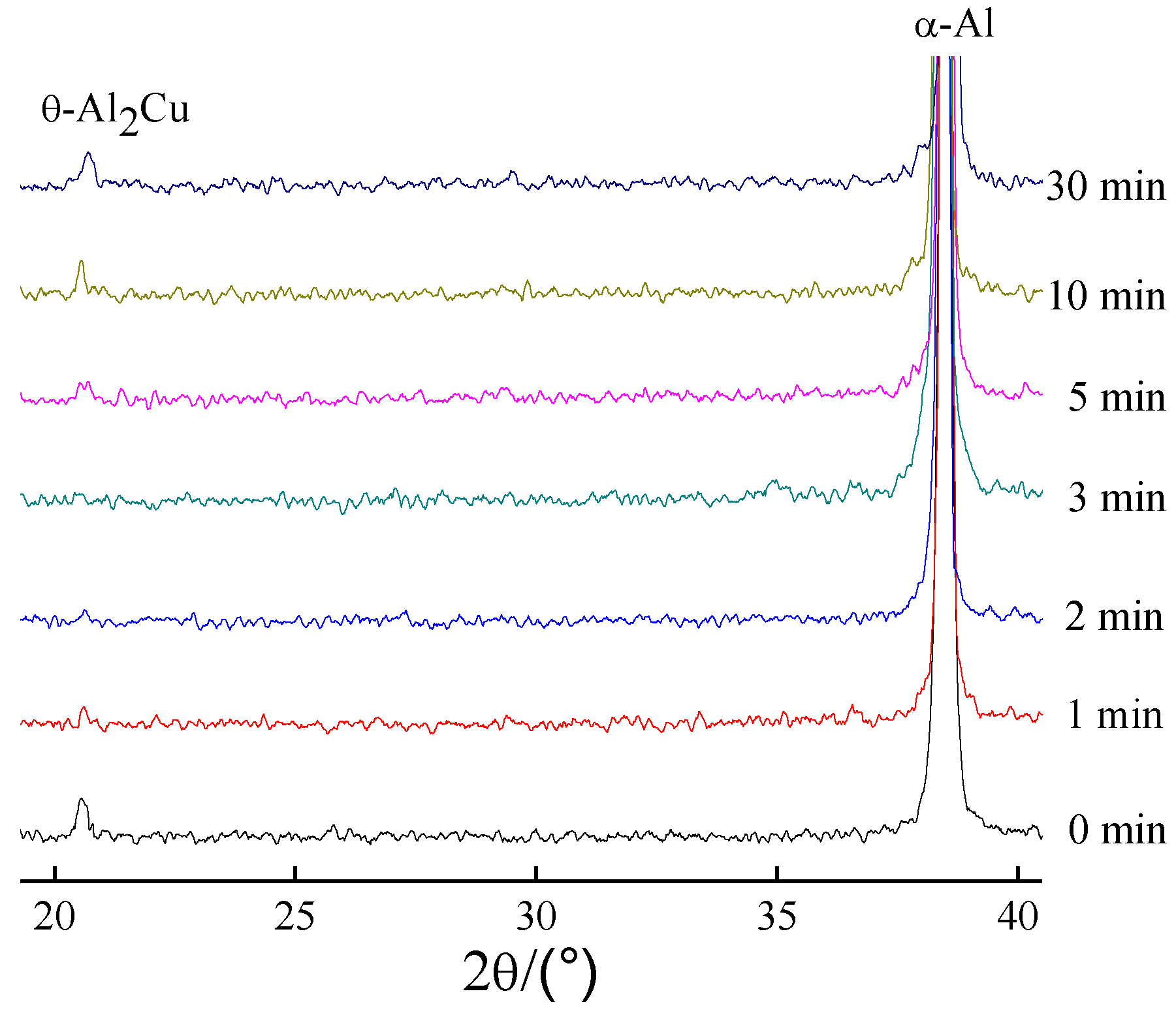

The Al-4Cu-1.3Mg (wt%) alloy is consisted three phases—α-Al, θ-CuAl

2, and S-Al

2CuMg [

18]. However, because the S phase within this Al

p is very small, the XRD can barely detect it (

Figure 4). Therefore, it can be deemed that the eutectics contain an θ phase and α-Al phase in this paper. According to the binary Al-Cu phase diagram [

19], the solubility of Cu in the primary α-Al phase increases and the binary Al-4Cu will experience a single α-Al phase interval (only considering the two main elements, Al and Cu) during reheating. So the eutectics should dissolve towards the primary α phase as the temperature rises, resulting in the decrease of the eutectic phases. This phenomenon is also found in other as-casting materials [

20,

21]. Most of the eutectics between the grains have dissolved or even disappeared because the eutectic size in the interdendritic zones is smaller. Based on this standpoint, it can be supposed that the disappearance of the interdendritic eutectics must result in the disappearance of grain boundaries, and then result in the coarsening of the fine α-Al grains through mergence. The original powders change into compact particles without grain boundaries. However, some small particles also appear when heated for 1 min (marked by the A arrows in

Figure 3b). It can be expected that the temperature rise in the powders should be very fast and the temperature will reach and exceed the eutectic reaction temperature in a short time. That is, there is not enough time for the complete dissolution of eutectics. Then the residual interdendritic eutectics melt and become a liquid phase. From the spherical morphology of the white particles in

Figure 3b, they should be liquid pools. The spherical liquid pools within the primary solid phase are also found in AZ91HP magnesium composites produced by the rotating cylinder method [

22]. However, some holes inside the powders are also liquid phase due to their etching during the stage of preparing metallographic samples (marked by B in

Figure 3b). Although the eutectics have not completely dissolved when heated for 1 min, the grain boundaries have already disappeared. Thus, grain coarsening is the main phenomenon during the period 0–1 min.

Figure 4.

XRD spectrum of the 2024 Aluminum alloy.

As the reheating increases from 1 min to 10 min, it can be found that the liquid phase amount within the particles decreases and that the size increases (comparing

Figure 3b,e). It can be expected that the solid/liquid interfacial energy within the powders should be very high because of the large solid/liquid interfacial area (

Figure 3b). To decrease the interfacial energy, the liquid pools migrate to the particles’ edges, as seen in

Figure 3d,e. The liquid pools also coarsen through mergence (comparing

Figure 3c,d). Simultaneously, the liquid phase should be rich in solutes (such as Cu) and some liquid phase dissolves towards the surrounding α Al phase due to the increase of the Cu solubility in the α phase with the rise in heating temperature. The above reasons result in the reduction of the liquid pool’s amount and an increase of the liquid pool’s size (

Figure 3e). In addition, the liquid amount around the particles obviously increases as the liquid pools within the particles decrease, and a continuous liquid layer forms around the particles when heated for 10 min (marked by C in

Figure 3e). The reason is that the primary particles (the original powders) partially melt, driven by the requirement for increasing liquid amount due to the temperature rise. Thus the main event occurring during the period of 1–10 min is the variations of the liquid pools and the formation of a continuous liquid layer on the primary particle surface.

When the heating time is further prolonged, the primary particles further melt due to the further rise of the temperature, which leads the liquid amount surrounding the primary particles to continuously increase (comparing

Figure 3e,f). More importantly, one powder evolves into one primary particle with a continuous liquid layer surface. Because the original alloy powders are quite spheroidal, the primary particles in the semisolid microstructure always remain spheroidal (

Figure 3). This phenomenon is different from the microstructural evolution of the as-cast materials, which generally needs to experience the spheroidization stage to obtain spheroidal primary particles [

20,

21]. Therefore, the main event occurring during the period of 10–30 min is the further increase of the liquid amount surrounding the primary particles.

Based on the above discussion, it can be concluded that the microstructural evolution of Alp can be divided into two stages: the initial rapid coarsening of the fine grains due to the dissolution of the eutectics (0–1 min) and the formation of a continuous liquid layer on the primary particle surface, ascribed to the partial melting of the primary particles (1–30 min). One spherical powder evolves into one spheroidal primary particle with a continuous liquid layer surface.

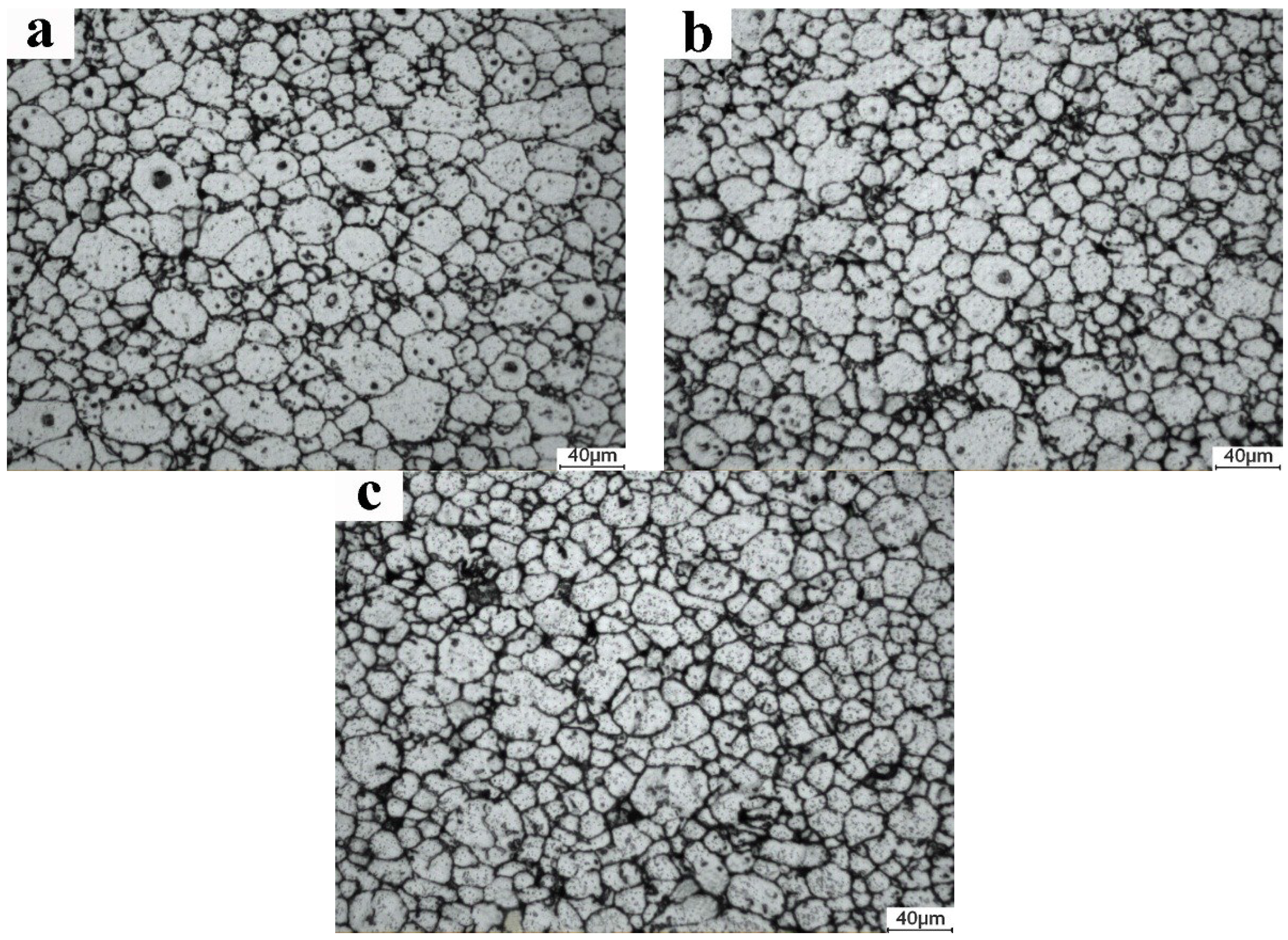

3.2. Microstructural Evolution of the Bulk Alloy during Partial Remelting

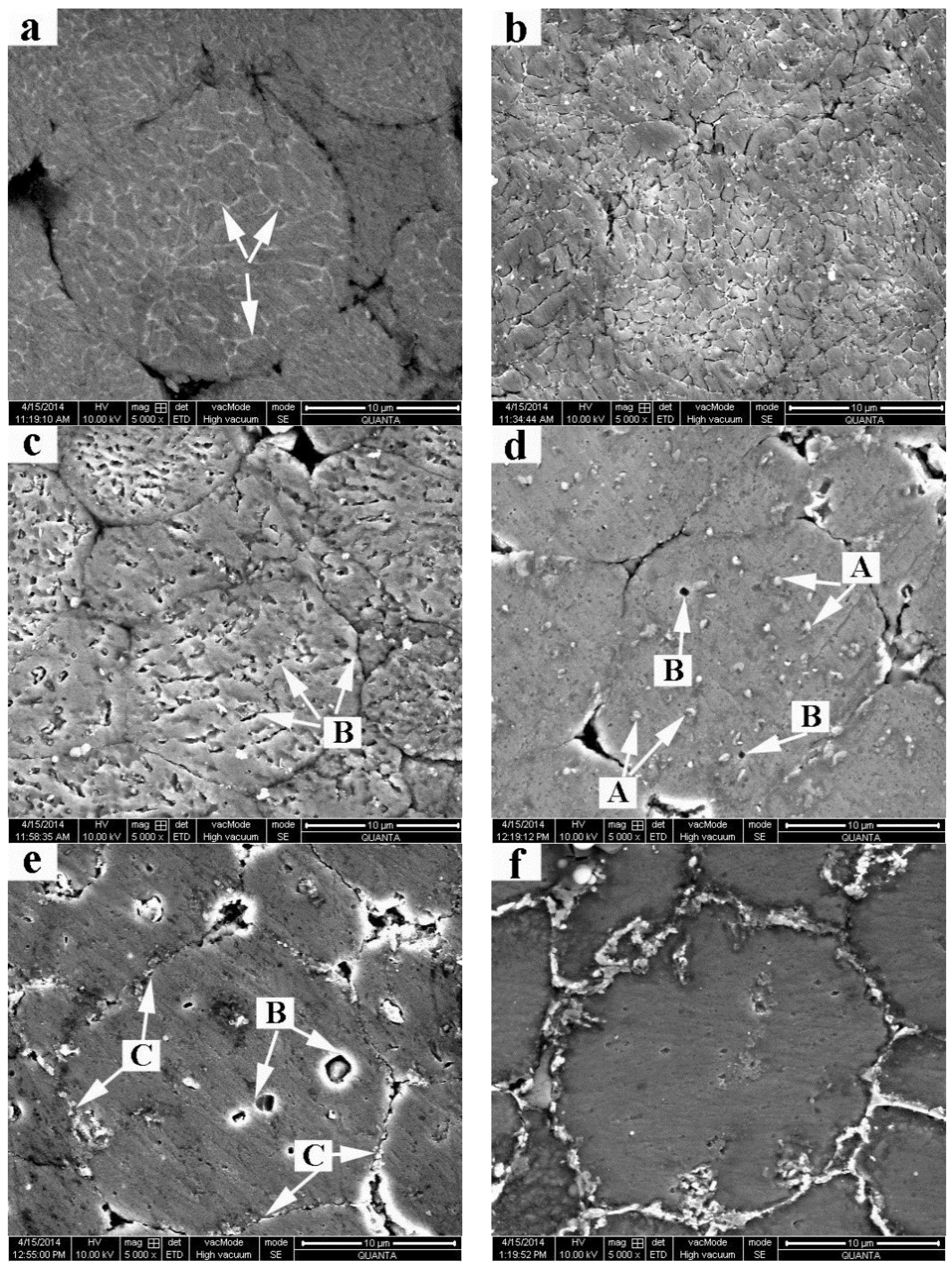

Figure 5 indicates the microstructures of the 2024 bulk alloy heated at the semisolid temperature of 635 °C for different durations. It shows that the eutectics (shown by arrows in

Figure 5a) gradually decrease and the grain boundaries within powders disappear during the heating period 0–3 min (

Figure 5a–d). As the reheating increases from 3 min to 10 min, the liquid amount around the particles obviously increases, accompanied by the decrease of the liquid pools within the particles (

Figure 5d–f). The above phenomena are basically consistent with the processes that the powders have experienced in this heating stage of 0–10 min.

For the same reasons as the powders, a continuous decrease in the eutectic amount and coarsening of the grains have occurred during the early heating stage 0–3 min (

Figure 5a–d). The liquid phase within the particles appears after being heated for 3 min (marked by A in

Figure 5d).

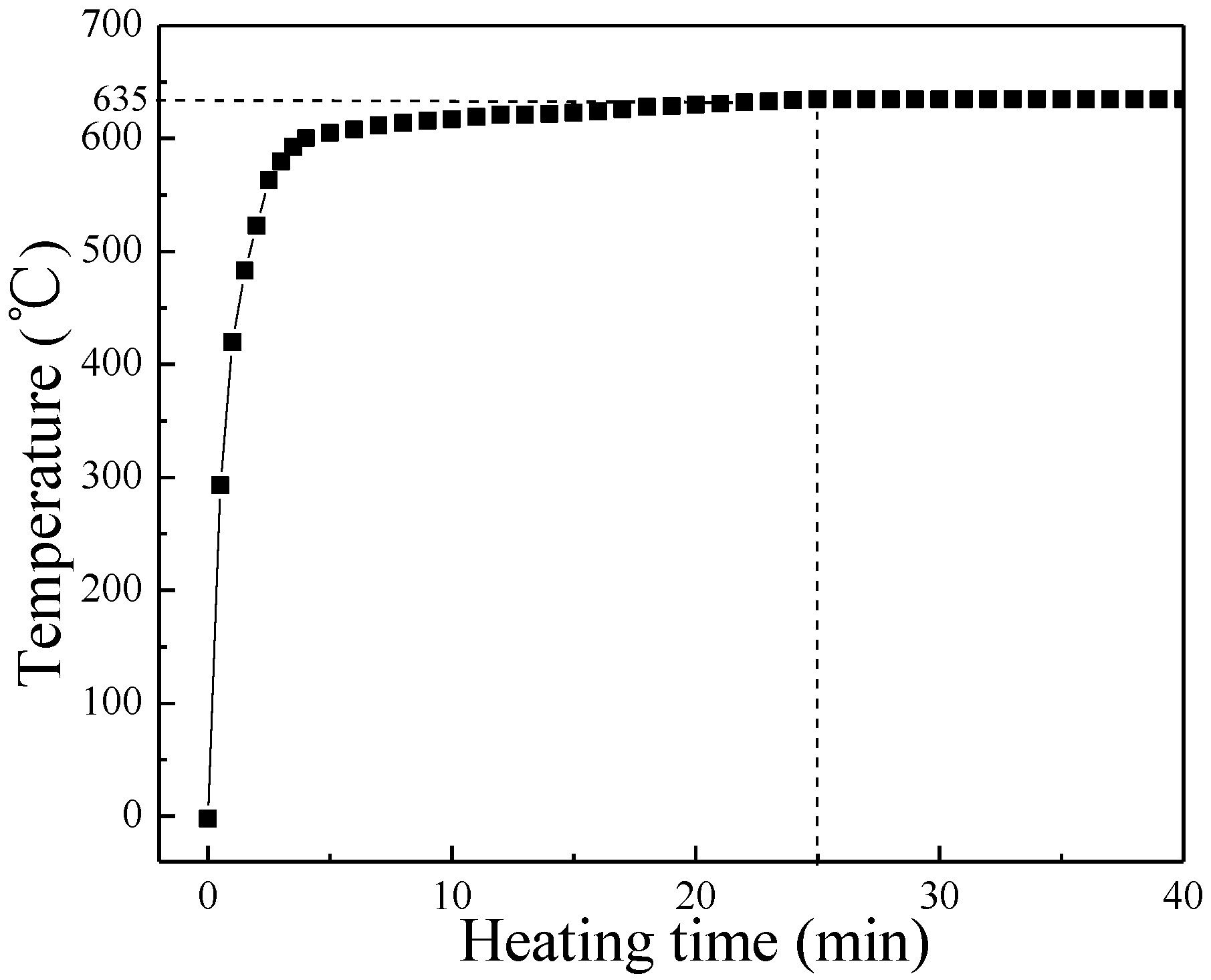

Figure 6 shows that the heating rate of the bulk alloy during the 0–3 min stage is rapid, so the eutectics have no enough time to completely dissolve into the primary α phase when the specimen’s temperature reaches the eutectic reaction temperature. The residual eutectic phases then melt to form liquid phase. However, some holes inside the particles also appear (marked by B in

Figure 5d). As discussed above, the holes are also the liquid phase. It is just for this reason that the arrows B in

Figure 5c and e represent the residual θ phase and liquid phase, respectively. The microstructure of the bulk alloy heated for 3 min—compact particles without grain boundaries—is similar to that of the powders heated for 1 min, but the liquid phase amount in the bulk alloy microstructure is obviously less than that of the powders (comparing

Figure 3b and

Figure 5d). The interdendritic eutectics only decrease when heated for 1 min (comparing

Figure 5a,b). The above phenomena should be attributed to the reason that the heating rate of the bulk alloy is relatively slower than that of the powders. Namely, the microstructural evolution rate of the bulk alloy lags behind that of the powders during the initial period of 0–3 min. Thus grain coarsening is the main phenomenon occurring in this period.

Figure 5.

Micrographs of the 2024 bulk alloy heated at 635 °C for different durations and then quenched. (a) 0 min; (b) 1 min; (c) 2 min; (d) 3 min; (e) 5 min; (f) 10 min.

As the heating time is further prolonged, the liquid phase gradually distributes between the neighboring particles as that within the particles decreases (

Figure 5d–f). As discussed above, the powders partially melt, driven by increasing liquid amount due to the temperature rise.

Figure 5e shows that some sites melt to form discontinuous liquid layers or small-sized liquid pools between the primary particles (marked by C in

Figure 5e). A continuous liquid layer forms around the primary particles when the particles further melt (

Figure 5f), which is similar to the phenomenon that the structure separation has completed in the as-casting materials during partial remelting [

20,

21]. The liquid pools within particles also generate dissolution towards the α phase, migration to the particles’ boundaries, and coalescence to decrease the solid/liquid interfacial energy (comparing

Figure 5d,f). Therefore, the main phenomenon occurring during the 3–10 min period is basically similar to that of the powders when heated for 1 min.

Figure 6.

Temperature variation in the specimen with heating time.

Figure 7 shows the microstructures of the 2024 bulk alloy heated at 635 °C for over 10 min. It can be seen that the microstructures always consist of large and small particles during the heating period 10–60 min. The neighboring particles are separated by black continuous eutectics. However, the amount of the small particles increases as that of the large particles decreases when heated for 20 min (comparing

Figure 7a,b). As the heating time is prolonged, it can be supposed that the liquid amount increases due to the temperature rise. The liquid phase solidifies into secondarily primary α-Al phase during quenching. However, the solidification rate of the liquid phase is very rapid during quenching, so the secondarily solidified particles are smaller than the primary α-Al particles anyhow. Thus it can be concluded that the relatively small particles in the quenched microstructures originate from the solidification of the liquid phase.

Figure 8 shows the full-liquid microstructure when heated at 710 °C for 30 min. It shows that this microstructure is all small particles and intergranular eutectics. The result of quantitative examination of

Figure 8 shows that the particle size is close to 5 μm. Therefore, the particles which are less than 5 μm are regarded as the liquid phase in this paper. Based on this standpoint,

Figure 7a clearly shows that the liquid phase (marked by circles) distributes between the particles.

Figure 7.

Micrographs of the 2024 bulk alloy heated at 635 °C for different durations and then quenched. (a) 10 min; (b) 20 min; (c) 30 min; (d) 60 min.

Figure 8.

Micrograph of the bulk alloy heated at 710 °C for 30 min and then quenched.

As shown in

Figure 7a–c, the liquid amount gradually increases through partial melting of the particles due to the temperature rise, and the primary particle size remains almost unchanged. Moreover, the shapes of the particles in the present microstructure are always spherical. The distance between the primary particles is small, and some of the neighboring particles are only separated by thin eutectics (

Figure 7a). Under this condition, the solid/liquid interfacial energy should be very high due to the large solid/liquid interfacial area. Thus, the particles should coarsen during the subsequent heating driving by decreasing the interfacial energy. However, the coarsening does not operate during the 10–30 min period. Alumina layers have already formed on the surfaces of the alloy powders [

23]. The great difference in the coefficient of thermal expansion between Aluminum and alumina will generate stress on the oxide shell during heating, leading to a dynamic oxide breakage and repair process if there is any oxygen in the atmosphere [

24]. Namely, the alumina on the surfaces of the alloy powders cannot disappear as the heating proceeds, and thus the healed or original oxide can hinder the merging of the neighboring particles (

Figure 7a–c). So it can be concluded that the low coarsening rate of the particles is due to the less active coalescence. In addition, because the as-received Al

p is spherical in shape with a particle size of 20 μm, and the coalescence of the particles which evolve from the original powders is impossible, the microstructure does not need to experience an additional spheroidization stage to obtain the spheroidal primary particles. Thus, it is not difficult to understand the present experimental results; the primary particles are always small and spheroidal. The main event occurring during the 10–30 min period is the further increase of the liquid amount.

Coarsening through mergence cannot be found during partial remelting (

Figure 5 and

Figure 7). This can be more clearly demonstrated by the fracture surfaces of the bulk alloy heated at 635 °C for different durations (

Figure 9). It shows that the plastic deformation of the powders occurs during cold pressing (shown by arrows in

Figure 9a).

Figure 9b shows that the powders are individual, which means that coalescence between neighboring powders is impossible during the initial heating stage of 0–3 min (

Figure 9a,b). The appearance of sintering necks demonstrates that transformation from mechanical bonding to good metallurgical bonding among the powders occurs (marked by arrows in

Figure 9b). This phenomenon is common in PM [

25]. However, the mergence between particles does not accompany microstructural evolution during the 3–30 min period (

Figure 9b–e). As discussed above, a continuous liquid layer on the primary particle surface gradually forms after being heated for 3 min, which can be better demonstrated by the fracture surfaces (marked by A in

Figure 9c–e). In short, coarsening through mergence is impossible during partial remelting.

Figure 9.

Fractographs of the bulk alloy heated at 635 °C for different durations and then quenched. (a) 0 min; (b) 3 min; (c) 5 min; (d) 10 min; (e) 30 min.

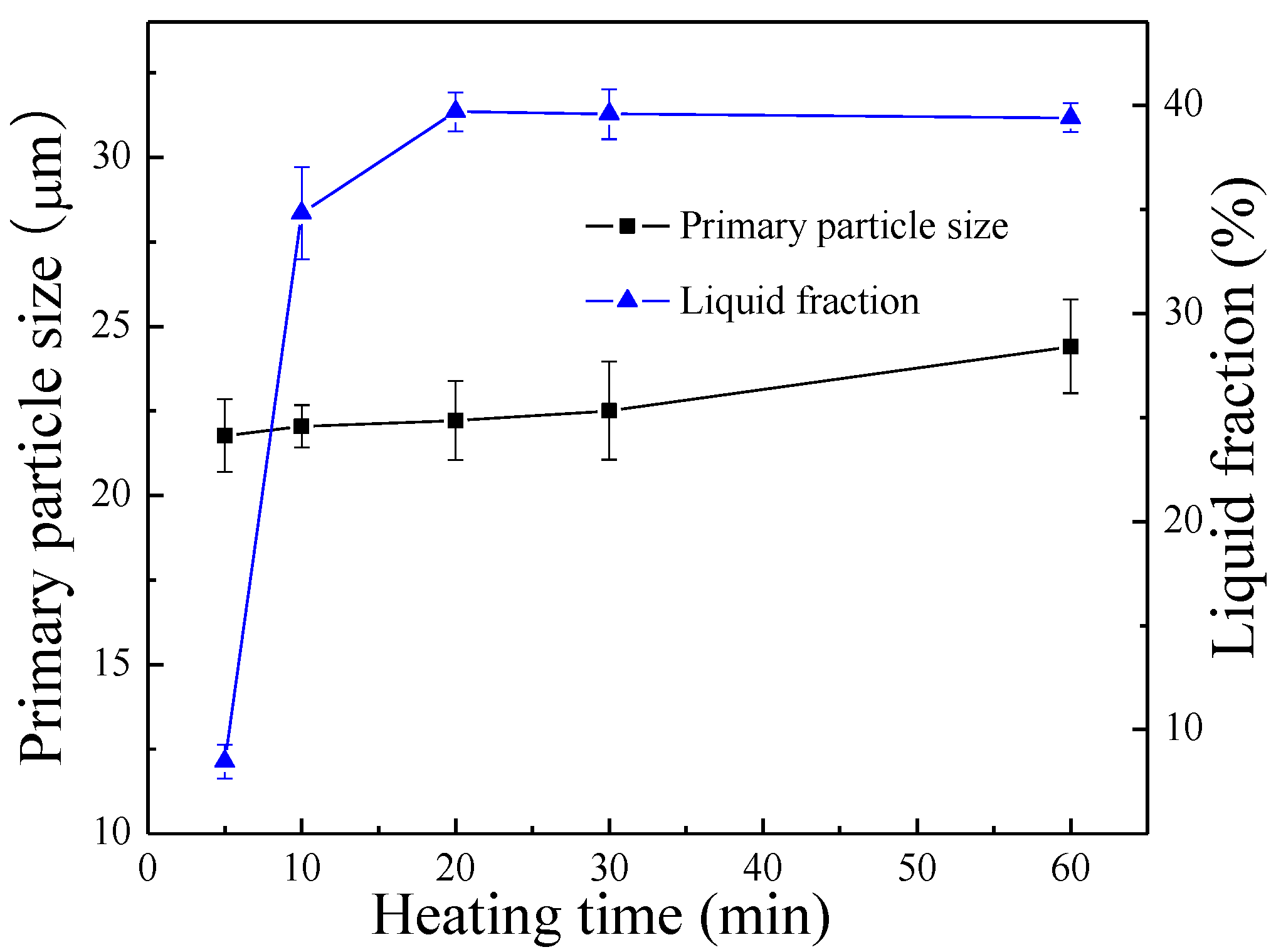

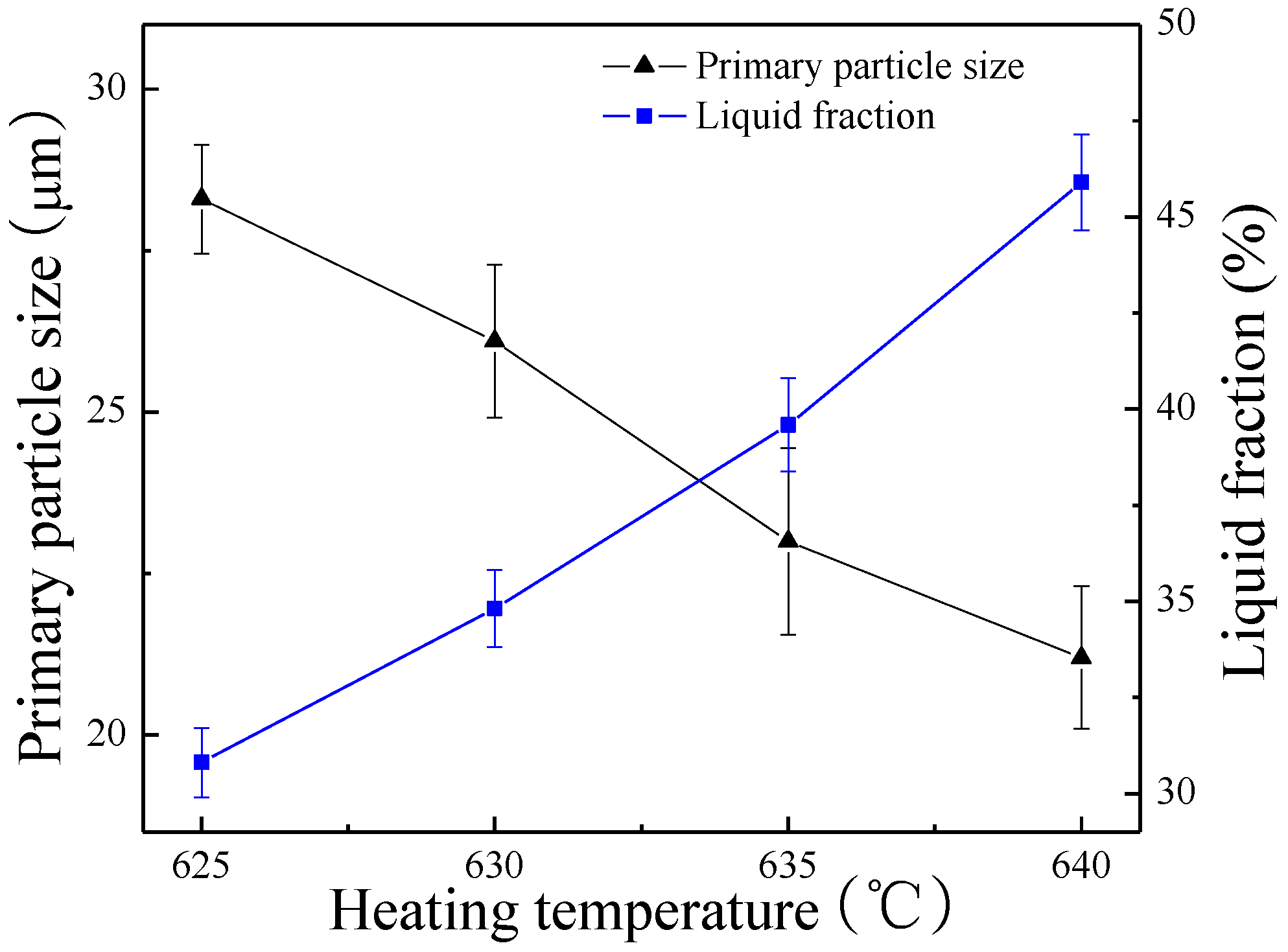

The liquid amount remains almost unchanged after being heated for 30 min (comparing

Figure 7c,d), which can be more obviously seen by the quantitative examinations shown in

Figure 10.

Figure 6 indicates that the specimen’s temperature reaches the final equilibrium temperature of 635 °C after being heated for 25 min, which implies that the system reaches its solid/liquid equilibrium state and the liquid amount is basically invariable after that. This phenomenon is consistent with metallographic analysis. The particle size slightly increases as the heating time is further prolonged (

Figure 10). Thus the main event occurring after heating for 30 min is the slight coarsening of the primary particles.

Figure 10.

Variations in the primary particle size and liquid fraction of the bulk alloy with heating time after being heated for 5 min at 635 °C.

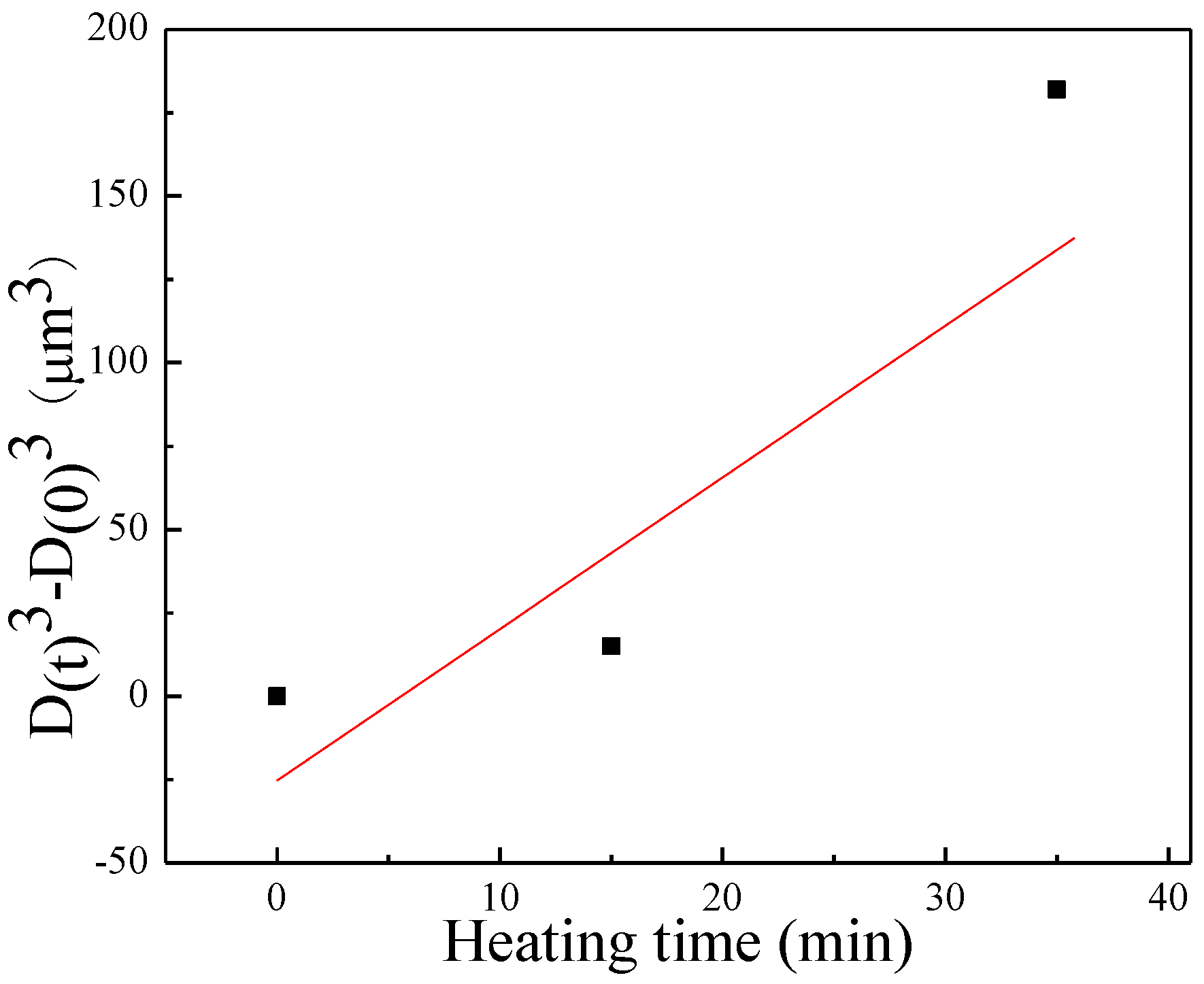

The coarsening mechanisms after being heated for 30 min should not be attributed to mergence. The particle size should sharply increase if coarsening through mergence operates. Thus the coarsening must be caused by another mechanism, Ostwald ripening. Ostwald ripening operates through the dissolution of small particles and the growth of large particles [

26]. That is to say, the particle coarsening is achieved through atom diffusion and the resulting coarsening rate should be milder than that from mergence. The variation of particle size with heating time should obey the formula

D(t)3 −

D(0)3 =

Kt, where

D(t) is the average particle size at time t,

D(0) is the initial particle size, and K is the coarsening rate constant [

26], if the coarsening results from Ostwald ripening. However,

Figure 11 indicates that the coarsening during the period from 25 to 60 min does not obey this regime. The alumina layer will hinder the diffusion ability of atoms, which should inhibit the Ostwald ripening. However, the oxide film can be effectively broken in some local zones due to the relative sliding and deformation of the powders during cold pressing, and local fresh contact surfaces between powders can be obtained [

27]. As the temperature in the specimen rises, these contact zones melt to form liquid paths. So the atom diffusion among the particles may be accelerated from these sites. According to this standpoint, slight coarsening results from Ostwald ripening. However, compared with other as-casting materials [

28], the coarsening rate of the primary particles after the semi-solid systems reach a solid/liquid equilibrium state is quite slow, even if the atoms’ diffusion ability through the local fresh paths among particles is enhanced to a certain degree. More importantly, it can be supposed that one powder in the as-pressed microstructure will basically evolve into one spheroidal particle in the semisolid microstructure. Thus the final coarsening after 30 min results from the impeditive Ostwald ripening.

Figure 11.

Cube of the primary particle size versus heating time, taking 25 min as starting time, t = 0.

Based on the above discussion, the microstructural evolution of the 2024 bulk alloy can be divided into three stages: the initial rapid coarsening of the fine grains due to the dissolution of eutectic θ phase (0–3 min), the formation of continuous liquid layer on the primary particle surface owing to the partial melting of the particles (3–30 min), and the final coarsening attributed to the influenced Ostwald ripening (30–60 min). The coarsening rate of the particles is so slow that one powder basically evolves into one spheroidal particle in the semisolid microstructure.