Sealing of Dry Particles with Grease-Filled Non-Contacting Sealing Systems

Abstract

:1. Introduction

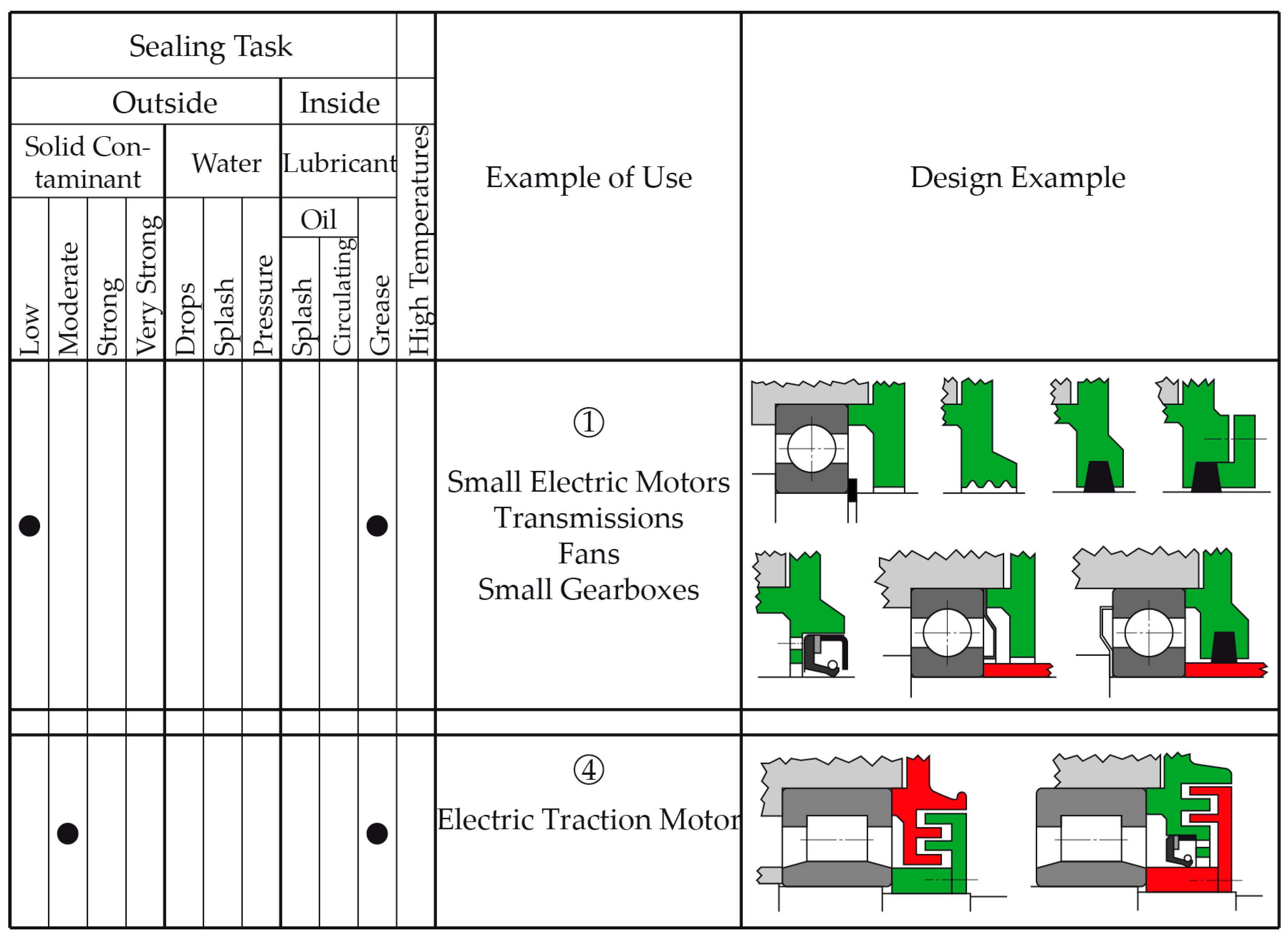

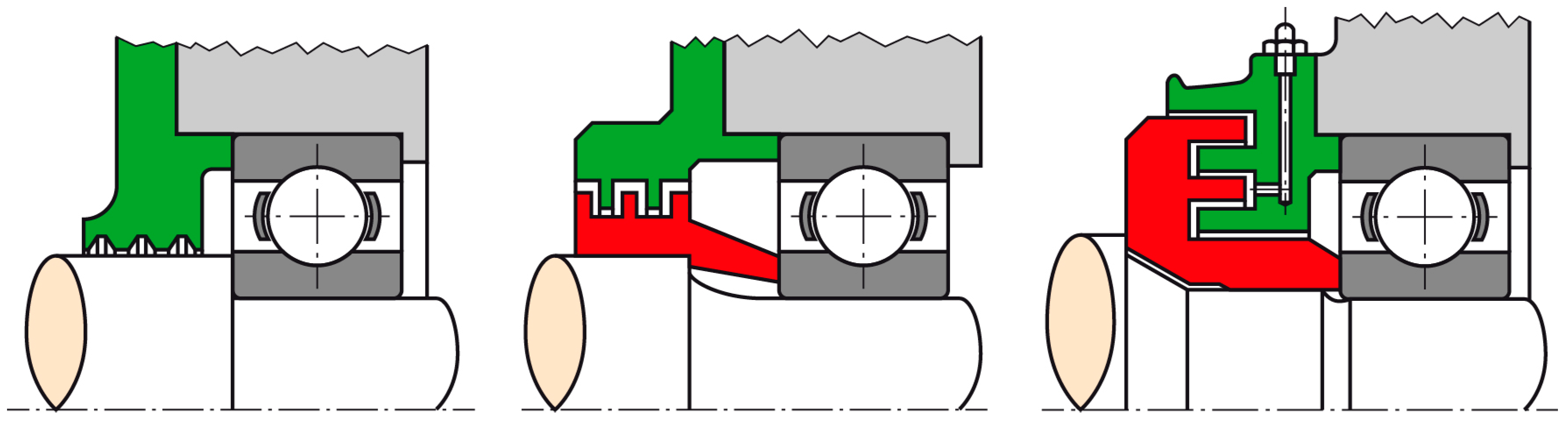

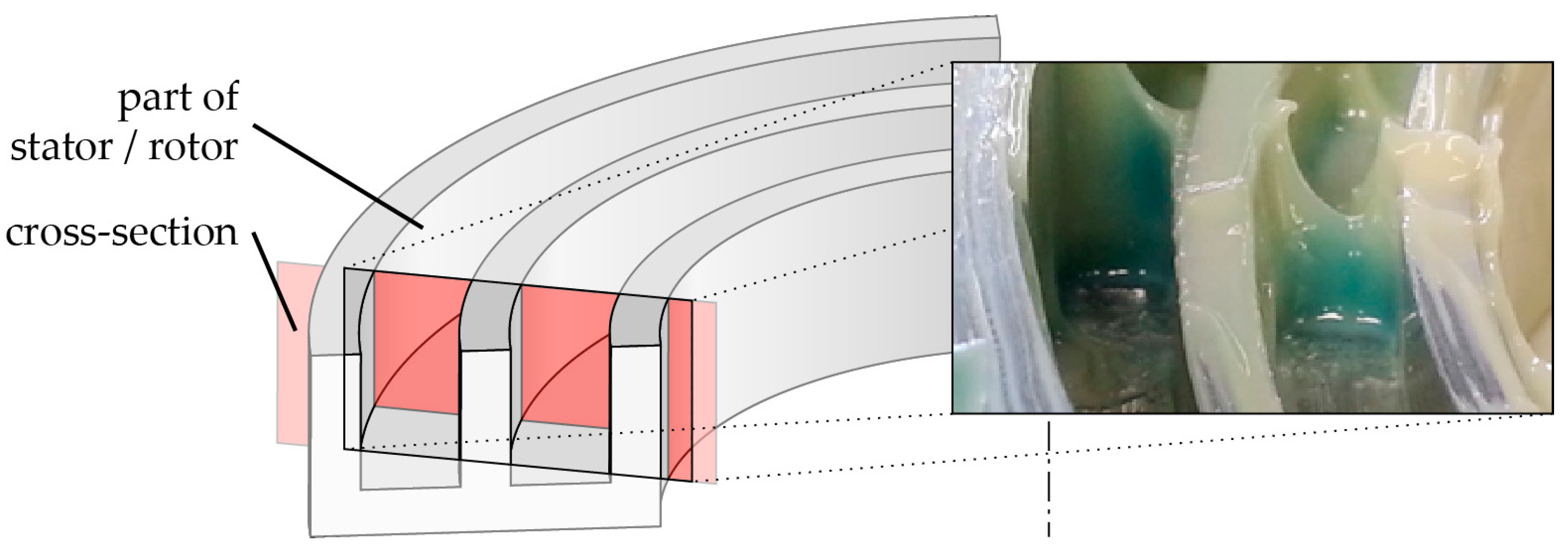

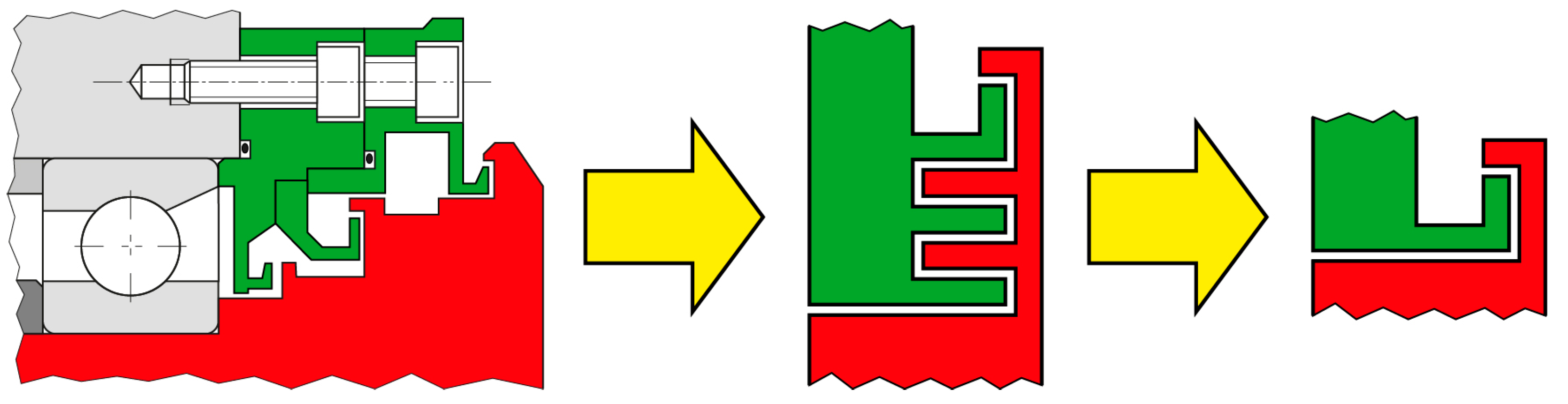

2. State of the Art

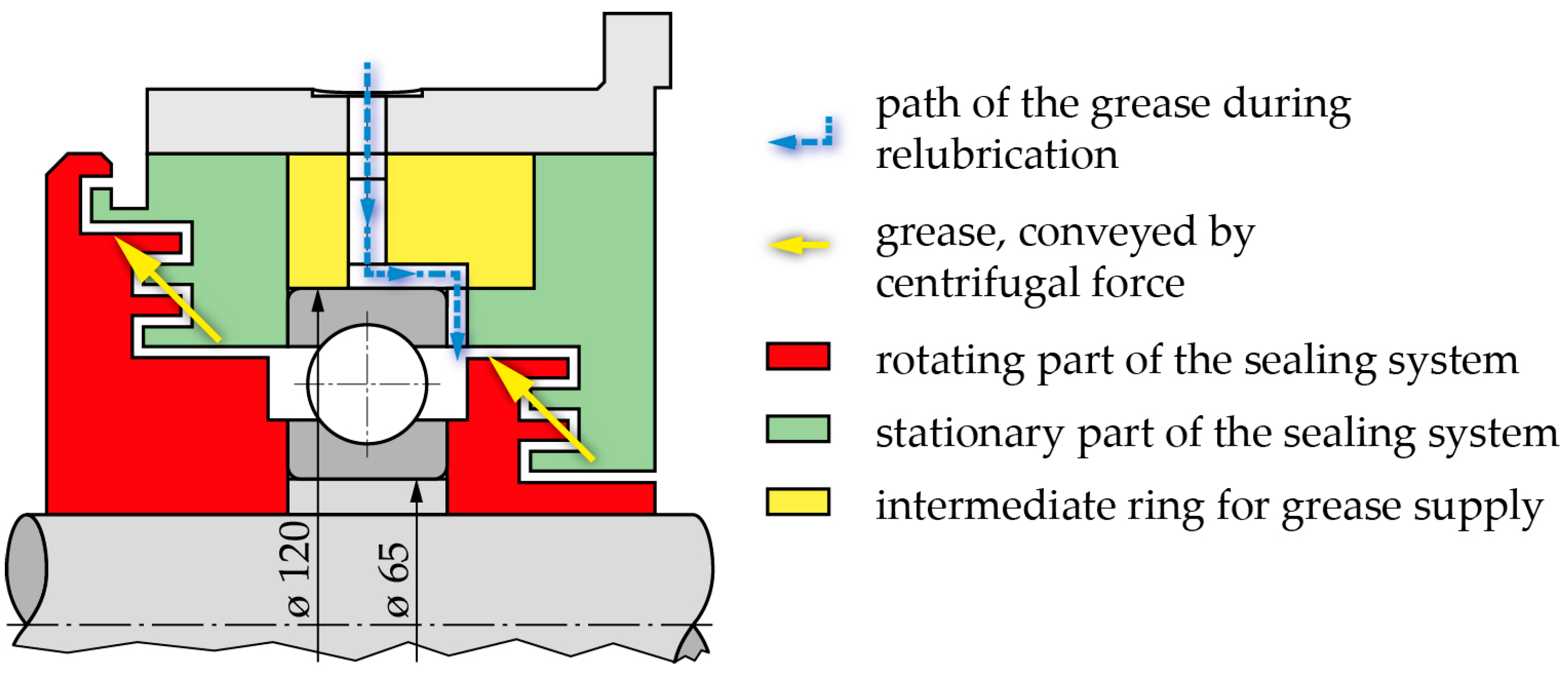

2.1. Design Examples of Grease-Filled Labyrinth Sealing Systems

2.2. Grease-Filled Labyrinth Sealing System to Seal against Particles

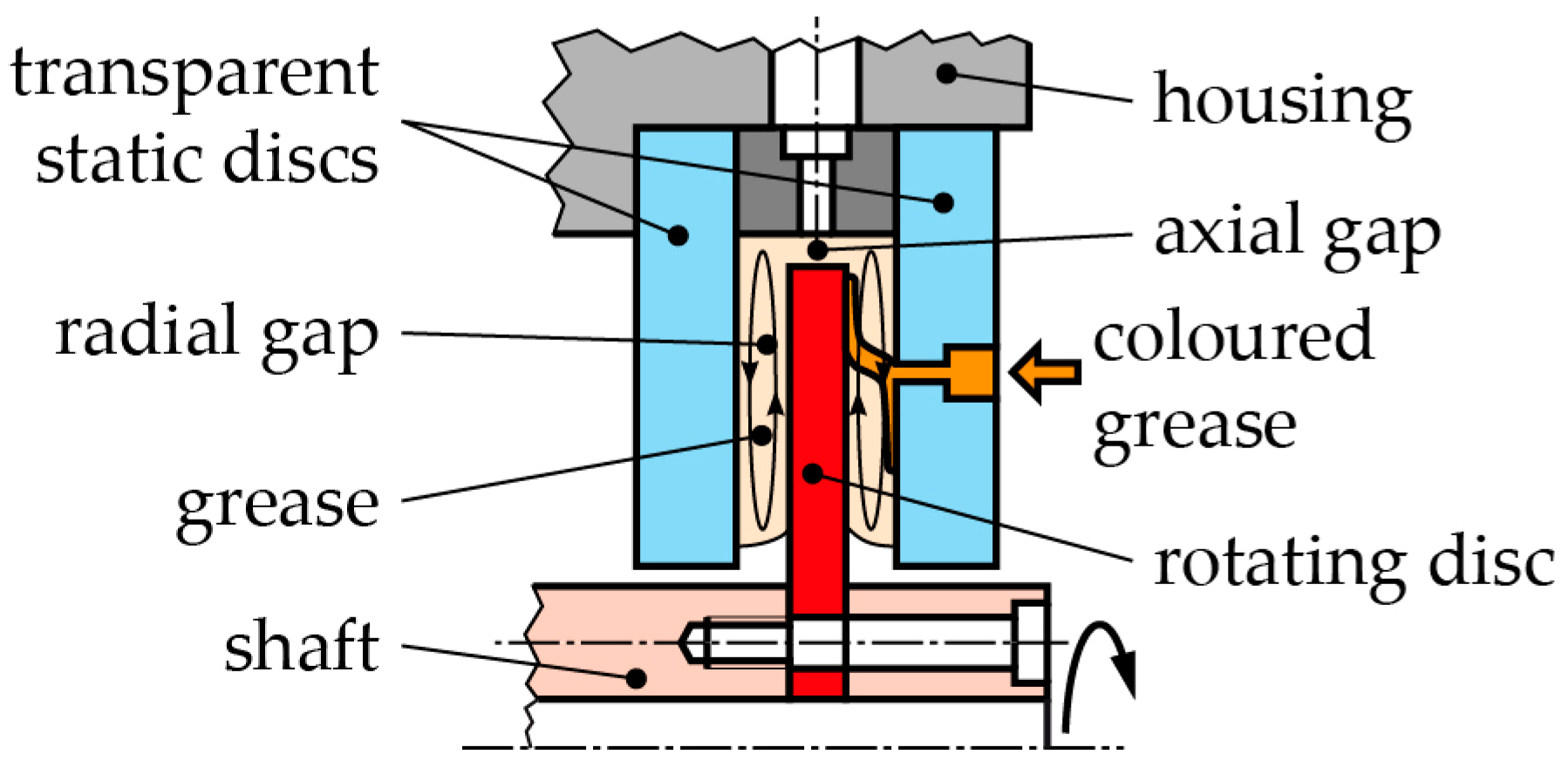

3. Relubrication of the Sealing System

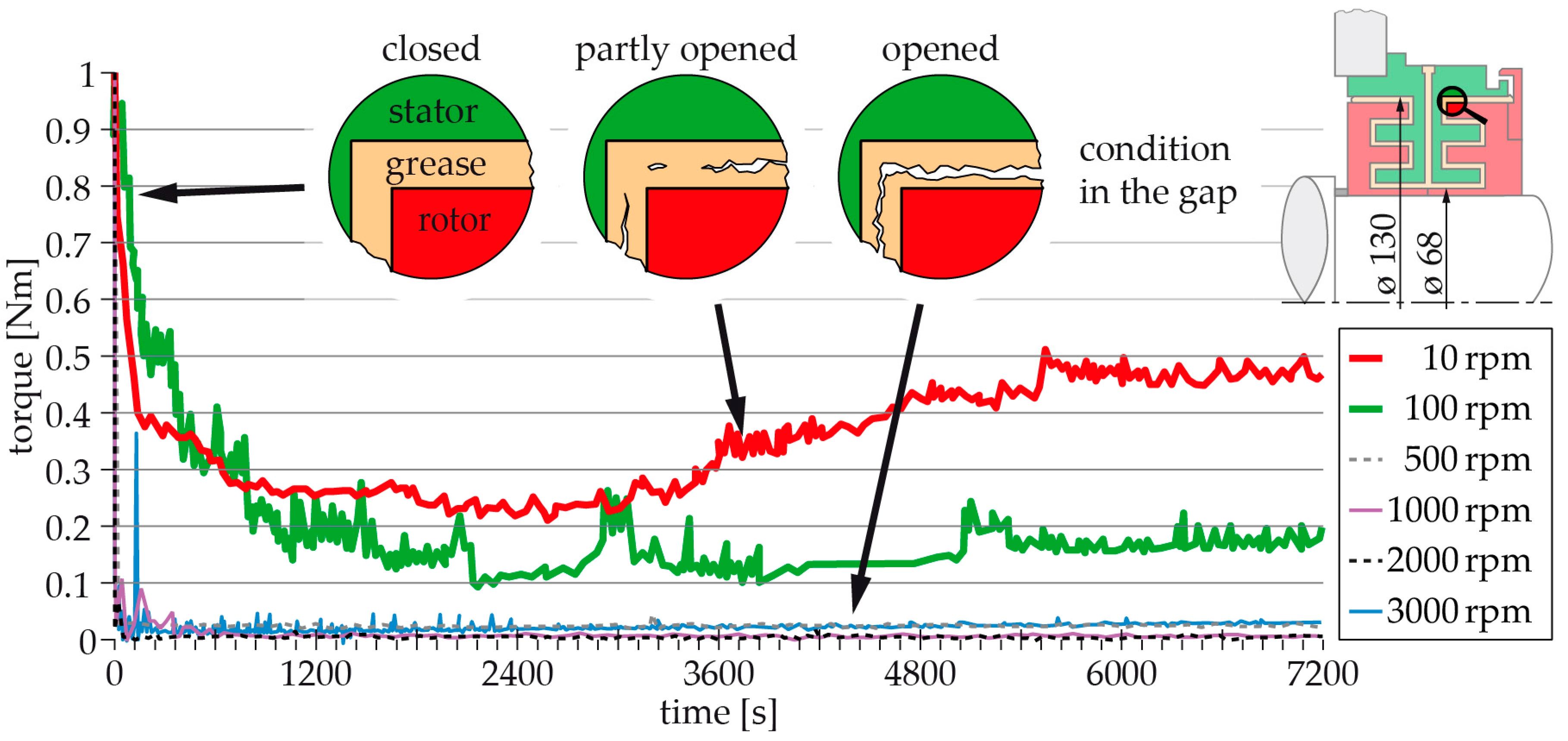

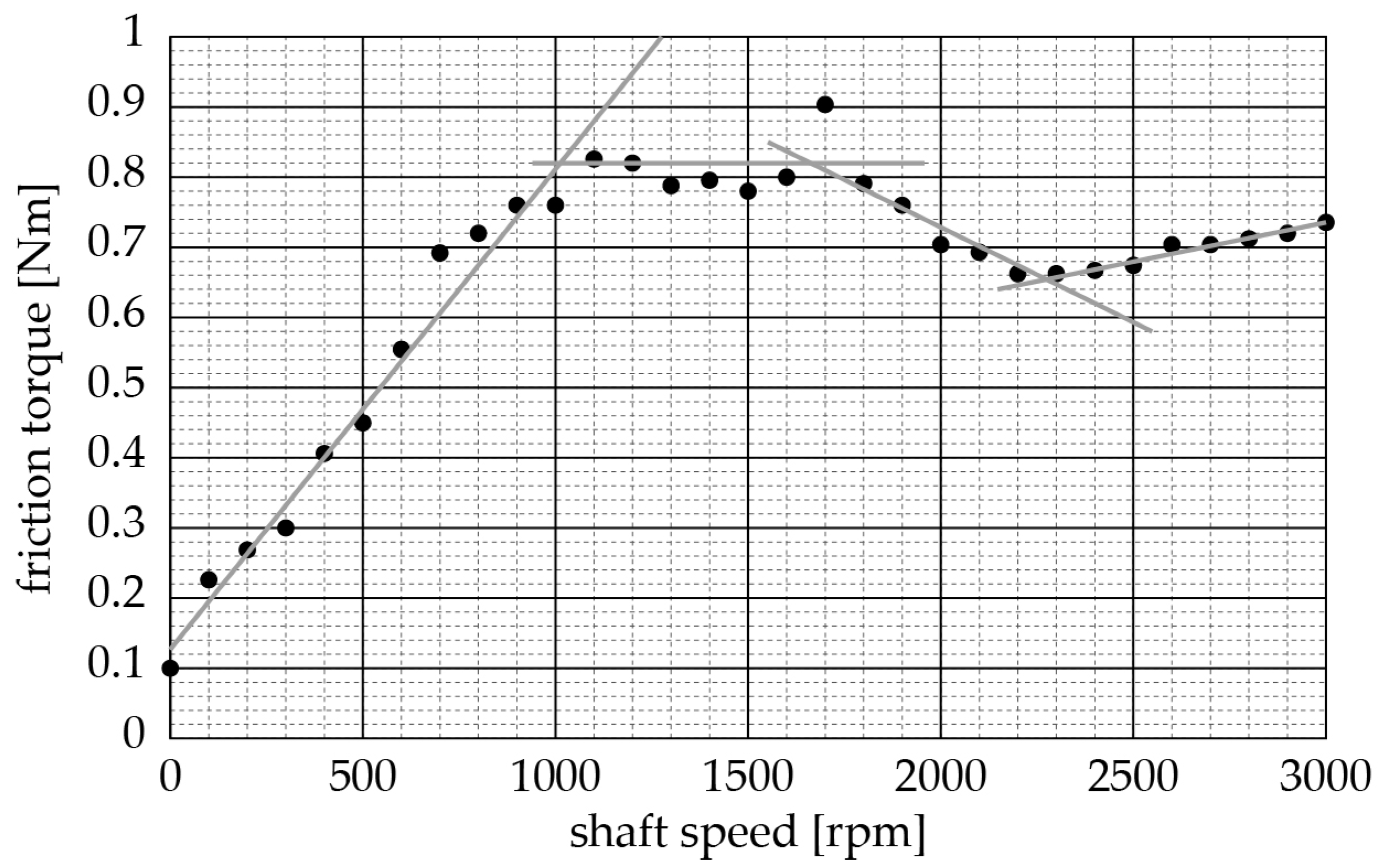

3.1. Preliminary Experiment

- The offset is caused by a low shaft speed. The torque increases almost linearly with increasing shaft speeds of up to 1000 rpm. The torque is caused by the friction of the bearing. In addition, the grease is displaced by the bearing and gets into the gaps of the sealing system with increasing speed, where it is sheared.

- Between 1000 rpm and 1700 rpm, the friction torque appears not to depend on the shaft speed. This is because the grease is nearly completely displaced by the bearing. There is no new grease getting into the gaps. In addition, some gaps begin to open.

- At more than 1700 rpm, the friction torque decreases with increasing shaft speed. This is caused by the opening gaps.

- At more than about 2000 rpm, the friction torque increases slowly with increasing shaft speed. It corresponds to the friction torque of a bearing that is lubricated with a minimal amount of grease. It follows that all gaps are open, and there is no sheared grease left in the gaps.

3.2. Test Procedure

- -

- Fresh grease;

- -

- Aged grease;

- -

- Grease polluted with particles.

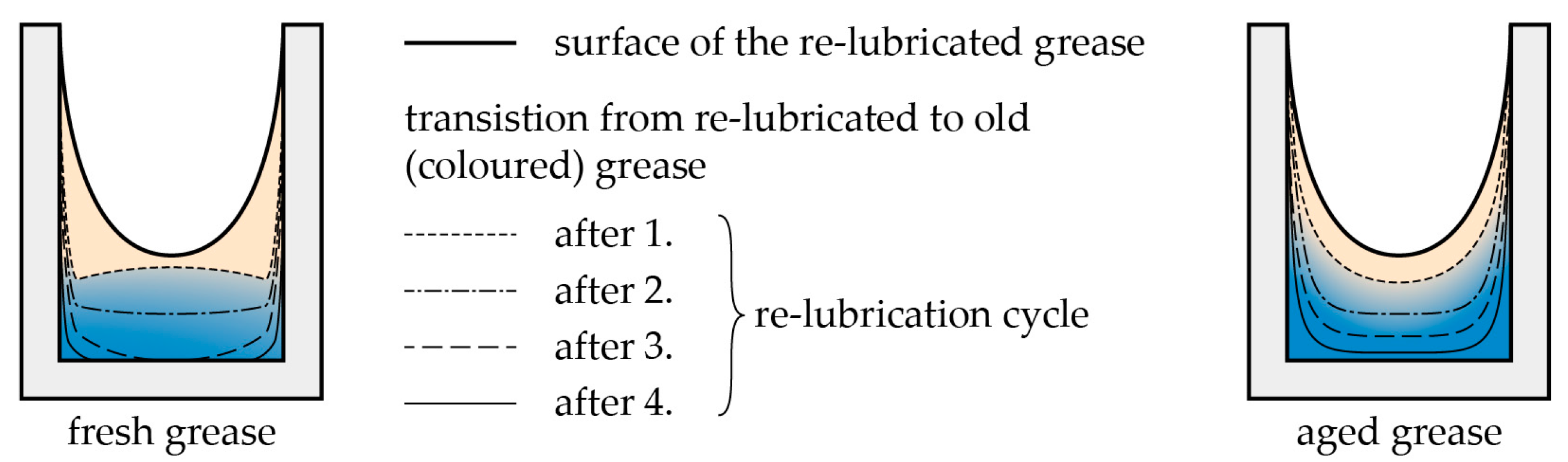

3.3. Results of Relubricating Experiments

3.4. Reduction of Complexity of the Sealing System

4. Functional Tests with the Optimized Sealing System

4.1. Test Procedure and Evaluation Method

- -

- Grease distribution run to ensure a opened gap; shaft speed is n = 500 rpm;

- -

- Contamination of the sealing system by spraying particles directly on entrance area of the sealing system normally for 10 min (other duration are given in the figures); shaft speed normally is n = 500 rpm;

- -

- Relubrication of the sealing system with m = 14 g, duration is t = 120 s.

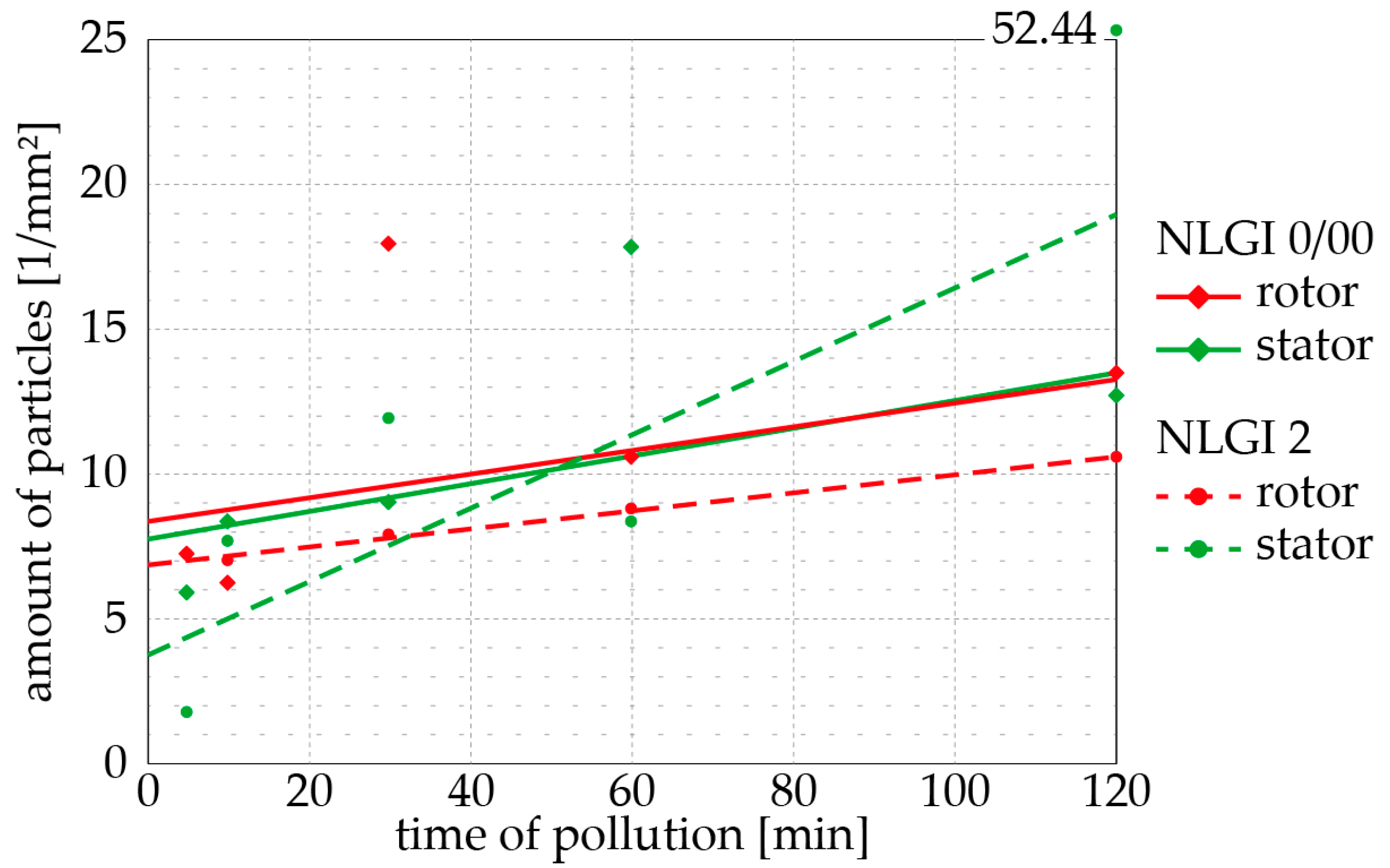

4.2. Experiments with Constant Pollution

4.3. Pollution of the Grease at Different Positions

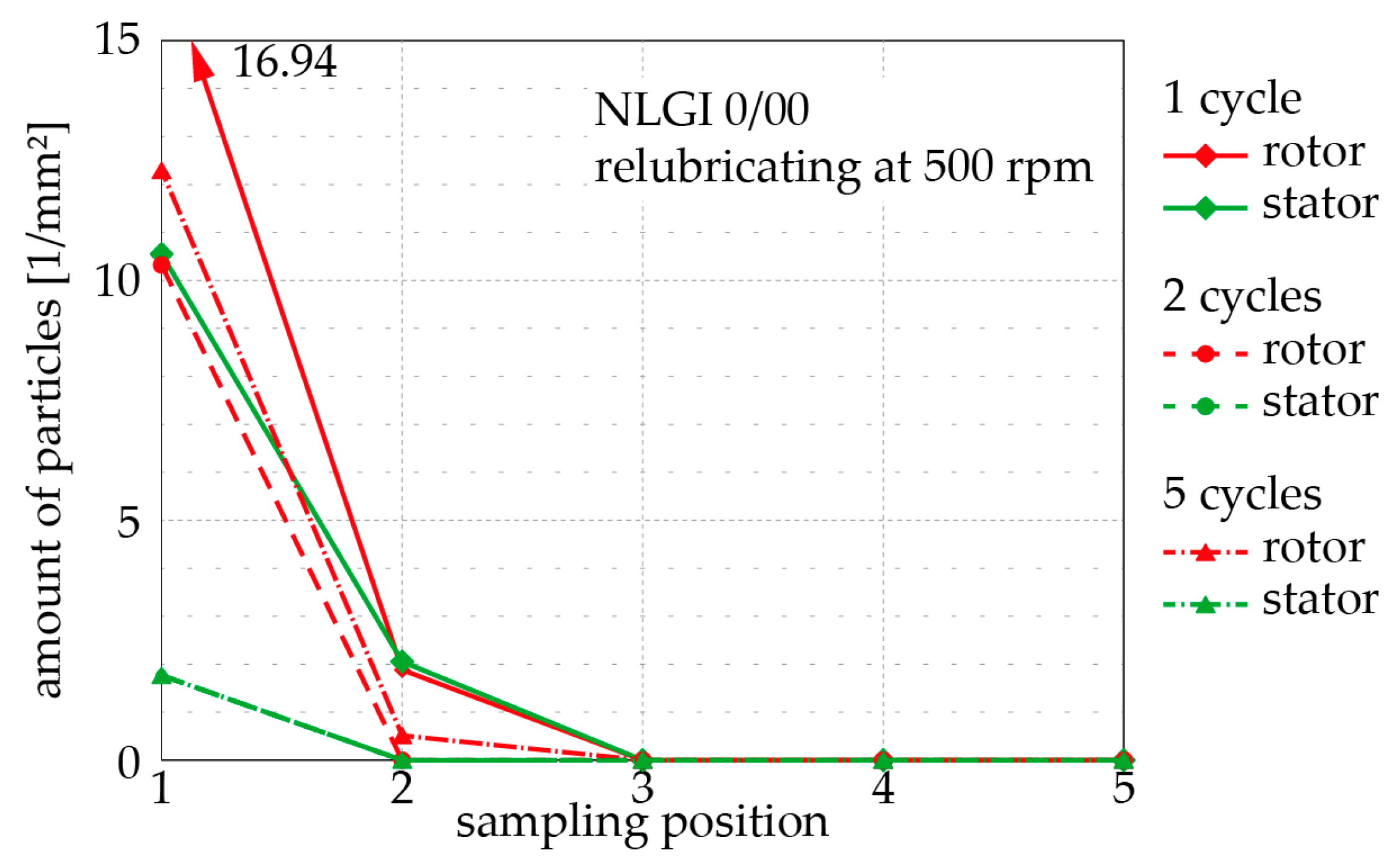

4.4. Experiments with Relubricating

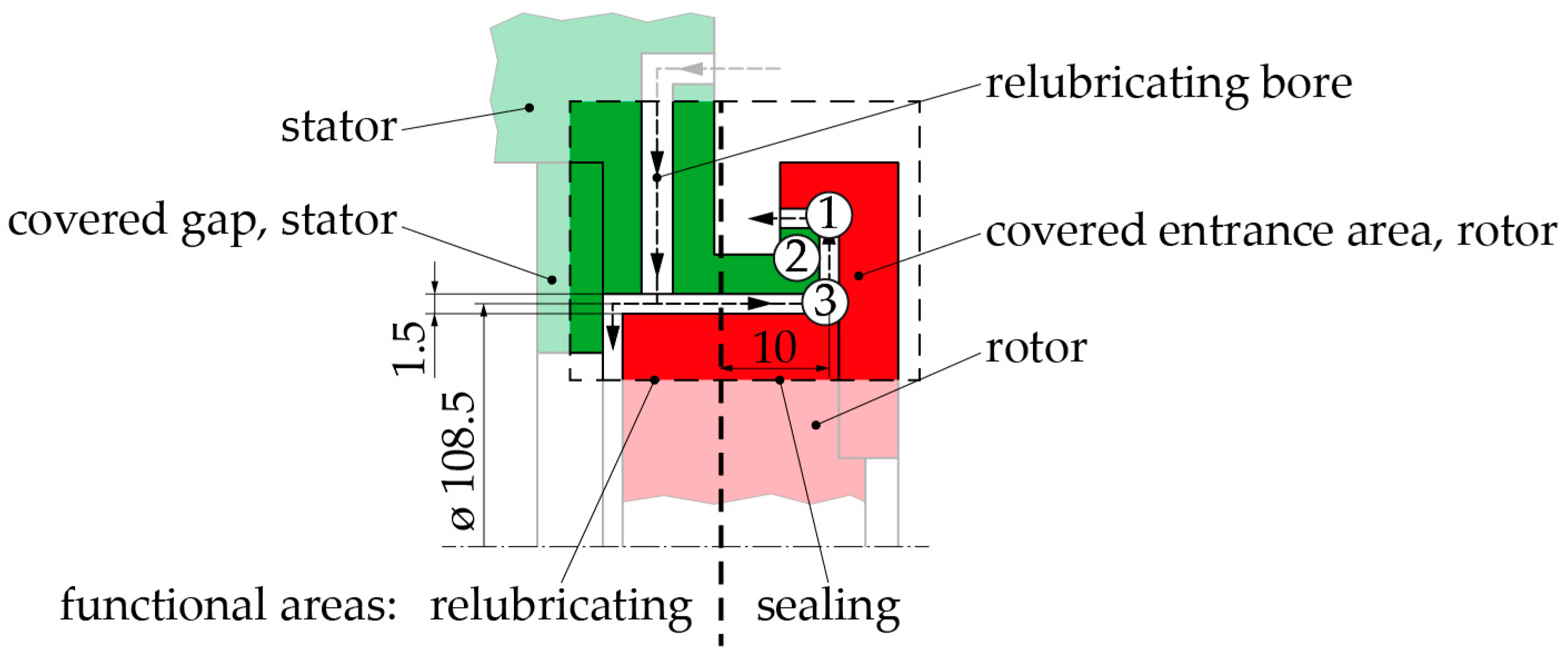

4.5. Defining Two Functional Areas of the Sealing System

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Bosch, F.; Haas, W. Relubricating of Grease Filled Labyrinth Seals; Poitiers-Futuroscope: Poitiers, France, 2016; pp. 42–52. [Google Scholar]

- Bosch, F.; Haas, W. Sealing of Lubricating Grease without Friction with Non-Contacting Sealing Systems; Poitiers-Futuroscope: Poitiers, France, 2014; pp. 118–129. [Google Scholar]

- Bosch, F.; Haas, W. Relubrication of Grease-Filled Labyrinth Sealing Systems. Konstruktion 2016, 68, 78–82. (In German) [Google Scholar]

- Bosch, F.; Haas, W. Sealing of Dry Particles with Grease-Filled Labyrinth Sealing Systems; Arnold Tross Kolloquium: Hamburg, Germany, 2017. (In German) [Google Scholar]

- Eschmann, P.; Hasbargen, L.; Weigand, K. The Practice of Rolling Bearing: Manual of the Calculation and Design of Bearings; R. Oldenbourg: München, Germany, 1953. (In German) [Google Scholar]

- Schaeffler Technologies AG & Co. KG: Wälzlagerpraxis. Handbuch zur Gestaltung und Berechnung von Wälzlagerungen, 4. Auflage, Mainz: Vereinigte Fachverlage, 2015, - ISBN 9783783004014.

- Dahlke, H. Manual of Rolling Bearing Practices; Part 2; Deutsche Koyo Wälzlager Verkaufsgesellschaft mbH: Hamburg, Germany, 1987. (In German) [Google Scholar]

- Kümmel, J.; Haas, W. Grease-Filled Labyrinth Sealing Systems—Labyrinth Sealing Systems Filled with Grease to Seal Dust Particles, Abschlussbericht, Forschungsvorhaben; FKM Forschungskuratorium Maschinenbau e-V: Frankfurt/Main, Germany, 2010. (In German) [Google Scholar]

- Bosch, F.; Kümmel, J.; Haas, W. Grease-filled labyrith sealing systems to seal dust and fluids. In Proceedings of the 17th ISC, Stuttgart, German, 13–14 September 2012. (In German). [Google Scholar]

- Fritz, E.; Haas, W.; Müller, H.K. Non-Contacting Sealing Systems for Macine Tool Spindles—Design Guidelines and Solution Proposals; Berichte aus dem Institut für Maschinenelemente, Stuttgart; IMA: Stuttgart, Germany, 1991; Volume 39, ISBN 3-921920-39-6. (In German) [Google Scholar]

- Stanger, N. Non-Contacting Sealing Systems for Small Installation Space. Ph.D. Thesis, Universität Stuttgart, Stuttgart, Germany, 1995; p. 111. (In German). [Google Scholar]

- Baart, P.; Green, T.M.; Li, J.X.; Lundström, T.S.; Westerberg, L.G.; Höglund, E.; Lugt, P.M. The Influence of Speed, Grease Type, and Temperature on Radial Contaminant Particle Migration in a Double Restriction Seal. Tribol. Trans. 2011, 54, 867–877. [Google Scholar]

- Baart, P. Grease Lubrication Mechanisms in Bearing Seals. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2011. [Google Scholar]

- NTN-SNR. Industry General Catalogue; TN04; Technical Catalogue: Annecy, France, 2009. [Google Scholar]

- SKF GmbH. Rolling Bearings, Schweinfurt; PUB BU/P1 10000/3 EN; SKF Group: Gothenburg, Sweden, 2016. [Google Scholar]

- FAG Kugelfischer Georg Schäfer AG. Rolling Bearing Lubrication; Publ. No. WL 81 115/4 EA; Industrial Bearings and Services: Green Bay, WI, USA, 2002. [Google Scholar]

- Klüber Lubrication München KG. Isoflex TOPAS NCA 5051, Synthetic Long-Term Grease. In Product Information; Klüber Lubrication München KG: Munich, Germany, 17 August 2017. [Google Scholar]

- Klüber Lubrication München KG. Klüberbio M 72–82. Readily Biodegradable Special Grease. In Product Information; Klüber Lubrication München KG: Munich, Germany, 17 August 2017. [Google Scholar]

- Bartz, W.J. Lubricating Greases: Composition, Charactersistics, Testing and Application; Band 500, Kontakt & Studium, Renningen-Malmsheim; Expert-Verlag: Renningen, Germany, 2000; ISBN 3-8169-1533-7. (In German) [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosch, F.; Haas, W. Sealing of Dry Particles with Grease-Filled Non-Contacting Sealing Systems. Lubricants 2017, 5, 38. https://doi.org/10.3390/lubricants5040038

Bosch F, Haas W. Sealing of Dry Particles with Grease-Filled Non-Contacting Sealing Systems. Lubricants. 2017; 5(4):38. https://doi.org/10.3390/lubricants5040038

Chicago/Turabian StyleBosch, Florian, and Werner Haas. 2017. "Sealing of Dry Particles with Grease-Filled Non-Contacting Sealing Systems" Lubricants 5, no. 4: 38. https://doi.org/10.3390/lubricants5040038