Comparative Analysis of Machining Procedures

Abstract

:1. Introduction

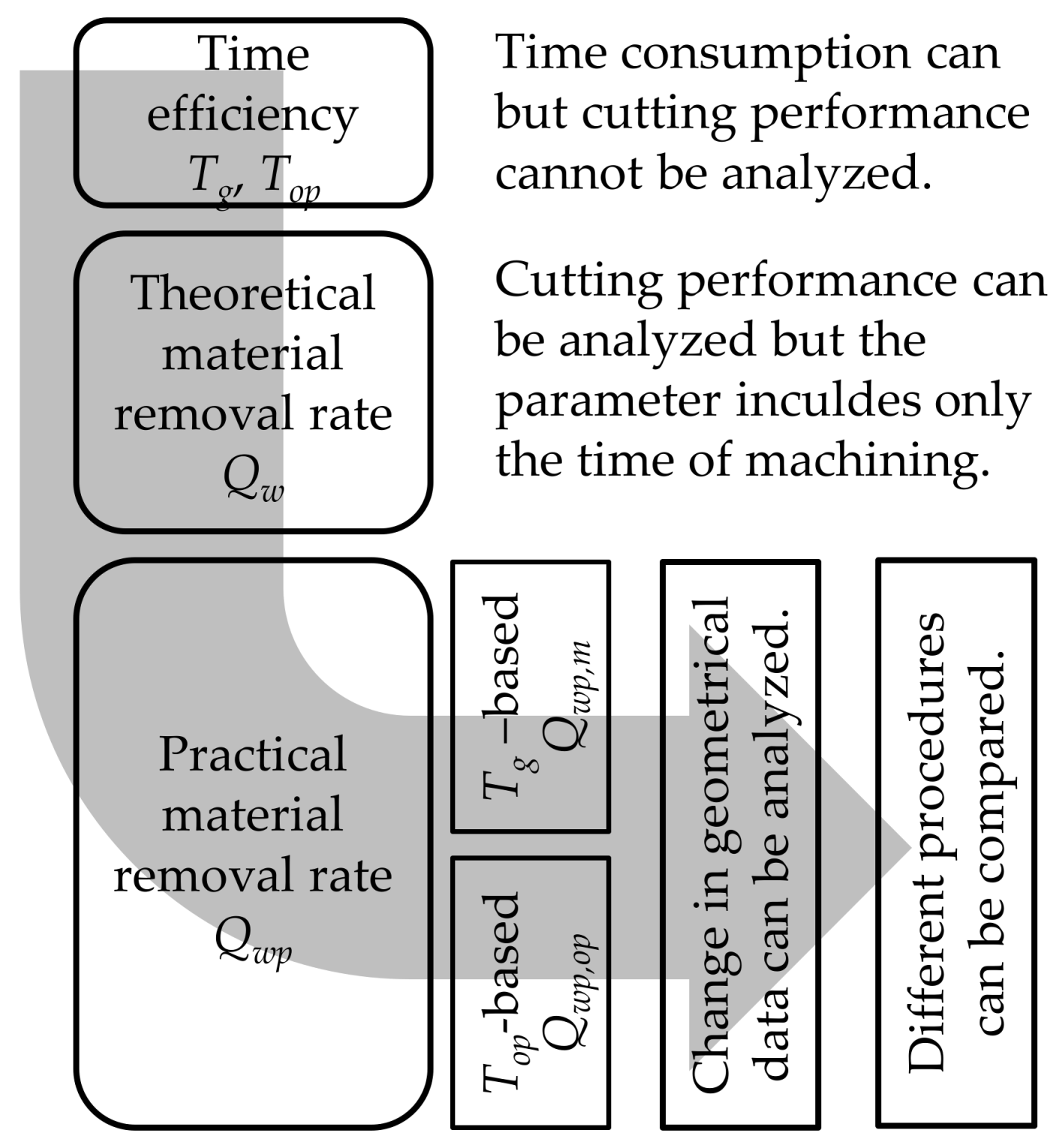

2. Method of Analysis

3. Material Removal Efficiency Measurement Parameters

3.1. Time Parameters

3.2. Material Removal Rate

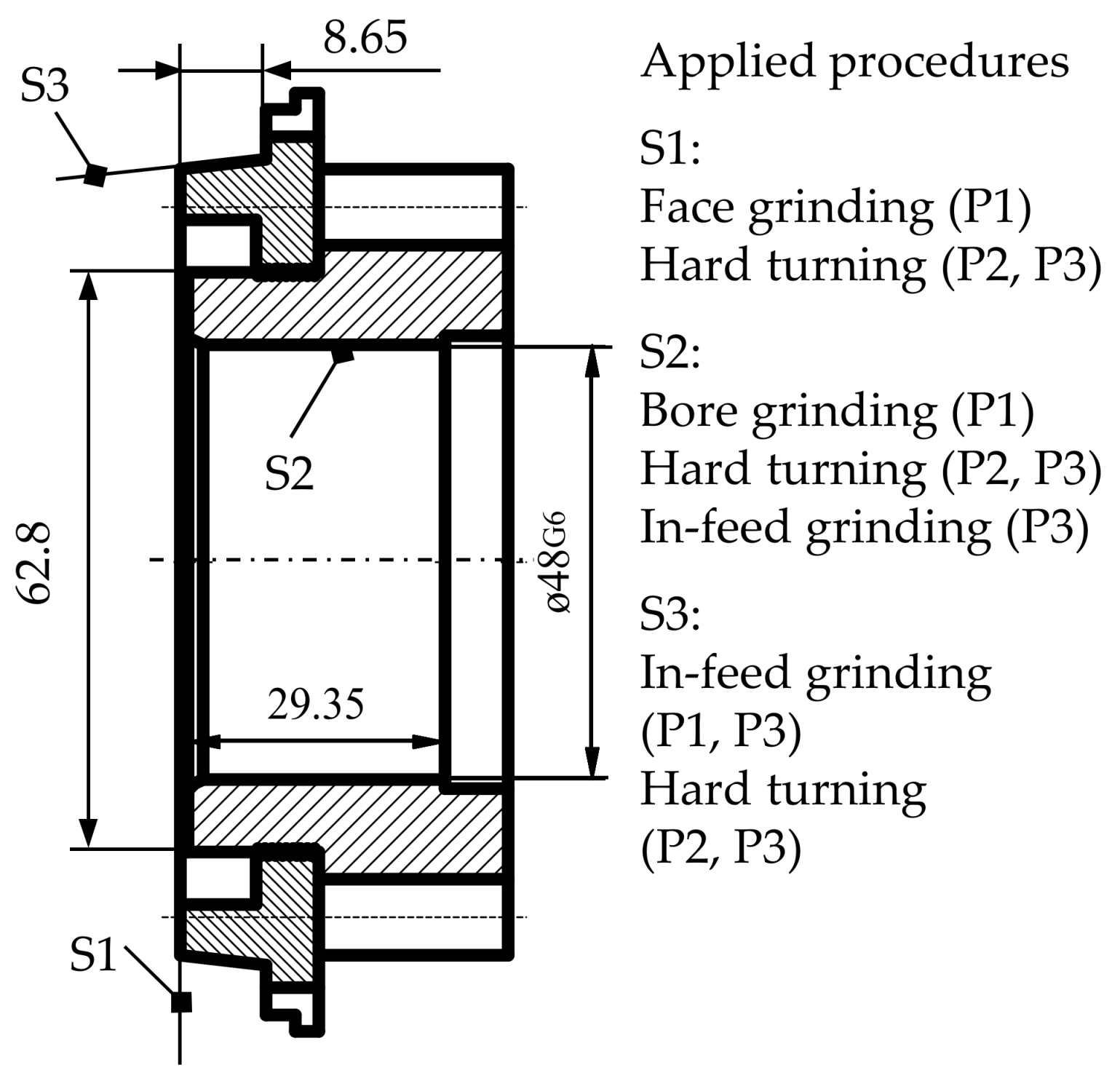

4. Basic Data of Comparison Analyses

- Procedures: P1: grinding; P2: hard turning; P3: combined procedure (P3/1: hard turning, P3/2: in-feed grinding)

- Surfaces: S1: face; S2: bore; S3: cone

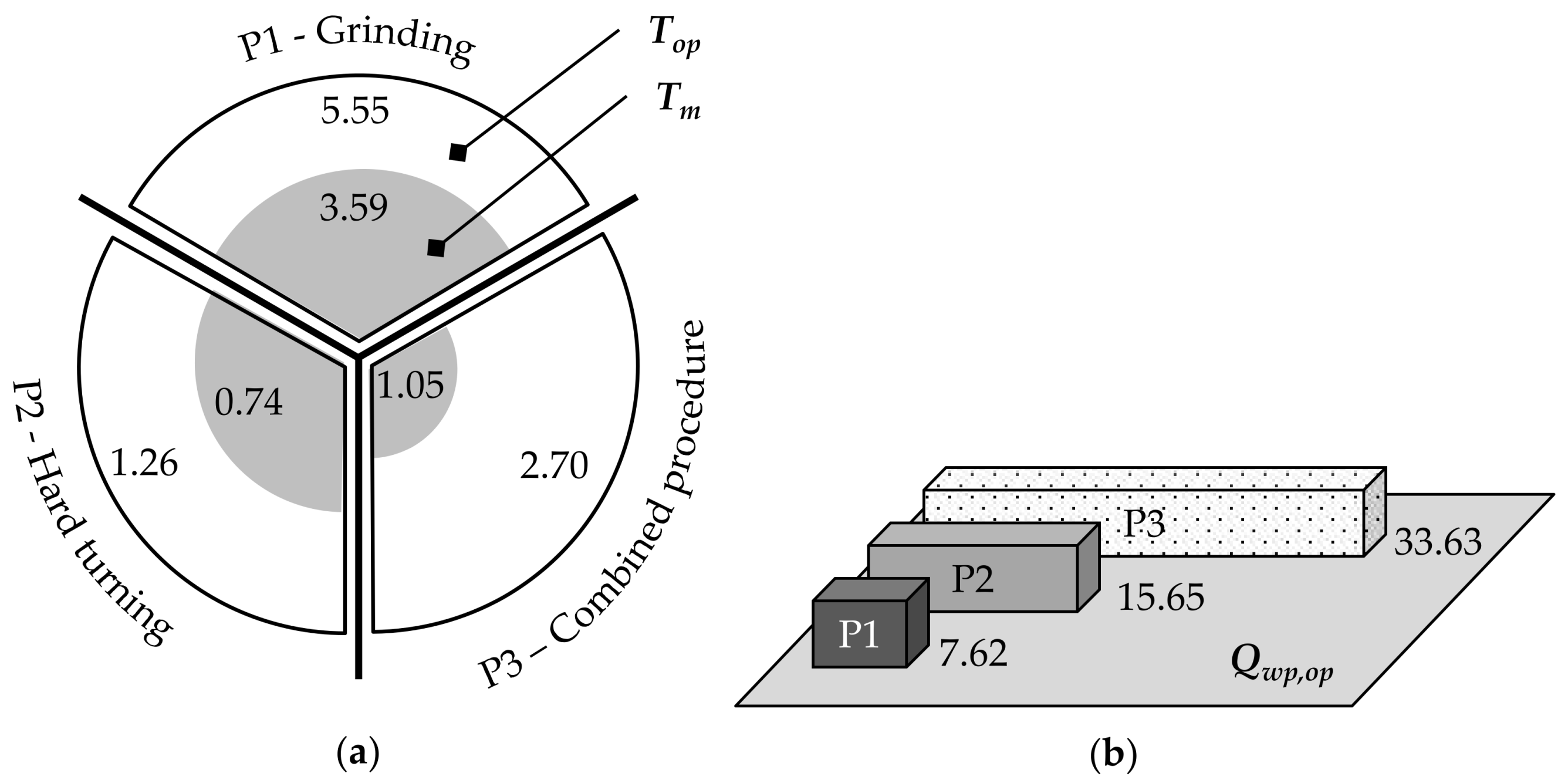

5. Results and Discussion

5.1. Theoretical Material Removal Rate

5.2. Practical Parameter of Material Removal

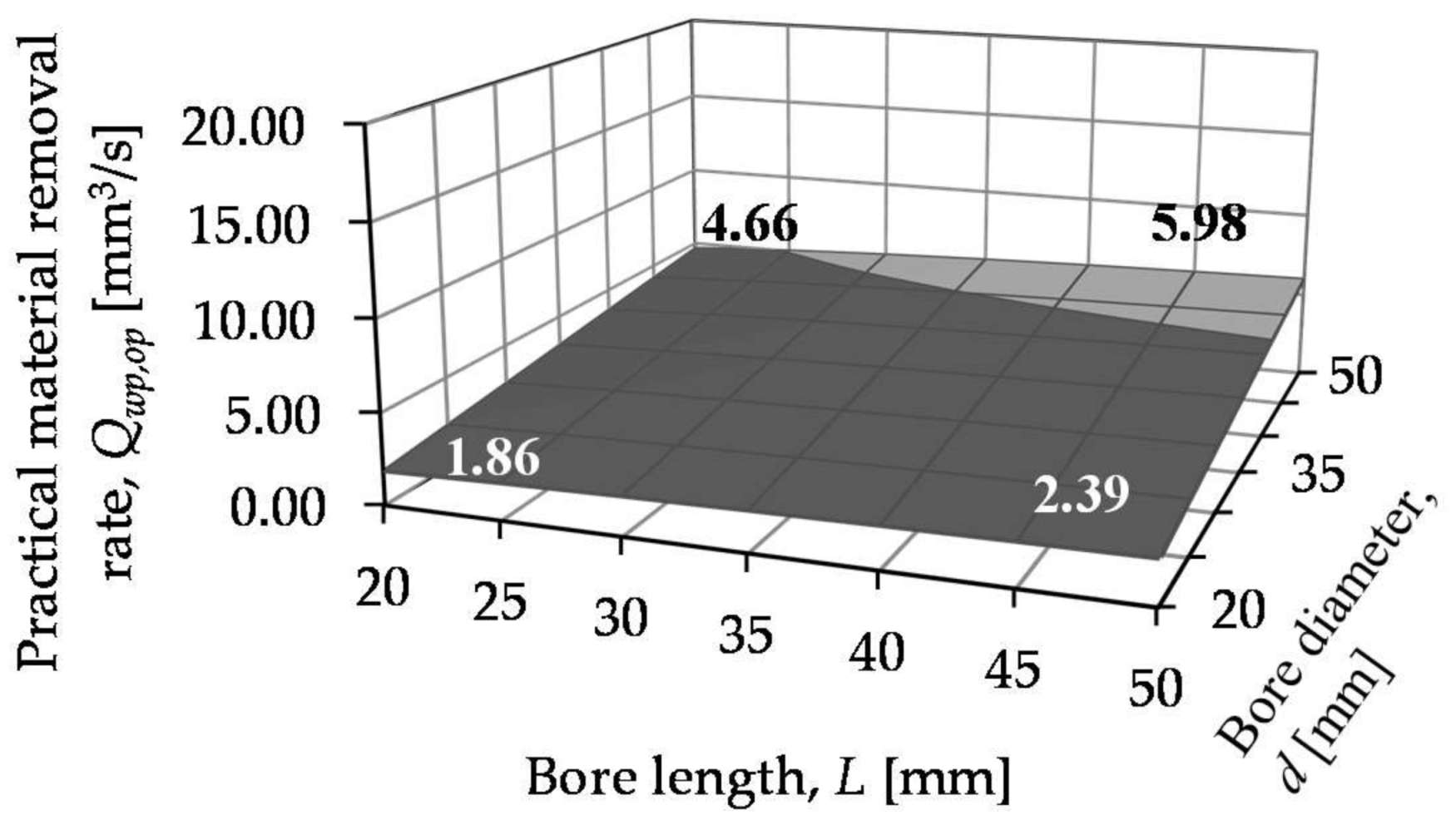

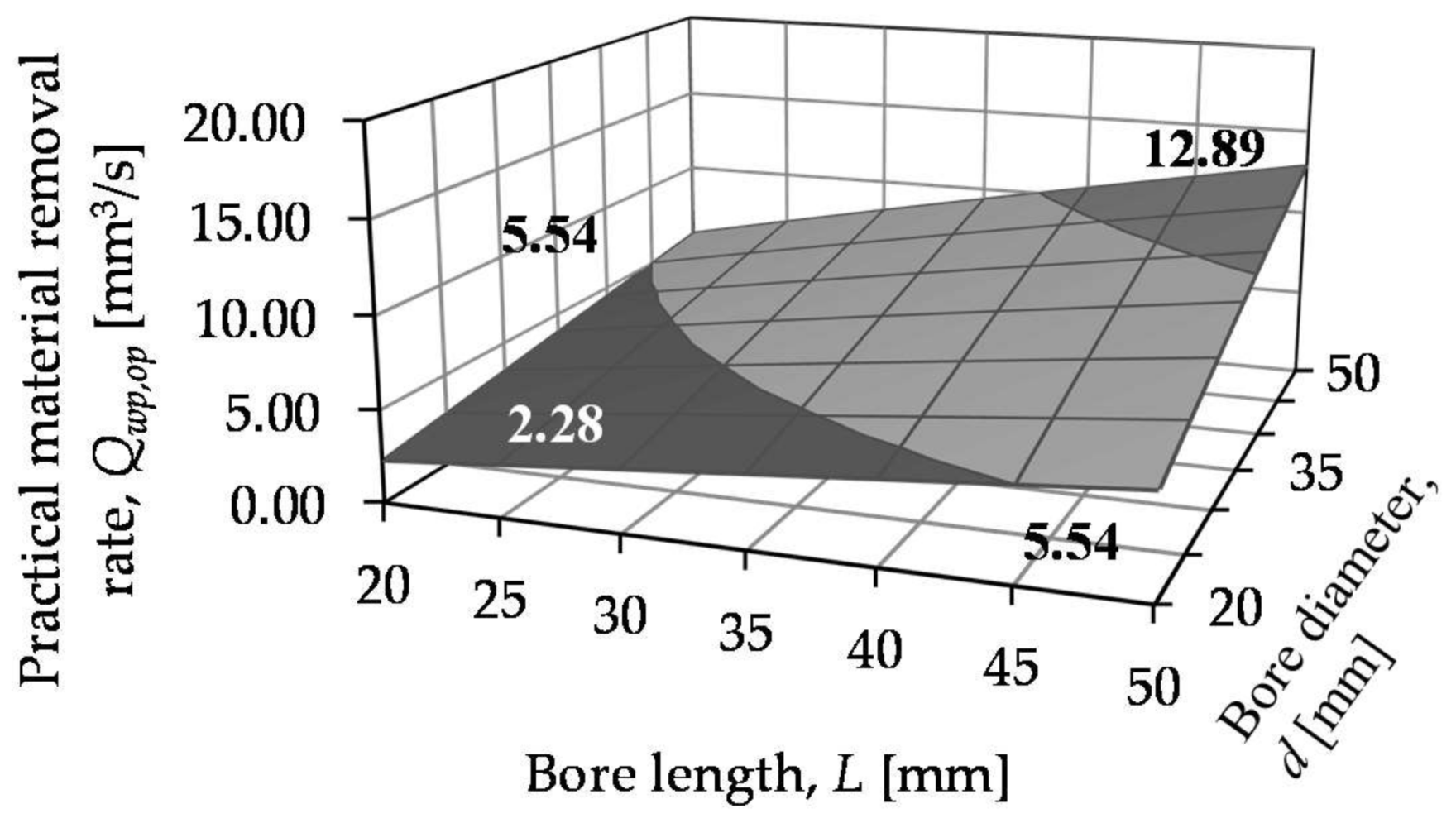

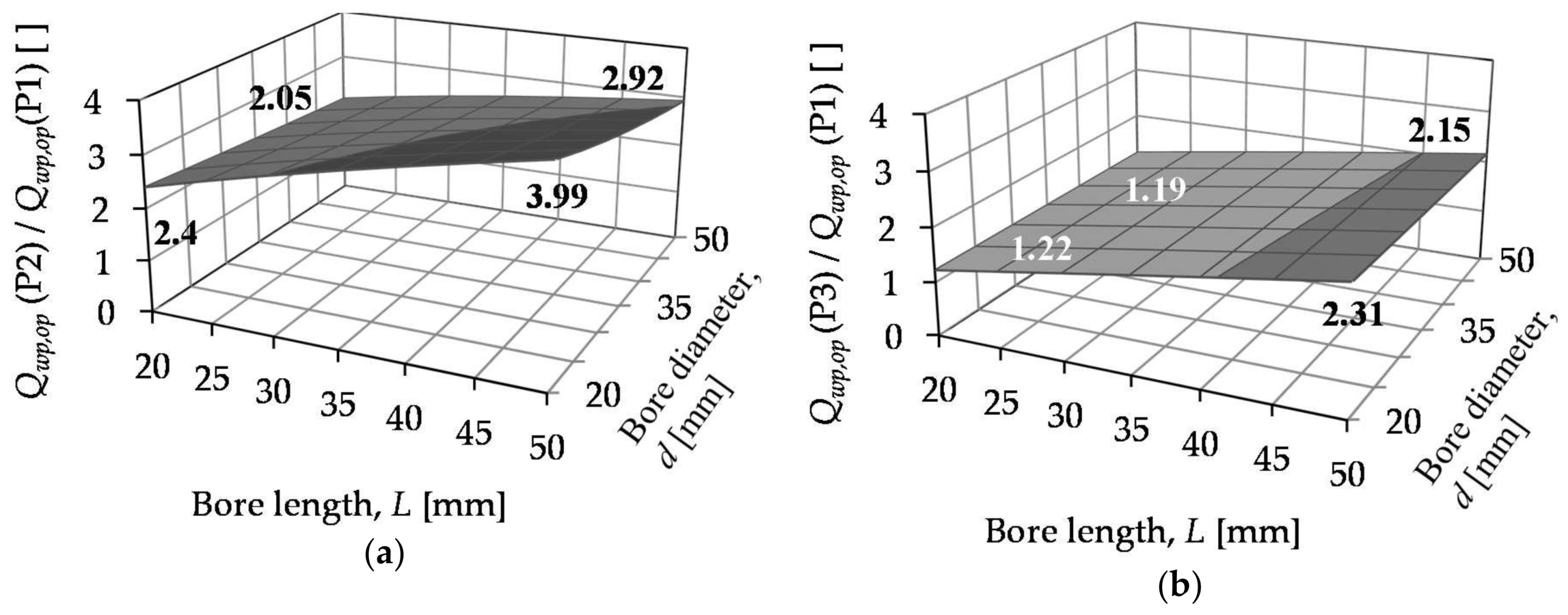

5.3. Effect of Bore Length and Diameter

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hammer, M.; Somers, K.; Karre, H.; Ramsauer, C. Profit per hour as a target process control parameter for manufacturing systems enabled by Big Data analytics and Industry 4.0 infrastructure. Procedia CIRP 2017, 63, 715–720. [Google Scholar] [CrossRef]

- Tamas, P.; Illes, B.; Dobos, P. Waste reduction possibilities for manufacturing systems in the industry 4.0. IOP Conference Series. Mater. Sci. Eng. 2016, 161, 1–8. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- König, W.; Berktold, A.; Koch, K.F. Turning versus grinding—A comparison of surface integrity aspects and attainable accuracies. Ann. CIRP 1993, 42, 39–43. [Google Scholar] [CrossRef]

- Jacobs, B.W.; Swink, M.; Linderman, K. Performance effects of early and late Six Sigma adoptions. J. Oper. Manag. 2015, 36, 244–257. [Google Scholar] [CrossRef]

- Castro, S.; Riedel, C. Assessment of the implementation of manufacturing excellence in a fiber based packaging manufacturing environment. Procedia CIRP 2017, 63, 113–118. [Google Scholar] [CrossRef]

- Kundrak, J.; Mamalis, A.G.; Markopoulos, A. Finishing of hardened boreholes: Grinding or hard cutting? Mater. Manuf. Process. 2004, 19, 979–993. [Google Scholar] [CrossRef]

- Klocke, F.; Brinkmeier, E.; Weinert, K. Capability profile of hard cutting and grinding process. Ann. CIRP 2005, 54, 22–54. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Kundrak, J. FEM/AI models for the simulation of precision grinding. Manuf. Technol. 2016, 16, 384–390. [Google Scholar]

- Dudas, L. Design of Nonconventional Grinding Wheels with Specialized CAD System. In Proceedings of the 4th IEEE International Symposium on Logistics and Industrial Informatics (LINDI 2012), Smolenice, Slovakia, 5–7 September 2012; pp. 21–26. [Google Scholar]

- Tönshoff, H.K.; Arendt, C.; Ben Amor, R. Cutting of Hardened Steel. Ann. CIRP 2000, 49, 547–566. [Google Scholar] [CrossRef]

- Waikar, R.A.; Guo, Y.B. A comprehensive characterization of 3D surface topography induced by hard turning versus grinding. J. Mater. Process. Technol. 2008, 197, 189–199. [Google Scholar] [CrossRef]

- Kundrak, J. Alternative machining procedures of hardened steels. Manuf. Technol. 2011, 11, 32–39. [Google Scholar]

- Kundrak, J.; Varga, G.; Deszpoth, I.; Molnar, V. Some aspects of machining of bore holes. Appl. Mech. Mater. 2013, 309, 126–132. [Google Scholar] [CrossRef]

| Symbol | Description |

|---|---|

| L | bore length |

| L′ | bore length + tool overrun |

| ZR; ZS; ZA | roughing, smoothing and air grinding allowance |

| vfL,R; vfL,S | traverse feed rate (roughing, smoothing) |

| ae,R; ae;S | depth-of-cut in grinding (roughing, smoothing) |

| iso | number of sparking out revolutions |

| vfR,R; vfR,S; vfR,A | radial feed rate in in-feed grinding (roughing, smoothing, air grinding) |

| nw | revolution per minute of the workpiece |

| ap,R; ap,S | depth-of-cut (roughing, smoothing) |

| fR, fS | roughing and smoothing feed |

| dw | workpiece diameter |

| vc | cutting speed in turning |

| tso | time of sparking out |

| Procedure | Qw [mm3/s] |

|---|---|

| Face grinding | apbvw |

| Bore grinding | aefvw |

| In-feed bore grinding | apdwπvfR |

| In-feed cone grinding | |

| Face turning | apfvc |

| Boring | |

| Cone turning |

| Surface 1 (S1)—Face | P1 | Surface 2 (S2)—Bore | P1 | Surface 3 (S3)—Cone | P1 | ||

| ae,R: 0.03 mm | nk,R: 40 ds/min | ae,R: 0.01 mm/ds | vc: 32 m/s | tso: 6 s | |||

| ae,S: 0.01 mm | nk,S: 36 ds/min | ae,S: 0.001 mm/ds | vw: 98 m/min | ZN: 0.04 mm | |||

| vw: 15 m/min | fR: 24.44 mm/r | vfL,R: 2200 mm/min | vfR,R: 0.009 mm/s | ZS: 0.01 mm | |||

| vc: 30 m/s | fS: 22.22 mm/r | vfL,S: 2000 mm/min | vfR,S: 0.003 mm/s | ||||

| iso: 8 | vw: 13.6 m/min | iso: 16 | P2 | P3/1 | |||

| P2 | vc: 29 m/s | ap: 0.3 mm | ap: 0.3 mm | ||||

| ap: 0.3 mm | P2 | P3/1 | f: 0.12 mm/r | f: 0.12 mm/r | |||

| f: 0.08 mm/rev | ap,R: 0.25 mm | ap: 0.25 mm | vc: 224 m/min | vc: 224 m/min | |||

| vc: 228 m/min | ap,S: 0.05 mm | f: 0.15 mm/r | P3/2 | ||||

| P3 | fR: 0.15 mm/r | vc: 180 m/min | vc: 32 m/s | ZN: 0.035 mm | |||

| ap: 0.3 mm | fS: 0.08 mm/r | vw: 98 m/min | ZS: 0.015 mm | ||||

| f: 0.08 mm/r | vc: 180 m/min | vfR,R: 0.008 mm/s | ZA: 0.27 mm | ||||

| vc: 228 m/min | P3/2 | vfR,S: 0.003 mm/s | tso: 6 s | ||||

| vc: 40 m/s | ZN: 0.04 mm | vfR,A: 0.1 mm/s | |||||

| vw: 86 m/min | ZS: 0.01 mm | ||||||

| vfR,R: 0.005 mm/s | ZA: 0.27 mm | ||||||

| vfR,S: 0.0033 mm/s | tso: 5 s | ||||||

| vfR,A: 0.1 mm/s | |||||||

| P1 | ||||||||

| S1 | R | 6.66 | S2 | R | 3.32 | S3 | R | 6.69 |

| S | 2.22 | S | 0.3 | S | 2.23 | |||

| P2 | ||||||||

| S1 | 5.47 | S2 | R | 6.75 | S3 | 8.06 | ||

| S | 0.72 | |||||||

| P3/1 | ||||||||

| S1 | 5.47 | S2 | 6.75 | S3 | 8.06 | |||

| P3/2 | ||||||||

| - | S2 | R | 20.62 | S3 | R | 10.44 | ||

| S | 13.61 | S | 3.91 | |||||

| P1 | P2 | P3 | |

| Tm | 3.59 | 0.74 | 1.05 |

| Top | 5.55 | 1.26 | 2.70 |

| Qwp,op | 7.62 | 33.63 | 15.65 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kundrak, J.; Molnar, V.; Deszpoth, I. Comparative Analysis of Machining Procedures. Machines 2018, 6, 13. https://doi.org/10.3390/machines6020013

Kundrak J, Molnar V, Deszpoth I. Comparative Analysis of Machining Procedures. Machines. 2018; 6(2):13. https://doi.org/10.3390/machines6020013

Chicago/Turabian StyleKundrak, Janos, Viktor Molnar, and Istvan Deszpoth. 2018. "Comparative Analysis of Machining Procedures" Machines 6, no. 2: 13. https://doi.org/10.3390/machines6020013