The Evidence of Decisive Effect of Both Surface Microstructure and Speciation of Chalcopyrite on Attachment Behaviors of Extreme Thermoacidophile Sulfolobus metallicus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Strain and Culture Medium

2.2. Mineral Samples

2.3. Electrochemical Experiments

2.4. Bioleaching Experiments

2.5. Adsorption Behaviors Analysis

2.6. Surface Structure and Chemical Species Analyses

3. Results

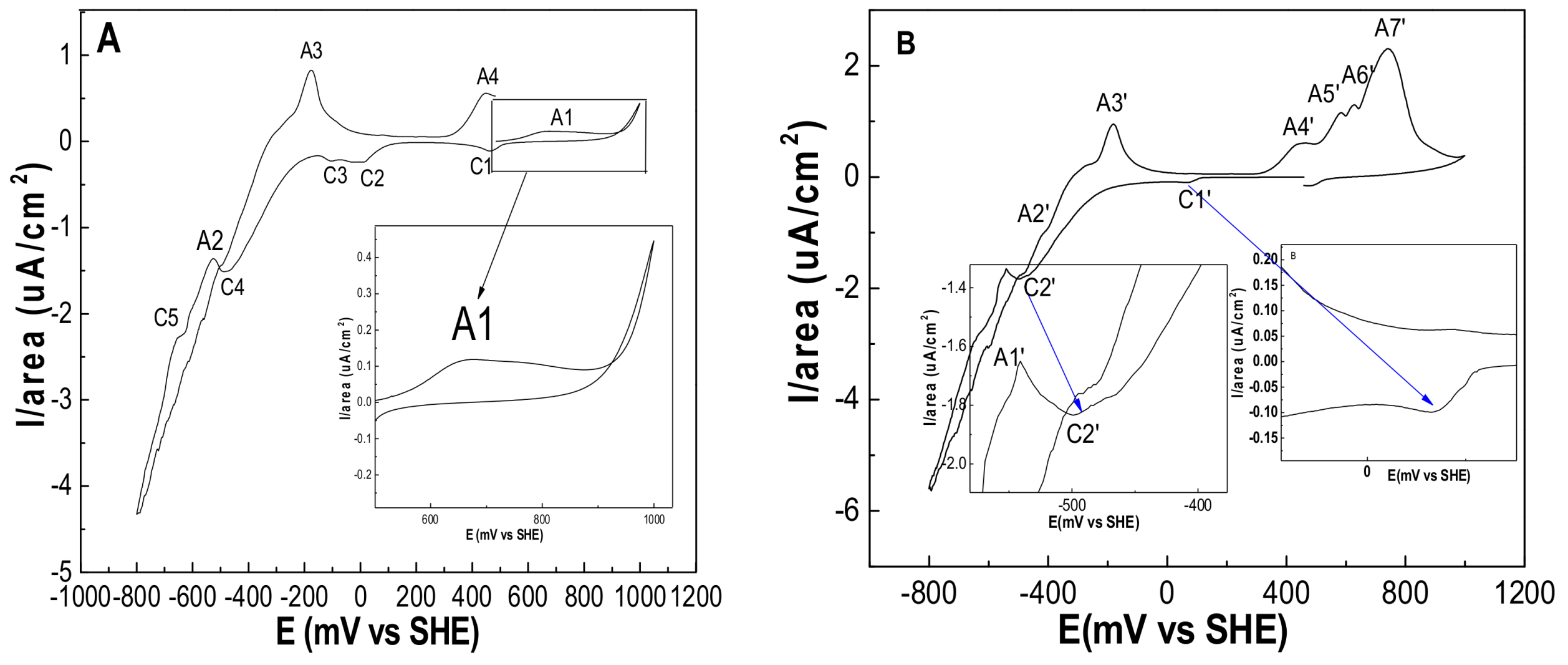

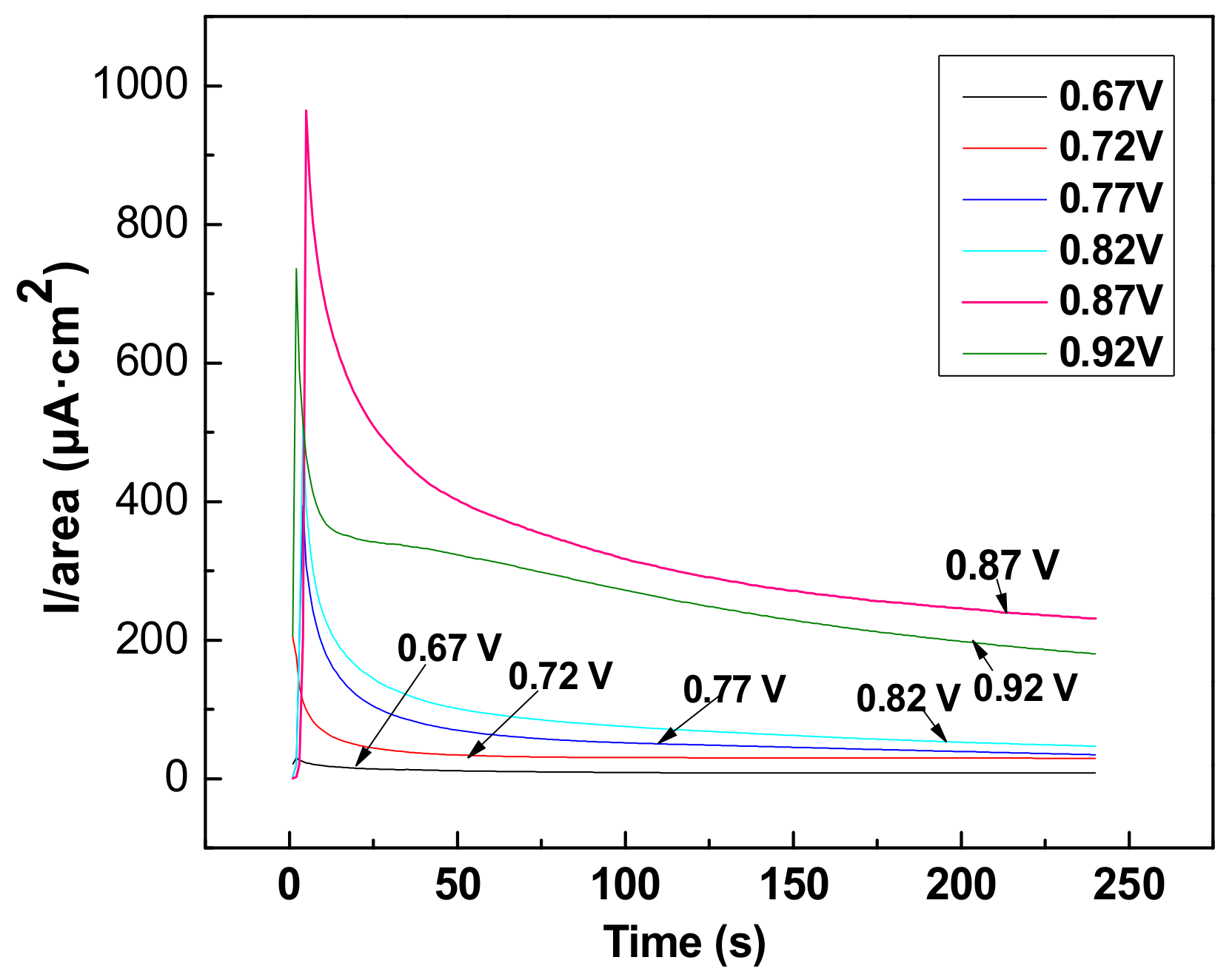

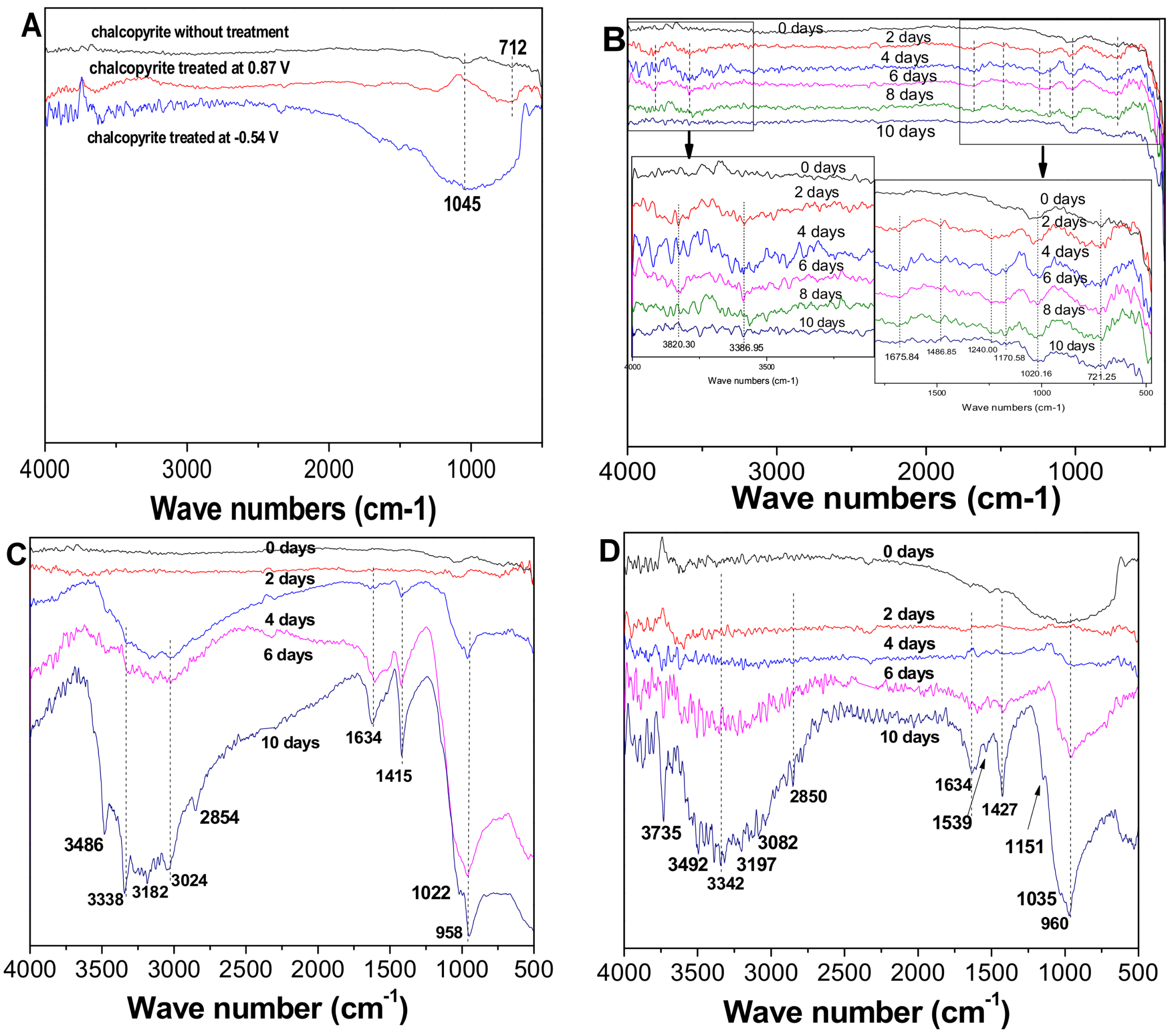

3.1. The Electrochemical Study and Characterization of Chalcopyrite

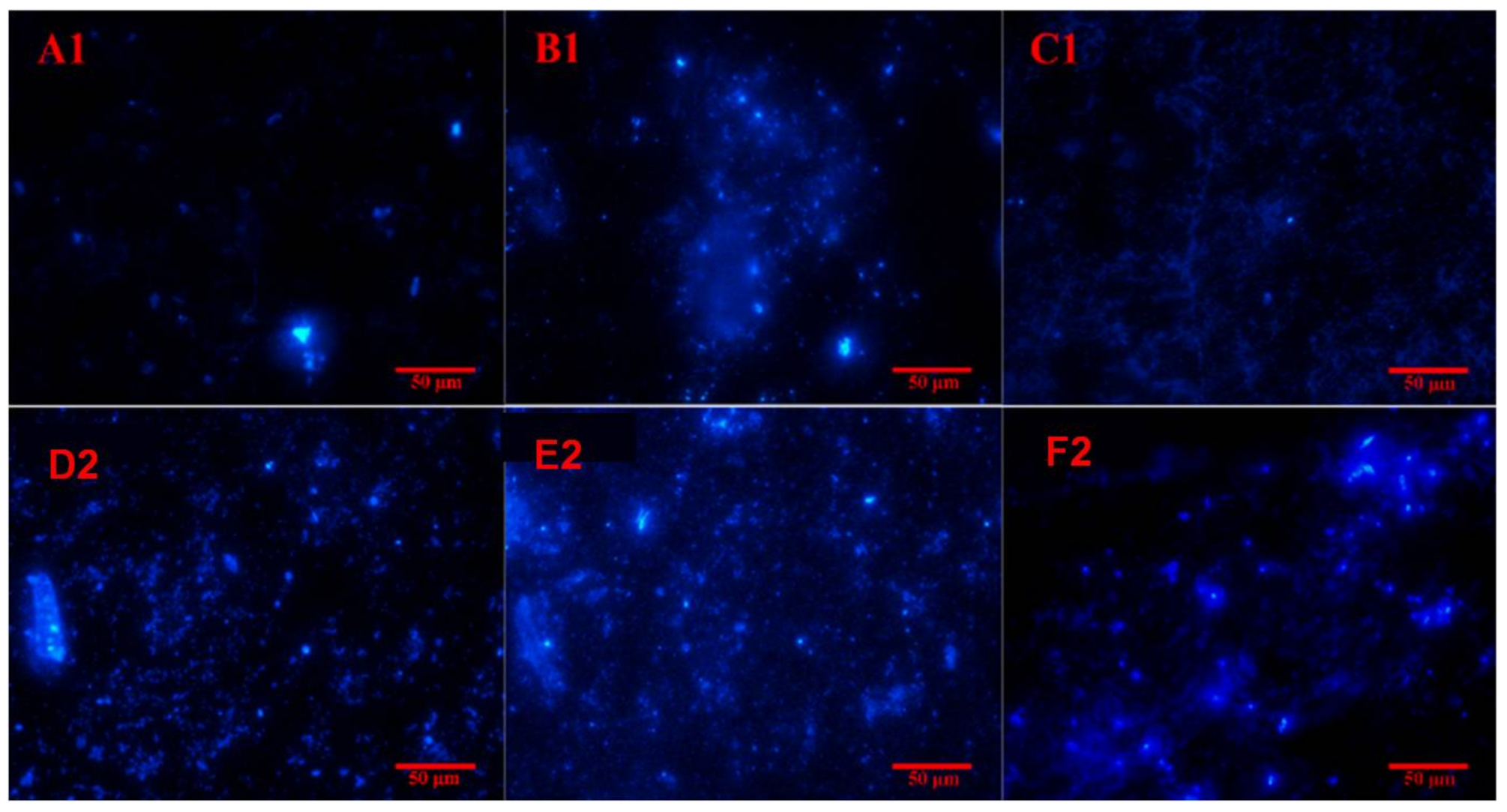

3.2. Cell Attachment and Biofilm Formation on Chalcopyrite Surface

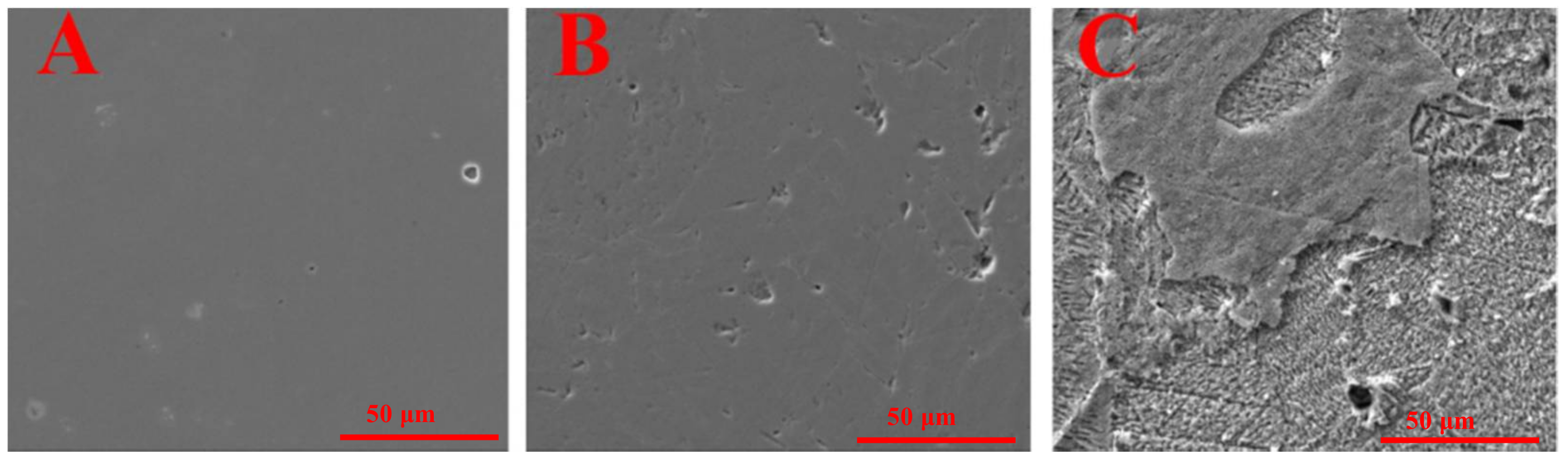

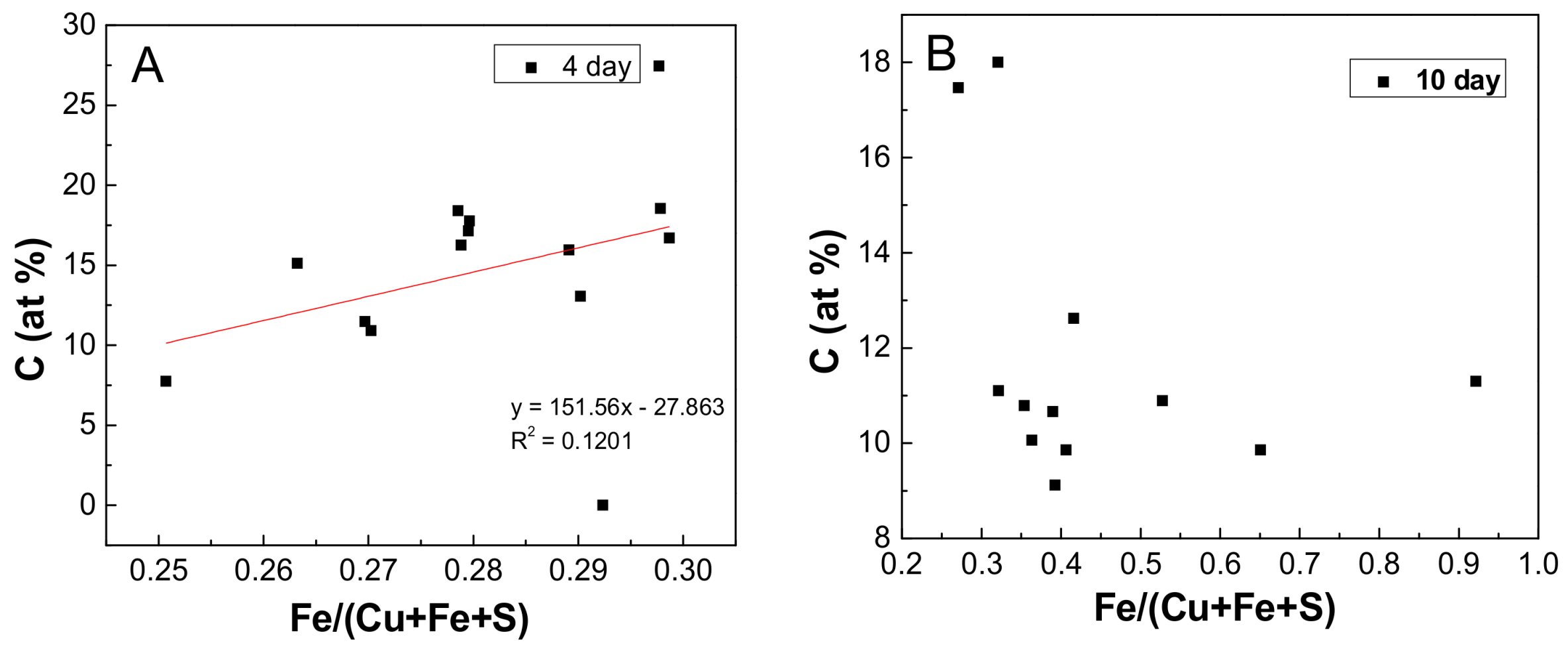

3.3. Analysis of Mineral Surface Morphology and Elemental Composition

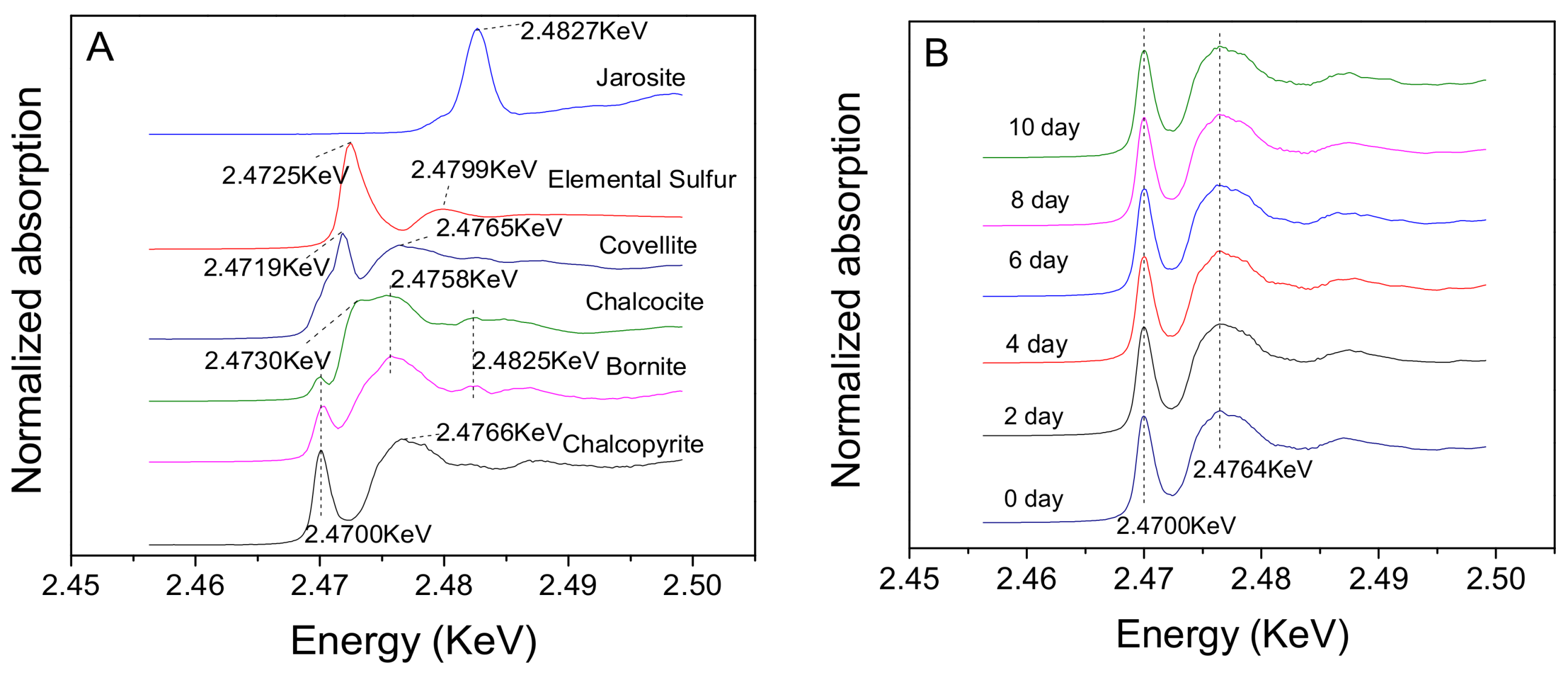

3.4. Analysis of Sulfur Speciation on the Chalcopyrite Surface

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fecht, S. Microbe Miners. Sci. Am. 2011, 305, 46. [Google Scholar] [CrossRef]

- George, F.; Vander, V. ASM Metal Handbook: Volume 9: Metallography and Microstructures, 9th ed.; ASM International: Geauga County, OH, USA, 2004; p. 12. ISBN 9780871707062. [Google Scholar]

- Zhang, R.Y.; Neu, T.R.; Bellenberg, S.; Kuhlicke, U.; Sand, W.; Vera, M. Use of lectins to in situ visualize glycoconjugates of extracellular polymeric substances in acidophilic archaeal biofilms. Microb. Biotechnol. 2015, 8, 448–461. [Google Scholar] [CrossRef] [PubMed]

- Vera, M.; Schippers, A.; Sand, W. Progress in bioleaching: Fundamentals and mechanisms of bacterial metal sulfide oxidation—Part A. Appl. Microbiol. Biotechnol. 2013, 97, 7529–7541. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.L.; Zhu, H.R.; Wang, L.; Liu, H.C.; Nie, Z.Y.; Zhao, Y.D.; Ma, C.Y.; Hong, C.H.; Zhen, X.J. In situ characterization of relevance of surface microstructure and electrochemical properties of chalcopyrite to adsorption of Acidianus manzaensis. Adv. Mater. Res. 2015, 1130, 183–187. [Google Scholar] [CrossRef]

- Price, D.W.; Warren, G.W. The influence of silver ion on the electrochemical response of chalcopyrite and other mineral sulfide electrodes in sulfuric acid. Hydrometallurgy 1986, 15, 303–324. [Google Scholar] [CrossRef]

- Ruiz, L.M.; Valenzuela, S.; Castro, M.; Gonzalez, A.; Frezza, M.; Soulère, L.; Rohwerder, T.; Queneau, Y.; Doutheau, A.; Sand, W.; et al. AHL communication is a widespread phenomenon in biomining bacteria and seems to be involved in mineral-adhesion efficiency. Hydrometallurgy 2008, 94, 133–137. [Google Scholar] [CrossRef]

- González, A.; Bellenberg, S.; Mamani, S.; Ruiz, L.; Echeverría, A.; Soulère, L.; Doutheau, A.; Demergasso, C.; Sand, W.; Queneau, Y.; et al. AHL signaling molecules with a large acyl chain enhance biofilm formation on sulfur and metal sulfides by the bioleaching bacterium Acidithiobacillus ferrooxidans. Appl. Microbiol. Biotechnol. 2013, 97, 3729–3737. [Google Scholar] [CrossRef] [PubMed]

- Velásquez, P.; Leinen, D.; Pascual, J.; Ramos-Barrado, J.R.; Grez, P.; Gómez, H.; Schrebler, R.; Del Río, R.; Córdova, R. A chemical, morphological, and electrochemical (XPS, SEMEDX, CV, and EIS) analysis of electrochemically modified electrode surfaces of natural chalcopyrite (CuFeS2) and pyrite (FeS2) in alkaline solutions. J. Phys. Chem. B 2005, 109, 4977–4988. [Google Scholar] [CrossRef] [PubMed]

- Brierley, C.L. Microbiological mining. Sci. Am. 1982, 247, 44–53. [Google Scholar] [CrossRef]

- Sheng, X.; Ting, Y.P.; Pehkonen, S.O. Force measurements of bacterial adhesion on metals using a cell probe atomic force microscope. J. Colloid Interface Sci. 2007, 310, 661–669. [Google Scholar] [CrossRef] [PubMed]

- Harneit, K.; Göksel, A.; Kock, D.; Klock, J.H.; Gehrke, T.; Sand, W. Adhesion to metal sulfide surfaces by cells of Acidithiobacillus ferrooxidans, Acidithiobacillus thiooxidans and Leptospirillum ferrooxidans. Hydrometallurgy 2006, 83, 245–254. [Google Scholar] [CrossRef]

- Alfonso, D.R. Computational investigation of FeS2 surfaces and prediction of effects of sulfur environment on stabilities. J. Phys. Chem. C 2010, 114, 8971–8980. [Google Scholar] [CrossRef]

- Zhang, R.Y.; Vera, M.; Bellenberg, S.; Sand, W. Attachment to minerals and biofilm development of extremely acidophilic archaea. Adv. Mater. Res. 2013, 825, 103–106. [Google Scholar] [CrossRef]

- Florian, B.; Noël, N.; Sand, W. Visualization of initial attachment of bioleaching bacteria using combined atomic force and epifluorescence microscopy. Miner. Eng. 2010, 23, 532–535. [Google Scholar] [CrossRef]

- Noël, N.; Florian, B.; Sand, W. AFM & EFM study on attachment of acidophilic leaching organisms. Hydrometallurgy 2010, 104, 370–375. [Google Scholar]

- Wang, S. Copper leaching from chalcopyrite concentrates. JOM 2005, 57, 48–51. [Google Scholar] [CrossRef]

- Zhu, W.; Xia, J.L.; Yang, Y.; Nie, Z.; Zheng, L.; Ma, C.; Zhang, R.; Peng, A.; Tang, L.; Qiu, G. Sulfur oxidation activities of pure and mixed thermophiles and sulfur speciation in bioleaching of chalcopyrite. Bioresour. Technol. 2011, 102, 3877–3882. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.Y.; Liu, J.; Neu, T.R.; Li, Q.; Bellenberg, S.; Sand, W.; Vera, M. Interspecies Interactions of metal-oxidizing thermo-acidophilic archaea Acidianus and Sulfolobus. Adv. Mater. Res. 2015, 1130, 105–108. [Google Scholar] [CrossRef]

- Huber, G.; Stetter, K.O. Sulfolobus metallicus, sp. nov. A novel strictly chemolithoautotrophic thermophilic archaeal species of metal-mobilizers. Syst. Appl. Microbiol. 1991, 14, 372–378. [Google Scholar] [CrossRef]

- Bathe, S.; Norris, P.R. Ferrous iron- and sulfur-induced genes in Sulfolobus metallicus. Appl. Environ. Microbiol. 2007, 73, 2491–2497. [Google Scholar] [CrossRef] [PubMed]

- Castro, C.; Zhang, R.; Liu, J.; Bellenberg, S.; Neu, T.R.; Donati, E.; Sand, W.; Vera, M. Biofilm formation and interspecies interactions in mixed cultures of thermo-acidophilic archaea Acidianus spp. and Sulfolobus metallicus. Res. Microbiol. 2016, 167, 604–612. [Google Scholar] [CrossRef] [PubMed]

- Dutrizac, J.E. The dissolution of chalcopyrite in ferric sulfate and ferric chloride media. Metall. Trans. B 1981, 12, 371–378. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Jeffrey, M.I.; Lawson, F. An electrochemical study of the effect of chloride ions on the dissolution of chalcopyrite in acidic solutions. Hydrometallurgy 2000, 56, 145–155. [Google Scholar] [CrossRef]

- Africa, C.J.; van Hille, R.P.; Sand, W.; Harrison, S.T.L. Investigation and in situ visualisation of interfacial interactions of thermophilic microorganisms with metal-sulphides in a simulated heap environment. Miner. Eng. 2013, 48, 100–107. [Google Scholar] [CrossRef]

- Xia, J.; Yang, Y.; He, H.; Liang, C.; Zhao, X.; Zheng, L.; Ma, C.; Zhao, Y.; Nie, Z.; Qiu, G. Investigation of the sulfur speciation during chalcopyrite leaching by moderate thermophile Sulfobacillus thermosulfidooxidans. Int. J. Miner. Process. 2010, 94, 52–57. [Google Scholar] [CrossRef]

- Newville, M. IFEFFIT: Interactive XAFS analysis and FEFF fitting. J. Synchrotron Radiat. 2001, 8, 322–324. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Neu, T.R.; Zhang, Y.; Bellenberg, S.; Kuhlicke, U.; Li, Q.; Sand, W.; Vera, M. Visualization and analysis of EPS glycoconjugates of the thermoacidophilic archaeon Sulfolobus metallicus. Appl. Microbiol. Biotechnol. 2015, 99, 7343–7356. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Zhao, X.; Liang, C.; Yang, Y.; Nie, Z.; Tang, L.; Zhao, Y.; Zheng, L.; Ma, C.; Qiu, G. Sulfur speciation transformation during bioleaching of pyrite-containing sphalerite concentrate by thermophile Sulfolobus metallicus at 65 °C. J. Cent. South Univ. Technol. 2012, 19, 1961–1966. [Google Scholar] [CrossRef]

- Li, A.; Huang, S. Comparison of the electrochemical mechanism of chalcopyrite dissolution in the absence or presence of Sulfolobus metallicus at 70 °C. Miner. Eng. 2011, 24, 1520–1522. [Google Scholar] [CrossRef]

- Liu, H.; Xia, J.; Nie, Z. Relatedness of Cu and Fe speciation to chalcopyrite bioleaching by Acidithiobacillus ferrooxidans. Hydrometallurgy 2015, 156, 40–46. [Google Scholar] [CrossRef]

- Liu, H.C.; Nie, Z.Y.; Xia, J.L.; Xia, J.L.; Yang, Y.; Zhao, C.; Zheng, L.; Zhao, Y. Investigation of copper, iron and sulfur speciation during bioleaching of chalcopyrite by moderate thermophile Sulfobacillus thermosulfidooxidans. Int. J. Miner. Process. 2015, 137, 1–8. [Google Scholar] [CrossRef]

- Gautier, V.; Escobar, B.; Vargas, T. The catalytic influence of Sulfolobus metallicus in the bioleaching of chalcopyrite: Role of attached and planktonic population. Adv. Mater. Res. 2007, 20, 354–357. [Google Scholar] [CrossRef]

- Gautier, V.; Escobar, B.; Vargas, T. Cooperative action of attached and planktonic cells during bioleaching of chalcopyrite with Sulfolobus metallicus at 70 °C. Hydrometallurgy 2008, 94, 121–126. [Google Scholar] [CrossRef]

- He, H.; Xia, J.L.; Yang, Y.; Jiang, H.; Xiao, C.; Zheng, L.; Ma, C.; Zhao, Y.; Qiu, G. Sulfur speciation on the surface of chalcopyrite leached by Acidianus manzaensis. Hydrometallurgy 2009, 99, 45–50. [Google Scholar] [CrossRef]

- He, H.; Xia, J.L.; Jiang, H.C.; Yan, Y.; Liang, C.; Ma, C. Sulfur species investigation in extra- and intracellular sulfur globules of Acidithiobacillus ferrooxidans and Acidithiobacillus caldus. Geomicrobiol. J. 2010, 27, 707–713. [Google Scholar] [CrossRef]

| Mineral | Original Chalcopyrite | Chalcopyrite Treated at 0.87 V | Chalcopyrite Treated at −0.54 V | ||||

|---|---|---|---|---|---|---|---|

| Time | Normalized Results | C (at %) | Normalized Results | C (at %) | Normalized Results | C (at %) | |

| 0 h | CuFe0.98S2.01 | 0 | CuFe1.00S2.16 | 0 | CuFe0.24S0.69 | 0 | |

| 1 h | CuFe1.02S1.98 | 6.47 | CuFe1.07S2.03 | 10.38 | CuFe0.67S1.68 | 6.28 | |

| 2 d | CuFe1.04S1.92 | 10.48 | CuFe1.07S1.90 | 16.51 | CuFe0.96S1.66 | 6.36 | |

| 4 d | CuFe1.12S1.81 | 11.47 | CuFe1.09S1.57 | 16.69 | CuFe1.04S1.46 | 9.27 | |

| 6 d | CuFe1.01S1.75 | 11.86 | CuFe1.25S1.28 | 15.23 | CuFe1.10S1.67 | 11.32 | |

| 8 d | CuFe0.97S1.59 | 13.47 | CuFe1.16S1.87 | 17.03 | CuFe1.02S1.76 | 14.85 | |

| 10 d | CuFe1.06S1.84 | 16.86 | CuFe1.62S1.83 | 18.07 | CuFe1.48S1.53 | 16.34 | |

| Mineral | Original Chalcopyrite | Chalcopyrite Treated at 0.87 V | Chalcopyrite Treated at −0.54 V | ||||

|---|---|---|---|---|---|---|---|

| Time | Normalized Results | C (at %) | Normalized Results | C (at %) | Normalized Results | C (at %) | |

| 0 h | CuFeS2.08 | 0 | CuFe1.05S2.16 | 0 | CuFe0.36S0.74 | 0 | |

| 1 h | CuFe1.01S2.05 | 2.53 | CuFe1.02S2.15 | 5.94 | CuFe0.63S1.53 | 1.97 | |

| 2 d | CuFe1.00S1.80 | 3.70 | CuFe1.05S1.94 | 8.28 | CuFe0.97S1.82 | 6.48 | |

| 4 d | CuFe1.02S1.77 | 4.81 | CuFe1.11S1.71 | 9.89 | CuFe1.02S1.71 | 5.49 | |

| 6 d | CuFe1.06S1.48 | 6.32 | CuFe1.03S1.40 | 7.07 | CuFe1.14S1.63 | 8.77 | |

| 8 d | CuFe0.96S1.54 | 8.9 | CuFe1.09S1.84 | 9.18 | CuFe0.99S1.72 | 13.92 | |

| 10 d | CuFe1.04S1.88 | 11.47 | CuFe1.80S1.78 | 10.9 | CuFe1.49S1.60 | 14.05 | |

| Sample | Time (d) | Percentage of Contribution of Reference Spectra (%) | R-Factor (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Chalcopyrite | Jarosite | Bornite | S0 | Chalcocite | Covellite | |||

| b: chalcopyrite untreated | 0 | 100 | - | - | - | - | - | 0.0017 |

| 2 | 100 | - | - | - | - | - | 0.0018 | |

| 4 | 100 | - | - | - | - | - | 0.0015 | |

| 6 | 100 | - | - | - | - | - | 0.0018 | |

| 8 | 98.9 | 1.1 | - | - | - | - | 0.0016 | |

| 10 | 96.6 | 2.1 | - | - | - | 1.3 | 0.0017 | |

| c: chalcopyrite treated at 0.87 V | 0 | 83.0 | - | - | 14.3 | - | 2.7 | 0.0015 |

| 2 | 98.8 | - | - | - | - | 1.2 | 0.0016 | |

| 4 | 98.8 | 0.7 | - | - | - | 0.0016 | ||

| 6 | 98.7 | 1.3 | - | - | - | - | 0.0015 | |

| 8 | 95.4 | 2.3 | - | 0.9 | - | 1.2 | 0.0014 | |

| 10 | 92.6 | 3.5 | - | 1.9 | - | 2.0 | 0.0013 | |

| d: chalcopyrite treated at −0.54 V | 0 | 68.8 | - | 23.0 | - | 9.2 | - | 0.0013 |

| 2 | 89.5 | - | 10.1 | - | - | 0.4 | 0.0018 | |

| 4 | 98.6 | - | 1.1 | - | - | 0.3 | 0.0015 | |

| 6 | 98.9 | 1.1 | - | - | - | - | 0.0012 | |

| 8 | 97.7 | 1.7 | - | 0.6 | - | - | 0.0014 | |

| 10 | 96.7 | 2.2 | - | 1.1 | - | - | 0.0016 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ling, W.; Wang, L.; Liu, H.; Nie, Z.; Yang, Y.; Yang, Y.; Ma, C.; Zheng, L.; Zhao, Y.; Xia, J. The Evidence of Decisive Effect of Both Surface Microstructure and Speciation of Chalcopyrite on Attachment Behaviors of Extreme Thermoacidophile Sulfolobus metallicus. Minerals 2018, 8, 159. https://doi.org/10.3390/min8040159

Ling W, Wang L, Liu H, Nie Z, Yang Y, Yang Y, Ma C, Zheng L, Zhao Y, Xia J. The Evidence of Decisive Effect of Both Surface Microstructure and Speciation of Chalcopyrite on Attachment Behaviors of Extreme Thermoacidophile Sulfolobus metallicus. Minerals. 2018; 8(4):159. https://doi.org/10.3390/min8040159

Chicago/Turabian StyleLing, Weibo, Lei Wang, Hongchang Liu, Zhenyuan Nie, Yun Yang, Yi Yang, Chenyan Ma, Lei Zheng, Yidong Zhao, and Jinlan Xia. 2018. "The Evidence of Decisive Effect of Both Surface Microstructure and Speciation of Chalcopyrite on Attachment Behaviors of Extreme Thermoacidophile Sulfolobus metallicus" Minerals 8, no. 4: 159. https://doi.org/10.3390/min8040159