An Innovative Longwall Mining Technology in Tangshan Coal Mine, China

Abstract

:1. Introduction

- (1)

- Large inclination, 30° on average, which leads to longwall equipment slide.

- (2)

- Cover depth is from −550 m to −658 m, and ground pressure is relatively high.

- (3)

- In order to avoid high side abutment pressure, a large gateway pillar has to be left between adjacent panels leading to low recovery. Moreover, top coal on the top of four shields on each end of the face and gateways cannot be recovered, which further leads to low recovery.

- (4)

- Coal bumps, rock bursts and severe convergence occur frequently in the gateway only a gateway pillar away from gob due to side abutment pressure, leading to support problems and even un-serviceable result of the gateway.

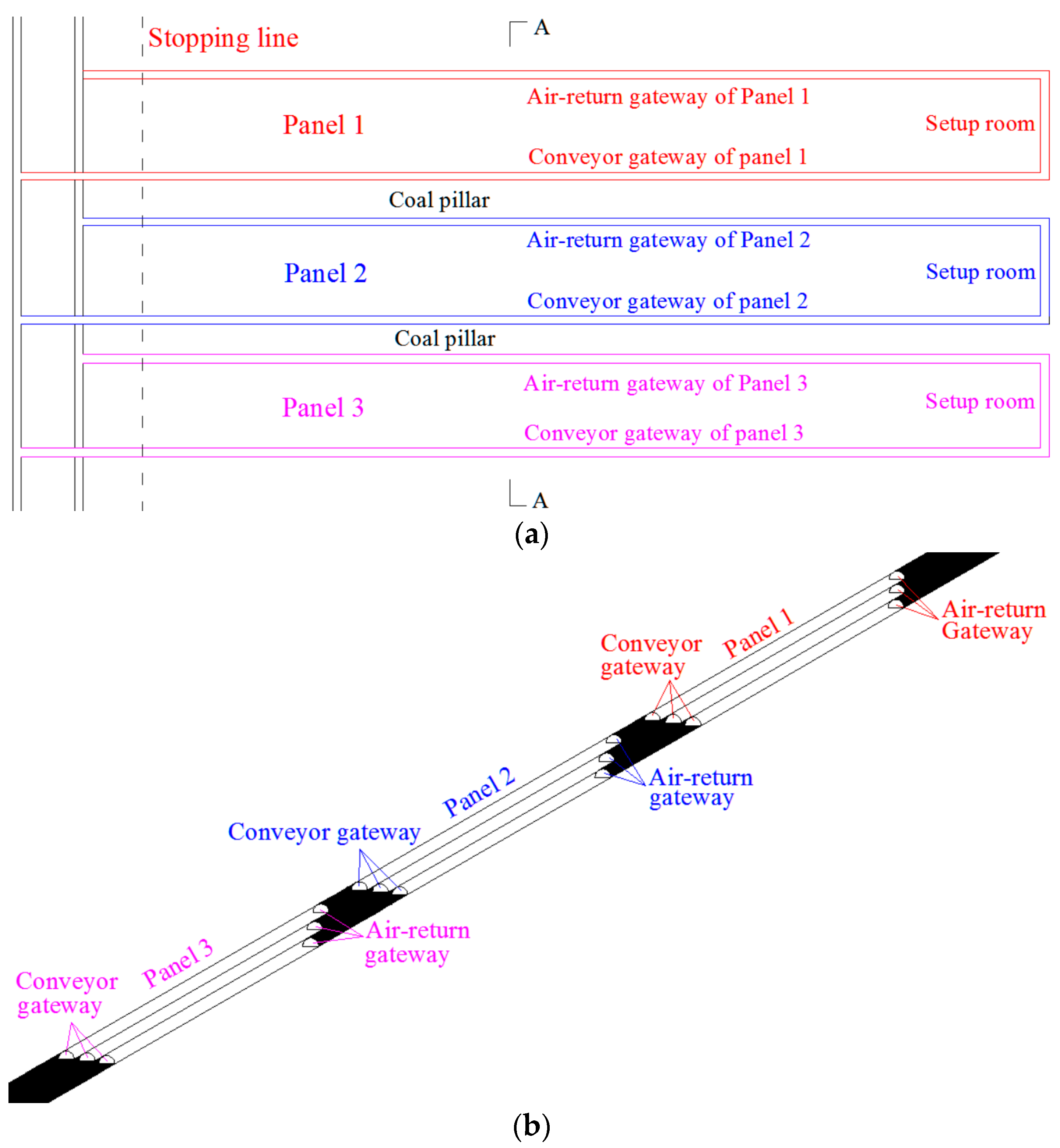

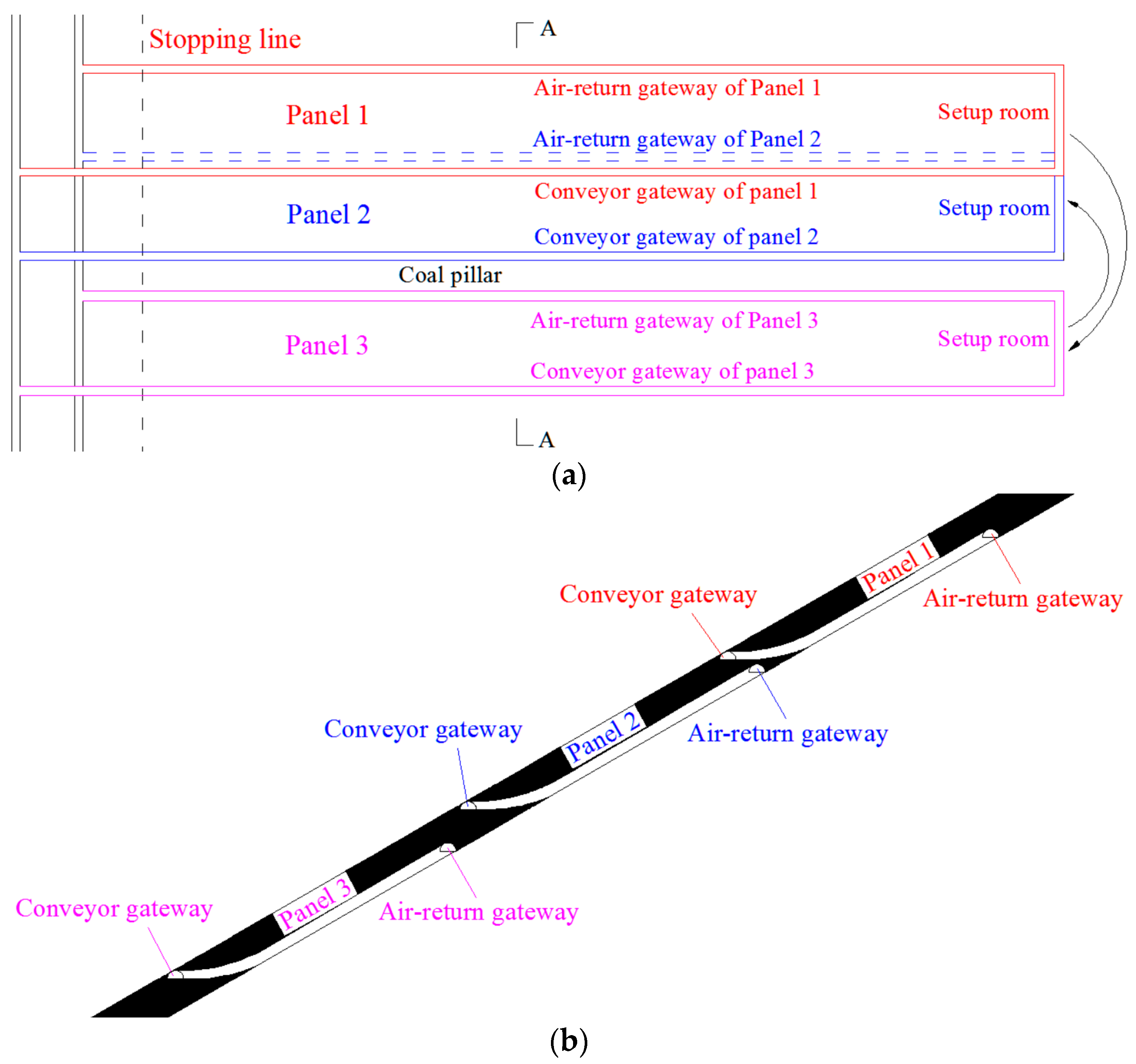

2. Mining Methods

2.1. Conventional Method

- (1)

- Machines in the face tend to slide due to inclination;

- (2)

- A large gateway pillar must be left unmined between adjoining panels, leading to low recovery;

- (3)

- Practice shows that MLM cannot achieve high productivity and high efficiency as tunneling work amount was large, longwall move was frequent and upper gob was repeatedly influenced by mining activity of the lower slices leading to spontaneous combustion and fires within the gob.

- (1)

- Low recovery: Practice shows that failing to extract top coal above gateways and above face end shields and large coal pillars led to low recovery, making it hard to meet the requirement of 75% of recovery for a longwall panel by law in China.

- (2)

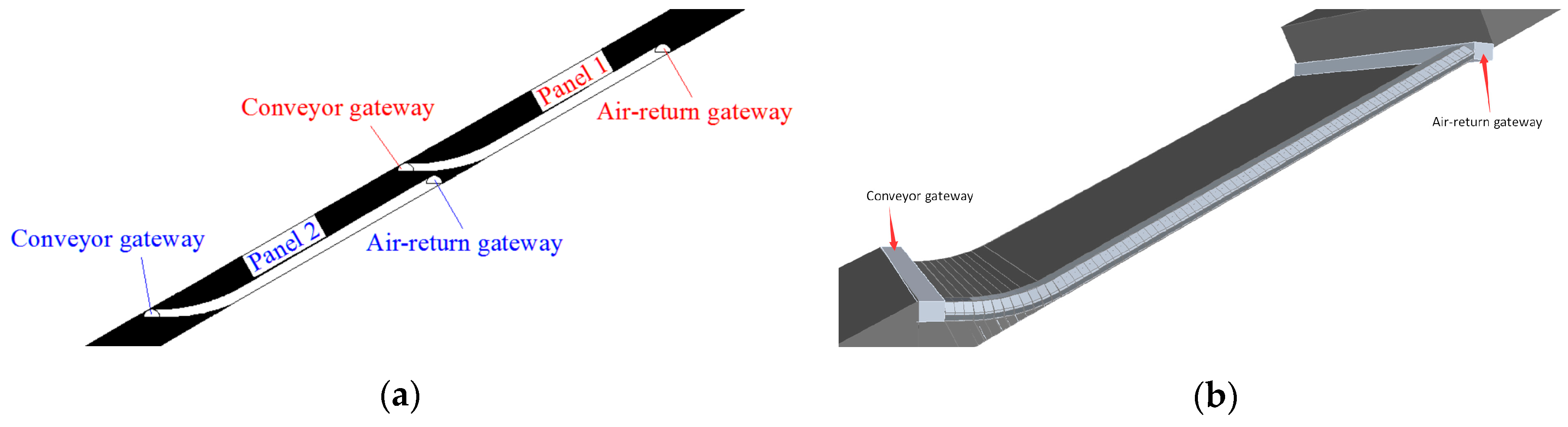

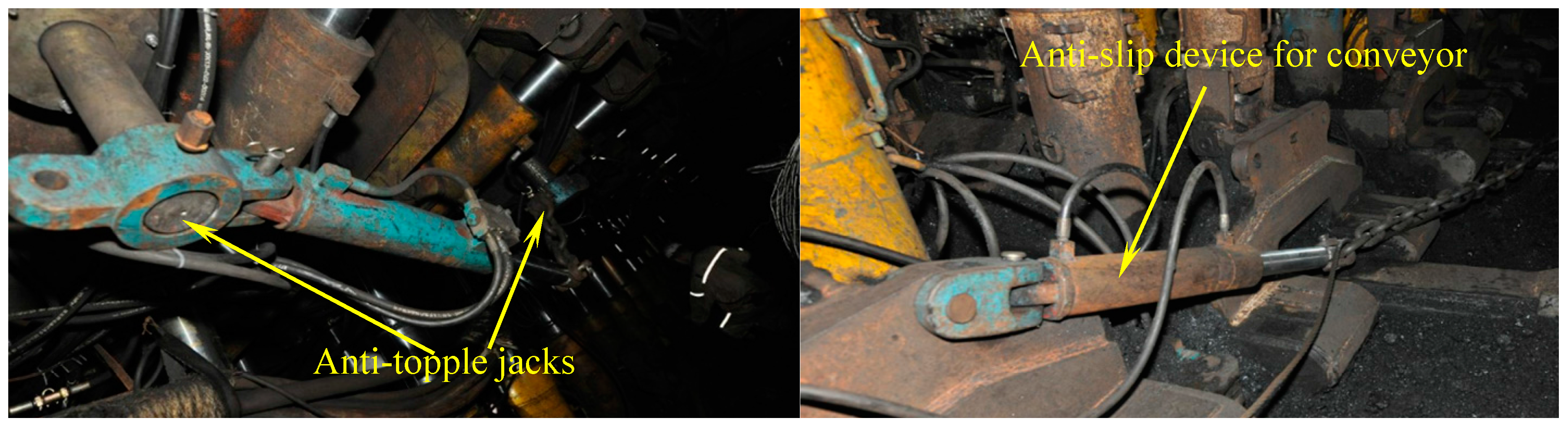

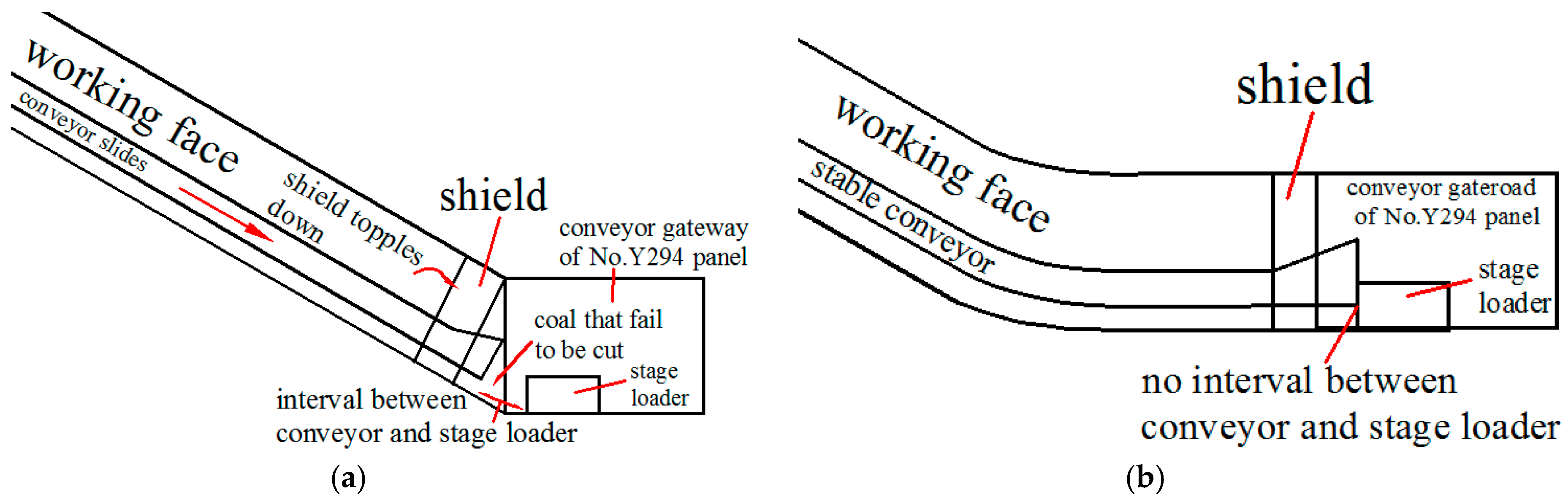

- Stability problems: As coal seam inclination is up to 30° on average, shields tend to slide or topple down, and shearer and conveyor tend to slide, too.

- (3)

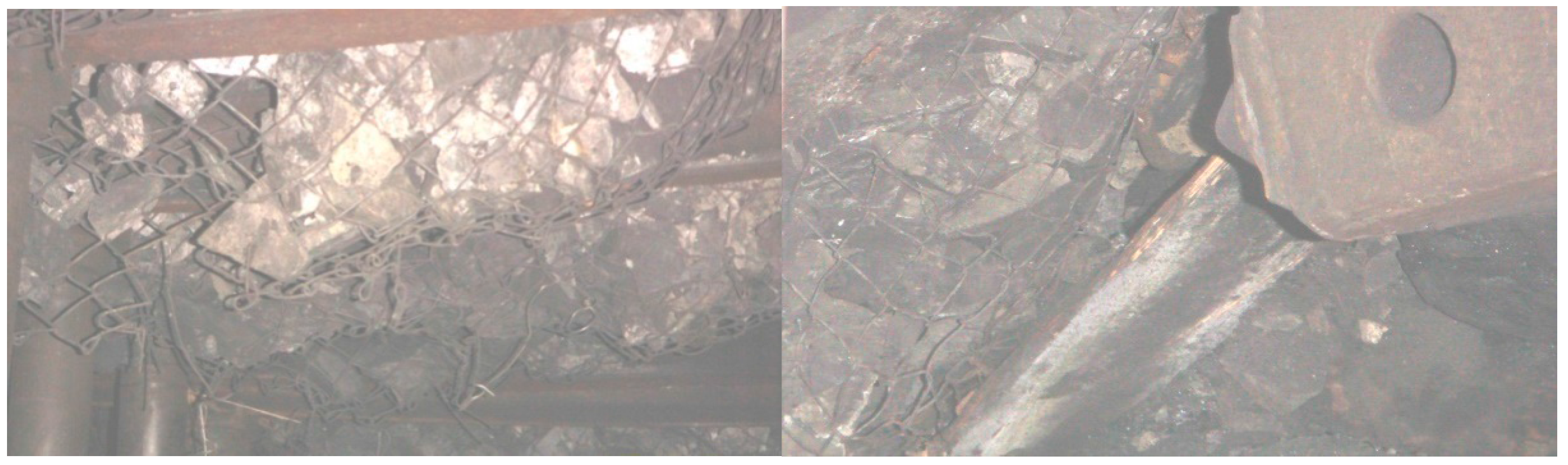

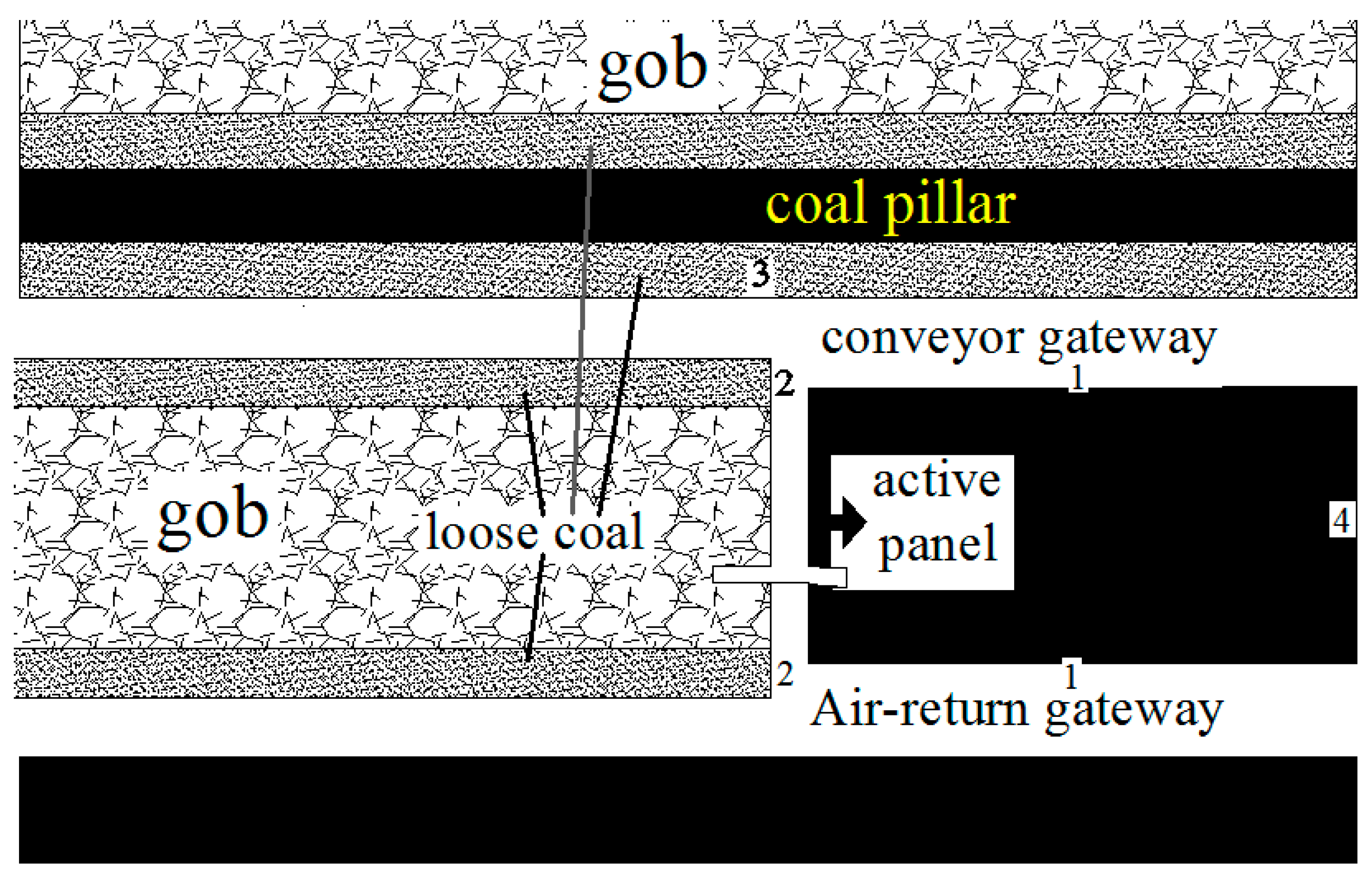

- Support problems in gateways. As gateways in CLTCC were driven along the floor, their roof was relatively soft coal and roof falls were frequent. In addition, due to the gateway pillar, stress concentration not only occurred on the pillar, but also transferred to the gateways leading to severe deformation and support difficulties in gateways.

- (4)

- Spontaneous combustion: Coal loss employing CLTCC gives rise to spontaneous combustion, especially in loose coal lost in gob. There were a few spontaneous combustion prone areas such as high coal roof failure areas of the gateways which accounted for two-thirds of fire disasters in the coal mine, and two ends of working face where top coal failed to be extracted and other locations where the amount of coal loss was large.

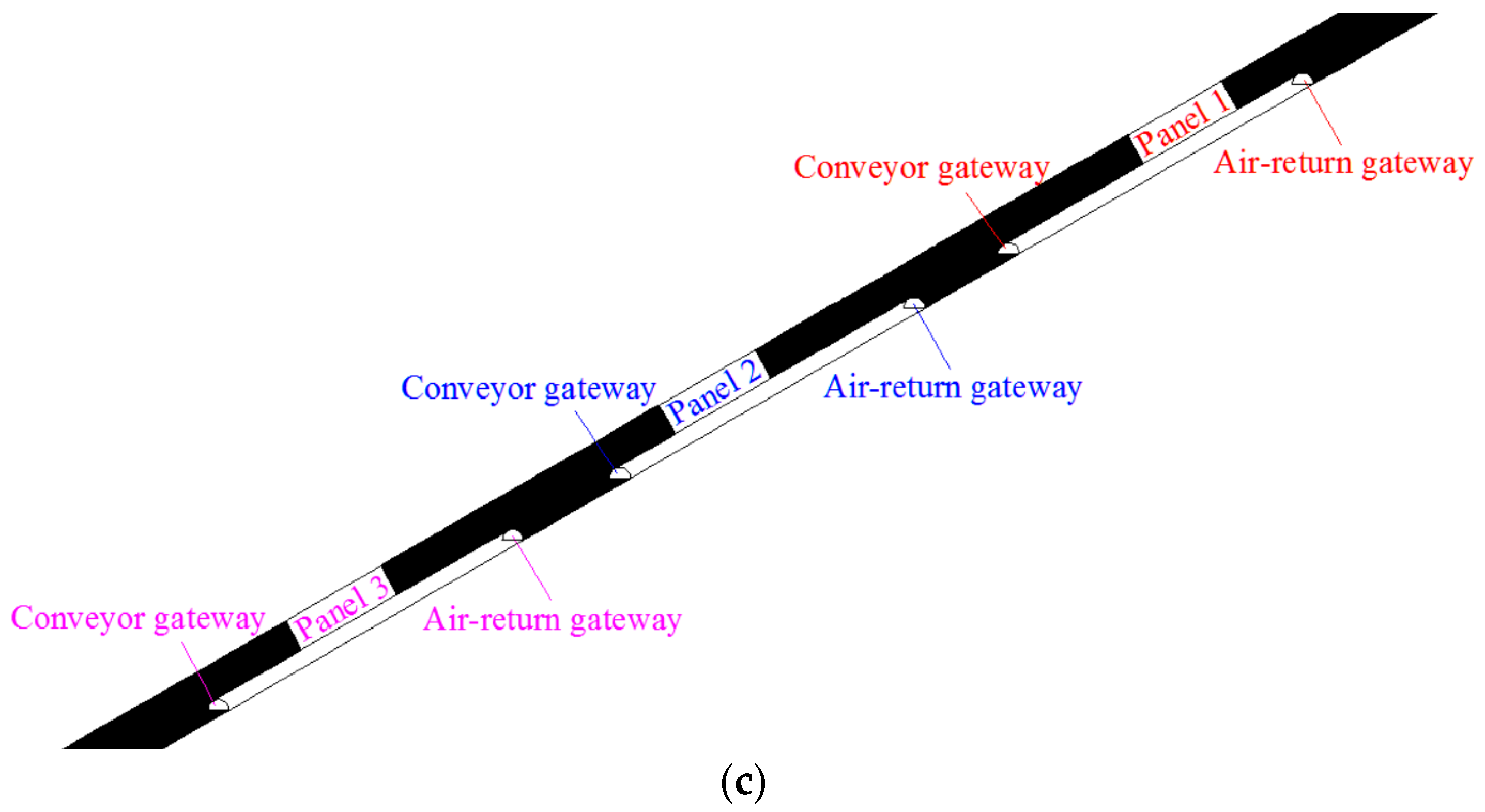

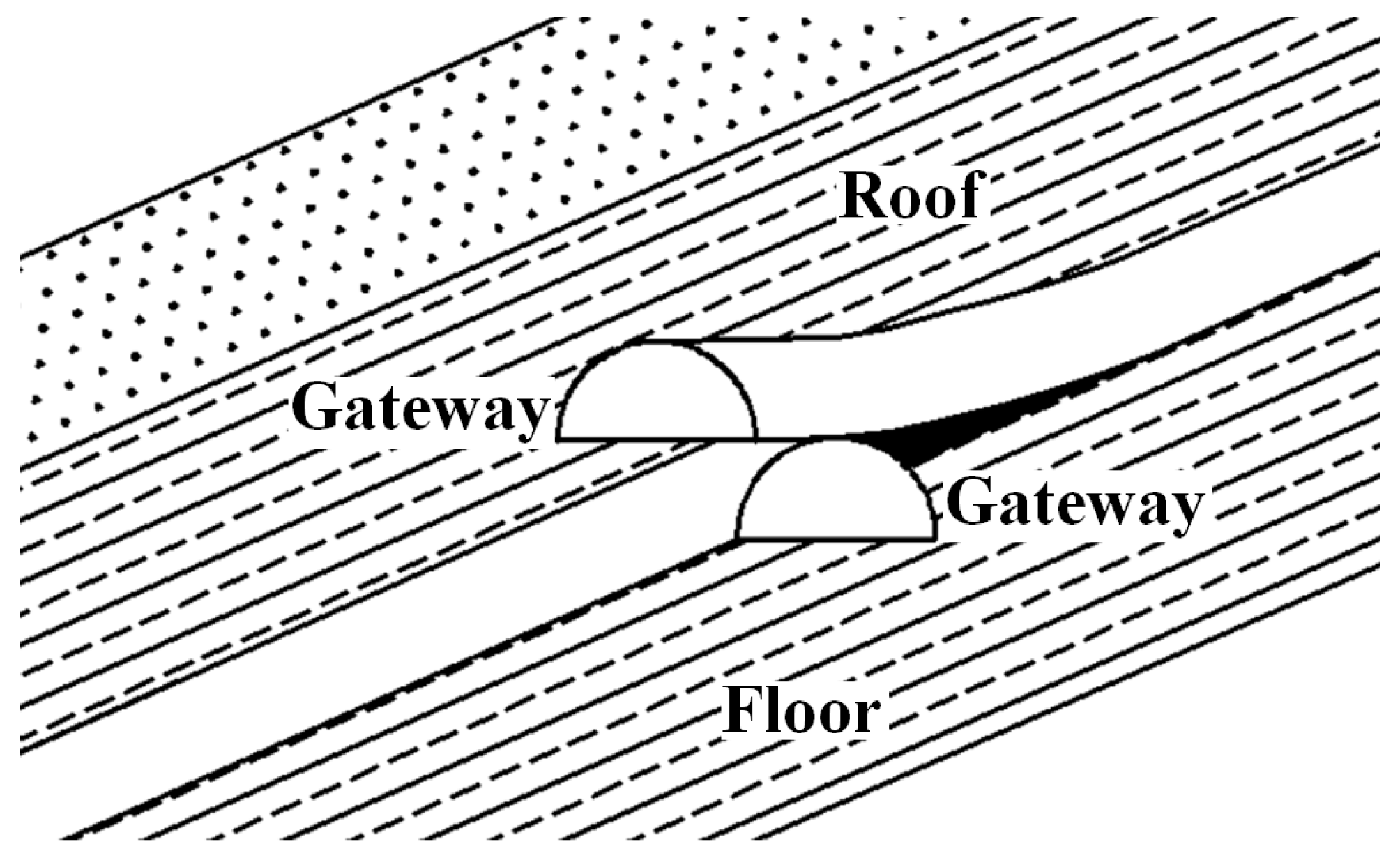

2.2. The New Strategy

2.3. Mining Operations in the LMSG

2.4. Panel Continuance

3. Advantages of the Technology and Concerns

3.1. Advantages

3.2. Concerns and Constraints

3.3. Pillar Design in the LMSG

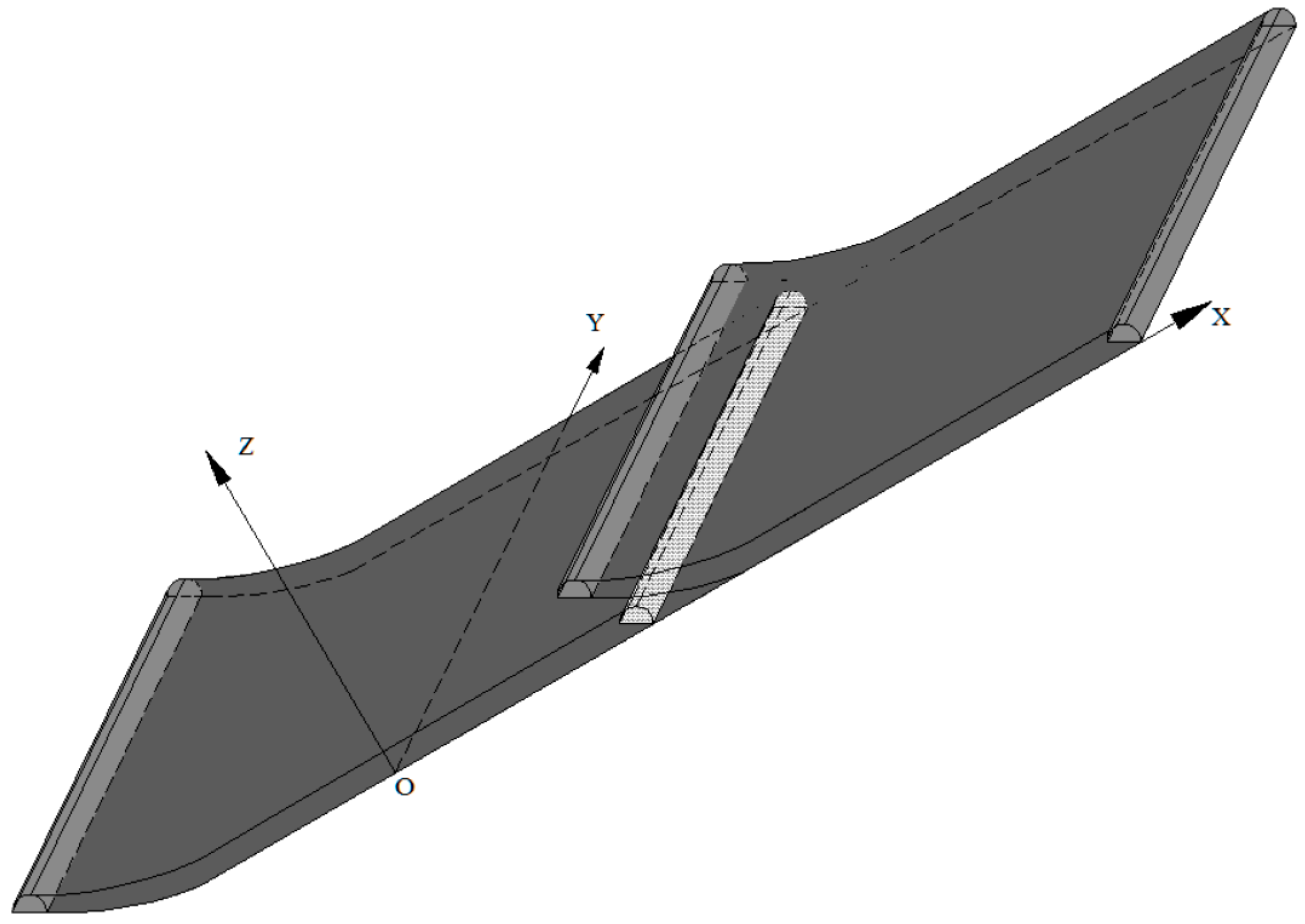

4. Physical Modelling of the LMSG Panel for Tangshan Coal Mine

5. Analysis and Discussion of Physical Modeling Results

6. Concluding Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, J.L. New Discussion on Whole Coal Seam Mining Techniques; China Coal Industry Publishing House: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Du, J.P.; Meng, X.R. Mining Technology; University of Mining and Technology Press: Xuzhou, China, 2009. (In Chinese) [Google Scholar]

- Wu, Y.P.; Yun, D.F.; Zhang, M.F. Study on the elementary problems of fully mechanized coal mining in greater pitching seam. J. China Coal Soc. 2000, 25, 465–468. (In Chinese) [Google Scholar]

- Wu, Y.P.; Xie, P.S.; Yang, Y.G.; Ren, S.G. Numerical simulation and complexity analysis of strata movement in exploiting steep coal seams group. J. Min. Saf. Eng. 2007, 24, 391–395. (In Chinese) [Google Scholar]

- Kailuan Energy Chemical. Available online: http://www.kkcc.com.cn:8010/en/address.htm (accessed on 21 September 2016).

- Zhang, J.C. Practice of LMSG in thick coal seams. Inn. Mong. Coal Econ. 2014, 12, 108–161. (In Chinese) [Google Scholar]

- Zhao, J.L. Whole Seam Longwall Mining with Split-Level Gateways (LMSG) In Thick Coal Seams. China Patent ZL98100544.6, 23 January 2002. [Google Scholar]

- Zhao, J.L.; Li, B. A study on raising the recovery ratio of fully-mechanized coal-talking about stagger-position-roadway-arrangement system. J. Liaoning Tech. Univ. (Nat. Sci.) 1998, 17, 237–239. (In Chinese) [Google Scholar]

- Zhao, J.L. Triple Sections Mining Technology (TSMT) in LMSG in Thick Coal Seams. China Patent 2004100395750, 10 February 2004. [Google Scholar]

- Zhao, J.L. Study on whole seam longwall mining with split-level gateroad. J. China Coal Soc. 2004, 2, 142–145. (In Chinese) [Google Scholar]

- Zhao, J.L. “3-Section” Technology of Full-Dimension Mining in Flat Thick-Seam. J. China Univ. Min. Technol. 2004, 14, 13–15. [Google Scholar]

- Peng, S.S. Longwall Mining, 2nd ed.; Society for Mining, Metallurgy, and Exploration, Inc. (SME): Englewood, CO, USA, 2006. [Google Scholar]

- Zhao, J.L. Development and outlook of 3-D stagger arrangement roadway layout technology. Coal Eng. 2014, 46, 1–3. (In Chinese) [Google Scholar]

- Qian, M.G.; Shi, P.W.; Xu, J.L. Ground Pressure and Strata Control; China University of Mining and Technology Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Qiao, J. Julia Sets and Complex Singularities of Free Energies; Memoirs of the American Mathematical Society: Providence, RI, USA, 2015; Volume 234, p. 1. Available online: http://www.ams.org/books/memo/1102/ (accessed on 28 July 2014).

- Ghabraie, B.; Ren, G.; Zhang, X.Y.; Smith, J. Physical modelling of subsidence from sequential extraction of partially overlapping longwall panels and study of substrata movement characteristics. Int. J. Coal Geol. 2015, 140, 71–83. [Google Scholar] [CrossRef]

- Zhu, W.S.; Li, Y.; Li, S.C.; Wang, S.G.; Zhang, Q.B. Quasi-three-dimensional physical model tests on a cavern complex under high in-situ stresses. Int. J. Rock Mech. Min. Sci. 2011, 48, 199–209. [Google Scholar]

| Lithology | Number | Height/m | Character Description |

|---|---|---|---|

| Medium grained sandstone | 1 | 9.8 | Dark gray, argillaceous texture, plenty of plant root fossils |

| Siltstone | 2 | 5.7 | Dark gray, mainly quartz and feldspar |

| Coal No. 5 | 3 | 3 | Simple structure. |

| Siltstone | 4 | 11 | Dark gray, argillaceous texture, horizontal bedding planes |

| Coal No. 6 | 5 | 1.4 | With pyrite concretion |

| Sandy mudstone | 6 | 5.7 | Dark gray, with plant root fossil at the top and siderite concretion at the bottom |

| Coal No. 7 | 7 | 0.34 | Unstable, locally tailing-out |

| Siltstone | 8 | 4.2 | Dark gray, compact, with siderite concretion and plant root fossils |

| Medium grained sandstone | 9 | 4.9 | Light gray, mainly quartz, partially detritus, siliceous cemented, partially clipping with thin sandstone bed, horizontally stratified beddings |

| Siltstone | 10 | 7.5 | Dark gray, homogeneous, compact, horizontal stratification. |

| Carbon mudstone | 11 | 0–2.3 | Black, mainly carbonaceous content, with 1–2 coal lines |

| Coal Nos. 8 and 9 | 12 | 8.7 | Mainly dark bright coal, semi bright coal, vitreous and shiny, simple and hard. There are 1–2 layers of 0.5 m of gangue of black carbonaceous mudstone in the coal seam. |

| Siltstone | 13 | 3.15 | Dark gray, compact, Homogeneous, fine, with small amount of plant root fossils, calcite vein and scattered siderite crystals are seen |

| Fine grained sandstone | 14 | 3.29 | Brown and grey, mainly quartz, partially dead color minerals and small amount of detritus with calcium locally, relatively hard |

| Siltstone | 15 | 4.75 | Dark gray, homogeneous, fine and relatively pure, with shell-shaped fractures. |

| Method | Panel Width Lp (m) | Coal Seam Thickness Hc (m) | Height of the Gateway Hg (m) | Width of the Coal Pillar Lc (m) | Recovery Ratio η |

|---|---|---|---|---|---|

| CLTCC | 90 | 8.7 | 3 | 20 | 74.7% |

| LMSG | 102 | 8.7 | 3 | −5 | 89.1% |

| Lithology | Height (m) | Density (kg/m3) | Modulus of Elasticity (MPa) | Poisson’s Ratio | Internal Friction Angle (°) | Tensile Strength (MPa) | Cohesion (MPa) | UCS (MPa) |

|---|---|---|---|---|---|---|---|---|

| Siltstone | 11.0 | 2650 | 18,000 | 0.24 | 35 | 7.0 | 5.2 | 127 |

| Coal No. 6 | 1.4 | 1500 | 3000 | 0.25 | 25 | 1.2 | 0.8 | 19.7 |

| Sandy mudstone | 5.7 | 2600 | 15,000 | 0.24 | 34 | 6.0 | 6.1 | 96.0 |

| Siltstone | 4.2 | 2700 | 18,000 | 0.24 | 35 | 7.0 | 5.2 | 127 |

| Medium grained sandstone | 4.9 | 2600 | 32,000 | 0.22 | 40 | 7.3 | 6.4 | 144 |

| Siltstone | 8.0 | 2700 | 18,000 | 0.24 | 35 | 7.0 | 5.2 | 127 |

| Coal Nos. 8 and 9 | 8.7 | 1500 | 3000 | 0.25 | 25 | 1.2 | 0.8 | 19.7 |

| Siltstone | 3.2 | 2700 | 18,000 | 0.24 | 35 | 7.0 | 5.2 | 127 |

| Fine grained sandstone | 3.3 | 2650 | 20,000 | 0.23 | 37 | 7.3 | 4.8 | 99.0 |

| Rock Types | UCS (MPa) | Unit Weight (g/cm3) | Proportion Number | Materials | Aggregate:Materials | Lime:Plaster (lime:soil) |

|---|---|---|---|---|---|---|

| Medium grained sandstone | 0.062 | 1.625 | 6:5:5 | Fine sand:lime:plaster | 6:1 | 7:5 |

| Fine grained sandstone | 0.043 | 1.656 | 8:6:4 | Fine sand:lime:plaster | 7:1 | 6:4 |

| Siltstone | 0.055 | 1.688 | 6:5:5 | Fine sand:lime:plaster | 6:1 | 5:5 |

| Sandy mudstone | 0.042 | 1.625 | 10:9:1 | Fine sand:lime:plaster | 8:1 | 9:1 |

| Coal | 0.0085 | 0.938 | 10:1:0 | Fine sand:lime:soil | 10:1 | 7:2 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Wang, P.; Su, Y. An Innovative Longwall Mining Technology in Tangshan Coal Mine, China. Minerals 2017, 7, 14. https://doi.org/10.3390/min7010014

Zhao J, Wang P, Su Y. An Innovative Longwall Mining Technology in Tangshan Coal Mine, China. Minerals. 2017; 7(1):14. https://doi.org/10.3390/min7010014

Chicago/Turabian StyleZhao, Jingli, Pengfei Wang, and Yue Su. 2017. "An Innovative Longwall Mining Technology in Tangshan Coal Mine, China" Minerals 7, no. 1: 14. https://doi.org/10.3390/min7010014