Scale Effect of Premixed Methane-Air Combustion in Confined Space Using LES Model

Abstract

:1. Introduction

2. Numerical Theories

2.1. Turbulence Model

2.2. Combustion Model

2.3. Chapman-Jouguet (CJ) Detonation Theory

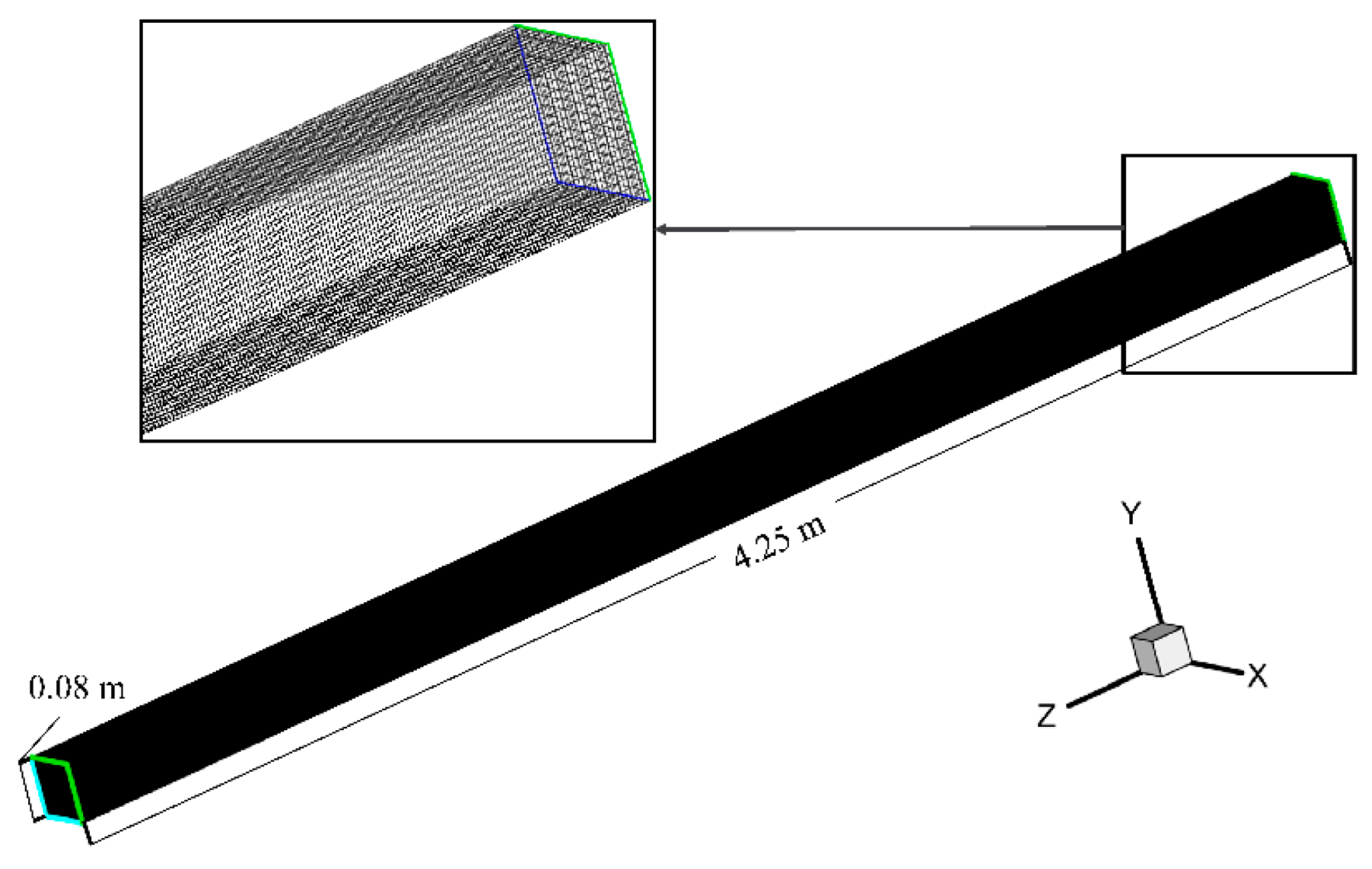

3. Computational Fluid Dynamics Details

3.1. Discretization

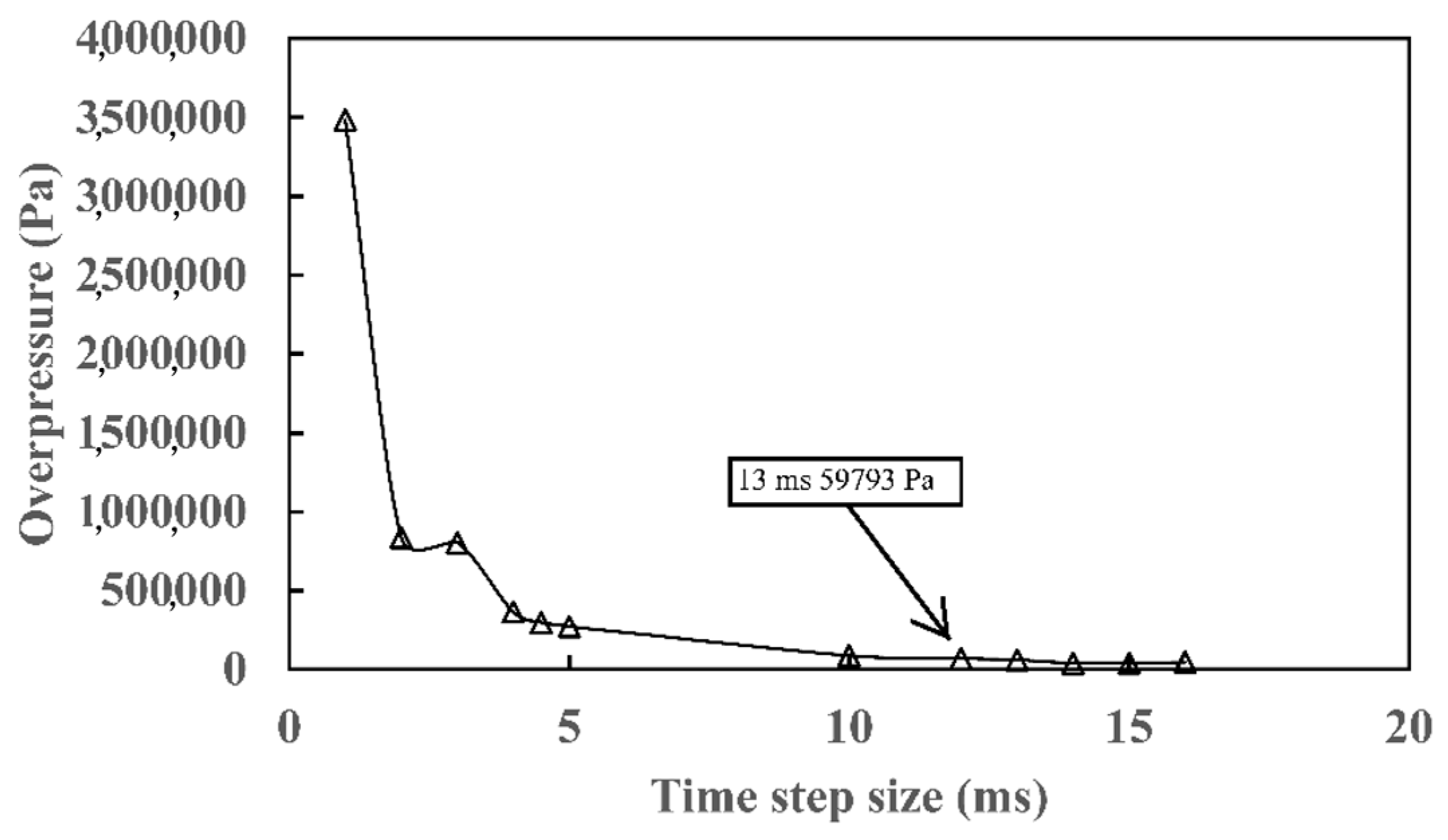

3.2. Numerical Details

4. Validation

5. Results and Discussion

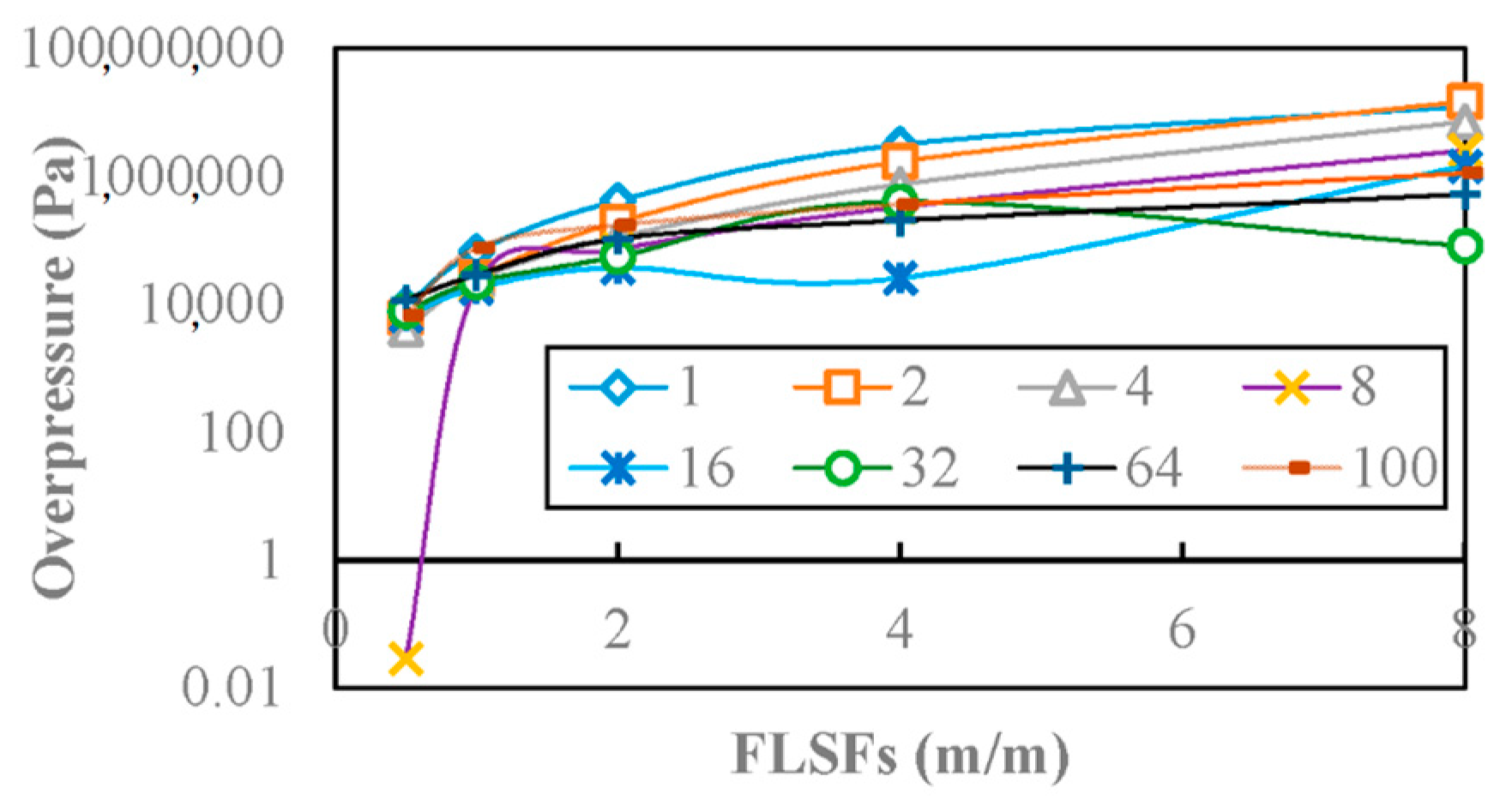

5.1. FLSFs

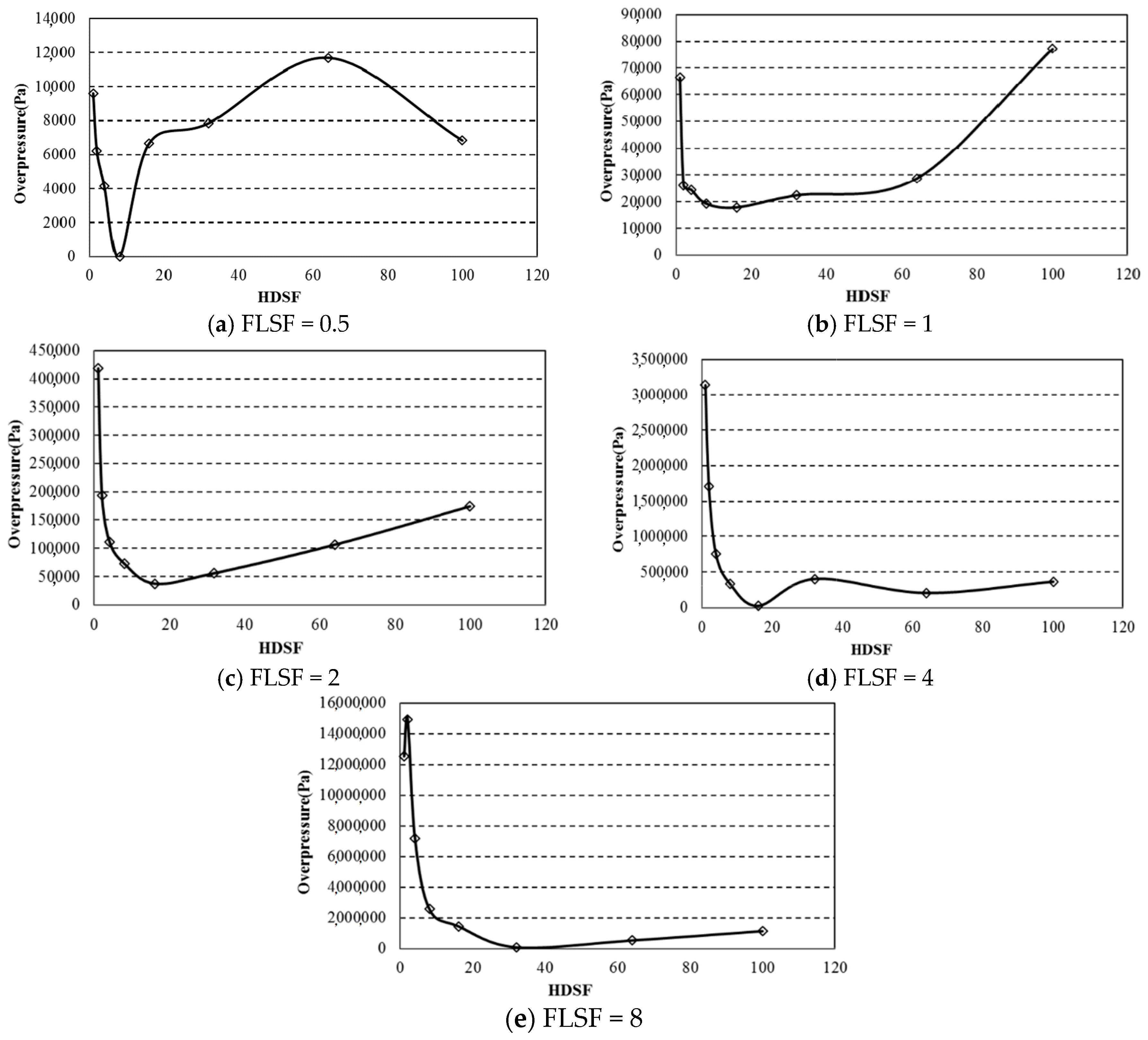

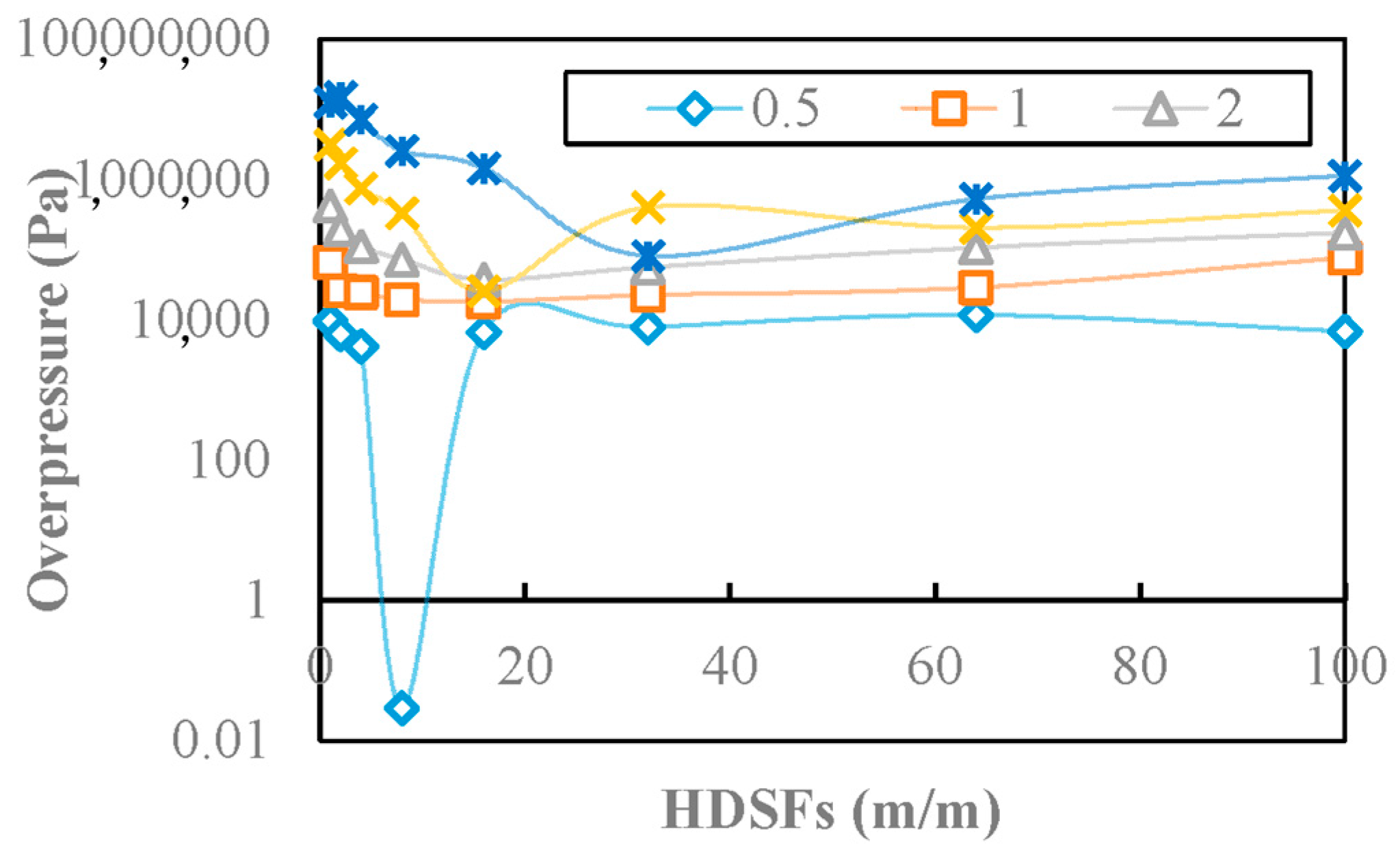

5.2. HDSFs

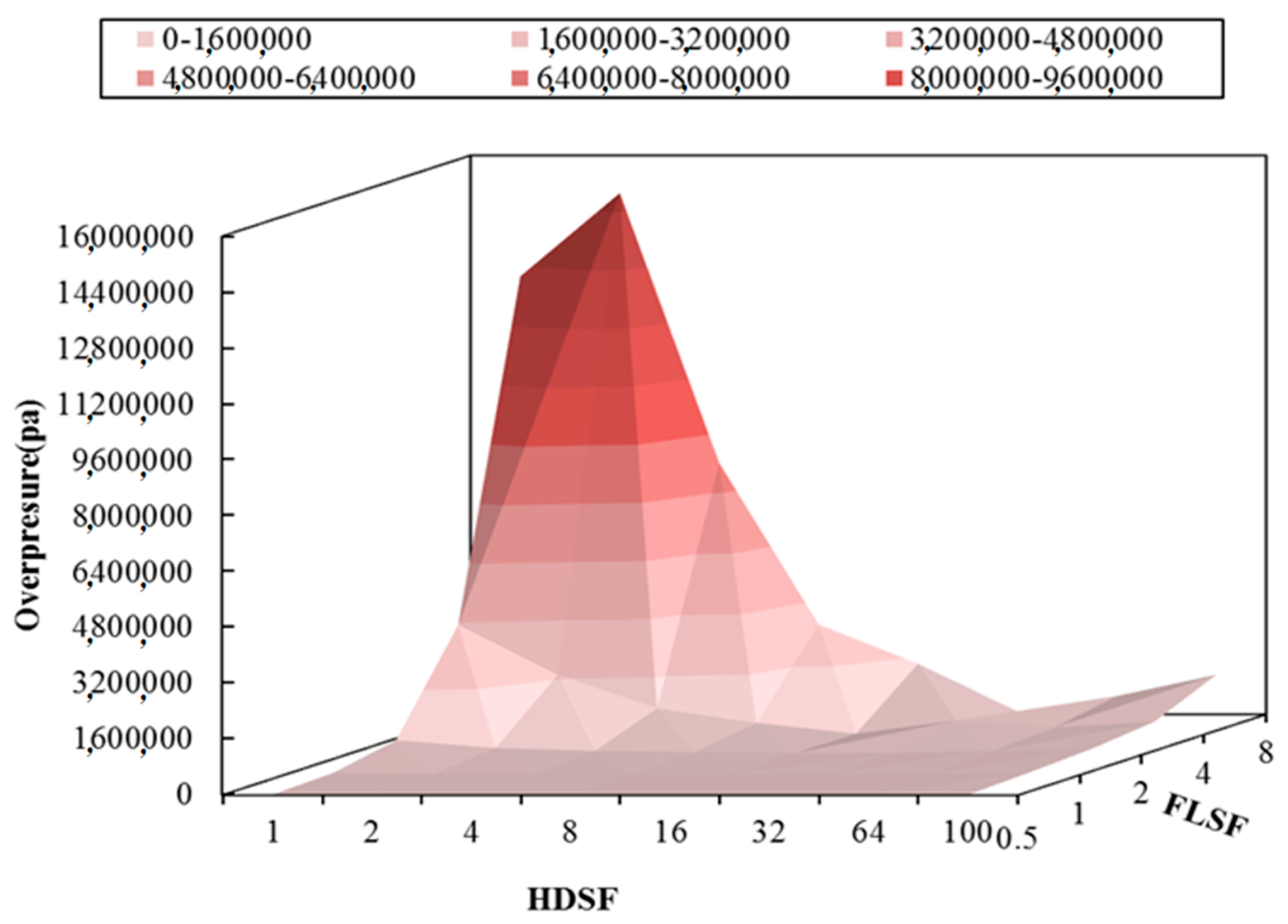

5.3. Combined Effect

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- McPherson, M.J. Subsurface Ventilation Engineering; Mine Ventilation Services: California, CA, USA, 1993; pp. 21.45–21.46. [Google Scholar]

- Catlin, C.A.; Johnson, D.M. Experimental scaling of the flame acceleration phase of an explosion by changing fuel gas reactivity. Combust. Flame 1992, 88, 15–27. [Google Scholar] [CrossRef]

- Catlin, C.A. Scale effect on the external combustion caused by venting of a confined explosion. Combust. Flame 1991, 83, 399–411. [Google Scholar] [CrossRef]

- Zhang, Q.; Pang, L.; Zhang, S.X. Effect of scale on flame speeds of methane-air. J. Loss Prev. Process Ind. 2011, 24, 705–712. [Google Scholar] [CrossRef]

- Van Wingerden, C.J.M. On the scaling of vapour cloud explosion experiments. Chem. Eng. Res. Des. 1989, 67, 339–347. [Google Scholar]

- Di Sarli, V.; di Benedetto, A.; Russo, G.; Jarvis, S.; Long, E.J.; Hargrave, G.K. Large eddy simulation and PIV measurements of unsteady premixed flames accelerated by obstacles. Flow Turbul. Combust. 2009, 83, 227–250. [Google Scholar] [CrossRef]

- Di Sarli, V.; di Benedetto, A.; Russo, G. Using large eddy simulation for understanding vented gas explosions in the presence of obstacles. J. Hazard. Mater. 2009, 169, 435–442. [Google Scholar] [CrossRef] [PubMed]

- Di Sarli, V.; di Benedetto, A.; Russo, G. Sub-grid scale combustion models for large eddy simulation of unsteady premixed flame propagation around obstacles. J. Hazard. Mater. 2009, 180, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Di Sarli, V.; di Benedetto, A. Sensitivity to the presence of the combustion submodel for large eddy simulation of transient premixed flame—Vortex interactions. Ind. Eng. Chem. Res. 2012, 51, 7704–7712. [Google Scholar] [CrossRef]

- Di Sarli, V.; di Benedetto, A. Effects of non-equidiffusion on unsteady propagation of hydrogen-enriched methane/air premixed flames. Int. J. Hydrog. Energy 2013, 38, 7510–7518. [Google Scholar] [CrossRef]

- Zhang, Q.; Pang, L.; Liang, H.M. Effect of scale on the explosion of methane in air and its shockwave. J. Loss Prev. Process Ind. 2011, 24, 43–48. [Google Scholar] [CrossRef]

- Hinze, J.O. Turbulence; McGraw-Hill Publishing Co.: New York, NY, USA, 1975. [Google Scholar]

- ANSYS, Inc. Anon ANSYS FLUENT Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2011. [Google Scholar]

- Zimont, V.; Polifke, W.; Bettelini, M.; Weisenstein, W. An efficient computational model for premixed turbulent combustion at high reynolds numbers based on a turbulent flame speed closure. J. Gas Turbines Power 1998, 120, 526–532. [Google Scholar] [CrossRef]

- Ewald, J. A Level Set Based Flamelet Model for the Prediction of Combustion in Homogeneous Charge and Direct Injection Spark Ignition Engines. Available online: tocs.ulb.tu-darmstadt.de/177689706.pdf (accessed on 13 December 2015).

- Londoño, L.F.; López, C.E.; Cadavid, F. Hugo burbano determination of laminar flame speed of methane/air flames at subatmospheric conditions using the cone method and CH emission. Dyna 2013, 80, 130–135. [Google Scholar]

- Zhou, X.Q.; Wu, B.; Xu, J.D. Basic characters of gas explosion in underground coal mines. China Coal Mines 2002, 28, 8–11. [Google Scholar]

- Needham, C.E. Shock Wave and High Pressure Phenomena. In Blast Wave; Springer Express: Somerset, UK, 2010; pp. 87–99, 293–302. [Google Scholar]

- Pekalski, A.A.; Schildberg, H.P.; Smallegange, P.S.D.; Lemkowitz, S.M.; Zevenbergen, J.F.; Braithwaite, M. Determination of the explosion behavior of methane and propane in air or oxygen at standard and elevated conditions. Process Saf. Environ. Prot. 2005, 83, 421–429. [Google Scholar] [CrossRef]

- Yáñez, J.; Kotchourko, A.; Lelyakin, A.; Gavrikov, A.; Efimenko, A.; Zbikowski, M.; Makarove, D.; Molkove, V. A comparison exercise on the CFD detonation simulation in large scale confined volumes. Int. J. Hydrog. Energy 2011, 36, 2613–2619. [Google Scholar] [CrossRef]

- Di Sarli, V.; di Benedetto, A.; Russo, G. Large eddy simulation of transient premixed flame—Vortex interactions in gas explosions. Chem. Eng. Sci. 2012, 71, 539–551. [Google Scholar] [CrossRef]

- Oran, E.S.; Gamezo, V.N. Origins of the deflagration-to-detonation transition in gas-phase combustion. Combust. Flame 2007, 148, 4–47. [Google Scholar] [CrossRef]

- Zipf, R.K.; Sapko, M.J.; Marchewka, W.P.; Mohamed, K.M.; Weiss, E.S.; Addis, J.D.; Karnack, F.A.; Sellers, D.D.; Gamezo, V.N.; Oran, E.S.; et al. Methane-air detonation experiments at NIOSH Lake Lynn laboratory. J. Loss Prev. Process Ind. 2013, 26, 295–301. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Que, S.; Tien, J.C.; Aouad, N.S. Scale Effect of Premixed Methane-Air Combustion in Confined Space Using LES Model. Minerals 2016, 6, 2. https://doi.org/10.3390/min6010002

Wang L, Que S, Tien JC, Aouad NS. Scale Effect of Premixed Methane-Air Combustion in Confined Space Using LES Model. Minerals. 2016; 6(1):2. https://doi.org/10.3390/min6010002

Chicago/Turabian StyleWang, Liang, Sisi Que, Jerry C. Tien, and Nassib S. Aouad. 2016. "Scale Effect of Premixed Methane-Air Combustion in Confined Space Using LES Model" Minerals 6, no. 1: 2. https://doi.org/10.3390/min6010002