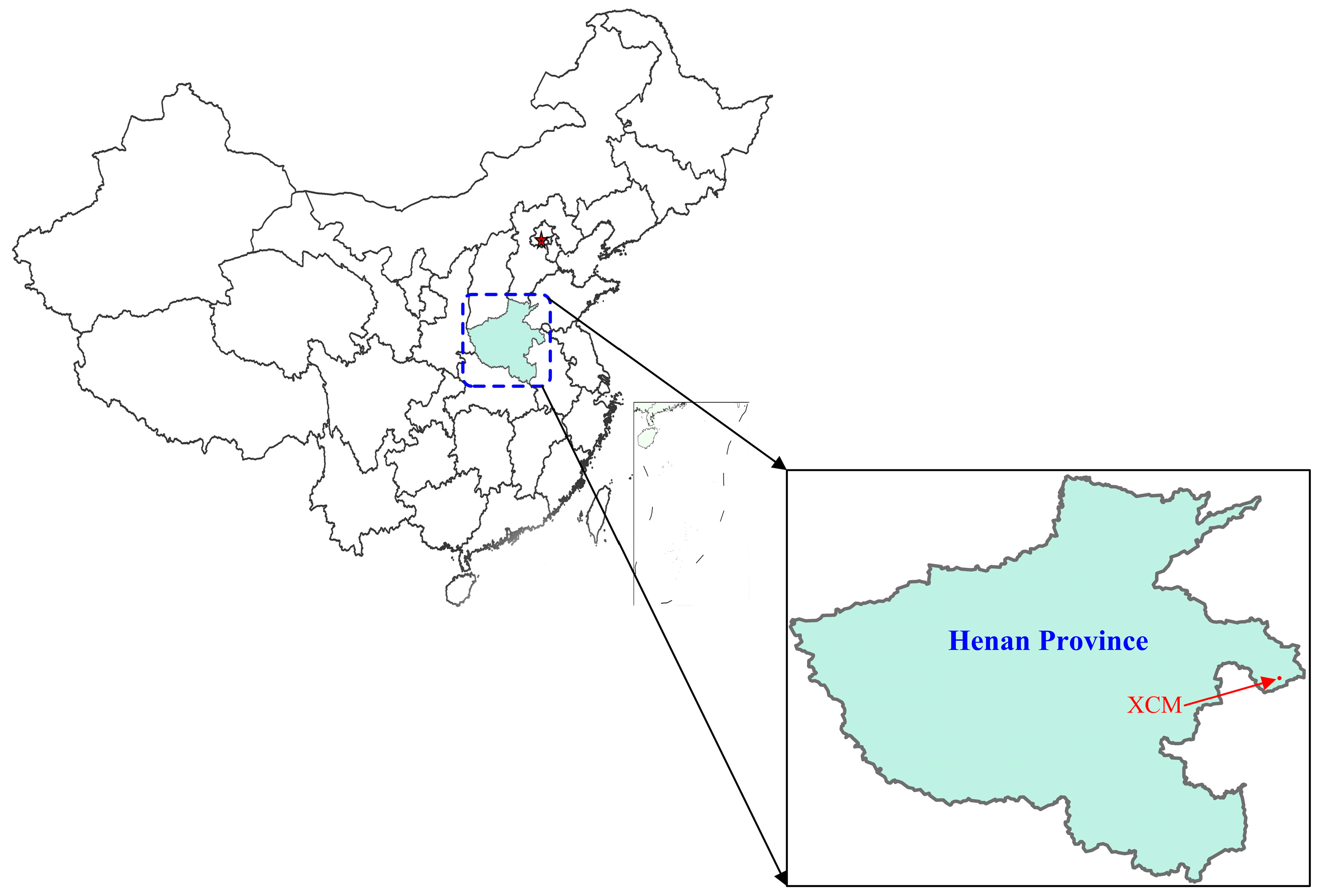

Comprehensive Technical Support for High-Quality Anthracite Production: A Case Study in the Xinqiao Coal Mine, Yongxia Mining Area, China

Abstract

:1. Introduction

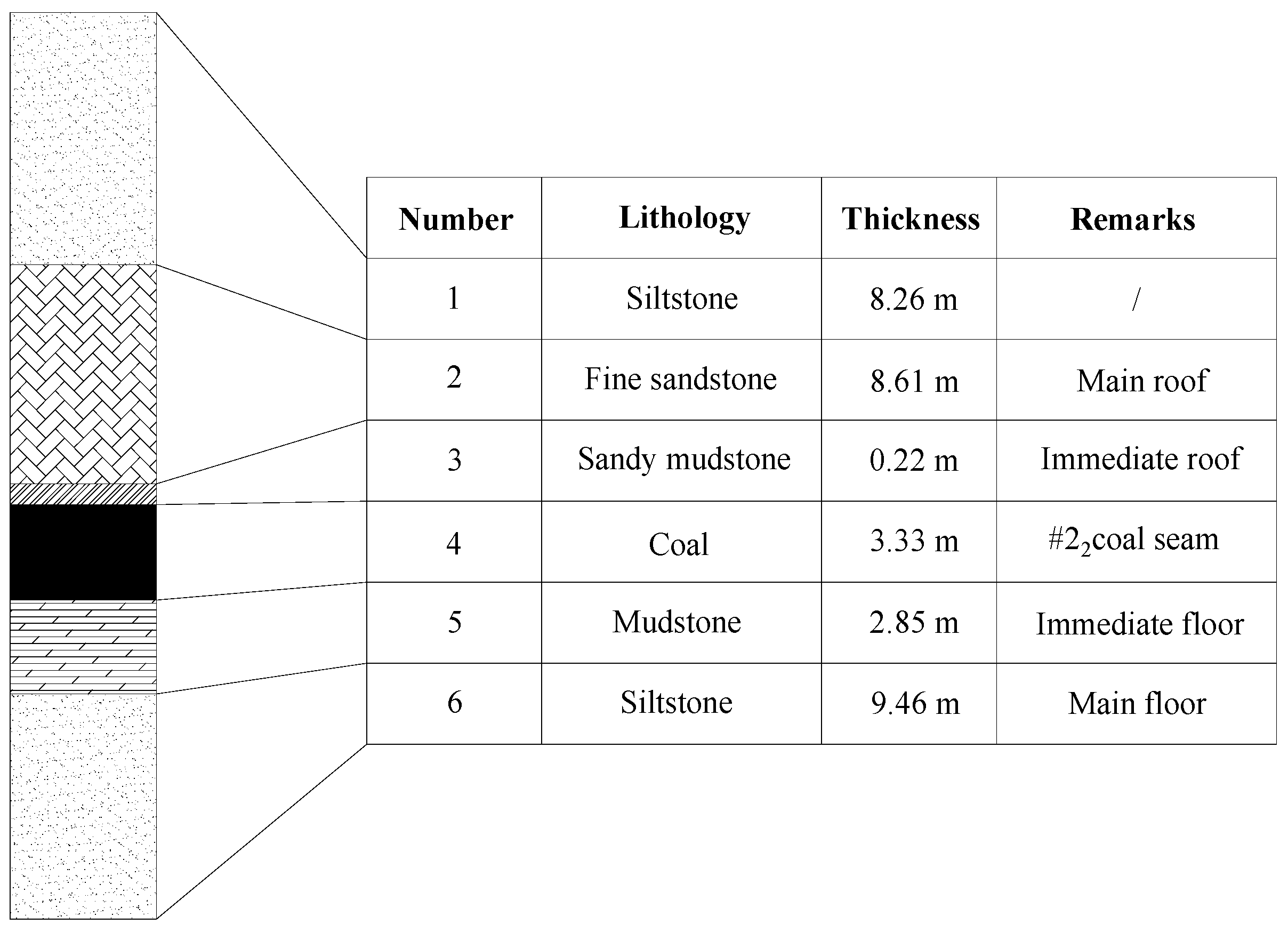

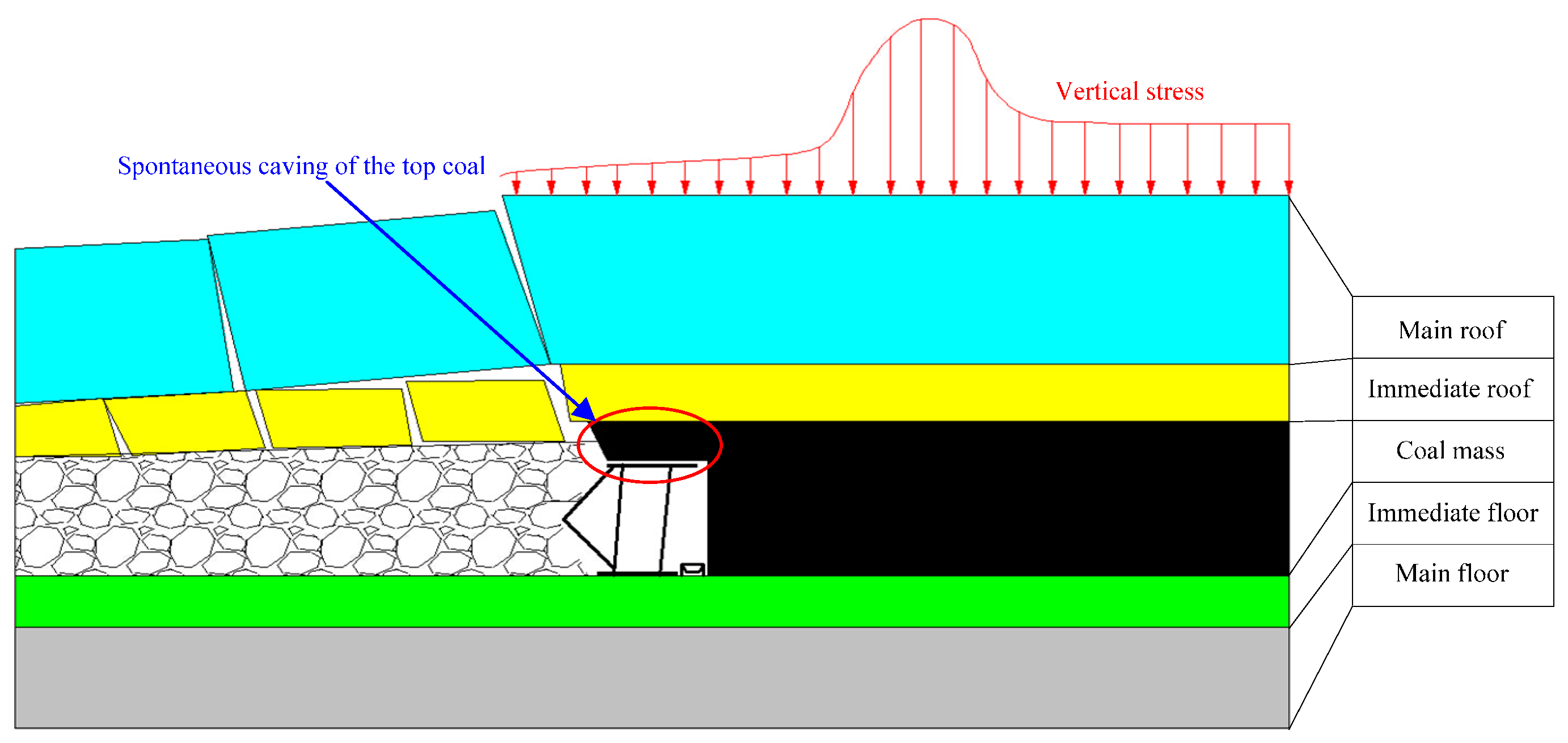

2. Mine Conditions and Mining Techniques

3. Techniques for Increased LCPR of Raw Coal

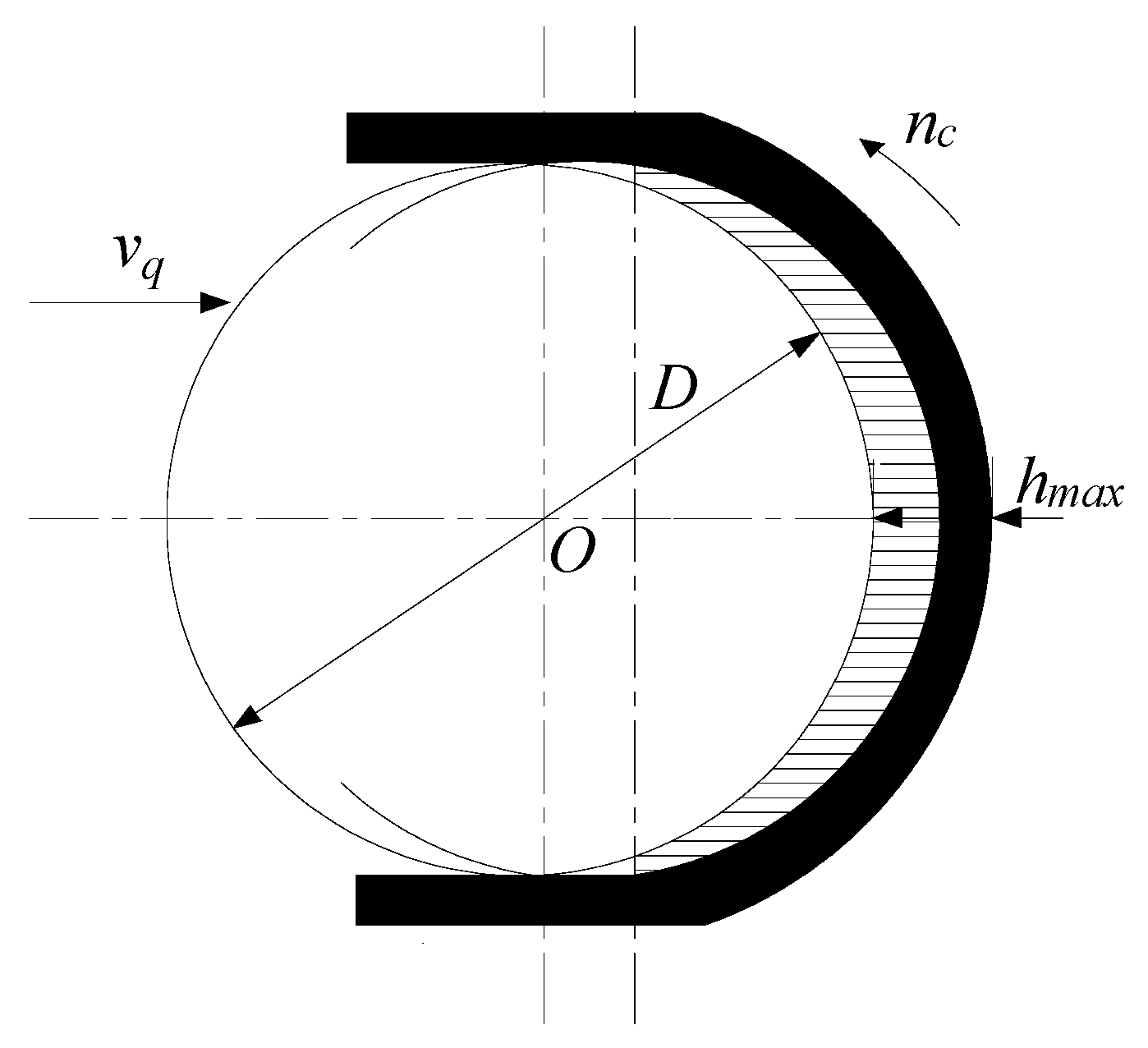

3.1. Optimization of Shearer’s Parameters

3.1.1. Mathematical Description of Shearer’s Cutting Thickness

3.1.2. Optimization of Running Parameters

3.1.3. Optimization of Cutting Pick Parameters

3.2. Allocation of Reasonable Mining Techniques

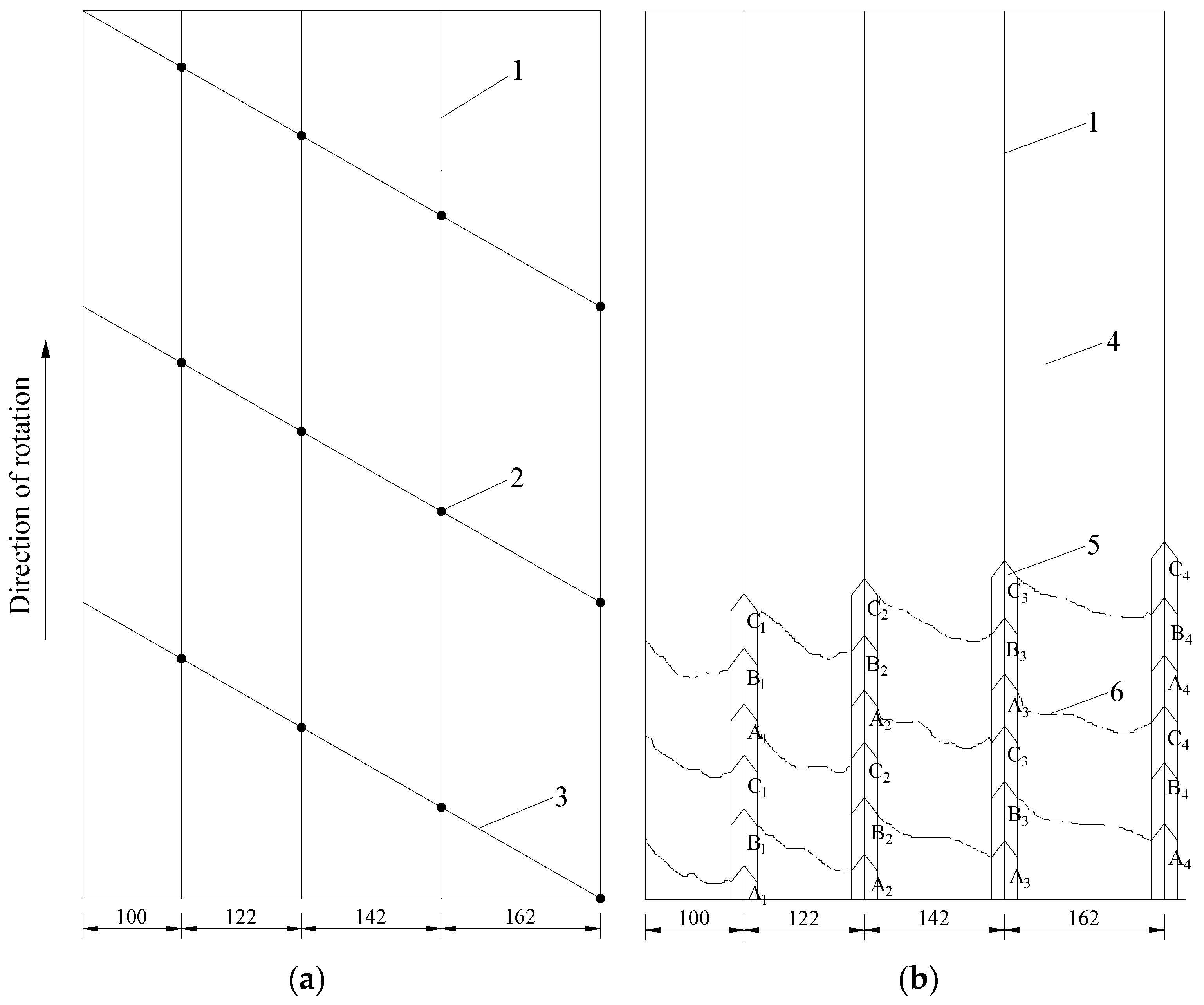

3.2.1. Selection of Rotating Direction of the Drums and Cutting Approach

3.2.2. Reduction of Mining Height and Roof Supporting Intensity

3.2.3. Implementation of LPMB on Coal Mass

| Mining Technique | Total Output (t) | Lump Quantity (t) | LCPR (%) | Cutting Way | |

|---|---|---|---|---|---|

| LPMB + FMM | 1st: 390 | 186.5 | 47.82 | Average: 46.47 | One-way |

| 2nd: 390 | 174.3 | 44.69 | |||

| 3rd: 390 | 182.9 | 46.90 | |||

| FMM | 1st: 390 | 134.5 | 34.49 | Average: 34.10 | One-way |

| 2nd: 390 | 131.9 | 33.82 | |||

| 3rd: 390 | 132.6 | 34.00 | |||

4. Fragmentation-Prevention Techniques for Lump Coal

4.1. Principles of Coal Fragmentation

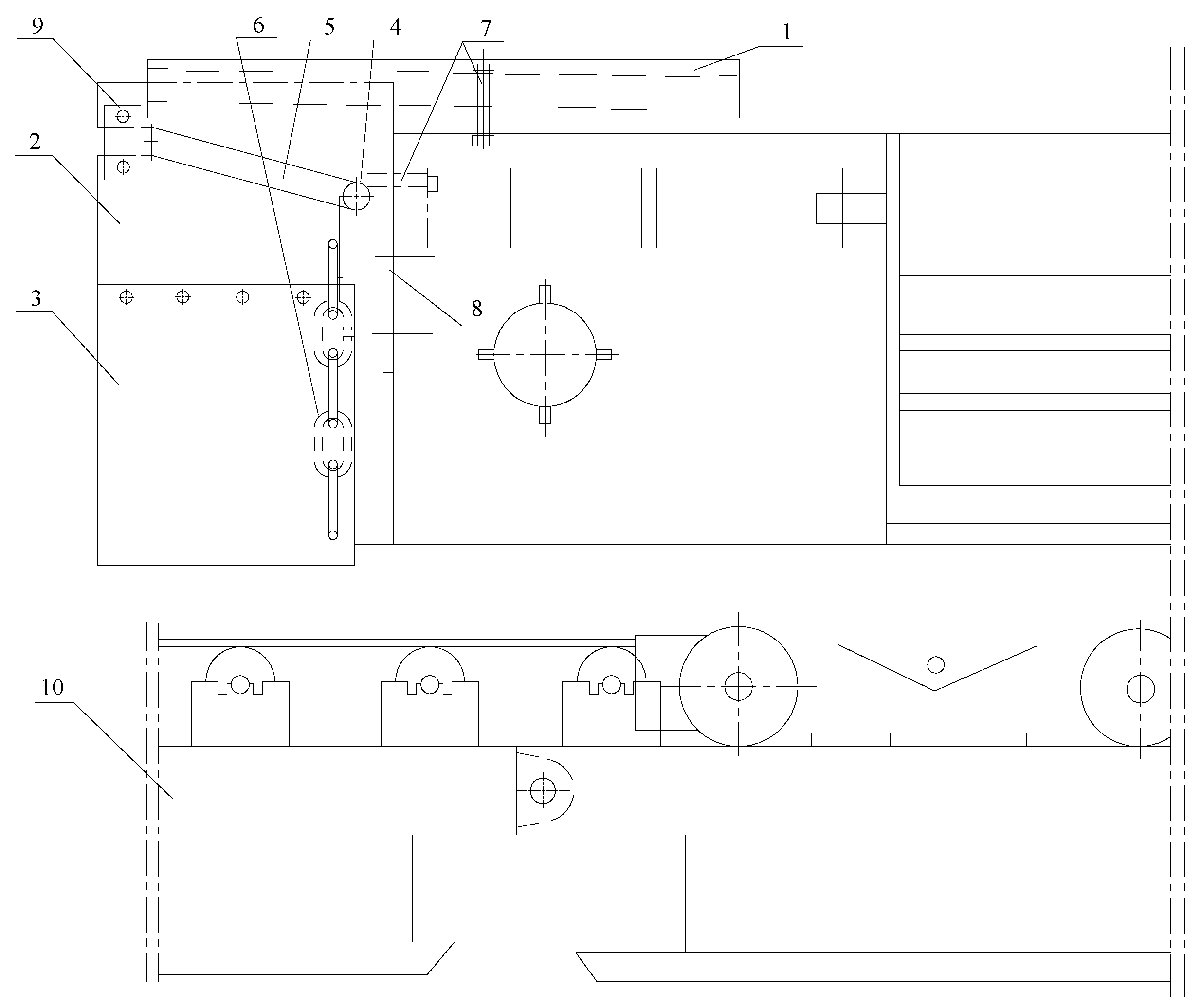

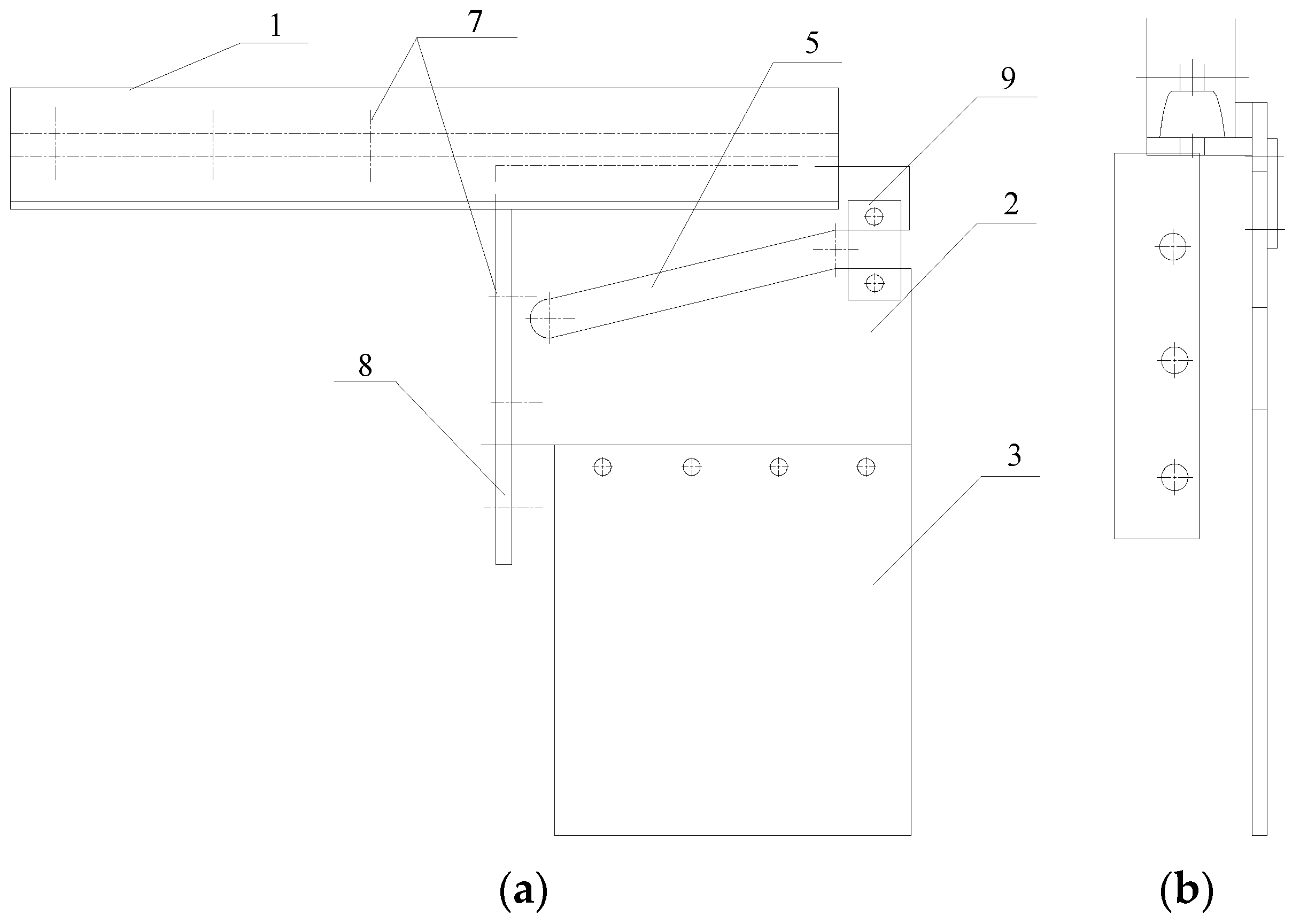

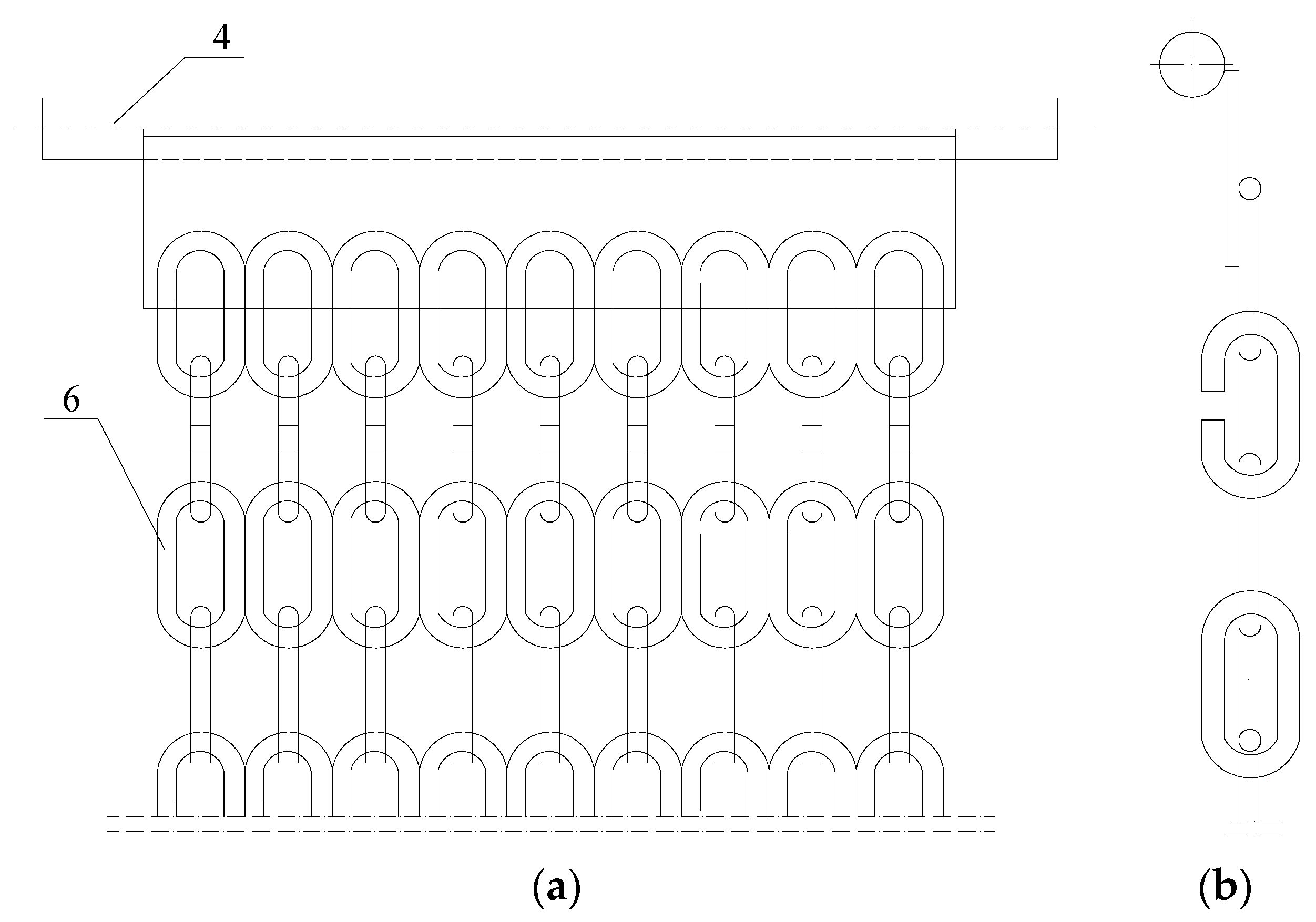

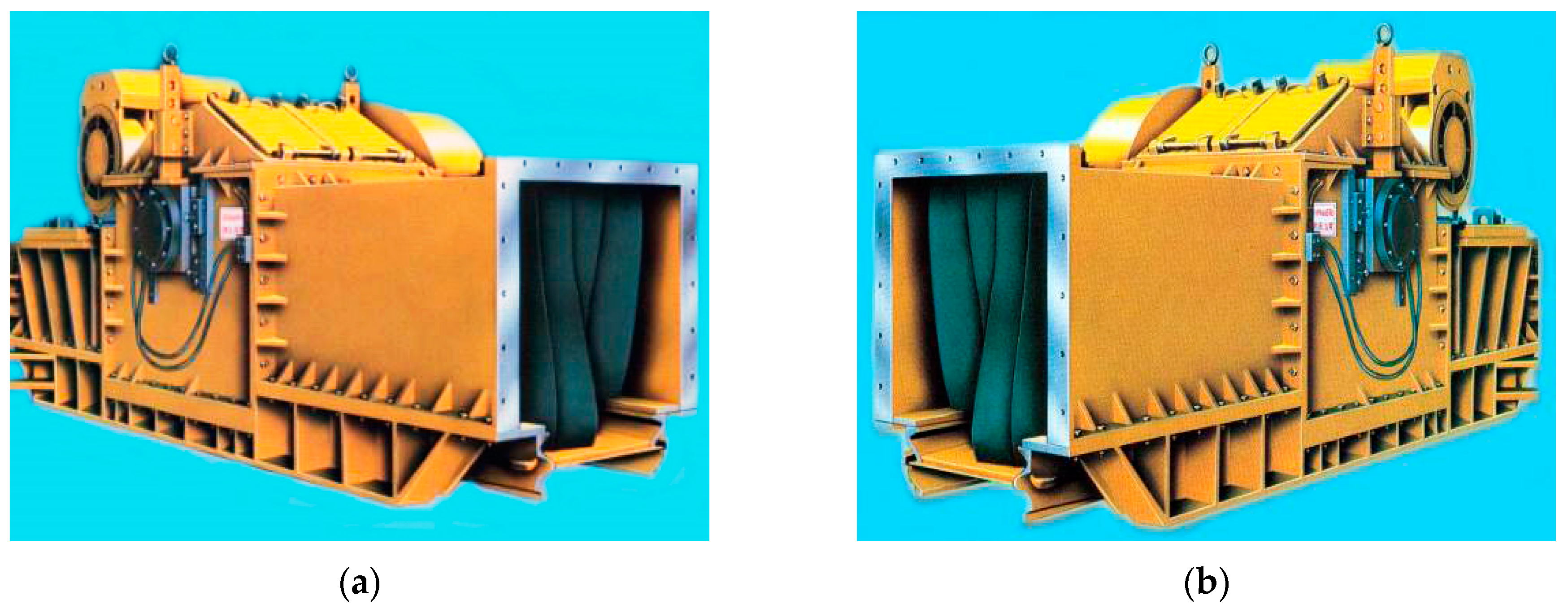

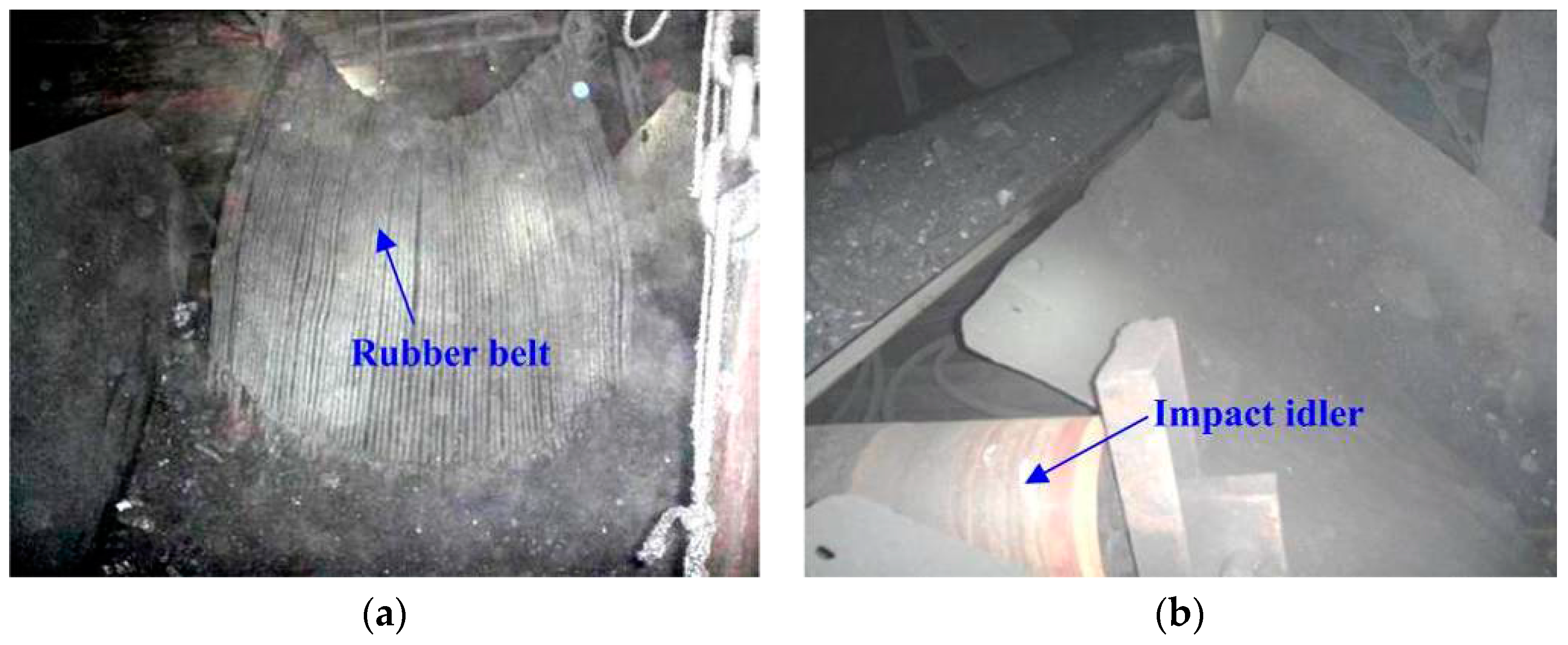

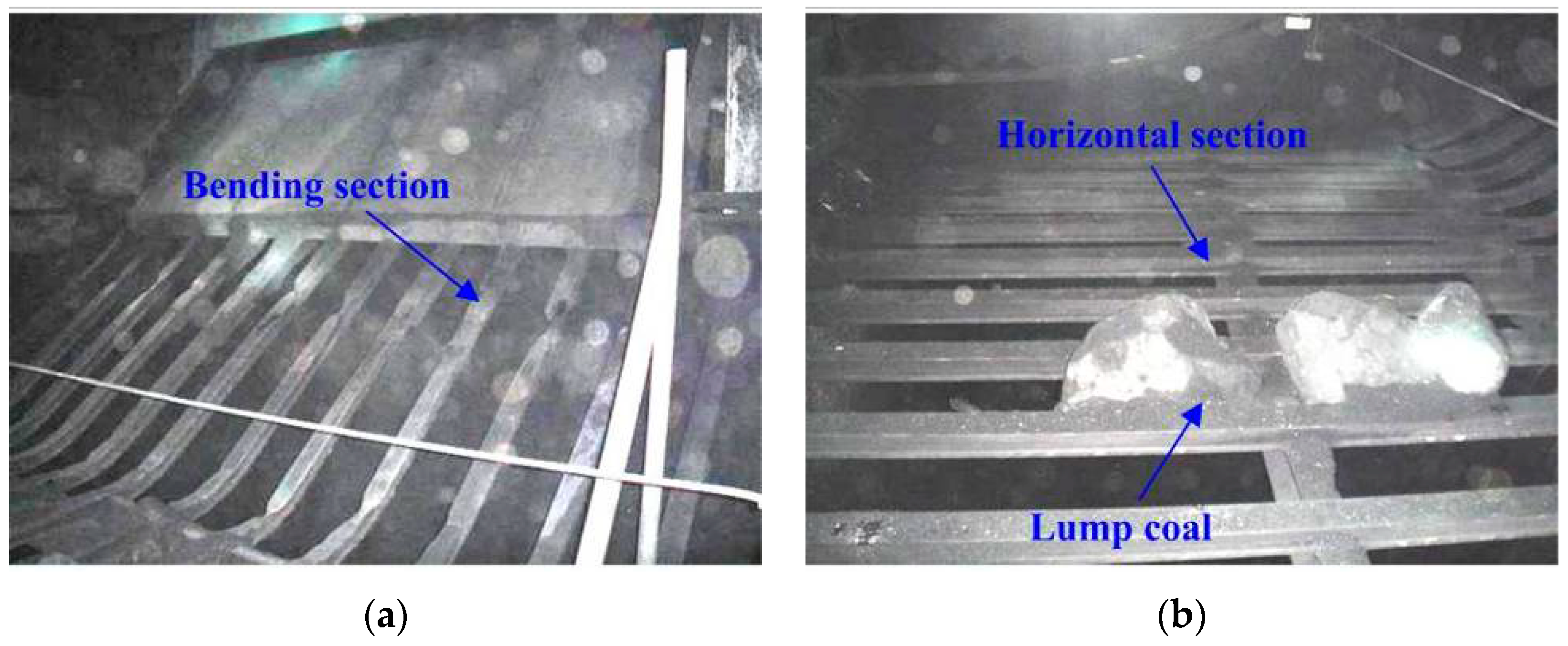

4.2. Reconstructions of Coalface End Transloading

4.3. Applications of Wheel Crusher

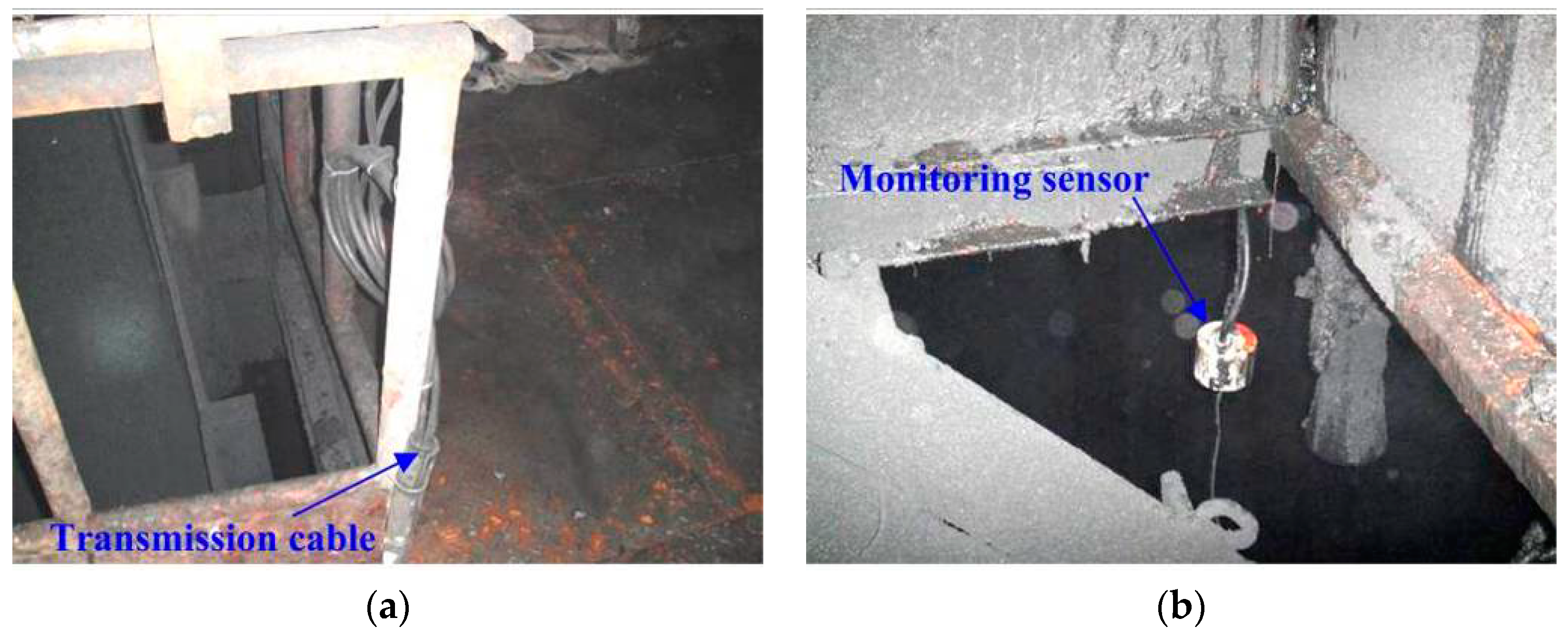

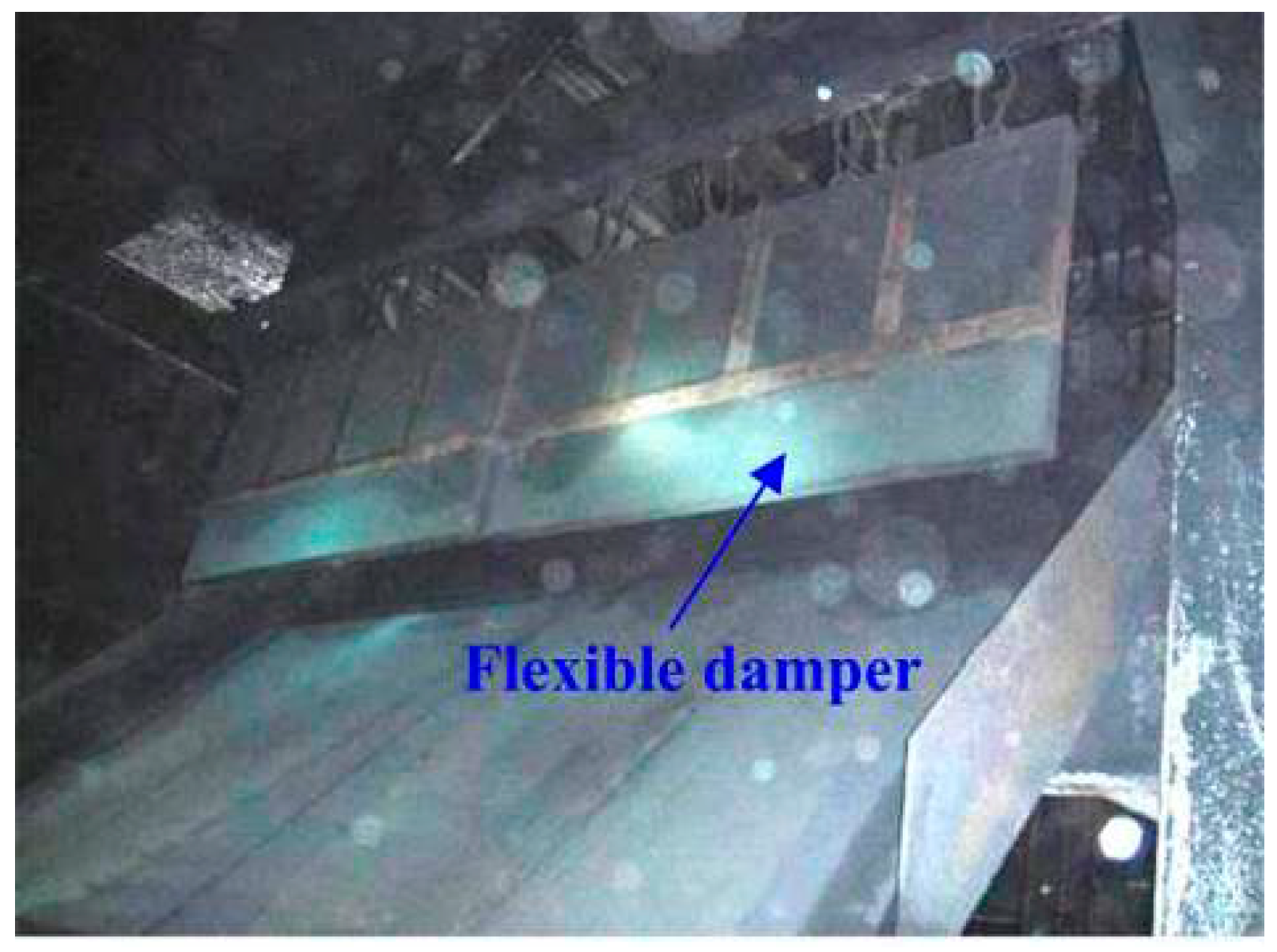

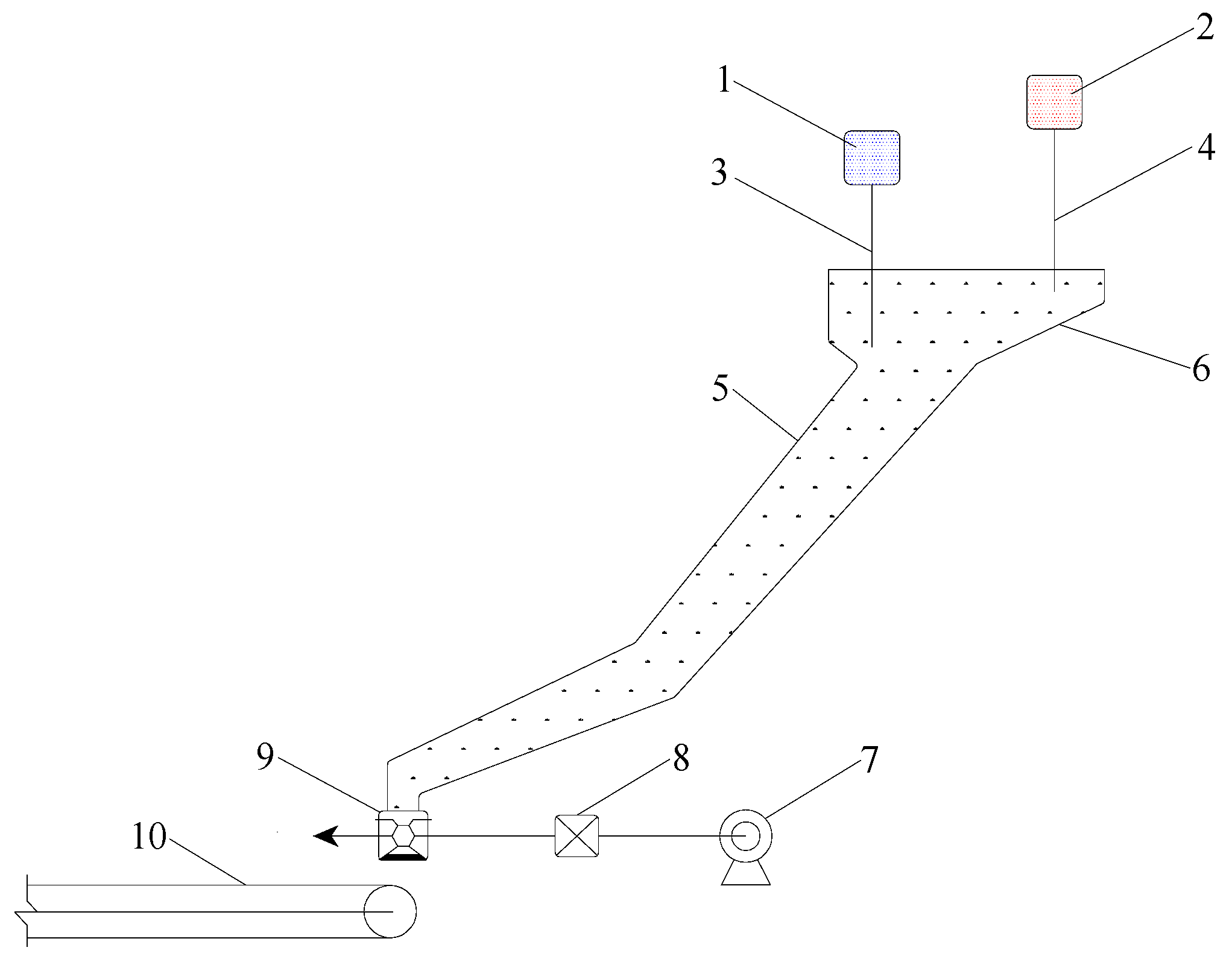

4.4. Adjustments in Transport Systems

4.5. Optimizations of Underground Storage

4.6. Improvements to the Main Shaft Skip Unloading Processes

4.7. Fragmentation-Prevention in Washing Processes

4.8. Fragmentation-Prevention in Railway Wagon Loading Processes

5. Economic Benefits

| Months | Raw Coal Quantity (t) | LCPR (%) | Ash Content (%) | Moisture Content (%) | Calorific Value (kcal·kg−1) | Incomes (CNY) | |

|---|---|---|---|---|---|---|---|

| Contents | |||||||

| 2009 | January | 155,736 | 20.65 | 10.10 | 4.9 | 6399 | - |

| February | 151,808 | 22.21 | 9.85 | 5.1 | 6449 | - | |

| March | 171,138 | 21.08 | 9.90 | 4.9 | 6369 | - | |

| April | 168,369 | 19.22 | 10.21 | 4.8 | 6193 | - | |

| May | 168,631 | 23.05 | 9.79 | 5.4 | 5960 | - | |

| June | 162,735 | 21.74 | 12.11 | 5.2 | 6072 | - | |

| July | 160,838 | 19.31 | 11.10 | 4.8 | 6131 | - | |

| August | 159,737 | 19.19 | 10.26 | 5.2 | 5820 | - | |

| September | 167,610 | 20.87 | 10.64 | 5.3 | 5651 | - | |

| October | 157,847 | 22.34 | 9.89 | 4.9 | 6057 | - | |

| November | 153,856 | 19.98 | 9.71 | 5.2 | 5848 | - | |

| December | 177,511 | 23.69 | 10.36 | 5.4 | 5943 | - | |

| Indexes of 2009 | 1,955,816 | 21.11 | 10.33 | 5.09 | 6074 | 586,744,800 | |

| Indexes of 2008 | 1,681,680 | 10.57 | 19.46 | 6.05 | 5876 | 472,892,807 | |

| Difference values | 274,136 | 10.54 | -9.13 | -0.96 | 198 | 113,851,993 | |

6. Conclusions

- (1)

- Based on the analysis of the cutting thickness of the shearer drums, the influence factors have been understood, including traction speed, drum rotating speed, arrangement of cutting picks, and the number of helical blades.

- (2)

- For optimized shearer performance in XCM, the following parameters should be employed: traction speed of 4–5 m/min, drum rotating speed of 35 r/min (initial design speed is 42 r/min), and 30 cutting picks (initial design number is 36). Additionally, the pick length was increased while the pick density was decreased. Moreover, a rear-front one-way cutting approach was used in the mining process, and the mining height and roof supporting intensity were reduced accordingly. A combination of LPMB and FMM was also applied.

- (3)

- Based on the principles of lump fragmentation, the coalface end transloading, coalface crushing, transport systems, underground storage, and main shaft skip unloading processes were all improved. Fragmentation-prevention techniques were also applied in the washing and wagon loading processes. As a result, fragmentation of the lump coal was obviously reduced. The LCPR was maintained at a high level, and a great increase in annual profits was achieved.

- (4)

- In order to widely and confidently use the parameters and techniques determined in this study, some research directions should be required in future studies such as more on-site measurements of LCPR, laboratory analysis of mechanical mechanisms for coal fragmentation, and techniques for high-quality anthracite production of open-pit mining.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| YMA | Yongxia Mining Area |

| XCM | Xinqiao Coal Mine |

| LCPR | Lump coal production rate |

| CBT | Cardox Blasting Technique |

| YCPLC | Yongcheng Coal & Power Company Limited |

| NSP | North Second Panel |

| LPMB | Loose presplitting millisecond blasting |

| FMM | Fully-mechanized mining |

References

- Guo, J.Q.; Kang, T.H.; Kang, J.T.; Zhao, G.F.; Huang, Z.M. Effect of the lump size on methane desorption from anthracite. J. Nat. Gas Sci. Eng. 2014, 20, 337–346. [Google Scholar] [CrossRef]

- Huang, B.X.; Wang, Y.Z.; Cao, S.G. Cavability control by hydraulic fracturing for top coal caving in hard thick coal seams. Int. J. Rock Mech. Min. Sci. 2015, 74, 45–57. [Google Scholar] [CrossRef]

- Yarushina, V.M.; Bercovici, D.; Oristaglio, M.L. Rock deformation models and fluid leak-off in hydraulic fracturing. Geophys. J. Int. 2013, 194, 1514–1526. [Google Scholar] [CrossRef]

- Pang, L.; Hosseini, A.; Hussein, H.M.; Deiab, I.; Kishawy, H.A. Application of a new thick zone model to the cutting mechanics during end-milling. Int. J. Mech. Sci. 2015, 96–97, 91–100. [Google Scholar] [CrossRef]

- Somanchi, S.; Kecojevic, V.J.; Bise, C.J. Analysis of force variance for a continuous miner drum using the Design of Experiments method. Int. J. Min. Reclam. Environ. 2006, 20, 111–126. [Google Scholar] [CrossRef]

- Liu, X.H.; Liu, S.Y.; Tang, P. Coal fragment size model in cutting process. Powder Technol. 2015, 272, 282–289. [Google Scholar] [CrossRef]

- Jiang, H.X.; Du, C.L.; Liu, S.Y.; Gao, K.D. Nonlinear dynamic characteristics of load time series in rock cutting. J. Vibroeng. 2014, 16, 292–302. [Google Scholar]

- Saurabh, D.; Somnath, C.; Sergej, H. Investigation into coal fragmentation analysis by using conical pick. Procedia Mater. Sci. 2014, 5, 2411–2417. [Google Scholar]

- Vidanovic, N.; Ognjanovic, S.; Ilincic, N.; Ilic, N.; Tokalic, R. Application of unconventional methods of underground premises construction in coal mines. Tech. Technol. Educ. Manag. 2011, 6, 861–865. [Google Scholar]

- Lai, X.P.; Shan, P.F.; Cao, J.T.; Sun, H.; Suo, Z.Y.; Cui, F. Hybrid assessment of pre-blasting weakening to horizontal section top coal caving (HSTCC) in steep and thick seams. Int. J. Min. Sci. Technol. 2014, 24, 31–37. [Google Scholar] [CrossRef]

- Reddy, S.K.; Sastry, V.R. Gallery monitoring in blasting gallery panel during depillaring—A case study. J. Mines Metals Fuels 2013, 61, 257–260. [Google Scholar]

- Satyanarayana, I.; Budi, G.; Deb, D. Strata behaviour during depillaring in Blasting Gallery panel by field instrumentation and numerical study. Arab. J. Geosci. 2015, 8, 6931–6947. [Google Scholar] [CrossRef]

- Wang, F.T.; Tu, S.H.; Yuan, Y.; Feng, Y.F.; Chen, F.; Tu, H.S. Deep-hole pre-split blasting mechanism and its application for controlled roof caving in shallow depth seams. Int. J. Rock Mech. Min. Sci. 2013, 64, 112–121. [Google Scholar] [CrossRef]

- Zhao, T.B.; Zhang, Z.Y.; Tan, Y.L.; Shi, C.Z.; Wei, P.; Li, Q. An innovative approach to thin coal seam mining of complex geological conditions by pressure regulation. Int. J. Rock Mech. Min. Sci. 2014, 71, 51–52. [Google Scholar] [CrossRef]

- Song, J.; Lian, Q.W. The relation between coal lump rate and cutting method of miner. Shanxi Coal 2003, 23, 20–21. (In Chinese) [Google Scholar]

- Zhang, L.M. The current situation and developing trend of extremely thin coal seam mining of China. Appl. Mech. Mater. 2013, 295, 2918–2923. [Google Scholar] [CrossRef]

- Li, Z.Q.; Oyediran, I.A.; Tang, C.; Hu, R.L.; Zhou, Y.X. FEM application to loess slope excavation and support: Case study of Dong Loutian coal bunker, Shuozhou, China. Bull. Eng. Geol. Environ. 2014, 73, 1013–1023. [Google Scholar] [CrossRef]

- Kozan, E.; Liu, S.Q. A demand-responsive decision support system for coal transportation. Decis. Support Syst. 2012, 54, 665–680. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, G.Q.; Zhang, G.W.; Han, R.S. Performance-based fire design of air-supported membrane coal storage shed. Procedia Eng. 2013, 52, 593–601. [Google Scholar] [CrossRef]

- Wang, X.W.; Qin, Y.; Tian, Y.K.; Yang, X.Y.; Yang, Z.J. Analysis on flow features of bulk coal during coal unloading period based on EDEM. Coal Sci. Technol. 2015, 43, 130–134. (In Chinese) [Google Scholar]

- Lv, H.L.; Ma, Y.; Zhou, S.C.; Liu, K. Case study on the deterioration and collapse mechanism and curing technique of RC coal bunkers. Procedia Earth Planet. Sci. 2009, 1, 606–611. [Google Scholar] [CrossRef]

- Liu, S.Q.; Kozan, E. Optimising a coal rail network under capacity constraints. Flex. Serv. Manuf. J. 2011, 23, 90–110. [Google Scholar] [CrossRef]

- Singh, G.; Sier, D.; Ernst, A.T.; Gavriliouk, O.; Oyston, R.; Giles, T.; Welgama, P. Mixed integer programming model for long term capacity expansion planning: A case study from The Hunter Valley Coal Chain. Eur. J. Oper. Res. 2012, 220, 210–224. [Google Scholar] [CrossRef]

- Wang, Y. Using the limiting transferring device to increase the lump coal rate of anthracite. Coal Process. Compr. Util. 2008, 3, 10–12. (In Chinese) [Google Scholar]

- Xie, W.N.; He, Y.Q.; Zhu, X.N.; Ge, L.H.; Huang, Y.J.; Wang, H.F. Liberation characteristics of coal middlings comminuted by jaw crusher and ball mill. Int. J. Min. Sci. Technol. 2013, 23, 669–674. [Google Scholar] [CrossRef]

- Chen, J.; Chu, K.W.; Zou, R.P.; Yu, A.B.; Vince, A. Prediction of the performance of dense medium cyclones in coal preparation. Miner. Eng. 2012, 31, 59–70. [Google Scholar] [CrossRef]

- Zeng, R.; Du, C.L.; Chen, R.J.; Wang, W.J. Reasonable location parameters of pick and nozzle in combined cutting system. J. Cent. South Univ. 2014, 21, 1067–1076. [Google Scholar] [CrossRef]

- Reid, A.W.; McAree, P.R.; Meehan, P.A.; Gurgenci, H. Longwall shearer cutting force estimation. J. Dyn. Syst. Meas. Control 2014, 136, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Gao, H.B.; Yang, Z.J. Fluctuation analysis of thickness about roller shearer. Coal Mine Mach. 2013, 34, 106–108. (In Chinese) [Google Scholar]

- Mazurkiewicz, D. Empirical and analytical models of cutting process of rocks. J. Min. Sci. 2000, 36, 481–486. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, J.; Feng, T.; Li, P. Intensity nonlinear analysis of central groove of coal shearer under limiting conditions. J. Southeast Univ. 2014, 44, 531–537. (In Chinese) [Google Scholar]

- Bilgin, N.; Balci, C.; Copur, H.; Tumac, D.; Avunduk, E. Cuttability of coal from the Soma coalfield in Turkey. Int. J. Rock Mech. Min. Sci. 2015, 73, 123–129. [Google Scholar] [CrossRef]

- Senneca, O.; Urciuolo, M.; Chirone, R. A semidetailed model of primary fragmentation of coal. Fuel 2013, 104, 253–261. [Google Scholar] [CrossRef]

- Zhou, Y.D.; Liu, Y.L.; Tang, X.W.; Cao, S.Q.; Chi, C.J. Numerical investigation into the fragmentation efficiency of one coal prism in a roller pulveriser: Homogeneous approach. Miner. Eng. 2014, 63, 25–34. [Google Scholar] [CrossRef]

- Thorpe, J.F. On the momentum theorem for a continuous system of variable mass. Am. J. Phys. 1962, 30, 637–640. [Google Scholar] [CrossRef]

- Hao, Q.S. Increase setting in use of middle digging coalface by modifying crusher and optimizing coal drift. Northwest Coal 2008, 6, 56–57. (In Chinese) [Google Scholar]

- Yu, T.F. Design and application of spiral chute in preventing lump coal crushing. Coal Mine Mach. 2014, 35, 207–209. (In Chinese) [Google Scholar]

- Deng, J.J.; Huang, J.Y.; Kuang, Y.L. Design of integrated manufacturing system of coal preparation plant based on multi-agent. Procedia Earth Planet. Sci. 2009, 1, 713–717. [Google Scholar] [CrossRef]

- Kou, B.F.; Liu, Q.Z.; Liu, C.Y.; Liang, Q. Characteristic research on the transverse vibrations of wire rope during the operation of mine flexible hoisting system. J. China Coal Soc. 2015, 40, 1194–1198. (In Chinese) [Google Scholar]

- Peterka, P.; Kresak, J.; Kropuch, S.; Fedorko, G.; Molnar, V.; Vojtko, M. Failure analysis of hoisting steel wire rope. Eng. Fail. Anal. 2014, 45, 96–105. [Google Scholar] [CrossRef]

- Wang, Z.G.; Kuang, Y.L.; Deng, J.J.; Wang, G.H.; Ji, L. Research on the intelligent control of the dense medium separation process in coal preparation plant. Int. J. Miner. Process. 2015, 142, 46–50. [Google Scholar] [CrossRef]

- Noble, A.; Luttrell, G.H. A review of state-of-the-art processing operations in coal preparation. Eng. Fail. Anal. 2015, 25, 511–521. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Zhang, D.; Wang, H.; Cheng, J. Comprehensive Technical Support for High-Quality Anthracite Production: A Case Study in the Xinqiao Coal Mine, Yongxia Mining Area, China. Minerals 2015, 5, 919-935. https://doi.org/10.3390/min5040533

Zhang W, Zhang D, Wang H, Cheng J. Comprehensive Technical Support for High-Quality Anthracite Production: A Case Study in the Xinqiao Coal Mine, Yongxia Mining Area, China. Minerals. 2015; 5(4):919-935. https://doi.org/10.3390/min5040533

Chicago/Turabian StyleZhang, Wei, Dongsheng Zhang, Hongzhi Wang, and Jixin Cheng. 2015. "Comprehensive Technical Support for High-Quality Anthracite Production: A Case Study in the Xinqiao Coal Mine, Yongxia Mining Area, China" Minerals 5, no. 4: 919-935. https://doi.org/10.3390/min5040533