Discrete Optimization with Fuzzy Constraints

Abstract

:1. Introduction

2. Structural Optimization and Fuzzy Set Theory

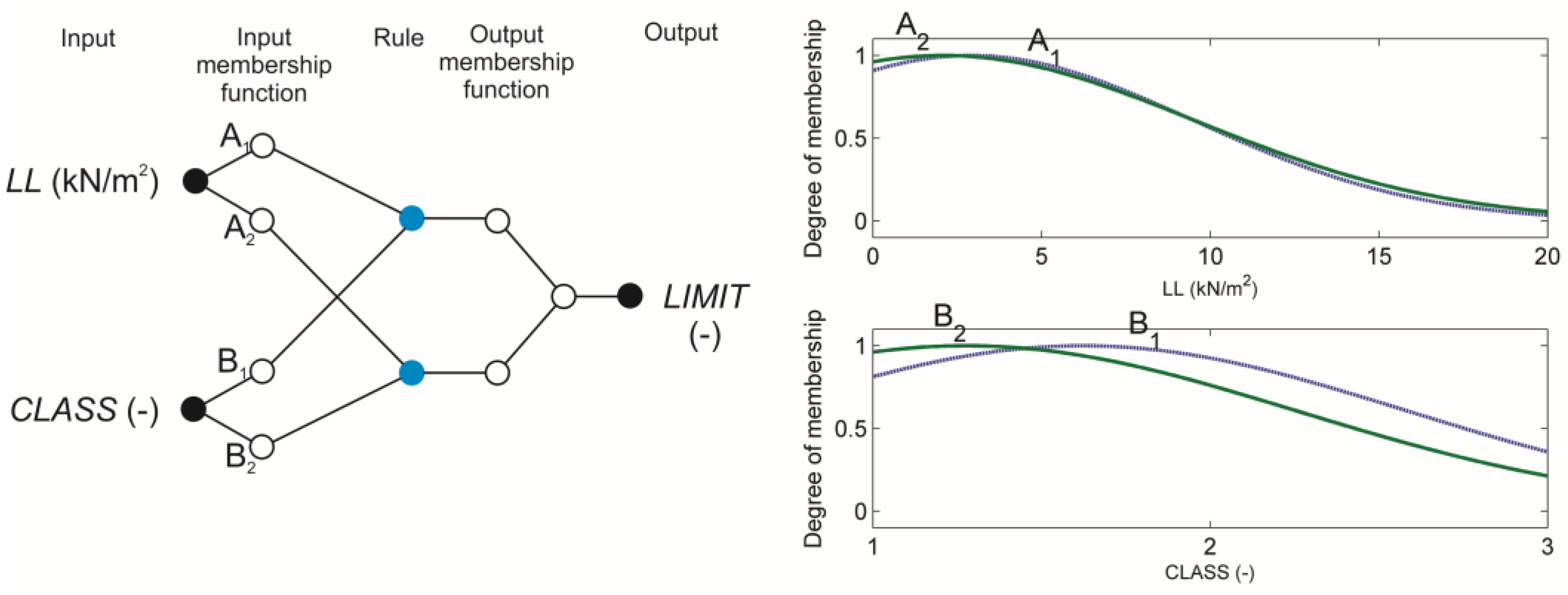

2.1. ANFIS Architecture for the Development of Soft Constraint Functions

3. Discrete Optimization

| Step 1. |

| For every allowable combination of |

| Solve optimization problem (solution K*) |

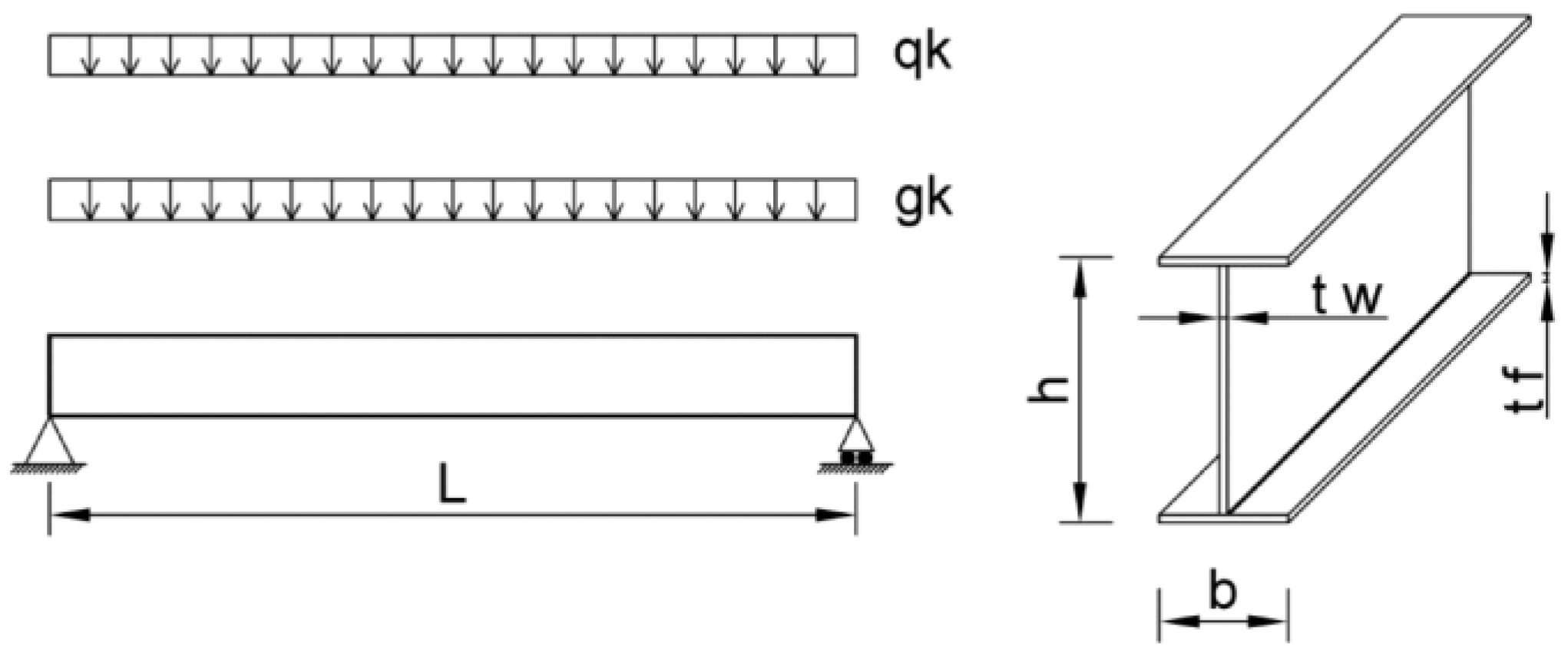

4. Example Design of a Simply-Supported Laterally-Restrained Beam Application

- (1)

- resistance of the cross-section to bending (ULS),

- (2)

- resistance to shear buckling (ULS),

- (3)

- resistance to flange-induced buckling (ULS),

- (4)

- resistance of the web to transverse forces (ULS) and

- (5)

- deflection (SLS).

4.1. Design Loads

4.2. Resistance of Steel Cross-Sections

4.2.1. Bending Moment

4.2.2. Shear

- b overall breadth

- r root radius

- tf flange thickness

- tw web thickness

- hw depth of the web

- η conservatively taken as 1.0

- A cross-sectional area

4.2.3. Resistance of Cross-Section-Bending and Shear

4.2.4. Shear Buckling Resistance

4.2.5. Flange-Induced Buckling

- Aw is the area of the web = (h−2∙tf)∙tw

- Afc is the area of the compression flange = b∙tf

- fyf is the yield strength of the compression flange

4.2.6. Resistance of the Web to Transverse Forces

- (a)

- forces resisted by shear in the web (loading Types (a) and (c)).

- (b)

- forces transferred through the web directly to the other flange (loading Type (b)).

- (i)

- crushing of the web close to the flange accompanied by yielding of the flange; the combined effect is sometimes referred to as web crushing

- (ii)

- localized buckling and crushing of the web beneath the flange; the combined effect is sometimes referred to as web crippling.

- (i)

- web crushing

- (ii)

- buckling of the web over most of the depth of the member.

- fyw is the yield strength of the web

- tw is the thickness of the web

- γM1 is the partial safety factor = 1.0

- Leff is the effective length of the web that resists transverse forces = χFly, in which χF is the reduction factor due to local buckling.

- ly is the effective loaded length, appropriate to the length of the stiff bearing ss. As stated in Clause 6.3 of Eurocode 3–5 [17], ss should be taken as the distance over which the applied load is effectively distributed at a slope of 1:1, but ss ≤ hw.

4.3. Deflections

4.3.1. ANFIS for the Development of the Constraint Function

- the membership grade of the fuzzy set (Ai, Bi, Ci, Di) is calculated;

- the product of membership function for each rule is calculated;

- the ratio between the i-th rule’s firing strength and the sum of all rules’ firing strengths is calculated;

- the output of each rule is calculated; and

- the weighted average of each rule’s output is calculated.

5. Fuzzy Optimization Model: Beam Implementation

- Condition 1, resistance of the cross-section to bending (ULS): verified by Equation (28), by which the design bending moment MEd (kNm) must not exceed the bending moment resistance MRd (kNm).

- Condition 2, resistance of the cross-section to shear (ULS): verified by Equation (33), by which the design shear force VEd (kN) must not exceed the shear resistance VRd (kNm).

- Condition 3, deflection (SLS) is considered: the calculated vertical deflection of the steel beam must be less than specified by the ANFIS-LIMIT model.

- Condition 4, resistance to flange-induced buckling (ULS): to prevent the possibility of the compression flange buckling in the plane of the web.

- Condition 5, Condition 6, Condition 7 and Condition 8, resistance of the web to transverse forces (ULS): to prevent the possibility of the local buckling of webs.

6. Conclusions

Author Contributions

Conflicts of Interest

Appendix A

| % Optimization of Fully Laterally Restrained Beams with soft constrain | |

| % Simply supported steel beam | |

| %-------------------------------------------------- | |

| %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% | |

| % Discrete Optimization with soft constrain | |

| % Dr. P. Jelusic | |

| % See Text for Problem description | |

| % The Beam Properties are loaded from the file | |

| % BeamPropertiesEU.m | |

| %*************************************************** | |

| %%% | |

| clear | |

| clear global | |

| clc | |

| close | |

| format compact | |

| warning off | |

| %%% Run File %%%%%%%%% | |

| BeamPropertiesEU | |

| %%%%%%%%%%%%%%%%%%%%%%%% | |

| %%% monitor cpu time | |

| starttime = cputime; | |

| fprintf('\n********************************') | |

| fprintf('\nSimply supported steel beam (Enumeration)') | |

| fprintf | |

| % %****************************** | |

| % % Computer Code | |

| % %******************************* | |

| %Span, safety factors and loads | |

| L = 25; | % span (m) |

| SFg = 1.35; | % safety factor for dead load (-) |

| SFq = 1.50; | % safety factor for imposed load (-) |

| gk = 5; | % dead load(kN/m) |

| qk = 15; | % imposed load(kN/m) |

| ss = 100; | % bearings width (mm) |

| eta = 1; | % shear factor eta (-) |

| k = 0.3; | % factor k (-) |

| lamflim = 0.5; | % factor lamflim (-) |

| ksiflim = 1; | % factor ksiflim (-) |

| CLASS = 1; | % use classification (-) |

| LL = 3; | % Applied live load (kN/m2) |

| %ANFIS model coefficients | |

| sigA1 = 6.61768494044089; | |

| sigA2 = 7.47150990794045; | |

| sigB1 = 0.962309787332703; | |

| sigB2 = 0.979723951565027; | |

| cA1 = 2.90117735987428; | |

| cA2 = 2.08316049335067; | |

| cB1 = 1.62121248482762; | |

| cB2 = 1.27590144219536; | |

| a01 = -771.211045670957; | |

| a11 = 8.40911494744558; | |

| a21 = 172.024353054372; | |

| a02 = 1535.72815330126; | |

| a12 = -29.7774593495827; | |

| a22 = -158.884574516486; | |

| %Material properties | |

| fy = 355; | % yield strength (MPa) |

| E = 210000; | % modulus of elasticity (MPa) |

| SFmo = 1.00; | % safety factor for material bending (-) |

| SFm1 = 1.05; | % safety factor for elastic resistance deflection (-) |

| gam = 7850; | % density (kg/m3) |

| %%%Start Exhaustive Enumeration : | |

| fstar = inf; | |

| xstar = [inf inf inf inf]; | |

| gstar = [inf inf inf]; | |

| istar = 1; | |

| % % | |

| % | |

| fprintf('\n----------------------------') | |

| fprintf('\nFeasible Beams') | |

| fprintf('\n-----------------------------\n\n') | |

| for i = 1:length(RolledSteelBeamSI) | |

| x1 = RolledSteelBeamSI(i).D; | |

| x2 = RolledSteelBeamSI(i).B; | |

| x3 = RolledSteelBeamSI(i).tw; | |

| x4 = RolledSteelBeamSI(i).tf; | |

| %******************************* | |

| A = RolledSteelBeamSI(i).Area; | |

| D = RolledSteelBeamSI(i).D; | |

| B = RolledSteelBeamSI(i).B; | |

| tw = RolledSteelBeamSI(i).tw; | |

| tf = RolledSteelBeamSI(i).tf; | |

| Rr = RolledSteelBeamSI(i).Rr; | |

| dd = RolledSteelBeamSI(i).dd; | |

| Ix = RolledSteelBeamSI(i).Ix; | |

| Welx = RolledSteelBeamSI(i).Welx; | |

| Wplx = RolledSteelBeamSI(i).Wplx; | |

| %Design action. The reason for discrete optimization is to choose off-the-shelf I-beam which will keep the cost and production time down. Several mills provide information on standard rolling stock they manufacture. | |

| Fed = (SFg*(gk+A*gam*9.81/10000000) + SFq*qk)*L; | %design action (kN) |

| Med = Fed*L/8; | %design bending moment (kNm) |

| Ved = Fed/2; | %design shear force (kN) |

| %Section resistance | |

| Mrd = Wplx*fy/(SFmo*1000); | %moment resistance (kNm) |

| Av = A*100-2*B*tf + (tw + 2*Rr)*tf; | %shear area(mm2) |

| Vrd = Av*(fy/(3)^0.5)/(SFmo*1000); | %design shear resistance(kN) |

| %Deflection | |

| Mmax = (gk+qk)*L^2/8; | %maximum bending moment due to working load (kNm) |

| Mcrd = Welx*fy/(SFm1*1000); | %elastic resistance (kNm) |

| u = 5*qk*(L*1000)^4/(384*E*Ix*10000); | %deflection (mm) |

| %ANFIS calculation procedure | |

| A1ev = exp(-0.5*(((LL-cA1)/(sigA1))^2)); | |

| A2ev = exp(-0.5*(((LL-cA2)/(sigA2))^2)); | |

| B1ev = exp(-0.5*(((CLASS-cB1)/(sigB1))^2)); | |

| B2ev = exp(-0.5*(((CLASS-cB2)/(sigB2))^2)); | |

| w1 = A1ev*B1ev; | |

| w2 = A2ev*B2ev; | |

| w1n = w1/(w1+w2); | |

| w2n = w2/(w1+w2); | |

| fun1 = a01+a11*LL+a21*CLASS; | |

| fun2 = a02+a12*LL+a22*CLASS; | |

| nfun1 = w1n*fun1; | |

| nfun2 = w2n*fun2; | |

| lim = nfun1+nfun2; | |

| uult = L*1000/lim; | %permissible deflection (mm) |

| %Section classification | |

| eps = (235/fy)^0.5; | %factor eps (-) |

| c = (B-tw-2*Rr)/2; | %depth between fillets (mm) |

| hw = D-2*tf; | %depth between flanges (mm) |

| %Flange-induced buckling | |

| Aw = (D-2*tf)*tw; | %area of the web (mm2) |

| Afc = B*tf; | %area of the compression flange (mm2) |

| Fib = hw/tw; | %criteria ratio of flange-induced buckling(-) |

| Fibalw = k*(E/fy)*(Aw/Afc)^0.5; | %criteria ratio (-) |

| %Web buckling | |

| kf = 2+6*(ss/hw); | %buckling coefficient (-) |

| kfalw = 6; | %limit of buckling coefficient(-) |

| Fcr = (0.9*kf*E*tw^3)/hw; | %elastic critical buckling load(N) |

| m1 = fy*B/(fy*tw); | %coefficient m1(-) |

| m2 = 0.02*(hw/tf)^2; | %coefficient m2(-) |

| le = min(kf*E*tw^2/(2*fy*hw),ss); | %effective loaded length(mm) |

| ly = min(le+tf*(m1/2+(le/tf)^2+m2)^0.5,le + tf*(m1+m2)^0.5); | %(mm) |

| lamf = (ly*tw*fy/Fcr)^0.5; | %reduction factor lamf (-) |

| lamflim = 0.5; | %permissible reduction factor lamflim(-) |

| ksif = 0.5/lamf; | %reduction factor ksif(-) |

| leff = ksif*ly; | %effective length of web(mm) |

| Frdweb = fy*leff*tw/1000; | %design resistance of web(kN) |

| %Objective function | |

| f = gam*L*A/10000; | %weight of steel beam (kg) |

| %Constraints | |

| g1 = Med - Mrd; | %bending (kNm) |

| g2 = Ved - Vrd; | %shear (kN) |

| g3 = u - uult; | %deflection(mm) |

| g4 = Fib - Fibalw; | %flange-induced buckling (-) |

| g5 = kf - kfalw; | %web buckling constraint 1 (-) |

| g6 = lamflim - lamf; | %web buckling constraint 2 (-) |

| g7 = ksif - 1; | %web buckling constraint 3(-) |

| g8 = Ved - Frdweb; | %resistance of web constraint (kN) |

| %%% total constraint vector | |

| G = [g1 g2 g3 g4 g5 g6 g7 g8]; | |

| if (g1 <= 0) & (g2 <= 0) & (g3 <= 0) | |

| if (g4 <= 0) & (g5 <= 0) & (g6 <= 0) | |

| if (g7 <= 0) & (g8 <= 0) | |

| if (f <= fstar) | |

| xstar = [x1 x2 x3 x4]; | |

| fstar = f | |

| Gstar = G; | |

| istar = i | |

| end | |

| end | |

| end | |

| end | |

| end | |

| fprintf('\n******************************************') | |

| fprintf('\nOptimum Fully Laterally Restrained Beam') | |

| fprintf('\n******************************************\n\n') | |

| fprintf('Rolled Beam Designation : '),disp(RolledSteelBeamSI(istar).Name) | |

| fprintf('Depth(mm) Width(mm) Web Thickness(mm) Flange Thickness (mm)\n') | |

| fprintf('%8.5f %8.5f %8.5f %8.3f\n',xstar) | |

| fprintf('\nObjective Function(kg): '),disp(fstar) | |

| fprintf('\nConstraints\n') | |

| fprintf('---------------\n') | |

| fprintf('Bending Stress Constraint - g1 (kNm): '),disp(Gstar(1)) | |

| fprintf('Shear Stress Constraint - g2 (kN): '),disp(Gstar(2)) | |

| fprintf('Deflection Constraint - g3 (mm): '),disp(Gstar(3)) | |

| fprintf('flange-induced buckling - g4 (-): '),disp(Gstar(4)) | |

| fprintf('web buckling constraint 1 - g5 (-): '),disp(Gstar(5)) | |

| fprintf('web buckling constraint 2 - g6 (-): '),disp(Gstar(6)) | |

| fprintf('web buckling constraint 3 - g7 (-): '),disp(Gstar(7)) | |

| fprintf('resistance of web constraint - g8 (kN): '),disp(Gstar(8)) | |

| %%% print time | |

| totaltime = cputime - starttime; | |

| fprintf('\n\nTotal cpu time (s)= %7.4f \n\n',totaltime) | |

| % EE - Exhaustive Enumeration | |

| % For constrained optimization of fully laterally restrained beams | |

| % Dr. P. Jelusic | |

| % University of Maribor, Faculty of Civil Engineering | |

| %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% | |

| %%% File UniversalbeamsEU.m | |

| %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% | |

| % Discrete Variables | |

| %-------------------------------------------------- | |

| % See Text for Problem description | |

| %********************************************** | |

| %%% COMPANION FILE FOR PROBLEM Fully laterally restrained beams | |

| %%% This file contains Beam Properties for universal beams | |

| %%% beams in SI Units | |

| %********************************************** | |

| %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% | |

| %%% Define the section properties | |

| %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% | |

| RolledSteelBeamSI(1).Name ='IPE AA 80'; | %beam identifier (-) |

| RolledSteelBeamSI(1).Area = 6.31; | %area (cm2) |

| RolledSteelBeamSI(1).D = 78; | %Depth of section (mm) |

| RolledSteelBeamSI(1).B = 46; | %width of section (mm) |

| RolledSteelBeamSI(1).tw = 3.2; | %web thickness (mm) |

| RolledSteelBeamSI(1).tf = 4.2; | %flange thickness (mm) |

| RolledSteelBeamSI(1).Rr = 5; | %root radius (mm) |

| RolledSteelBeamSI(1).dd = 59.6; | %depth between fillets(mm) |

| RolledSteelBeamSI(1).Ix = 64.1; | %second moment of area Ixx (cm4) |

| RolledSteelBeamSI(1).Welx = 16.4; | %elastic modulus Welx (cm3) |

| RolledSteelBeamSI(1).Wplx = 18.9; | %plastic modulus Wplx (cm3) |

| RolledSteelBeamSI(2) = struct('Name','IPE A 80','Area',6.38, ... | |

| 'D',78,'B',46,'tw',3.3,'tf',4.2, ... | |

| 'Rr',5,'dd',59.6,'Ix',64.4, ... | |

| 'Welx',16.5,'Wplx',19); | |

| RolledSteelBeamSI(3) = struct('Name','IPE 80','Area',7.64, ... | |

| 'D',80,'B',46,'tw',3.8,'tf',5.2, ... | |

| 'Rr',5,'dd',59.6,'Ix',80.1, ... | |

| 'Welx',20,'Wplx',23.2); | |

| RolledSteelBeamSI(75) = struct('Name','HE 1000 X 584','Area',743.7, ... | |

| 'D',1056,'B',314,'tw',36,'tf',64, ... | |

| 'Rr',30,'dd',868,'Ix',1246100, ... | |

| 'Welx',23600,'Wplx',28039); | |

| return; | |

| ****************************************** | |||

| Optimum Fully Laterally Restrained Beam | |||

| ****************************************** | |||

| Rolled Beam Designation : HE 1000 X 393 | |||

| Depth(mm) | Width(mm) | Web Thickness(mm) | Flange Thickness (mm) |

| 1016.00000 | 303.00000 | 24.40000 | 43.900 |

| Objective Function(kg): | 9.8164e+003 | ||

| Constraints | |||

| --------------- | |||

| Bending Stress Constraint | - g1 (kNm): | -3.8903e+003 | |

| Shear Stress Constraint | - g2 (kN): | -5.1282e+003 | |

| Deflection Constraint | - g3 (mm): | -12.9339 | |

| flange-induced buckling | - g4 (-): | -193.5248 | |

| web buckling constraint 1 | - g5 (-): | -3.3536 | |

| web buckling constraint 2 | - g6 (-): | -0.0742 | |

| web buckling constraint 3 | - g7 (-): | -0.1293 | |

| resistance of web constraint | - g8 (kN): | -1.8169e+003 | |

| Total cpu time (s)= | 0.2184 | ||

Appendix B

| Designation | A | h | b | tw | tf | r | d | Iy | Wel.y | Wpl.y | Designation | A | h | b | tw | tf | r | d | Iy | Wel.y | Wpl.y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Serial Size | cm2 | mm | mm | mm | mm | mm | mm | cm4 | cm3 | cm3 | Serial Size | cm2 | mm | mm | mm | mm | mm | mm | cm4 | cm3 | cm3 |

| IPE AA 80 | 6.31 | 78 | 46 | 3.2 | 4.2 | 5 | 59.6 | 64.1 | 16.4 | 18.9 | IPE O 360 | 84.1 | 364 | 172 | 9.2 | 14.7 | 18 | 298.6 | 19,050 | 1047 | 1186 |

| IPE A 80 | 6.38 | 78 | 46 | 3.3 | 4.2 | 5 | 59.6 | 64.4 | 16.5 | 19 | IPE A 400 | 73.1 | 397 | 180 | 7 | 12 | 21 | 331 | 20,290 | 1022 | 1144 |

| IPE 80 | 7.64 | 80 | 46 | 3.8 | 5.2 | 5 | 59.6 | 80.1 | 20 | 23.2 | IPE 400 | 84.5 | 400 | 180 | 8.6 | 13.5 | 21 | 331 | 23,130 | 1160 | 1307 |

| IPE AA 100 | 8.56 | 97.6 | 55 | 3.6 | 4.5 | 7 | 74.6 | 136 | 27.9 | 31.9 | IPE O 400 | 96.4 | 404 | 182 | 9.7 | 15.5 | 21 | 331 | 26,750 | 1324 | 1502 |

| IPE A 100 | 8.8 | 98 | 55 | 3.6 | 4.7 | 7 | 74.6 | 141 | 28.8 | 33 | IPE A 450 | 85.6 | 447 | 190 | 7.6 | 13.1 | 21 | 378.8 | 29,760 | 1331 | 1494 |

| IPE 100 | 10.3 | 100 | 55 | 4.1 | 5.7 | 7 | 74.6 | 171 | 34.2 | 39.4 | IPE 450 | 98.8 | 450 | 190 | 9.4 | 14.6 | 21 | 378.8 | 33,740 | 1500 | 1702 |

| IPE AA 120 | 10.7 | 117 | 64 | 3.8 | 4.8 | 7 | 93.4 | 244 | 41.7 | 47.6 | IPE O 450 | 118 | 456 | 192 | 11 | 17.6 | 21 | 378.8 | 40,920 | 1795 | 2046 |

| IPE A 120 | 11 | 117.6 | 64 | 3.8 | 5.1 | 7 | 93.4 | 257 | 43.8 | 49.9 | IPE A 500 | 101 | 497 | 200 | 8.4 | 14.5 | 21 | 426 | 42,930 | 1728 | 1946 |

| IPE 120 | 13.2 | 120 | 64 | 4.4 | 6.3 | 7 | 93.4 | 318 | 53 | 60.7 | IPE 500 | 116 | 500 | 200 | 10.2 | 16 | 21 | 426 | 48,200 | 1930 | 2194 |

| IPE AA 140 | 12.8 | 136.6 | 73 | 3.8 | 5.2 | 7 | 112.2 | 407 | 59.7 | 67.6 | IPE O 500 | 137 | 506 | 202 | 12 | 19 | 21 | 426 | 57,780 | 2284 | 2613 |

| IPE A 140 | 13.4 | 137.4 | 73 | 3.8 | 5.6 | 7 | 112.2 | 435 | 63.3 | 71.6 | IPE A 550 | 117 | 547 | 210 | 9 | 15.7 | 24 | 467.6 | 59,980 | 2193 | 2475 |

| IPE 140 | 16.4 | 140 | 73 | 4.7 | 6.9 | 7 | 112.2 | 541 | 77.3 | 88.3 | IPE 550 | 134 | 550 | 210 | 11.1 | 17.2 | 24 | 467.6 | 67,120 | 2440 | 2787 |

| IPE AA 160 | 15.4 | 156.4 | 82 | 4 | 5.6 | 7 | 131.2 | 646 | 82.6 | 93.3 | IPE O 550 | 156 | 556 | 212 | 12.7 | 20.2 | 24 | 467.6 | 79,160 | 2847 | 3263 |

| IPE A 160 | 16.2 | 157 | 82 | 4 | 5.9 | 9 | 127.2 | 689 | 87.8 | 99.1 | IPE A 600 | 137 | 597 | 220 | 9.8 | 17.5 | 24 | 514 | 82,920 | 2778 | 3141 |

| IPE 160 | 20.1 | 160 | 82 | 5 | 7.4 | 9 | 127.2 | 869 | 109 | 124 | IPE 600 | 156 | 600 | 220 | 12 | 19 | 24 | 514 | 92,080 | 3070 | 3512 |

| IPE AA 180 | 19 | 176.4 | 91 | 4.3 | 6.2 | 9 | 146 | 1020 | 116 | 131 | IPE O 600 | 197 | 610 | 224 | 15 | 24 | 24 | 514 | 118,300 | 3879 | 4471 |

| IPE A 180 | 19.6 | 177 | 91 | 4.3 | 6.5 | 9 | 146 | 1063 | 120 | 135 | IPE 750 × 134 | 171 | 750 | 264 | 12 | 15.5 | 17 | 685 | 150,700 | 4018 | 4644 |

| IPE 180 | 23.9 | 180 | 91 | 5.3 | 8 | 9 | 146 | 1317 | 146 | 166 | IPE 750 × 147 | 188 | 753 | 265 | 13.2 | 17 | 17 | 685 | 166,100 | 4411 | 5110 |

| IPE O 180 | 27.1 | 182 | 92 | 6 | 9 | 9 | 146 | 1505 | 165 | 189 | IPE 750 × 173 | 221 | 762 | 267 | 14.4 | 21.6 | 17 | 685 | 205,800 | 5402 | 6218 |

| IPE AA 200 | 22.9 | 196.4 | 100 | 4.5 | 6.7 | 12 | 159 | 1533 | 156 | 176 | IPE 750 × 196 | 251 | 770 | 268 | 15.6 | 25.4 | 17 | 685 | 240,300 | 6241 | 7174 |

| IPE A 200 | 23.5 | 197 | 100 | 4.5 | 7 | 12 | 159 | 1591 | 162 | 182 | HE 100 A | 21.2 | 96 | 100 | 5 | 8 | 12 | 56 | 349.2 | 72.76 | 83.01 |

| IPE 200 | 28.5 | 200 | 100 | 5.6 | 8.5 | 12 | 159 | 1943 | 194 | 221 | HE 100 B | 26 | 100 | 100 | 6 | 10 | 12 | 56 | 449.5 | 89.91 | 104.2 |

| IPE O 200 | 32 | 202 | 102 | 6.2 | 9.5 | 12 | 159 | 2211 | 219 | 249 | HE 120 A | 25.3 | 114 | 120 | 5 | 8 | 12 | 74 | 606.2 | 106.3 | 119.5 |

| IPE AA 220 | 27 | 216.4 | 110 | 4.7 | 7.4 | 12 | 177.6 | 2219 | 205 | 230 | HE 120 B | 34 | 120 | 120 | 6.5 | 11 | 12 | 74 | 864.4 | 144.1 | 165.2 |

| IPE A 220 | 28.3 | 217 | 110 | 5 | 7.7 | 12 | 177.6 | 2317 | 214 | 240 | HE 140 A | 31.4 | 133 | 140 | 5.5 | 8.5 | 12 | 92 | 1033 | 155.4 | 173.5 |

| IPE 220 | 33.4 | 220 | 110 | 5.9 | 9.2 | 12 | 177.6 | 2772 | 252 | 285 | HE 140 B | 43 | 140 | 140 | 7 | 12 | 12 | 92 | 1509 | 215.6 | 245.4 |

| IPE O 220 | 37.4 | 222 | 112 | 6.6 | 10.2 | 12 | 177.6 | 3134 | 282 | 321 | HE 300 A | 112.5 | 290 | 300 | 8.5 | 14 | 27 | 208 | 18,260 | 1260 | 1383 |

| IPE AA 240 | 31.7 | 236.4 | 120 | 4.8 | 8 | 15 | 190.4 | 3154 | 267 | 298 | HE 300 B | 149.1 | 300 | 300 | 11 | 19 | 27 | 208 | 25,170 | 1678 | 1869 |

| IPE A 240 | 33.3 | 237 | 120 | 5.2 | 8.3 | 15 | 190.4 | 3290 | 278 | 312 | HE 300 M | 303.1 | 340 | 310 | 21 | 39 | 27 | 208 | 59,200 | 3482 | 4078 |

| IPE 240 | 39.1 | 240 | 120 | 6.2 | 9.8 | 15 | 190.4 | 3892 | 324 | 367 | HE 700 A | 260.5 | 690 | 300 | 14.5 | 27 | 27 | 582 | 215,300 | 6241 | 7032 |

| IPE O 240 | 43.7 | 242 | 122 | 7 | 10.8 | 15 | 190.4 | 4369 | 361 | 410 | HE 700 B | 306.4 | 700 | 300 | 17 | 32 | 27 | 582 | 256,900 | 7340 | 8327 |

| IPE A 270 | 39.2 | 267 | 135 | 5.5 | 8.7 | 15 | 219.6 | 4917 | 368 | 413 | HE 800 AA | 218.5 | 770 | 300 | 14 | 18 | 30 | 674 | 208,900 | 5426 | 6225 |

| IPE 270 | 45.9 | 270 | 135 | 6.6 | 10.2 | 15 | 219.6 | 5790 | 429 | 484 | HE 800 A | 285.8 | 790 | 300 | 15 | 28 | 30 | 674 | 303,400 | 7682 | 8699 |

| IPE O 270 | 53.8 | 274 | 136 | 7.5 | 12.2 | 15 | 219.6 | 6947 | 507 | 575 | HE 900 AA | 252.2 | 870 | 300 | 15 | 20 | 30 | 770 | 301,100 | 6923 | 7999 |

| IPE A 300 | 46.5 | 297 | 150 | 6.1 | 9.2 | 15 | 248.6 | 7173 | 483 | 542 | HE 900 A | 320.5 | 890 | 300 | 16 | 30 | 30 | 770 | 422,100 | 9485 | 10,810 |

| IPE 300 | 53.8 | 300 | 150 | 7.1 | 10.7 | 15 | 248.6 | 8356 | 557 | 628 | HE 900 × 466 | 593.7 | 938 | 312 | 30 | 54 | 30 | 770 | 814,900 | 17,380 | 20,380 |

| IPE O 300 | 62.8 | 304 | 152 | 8 | 12.7 | 15 | 248.6 | 9994 | 658 | 744 | HE 1000 AA | 282.2 | 970 | 300 | 16 | 21 | 30 | 868 | 406,500 | 8380 | 9777 |

| IPE A 330 | 54.7 | 327 | 160 | 6.5 | 10 | 18 | 271 | 10,230 | 626 | 702 | HE 1000 A | 346.8 | 990 | 300 | 16.5 | 31 | 30 | 868 | 553,800 | 11,190 | 12,820 |

| IPE 330 | 62.6 | 330 | 160 | 7.5 | 11.5 | 18 | 271 | 11,770 | 713 | 804 | HE 1000 × 393 | 500.2 | 1016 | 303 | 24.4 | 43.9 | 30 | 868 | 807,700 | 15,900 | 18,540 |

| IPE O 330 | 72.6 | 334 | 162 | 8.5 | 13.5 | 18 | 271 | 13,910 | 833 | 943 | HE 1000 × 415 | 528.7 | 1020 | 304 | 26 | 46 | 30 | 868 | 853,100 | 16,728 | 19,571 |

| IPE A 360 | 64 | 357.6 | 170 | 6.6 | 11.5 | 18 | 298.6 | 14,520 | 812 | 907 | HE 1000 × 438 | 556 | 1026 | 305 | 26.9 | 49 | 30 | 868 | 909,200 | 17,720 | 20,750 |

| IPE 360 | 72.7 | 360 | 170 | 8 | 12.7 | 18 | 298.6 | 16,270 | 904 | 1019 | HE 1000 × 494 | 629.1 | 1036 | 309 | 31 | 54 | 30 | 868 | 1,028,000 | 19,845 | 23,413 |

References

- Adeli, H.; Sarma, K.C. Cost Optimization of Structures: Fuzzy Logic, Genetic Algorithms, and Parallel Computing; John Wiley & Sons: Chichester, UK, 2006. [Google Scholar]

- Adeli, H. Knowledge Engineering: Fundamentals; McGraw-Hill: New York, NY, USA, 1990. [Google Scholar]

- Soh, C.K.; Yang, J. Fuzzy controlled genetic algorithm search for shape optimization. J. Comput. Civ. Eng. 1996, 10, 143–150. [Google Scholar] [CrossRef]

- Smith, A.E.; Tate, D.M. Genetic optimization using a penalty function. In Proceedings of the Fifth International Conference on Genetic Algorithms, Champaign, IL, USA, 17–21 July 1993; pp. 499–505. [Google Scholar]

- Kim, J.H.; Myung, H. Evolutionary programming techniques for constrained optimization problems. IEEE Trans. Evolut. Comput. 1997, 1, 129–140. [Google Scholar]

- Adeli, H.; Cheng, N.T. Augmented Lagrangian genetic algorithm for structural optimization. J. Aerosp. Eng. 1994, 7, 104–118. [Google Scholar] [CrossRef]

- Adeli, H.; Park, H.S. Optimization of space structures by neural dynamics model. Neural Netw. 1995, 8, 769–781. [Google Scholar] [CrossRef]

- Adeli, H.; Park, H.S. Neurocomputing for Design Automation; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Wang, G.; Wang, W. Fuzzy optimum design of aseismic structures. Earthq. Eng. Struct. Dyn. 1985, 13, 827–837. [Google Scholar]

- Rao, S.S. Description and optimum design of fuzzy mechanical systems. J. Mech. Transm. Autom. Des. 1987, 109, 126–132. [Google Scholar] [CrossRef]

- Yeh, Y.; Hsu, D. Structural optimization with fuzzy parameters. Comput. Struct. 1990, 37, 917–924. [Google Scholar]

- Jelusic, P. Soil compaction optimization with soft constrain. J. Intell. Fuzzy Syst. 2015, 29, 955–962. [Google Scholar] [CrossRef]

- Bellman, R.E.; Zadeh, L.A. Decision-making in a fuzzy environment. Manag. Sci. 1970, 17, B141–B164. [Google Scholar] [CrossRef]

- Zimmermann, H.J. Fuzzy programming and linear programming with several objective functions. Fuzzy Sets Syst. 1978, 1, 45–55. [Google Scholar] [CrossRef]

- Jang, J.S.R. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar]

- MathWorks. MATLAB Function Reference; The MathWorks, Inc.: Natick, MA, USA, 2010. [Google Scholar]

- European Committee for Standardization. Eurocode 3: Design of Steel Structures; EN 1993; CEN: Brussels, Belgium, 2002. [Google Scholar]

- European Committee for Standardization. Eurocode: Basis of Structural Design; EN 1990; CEN: Brussels, Belgium, 2002. [Google Scholar]

- British Standard. Structural Use of Steelwork in Building—Part 1: Code of Practice for Design—Rolled and Welded Sections; BS 5950-1; BSI: London, UK, 2000. [Google Scholar]

- American Institute of Timber Construction. Timber Construction Manual, 5th ed.; John Wiley and Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Sugeno, M. Industrial Applications of Fuzzy Control; Elsevier Science Pub. Co: New York, NY, USA, 1985. [Google Scholar]

- Jelušič, P.; Žlender, B. Soil-nail wall stability analysis using ANFIS. Acta Geotech. Slov. 2013, 10, 61–73. [Google Scholar]

- Jelušič, P.; Žlender, B. An adaptive network fuzzy inference system approach for site investigation. Geotech. Test. J. 2014, 37, 400–411. [Google Scholar] [CrossRef]

| Use Classification | Deflection Limit |

|---|---|

| Roof beams (industrial) | L/180 |

| Roof beams (commercial and institutional without plaster ceiling) | L/240 |

| Roof beams (commercial and institutional with plaster ceiling) | L/360 |

| Floor beams (ordinary usage) | L/360 |

| Highway bridge stringers | L/200 to L/300 |

| Railway bridge stringers | L/300 to L/400 |

| LL < 2.5 kN/m2 | L/480 |

| 2.5 kN/m2 < LL < 4.0 kN/m2 | L/420 |

| LL > 4.0 kN/m2 | L/360 |

| Inputs | Output | |

|---|---|---|

| Applied Live Load LL | Classification | Deflection Limit |

| (kN/m2) | CLASS * | LIMIT |

| 20 | 1 | 360 |

| 10 | 1 | 360 |

| 4 | 1 | 360 |

| 3.5 | 1 | 420 |

| 3 | 1 | 420 |

| 2.5 | 1 | 480 |

| 2 | 1 | 480 |

| 1.5 | 1 | 480 |

| 1 | 1 | 480 |

| 0.5 | 1 | 480 |

| 0 | 1 | 480 |

| 20 | 2 | 240 |

| 10 | 2 | 240 |

| 4 | 2 | 240 |

| 3.5 | 2 | 280 |

| 3 | 2 | 280 |

| 2.5 | 2 | 320 |

| 2 | 2 | 320 |

| 1.5 | 2 | 320 |

| 1 | 2 | 320 |

| 0.5 | 2 | 320 |

| 0 | 2 | 320 |

| 20 | 3 | 180 |

| 10 | 3 | 180 |

| 4 | 3 | 180 |

| 3.5 | 3 | 210 |

| 3 | 3 | 210 |

| 2.5 | 3 | 240 |

| 2 | 3 | 240 |

| 1.5 | 3 | 240 |

| 1 | 3 | 240 |

| 0.5 | 3 | 240 |

| 0 | 3 | 240 |

| Membership Function | Premise Parameters | Consequent Parameters | ||

|---|---|---|---|---|

| i | σi | ci | - | |

| A1 | 6.61768494044089 | 2.90117735987428 | a01 | −771.211045670957 |

| A2 | 7.47150990794045 | 2.08316049335067 | a11 | 8.40911494744558 |

| B1 | 0.962309787332703 | 1.62121248482762 | a21 | 172.024353054372 |

| B2 | 0.979723951565027 | 1.27590144219536 | a02 | 1535.72815330126 |

| - | - | - | a12 | −29.7774593495827 |

| - | - | - | a22 | −158.884574516486 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jelušič, P.; Žlender, B. Discrete Optimization with Fuzzy Constraints. Symmetry 2017, 9, 87. https://doi.org/10.3390/sym9060087

Jelušič P, Žlender B. Discrete Optimization with Fuzzy Constraints. Symmetry. 2017; 9(6):87. https://doi.org/10.3390/sym9060087

Chicago/Turabian StyleJelušič, Primož, and Bojan Žlender. 2017. "Discrete Optimization with Fuzzy Constraints" Symmetry 9, no. 6: 87. https://doi.org/10.3390/sym9060087